Method for treating petroleum refining waste water

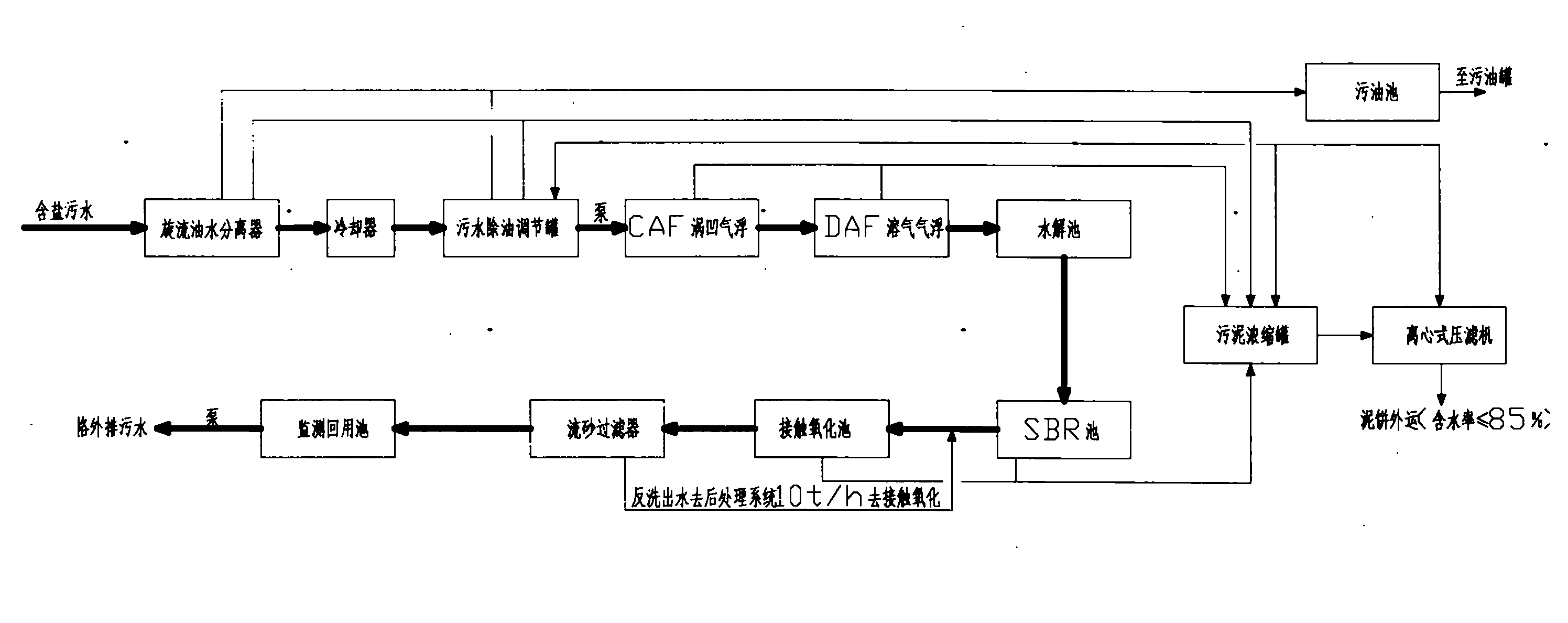

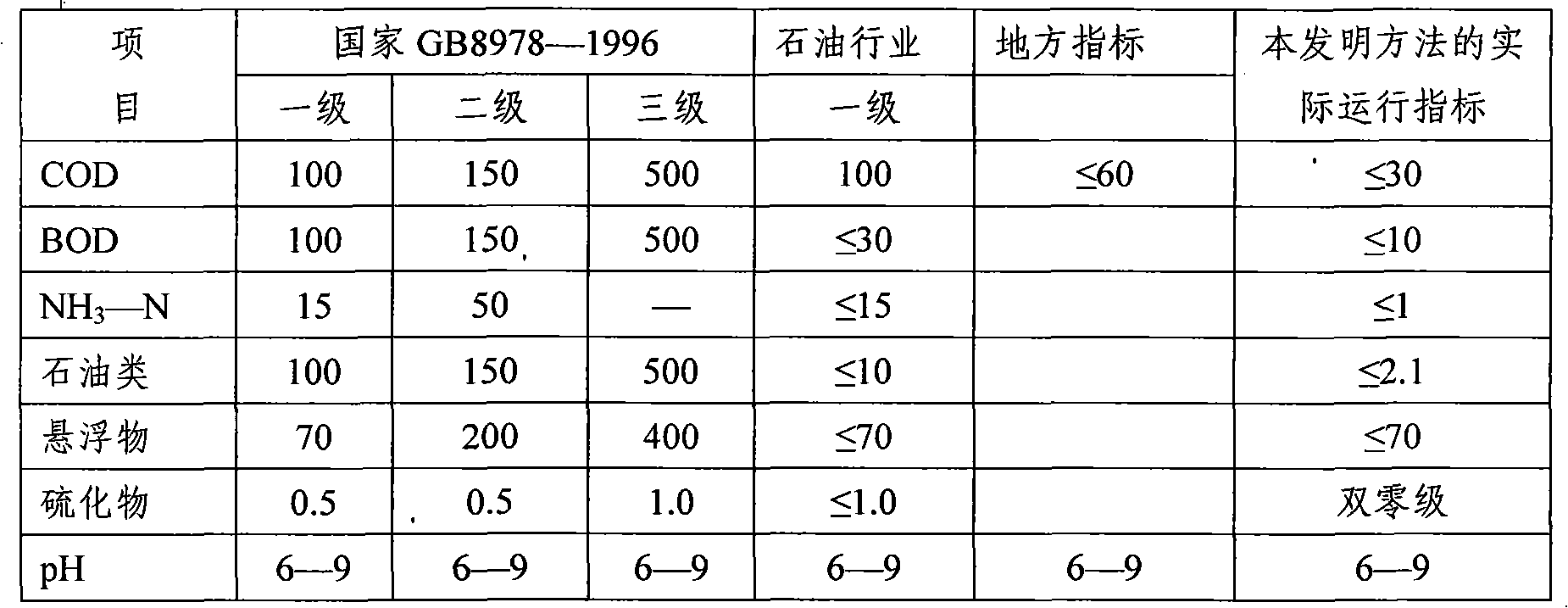

A technology for oil refining wastewater and treatment method, which is applied in the fields of water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. transfer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0191] Embodiment 1: adopt the inventive method to process the refinery waste water of certain petroleum refinery

[0192] COD1500mg / L, NH of the refinery wastewater 3 -N80mg / l, petroleum 1500mg / L.

[0193] This is handled as follows:

[0194] A. Natural separation of oil and water

[0195] Allow petroleum refinery wastewater to flow into the cyclone oil-water separator produced by Yangzhou Hengchuan Environmental Engineering Co., Ltd., and the cyclone oil-water separator operates under the following conditions:

[0196] Water inlet pressure Atmospheric pressure -0.6MPa;

[0197] Water temperature 50-60℃;

[0198] The wastewater residence time was 40 minutes.

[0199] The aqueous heavy phase of the wastewater is thrown to the inner wall of the cyclone under the action of centrifugal force and discharged from the bottom outlet in a spiral state. The oil content of the discharged aqueous phase is less than 150 mg / L, while the oily light phase gathers towards the center of t...

Embodiment 2

[0244] Embodiment 2: Adopt the method of the present invention to process the refinery waste water of a refinery in Liaohe

[0245] The COD and petroleum of this refinery wastewater were 4500 mg / l and 1500 mg / l, respectively.

[0246] The implementation mode of this embodiment is identical with embodiment 1, just changes following condition:

[0247] The sewage treated in this embodiment is pure electric desalination sewage, the water quality is even worse, and the COD concentration is 4-5 times higher than that of conventional refinery sewage.

[0248] The oil separation unit adopts a two-stage oil separation tank of the advection type oil separation tank and the inclined plate grease separation tank.

[0249] The operating conditions of the hydrolytic acidification unit are as follows:

[0250] Inlet water temperature: 25℃

[0251] Influent COD: 2700mg / l

[0252] Influent B / C ratio: ≥0.2

[0253] Effluent B / C ratio: ≥0.35

[0254] Dissolved oxygen: 0.1mg / L

[0255] pH...

Embodiment 3

[0263] Embodiment 3: Adopt the method of the present invention to process the refinery wastewater of a refinery in Jinzhou

[0264] The CODCr and petroleum of this refinery wastewater were 1200 mg / l and 500 mg / l, respectively.

[0265] This embodiment implementation mode is identical with embodiment 1, just changes following condition:

[0266] The hydrolytic acidification tank adopts the fully mixed anaerobic activated sludge method, which is combined with the primary sedimentation tank to form an anaerobic hydrolytic acidification unit, and operates under the following conditions:

[0267] Water inlet pressure Atmospheric pressure;

[0268] Water temperature 20-25℃;

[0269] The wastewater residence time is 8h;

[0270] Sludge return ratio 50-100%

[0271] Dissolved oxygen 0-0.2mg / l

[0272] Sludge concentration 3000-4500mg / l

[0273] The aerobic biochemical unit adopts the plug-flow activated sludge method, that is, the plug-flow activated sludge reaction tank, and op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com