Preliminary dexidation-anaerobism-oxygen deficit-multistage aerobic/anaerobic biological N and P removing method and device

A pre-deoxidation and super-aerobic technology, applied in the field of environmental engineering, can solve the problems affecting denitrification and denitrification, shorten the sludge age, and low treatment efficiency, so as to improve the denitrification capacity, save civil construction costs, and reduce the air supply volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

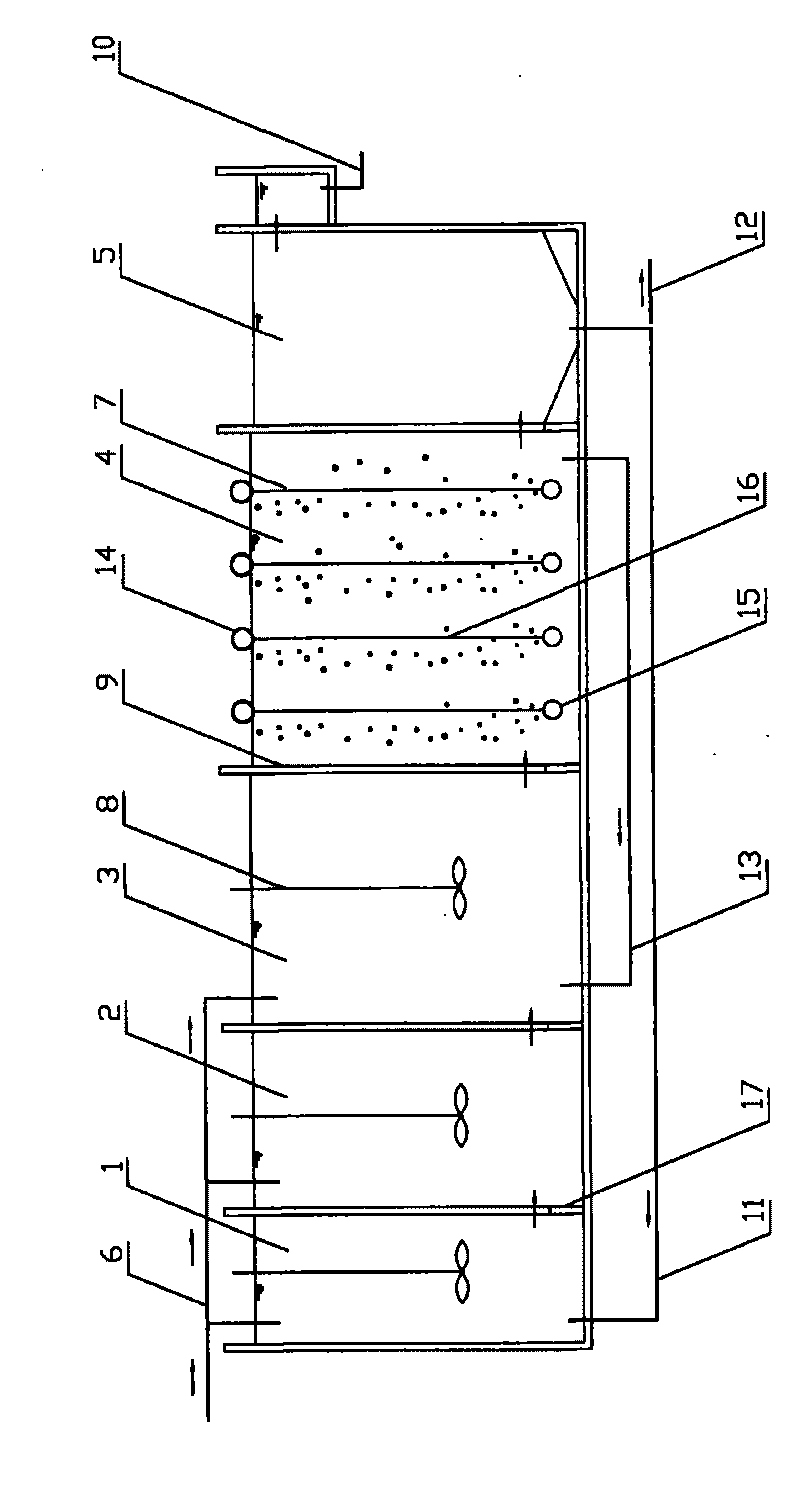

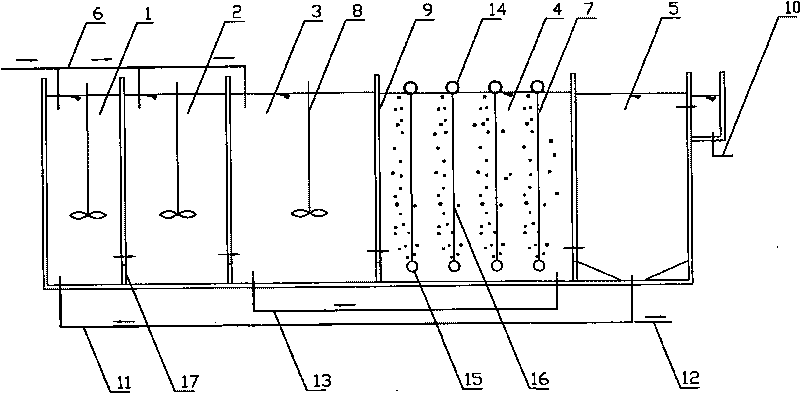

[0035] see figure 1 , is a schematic diagram of the device structure of the present invention, mainly including five unit structures of pre-deoxygenation tank 1, anaerobic tank 2, anoxic tank 3, multi-stage aerobic / anoxic tank 4 and secondary sedimentation tank 5, each two adjacent The units are separated by the pool wall 9, and the pool wall 9 is provided with holes 17, so that between the deoxygenation pool 1 and the anaerobic pool 2, between the anaerobic pool 2 and the anoxic pool 3, and between the anoxic pool 3 and the poly The level aerobic / anoxic tanks 4, the multi-level aerobic / anoxic tanks 4 and the secondary sedimentation tanks 5 are connected to each other. The pretreated sewage enters the pre-deoxygenation pool 1, the anaerobic pool 2 and the anoxic pool 3 respectively through the water distribution pipeline 6.

[0036] Several suspended aeration chains 7 are installed in the multi-stage aerobic / anoxic tank, and the microporous aerator 15 on the aeration chain 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com