Patents

Literature

72 results about "Refinery wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbe bacteria agent for treatment of refinery waste water, its preparation method and application

InactiveCN1789406AImprove preservation methodExtended service lifeFungiBacteriaWater in oilPollutant

The invention discloses a microbiological bacterium for processing waste water in oil refining, its preparing process and use. The bacterium comprises Rhodococcus, Microbacterium spp, bacillus, Candida and Brachybacterium by the ratio of 0-10:0-10:0-10:0-10:0-10:0-10. The bacterium can be activated for treating waste water.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

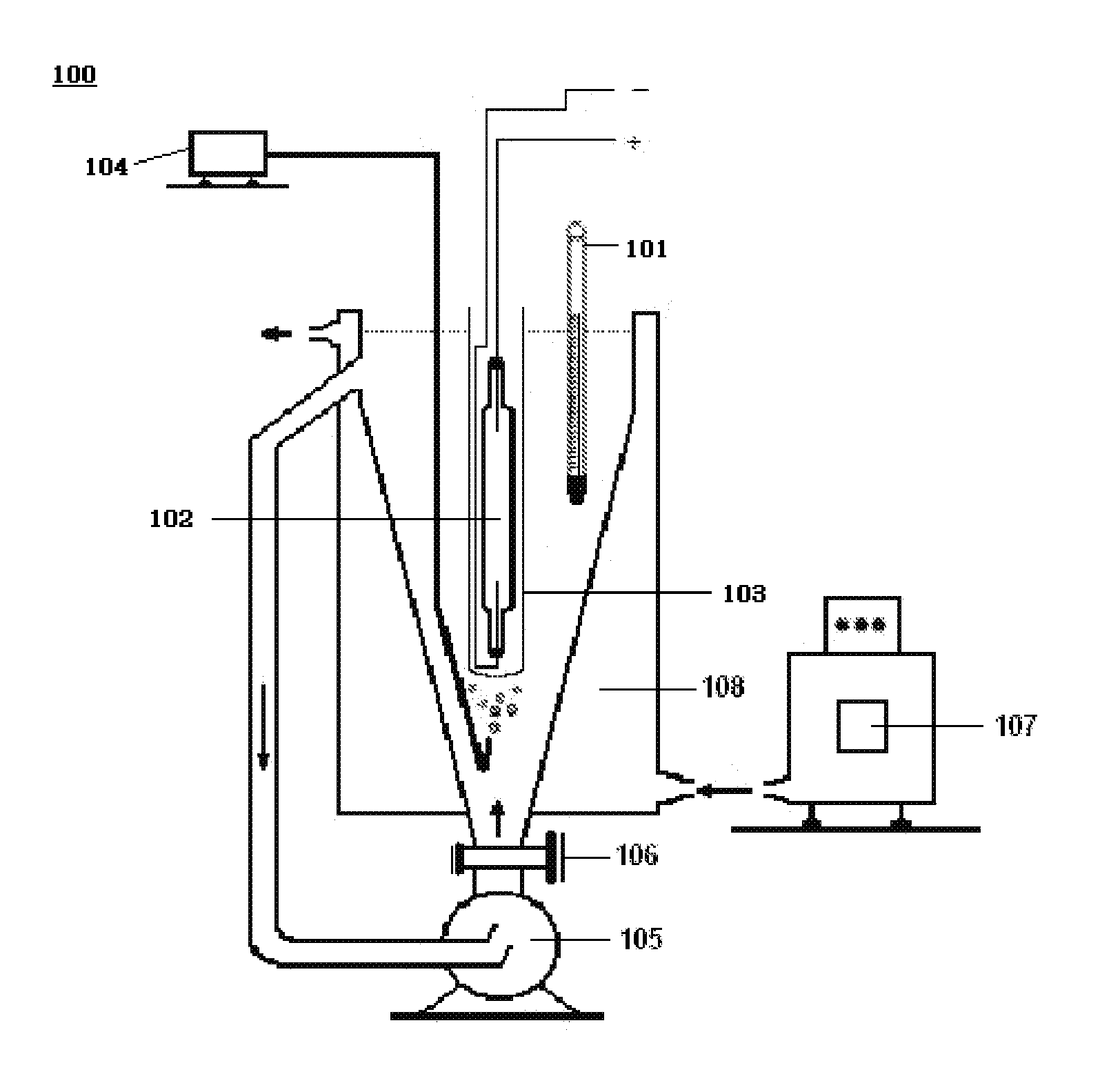

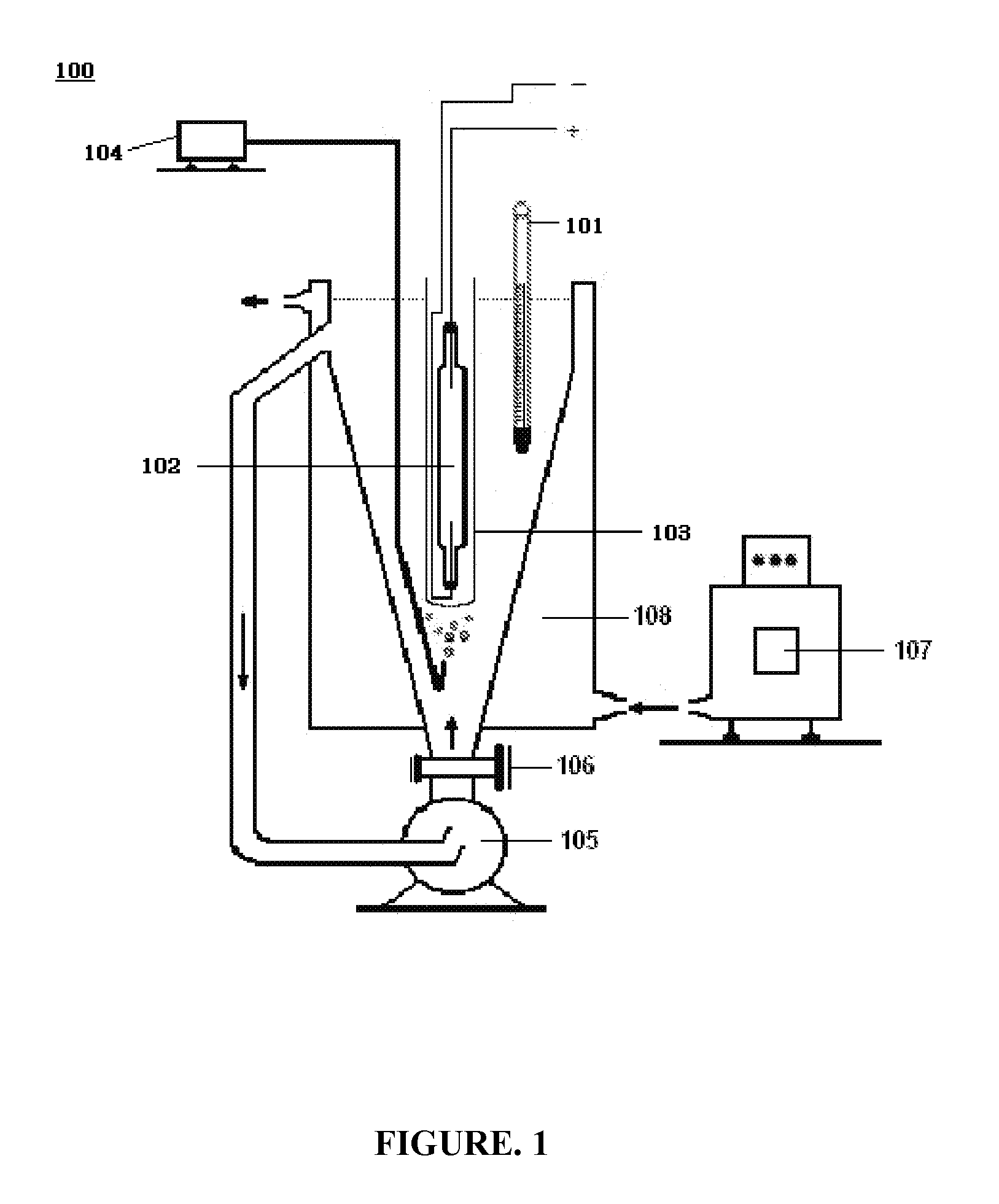

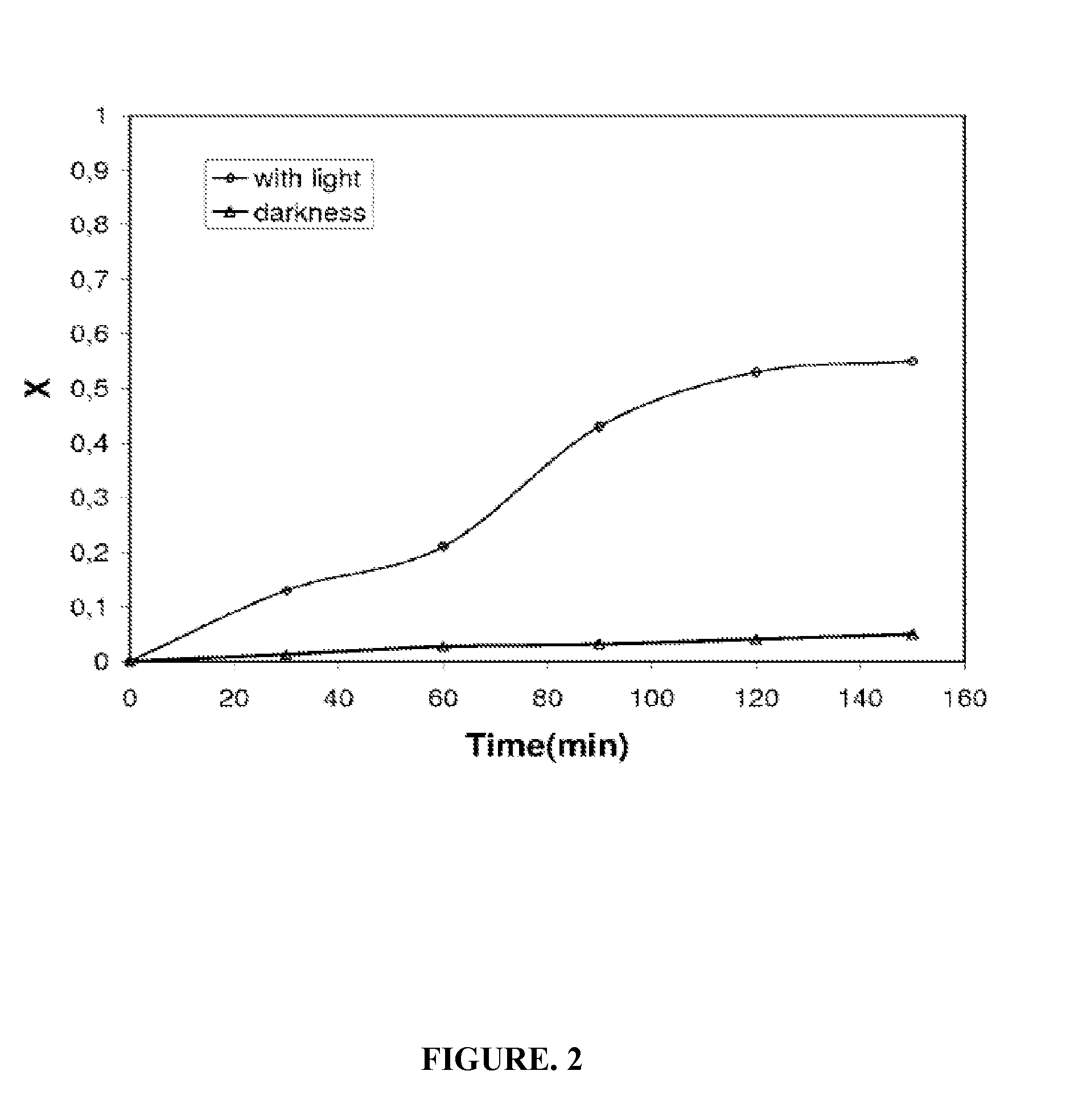

Treatment of the refinery wastewater by NANO particles of tio2

InactiveUS20100200515A1Improve efficiencyPromote degradationWater/sewage treatment by irradiationWater treatment compoundsReactor systemPhotocatalytic reaction

The embodiments herein relate to a photocatalytic reactor system and photo-degrading method for eliminating organic and high molecular oil contaminant (or pollutants) from industrial wastewater. A more economical and stable titanium dioxide (TiO2) having a diameter of 21±10 nm is used as the photocatalyst. Method and system of present invention is highly efficient, compatibles with the environment and does not require secondary or additional treatments. In one embodiment, an optimal and very low catalyst concentration (100 ppm) is used for high degradation of the pollutant which is irradiated for utmost 120 min using UV light. This has an industrially interest as this method is considered as an alternative or synergetic process for biological degradation, having high residence times, required to provide significant COD removal. The analysis of the contained materials showed that the efficiency of the applied degradation system is high for all the identified present organic pollutants.

Owner:IRANIAN ACADEMIC CENT FOR EDUCATION CULTURE & RES ACECR

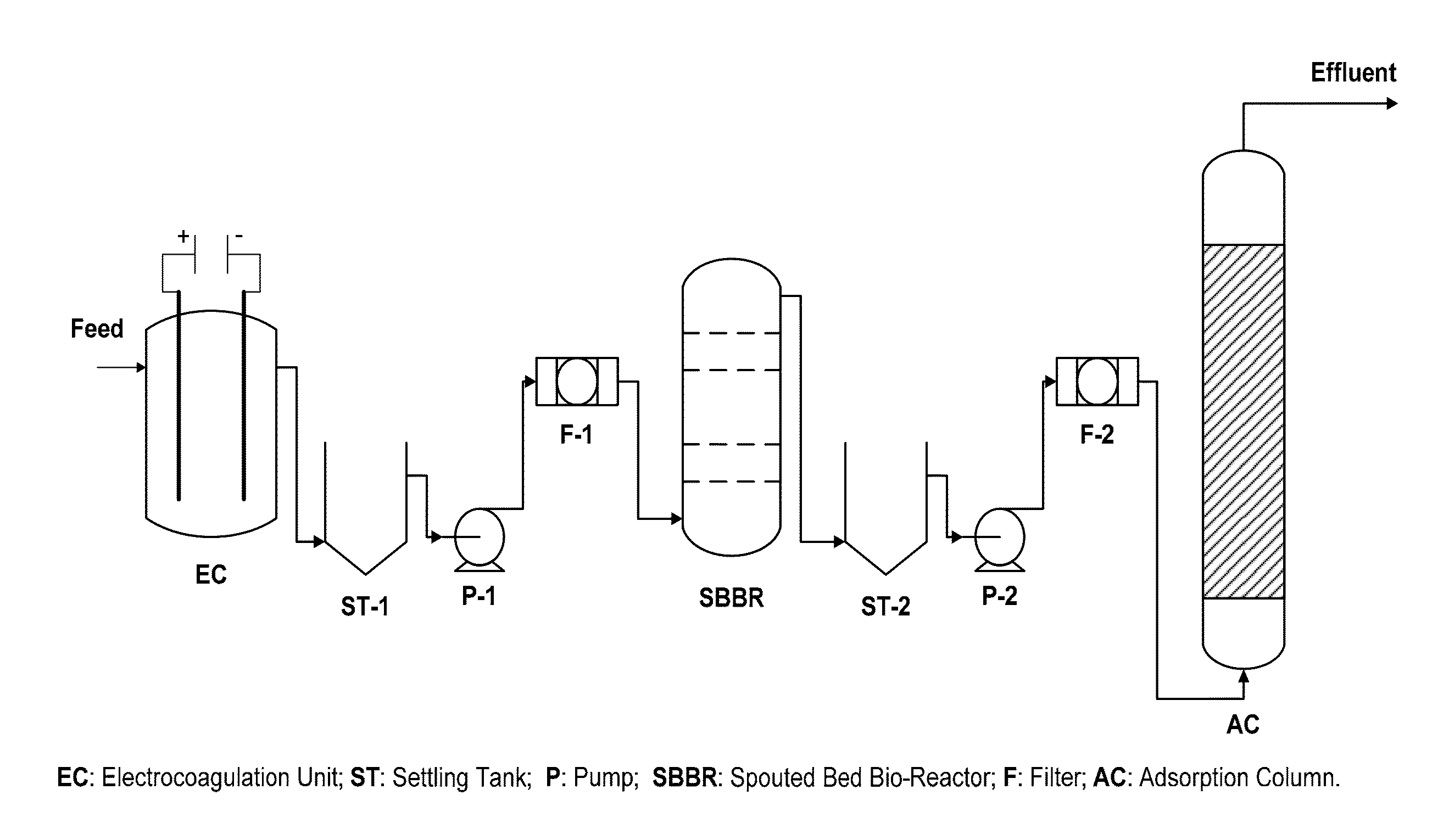

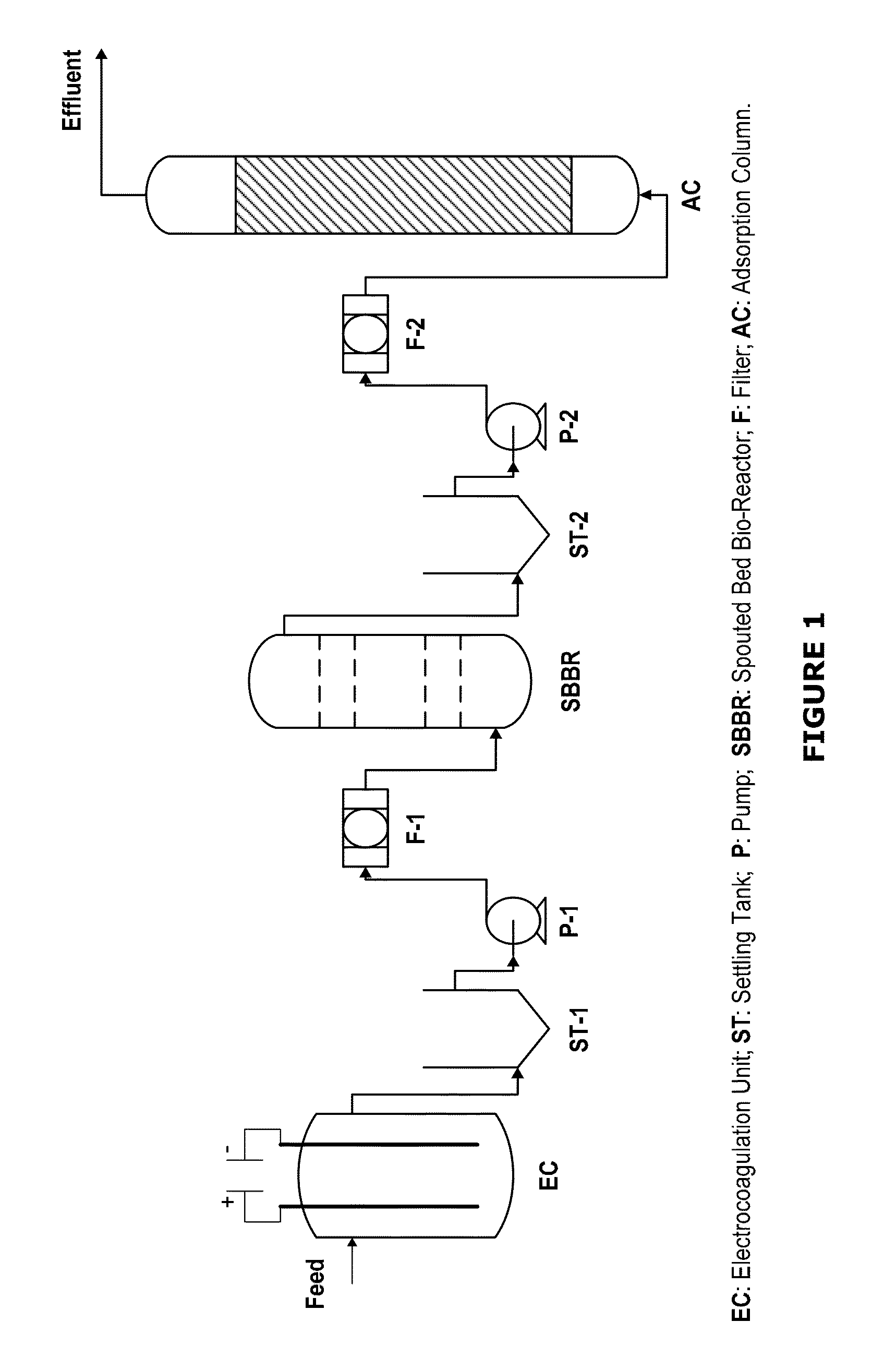

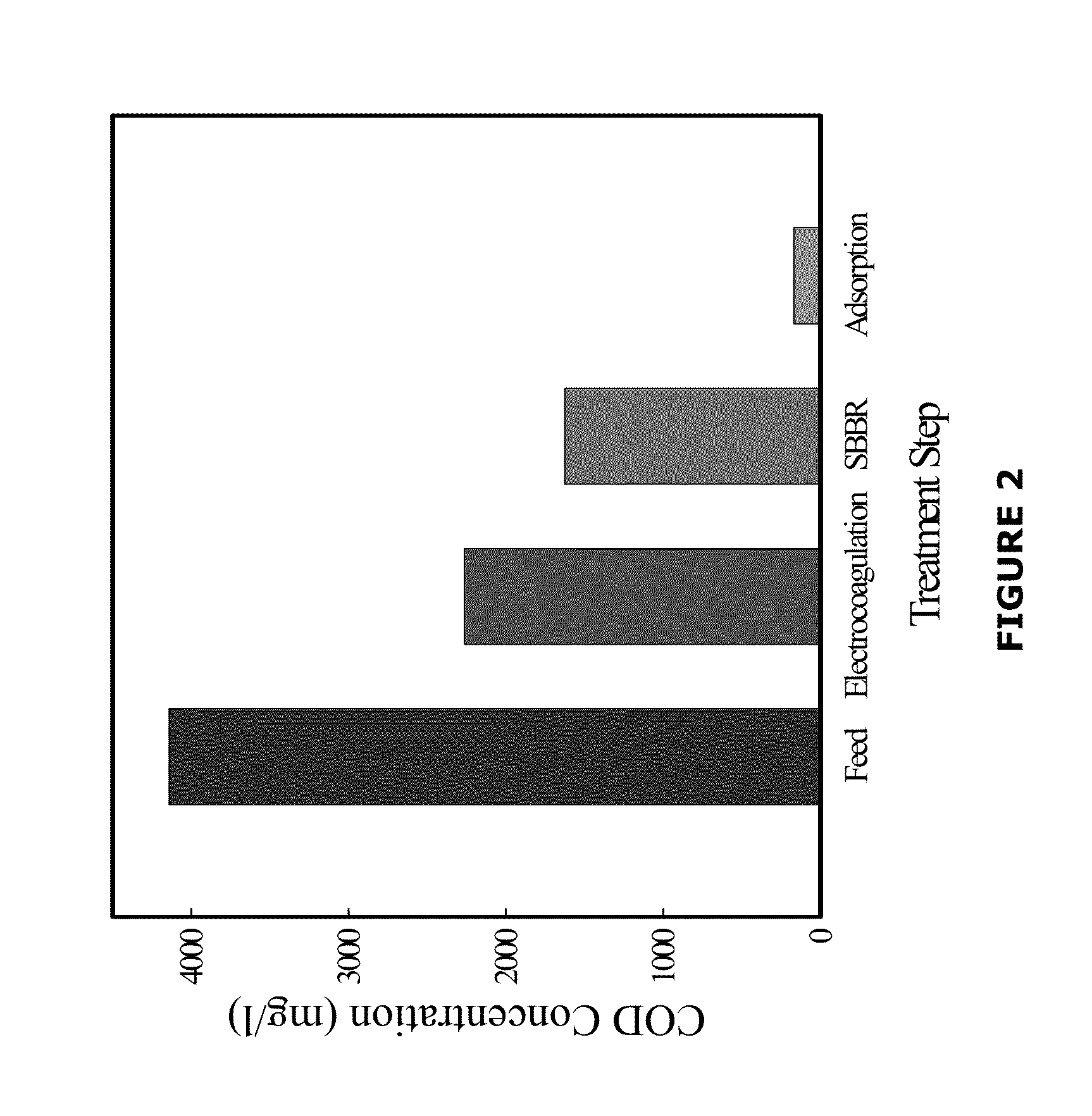

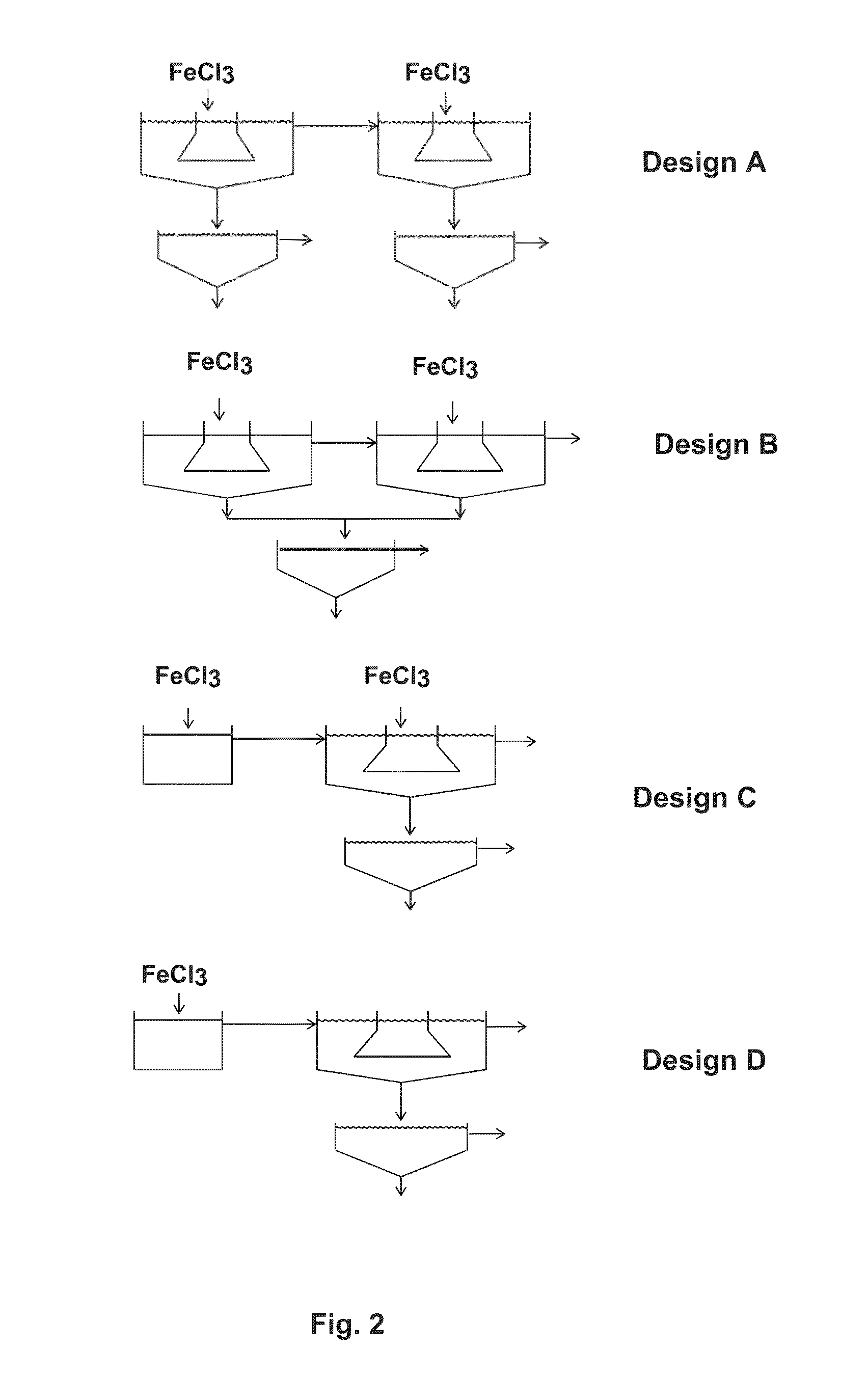

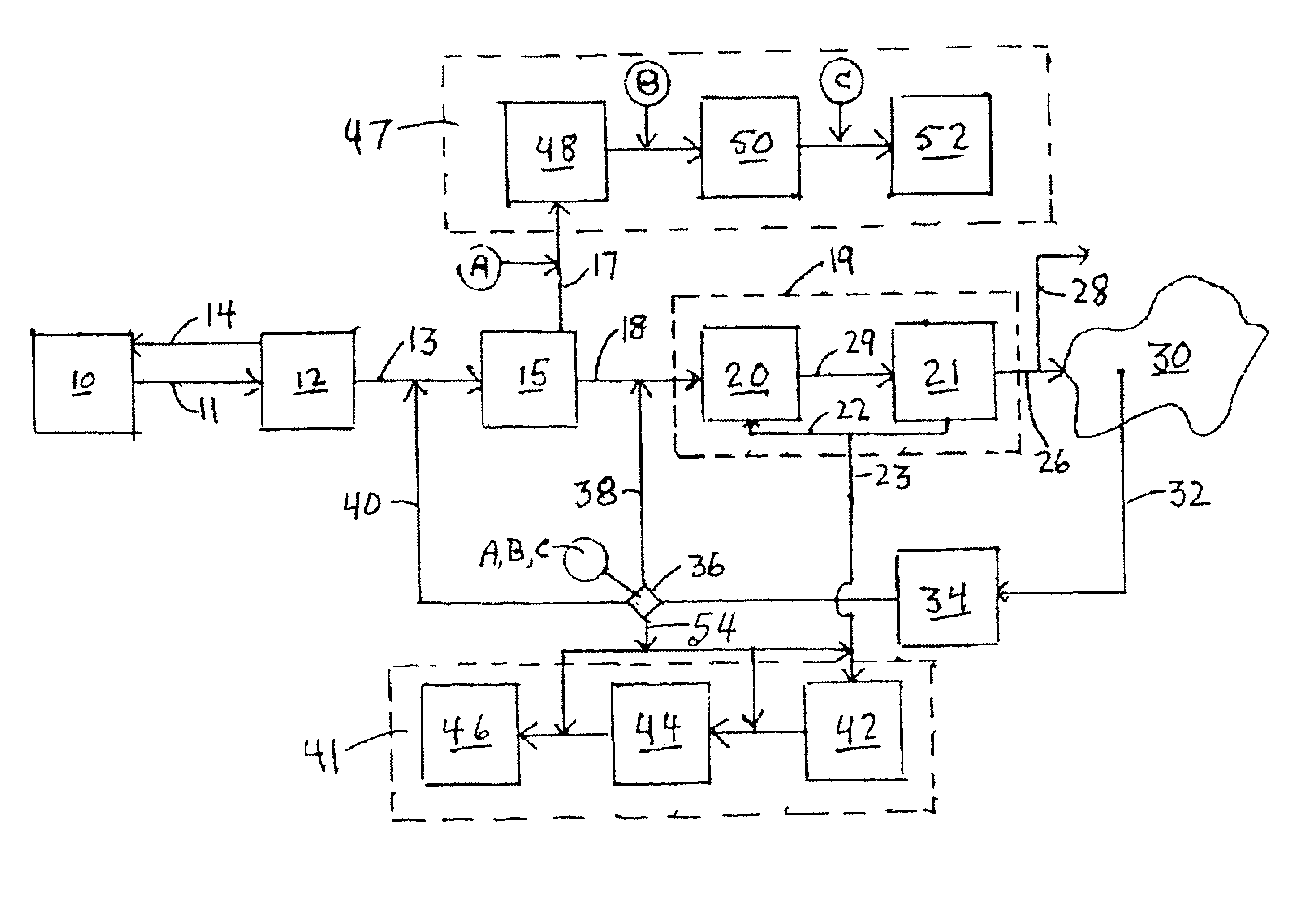

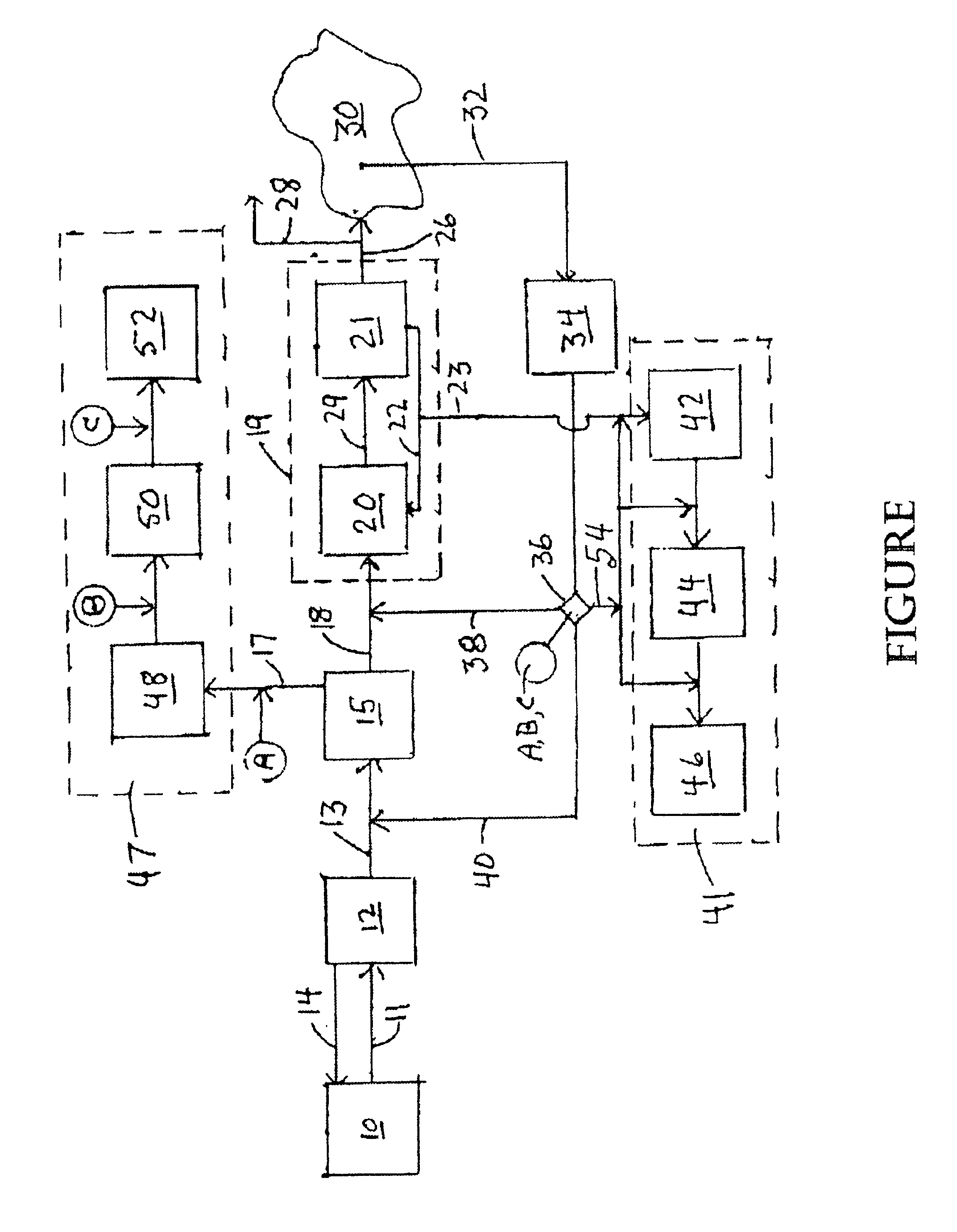

Process And System For The Treatment Of Industrial And Petroleum Refinery Wastewater

InactiveUS20130206688A1Reduce concentrationReduce replacement costsTreatment using aerobic processesWater contaminantsElectrocoagulationAfter treatment

There is provided a process of reducing concentration of contaminants in a contaminated wastewater stream, such as contaminated wastewater output from a refinery, such as an oil-refinery; the process comprising: first, passing the contaminated wastewater stream into an electrocoagulation reactor for coagulating dispersed particles, filtering the wastewater stream after electrocoagulation for removing the coagulated dispersed particles, and providing a first stream of treated wastewater after the first filtration; second, passing the first stream of treated wastewater into a Spouted Bed Bio-Reactor (SBBR) containing a micro-organism or bacterium immobilized in polyvinyl alcohol (PVA) gel, filtering the first stream after treatment by the SBBR and providing a second stream of treated wastewater after the second filtration; and third, passing the second stream of treated wastewater into an adsorption column containing granular activated carbon (GAC) and providing a third stream of treated wastewater. There is also provided a system for doing the same.

Owner:UNITED ARAB EMIRATES UNIVERSITY +1

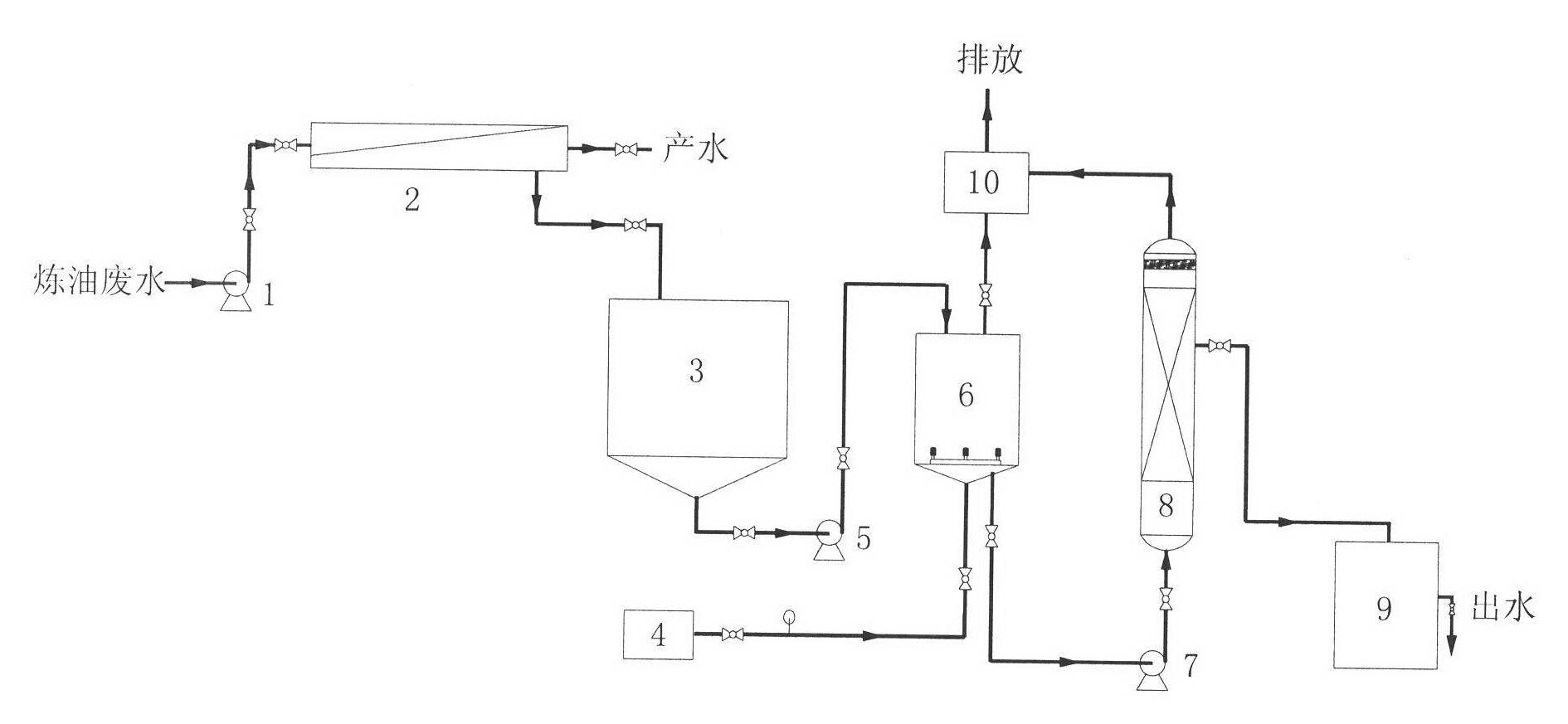

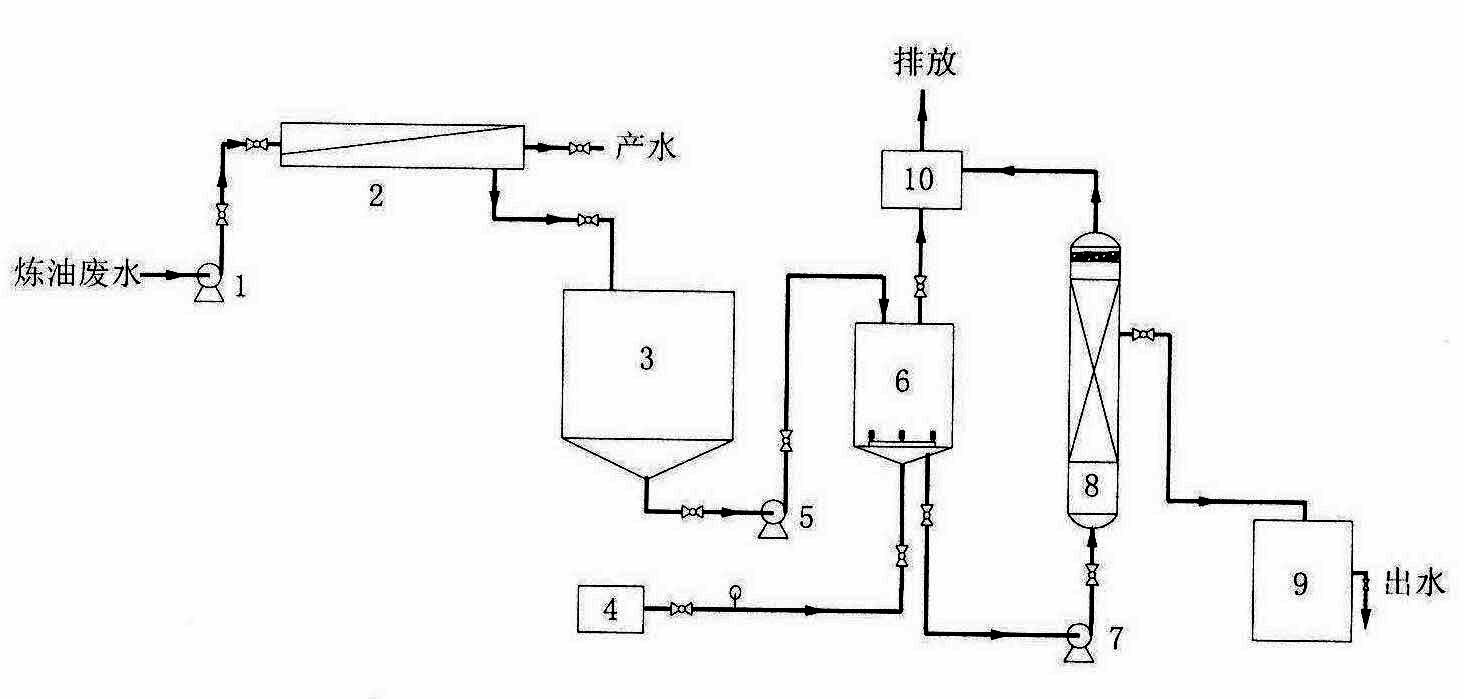

Combined method for treating refinery wastewater by adopting reverse osmosis and catalytic ozonation

InactiveCN102153171AWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentReverse osmosisCatalytic oxidation

The invention provides a combined method for treating refinery wastewater by adopting reverse osmosis and catalytic ozonation. The method is characterized in that the reverse osmosis process is firstly adopted to treat the refinery wastewater to ensure the produced water to achieve the reuse standard and then the reverse osmosis concentrated water is subjected to deep treatment by adopting the catalytic ozonation process and is discharged after reaching the standard; the specific process flows are as follows: the ultra-filtrated produced water enters into a reverse osmosis membrane (2) through a high pressure pump (1) and is reused in the production process; the discharged reverse osmosis concentrated water enters into a regulating tank (3) to be regulated and then enters into a preaeration tank (6) through a water supply pump (5); the water is fully mixed with and reacts with ozone provided by an ozone generator (4) in the tank; the effluent enters into a catalytic oxidation reaction tower (8) through a lift pump (7) and flows into a clear water tank (9); and the tail gases discharged from the preaeration tank (6) and the catalytic oxidation reaction tower (8) enter into a tail gas purifier (10) and the purified gases are discharged.

Owner:CHINA NAT OFFSHORE OIL CORP +1

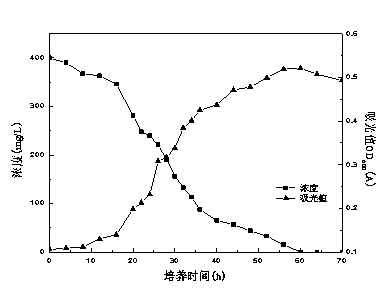

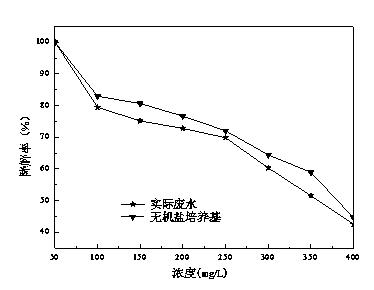

Dibutyl phthalate degrading bacteria and application of dibutyl phthalate degrading bacteria

InactiveCN102703347AGood bioaugmentation effectEfficient degradation abilityBacteriaWater contaminantsBiotechnologyBacterial strain

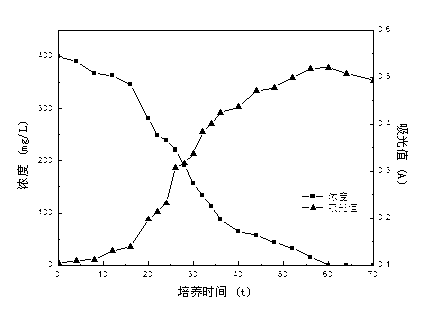

The invention discloses a strain of dibutyl phthalate degrading bacteria and application of the dibutyl phthalate degrading bacteria. The strain of dibutyl phthalate degrading bacteria D8 provided by the invention belongs to Elizabethkingiasp and is preserved in the China Center for Type Culture Collection, wherein the preservation date is March 23 2012; the preservation number is CCTCCNO:M2012088, and the GenBank accession number of a bacterial strain 16SrDNA is JQ673498. The bacterium is Gram-negative bacterium; the bacterial colony is yellow, round, smooth and humid; the brim is regular, and the centre protrudes. The bacterium utilizes dibutyl phthalate as sole carbon source and energy source to grow and breed. The bacterium can completely degrade 400mg / L of DBP (dibutyl phthalate) within 60 hours when being purely cultivated. The bacterial strain D8 can tolerate DBP of which the concentration can be up to 2000mg / L, and has excellent degradation effect on high-concentration DBP industrial wastewater. The bacterium is applied to bioaugmentation treatment of refinery waste water, pesticide wastewater, brewery wastewater and coking wastewater, and has excellent application prospect.

Owner:WUHAN UNIV OF SCI & TECH

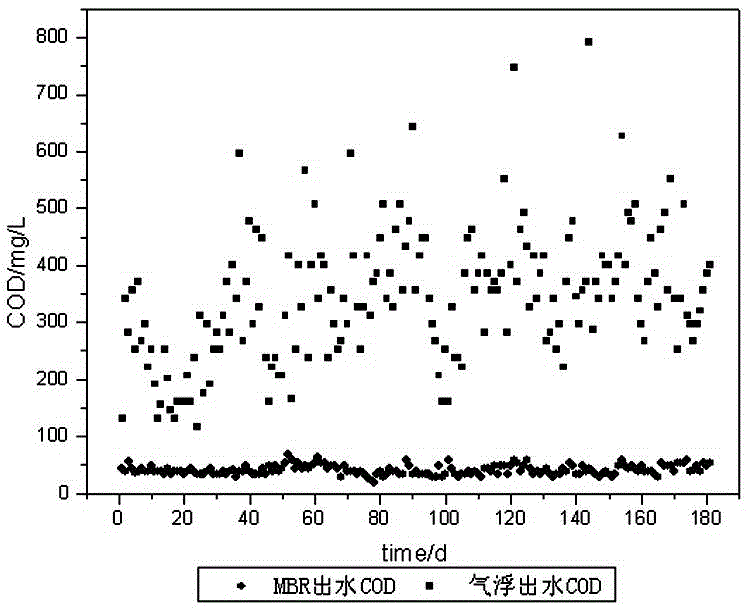

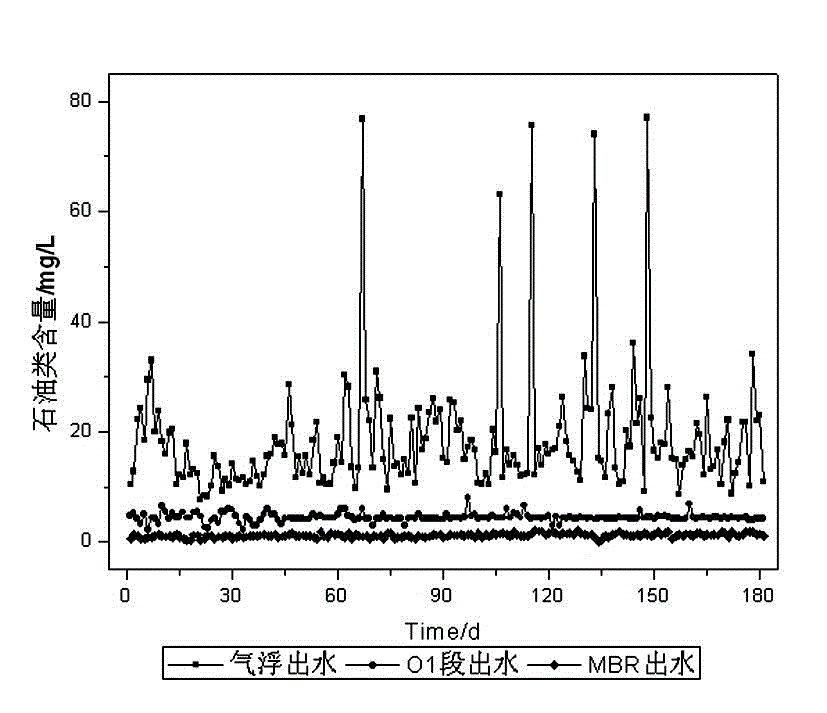

MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and membrane component cleaning method

ActiveCN102718359AImprove adsorption capacitySlow the rate of pollutionSemi-permeable membranesMultistage water/sewage treatmentHigh concentrationMembrane bioreactor

The invention discloses an MBR (membrane bioreactor)-based system and method for oil refining wastewater biochemical treatment and a membrane component cleaning method. A biochemical treatment system comprises an aerobic aeration tank, a middle sedimentation tank, an anoxic tank and a membrane bioreactor. The aerobic aeration tank allows pretreated oil refining wastewater to enter, and the middle sedimentation tank connected with the aerobic aeration tank is used for separation mud and water in the aerobic aeration tank to enable part of sludge to be discharged and part of precipitated sludge to flow back into the aerobic aeration tank. The anoxic tank is connected with the middle sedimentation tank, supernatant in the middle sedimentation tank enters the anoxic tank for denitrification, and the membrane bioreactor which forms an organic pollutant main removing unit is connected with the anoxic tank. The MBR system membrane component cleaning method includes: air scrubbing, online backwashing, online chemical cleaning and offline cleaning, especially online cleaning adopts high-concentration NaClO solution and low-concentration NaClO solution alternately, and offline cleaning adopts sodium dodecyl sulfate and sodium carbonate solution for cleaning or NaClO solution for cleaning.

Owner:ZHEJIANG SHUANGYI ENVIRONMENTAL PROTECTION TECH DEV

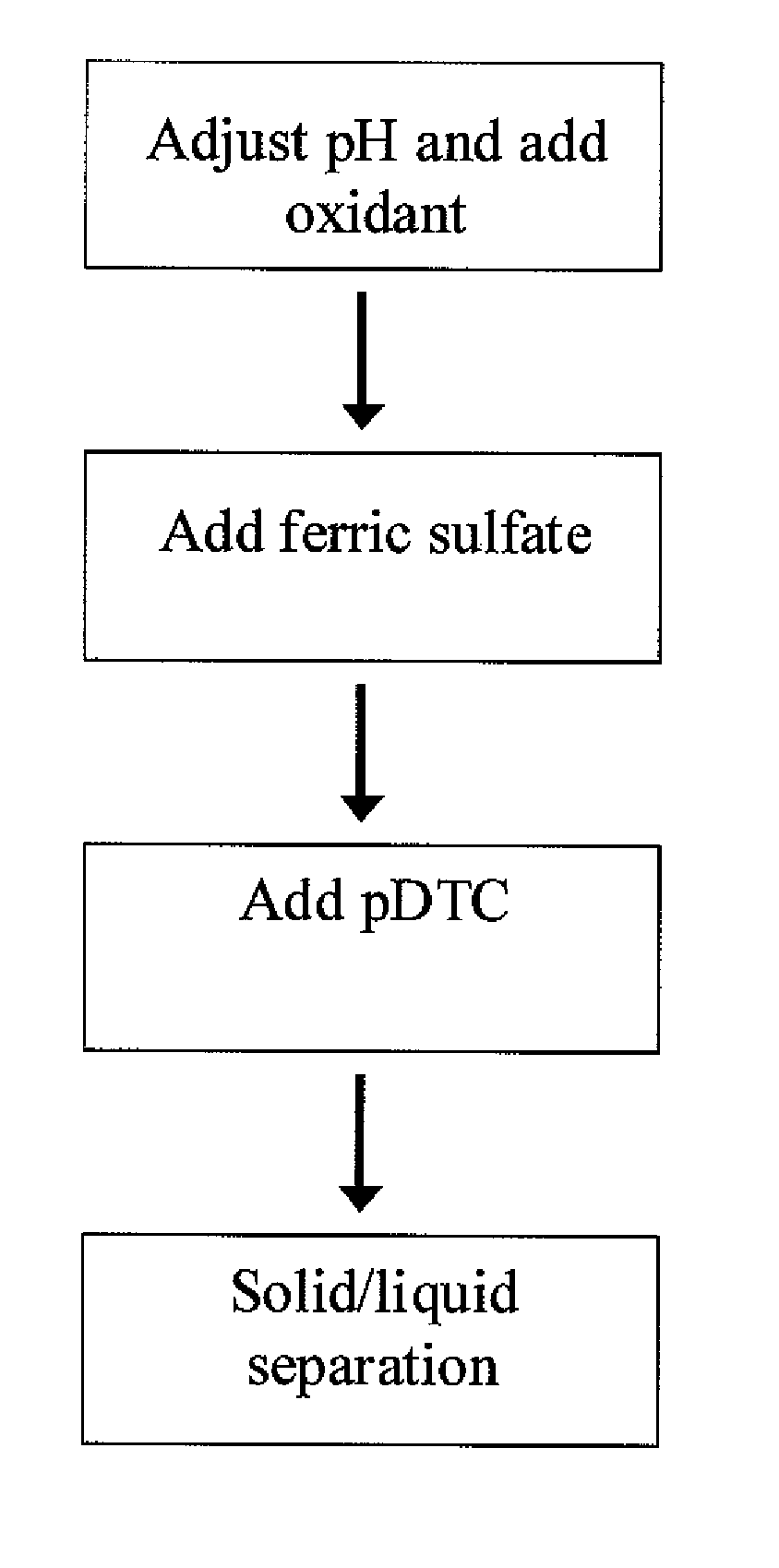

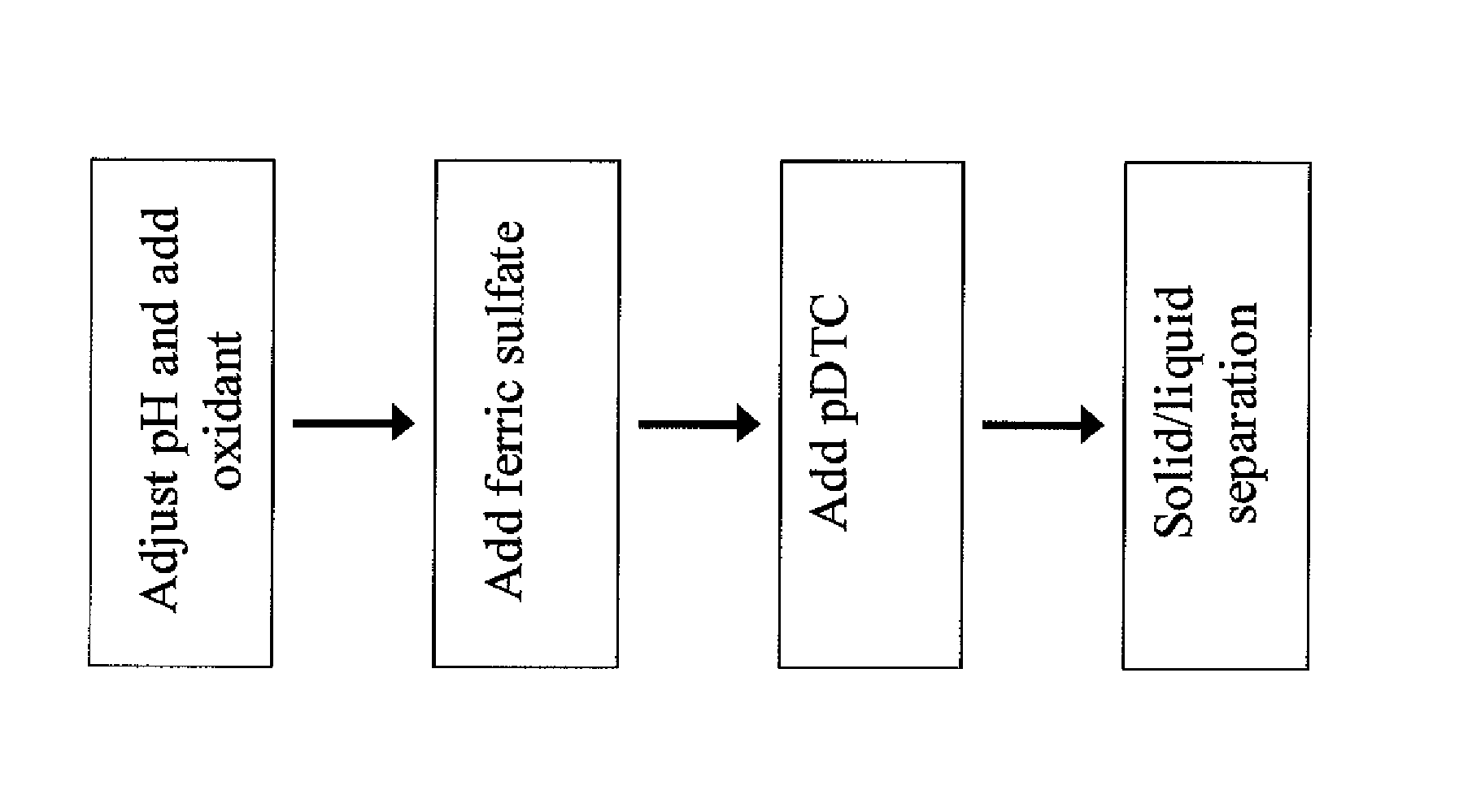

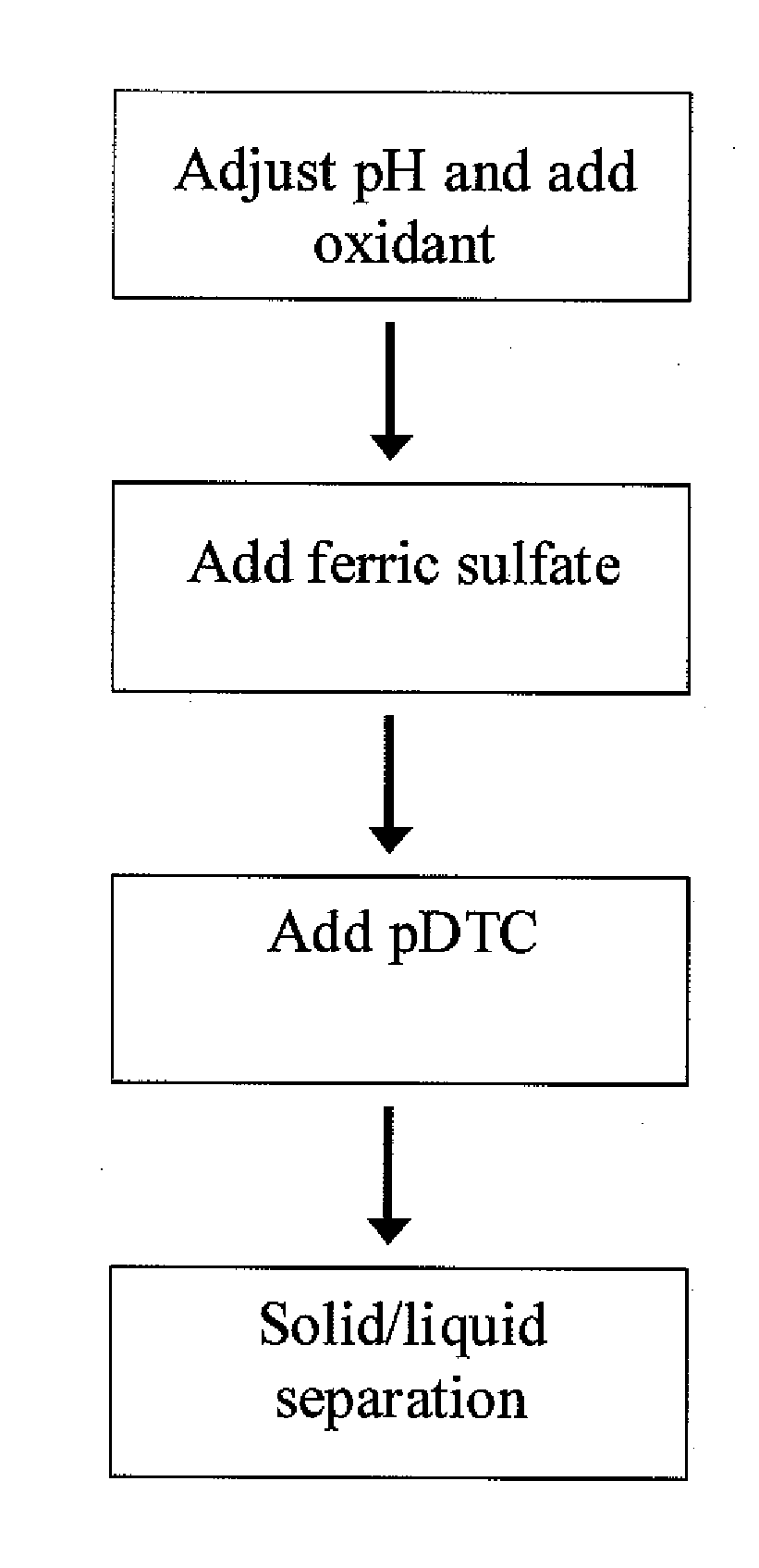

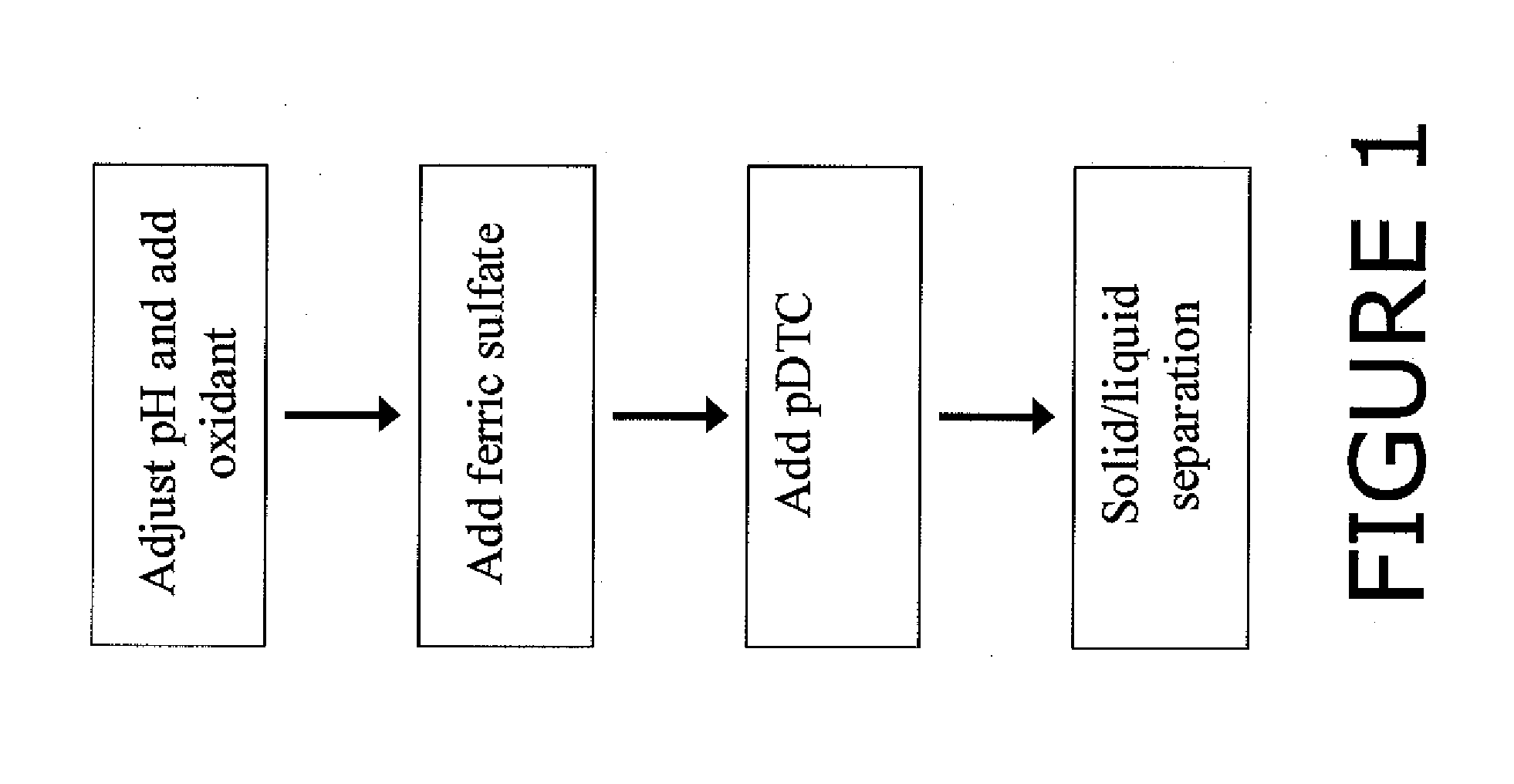

Removal of selenium from refinery wastewater

ActiveUS8282835B2Reduce the amount requiredWater contaminantsSedimentation separationEnvironmental standardSe element

The invention provides a method of efficiently removing selenium from water. The method involves: adding an oxidant to the liquid, adjusting the liquid's pH to below 7.5, adding ferric salt in an amount such that less than a quarter of selenium in the liquid precipitates and adding a poly dithiocarbamate material to the liquid in an amount such that the amount of poly dithiocarbamate material (in ppm) is greater than the amount of ferric salt (in ppm). This method removes far more selenium than previous methods, and does it using a smaller amount of expensive chemicals. Moreover this method makes it far more likely to achieve cost effective compliance with the ever-increasing environmental standards for selenium in water.

Owner:NALCO CO

Biological packing as well as preparation method and application thereof

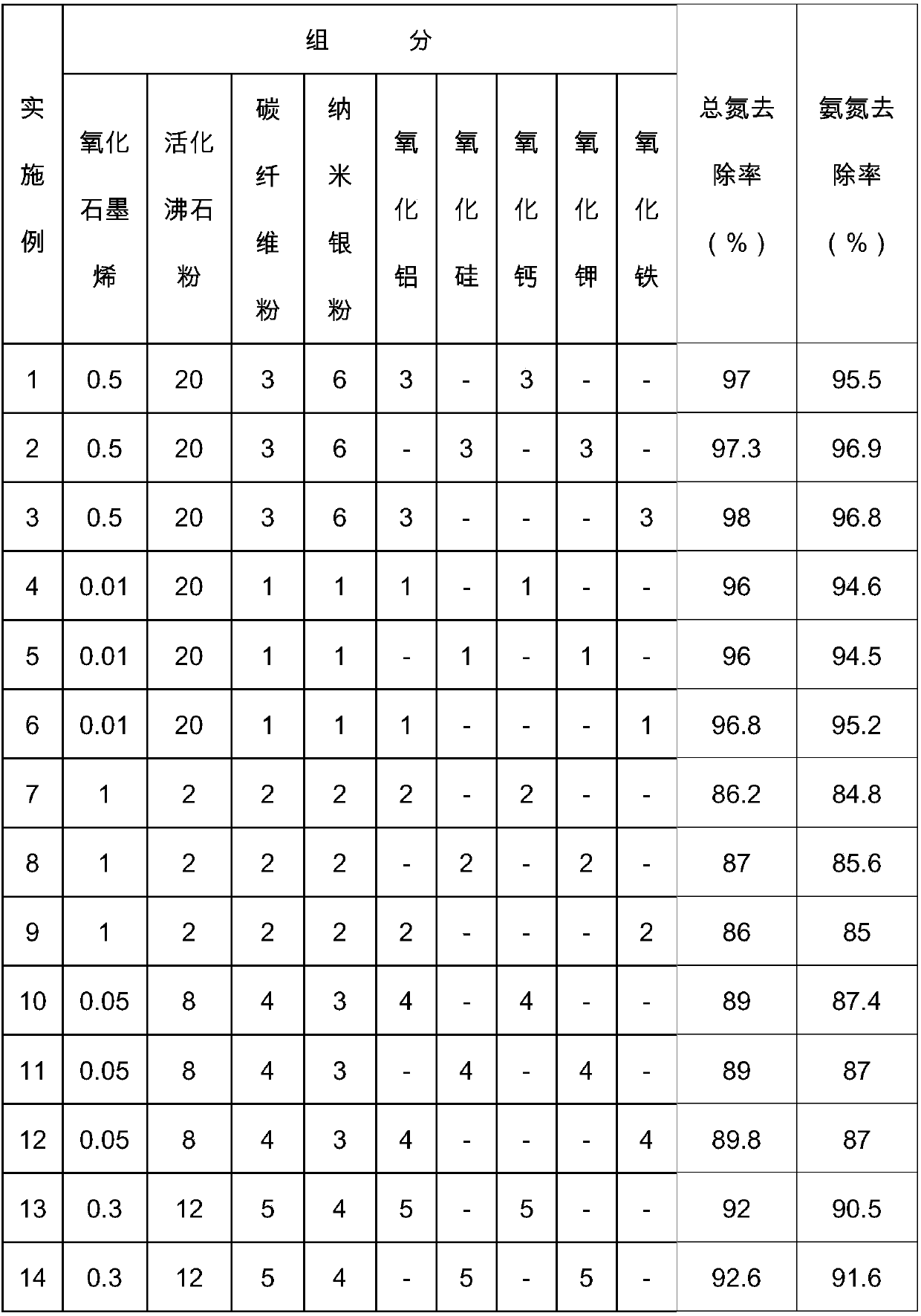

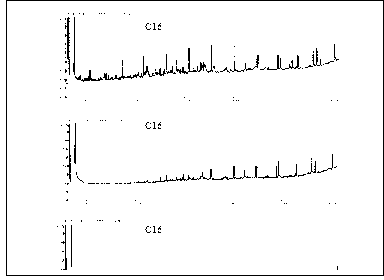

InactiveCN107628683AReduce use costEasy to useSustainable biological treatmentBiological water/sewage treatmentFiberHigh concentration

The invention provides biological packing. The biological packing is prepared from components in parts by weight as follows: 0.01-1 part of graphene oxide, 2-20 parts of activated zeolite powder, 1-6parts of carbon fiber powder, 1-6 parts of nanometer silver powder, 1-6 parts of filler I and 1-6 parts of filler II. The biological packing is low in use cost, resistant to load impact, good in hydrophilicity and high in biological activity, has a large specific surface area, can purify sewage in flowing water, is less influenced by current scour, is high in sewage treatment efficiency and good in sewage treatment effect and convenient to use and cannot block river channels. The biological packing is suitable for sewage treatment projects such as nitrogen and phosphorus removal and the like of high-concentration organic wastewater, various types of industrial wastewater, refinery wastewater, commodity chemical wastewater, pharmaceutical wastewater and municipal domestic sewage.

Owner:钟华

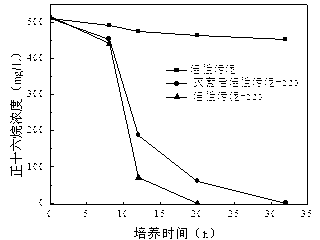

Alkane degrading bacteria and application thereof

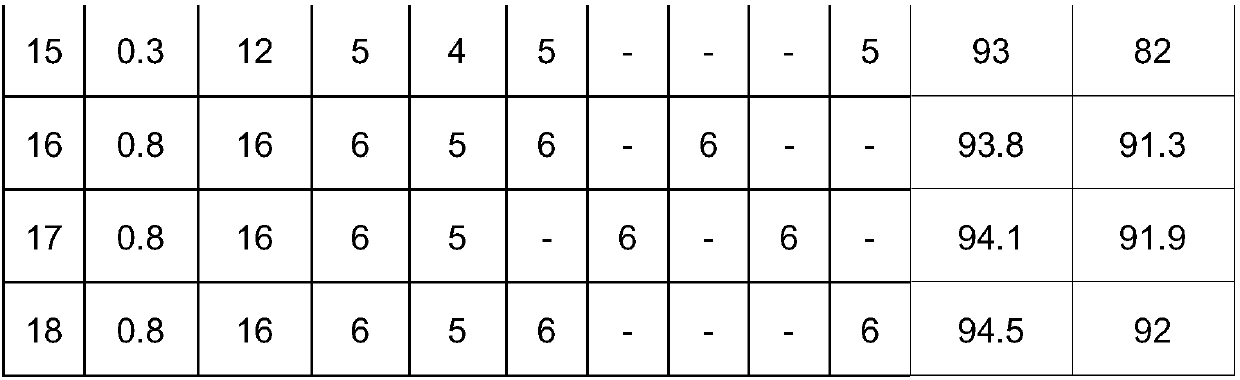

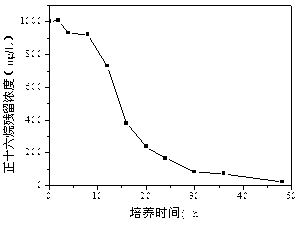

InactiveCN102703348APromote degradationImprove solubilityBacteriaContaminated soil reclamationBiotechnologyPositive gram bacteria

The invention discloses an alkane degrading bacterium and an application thereof. The alkane degrading bacterium C20 provided by the invention belongs to Tsukamurellasp. The alkane degrading bacterium is preserved in China Center for Type Culture Collection on 23rd, March, 2012; the preservation number is CCTCC NO: M2012089; the GenBank accession number of the strain 16SrDNA is JQ806393. The alkane degrading bacterium is a gram-positive bacterium; the bacterial colony is chrysanthemum yellow, has regular edge, is round, has drying surface and raised centre; the thallus is in short-rod shape, is arranged in a chain shape and has no capsule under observation of a microscope. The degradation rate of the alkane degrading bacterium for 1000mg / L of n-hexadecane in 48h is more than 98%; medium-long-chain alkane (C12-C24) in the diesel can effectively degraded, and the alkane degrading bacterium metabolizes to produce a bio-emulsifier for accelerating oil to dissolve. The alkane degrading bacterium can be applied in biological strengthening treatment and repairing of refinery waste water, petroleum-polluted water and soil and has good prospect.

Owner:WUHAN UNIV OF SCI & TECH

Removal of selenium from refinery wastewater

ActiveUS20110220583A1Reduce the amount requiredWater contaminantsSedimentation separationEnvironmental standardOxidizing agent

The invention provides a method of efficiently removing selenium from water. The method involves: adding an oxidant to the liquid, adjusting the liquid's pH to below 7.5, adding ferric salt in an amount such that less than a quarter of selenium in the liquid precipitates and adding a poly dithiocarbamate material to the liquid in an amount such that the amount of poly dithiocarbamate material (in ppm) is greater than the amount of ferric salt (in ppm). This method removes far more selenium than previous methods, and does it using a smaller amount of expensive chemicals. Moreover this method makes it far more likely to achieve cost effective compliance with the ever-increasing environmental standards for selenium in water.

Owner:NALCO CO

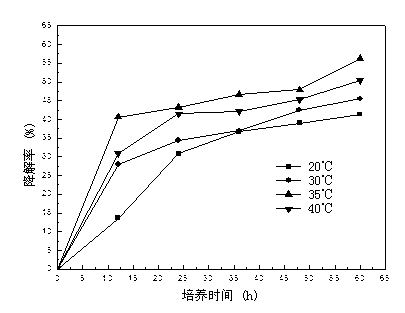

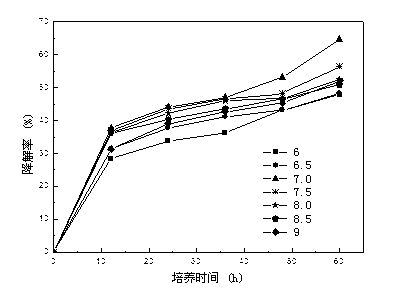

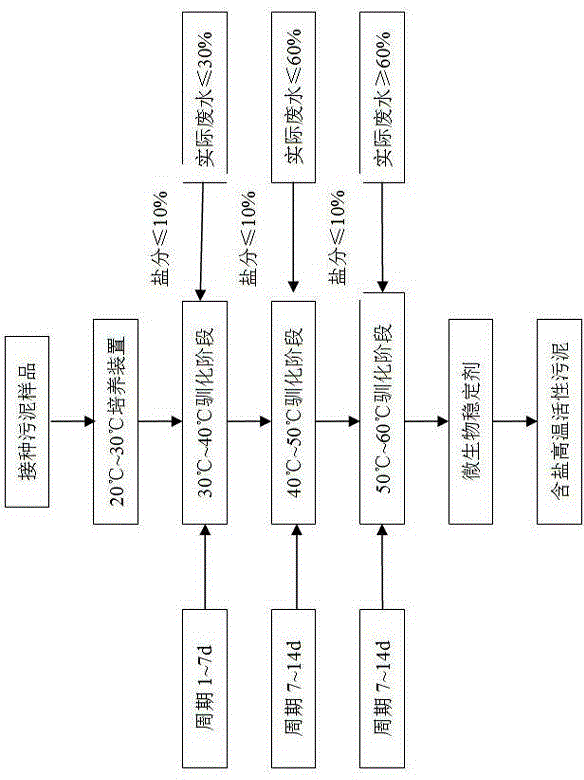

Cultivating method for activated sludge for biochemically treating high-temperature salt-containing wastewater

ActiveCN104649405AHigh salt toleranceHigh removal efficiency of organic matterWaste water treatment from quariesBiological water/sewage treatmentHot springActivated sludge

The invention discloses a cultivating method for activated sludge for biochemically treating high-temperature salt-containing wastewater. The method comprises the steps of inoculating a sludge sample from soil in a hot spring, a volcanic basin, a hot area and the like into a 20-30-DEG C cultivating device; cultivating in an intermittent habituated cultivation way and in three stages, namely cultivating at the temperature of 30-40 DEG C for 1-7 days, cultivating at the temperature of 40-50 DEG C for 7-14 days and cultivating at the temperature 50-60 DEG C for 7-14 days; and adding a microbiological stabilizer to obtain the activated sludge for treating high-temperature salt-containing wastewater. The method disclosed by the invention is simple and easy and relatively low in operation energy consumption; the obtained activated sludge has the characteristics of strong salt and temperature tolerance and high organism removing efficiency; a biochemical system constructed by using the activated sludge is strong in stability; the effluent quality is relatively good; the high-temperature salt-containing wastewater can be discharged up to the standard; and the activated sludge can be used for biochemically treating refinery wastewater and oil producing wastewater.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

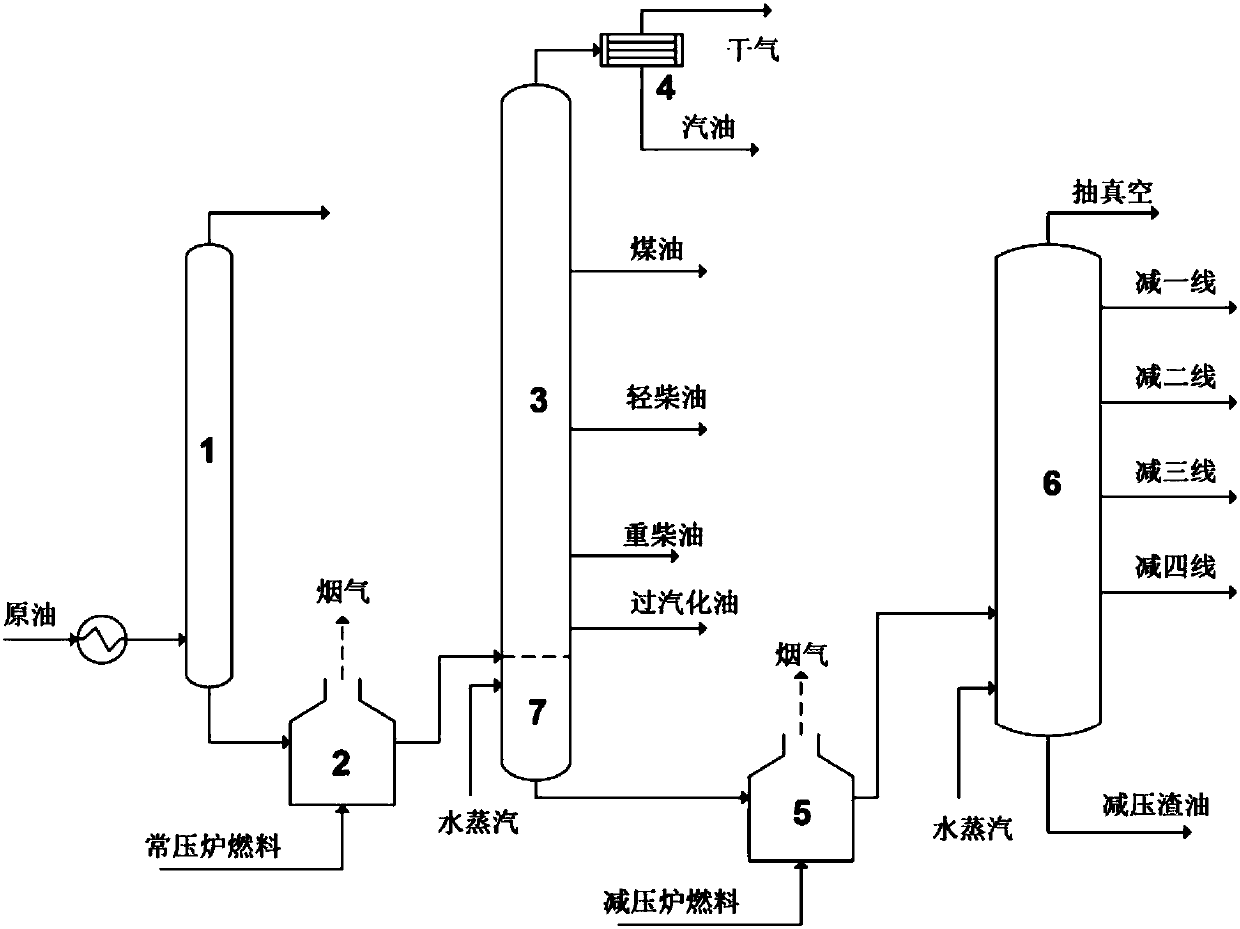

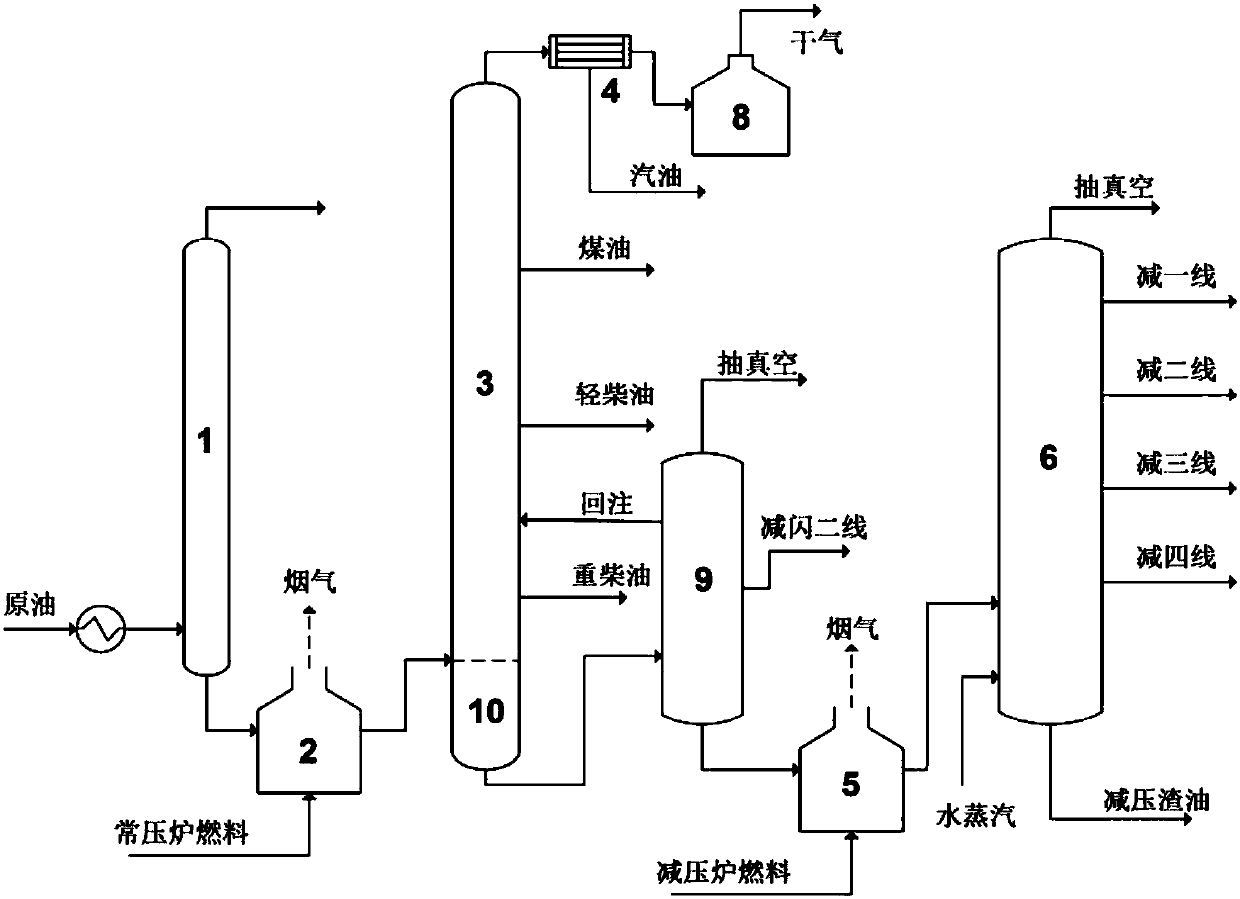

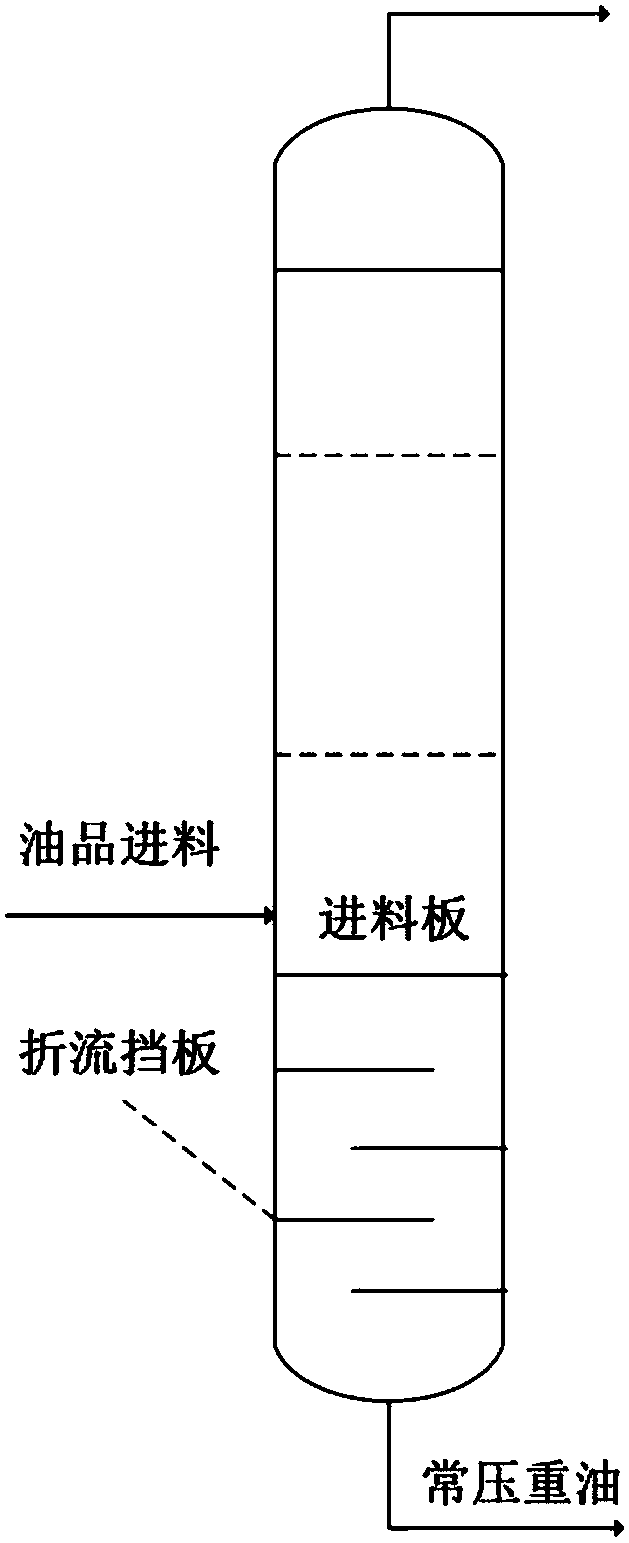

Water-free atmospheric vacuum distillation technology and device

ActiveCN107699273AEasy to separateSolve the problem of low temperature dew point corrosionHydrocarbon distillation control/regulationVacuum distillationReboilerFuel oil

The invention provides a water-free atmospheric vacuum distillation technology and device. The technology is characterized in that a normal-pressure tower and a vacuum tower adopt a four-time gasification and feeding manner; after crude oil is heated through a normal-pressure furnace, materials are fed from a tower kettle of the normal-pressure tower; water steam is not introduced into the tower kettle; each sideline product is heated by adopting a reboiler; alkali washing is carried out on tower top dry gas which is condensed and cooled at a tower top of the normal-pressure tower; a vacuum flashing tower is additionally arranged between the normal-pressure tower and a vacuum furnace; normal-pressure heavy oil from the tower kettle of the normal-pressure tower enters the vacuum flashing tower; the vacuum flashing tower is provided with a plurality of sidelines for drawing out products; the product drawn out from the first sideline is injected into the normal-pressure tower again; the heavy oil of the tower kettle enters the vacuum furnace and is further heated, and then enters the vacuum tower; pressure of the vacuum flashing tower is controlled between the pressure of the normal-pressure tower and the pressure of the vacuum tower. The invention further provides the water-free atmospheric vacuum distillation device. By adopting the device and the technology, provided by the invention, the low-temperature dew-point corrosion problem of the top of the normal-pressure tower can be solved, refinery wastewater is reduced and the diesel oil extraction rate of the normal-pressureheavy oil is improved; serious entrainment of the vacuum tower is alleviated and the decompression and deep drawing vacuum degree is reduced. The long-period, safe, stable and operation performance ofthe device is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

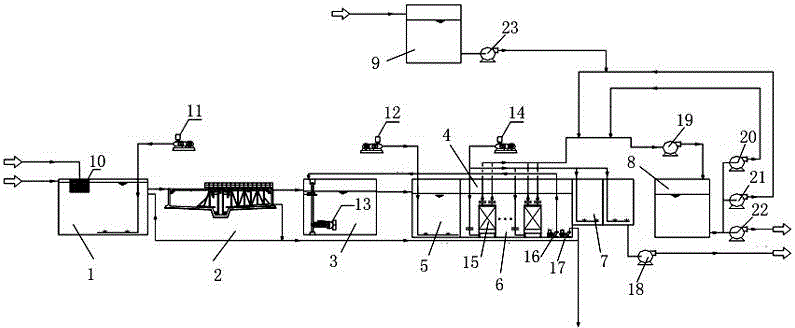

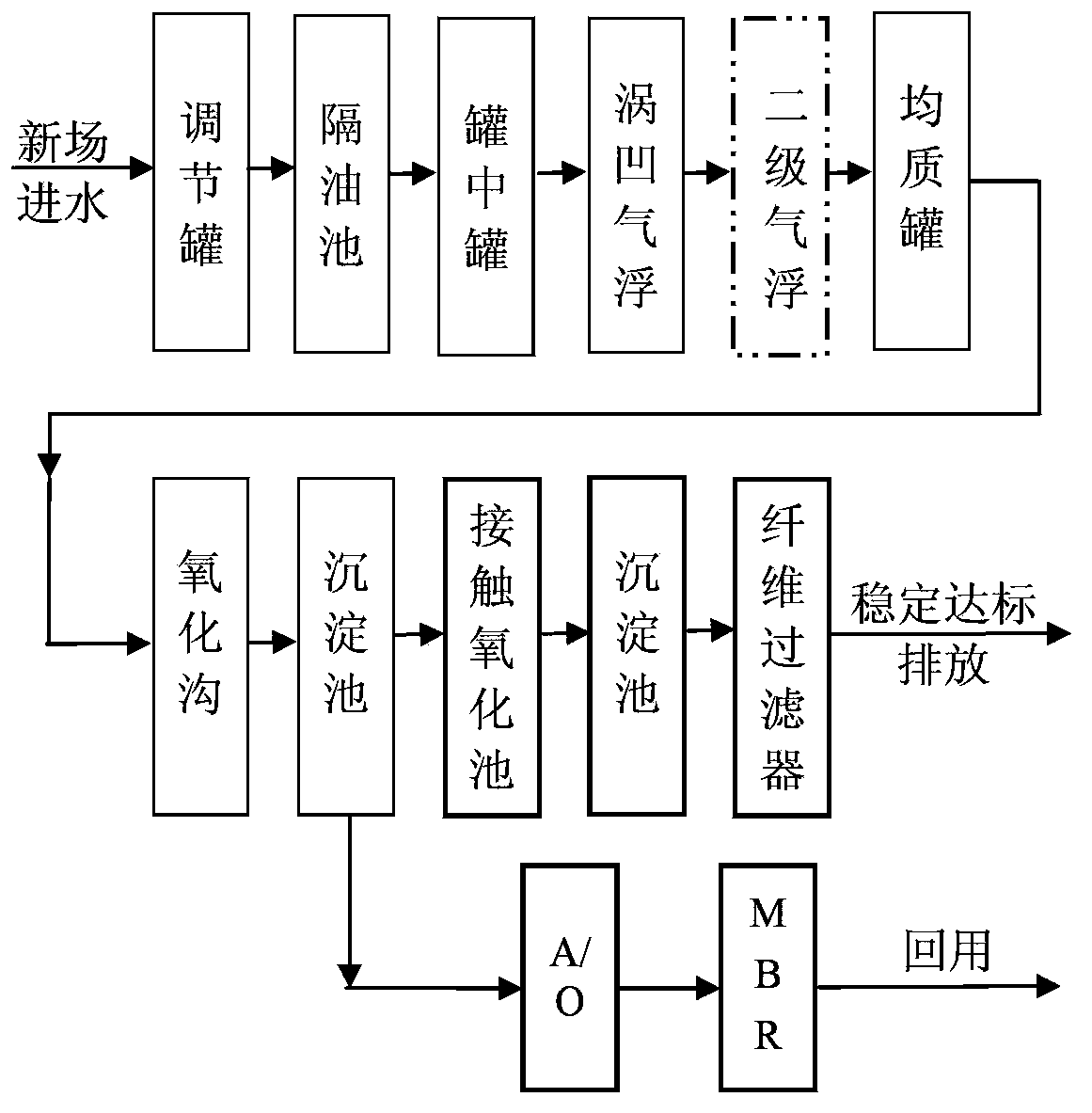

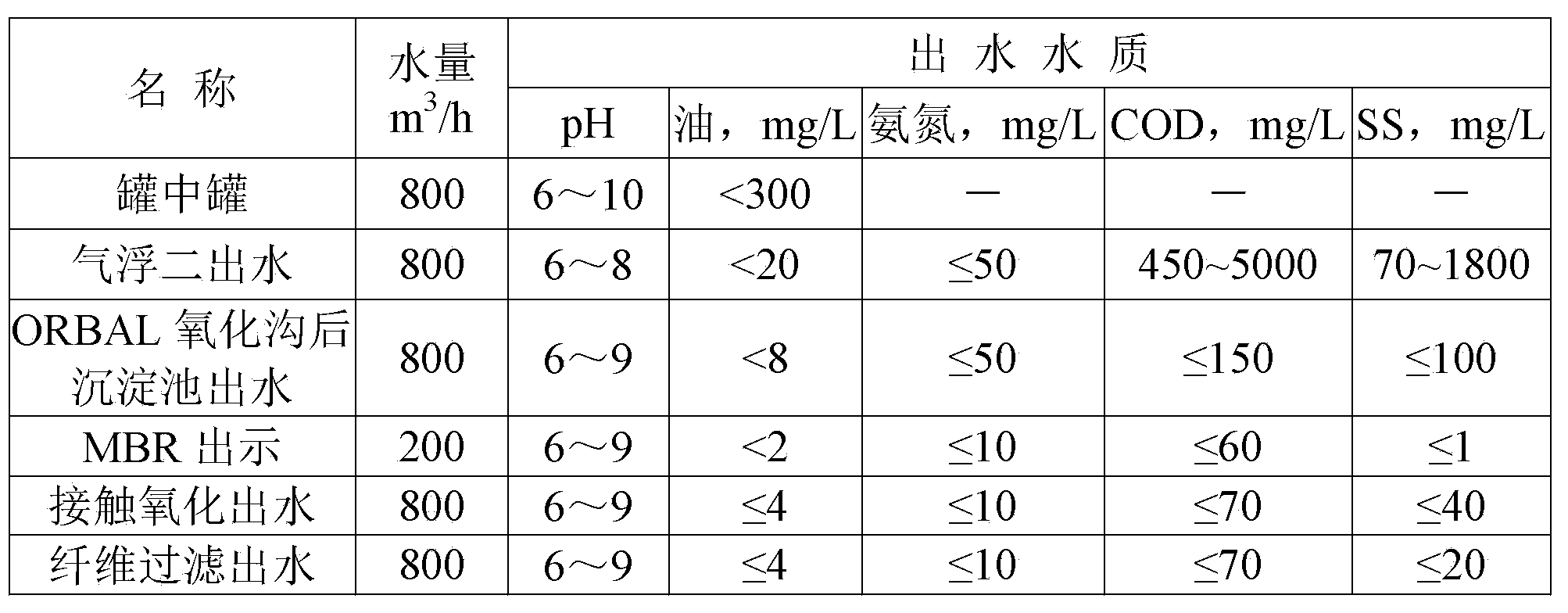

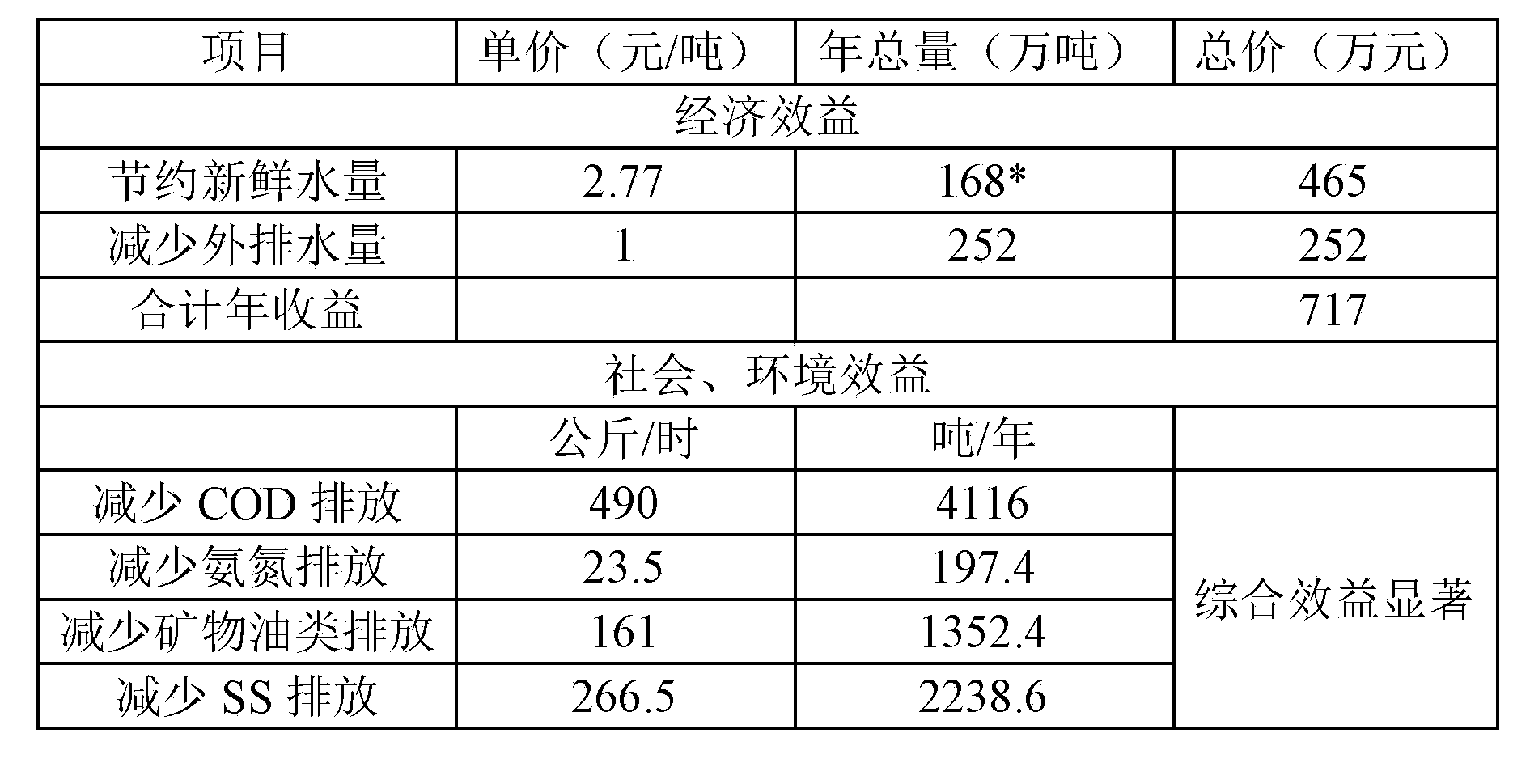

Method for stable up-to-standard treatment and resource utilization of refinery wastewater

ActiveCN103663847AStable emissionsStable up-to-standard dischargeMultistage water/sewage treatmentWater/sewage treatment by flotationResource utilizationSewage

The invention provides a method for stable up-to-standard treatment and resource utilization of refinery wastewater. The method can realize process flows of stable up-to-standard release of refinery wastewater and sewage recycling at the same time. According to the method, regulating tanks are additionally arranged to strengthen a pretreatment flow and the treatment depth of a sewage treatment system to ensure that important indexes of discharged water can stably reach standards, and a membrane bioreactor process is adopted to reach a sewage recycling standard, so that the stable up-to-standard release of discharged water of the refinery wastewater generated after crude oil poor-quality treatment as well as water saving and emission reduction recycling of the refinery wastewater are realized, and the process flow of ensuring the stable up-to-standard release of the refinery wastewater is realized by strengthening pretreatment and increasing the biological treatment depth. Meanwhile, the water saving and emission reduction of the refinery wastewater are realized through a sewage recycling process, part of the sewage is recycled, and the discharged quantity of the sewage can be reduced. The method provided by the invention can be used in the field of stable up-to-standard release and recycling of the refinery wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

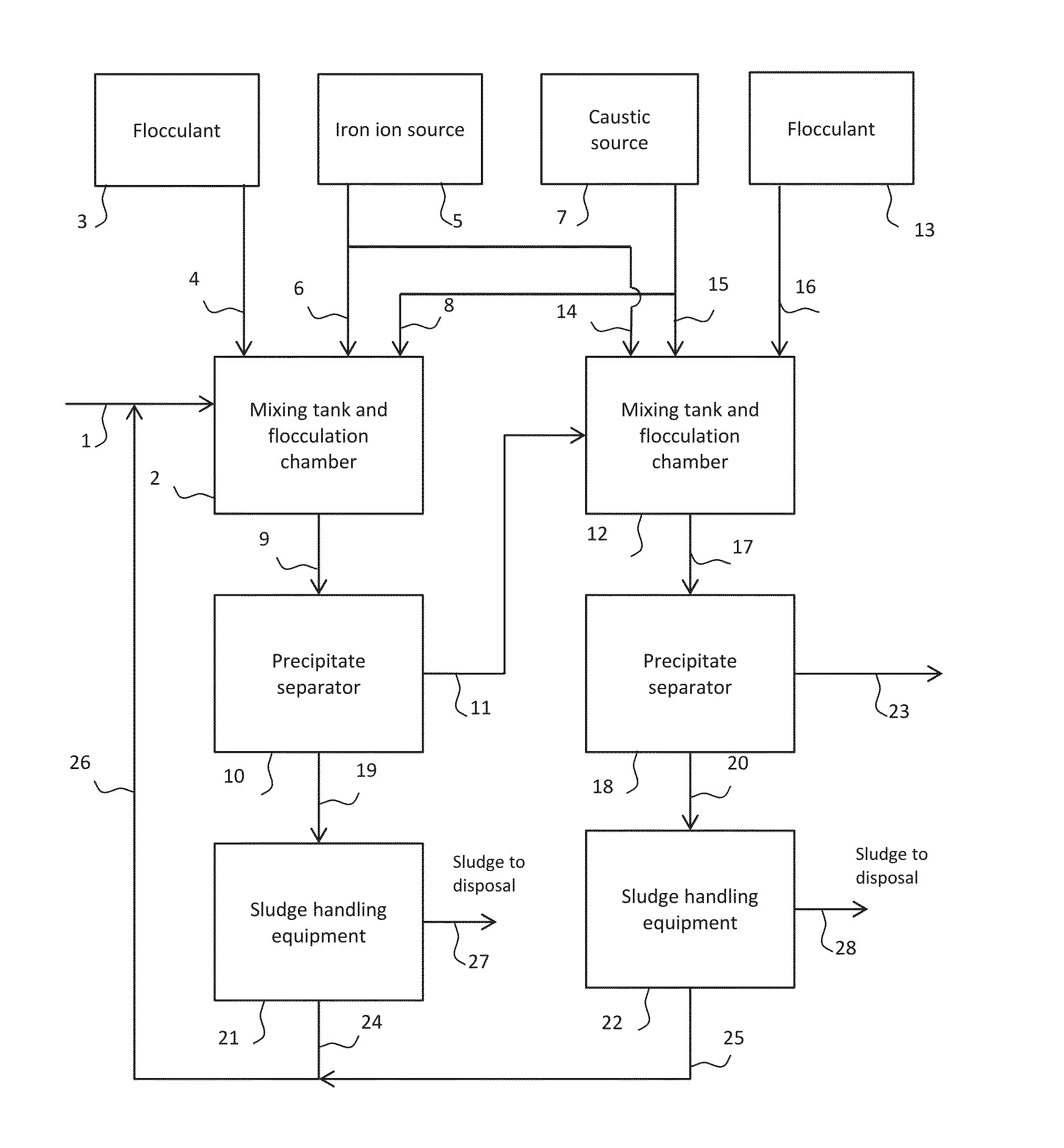

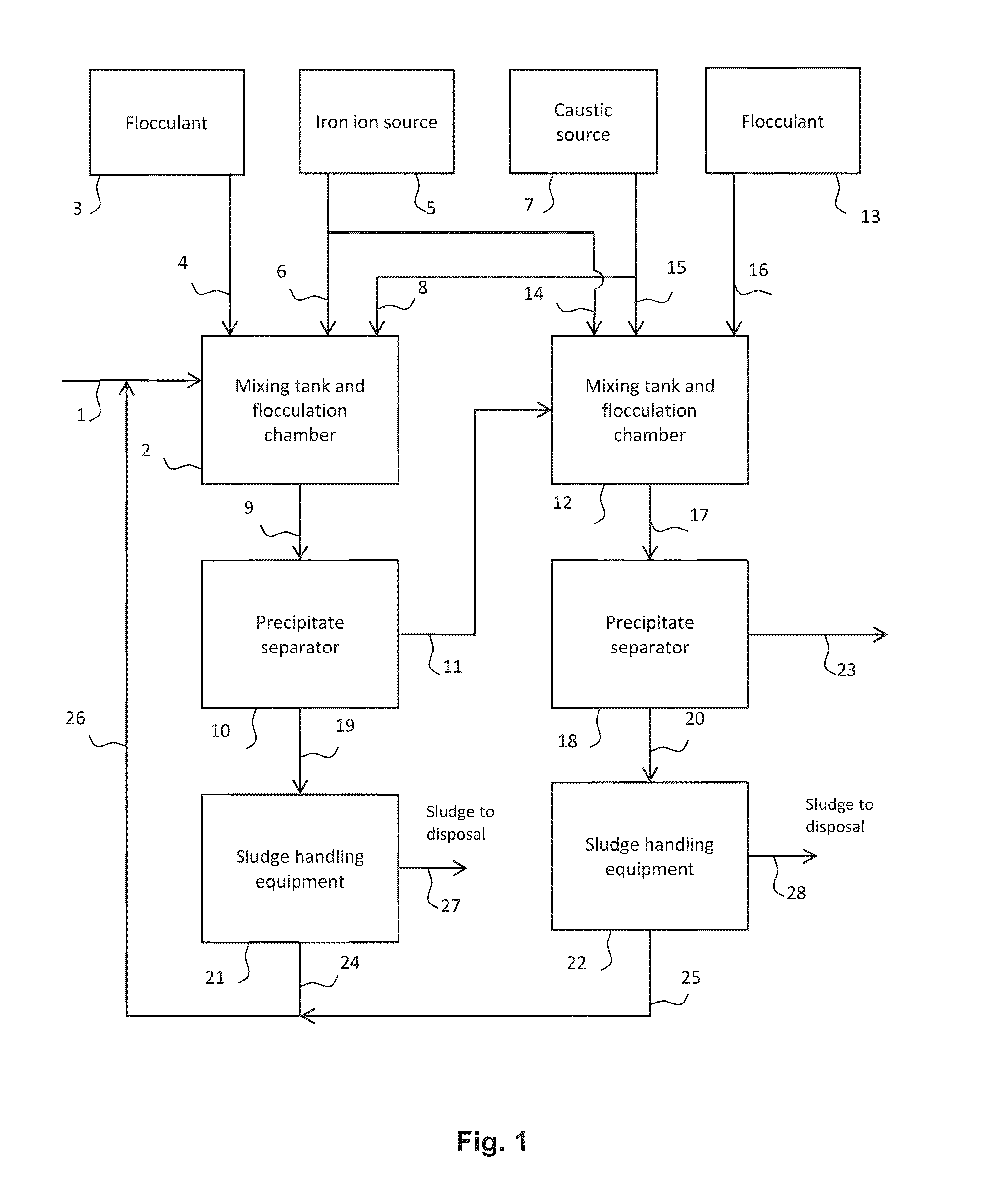

Removal of metals from wastewater

InactiveUS20160159669A1Reduce concentrationTreatment using aerobic processesWater contaminantsBillionthParticulates

A method for effecting a comprehensive removal of heavy metals from wastewater in a two stage process in which the wastewater is contacted in a first stage with a source of ferric ions under mildly acidic conditions (pH 5 to pH 8), preferably followed by the removal of the precipitated solids using a solid-liquid separation; a second stage follows in which the wastewater from the first step is contacted with a source of ferric ions under alkaline conditions (pH 8+) followed by the removal of the precipitated solids using a second solid-liquid separation. Used in conjunction with an initial oxidation step, the present method makes possible the removal of a whole suite of heavy metals present in both the anionic and cationic form in refinery wastewater. The treatment also removes metal compounds in the particulate phase. Metals concentrations can be significantly decreased from the mid to high ppb (parts per billion) range down to the low ppb range to meet the quality criteria for discharge.

Owner:EXXON RES & ENG CO

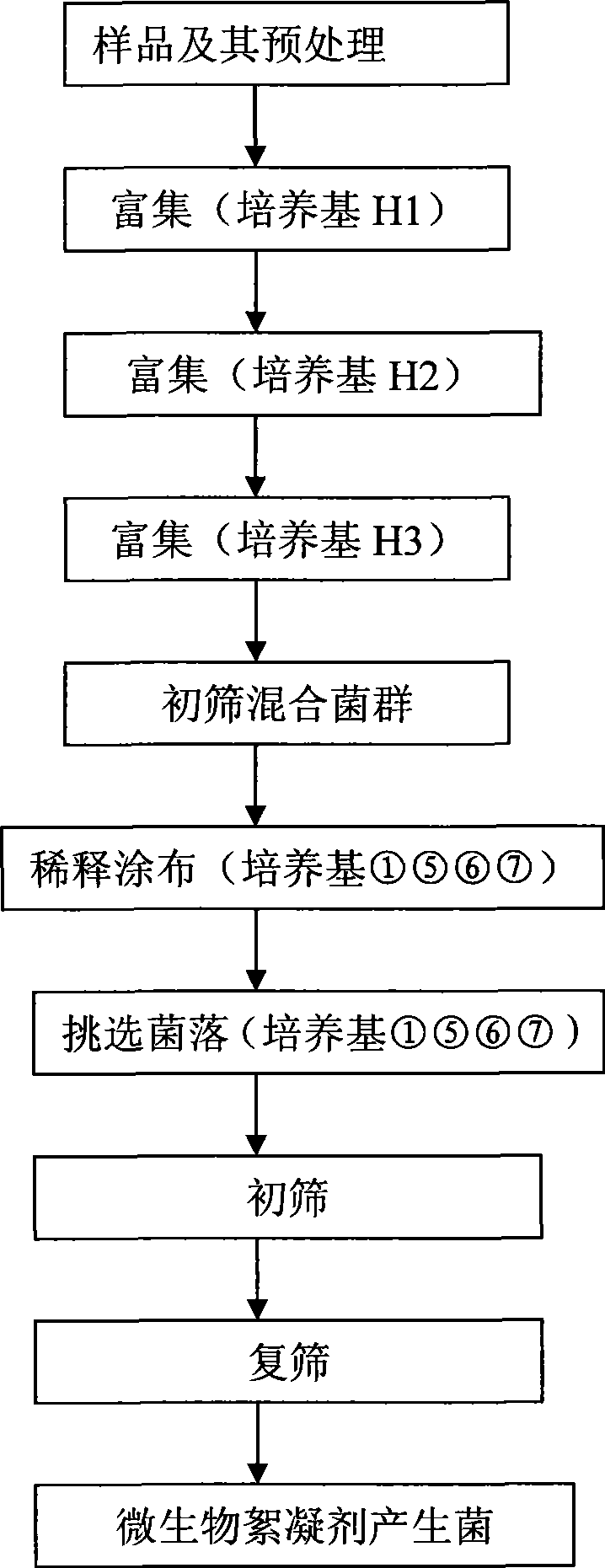

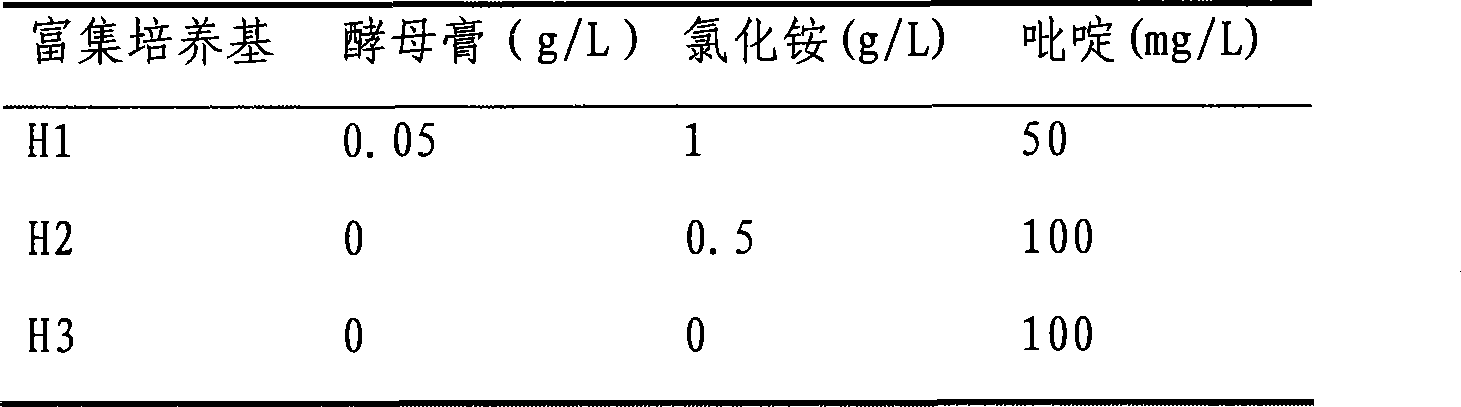

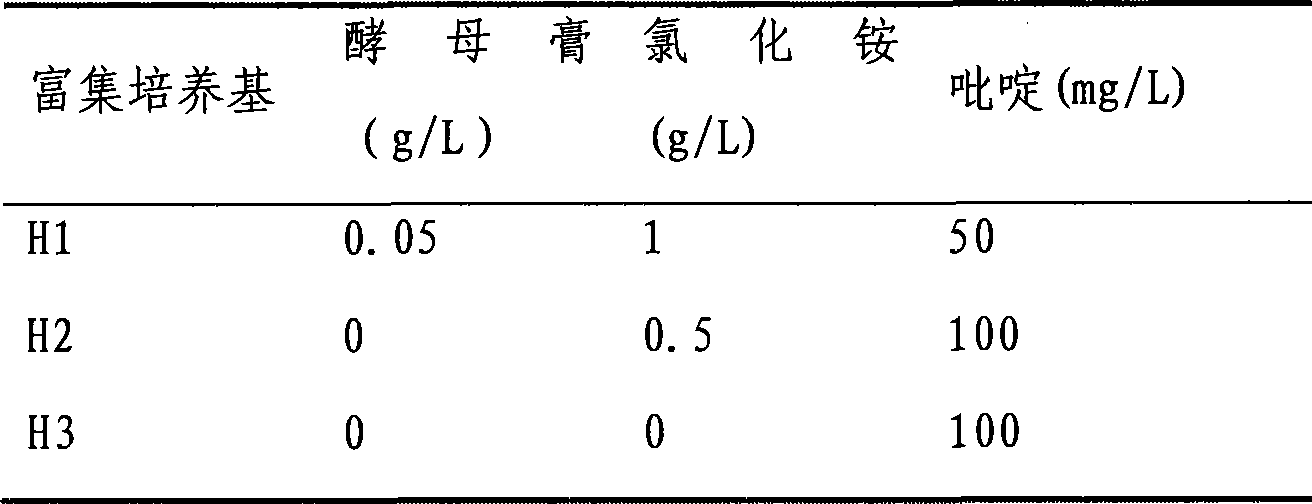

Method for rapidly screening oil refining wastewater bioflocculant-producing bacteria

InactiveCN101440347AMicroorganismsWater/sewage treatment by flocculation/precipitationMicroorganismScreening method

The invention discloses a method for rapidly screening a producing strain of a microbial flocculent of refinery wastewater, which can overcome the disadvantages of the prior screening method of the producing strain of the microbial flocculent, and can directionally screen producing strain of the microbial flocculent of the refinery wastewater according to the flocculent which needs to obtain corresponding application. The experiment shows that the average screening rate of the prior screening method is 26.6 percent, and the screening rate of the pyridine screening method is 44.3 percent. The method has the advantages of simple process, small workload, short period, and high screening efficiency.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Novel environment-friendly refinery wastewater deodorizer and application thereof

ActiveCN102757103AEliminate bad smellHarmless to healthWater/sewage treatmentActivated carbonOrganosolv

The invention relates to a novel environment-friendly refinery wastewater deodorizer and application thereof. The invention has the technical scheme that the novel environment-friendly refinery wastewater deodorizer is composed of the following raw materials in percentage by mass: 50-60 % of potassium permanganate, 20-30 % of activated carbon, 10-20 % of clay, and 2-7% of ionic liquid containing metal ion of Pt<2+>. A method which utilizes the deodorizer disclosed by the invention for treating refinery wastewater comprises the following steps of: taking the deodorizer and the refinery wastewater according to the volume ratio of the refinery wastewater to the deodorizer of 2000 : (1-3) under the room temperature, adding concentrated sulfuric acid, and controlling the temperature to be 20-30 DEG C and the reaction time to be 10-13 hours; and adding calcium oxide into a reacted solution for removing metal ions of Mn<2+> and the Pt<2+> and avoiding secondary pollution. The novel environment-friendly refinery wastewater deodorizer disclosed by the invention is simple in operation and low in cost; an organic solvent is not used in an operation process, thus obtained bottom mud is subjected to innocent treatment, can be reused, cannot cause environmental pollution and is innocuousness for the health of an operator.

Owner:爱瑞克(大连)安全技术集团有限公司

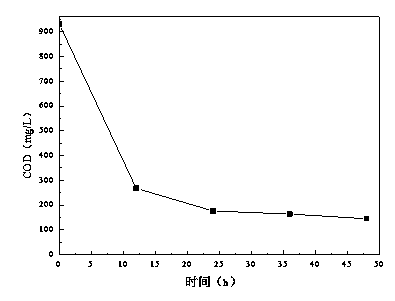

Method for lowering COD (Chemical Oxygen Demand) of oil refining wastewater by using dibutyl phthalate degrading strain

InactiveCN103613203AEfficient degradationReduce CODContaminated groundwater/leachate treatmentBiological water/sewage treatmentChemical oxygen demandPulp and paper industry

The invention relates to a method for lowering the COD (Chemical Oxygen Demand) of oil refining wastewater by using a dibutyl phthalate degrading strain. The dibutyl phthalate degrading strain D8 provided by the invention is collected in CCTCC (China Center for Type Culture Collection), the collection date is March 20, 2012, and the collection number is CCTCC NO: M2012088. The strain D8 is a Gram-negative bacterium, is yellow in colony and neat in edge, is circular, smooth and wet, has a bulged center and can grow and propagate in a manner of taking dibutyl phthalate as a unique carbon source and energy. The strain not only can effectively degrade dibutyl phthalate in the oil refining wastewater, but also can effectively degrade other organic substances and wastewater biochemical intermediates in the wastewater so as to lower the COD of the oil refining wastewater. The strain can be applied to the bioaugmentation treatment of the oil refining wastewater and has a broad application prospect.

Owner:WUHAN UNIV OF SCI & TECH

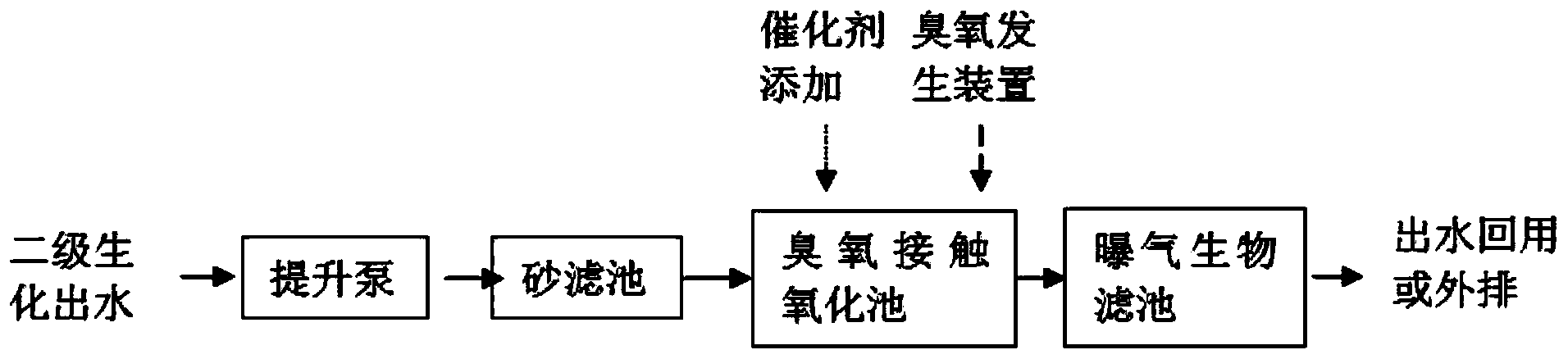

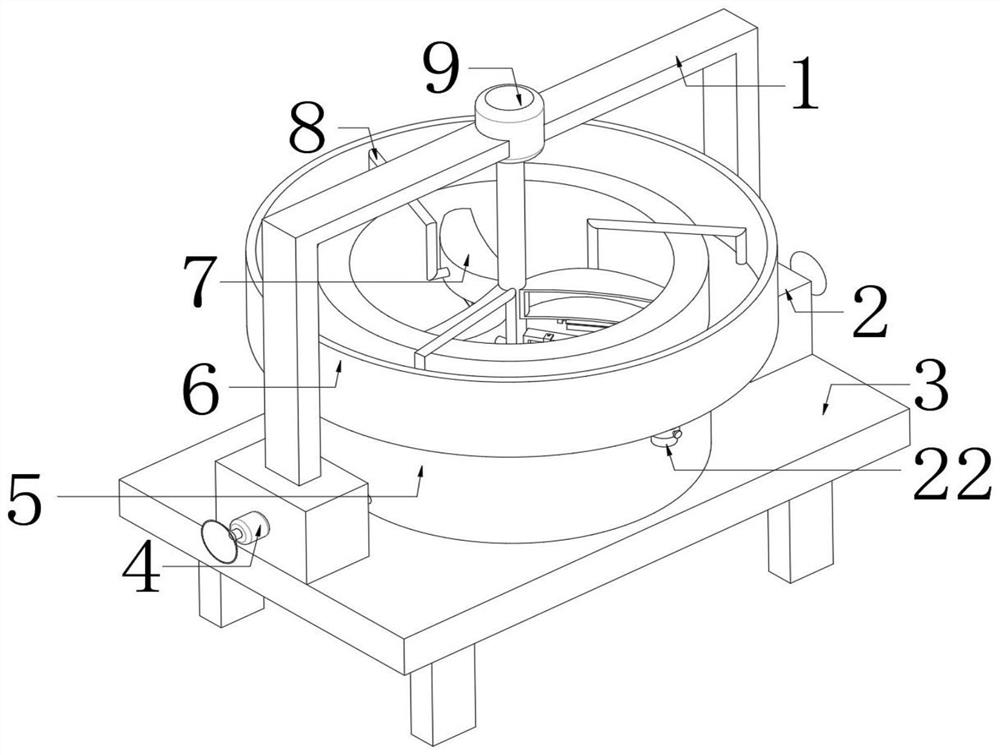

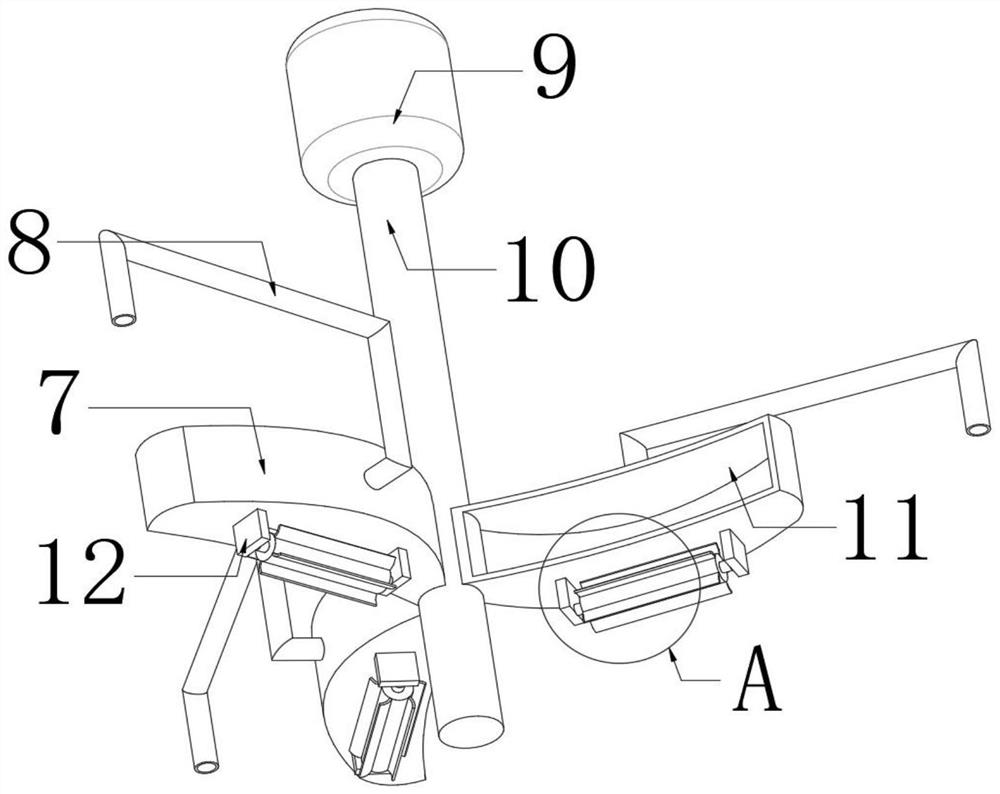

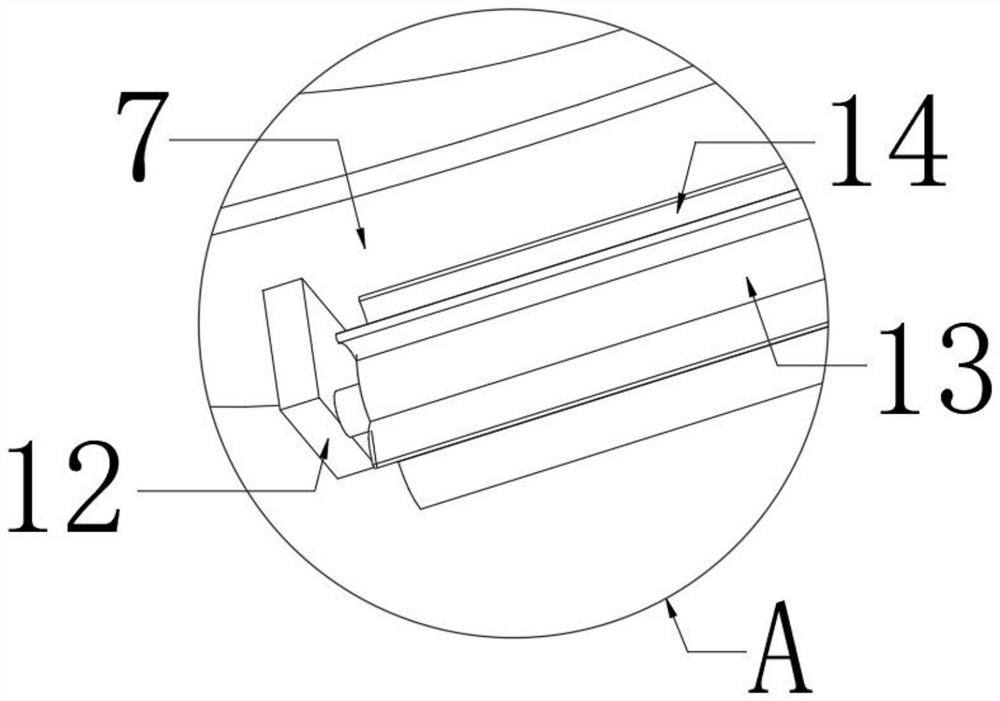

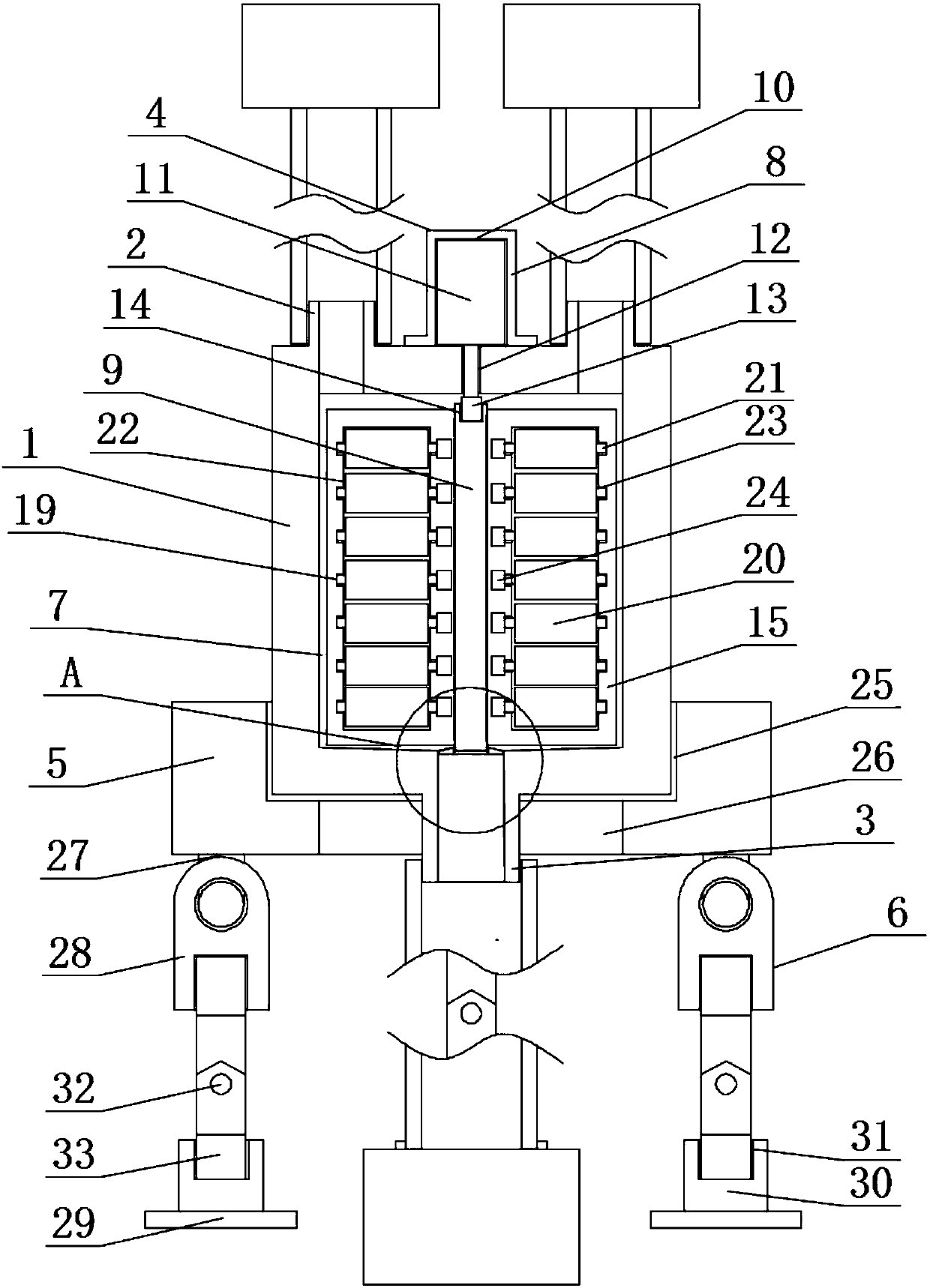

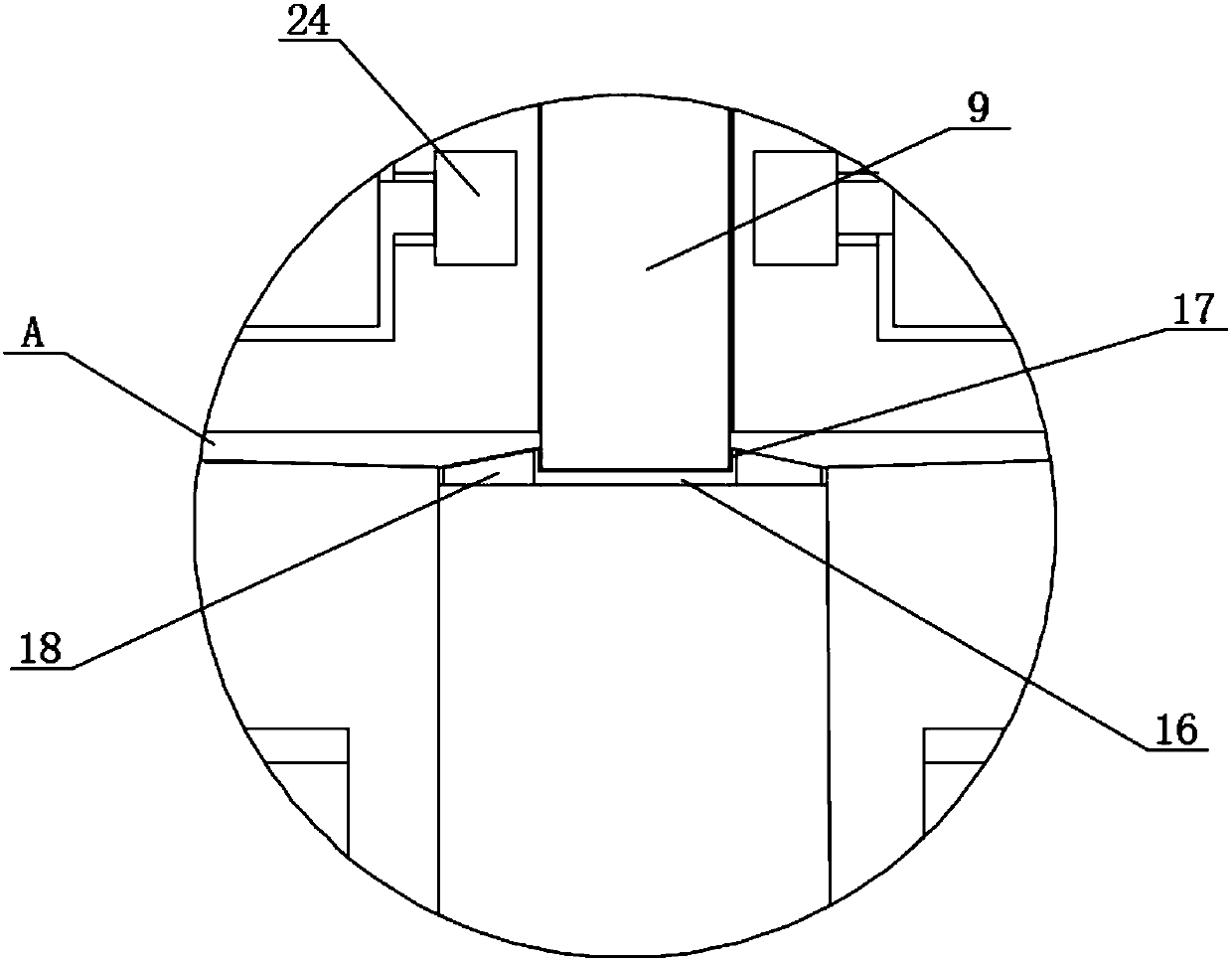

Ozone contact oxidation tank and refinery wastewater advanced treatment method thereof

ActiveCN104370359AImprove the mixing effectGuaranteed uptimeTreatment using aerobic processesMultistage water/sewage treatmentChemical oxygen demandPtru catalyst

The invention discloses an ozone contact oxidation tank and an advanced treatment refinery wastewater method thereof. Aromatic compounds are decomposed into micromolecule aliphatic hydrocarbons by ozone under the catalytic action of a catalyst, and the COD (chemical oxygen demand) content in the wastewater is lowered under the biodegradation action of a BAF (biological aerated filter); and meanwhile, the unique adsorption filtration action of the BAF can effectively lower the SS (suspended sediment), thereby forming stable effluent water quality. The unique three-chamber structure of the ozone contact oxidation tank greatly enhances the ozone-wastewater mixing effect, and improves the oxidation action of ozone on the pollutants; and the effluent water partition is arranged to avoid the shortage of effluent water and prevent the oxidized effluent water from carrying ozone to enter the biochemical unit so as to generate adverse effects on the biochemical bacteria, thereby enhancing the operation effect of the whole technique and saving the operating cost.

Owner:南京智仁环保科技有限公司

Oil refining wastewater oil stain separation device utilizing air flotation method

InactiveCN112374623AIncrease collection speedPracticalWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesInduced gas flotationProcess engineering

The invention belongs to the technical field of oil stain separation, particularly relates to an oil refining wastewater oil stain separation device utilizing an air flotation method, and provides thefollowing scheme aiming at the problems that an existing oil refining wastewater oil stain separation device can basically separate oil stains in wastewater, but solid impurities such as sand grainsin the wastewater are difficult to collect and separate. The device comprises a workbench, a separation cylinder is fixed to the outer wall of the top of the workbench through bolts, an air bag is fixed to the inner wall of the bottom of the separation cylinder through bolts, air outlet holes distributed at equal intervals are formed in the outer wall of the top of the air bag, and air outlet pipes are inserted into the inner walls of the air outlet holes. The slag scraping hopper can drive the rotating roller and the stirring blades to rotate while rotating, the stirring blades can further stir sand grains in waste water while rotating, accordingly, the sand grain collecting speed of the filtering net bag can be increased, and people can take down the filtering net bag through the fixingbuckles to treat solid impurities in the net bag after separation is completed.

Owner:WUXI GONGYUAN MACHINERY

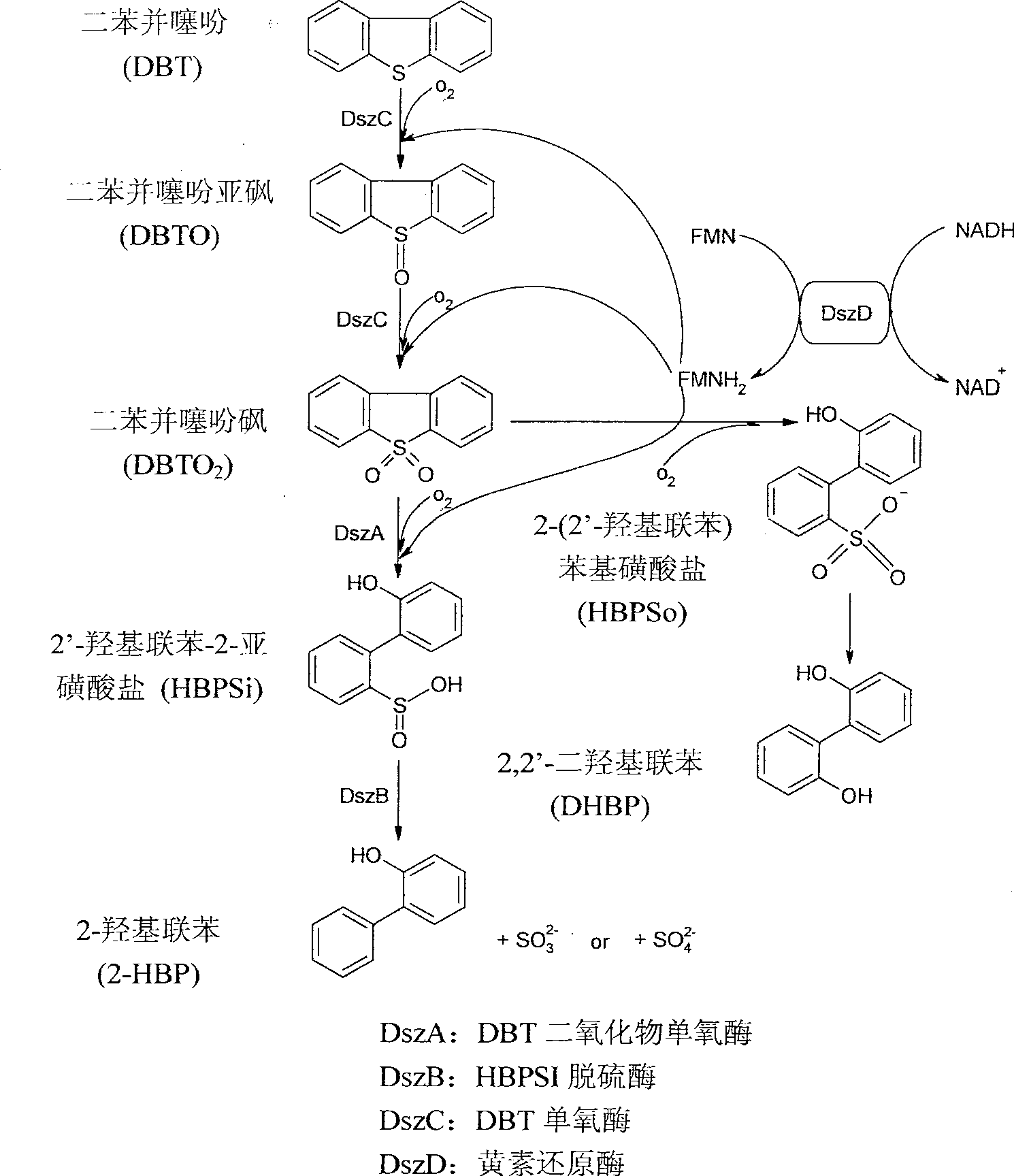

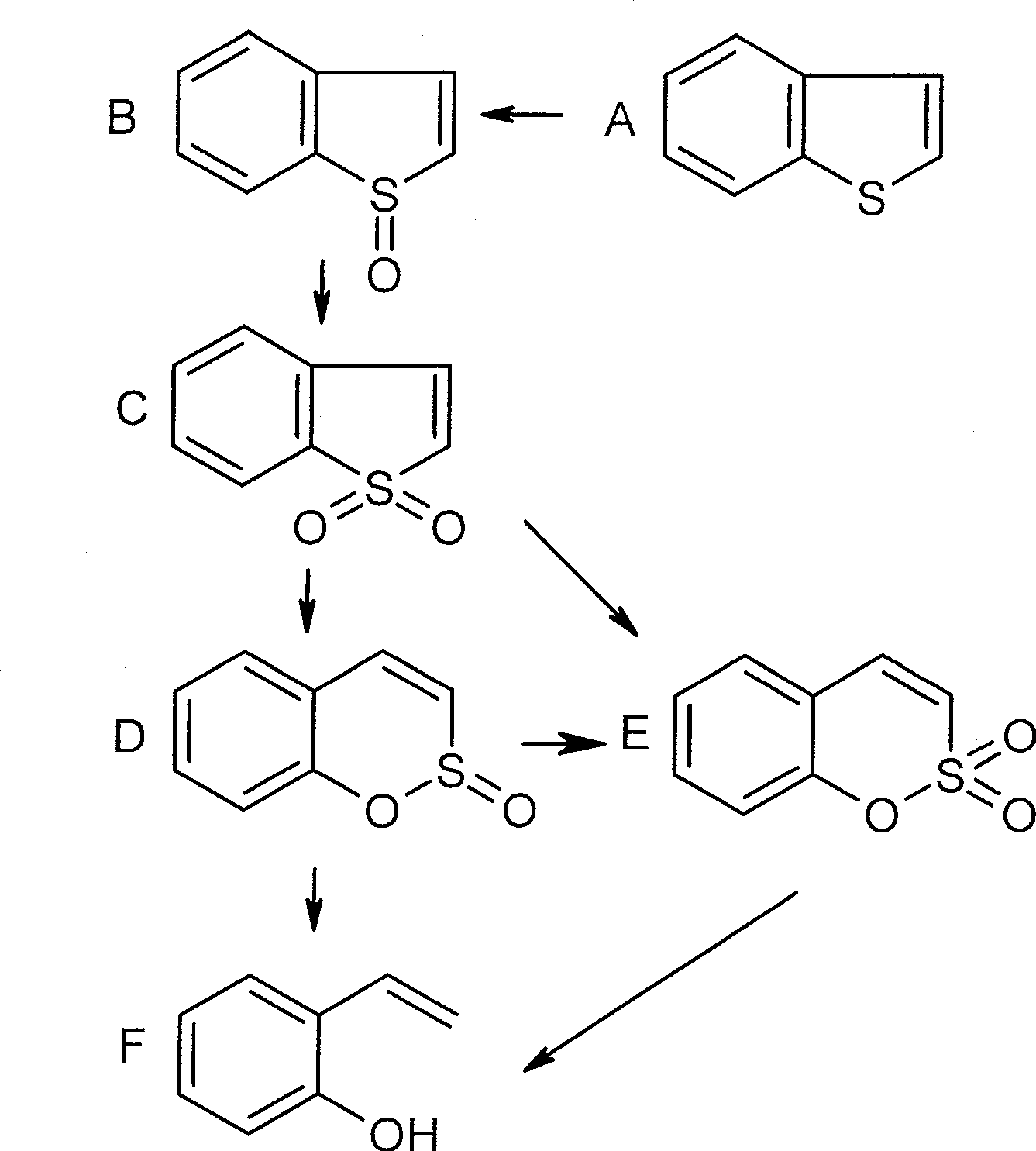

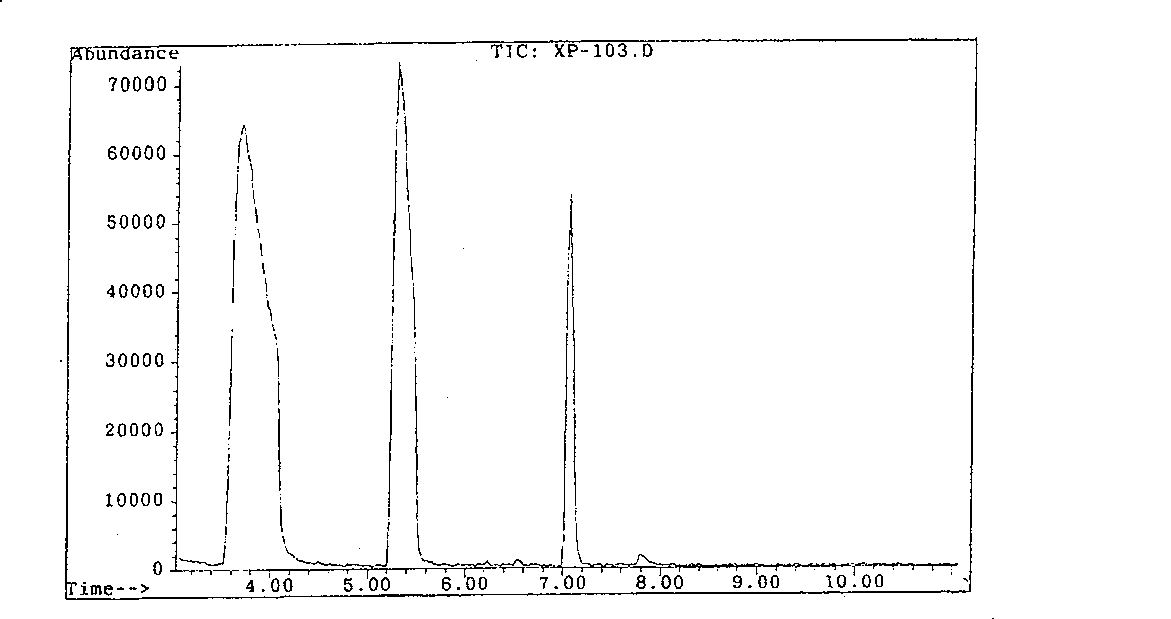

Sulfate-resistant Rhodococcus erythropolis and use thereof

The Rhodococcus erythropolis involved in the present invention is Rhodococcus erythropolis SDUZAWQ, which was preserved in the "General Microorganism Center of China Committee for the Collection of Microorganisms" on March 1, 2004, and its preservation number is CGMCC No.1129. The strain is isolated from refinery sewage and soil; the cell culture fluid of the strain can efficiently remove dibenzothiophene, 4,6-dimethyl-dibenzothiophene, 4-methanol through oxidative cleavage of C-S bond Sulfur in base-dibenzothiophene, benzothiophene, and 5-methyl-benzothiophene; Rhodococcus erythropolis SDUZAWQ was cultured with a mixed sulfur source of dibenzothiophene and sodium sulfate, and the resting cell culture medium obtained could effectively remove the Sulfur in Hydrotreated Diesel.

Owner:CHINA PETROLEUM & CHEM CORP +2

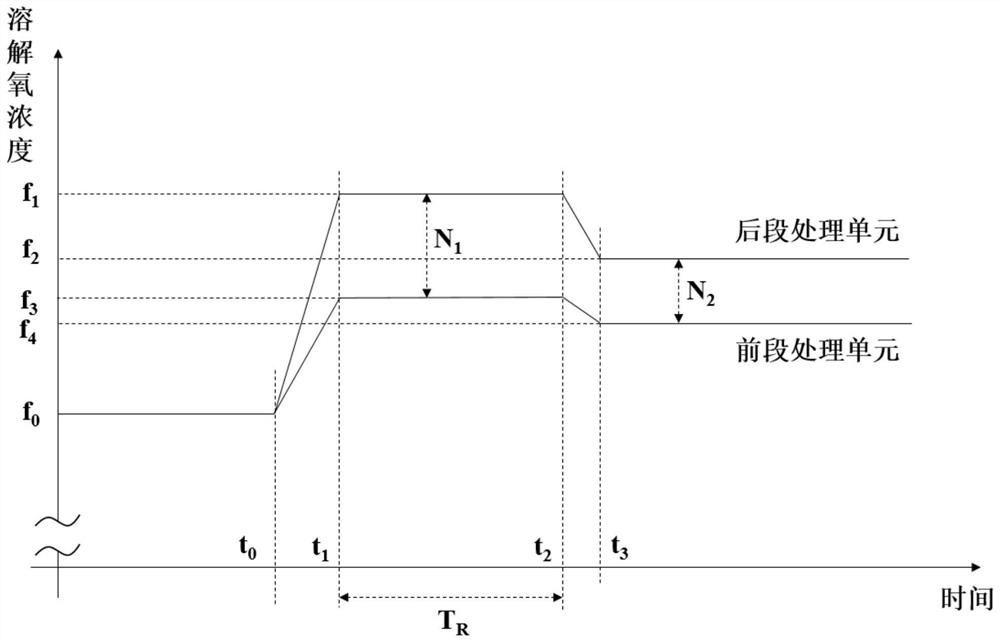

MBBR and oil refining wastewater treatment system

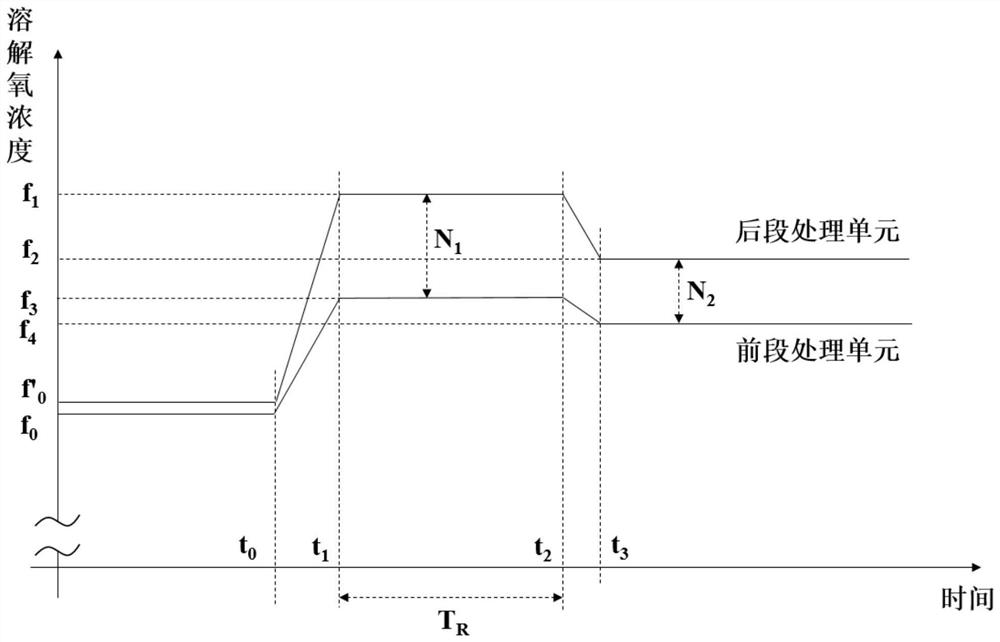

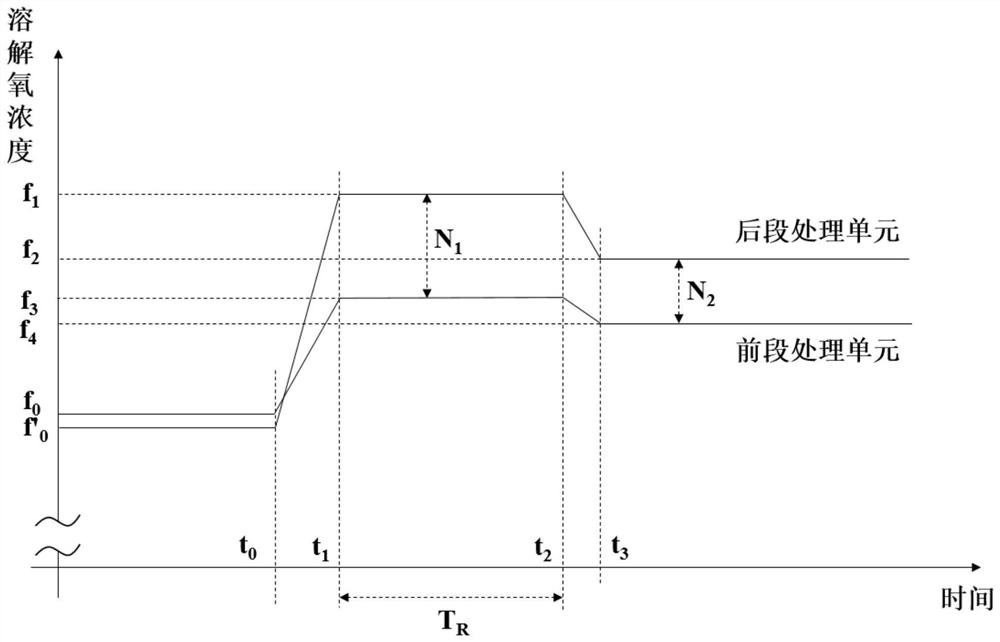

ActiveCN113044969AImprove processing efficiencyImprove impact resistanceWater treatment parameter controlWater treatment compoundsActivated sludgeBiofilm

The invention belongs to the field of wastewater treatment, and particularly relates to an MBBR and an oil refining wastewater treatment system. The invention provides an MBBR. Dissolved oxygen concentrations of different treatment sections are controlled according to a specific DO curve, a bacterial colony structure is adjusted, and a front-section treatment unit is used for carrying out buffer adjustment on wastewater; the microorganisms in the rear-section treatment unit further reduce COD and BOD in the wastewater, so that stable effluent quality is ensured; based on the MBBR, the invention further provides a treatment system. An A+MBBR+O combined process is matched with an efficient microbial preparation to treat the oil refining wastewater. The treatment efficiency and the impact resistance of the system are improved, the stability of the effluent quality is ensured, the impact caused by water quality fluctuation is relieved, the operation stability is improved, meanwhile, the MBBR is used as a process combining a suspension growth activated sludge method and an adhesion growth biological membrane method, the occupied area is small, the system operation cost is further reduced, and the capital construction cost is reduced.

Owner:青岛万慧源环保科技有限公司

Oil-refining-wastewater recycling device and utilizing method thereof

InactiveCN108017115AAvoid Stirring Dead AngleImprove the mixing effectFatty/oily/floating substances removal devicesTransportation and packagingWastewaterPtru catalyst

The invention discloses an oil-refining-wastewater recycling method and device. The oil-refining-wastewater recycling device comprises an oil-refining device body, an oil refining catalyst body, a wastewater collecting pond and a device shell, wherein pipe connecting pieces are arranged on the two sides of the top face of the device shell respectively, the device shell is connected with a deliverypipe through the two pipe connecting pieces respectively, and is connected with the oil-refining device body and the oil refining catalyst body through delivery pipes on the two sides respectively, asecond pipe connecting piece is arranged in the middle of the bottom face of the device shell, the device shell is connected with the wastewater collecting pond through the second pipe connecting piece and a delivery pipe, a pumping device is arranged on one side of the wastewater collecting pond, and the wastewater collecting pond is connected with the oil-refining device body through a pumpingassembly. The problem that the catalytic process between oil-refining wastewater and the catalyst is long is solved, and the oil-refining-wastewater recycling method and device can be widely applied to the field of oil-refining-wastewater treating.

Owner:石媛瑗

Method for deep processing and recycling oil refining wastewater

InactiveCN105923838AGood removal effectImprove the coagulation effectMultistage water/sewage treatmentNature of treatment waterPtru catalystUltrafiltration

The invention relates to a method for deep processing and recycling oil refining wastewater. A technical scheme of the invention includes: adding 15-25 mg / L inorganic / organic composite coagulant into biochemically-treated oil refining wastewater for coagulating, and removing colloid and residual macromolecular organics in the oil refining wastewater; pumping the coagulated oil refining wastewater into an ozone catalytic oxidation column, wherein a ceramsite catalyst using manganese nitrate, titanium dioxide and copper nitrate as active ingredients is disposed in the ozone catalytic oxidation column; introducing ozone gas, keeping ozone concentration in a liquid phase under 25-35 mg / L, and reacting for 12-15 min; finally, pumping the oil refining wastewater subjected to ozone catalytic oxidation into a polyvinylidene fluoride tubular-membrane ultrafiltration membrane assembly, and using effluent of the polyvinylidene fluoride tubular-membrane ultrafiltration membrane assembly as supplementary water of recirculating cooling wat4er of a refinery for refuse.

Owner:WUHAN UNIV OF SCI & TECH

Composite flocculant for refinery wastewater treatment, and refinery wastewater treatment method

InactiveCN110877923AStable structureGood degreasingNature of treatment waterWater/sewage treatment by flocculation/precipitationFlocculationPulp and paper industry

The invention provides a composite flocculant for refinery wastewater treatment, and a refinery wastewater treatment method. The composite flocculant for refinery wastewater treatment is prepared fromthe following components in parts by weight: 8-15 parts of an aluminum salt, 6-10 parts of a zinc salt, 0.02-0.05 part of an organic flocculant, 3-4 parts of an organic complexing agent, 70-85 partsof water and an inorganic strong acid, wherein the concentration of the inorganic strong acid in the composite flocculant is 0.025-0.085 mol / 100 g. The composite flocculant for refinery wastewater treatment provided by the invention solves the problem of loose floc of a single organic flocculant, and has the advantages of high flocculation efficiency, large and compact floc, small addition amount,low cost and the like when being used for treating refinery wastewater.

Owner:PETROCHINA CO LTD

Disposal of sediment from pond or lagoon at petroleum refinery

InactiveUS6837997B2Efficient and cost-effective operationFatty/oily/floating substances removal devicesTreatment using aerobic processesOil separationSediment

Method and system for removing accumulated sediment at the bottom of a waste pond or lagoon of a wastewater treatment plant for a petroleum refinery. The system comprises a primary oil separation stage for separating hydrocarbons from the wastewater stream by gravity, a secondary oil removal stage and a biological treatment stage downstream of the secondary oil removal stage. A portion of the sediment from the bottom of the waste pond or lagoon is passed to the secondary oil removal stage and / or the biological treatment stage for processing with the refinery wastewater being treated in these stages.

Owner:EXXON RES & ENG CO

Bacteria agent for deeply processing phenylamine oil refinery effluent and preparation method thereof

InactiveCN101555462ASolve efficiency problemsSolve pollutionBacteriaWater contaminantsAnaerobic bacteriaGreenhouse

The invention discloses a bacteria agent for deeply processing phenylamine oil refinery effluent by a biological method and a preparation method thereof; the preparation method comprises the following steps: totaled 17 grafting aerobic microorganism strains and anaerobic microorganism strains are respectively grafted into 17 prepared triangular flasks, each of which contains 50ml to 150ml of liquid seed culture medium, according to a proportion of 2 percent to 7 percent by volume; the 17 triangular flasks are all placed in a shaking culture bed with constant temperature ranging from 28 DEG C to 35 DEG C to conduct shaking culture for 4 days to 7 days; the 17 strains in the liquid culture media are respectively grafted to 17 solid extension culture media and then all put in a greenhouse with temperature of 30 DEG C to 35 DEG C for 7 days to 11 days; next, 13 aerobic microorganism solid expansion culture products are mixed to prepare an aerobic microorganism solid bacteria agent, and 4 anaerobic microorganism solid expansion culture products are mixed to prepare an anaerobic microorganism solid bacteria agent. The invention adopts a biological deep processing technology and has low production energy consumption, high recycling rate and high degradation rate, thus being capable of realizing the industrial cleaning and continuous deeply processing of the phenylamine-contained oil refinery effluent.

Owner:王治业 +1

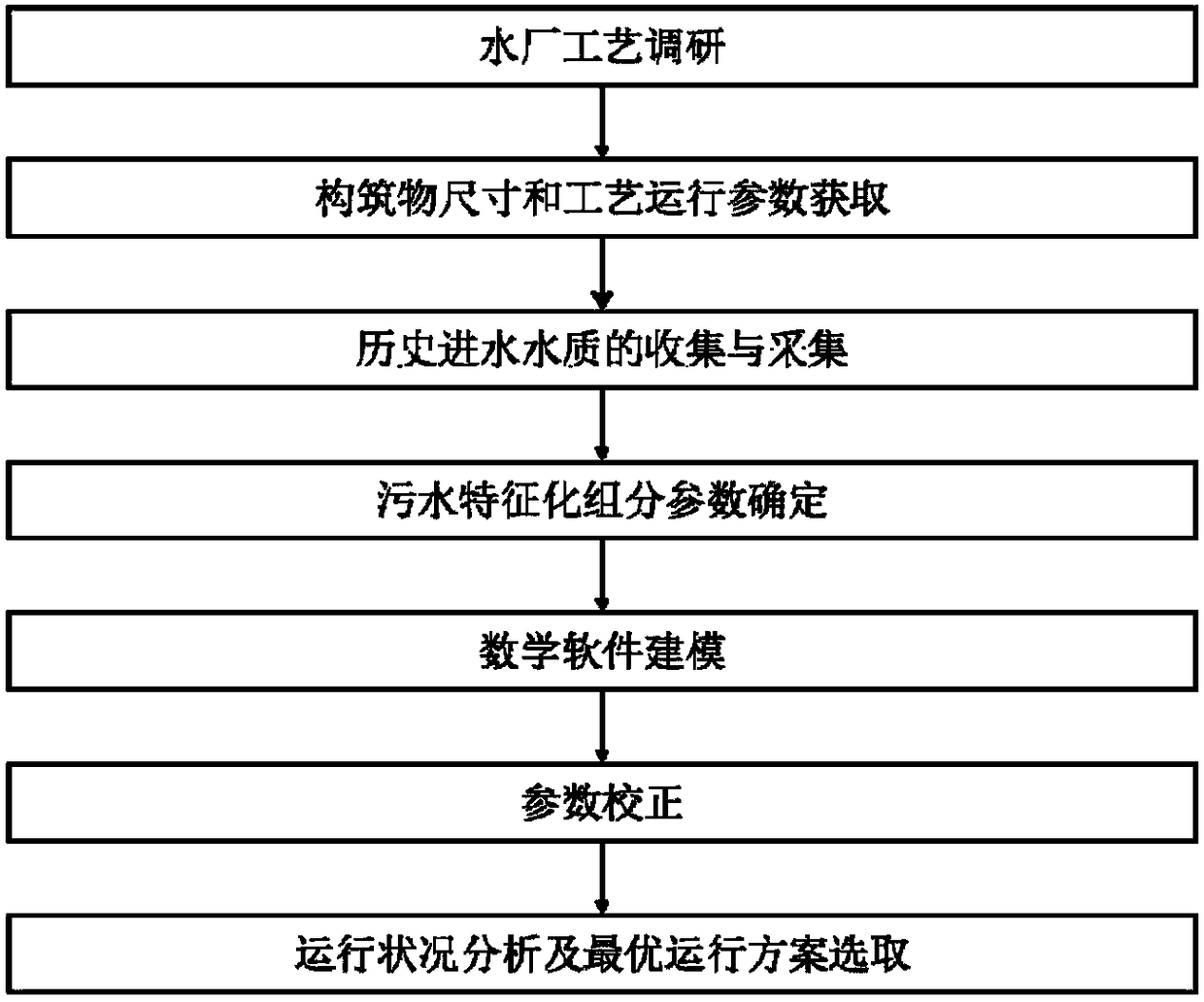

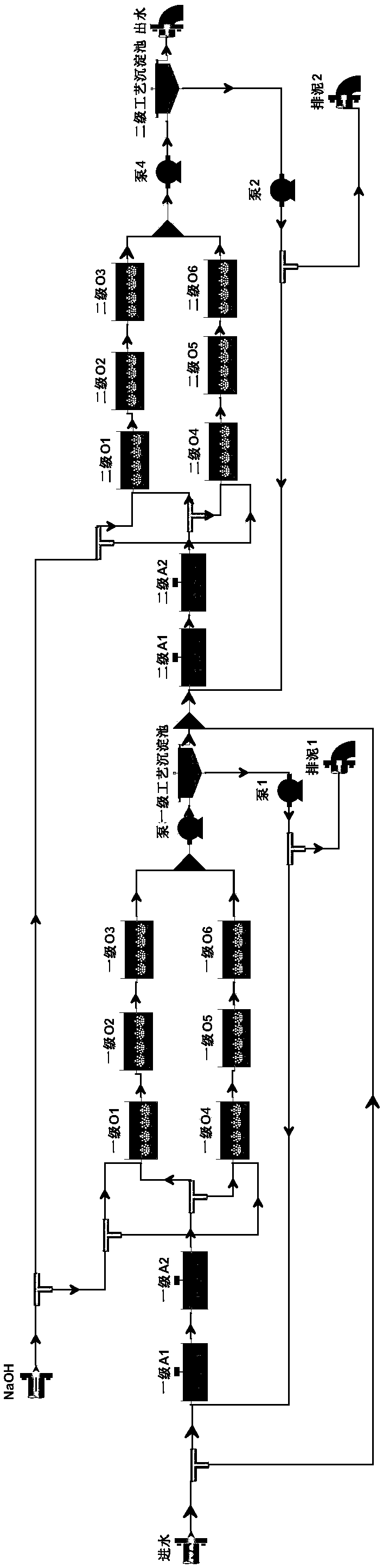

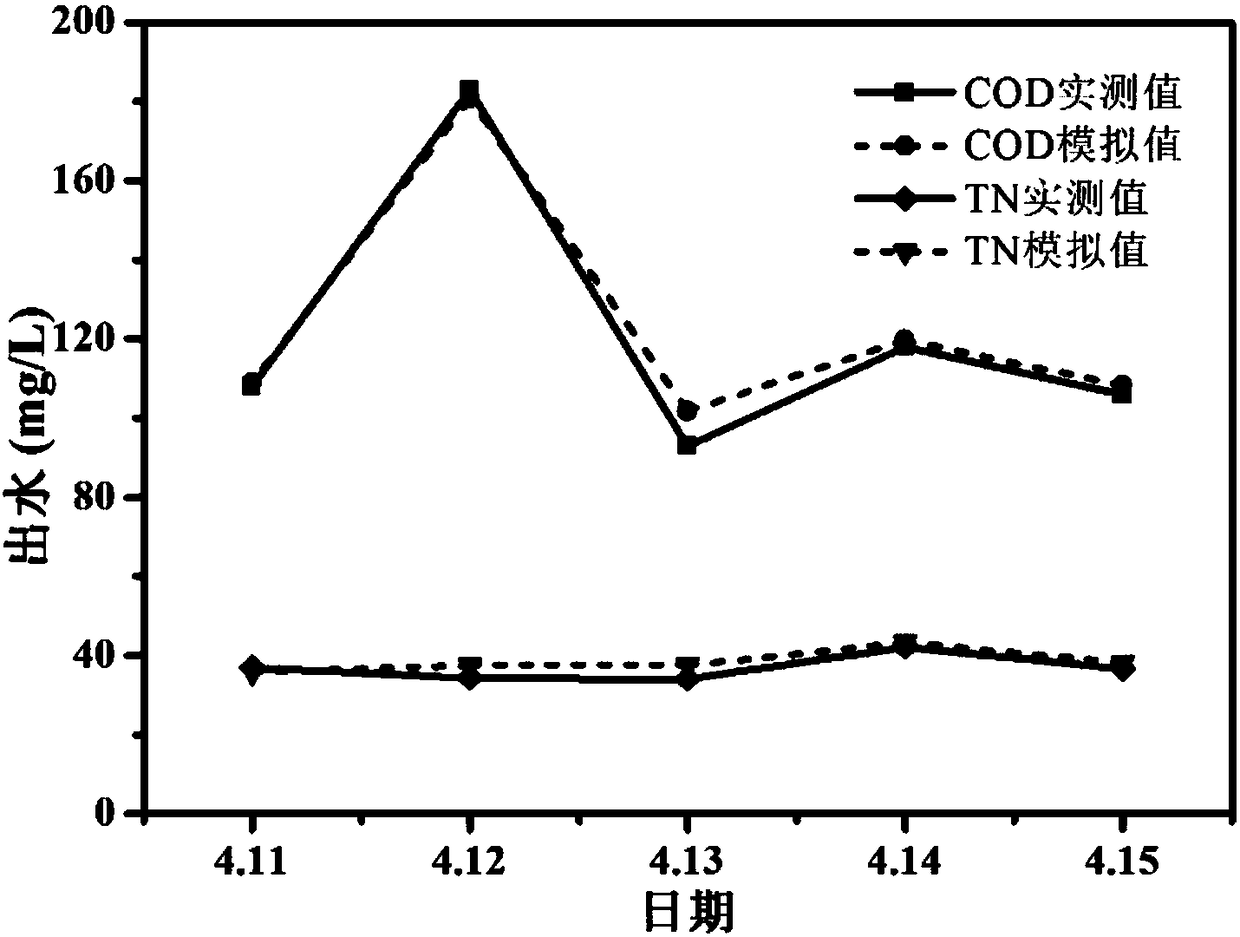

Method for optimizing refinery wastewater biochemical processing unit based on software simulation

InactiveCN108804727AImprove processing efficiencyGuaranteed emission standardsGeneral water supply conservationSpecial data processing applicationsWater qualitySoftware simulation

The invention discloses a method for optimizing a refinery wastewater biochemical processing unit based on software simulation, which comprises the following steps: a, investigating the refinery wastewater biochemical processing unit to determine the process flow; b, obtaining the sizes and process operation parameters of the structures of each biochemical section; c, obtaining historical inflow water quality data from a laboratory system of a water plant; d, supplementing to measure the inflow and outflow water quality parameters of the process over a period of time, and determining the characterization component parameters of the oily wastewater by component calculation; e, using mathematical software to build a model, inputting the sizes and the process operation parameters of the structures, the characterization component parameters of the oily wastewater, the historical inflow water quality and the water volume to carry out static and dynamic simulation; f, adjusting kinetic parameters and stoichiometric numbers to correct the model; g, carrying out a plurality of running state analyses and selecting an optimal operation plan. According to the method for optimizing a refinerywastewater biochemical processing unit based on software simulation in the invention, the effluent and energy consumption in different situations are analyzed through the corrected model; an optimal operation scheme is proposed; the unit processing efficiency is improved; and energy consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of recycling treatment method of oil refinery wastewater

ActiveCN103771656BSmall footprintSolve the blockageMultistage water/sewage treatmentReverse osmosisWater quality

The invention discloses a reusing treatment method of refinery waste water. Oil removing and suspended matter treatment, sequencing bath reactor (SBR) treatment and osmotic membrane bioreactor (OMBR) treatment are performed in sequence on the refinery waste water. The reusing treatment method is suitable for deep purification and reusing treatment of various types of waste water in an oil refinery, and the water quality of treated water is similar to that of reverse osmosis outlet water.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processes for removing metal particles from water

ActiveUS10093556B2Waste water treatment from quariesFatty/oily/floating substances removal devicesSorbentWastewater

Disclosed is a process to remove neutrally buoyant metal particles composed of solid particles and droplets of oil from water such as produced water from petroleum production or refinery wastewater. In one aspect, the water is contacted with oleophilic adsorbent materials which adsorb the neutrally buoyant metal particles. Also disclosed is a process for removing metal particles from a fluid volume that includes crude oil and / or condensate. The fluid volume is washed with a volume of water to form a volume of wastewater, thereby transferring at least a portion of the metal particles from the fluid into the wastewater. The volume of wastewater including the transferred metal particles is then contacted with an oleophilic adsorbent material wherein the neutrally buoyant metal particles are adsorbed by the adsorbent material. The adsorbent material is then separated from the wastewater. Finally, the treated wastewater is used to wash the crude and / or condensate.

Owner:CHEVROU USA INC

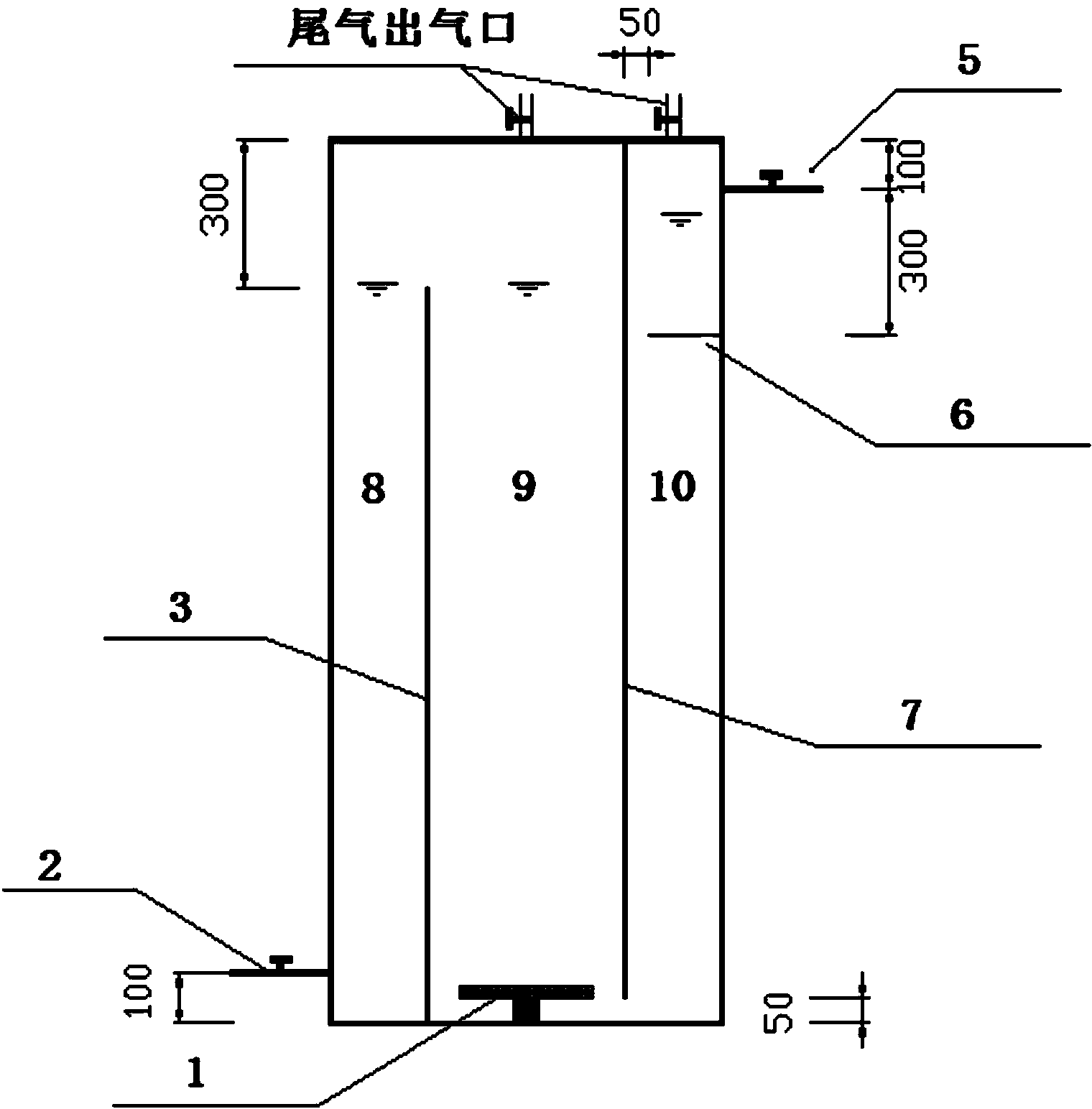

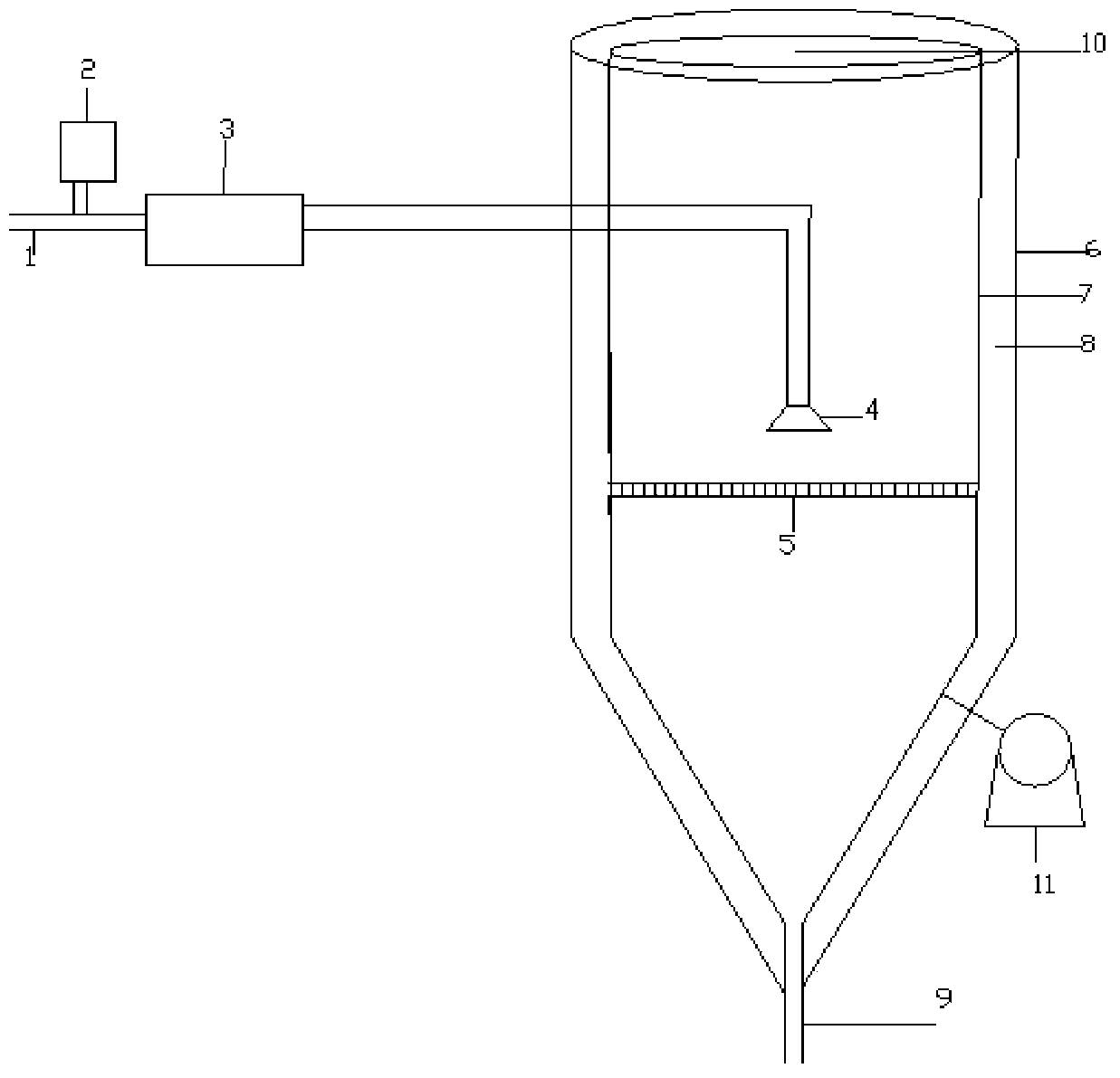

Device for treating high-concentration ammonia nitrogen in refinery wastewater by using surface activity catalyst

InactiveCN104229970AWill not cause secondary pollutionHigh removal rateWater contaminantsWater/sewage treatment by reductionHigh concentrationSURFACTANT BLEND

The invention relates to a device for treating high-concentration ammonia nitrogen in refinery wastewater by using a surface activity catalyst, belonging to the field of sewage treatment. The device is composed of a wastewater inlet (1), a surfactant inlet (2), a pipeline mixer (3), an injection pipe (4), a heavy metal catalyst network (5), a denitrification cylinder outer shell (6), a denitrification cylinder inner shell (7), a wastewater channel (8), a wastewater outlet (9), a diversion intake port (10) and a blast blower (11), wherein the surfactant inlet (2) is positioned above the pipeline mixer (3) and connected with the pipeline mixer (3); the wastewater inlet (1) is connected with the pipeline mixer (3); and the pipeline mixer (4) is positioned above the heavy metal catalyst network (5). The device is simple in technique and feasible in operation, can directly reduce the ammonia nitrogen in the refinery wastewater into nitrogen to be discharged, can not cause secondary pollution to the environment, and has the advantages of low cost and high ammonia nitrogen removal ratio. The ammonia nitrogen removal ratio in the high-concentration ammonia nitrogen wastewater treated by the device can reach 99.9% above.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com