Intelligent control system of industrial furnace

An intelligent control system and industrial furnace technology, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of lack of highly integrated control devices, and achieve long maintenance cycle, extended service life and high control precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this embodiment, the components of the conventional known structures are not described and shown in the figure.

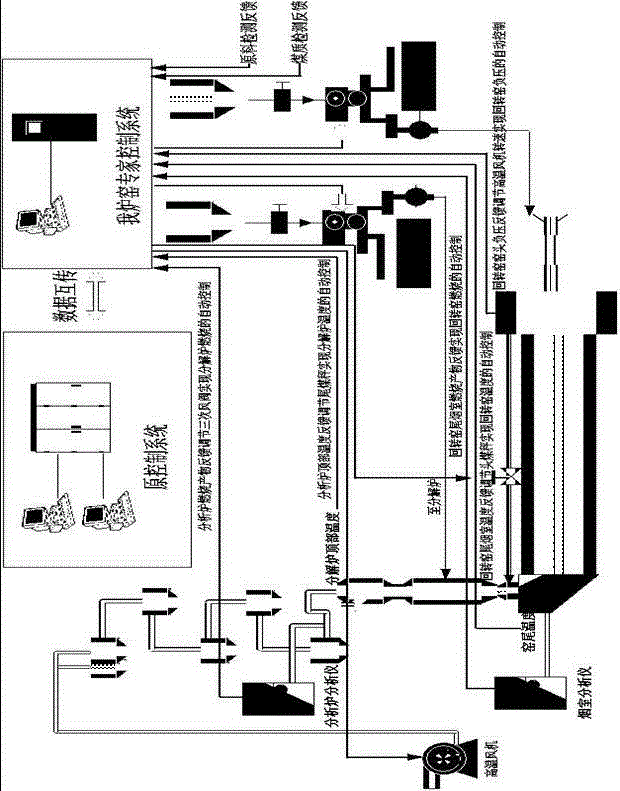

[0032] Such as figure 1 As shown, the industrial kiln intelligent control system disclosed in this embodiment, the industrial kiln intelligent control system, includes the main body of the cement kiln and the online flue gas analyzer of the analysis furnace connected to the main body, and the online flue gas analyzer of the rotary kiln smoke chamber. Analyzer, high-temperature fan, tertiary air valve, raw material detection analyzer, coal quality detection analyzer, kiln head scale and kiln tail scale, set cement kiln control system and industrial kiln intelligent control system to interact with the main body of the cement kiln connected, the control and sampling signals of the industrial kiln intelligent control system and the cement kiln control system are transmitted in a communication manner; the control signals and sampling signals of the industrial ...

Embodiment 2

[0038] The complete set of equipment for industrial furnace intelligent control system is divided into: rotary kiln combustion status sampling system, calciner combustion status sampling system, industrial furnace intelligent control system, host computer monitoring system, and remote monitoring system. Install an online flue gas analyzer at the outlet of the cement kiln calciner to measure the actual combustion state of the cement kiln calciner. The measurement signals are: oxygen content signal and carbon monoxide signal. Install an online flue gas analyzer in the tail smoke chamber of the cement kiln to measure the actual combustion state of the cement kiln rotary kiln. The measurement signals are: oxygen content signal and carbon monoxide signal. An industrial kiln intelligent control system (central control cabinet) is installed next to the cement kiln control system, and the control and sampling signals of the industrial kiln intelligent control system and the cement kiln...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com