Method for stable up-to-standard treatment and resource utilization of refinery wastewater

A technology for oil refinery sewage and resource treatment, which is applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problem of inability to meet the standards stably and the impossibility of reduction and reuse of oil refinery sewage , Refining drainage water can not meet the standard and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

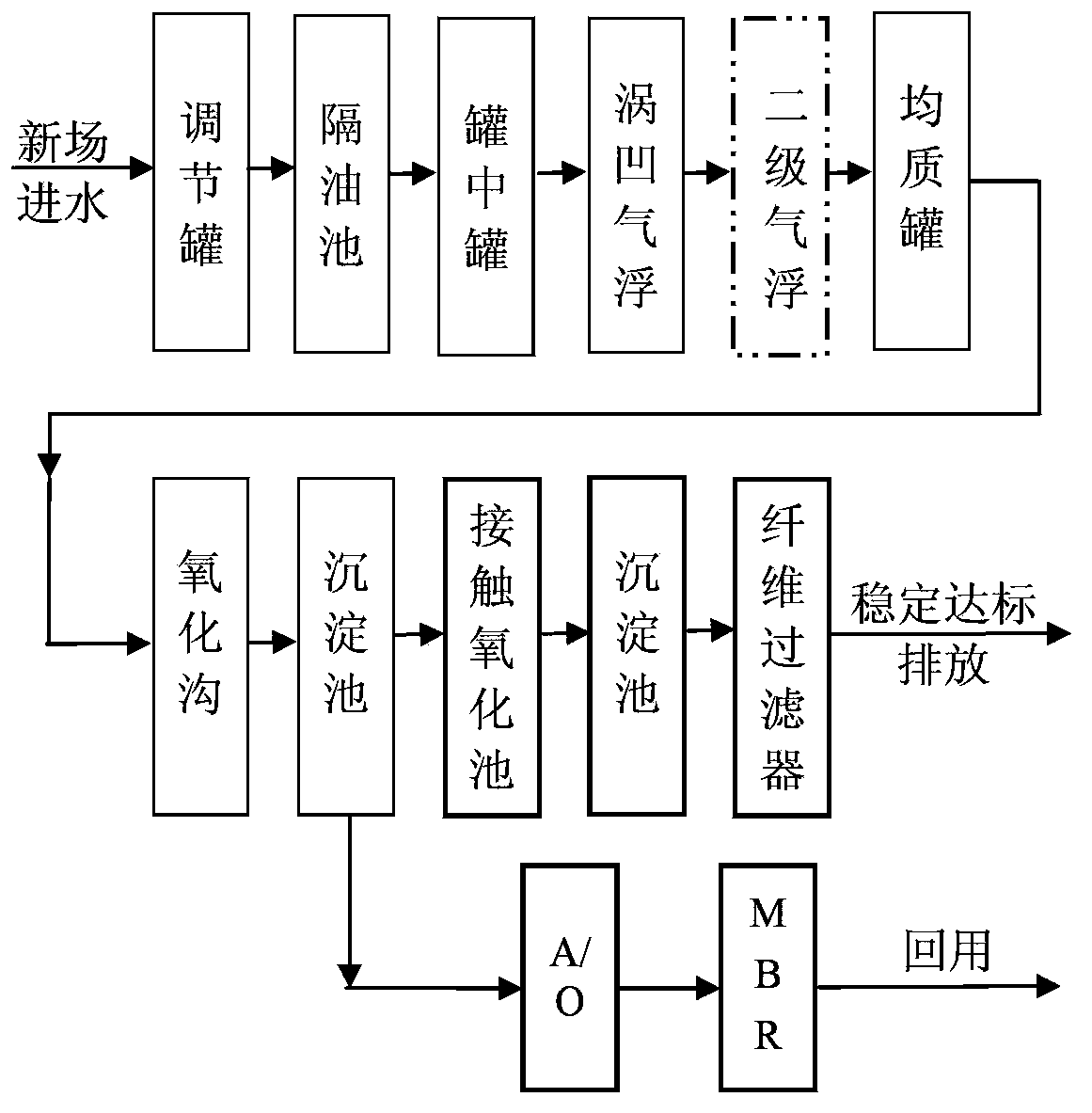

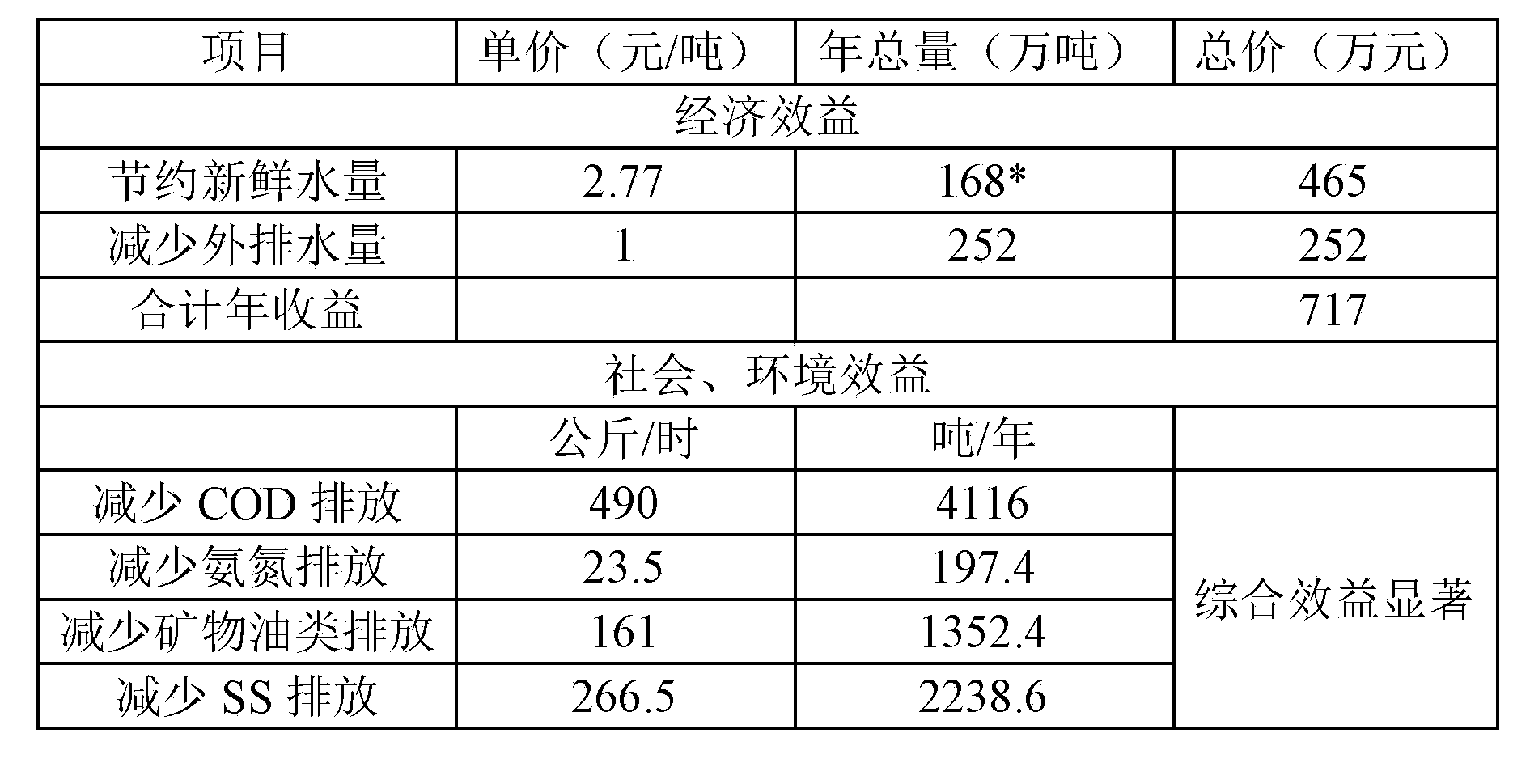

[0044] An oil refinery in the south adopts the above-mentioned technological process to discharge and reuse refinery wastewater. Refining sewage treatment and discharge process is: regulating tank + grease trap + tank in tank + vortex concave air flotation + secondary dissolved air flotation + homogeneous tank + ORBAL oxidation ditch + sedimentation tank + contact oxidation + sedimentation tank + fiber filtration Refining wastewater treatment and reuse process is: regulating tank + grease trap + tank in tank + vortex concave air flotation + secondary dissolved air flotation + homogeneous tank + ORBAL oxidation ditch + sedimentation tank + A / O + MBR; where " Regulating tank + grease trap + tank in tank + vortex concave air flotation + secondary dissolved air flotation + homogeneous tank + ORBAL oxidation ditch + sedimentation tank" is the process used by both, the flow chart is attached figure 1 .

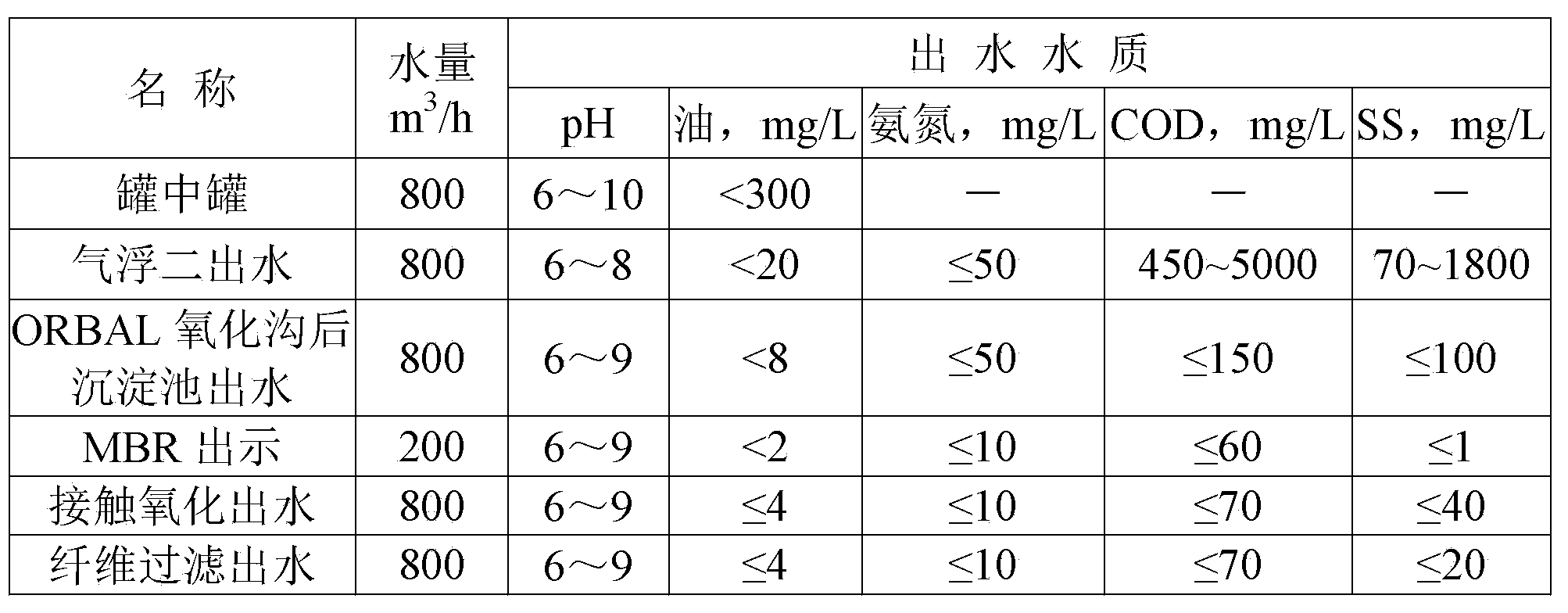

[0045] Among them, the refinery sewage treatment and discharge process, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com