Patents

Literature

133results about How to "Save civil cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

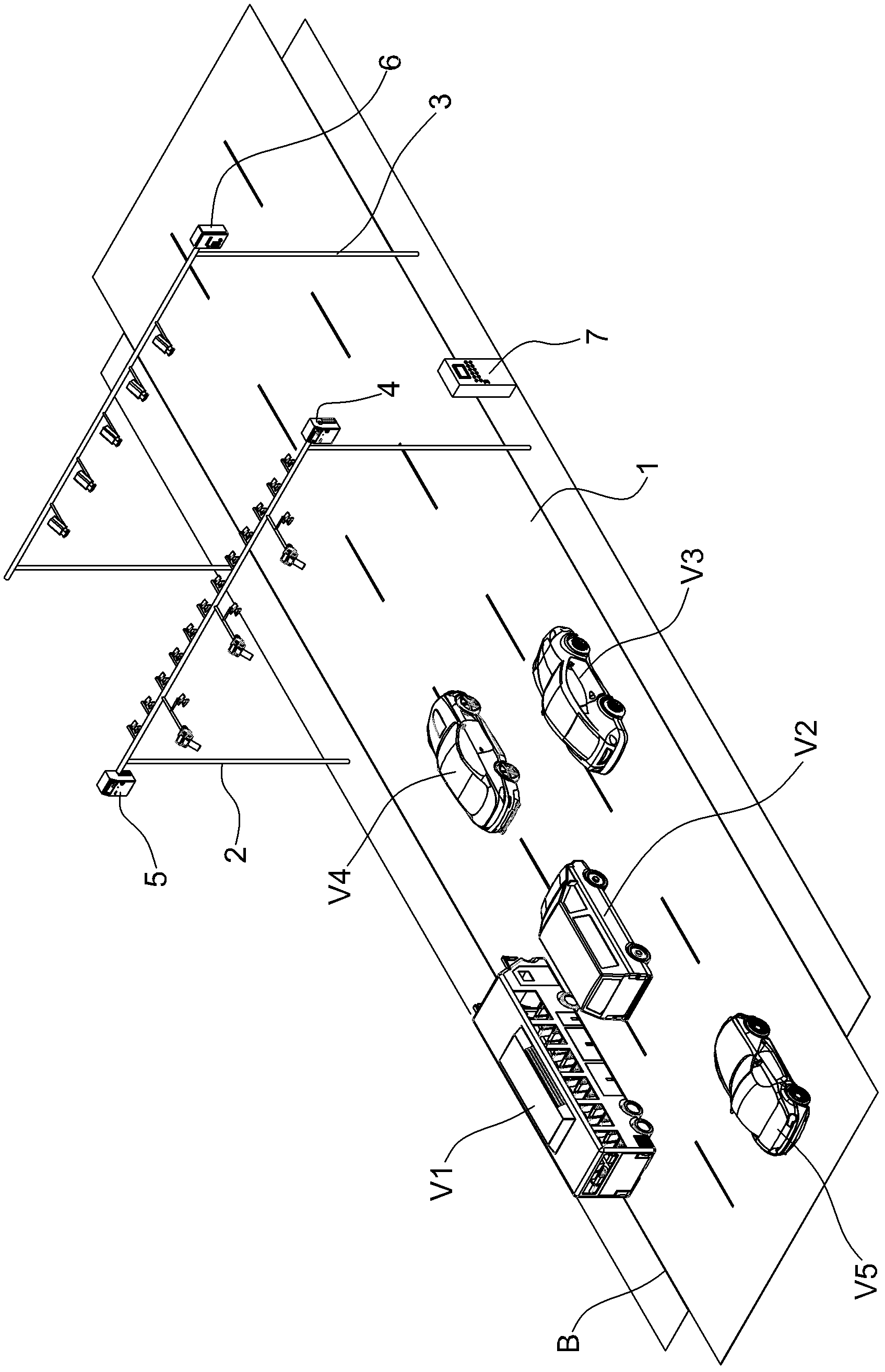

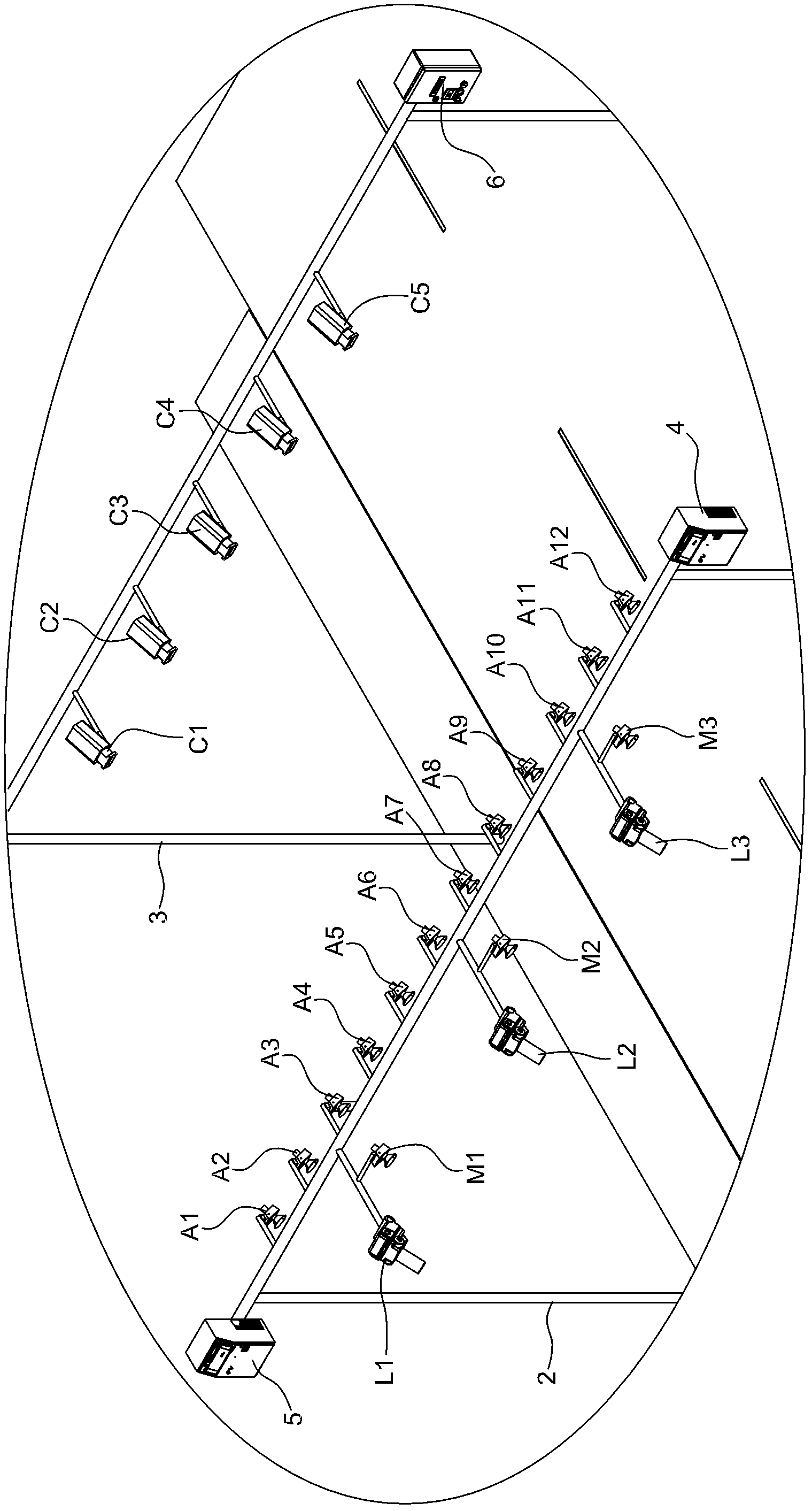

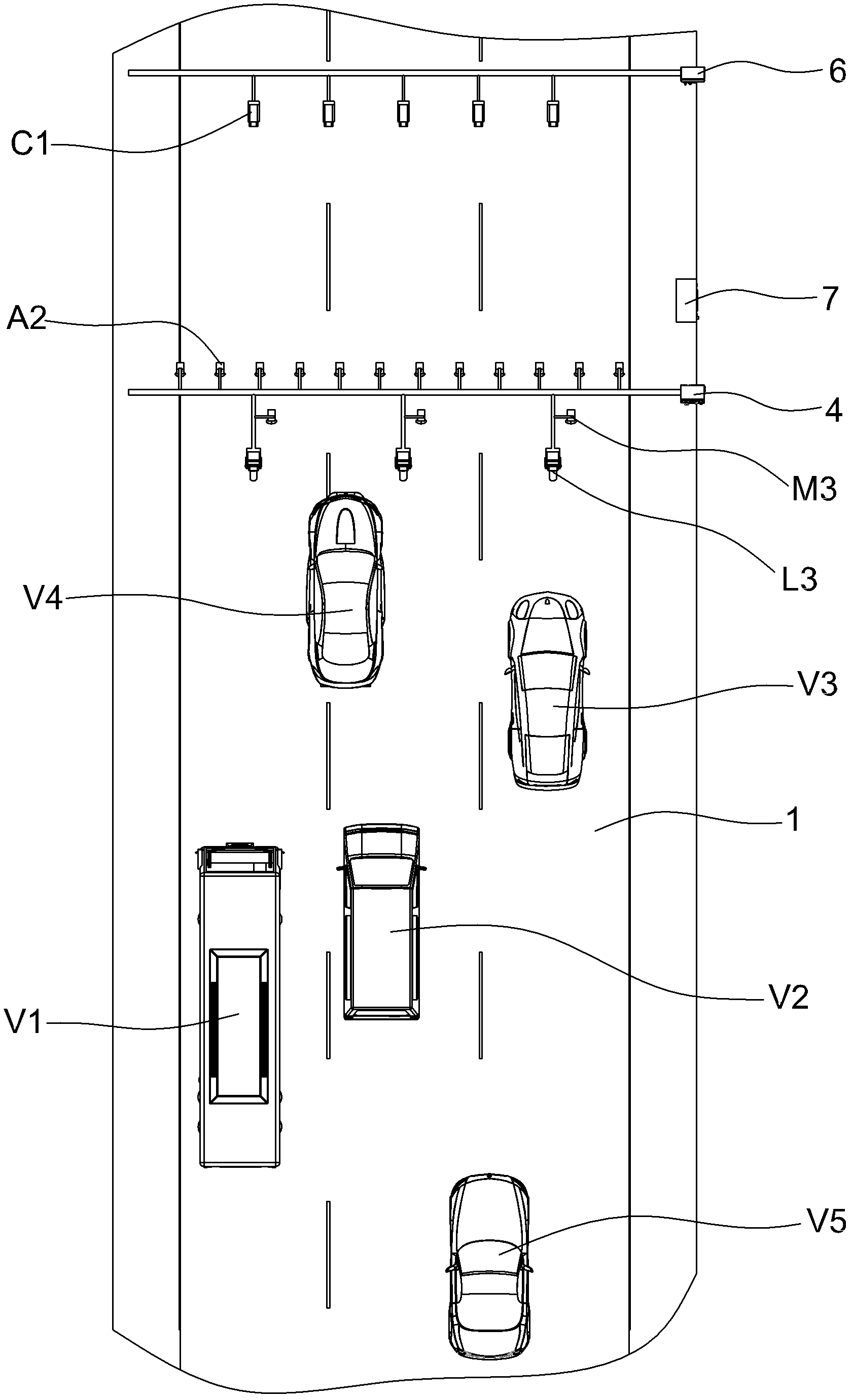

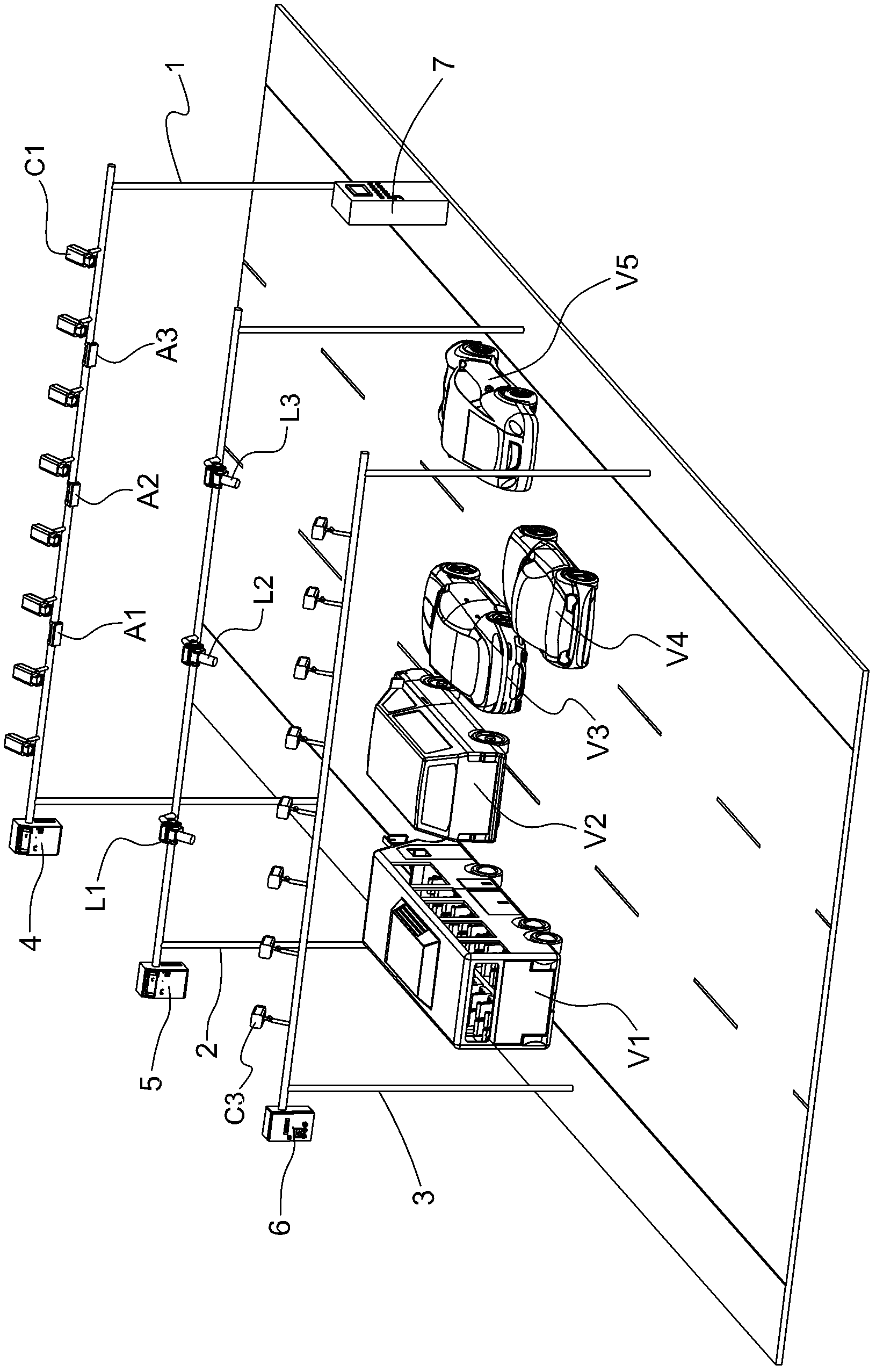

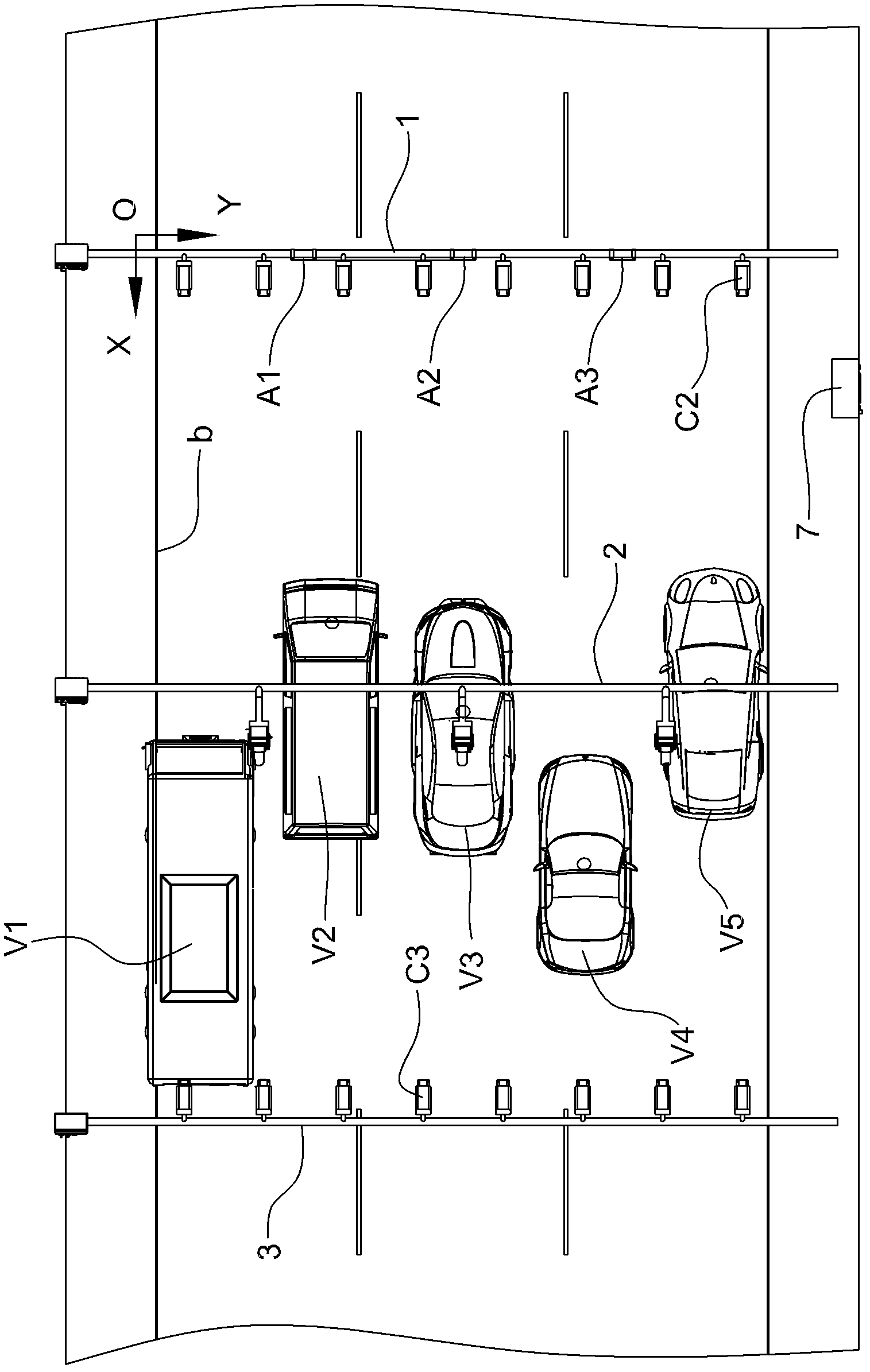

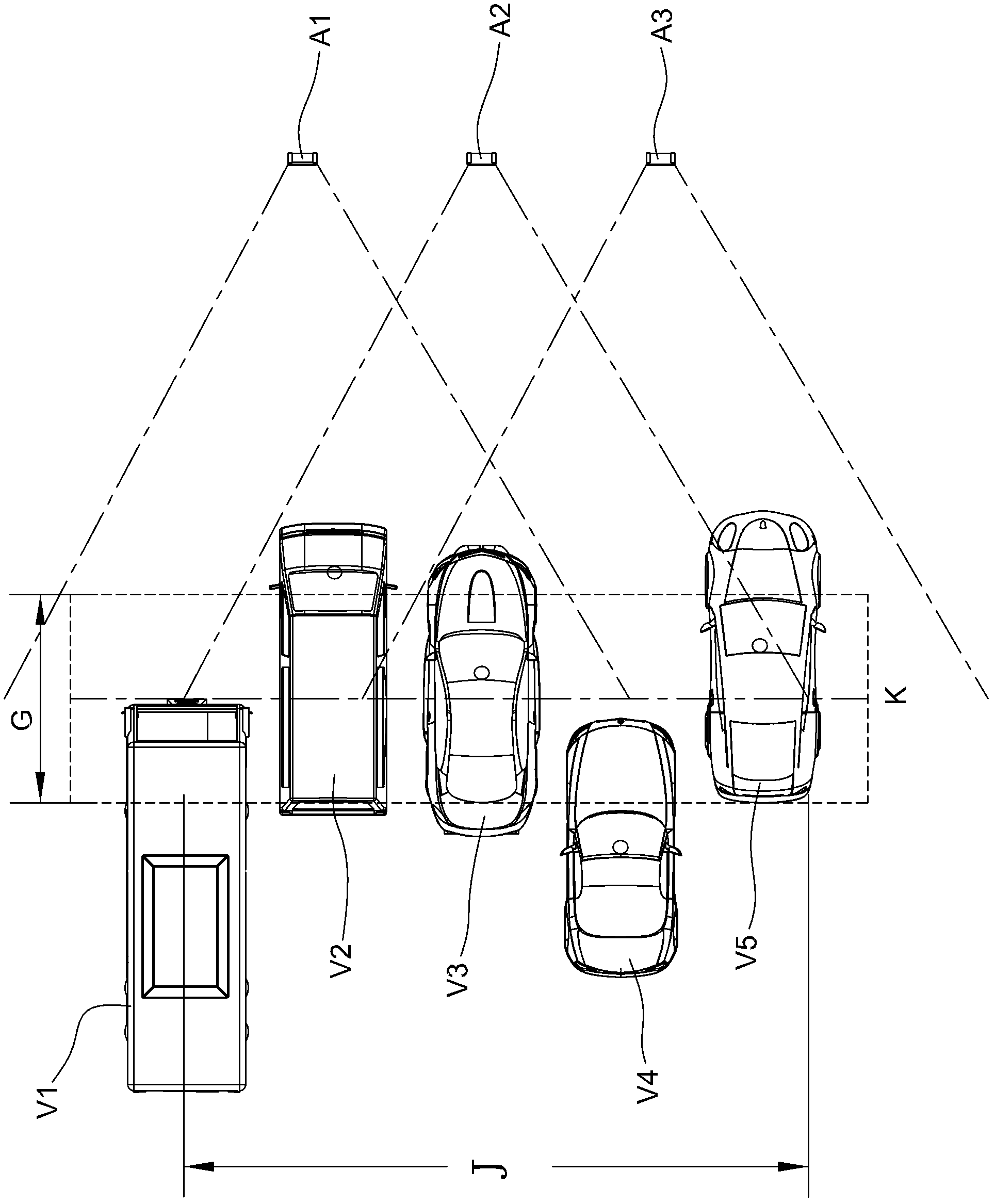

Multilane free-flow electronic toll collection method based on accurate position match

ActiveCN102622783ASave land resourcesSave civil costTicket-issuing apparatusFree flowElectronic tagging

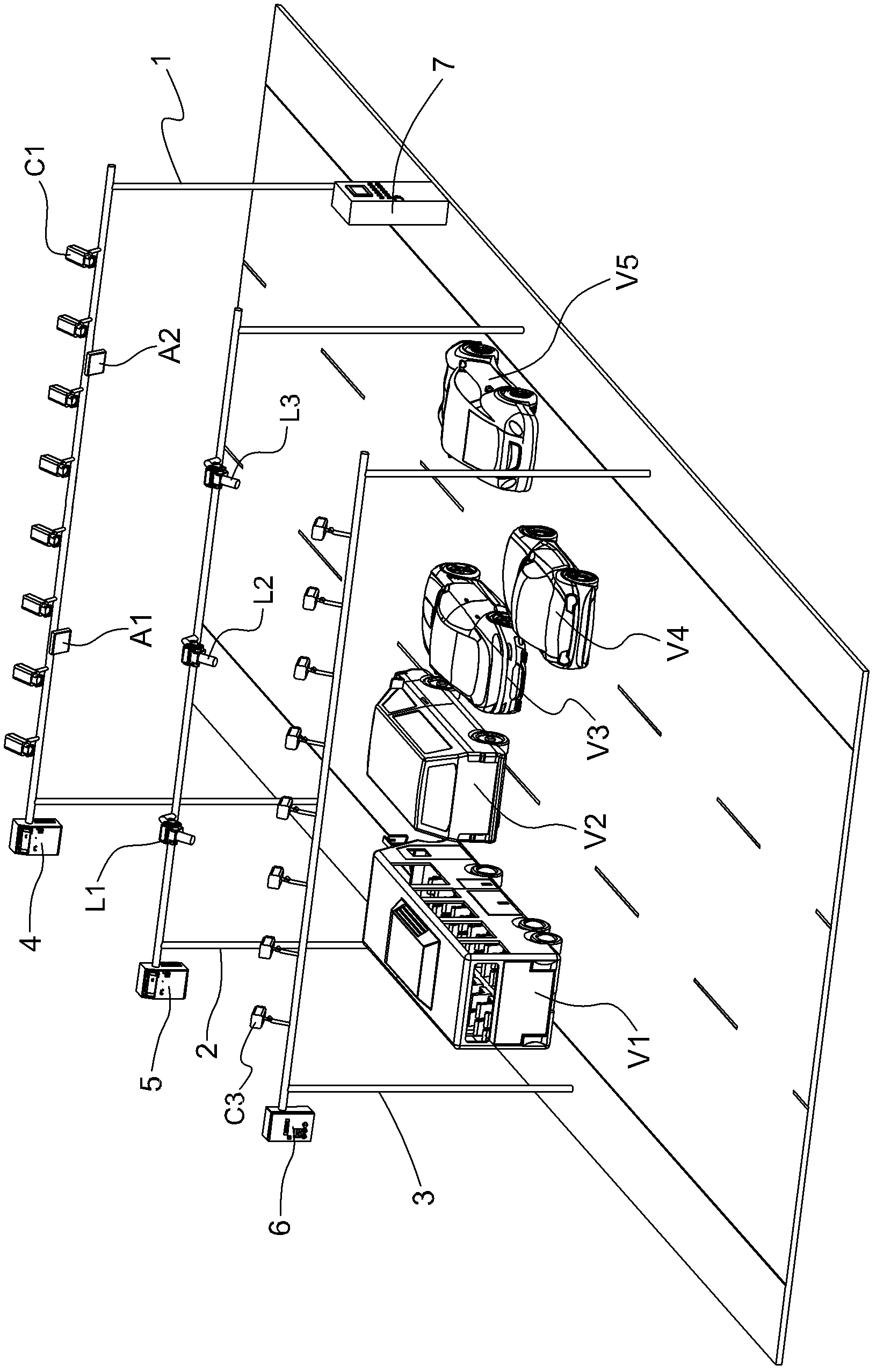

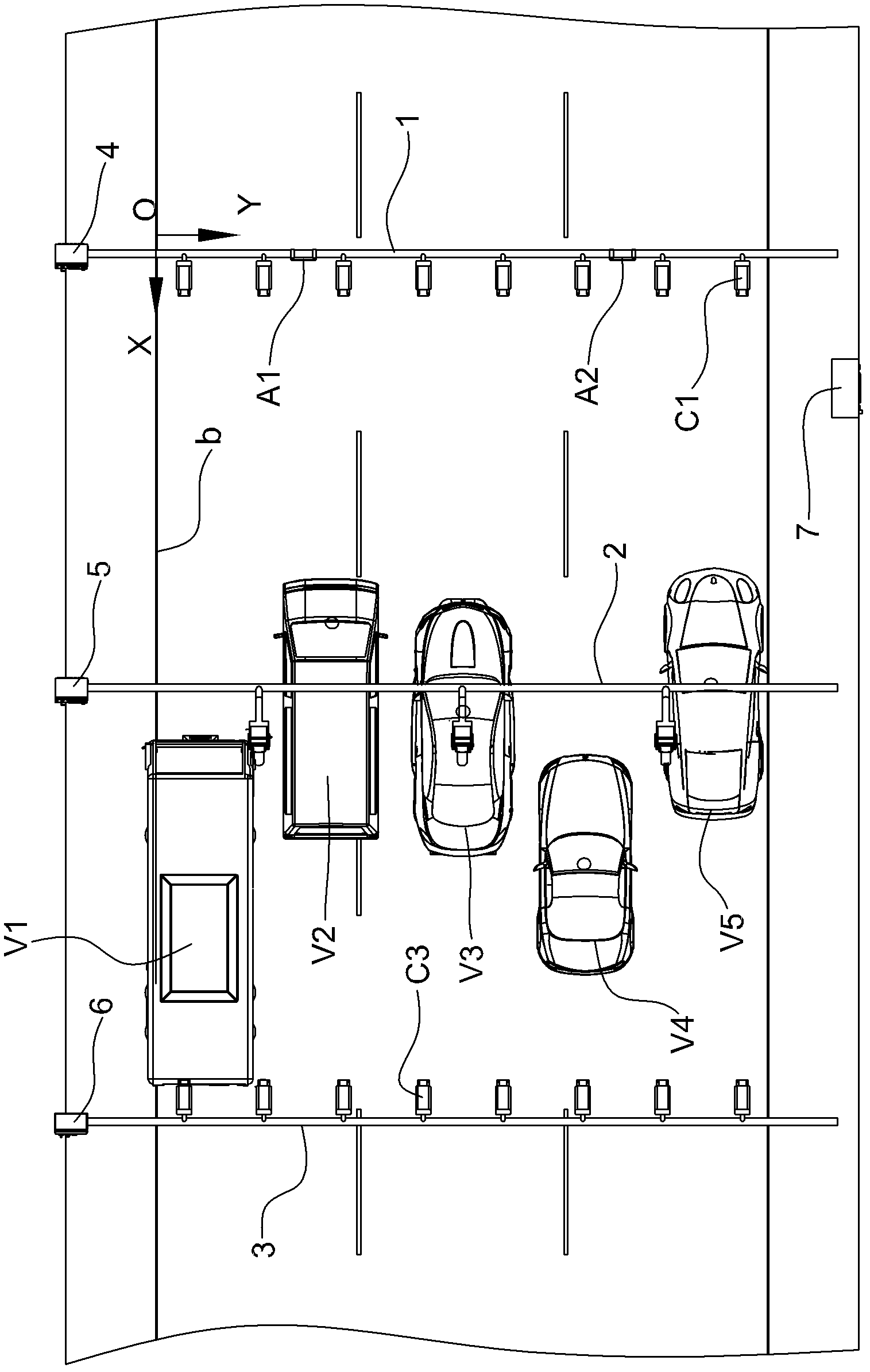

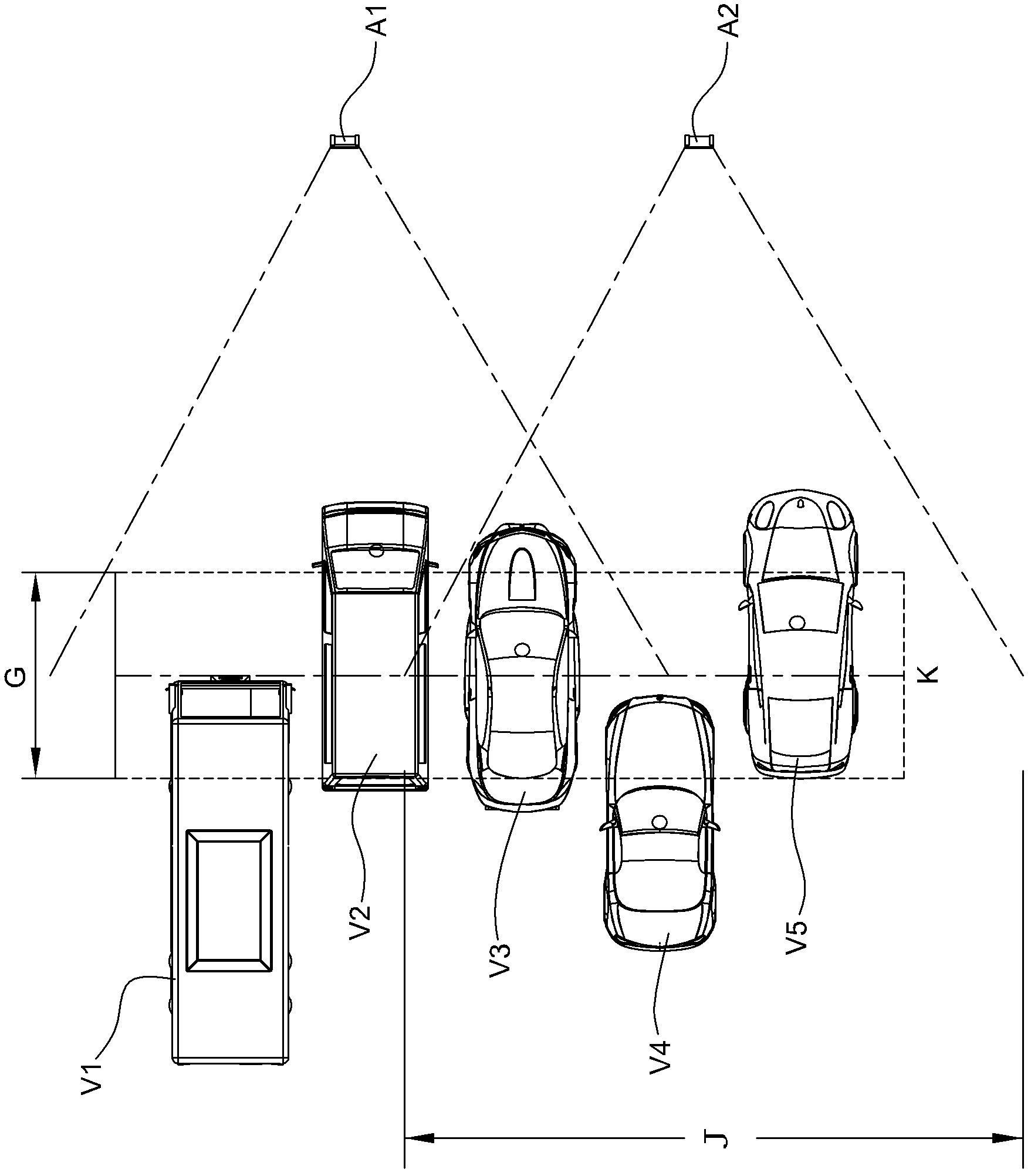

A multilane free-flow electronic toll collection method based on accurate position match is characterized in that electronic tag positioning and vehicle position detected results are matched to achieve multilane free-flow electronic toll collection. The method comprises the following steps: 1, obtaining vehicle-mounted electronic tag positions, vehicle positions and vehicle images to perform electronic on-stream toll collection; 2, accurately matching the vehicle-mounted electronic tag positions and the vehicle positions to distinguish legal vehicles and illegal vehicles; and 3, performing background data processing, storing images, license numbers and illegal passing records of the illegal vehicles to be used as the basis of toll collection. By accurately matching the vehicle detected results and electronic tag positioning results, the judgment of the legal vehicles and the illegal vehicles is achieved, and accordingly the multilane free-flow electronic toll collection is achieved.

Owner:北京速通科技有限公司

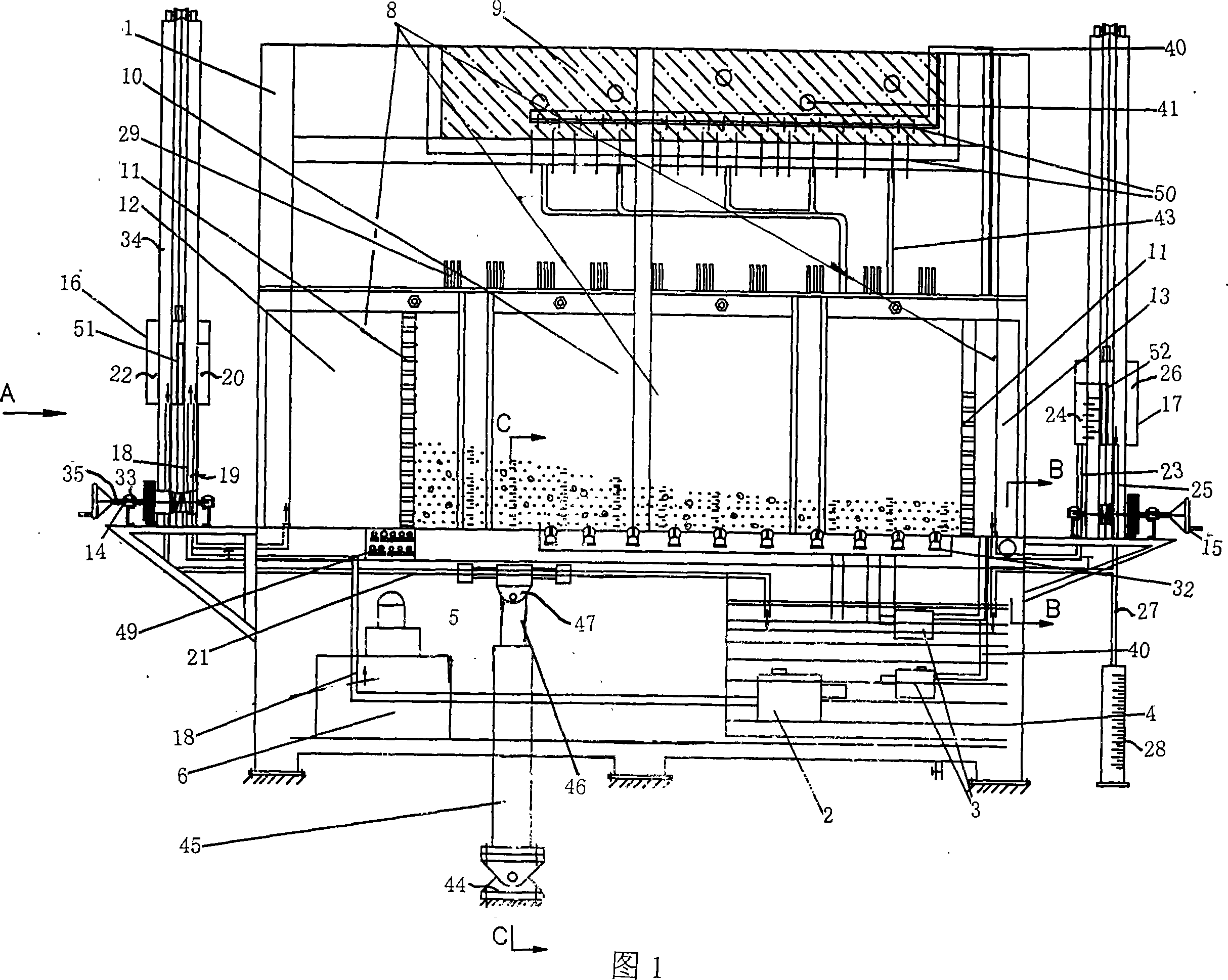

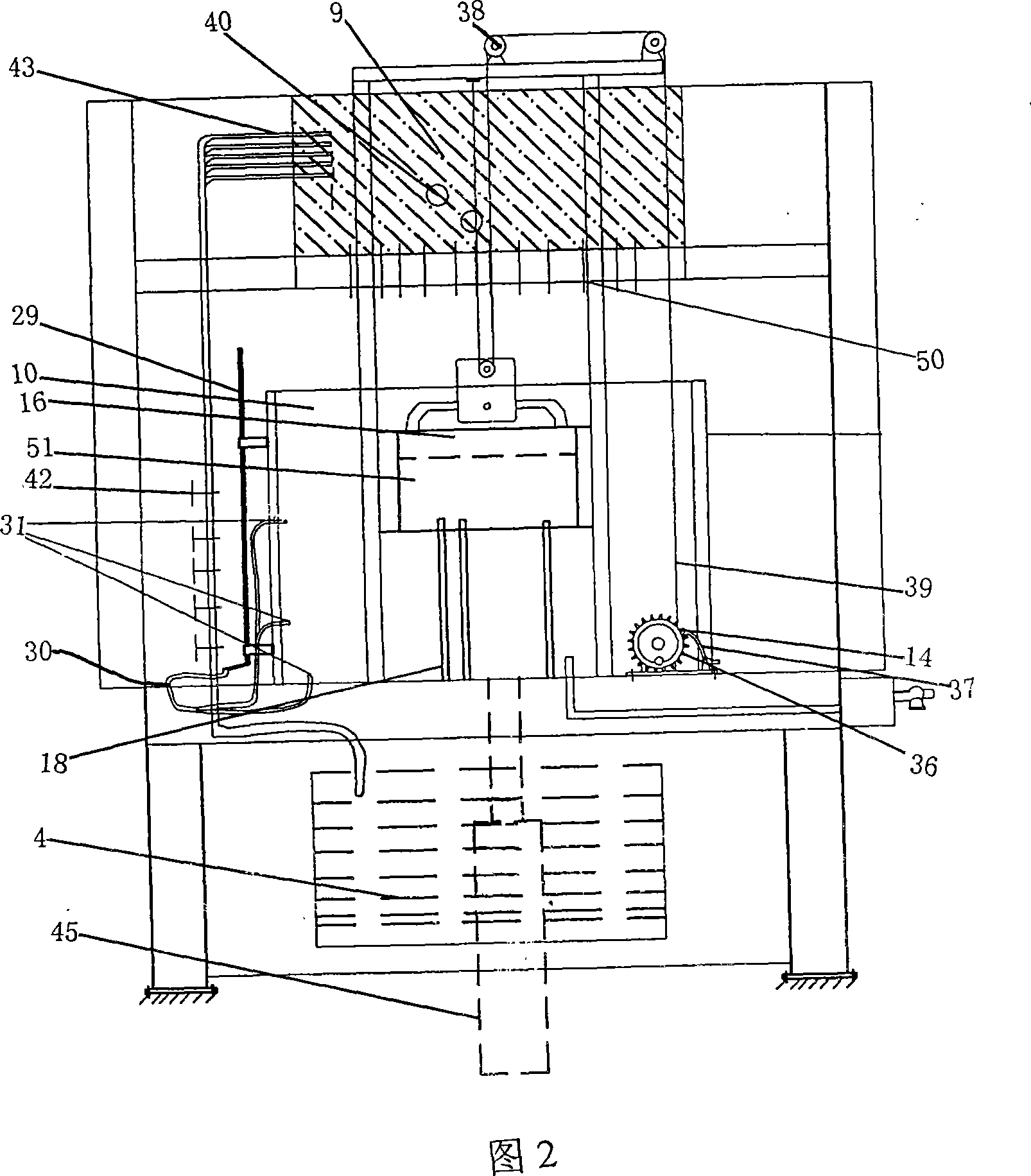

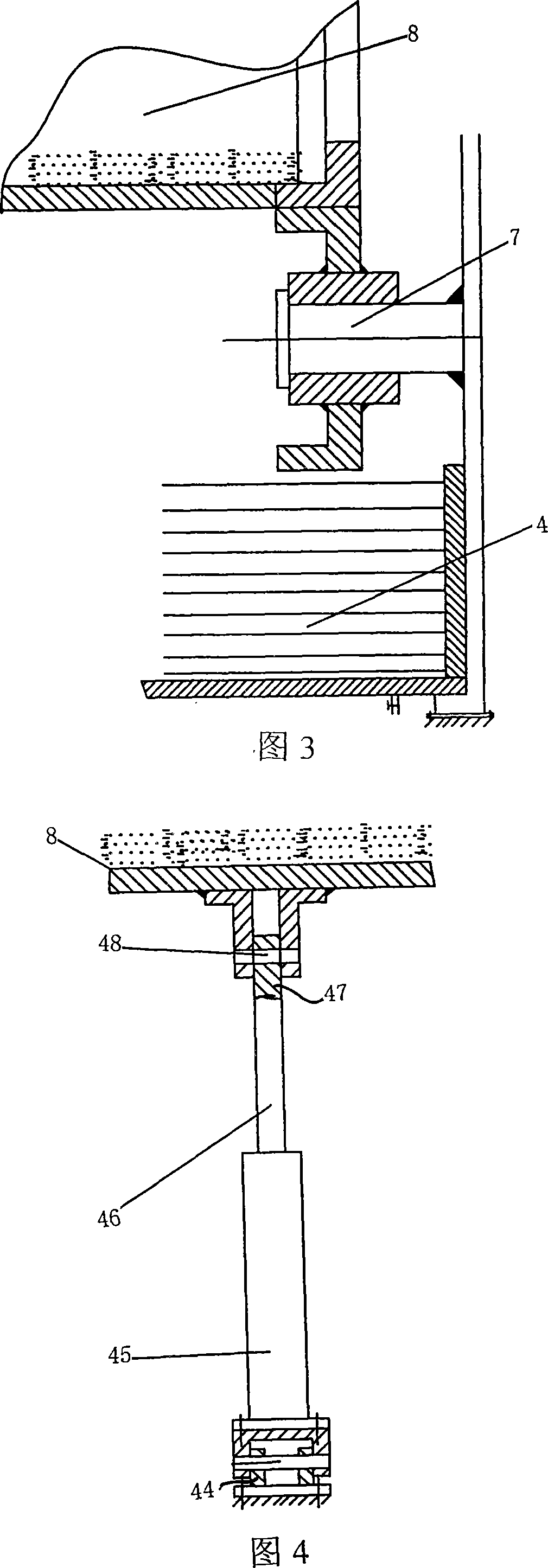

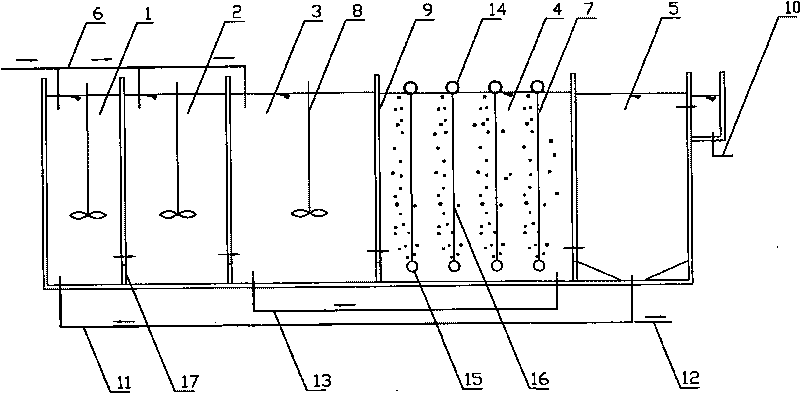

Geological environment simulating experiment device

InactiveCN101110175AStructural tightnessSmall footprintEducational modelsWater dischargeWater storage tank

The invention provides a geologic environment simulation experiment device, which comprises a machine stand, a water storage tank, a simulation case with its lower reach end hinged with the machine stand, a rainfall case installed at the top of the machine stand, a geologic body simulation cavity in the simulation case, a water supply cavity and a water discharge cavity that are respectively positioned at the upper and lower reach ends of the geologic simulation cavity and are communicated to the geologic body simulation case, a conatant head water level overflow case and a discharge overflow case that are respectively positioned at the external side end of the upper and lower reaches of the simulation case, a conatant head overflow cavity that are respectively communicated to the water storage tank and the water supply cavity via a pipeline and a conatant head overflow backwater cavity that is communicated to the water storage tank via an overflow backwater pipe are positioned in the conatant head water level overflow case; at least three groups of piezometer are mounted vertically on the wall of the simulation cavity; one end of a piezometer hose that is communicated to the bottom of the piezometer passes the a simulation wall and extends into the simulation cavity. Therefore, the invention is able to simulate the formation and control of geologic disaster as well as the rules for the motion of groundwater.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

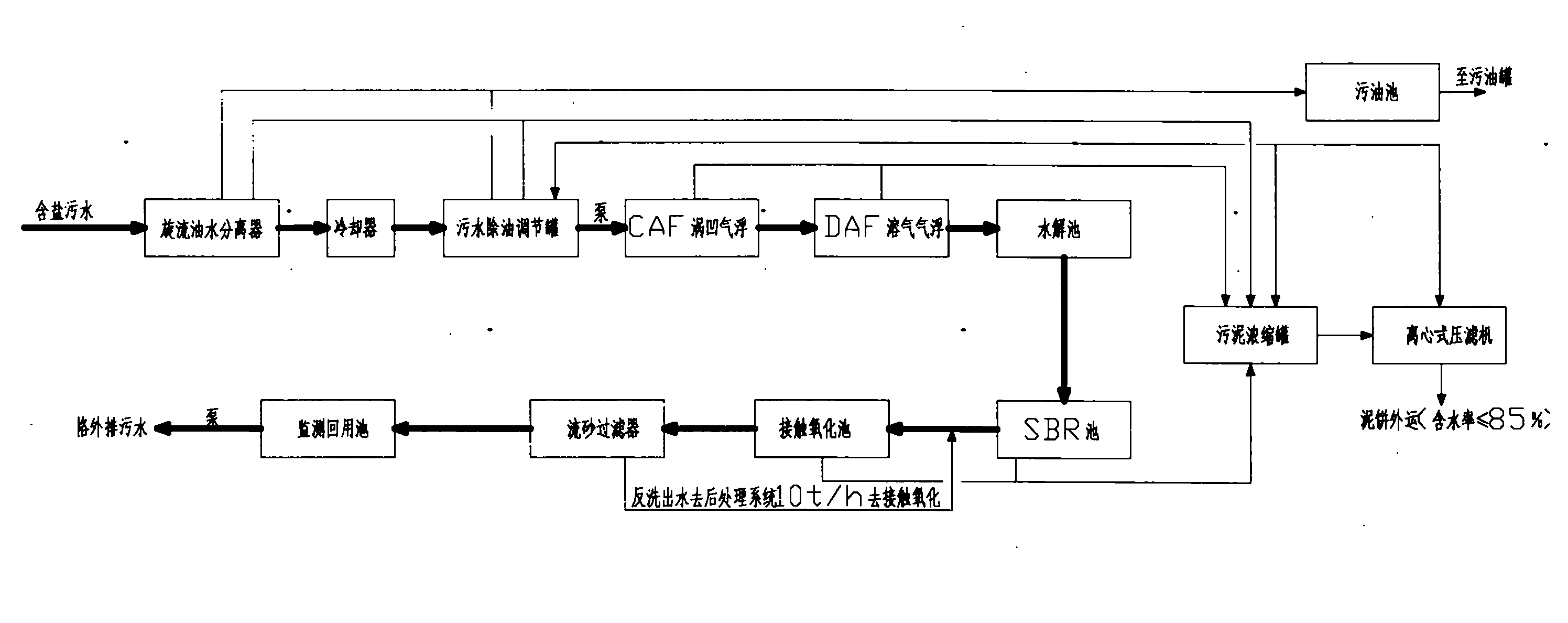

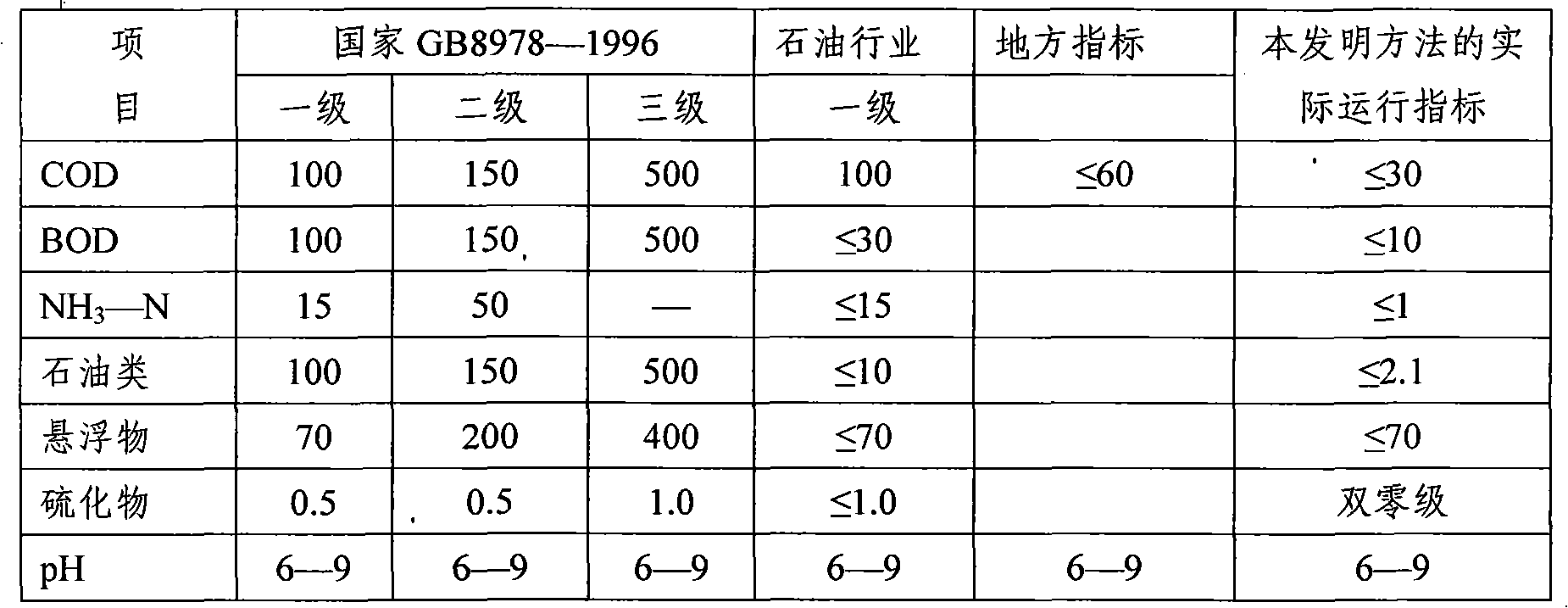

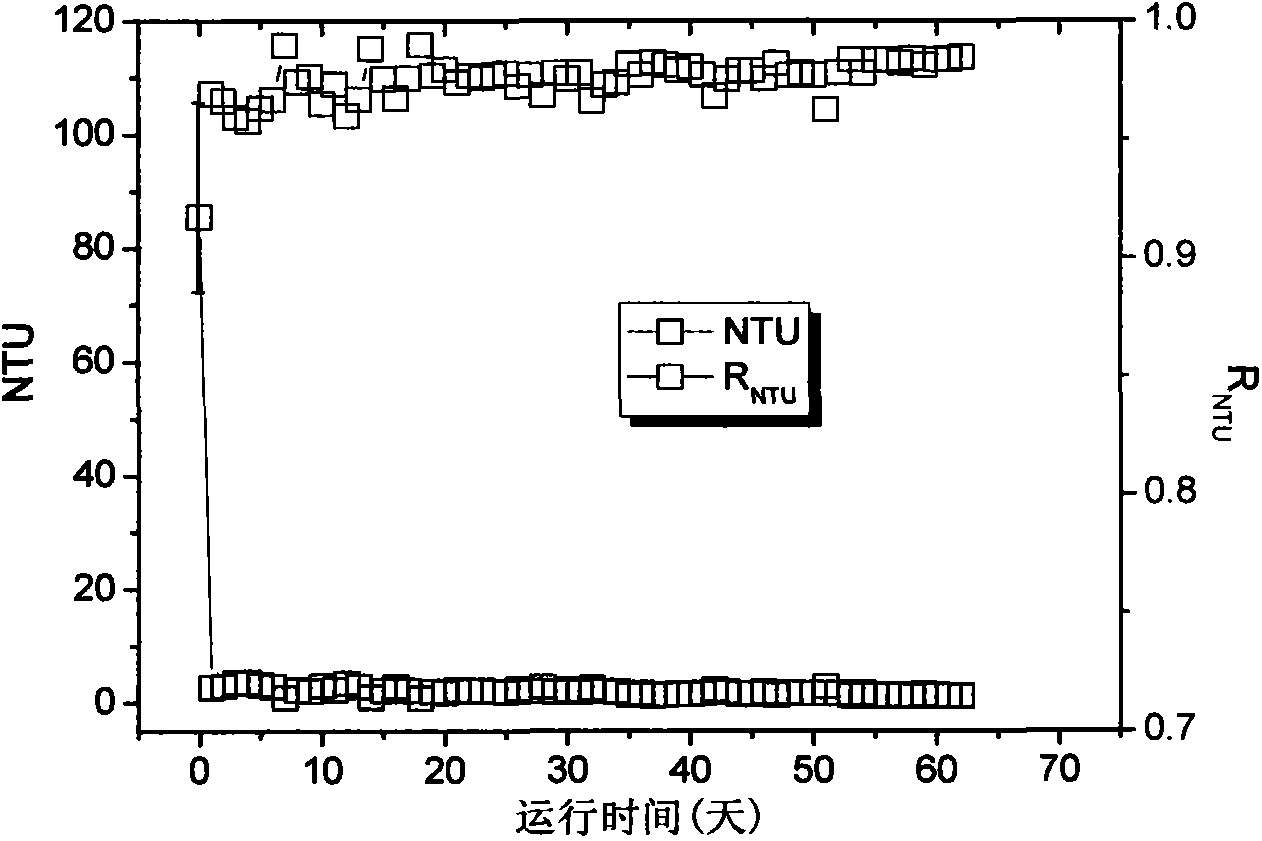

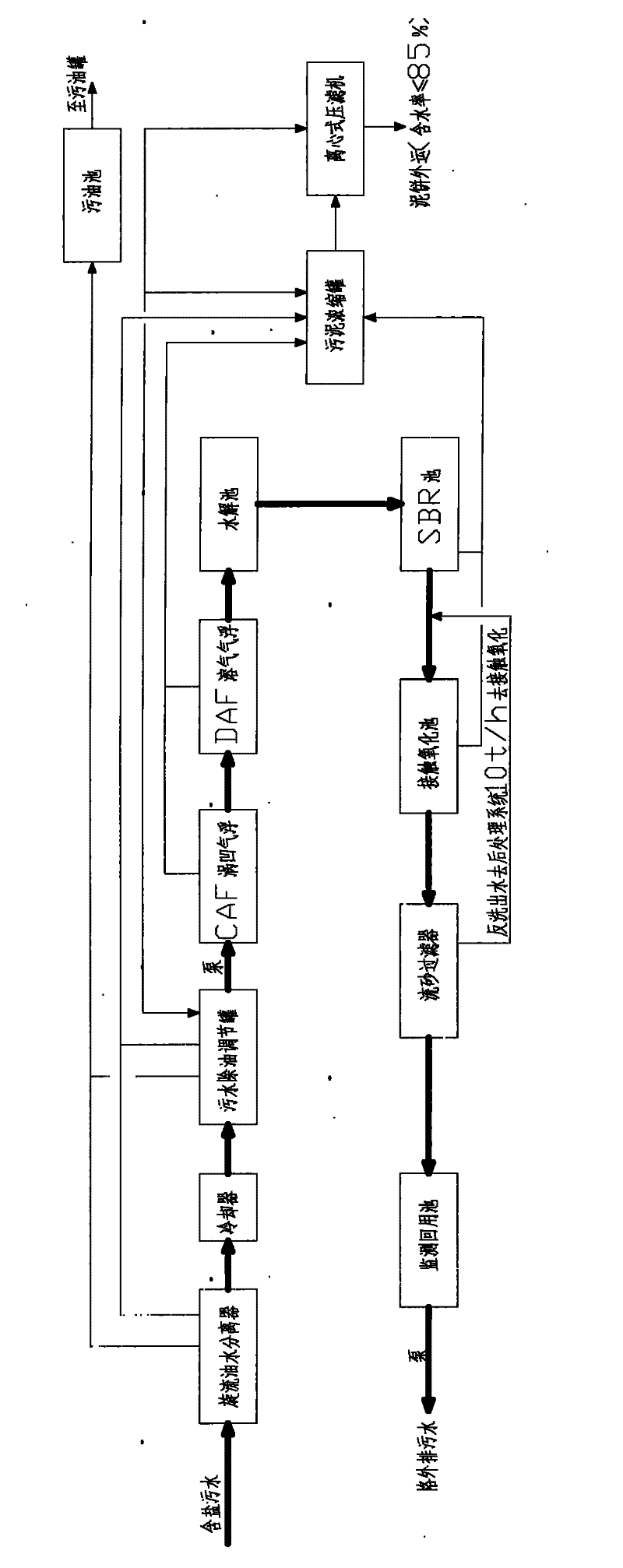

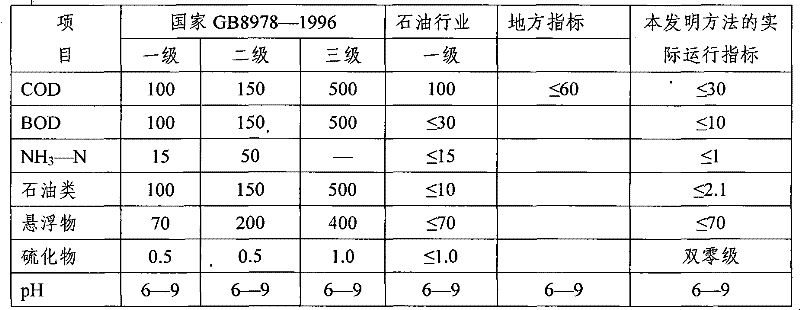

Method for treating petroleum refining waste water

InactiveCN101870544AEasy to handleHigh implementabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTechnical standardEmission standard

The invention relates to a method for treating petroleum refining waste water. The method for treating petroleum refining waste water comprises the steps of a gravity oil-separating unit, a two-stage air floatation treatment unit, an anaerobic and aerobic two-stage biochemical treatment unit, a biochemical posttreatment unit and the like. Through the analysis of the specific implementation effect, the technical implementation effect of the method is much more excellent than the conventional technical standards. Compared with the prior art, the treatment effect of the method is obviously more excellent than the traditional process method; qualitative improvement on the quality of the treated water is achieved; the current newest national and local emission standard is completely met; and therefore, the method has a very wide application prospect.

Owner:大庆市新中瑞环保有限公司

Method for realizing multilane free stream electronic charging through orthogonal phase control array antenna

ActiveCN102622784ASolve the crowded queuing problemImprove traffic capacityTicket-issuing apparatusData processing systemControl system

The invention discloses a method for realizing multilane free stream electronic charging through an orthogonal phase control array antenna, and the method comprises the steps that: step 1. vehicle detection and electronic charging transaction; step 2. vehicle position matching and validity verification; and step 3. background data process. In the step 1, a vehicle and road communication and electronic tag locating subsystem receives and scans an uplink signal through an orthogonal phase control radiating unit of the antenna, detects the transverse and vertical migration angles of a vehicle-mounted electronic tag relative to the antenna, and calculates the position of the vehicle-mounted electronic tag, a vehicle detecting and locating subsystem detects the contour of a vehicle, provides station passing time and position information of the vehicle and triggers an image snap-shot procedure, and an image snap-shot and plate number identification subsystem performs image snap-shot and plate number identification of the vehicle; in the step 2, a lane logic coordination control system is used for matching the vehicle-mounted electronic tag position with the vehicle position to find out legal vehicles and illegal vehicles; and in the step 3, a background data processing system performs successive performs following-up processing on a locating matching result in the step 2, an electronic non-parking charging transaction result, and vehicle image snap-shot and plate number identification results.

Owner:北京速通科技有限公司

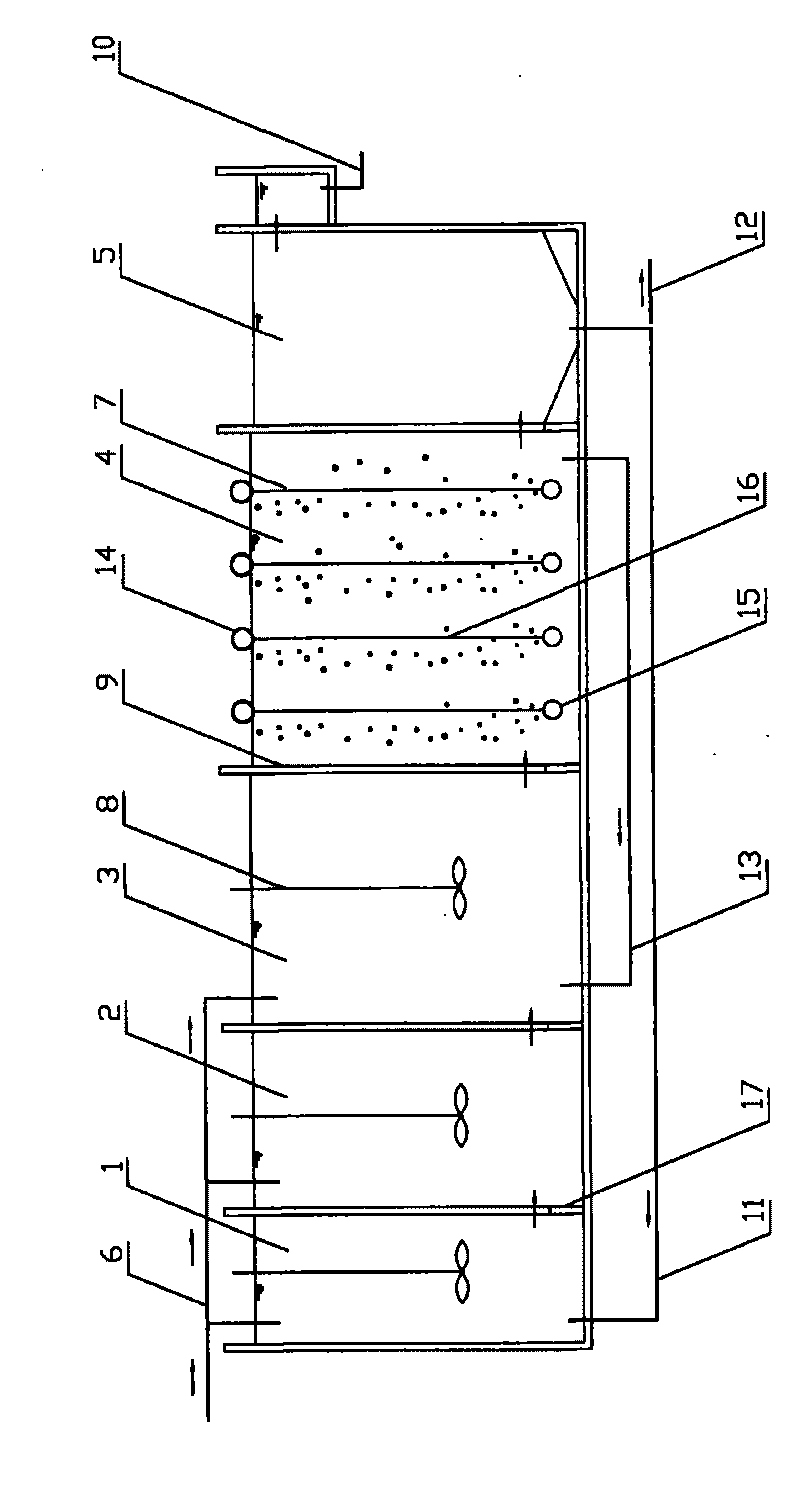

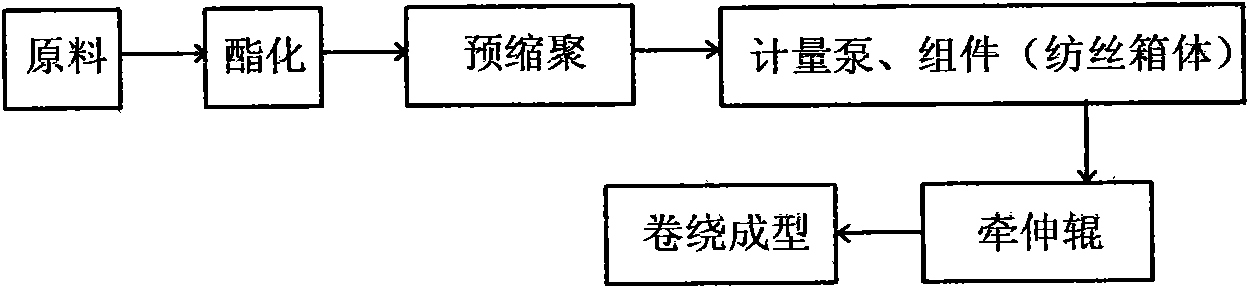

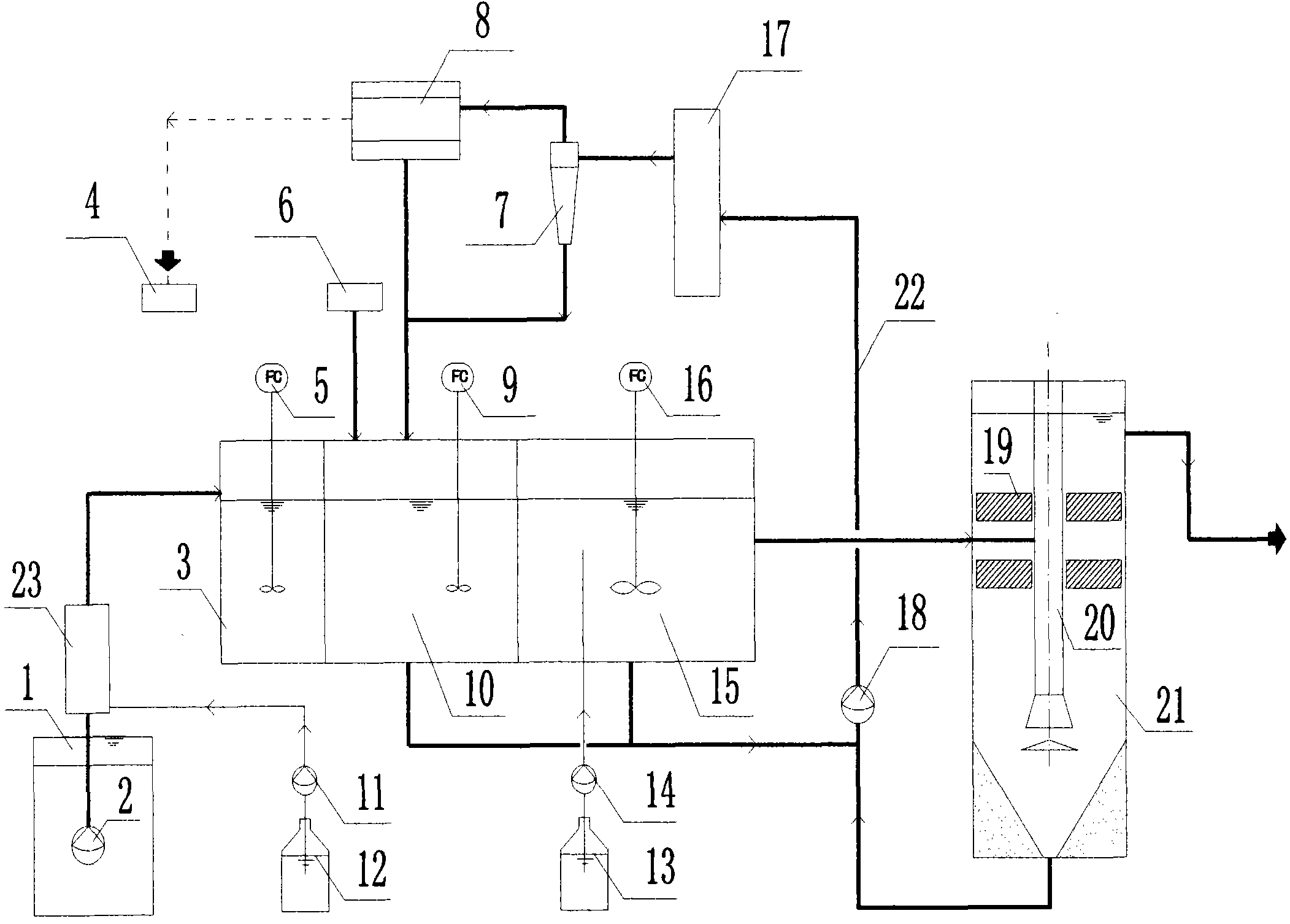

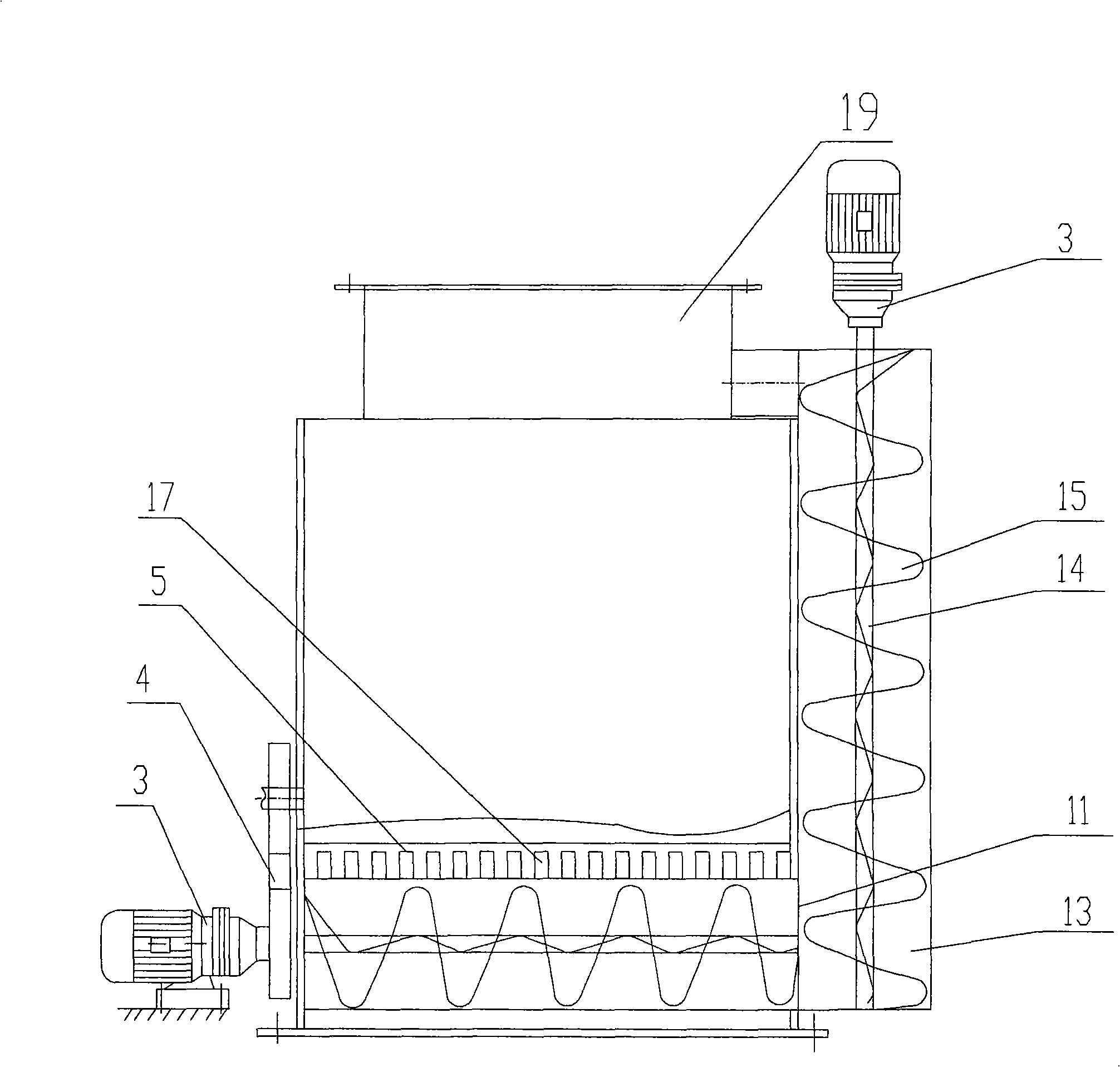

Preliminary dexidation-anaerobism-oxygen deficit-multistage aerobic/anaerobic biological N and P removing method and device

InactiveCN101723510ASmall volumeImprove the effect of nitrogen and phosphorus removalTreatment with aerobic and anaerobic processesRefluxAeration system

The invention relates to a preliminary dexidation-anaerobism-oxygen deficit-multistage aerobic / anaerobic biological N and P removing technology, including the steps: a) deoxygenation denitrification is carried out on returned sludge and part of sewage; b) anaerobic phosphorus releasing is carried out on the mixed liquid and part of sewage treated by the step a; c) denitrification is carried out on the mixed liquid and part of sewage treated by the step b and returned nitrification liquid; d) synchronous nitrification denitrification and decarbonising phosphorous absorption is carried out on the mixed liquid treated by the step c; e) nitrification liquid treated by the step d is returned to the step c; f) nitrification liquid treated by the step d is precipitated, part of sludge is returned to the step a, excess sludge is discharged, clean water is discharge or recycled after reaching standards. The device comprises a preliminary dexidation tank, an anearobism tank, an anaerobic tank, a multistage aerobic / anaerobic tank and a secondary sedimentation tank which are sequentially communicated; wherein the multistage aerobic / anaerobic tank is internally provided with a suspension chain aeration system, an inflow water distributing pipeline is connected with the preliminary dexidation tank, the anaerobism tank and the anaerobic tank, and sludge reflux quantity and nitrification liquid reflux quantity can all be regulated by a refluxing device.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

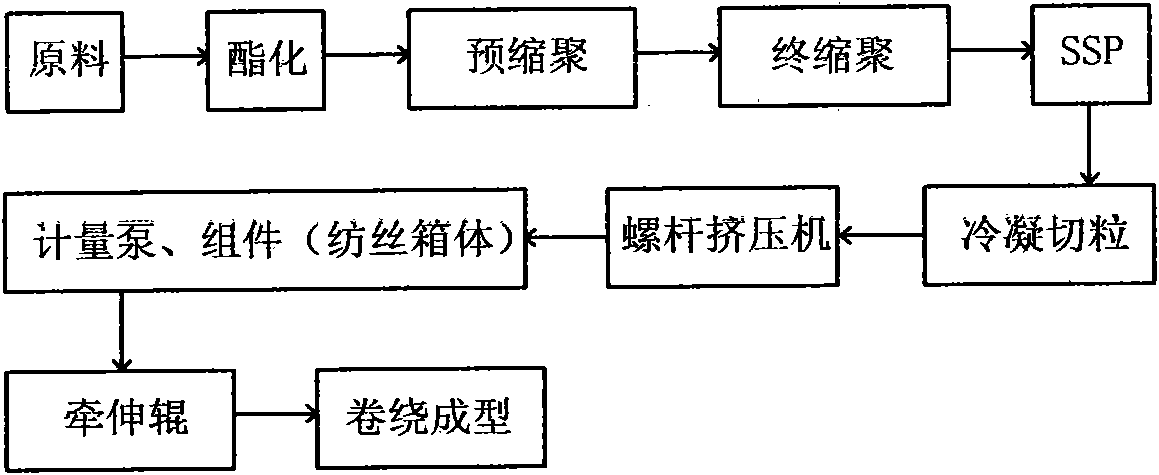

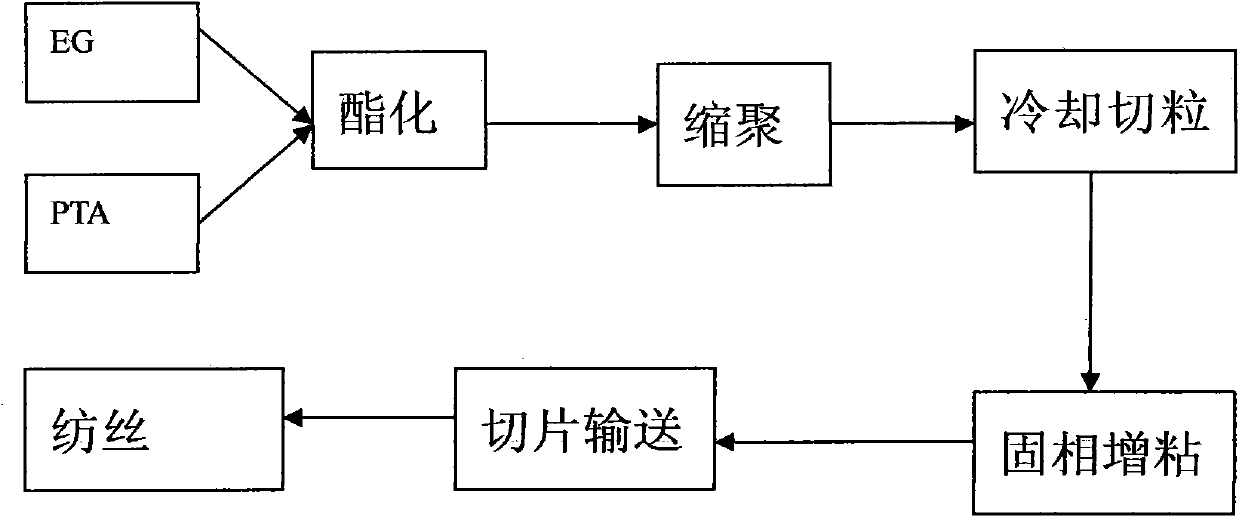

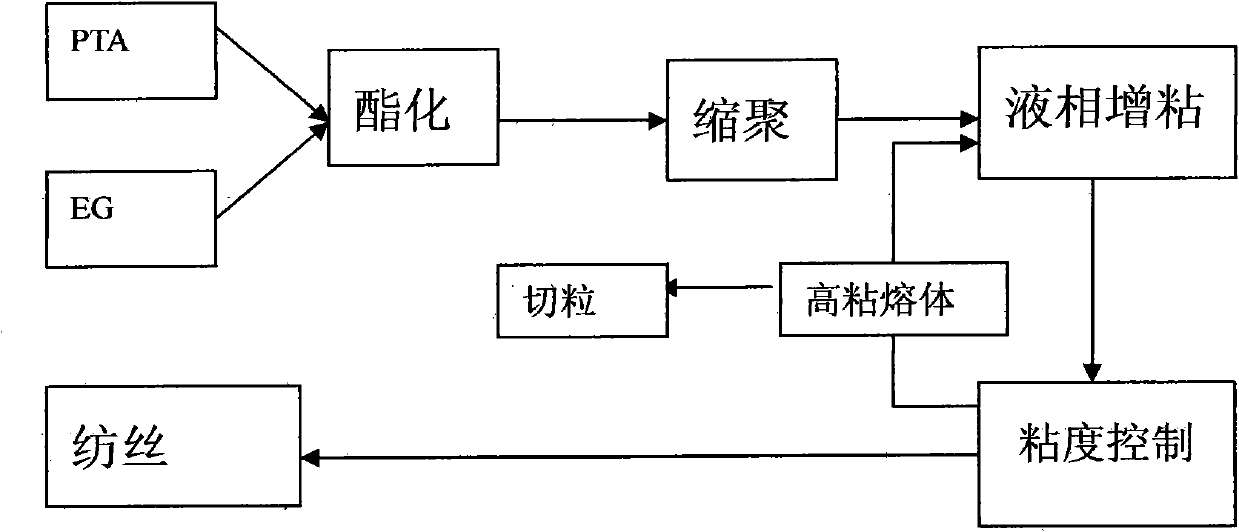

Technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer

ActiveCN101914820AShort processReduce energy costsSpinning head liquid feederMelt spinning methodsPolyesterLiquid state

The invention discloses technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer and belongs to the technical field of spinning. The technology comprises the processes of esterification, prepolycondensation, liquid state polycondensation, and spinning, and is characterized by comprising the following steps of: performing prepolycondensation reaction on esterified ethylene glycol and phthalic acid to prepare a melt with the viscosity of 0.3 to 0.4dl / g, and conveying the melt to a liquid state polycondensation kettle for liquid state polycondensation by using a booster pump; and conveying the melt to a spinning beam for spinning through a gear pump, wherein the inherent viscosity of the polyester melt after liquid state polycondensation is 0.85 to 1.05dl / g. By directly conveying the melt into the liquid state polycondensation kettle for polycondensation and performing the production technology of directly spinning the melt, the production technology for producing the direct spinning terylene industrial filaments after the liquid state polycondensation of the prepolymer shortens the process flow, reduces the production energy consumption and production cost, and solves the technical problem of difficulty in conveying the melt simultaneously.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Method for realizing electronic fee collection on multilane free flow by one-dimension phased array antenna

ActiveCN102622785ASolve the crowded queuing problemImprove traffic capacityTicket-issuing apparatusControl systemElectronic tagging

The invention discloses a method for realizing an electronic fee collection on a multilane free flow by a one-dimension phased array antenna, which comprises that step 1: vehicle detection and electronic fee collection transaction, step 2: vehicle position matching and validity verification, and step 3: background data treatment. In step 1, an uplink signal is received and scanned by a vehicle-road communication and electronic tag positioning sub-system with an one-dimension linear array radiation unit of an antenna, an angular offset of the vehicle electronic tag relative to the antenna is detected, the position of the vehicle electronic tag is calculated, a contour of the vehicle is detected by the vehicle detection and positioning sub-system, information on time and position of the vehicle passes a station is provided, and a picture snapping is triggered; and the picture snapping of the vehicle and a number plate identification are carried out by a picture snapping and number plate identification sub-system. In step 2, the positions of the vehicle electronic tag and the vehicle are matched by a lane logic coordination controlling system to find legal and illegal vehicles. In step 3, subsequent treatments are carried out on the result of positions matching in step 2, and the results of the electronic fee collection transaction without vehicles stop, the picture snapping of vehicles and the number plate identification by a background data treatment system.

Owner:北京速通科技有限公司

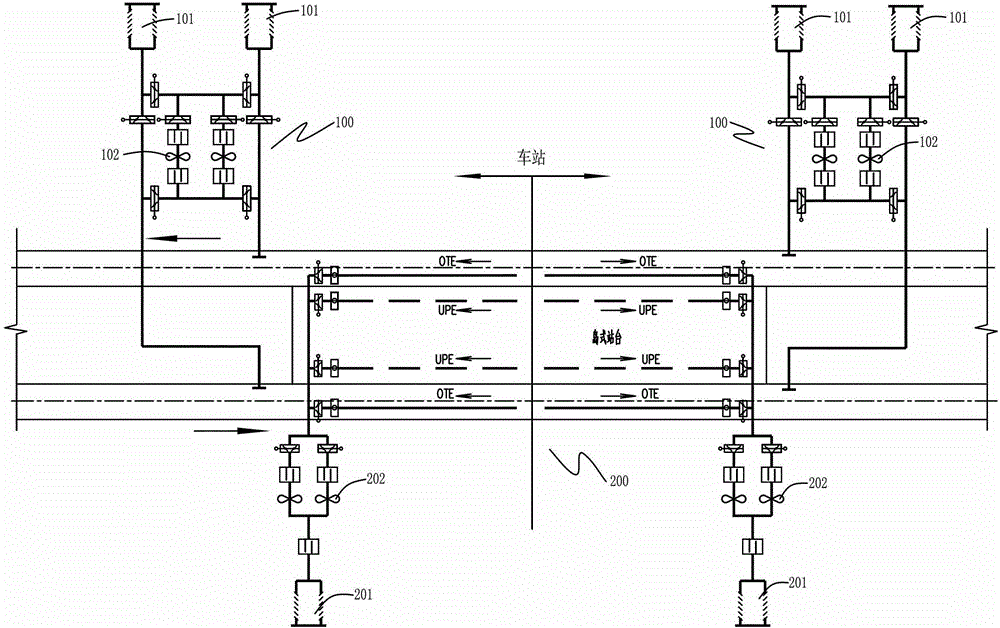

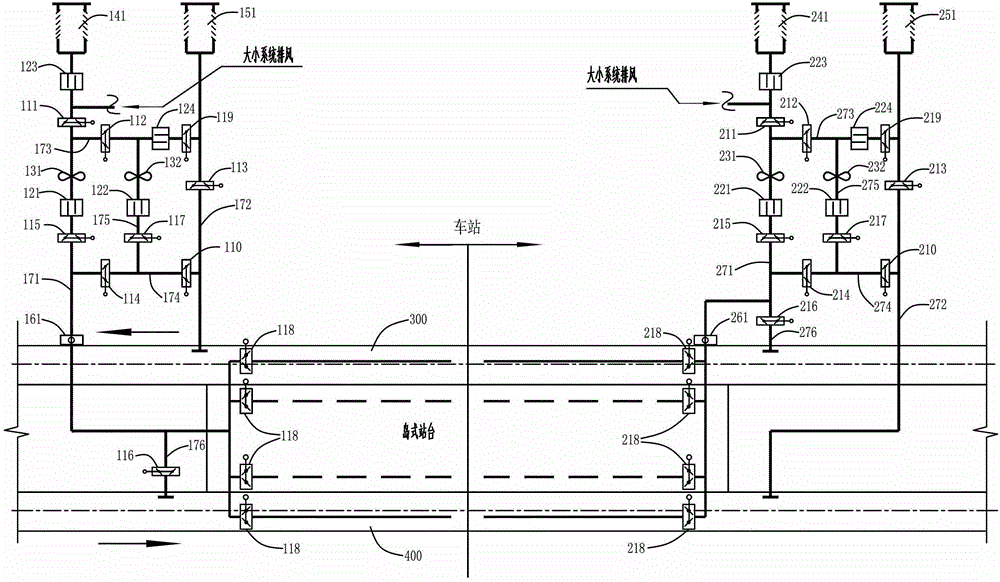

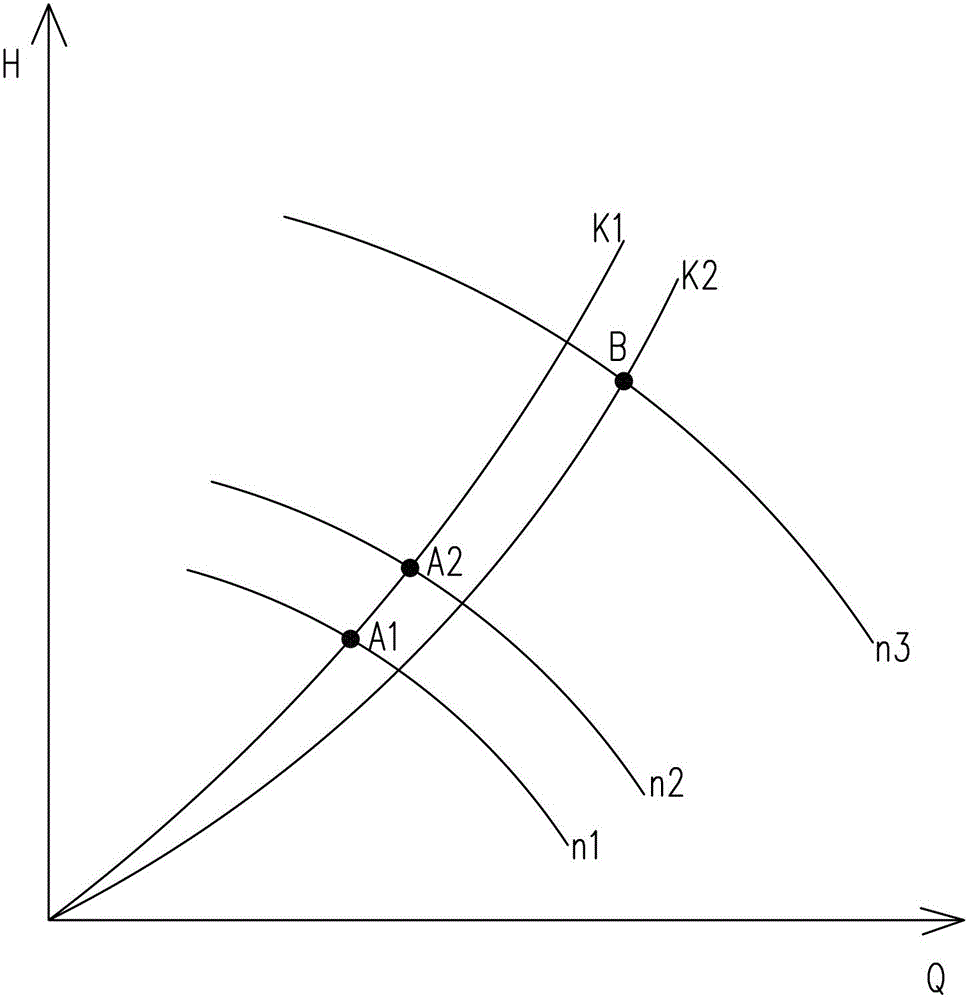

Novel tunnel ventilation system for subway station

ActiveCN102720519AReduce in quantitySave ground areaTunnel/mines ventillationSubway stationTunnel ventilation

The invention relates to a novel tunnel ventilation system for a subway station, which is applied to ventilation of an inter-region tunnel and a station tunnel. The novel tunnel ventilation system is characterized by comprising first and second exhaust shafts, first and second piston air shafts, a first exhaust passage, a first communication air duct, a first piston air duct, a second exhaust passage, a second communication air duct, a second air duct, first and second upper air ducts, and first and second lower air ducts, wherein a first tunnel blower is arranged on the first exhaust passage or the first piston air duct, a second tunnel blower is arranged on the second exhaust passage or the second piston air duct, and electric blast gates are arranged on the individual air ducts. The ventilation system incorporates the inter-region tunnel ventilation system and the station tunnel ventilation system and reduces the number of station piston air shafts, so as to not only reduce the civil engineering cost but also reduce the floor area occupied.

Owner:GUANGZHOU METRO DESIGN & RES INST

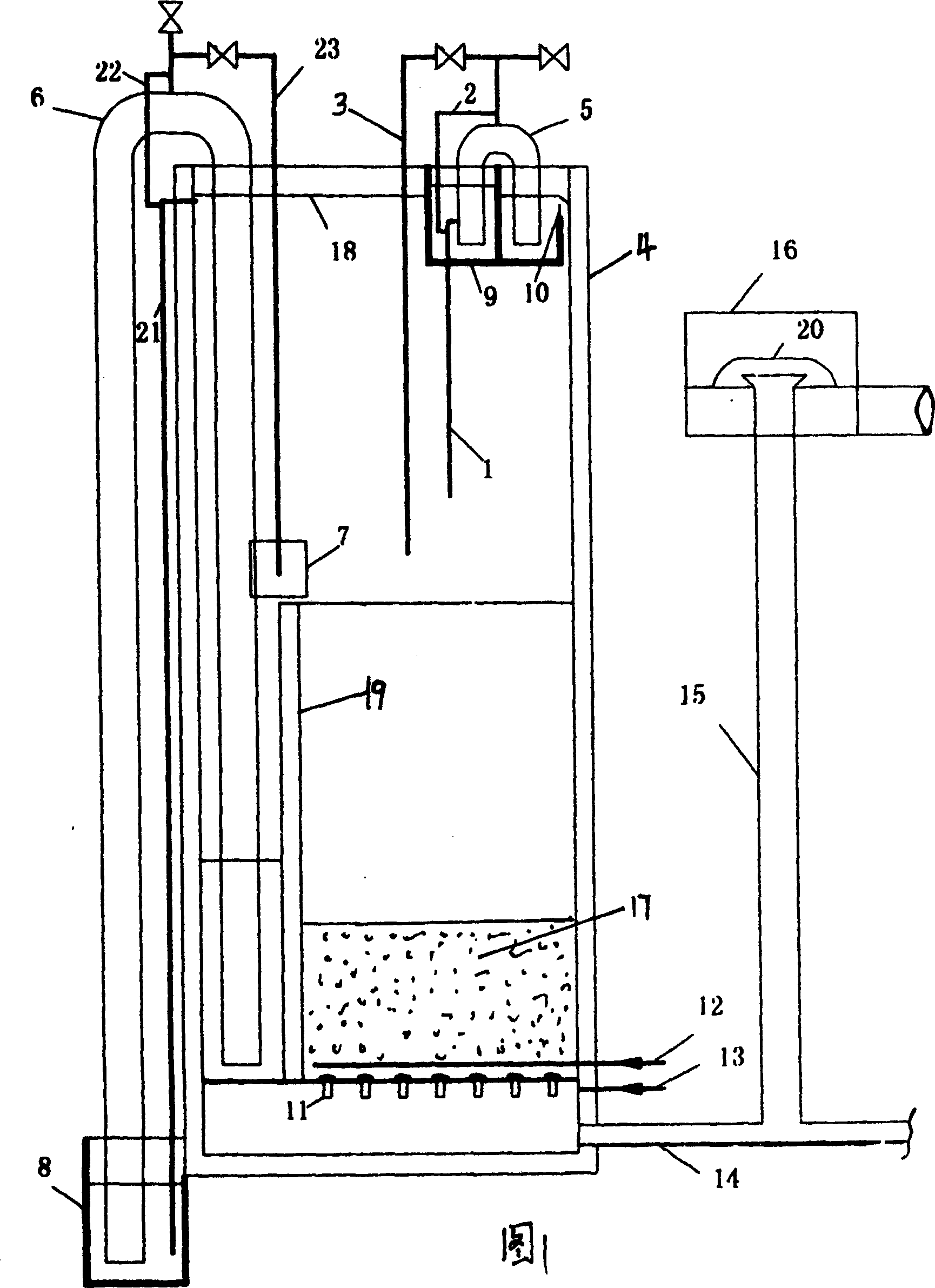

Siphon type full automatic aeration biologicall filtering chamber

InactiveCN1911832AGuaranteed uptimeEasy to manageTreatment using aerobic processesSustainable biological treatmentSiphonAutomatic control

The siphoning automatic aerating biofilter includes filter basin with filtering material, inlet channel, water outlet weir and timing water tank. It has also water outlet pipe connected to the lattices of the filter basin and water outlet tank, draining siphon pipe connected to the water seal well, water inlet siphon pipe connected to the water inlet channel, auxiliary water inlet siphon pipe connected to the water inlet siphon pipe, water inlet exhaust pipe, water inlet siphonage eliminating pipe, auxiliary water drainage siphon pipe connected to the draining siphon pipe, draining exhaust pipe, draining siphonage eliminating pipe, etc. The present invention has the advantages of completely hydraulic controlling, easy running, no need of clear water tank, no need of back flush pump, low cost, etc.

Owner:NANCHANG UNIV

High-efficiency dense-medium coagulating sedimentation water treatment process

InactiveCN103708594AReduce the use of areaImprove stabilityWater/sewage treatment by flocculation/precipitationSludgeCost savings

The invention discloses a high-efficiency dense-medium coagulating sedimentation water treatment process. The high-efficiency dense-medium coagulating sedimentation water treatment process mainly comprises a water tank, a submersible pump, a coagulating tank, a sludge tank, a stirrer, a dense medium automatic feeding device, a primary separator, a secondary separator, a dense medium mixing reaction tank, a dosing pump, a dosing tank, a curing tank, a deflocculating machine, a sludge pump, a rapid sedimentation tank, a sludge pipe, a pipeline mixer and the like, wherein the raw water tank is connected to a flocculating reactor through a pipeline of the submersible pump; the flocculating reactor comprises the coagulating tank, the dense medium mixing reaction tank and the curing tank which are sequentially communicated with one another; the flocculating reactor and the rapid sedimentation tank are connected with each other through a pipeline; the excess sludge at bottoms of the flocculating reactor and the rapid sedimentation tank is connected to a dense medium recovery system through pipelines; a dense medium enters the flocculating reactor through the pipeline after the recovery is completed so as to form circulation. The process disclosed by the invention has the characteristics of land using area and civil engineering cost saving, relatively high stability of water treatment effect, cyclic utilization of the dense medium and the like.

Owner:PACIFIC WATER TREATMENT ENG

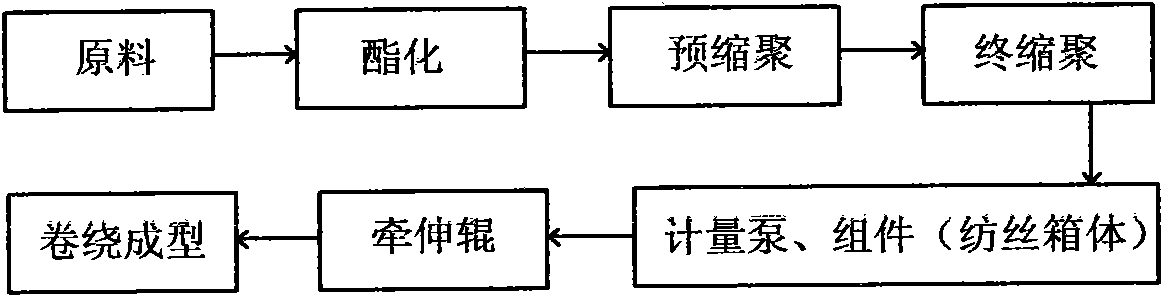

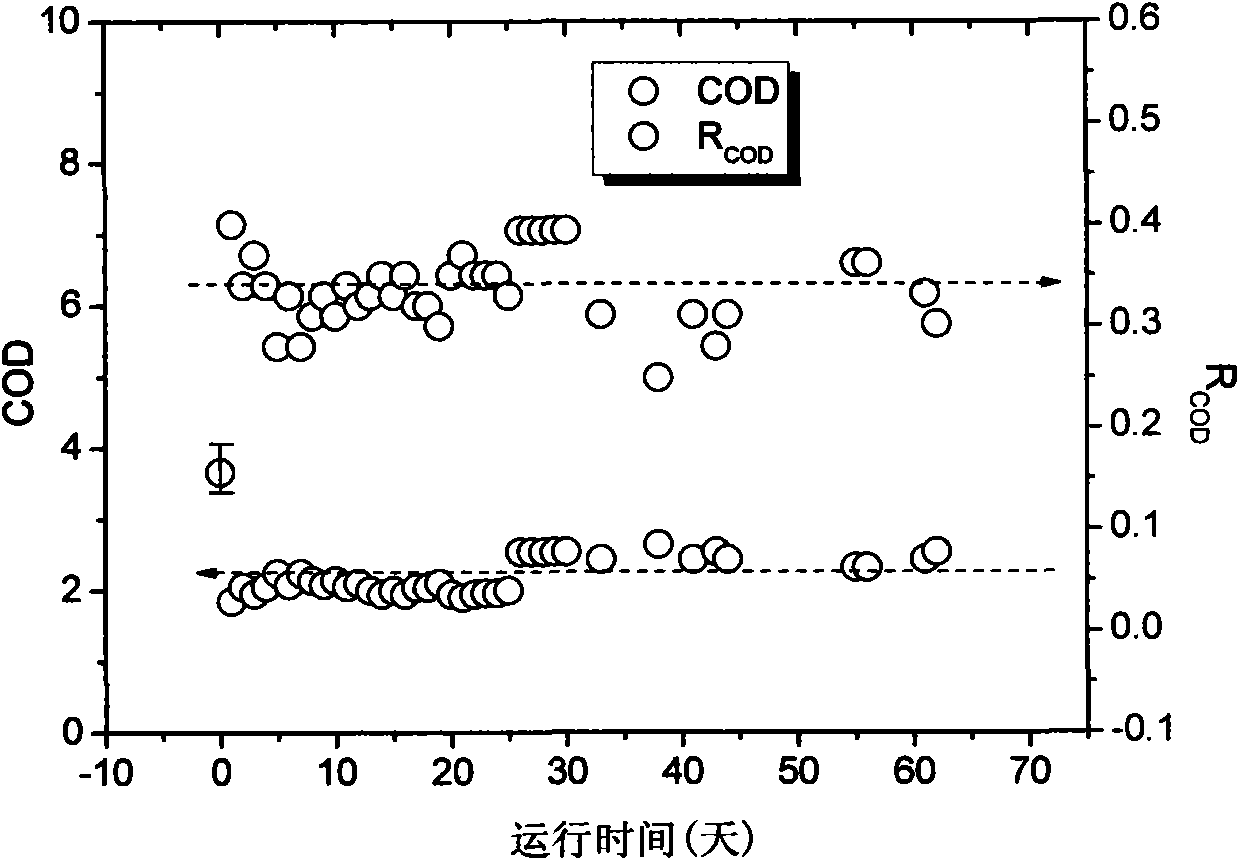

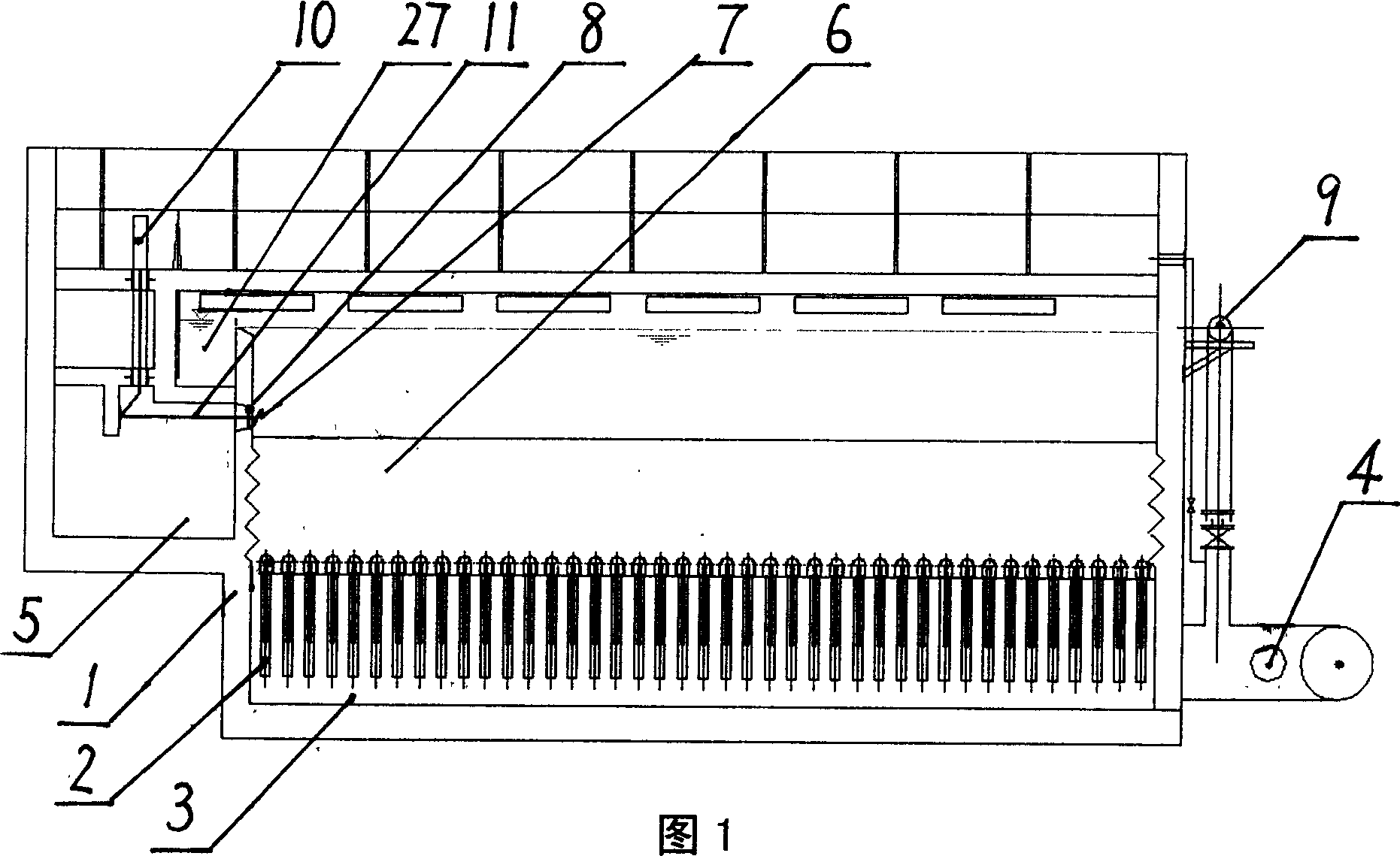

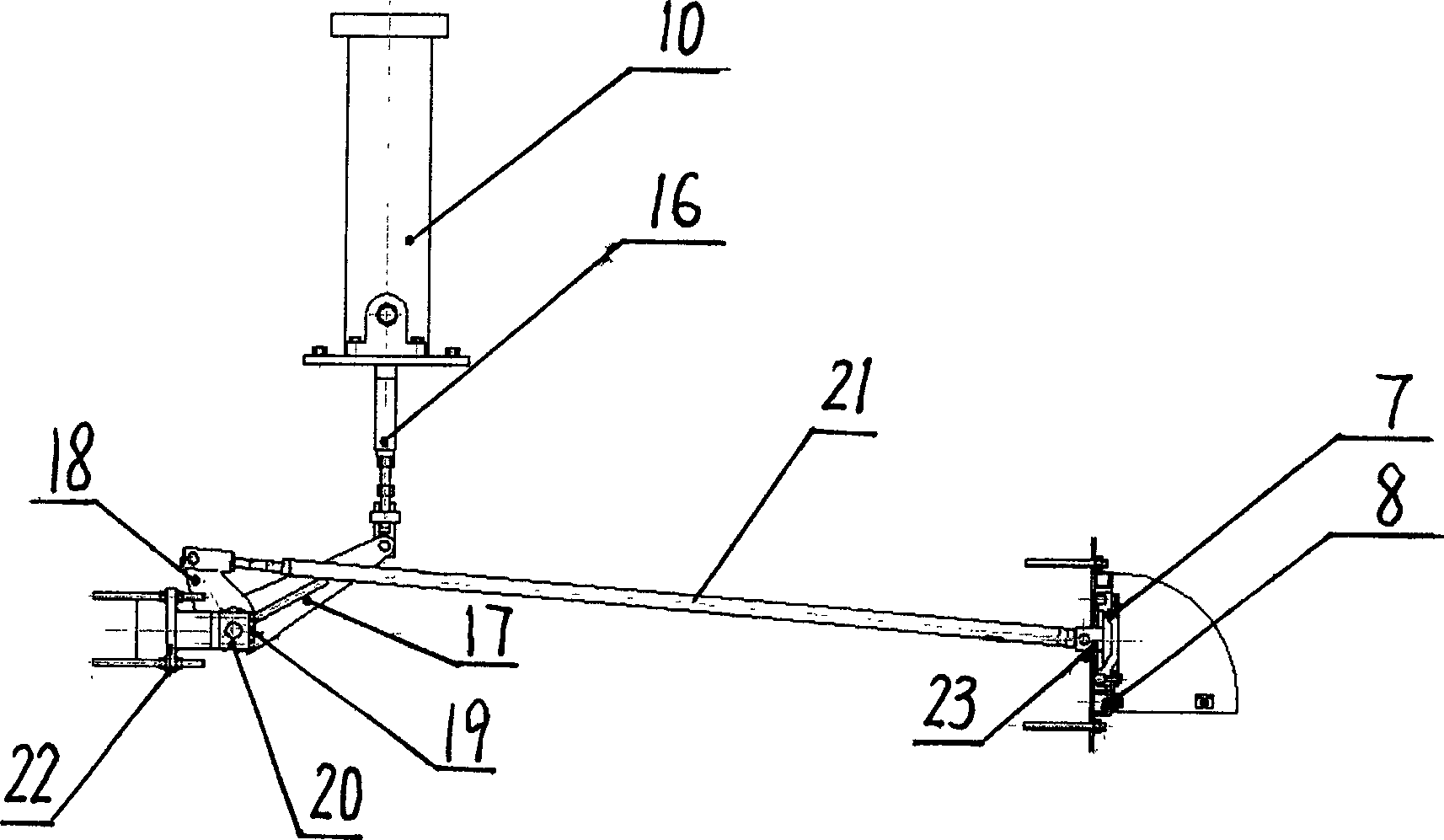

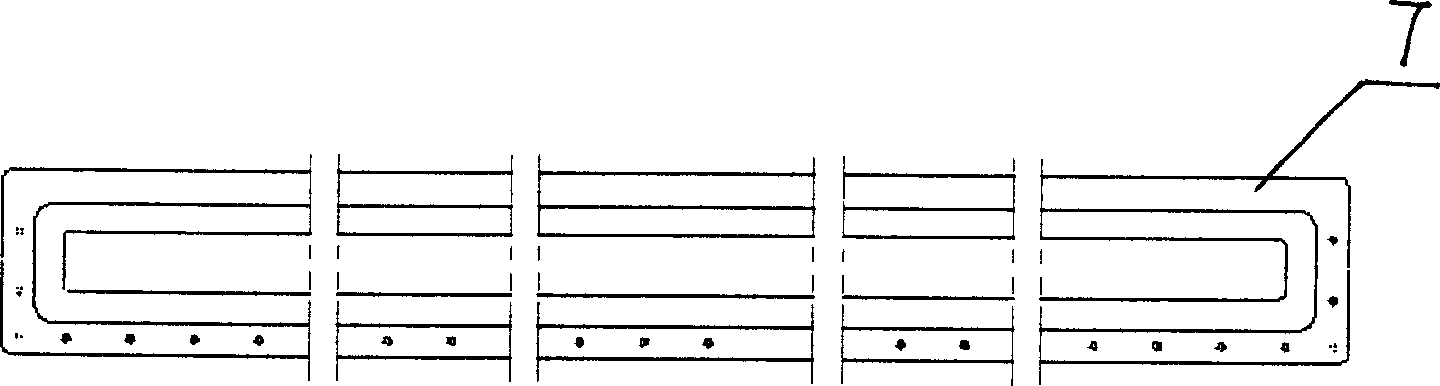

Production process for directly-spun terylene industrial filament of liquid-phase tackifying fusant

ActiveCN101768788AEasy to degradeReduce manufacturing costFilament forming substance formingMelt spinning methodsChemistryPolyester

The invention discloses a production process for a directly-spun terylene industrial filament of a liquid-phase tackifying fusant, belonging to the technical field of spinning. The production process includes the following steps: esterification, polycondensation, liquid-phase tackification and spinning. The production process is characterized in that: in a vertical reaction kettle, liquid-phase tackfication is carried out on the fusant obtained through esterification and polycondensation of glycol and phthalic acid; the vertical reaction kettle adopts a tower type film forming structure; the fusant enters the vertical reaction kettle from the top part for distribution, and the film forming is naturally finished under the action of gravity; a backflow pipeline is provided for the discharging of the reaction kettle, the viscosity and flow rate of the fusant are controlled by the backflow adjusting, the intrinsic viscosity of the polyester fusant after being tackified in a liquid-phase manner is within 0.85 to 1.0dl / g, and the fusant is conveyed to a spinning box body by a gear pump for spinning. By reasonably designing the reaction kettle and allocating the process, the invention effectively solves the consistency between the fusant reacting condition and the staying time; meanwhile, the consumption of a public medium is reduced, and the cost is lowered; by optimizing the process, the invention increases the production efficiency of a system and improves the product quality.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

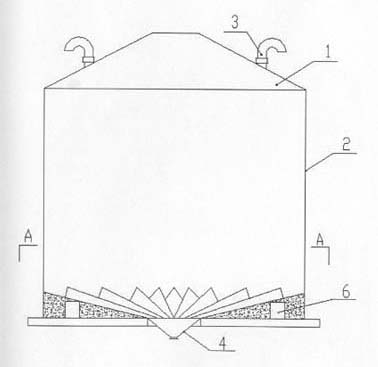

Flap valve and flap filter tank

InactiveCN1660466AReduce the cost of civil constructionLess investment in infrastructureLoose filtering material filtersGravity filtersPipingPush pull

A turn-over plate type filter pool is composed of pool body, filtering tubes, water collecting chamber, water draining pipe, back flushing pipe, filtering material layer, the canal and overflow dam for draining the black flushing water, and the flap valve consisting of valve frame, flap, sealing rubber ring and drive mechanism which comprises drive cylinder and push-pull connecting rod.

Owner:珠海市沃特金水处理技术有限公司

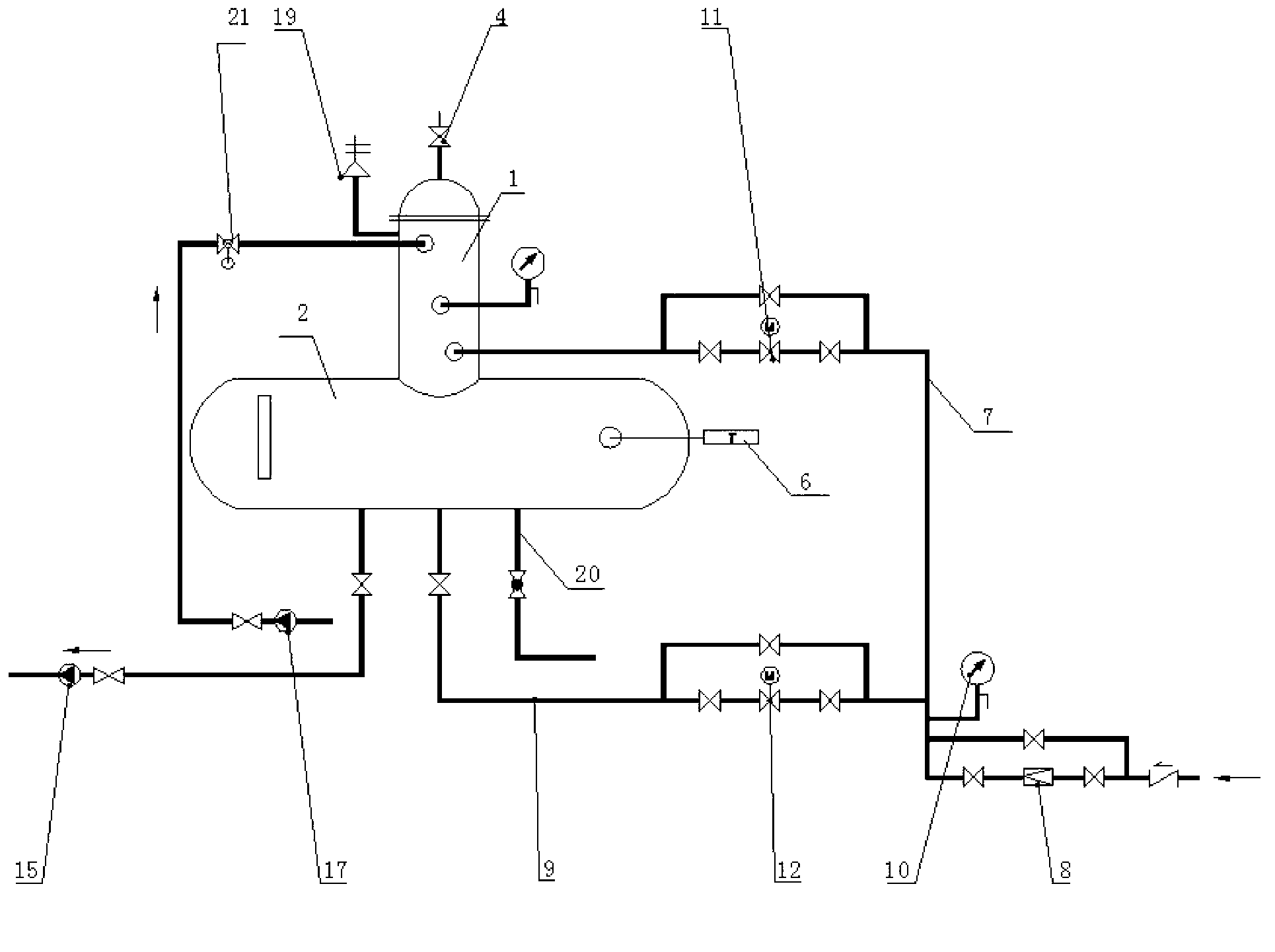

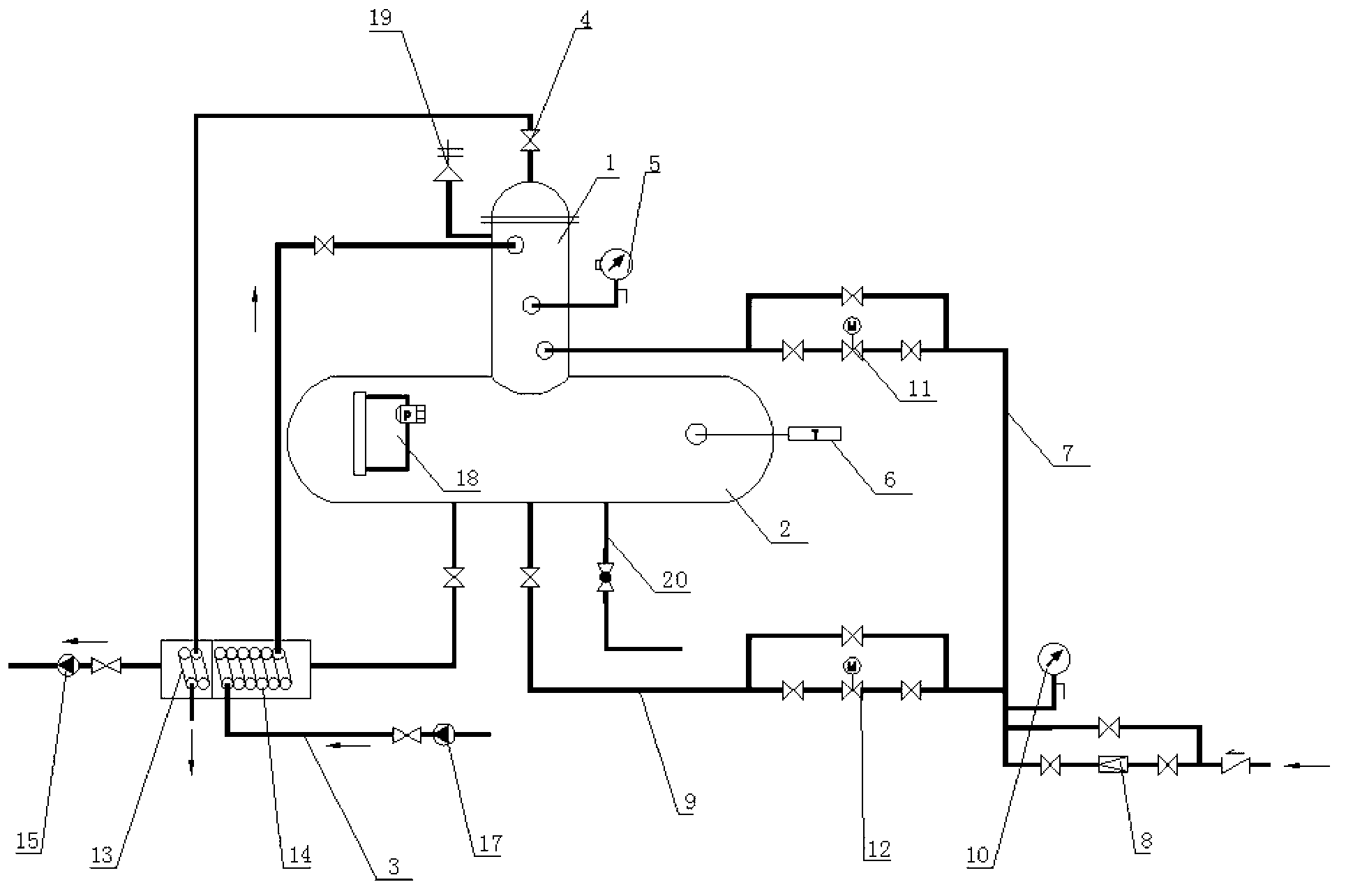

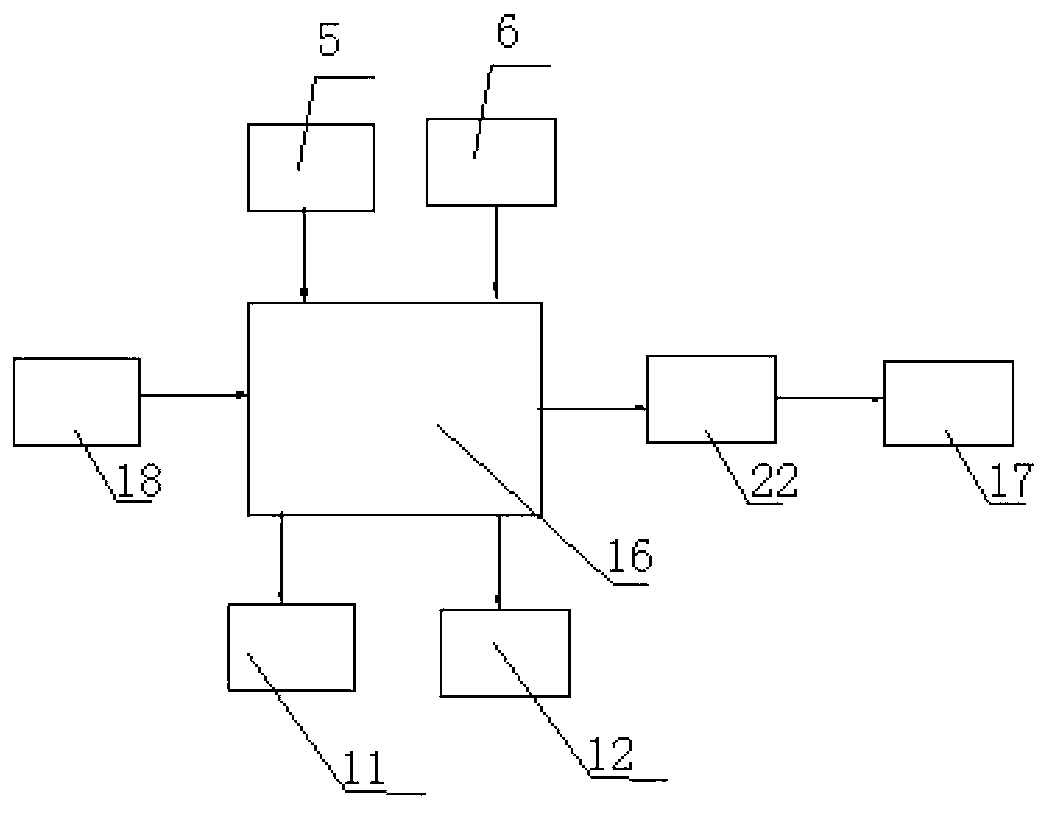

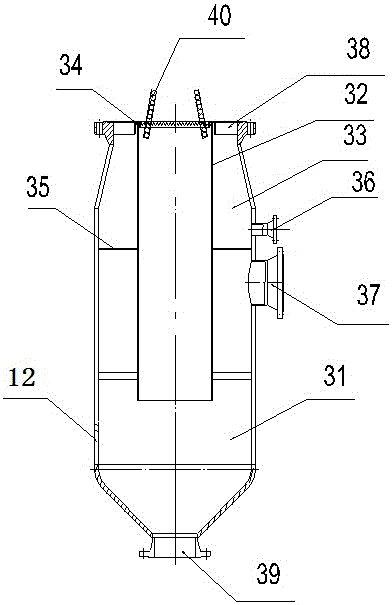

Heat filler type deaerator with stable deaerating function and atomizing function

InactiveCN103292311AConstant and reliable water levelEnsure water qualityLiquid degasificationBlowoff valveDifferential pressure

The invention discloses a heat filler type deaerator with a stable deaerating function and an atomizing function. The heat filler type deaerator is characterized in that a heat-side inlet of an exhaust heat exchanger is communicated with a blowoff valve through a pipeline, a cold-side inlet of the exhaust heat exchanger is communicated with a deaerator water supply pipe, a cold-side water outlet of the exhaust heat exchanger is communicated with a deaerator water supply inlet through a pipeline, a heat-side inlet of a water outlet heat exchanger is communicated with a deaerator water outlet, a boiler water supply pump is connected to a heat-side outlet pipeline, a cold-side water inlet of the water outlet heat exchanger is communicated with the deaerator water supply pipe, a water supply pump is arranged on the deaerator water supply pipe, a differential pressure transmitter is arranged in a deaerator water tank, detected water level signals in the deaerator water tank are transmitted to a controller through the differential pressure transmitter, the controller transmits signals to a frequency converter, the frequency converter controls rotation speed of the water pump to adjust water supply, a pressure control gauge transmits pressure signals to the controller which controls opening of preheating pipeline electromagnetic valves, a temperature sensor transmits temperature signals to the controller, and then the controller controls opening of reheating steam electromagnetic valves.

Owner:JIHUA 3539 SHOE MAKING

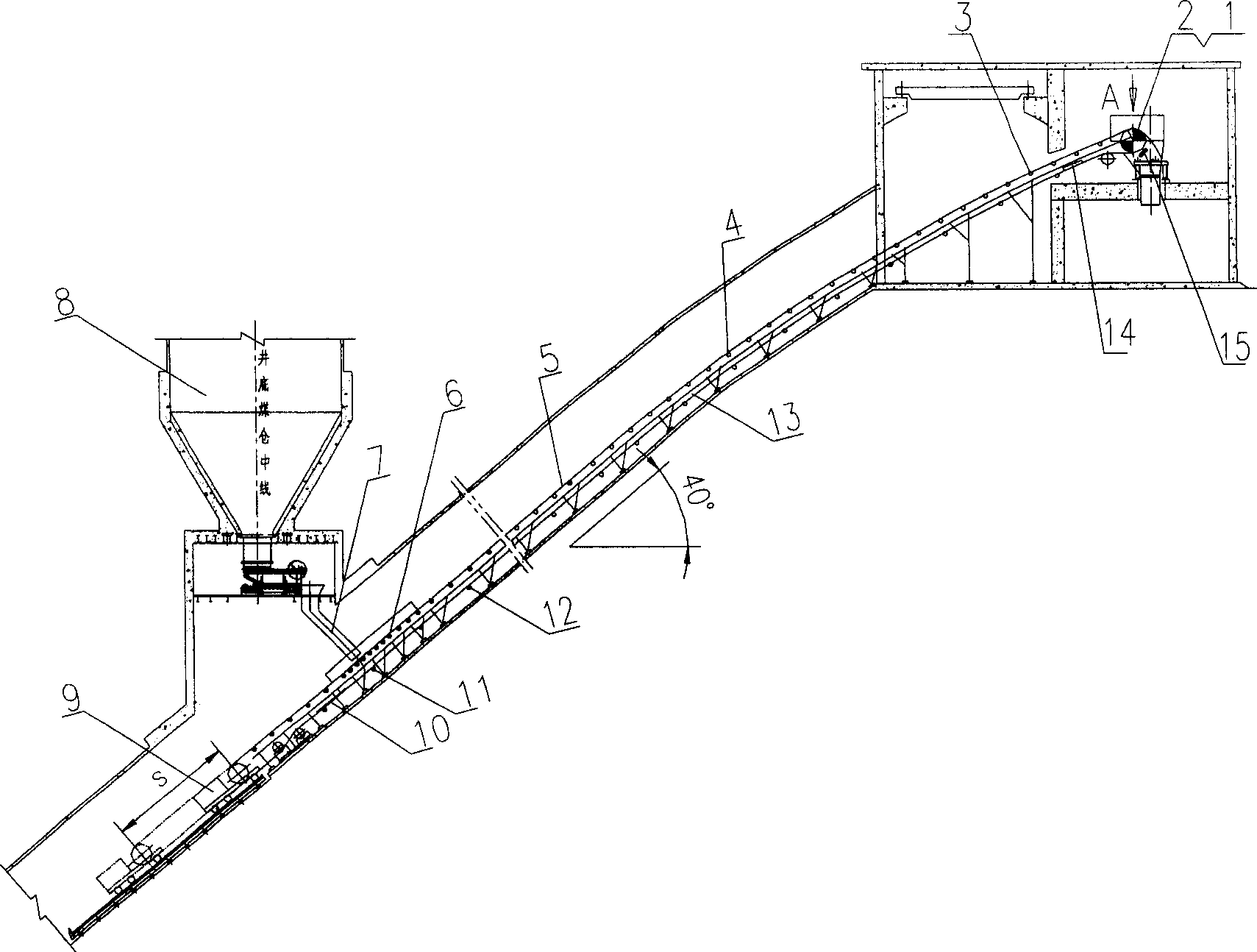

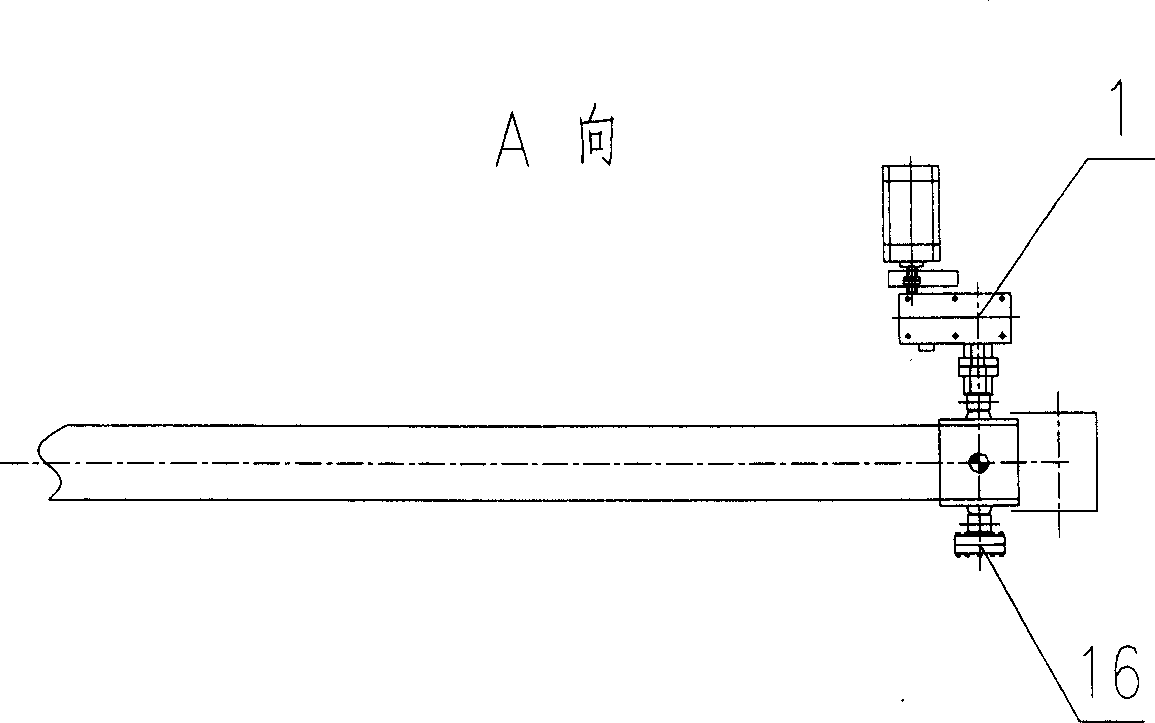

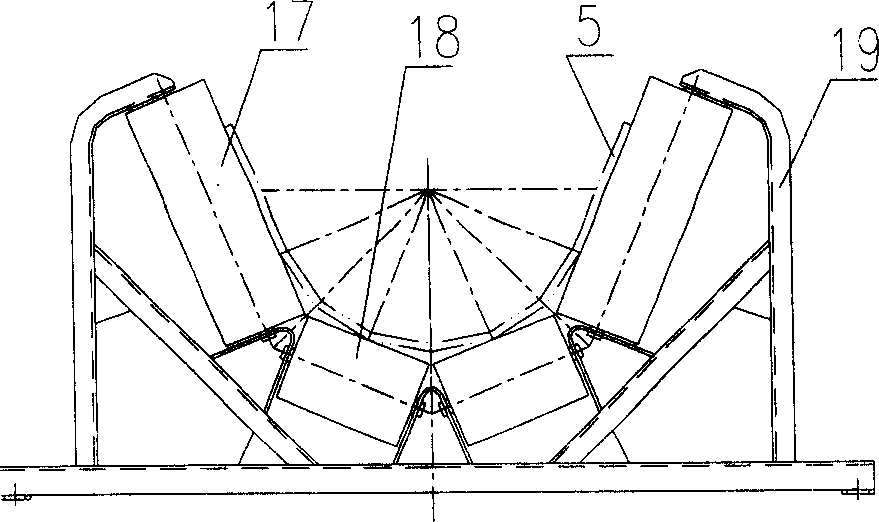

Semicircular belt conveyor with deep groove and big dig

A belt conveyer with deep semi-circular channel and big inclination up to 40 deg is composed of a machine frame, a drum group, a group of supporting rollers including central supporting rollers and side supporting rollers for rolling the conveying belt to become a deep semi-circular channel, a conveying patterned rubber belt, a carriage-type tension unit for the pull drum, and cleaning unit with brush and vibration cleaner.

Owner:SHENYANG MINING MACHINERY GROUP

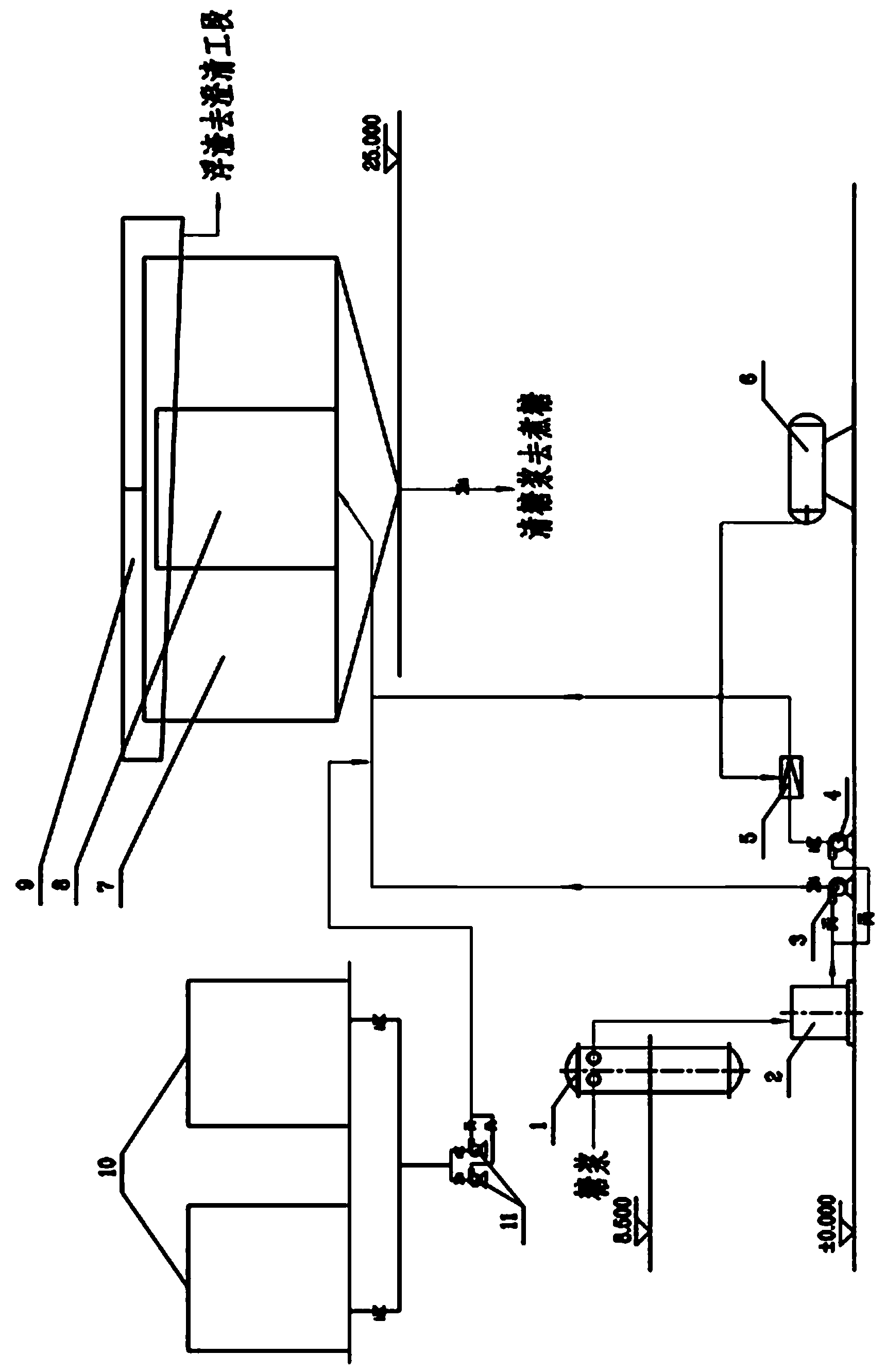

Method for automatically clearing syrup in conveying and storing processes

InactiveCN104313193AAdd cleaning functionReduce sulfur dioxide contentPurification using chemicalsThermodynamicsEconomic benefits

The invention provides a method for automatically clearing syrup in conveying and storing processes. After syrup is discharged from the former procedure, the syrup is firstly heated to a temperature of 80-85 DEG C and then discharged into a syrup box on +_0.000 layer. Then, the syrup is conveyed into a syrup storage box at the top layer of a sugar boiling building through a main and auxiliary pipeline, and a high-molecular flocculant is added before the syrup enters the syrup storage box. On the +_0.000 layer, gas is absorbed and dissolved through an online pipeline air breather and pressure formed by liquid level height difference. After the syrup enters the syrup storage box at the top layer of the sugar boiling building, impurities and air bubbles in the syrup rise to the top of the syrup storage box and are discharged out, and pure syrup is discharged from the bottom of the syrup storage box. The function of automatically clearing the syrup is increased under the condition of storing the syrup by the syrup storage box. The impurities are effectively removed from the syrup, the syrup purity is improved, the syrup conversion losses are reduced, the quality of a white granulated sugar product is effectively improved, and the economical benefit of a sugar making industry is improved.

Owner:CHINA LIGHT IND NANNING DESIGN ENG

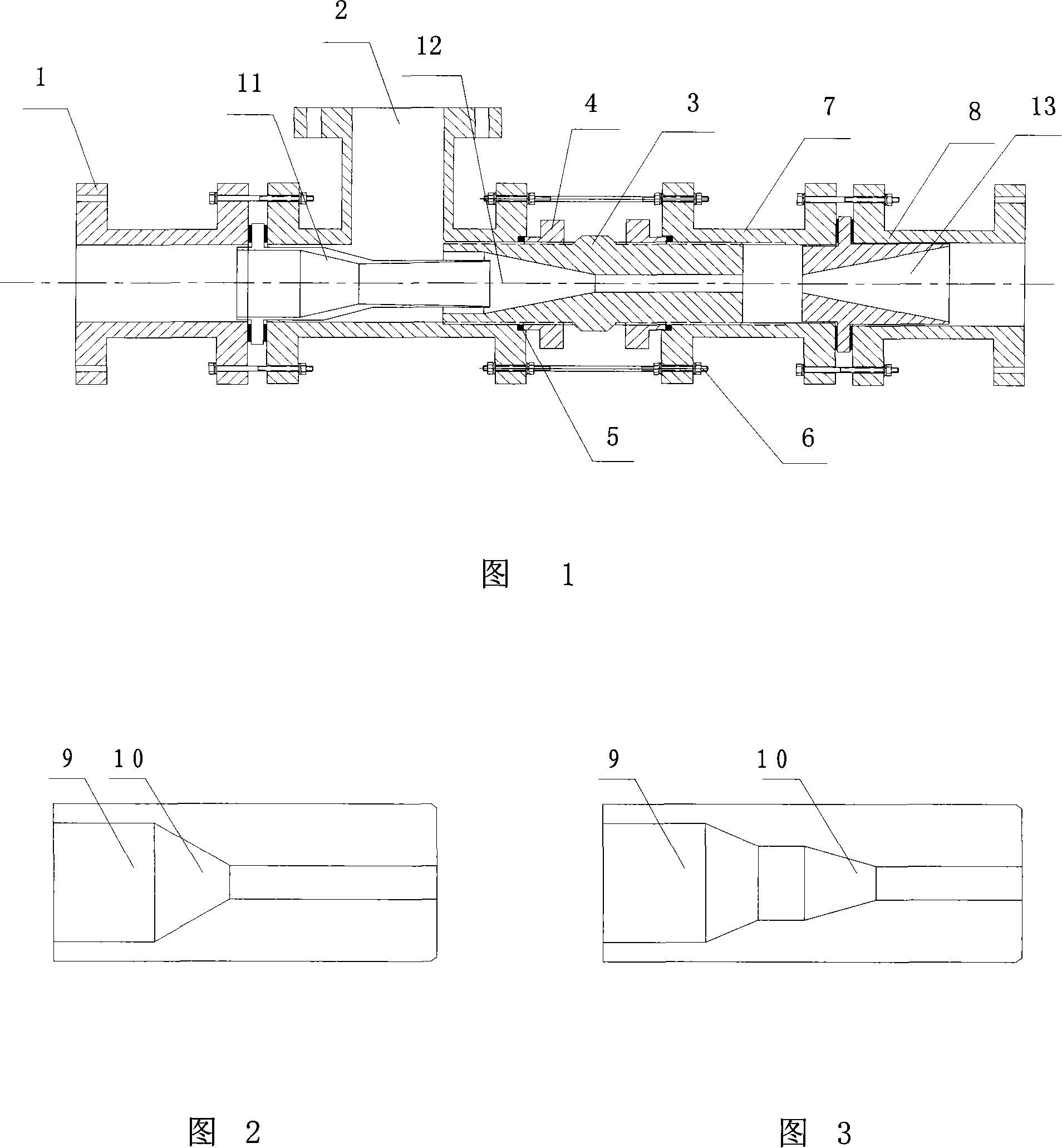

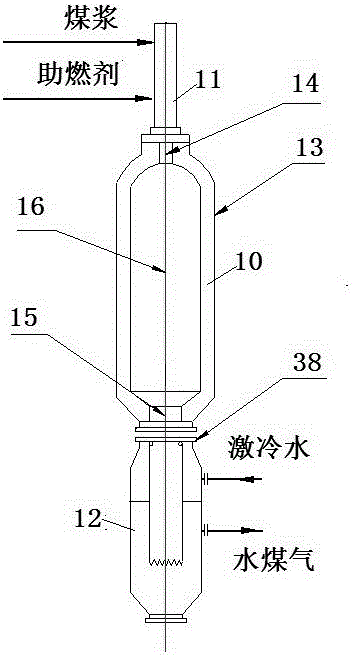

Dynamic adjustment type sonic velocity variable supercharging heat-exchanging device

InactiveCN101144616ASave electricityReduce volumeSuperheating controlDirect contact heat exchangersMass ratioWater flow

The invention discloses dynamic regulation type sonic speed changing pressurization heat exchanging device, and comprises a front two-way pipe (1), a steam jet pipe (11), a middle three-way pipe (2), a middle two-way pipe (7), a diffusing pipe (13) and a rear two-way pipe (8). The steam jet pipe is coaxially arranged in the middle three-way pipe, the diffusing pipe is embedded between the middle two-way pipe and the rear two-way pipe, an adjustable core (3) is arranged between the middle three-way pipe and the middle two-way pipe, the adjustable core (3) can make axial fore and aft horizontal movement, the center thereof is provided with an axially interpenetrated mixing chamber (12), the mixing chamber consists of a conical curve line part and a horizontal straight line part, wherein, the conical curve line part is a flow regulating section (10) which is used for regulating the inlet water flow, and the horizontal straight line part is a state and pressure regulating section (9) which is used to regulate the steam water mixing ratio in the mixing chamber. The invention achieves the goal of dynamic regulation in the condition of not stopping the system operation when the steam water parameter changes, makes the steam water mixing mass ratio and pressure ratio in the heat exchanger be in the optimum condition, effectively reduces the equipment operation noise and the operating cost, as well as enhances the heat transfer efficiency and the operation safety.

Owner:LUOYANG BLUE SEA INDAL

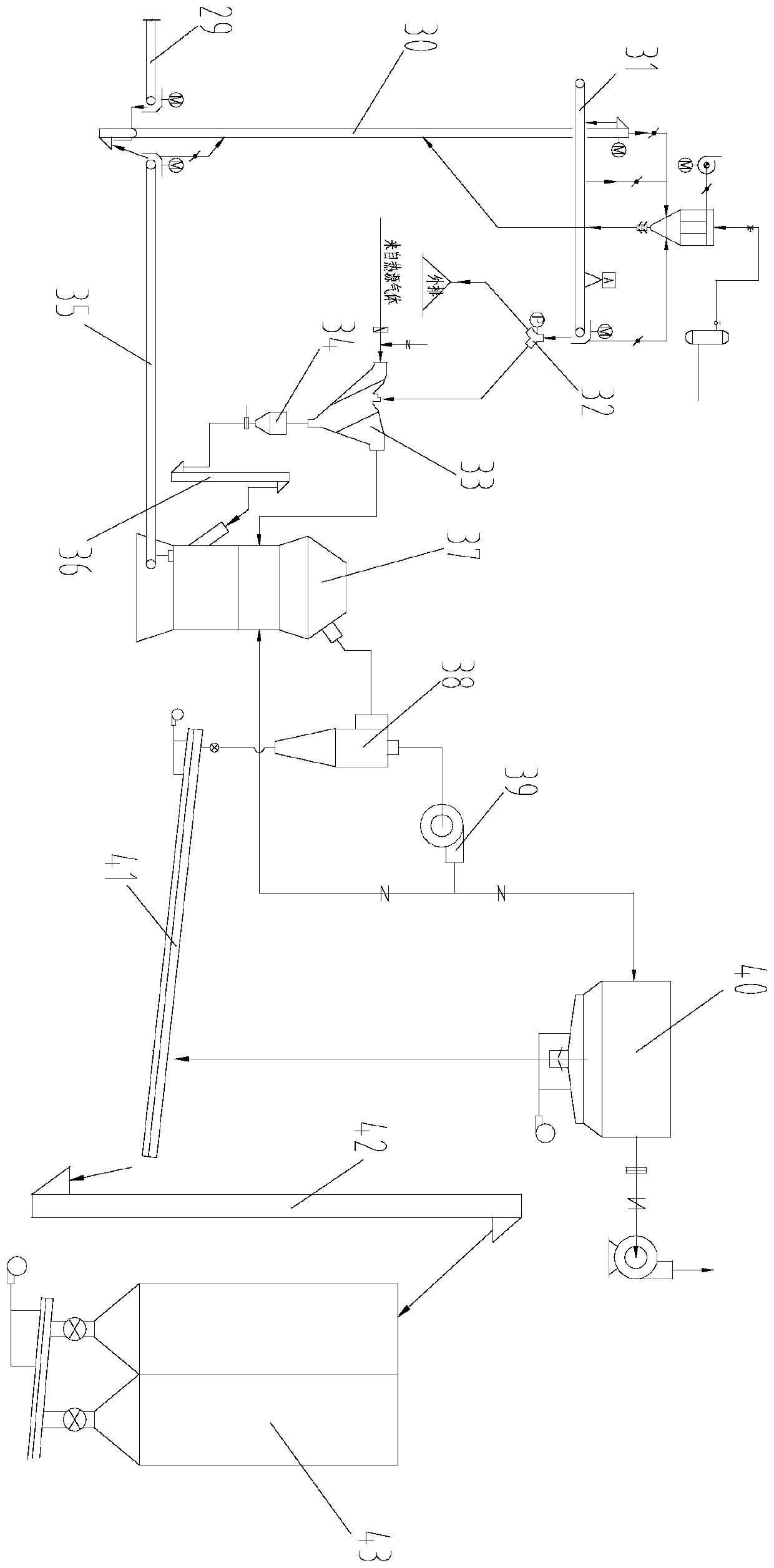

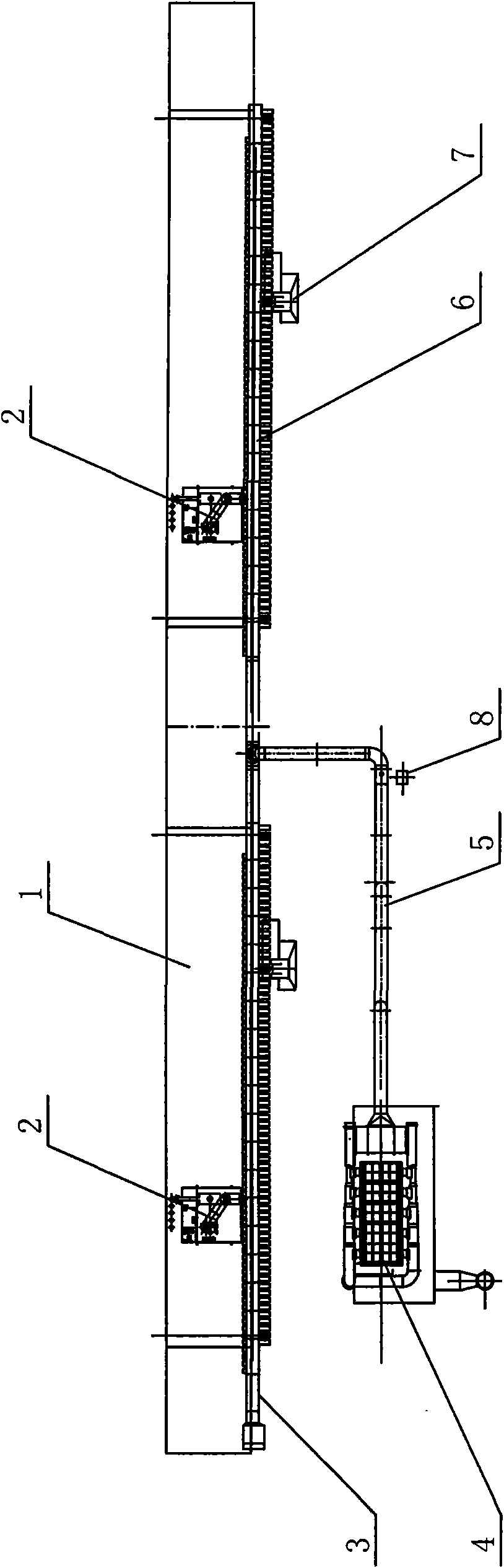

Raw material vertical mill external circulation system and process

PendingCN110860343AImprove sorting efficiencyLow air resistanceVortex flow apparatusGrain treatmentsPowderMaterials science

The invention discloses a raw material vertical mill external circulation system comprising a material proportioning belt conveyor, an elevator, a feeding conveying mechanism, a feeding three-way joint, a V-shaped powder concentrator, an external circulation roller type vertical mill, a cyclone, a circulation draught fan and a dust remover. The external circulation roller type vertical mill comprises a powder milling barrel on the lower portion and a powder concentration barrel on the upper portion. A mill is arranged in the powder milling barrel. The powder concentrator is arranged in the powder concentration barrel. The powder milling barrel and the powder concentration barrel are separated through a partition plate. An outlet of a powder concentration coarse powder ash hopper of the powder concentrator penetrates through the partition plate and extends into the powder milling barrel. Materials are not conveyed to the powder concentrator in a pneumatic manner to be subjected to separation any more, and due to the adoption of concentrated mechanical conveying of the elevator, the gas flow resistance is greatly reduced, and the electricity consumption is substantially reduced. Thepowder concentrator is still above the vertical mill, the civil engineering cost can be greatly reduced, and the device input can also be greatly saved.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

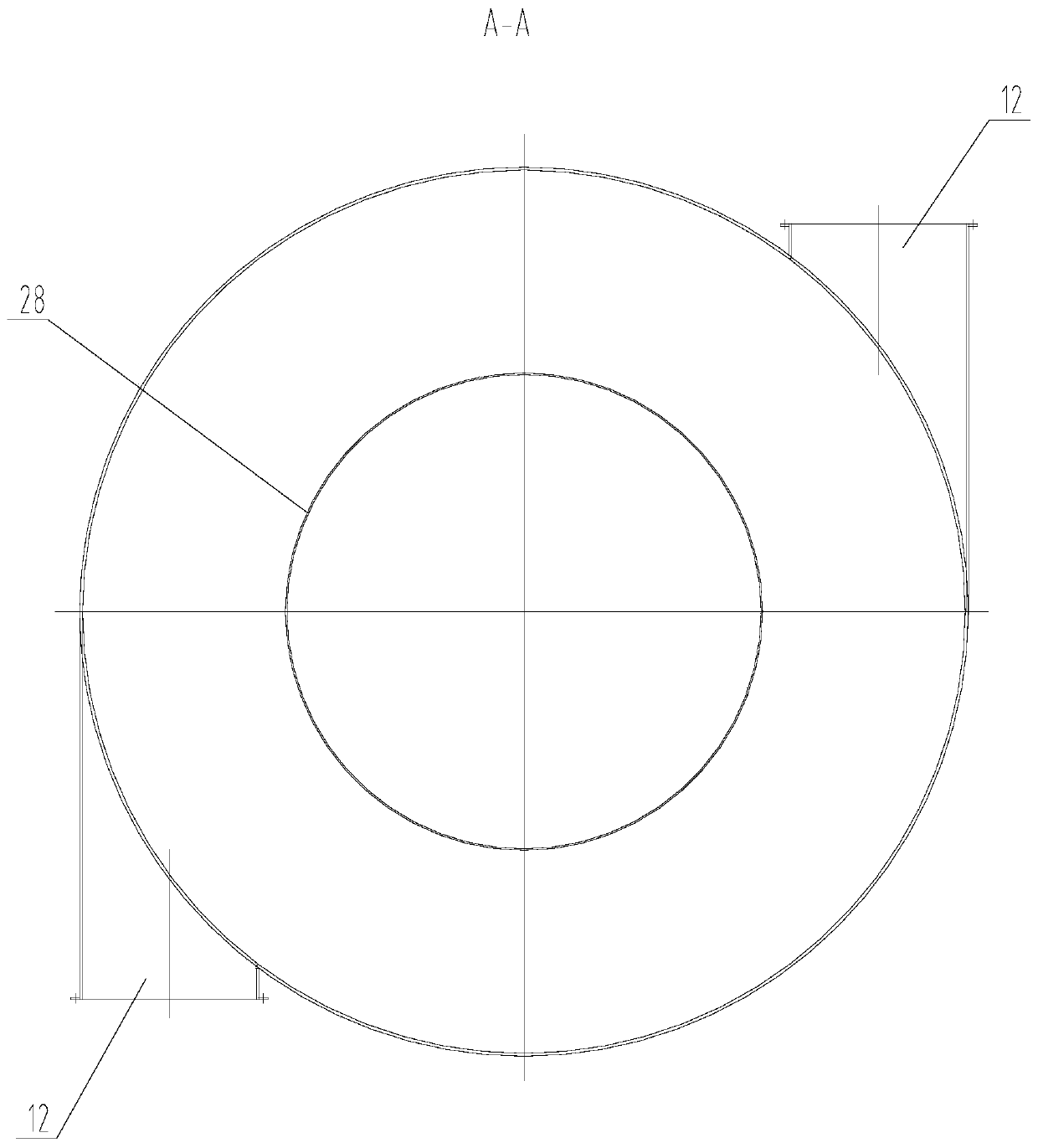

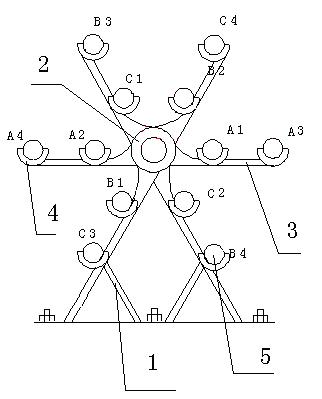

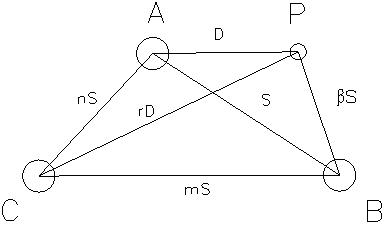

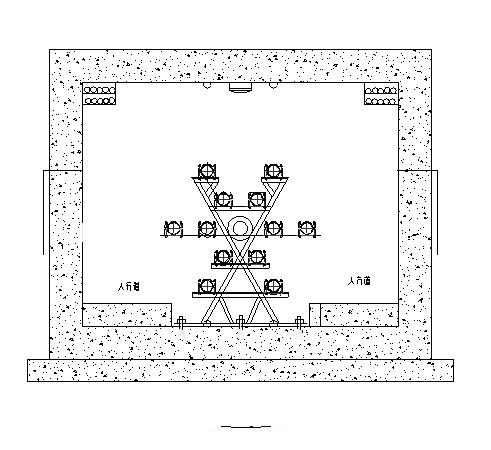

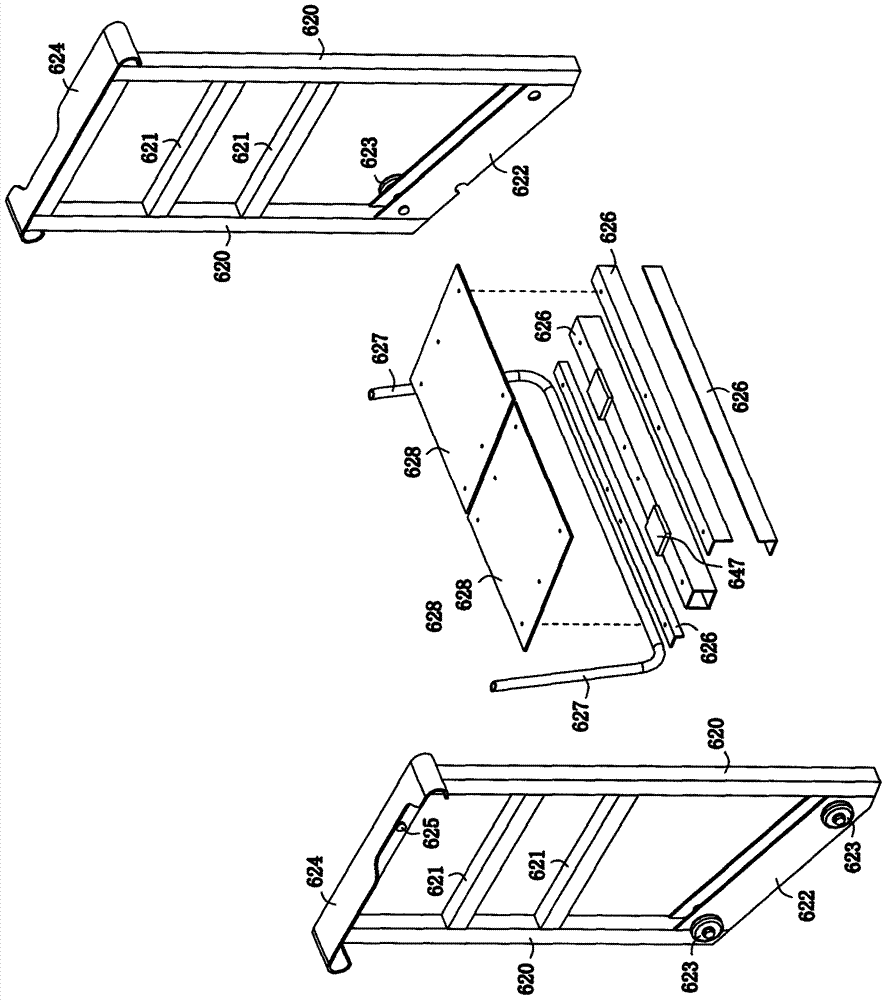

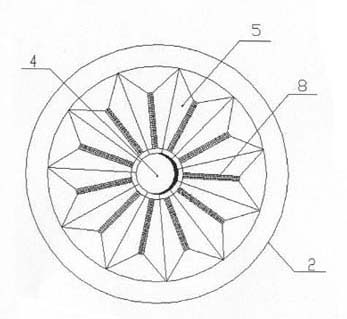

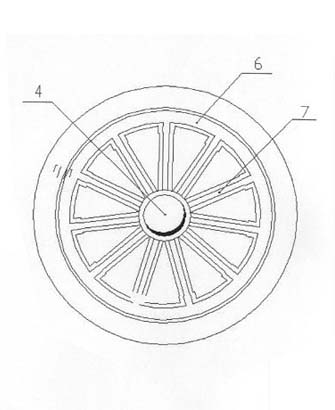

Cable laying method and bracket thereof

InactiveCN102623935AReduce ampacitySave civil costElectrical apparatusStructural engineeringEngineering

The invention discloses a cable laying method and a bracket thereof. More than one group of three-phase cables is arranged along the circumference direction of a concentric circle, so that the same group of three cables is arranged on the same circumference, and included angles between every two cables are 120 DEG. The bracket has the advantages of simple structure, low cost, minimum longitudinal induced voltage, and better energy saving effect because longitudinal induced voltages in the whole circulating section are mutually cancelled out as smallest as possible, even zero.

Owner:李超 +2

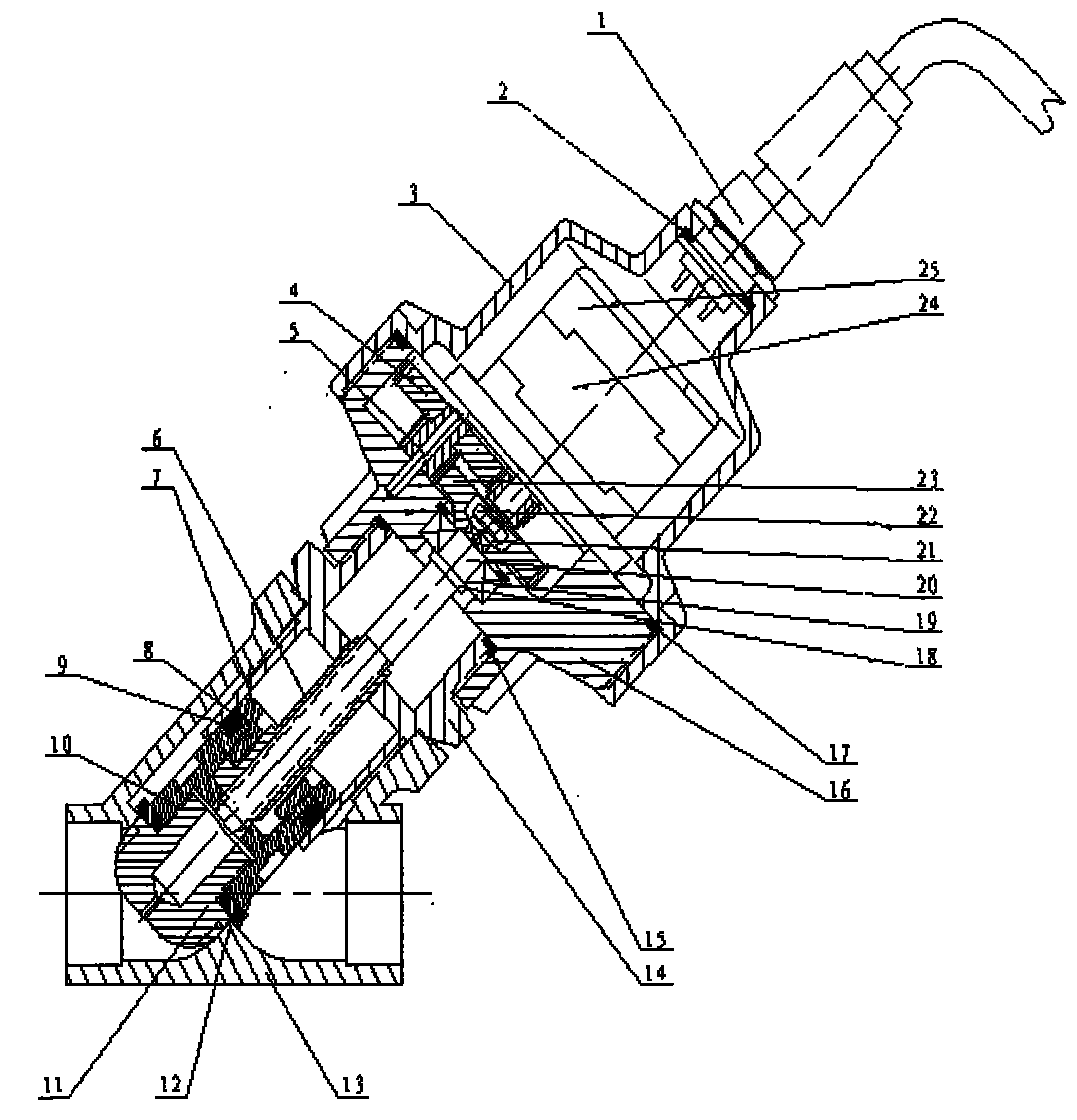

Electric control valve

InactiveCN101858455AReduce volumeReduce noiseOperating means/releasing devices for valvesValve housingsLow noiseAviation

The invention relates to an electric control valve, in particular to an electric control valve suitable to be used on a hyperbaric oxygen chamber, and belongs to the technical field of the valve structure. The electric control valve is characterized by comprising an aviation socket for providing a power signal, wherein the aviation socket is connected with a motor; the periphery of the motor is sleeved with a motor shell which is in sealing connection with the motor by an O-shaped sealing ring; the lower end of the motor shell is connected with a motor reduction seat by the O-shaped sealing ring; the motor drives a motor gear to rotate; the motor gear is meshed with a screw rod gear; and the screw rod gear drives a screw rod to move. Compared with a pneumatic control valve in the prior art, the electric control valve of the invention not only has small volume and saves occupied space, but also does not need to arrange the oxygen chamber in an oxygen chamber basement when the oxygen chamber is arranged and used, thus, a user does not need to carrying out digging on the civil engineering. Therefore, the electric control valve not only has convenient installation, but also can save civil engineering cost and pipeline installation cost. Moreover, the electric control valve has low noise.

Owner:烟台豪特氧业设备有限公司

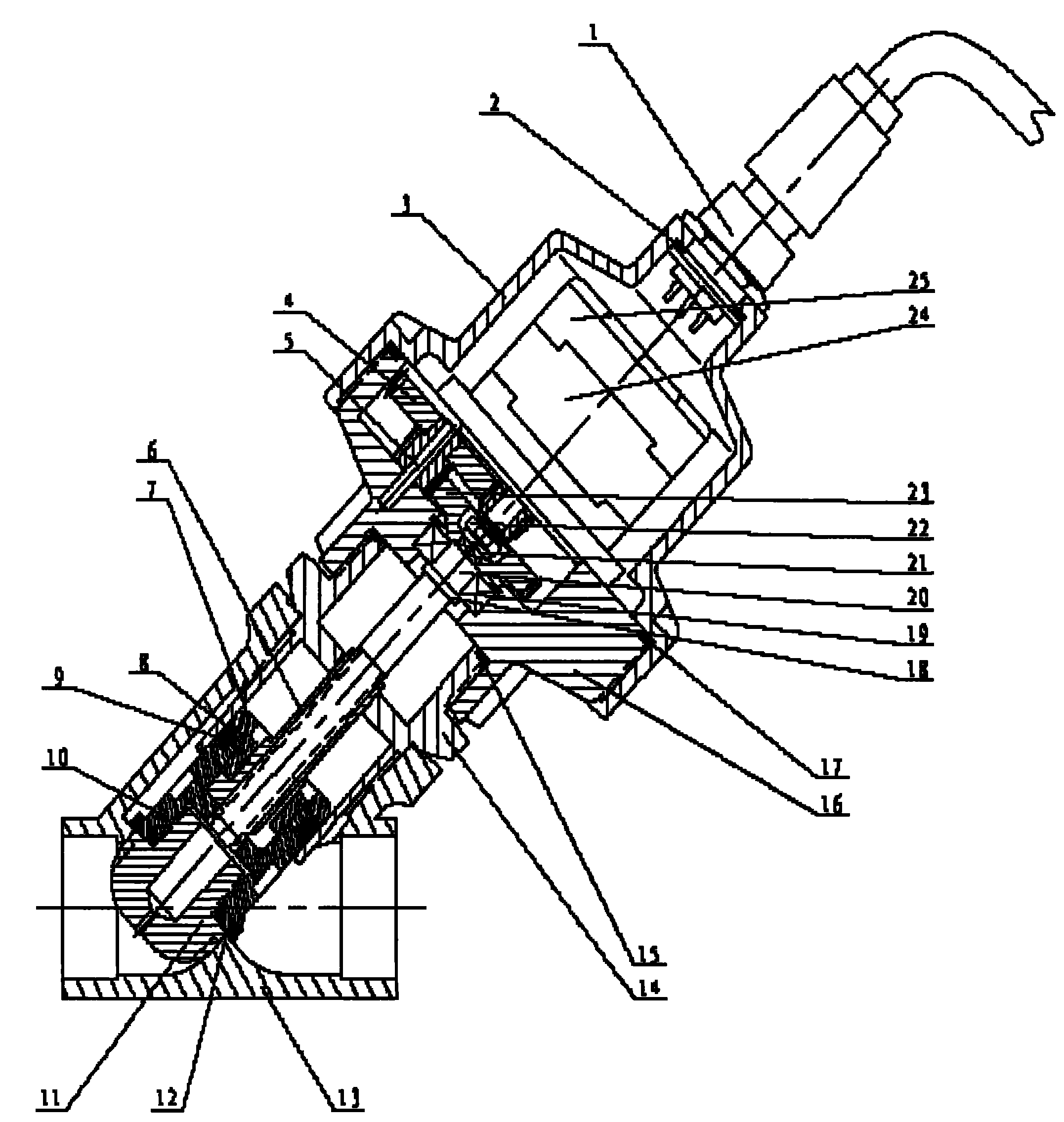

Combustion and quenching separated type water-coal-slurry gasifier

InactiveCN106433794ASimple structureCompact designGasification apparatus detailsGranular/pulverulent flues gasificationCombustion chamberSlag

The invention relates to the technical field of chemical equipment, in particular to a combustion and quenching separated type water-coal-slurry gasifier. The combustion and quenching separated type water-coal-slurry gasifier comprises a gasifier hearth, a nozzle and a quenching chamber. The gasifier hearth comprises a shell, a hearth inlet, a hearth outlet and a combustion chamber. The hearth inlet is connected with the nozzle, and the hearth outlet is connected with a quenching chamber inlet big flange; the nozzle comprises a central tube, a coal-slurry channel, a fire retardant outer ring, a water jacket, a water jacket inlet, a water jacket outlet, a nozzle big flange and a fuel gas pipe. The nozzle big flange is connected with the hearth inlet; the nozzle adopts a three-channel design, the nozzle three channels include the center tube, the coal-slurry channel and the fire retardant outer ring from inside to outside. According to the combustion and quenching separated type water-coal-slurry gasifier, high-temperature water gas can be quenched to lower the temperature, the slag generated from gasification is effectively separated from the water gas, the washing separation and heat transfer effects are good, the gasifier is compact and reliable, cost is low, and the high-temperature water gas can be transformed into relatively clean water coal gas.

Owner:江西昌昱实业有限公司

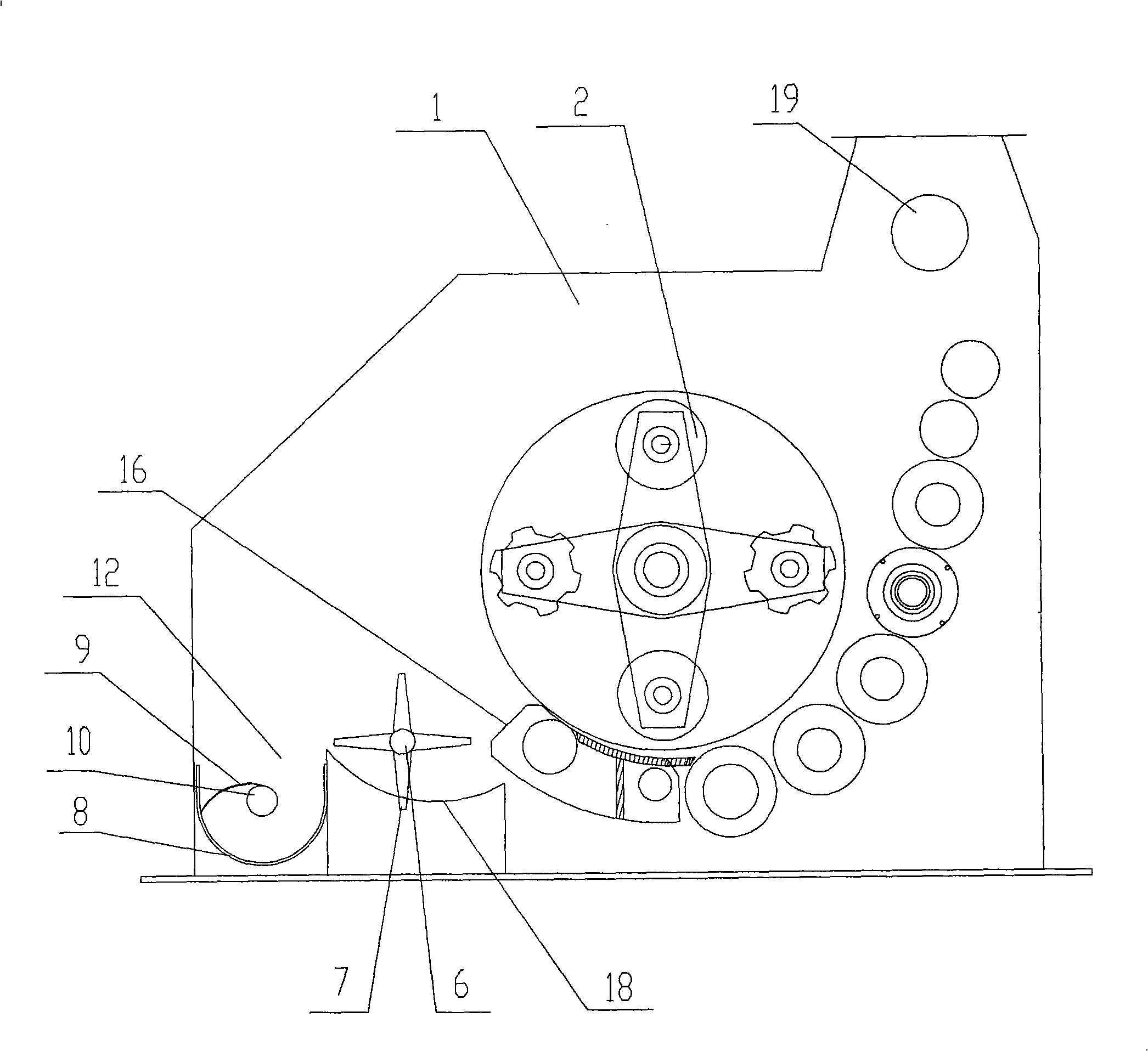

Automatic cycle crusher

The invention discloses an automatic cycle crusher, comprising a frame, wherein, a feeding port, a crushing cavity and a discharge port are arranged on the frame, the discharge port is provided with a screening device for firstly screening crushed materials, the materials-screening part of the screening device is provided with a horizontal screening conveying device for horizontally conveying the materials and secondly screening the materials, the outlet of the horizontal screening conveying device is provided with a lift conveying device for lifting and conveying the materials into the feeding port so that the materials enter into the crushing cavity for recycling crushing, and the screening device, the horizontal screening conveying device and the lift conveying device are all driven by a drive mechanism. The invention has the advantages that the crushed materials are firstly and secondly screened during horizontal conveying, and conveyed to the feeding port in a lifting way and recrushed by the crusher.

Owner:张世洪 +1

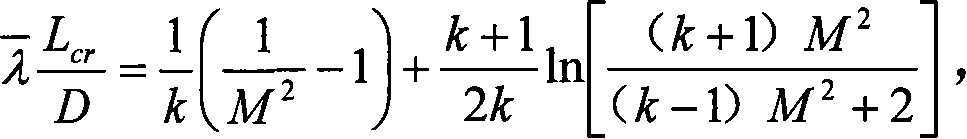

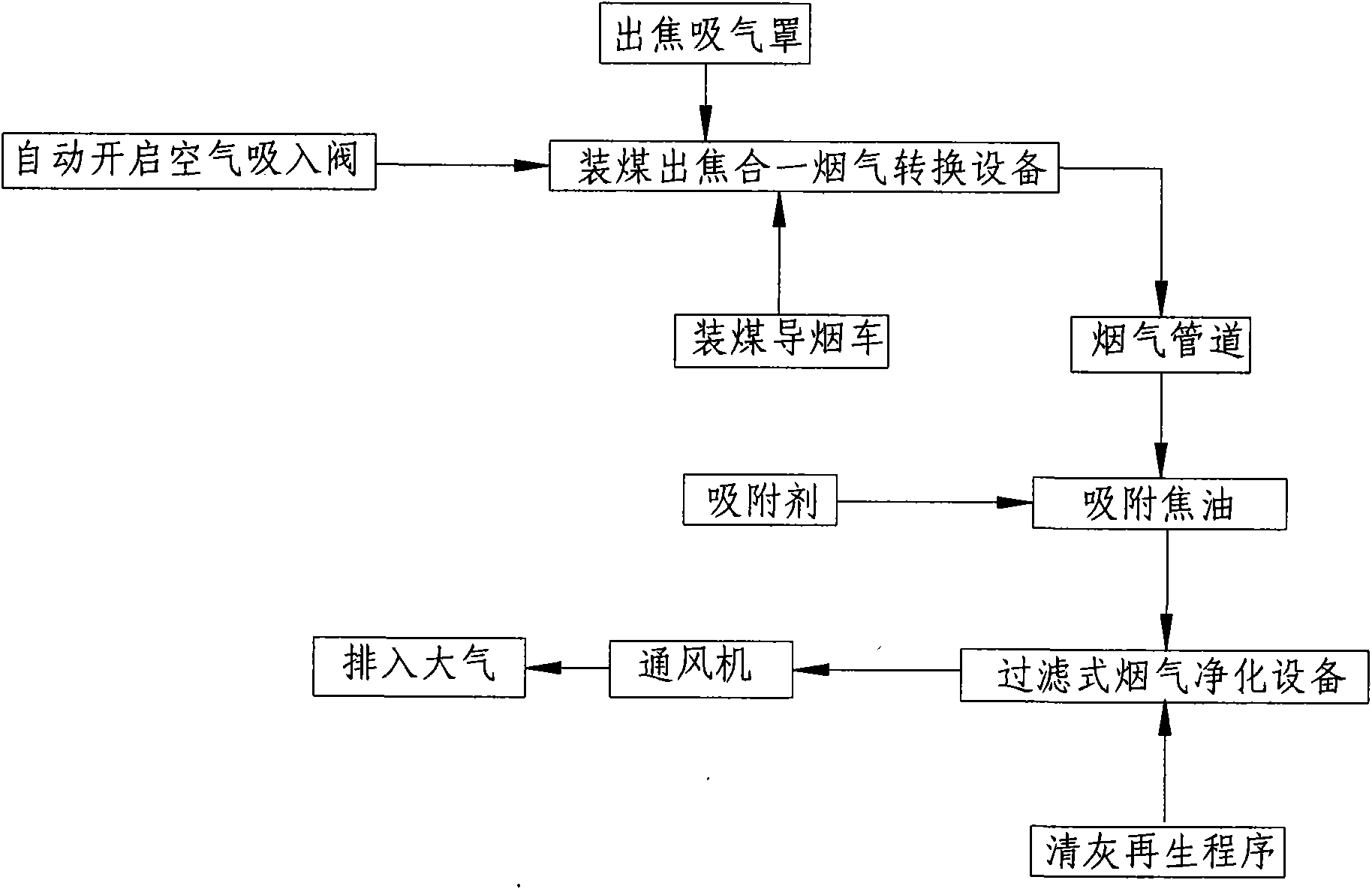

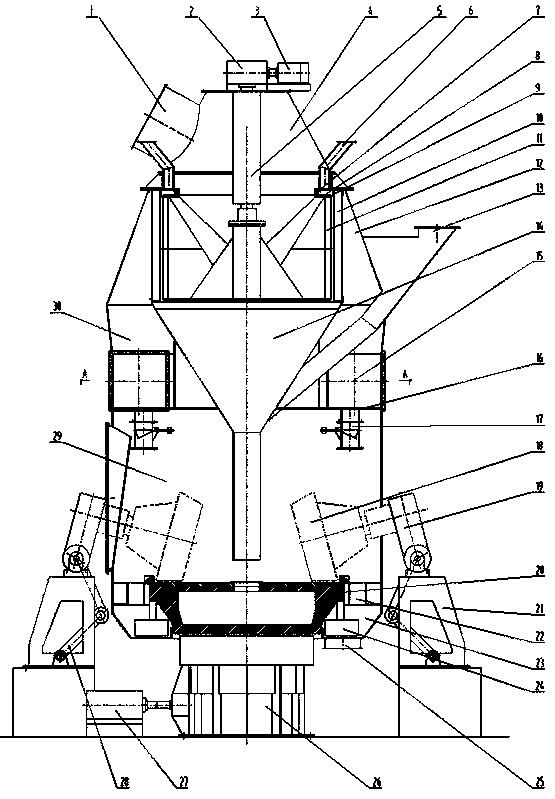

Coal-charging and coke-discharging flue gas integration dust-removal process for side coal-charging coke oven

InactiveCN101602951ASave civil costSave equipment costsCharging-discharging device combinationsOven incrustations prevention/removalAtmospheric airFlue gas

The invention relates to a coal-charging and coke-discharging flue gas integration dust-removal process for a side coal-charging coke oven. A two-way connector valve is arranged on an oven column for the coke oven, the flue gas generated during the coal charging process of the coke oven and the flue gas generated during the coke discharging process of the coke oven enter in a common flue gas pipeline respectively through the two-way connector valve, and the dust removal is performed through a filtering type flue gas dust-removal device connected with the flue gas pipeline; the tar adsorption adopts a method that active powder adsorbent is sprayed in the flue gas pipeline, and the flue gas is discharged into atmosphere through a ventilator after being filtered and purified in a filtering type flue gas purification device; and the filtering type flue gas purification device performs off-line dust-cleaning regeneration after finishing coke discharging until the next coke discharging of the coke oven. No dust deposits in the process pipeline, the tar adsorption is complete, the dew point is not reached, the filter bag dust-cleaning regeneration is good, and the system is reliable and stable, thereby effectively ensuring the normal running of the coke oven with flue gas dust removal.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

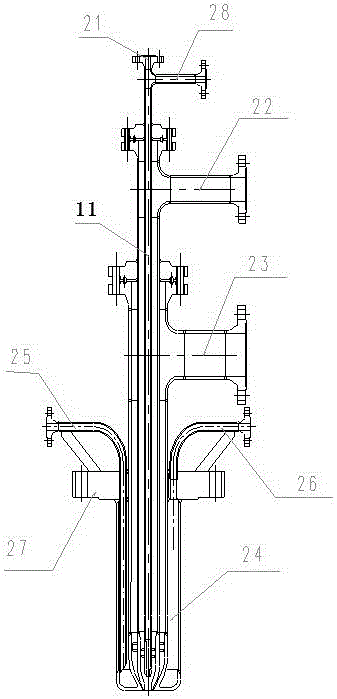

Outer circulation vertical roller mill

PendingCN110860342AImprove negative pressureReduce energy consumptionGrain treatmentsEngineeringMechanical engineering

The invention discloses an outer circulation vertical roller mill. A partition board is arranged on the middle upper portion of a mill shell and divides the mill shell into a powder milling barrel anda powder screening barrel. A powder screening machine is arranged in the powder screening barrel. An outlet of a powder screening coarse powder hopper of the powder screening machine penetrates through the partition board to extend into the powder milling barrel. The lower portion of the powder screening barrel is provided with air inlets. A grinding disk and grinding rollers are arranged on thelower portion of the powder milling barrel. A spray port ring is arranged between the outer circumference of the grinding disk and the mill shell. The lower portion of the spray port ring is providedwith a discharge ring channel. The bottom of the discharge ring channel is provided with a discharge port. A material is fed into feed pipes of the powder screening machine in the powder screening barrel through a material elevator mechanism at the discharge port. Through the outer circulation vertical roller mill, a mode that the material is conveyed completely with effort is changed thoroughly to a high-efficiency mechanical centralized conveying mode, and energy consumption can be greatly reduced. Moreover, two independent powder milling systems and a screening system are organically combined, the space is saved, and the civil engineering cost is greatly saved.

Owner:NANJING JULI INTELLIGENT MFG TECH INST CO LTD +1

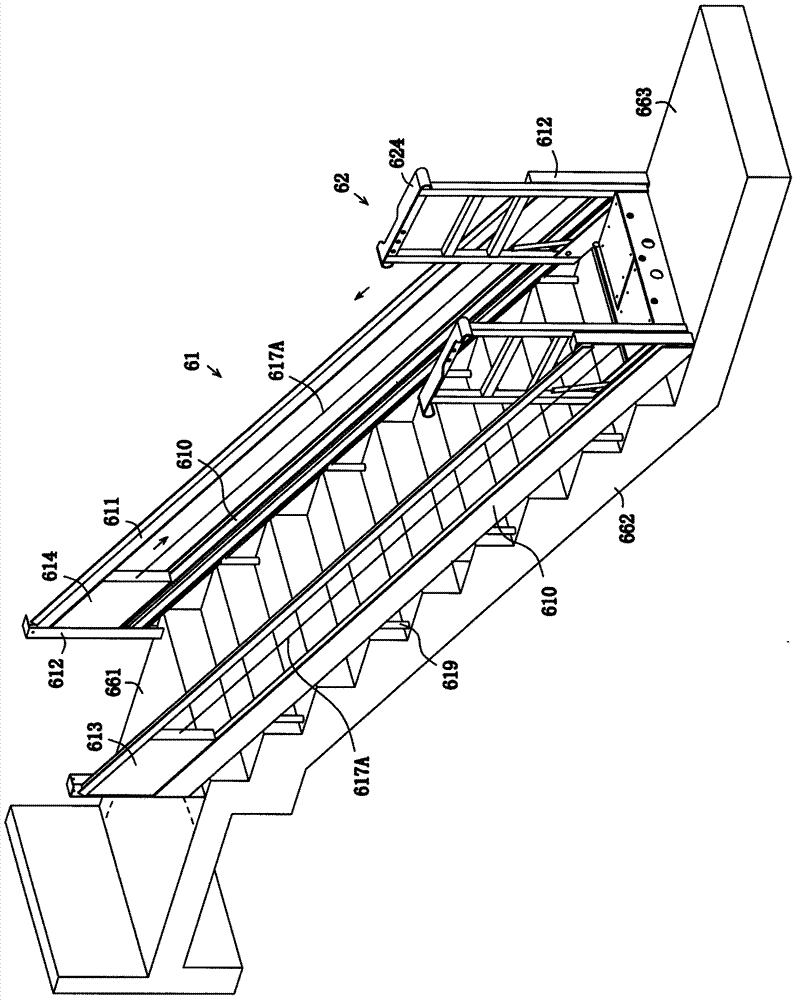

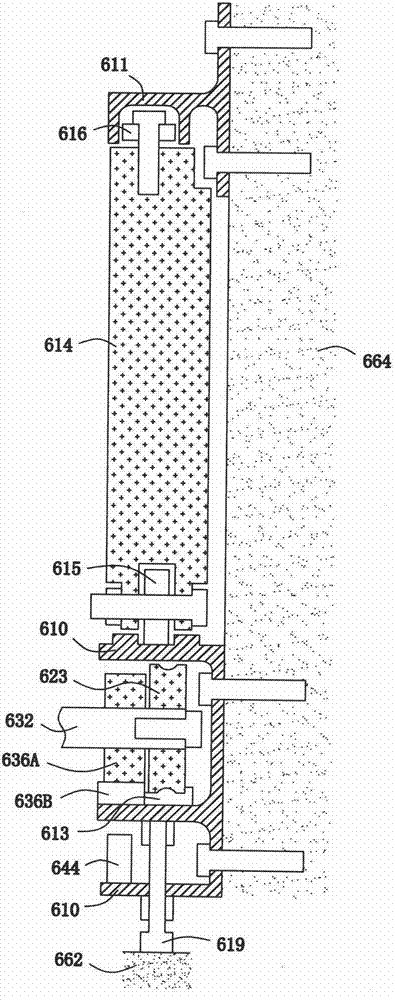

Corridor double escalator with balancing units

ActiveCN107352356AChange appearanceDoes not affect ventilation and lightingElevatorsBuilding liftsEngineeringElectromagnetic brake

The invention discloses a corridor double escalator with balancing units, and relates to an elevating device. The escalator is arranged in a corridor, and is advantaged in that the escalator does not affect ventilation and natural lighting, operates safely and reliably, can keep the corridor unobstructed, and is simple and convenient to use, low in cost and short in construction period and the like. The corridor double escalator comprises guide frames, main frames, the balancing units, a driving unit and safety protection units, the guide frames are symmetrically and fixedly arranged on walls at two sides of the corridor and are parallel to the slope of stairs, the main frames are movably arranged on the guide frames and move on the guide frames through the driving unit, the balancing units are arranged on the guide frames and are connected with the main frames through wire ropes and rope guide wheels, and the safety protection units are arranged on the main frames or the guide frames, and are connected with a controller and an electromagnetic brake. The corridor double escalator with the balancing units can be used as an escalator and also can be used as a staircase. By employing the corridor double escalator with the balancing units, conflict of residents on high and low floors can be alleviated, the elevator mounting problem which puzzles us for many years is solved, and the corridor double escalator can be widely applied to duplex apartments, small villas and urban and rural low-rise buildings.

Owner:张向阳

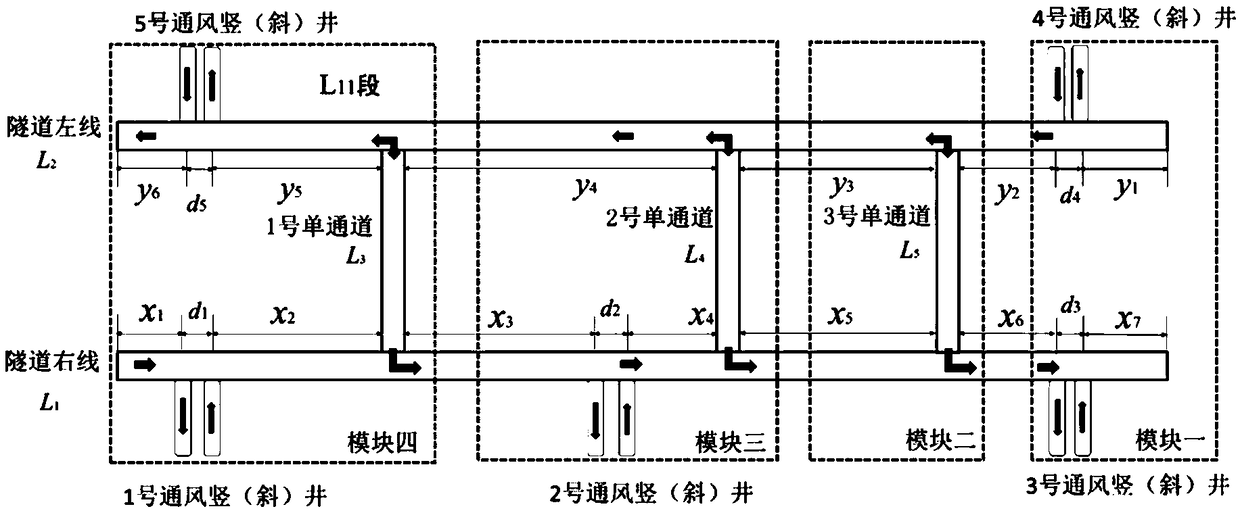

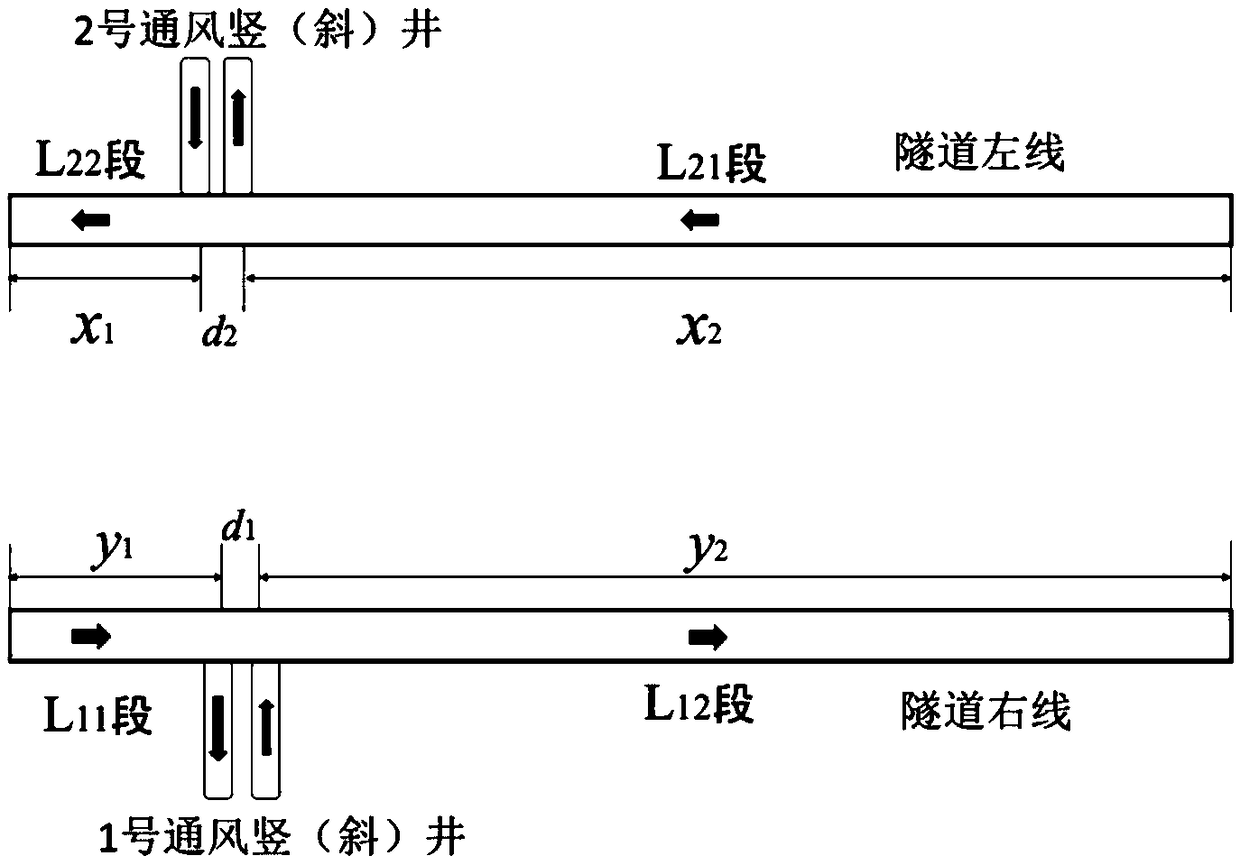

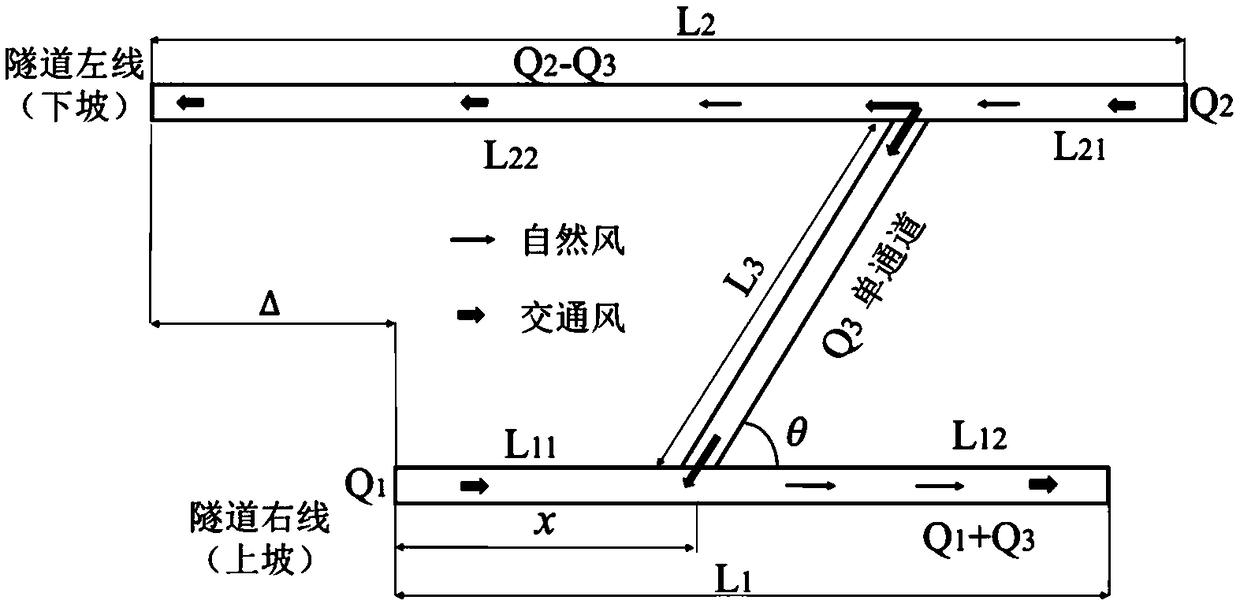

Single-channel and vertical inclined well modular ventilation system in long and large tunnel

ActiveCN109209461AReduce concentrationReduce wind speedMining devicesTunnel/mines ventillationModular designModularity

The invention relates to a single-channel and vertical inclined well modular ventilation system in a long and large tunnel. The single-channel and vertical inclined well modular ventilation system isformed by splicing and combining one or more of a first ventilation module, a second ventilation module, a third ventilation module and a fourth ventilation module, and is used for satisfying requirements for ventilation of the long and large tunnel through real-time monitoring of ventilation parameters in the tunnel, dynamic intelligent calculation and fan operating state adjustment. Compared tothe prior art, the single-channel and vertical inclined well modular ventilation system has the advantages of modular design, low energy consumption, dynamic intelligent control, energy-saving tunneloperation, rapid transformation of normal and fire working conditions, and the like.

Owner:TONGJI UNIV

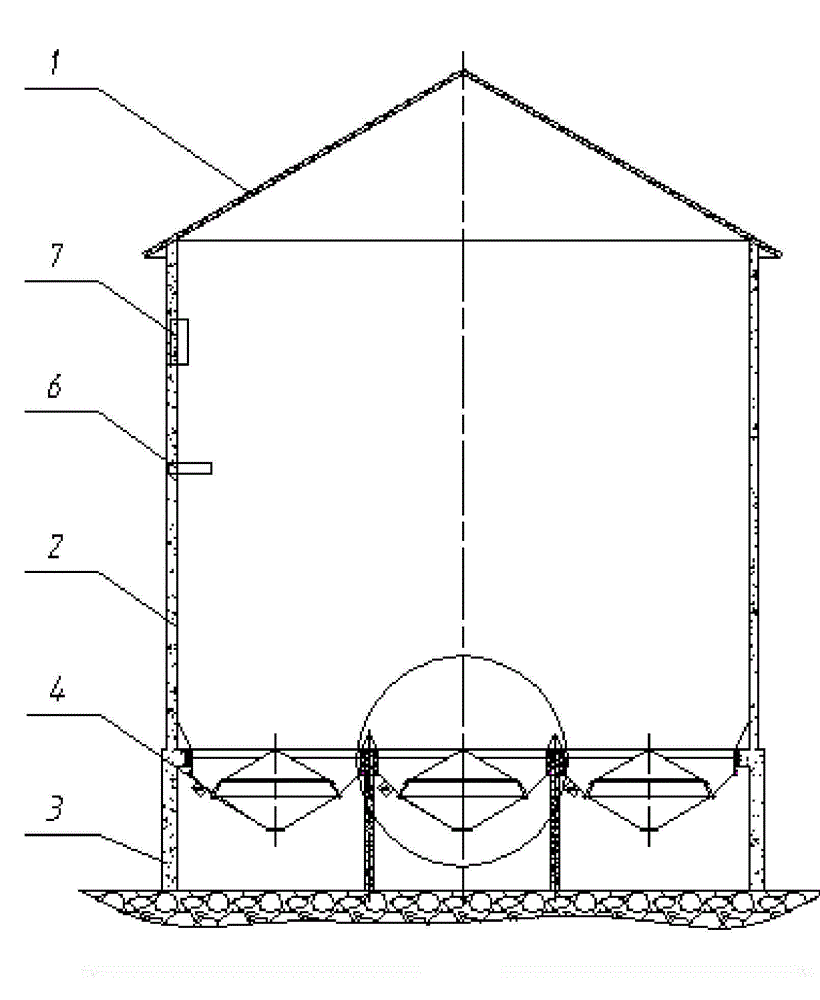

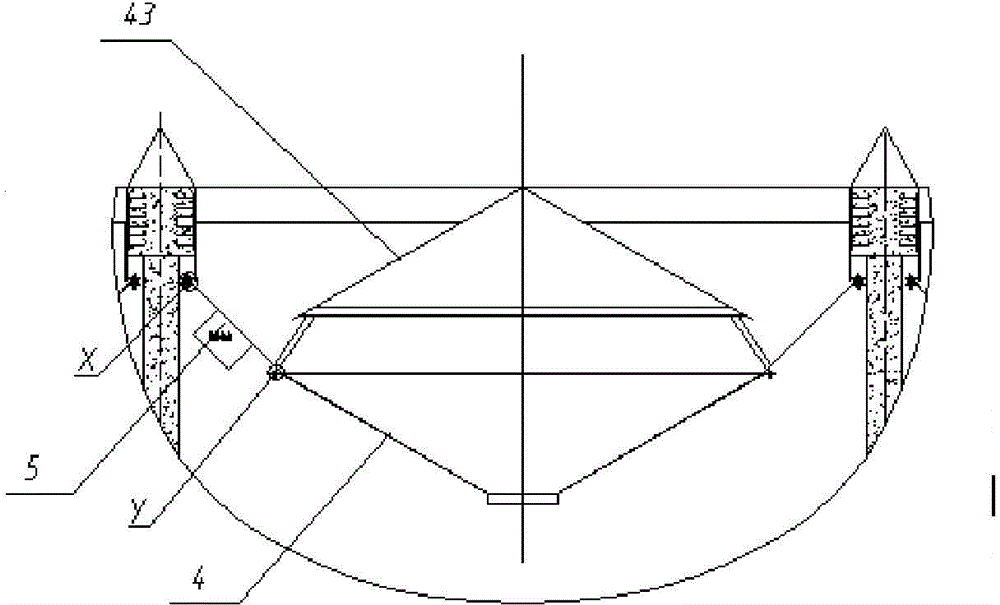

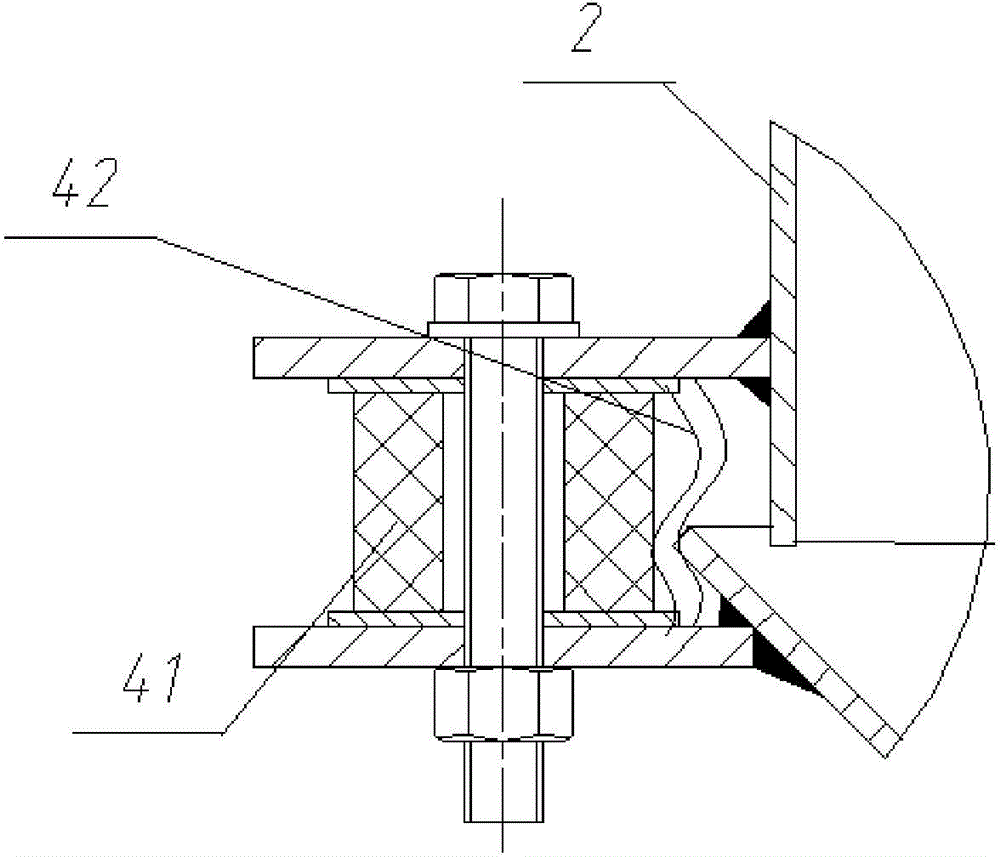

Multi-bucket vibratory discharge silo and layered discharge method thereof

ActiveCN102975988AGuaranteed freshEnsure safetyLarge containersElectric machineStructural engineering

Owner:HARBIN BEICANG GRAIN STORAGE PROJECT & EQUIP

Fluidized discharge ventilation system for grain steel silos

InactiveCN101999281ALower the altitudeSave civil costAgriculture tools and machinesHarvested fruit hanging devicesMetallurgyGrain storage

The invention discloses a fluidized discharge ventilation system for steel grain silos, which comprises a grain steel silo body, and the grain steel silo body is composed of a silo roof, a silo wall and a silo bottom by way of an enclosing mode; the silo roof is provided with a vent hole, and the silo bottom is of a conical-surface structure that the center of the silo bottom is lower than the periphery of the silo bottom; the central position of the silo bottom is provided with a discharge outlet; acclivitous V-shaped troughs are arranged evenly along the discharge outlet towards the silo wall, and the lower part of the silo body is provided with an annular air-duct along the silo wall, wherein the annular air-duct is communicated with an external air source; branch air ducts communicated with the annular air-duct are arranged below the V-shaped troughs, the branch air ducts are communicated with the cavity of the silo body by a sieve plate arranged at the bottom of the V-shaped troughs, and the air inlet of each branch air duct is provided with an air door. The system of the invention has the advantages that: for the grain steel silo with large diameter, the height of a foundation platform of the grain steel silo can be effectively reduced, the civil engineering cost can be reduced, the phenomenon of large slope filling can be avoided, and the problem of artificial silo emptying can be solved; and when the grain silo is completely filled, the fluidized discharge ventilation system also has the effects of ventilation and cooling according to the situation of grains and the weather conditions, thereby ensuring safe grain storage.

Owner:安阳市大正钢板仓有限责任公司

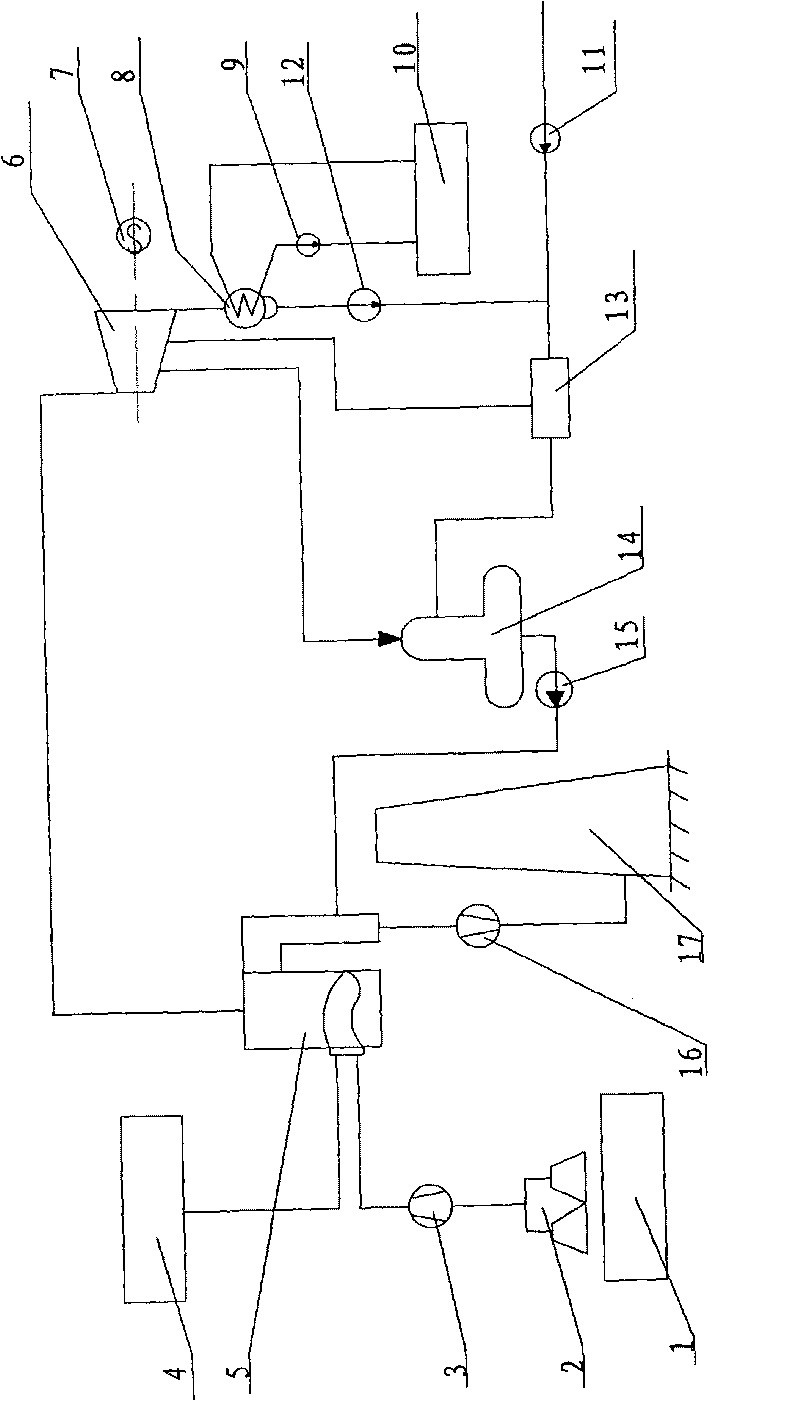

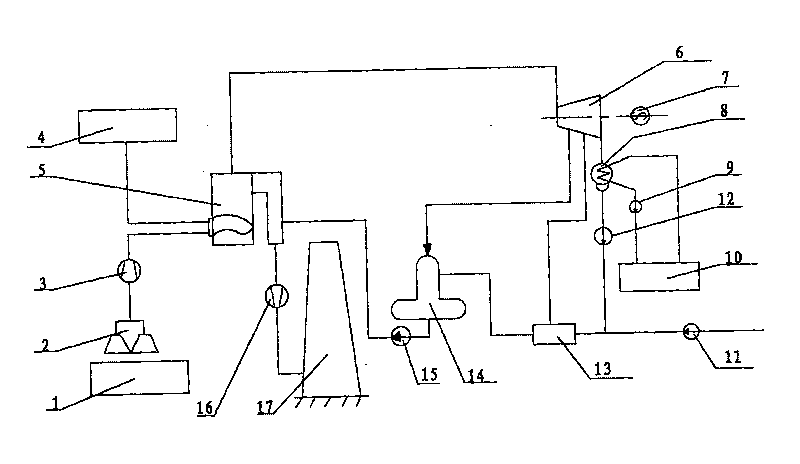

Sintering ore cooling waste gas full combustion-supporting generating set

InactiveCN101699038AImprove waste heat recovery rateSave land resourcesSteam engine plantsCombustion chamberWater supply

The invention relates to a method for reclaiming sintering ore cooling waste gas low-temperature waste heat, in particular to a sintering ore cooling waste gas full combustion-supporting generating set, which comprises a fuel supply system forming a conventional fuel boiler generating system, a generating boiler, a steam turbine, a generator, a condenser, a circulating water pump, a cooling tower, a water supplementing pump, a condensed water pump, a low-pressure heater, a deaerator, a water supply pump, a draft fan and a chimney, and also comprises a sintering ore cooling waste gas collector and a waste gas pressurizer, wherein the waste gas collector is placed above a sintering machine of which a water gas output pipe is connected with a combustion chamber of the generating boiler, and the water gas output pipe is provided with the waste gas pressurizer. The device has the advantages that: the reclaiming rate of the waste heat of the sintering ore cooling waste gas is greatly improved, the waste heat grade of the sintering ore cooling waste gas is greatly improved, the basic Rankine cycle efficiency of the generating system is greatly improved, the vast disposable investment and precious land resources are saved, the running expense of the generating system is greatly reduced, and the management fee of the generating system is greatly reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

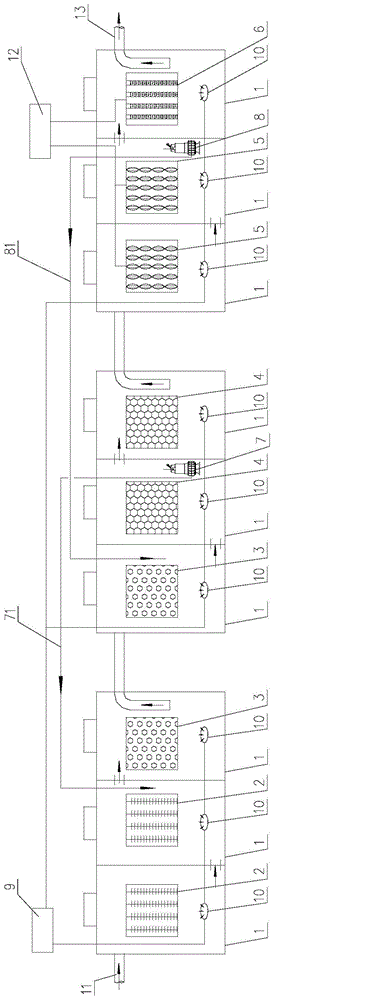

Sewage treatment system

ActiveCN104556412AGood decontamination effectLow running costWater contaminantsBiological treatment apparatusHoneycombSewage

The invention provides a sewage treatment system and aims at solving a problem that the sewage treatment effect is poor in the prior art. The sewage treatment system comprises an aerator, a backwash system and nine aeration tanks which are sequentially numbered from the first aeration tank to the ninth aeration tank from the left to the right, wherein an aeration tray is arranged in each aeration tank; the first aeration tank and the second aeration tank are filled with elastic packing; the third aeration tank and the fourth aeration tank are filled with composite ball packing; the fifth aeration tank and the sixth aeration tank are filled with honeycomb packing; the seventh aeration tank and the eighth aeration tank are filled with biofilm packing; an earthenware pipe is arranged in the ninth aeration tank; a water inlet pipe is arranged on the first aeration tank; a water outlet pipe is arranged on the ninth aeration tank; a first water return pump is arranged in the fifth aeration tank, and a first water return pipe is connected to the first water return pump; and a second water return pump is arranged in the eighth aeration tank, and a second return pipe is connected to the second water return pump. According to the sewage treatment system disclosed by the invention, organic matters in sewage can be treated, biological bacterium precipitation is promoted, and the SS value and numerical values of phosphorus and other pollutants are greatly reduced.

Owner:浙江全景环保科技有限公司

Method for treating petroleum refining waste water

InactiveCN101870544BEasy to handleHigh implementabilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentEmission standardTechnical standard

The invention relates to a method for treating petroleum refining waste water. The method for treating petroleum refining waste water comprises the steps of a gravity oil-separating unit, a two-stage air floatation treatment unit, an anaerobic and aerobic two-stage biochemical treatment unit, a biochemical posttreatment unit and the like. Through the analysis of the specific implementation effect, the technical implementation effect of the method is much more excellent than the conventional technical standards. Compared with the prior art, the treatment effect of the method is obviously more excellent than the traditional process method; qualitative improvement on the quality of the treated water is achieved; the current newest national and local emission standard is completely met; and therefore, the method has a very wide application prospect.

Owner:大庆市新中瑞环保有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com