Patents

Literature

127results about How to "Stable furnace condition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

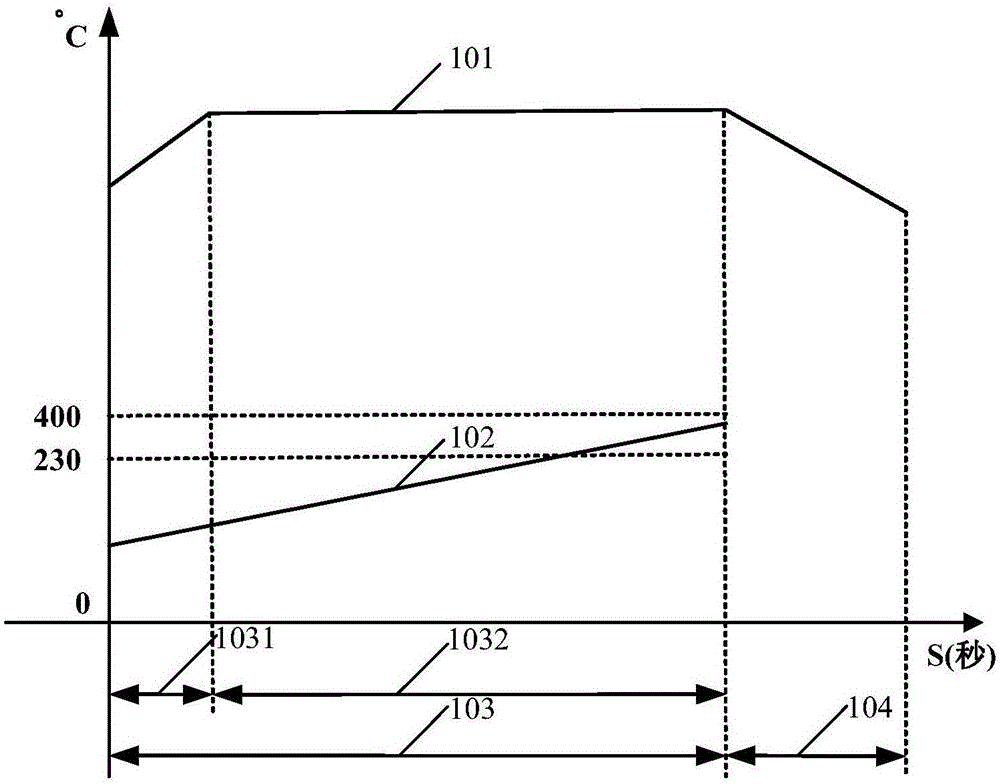

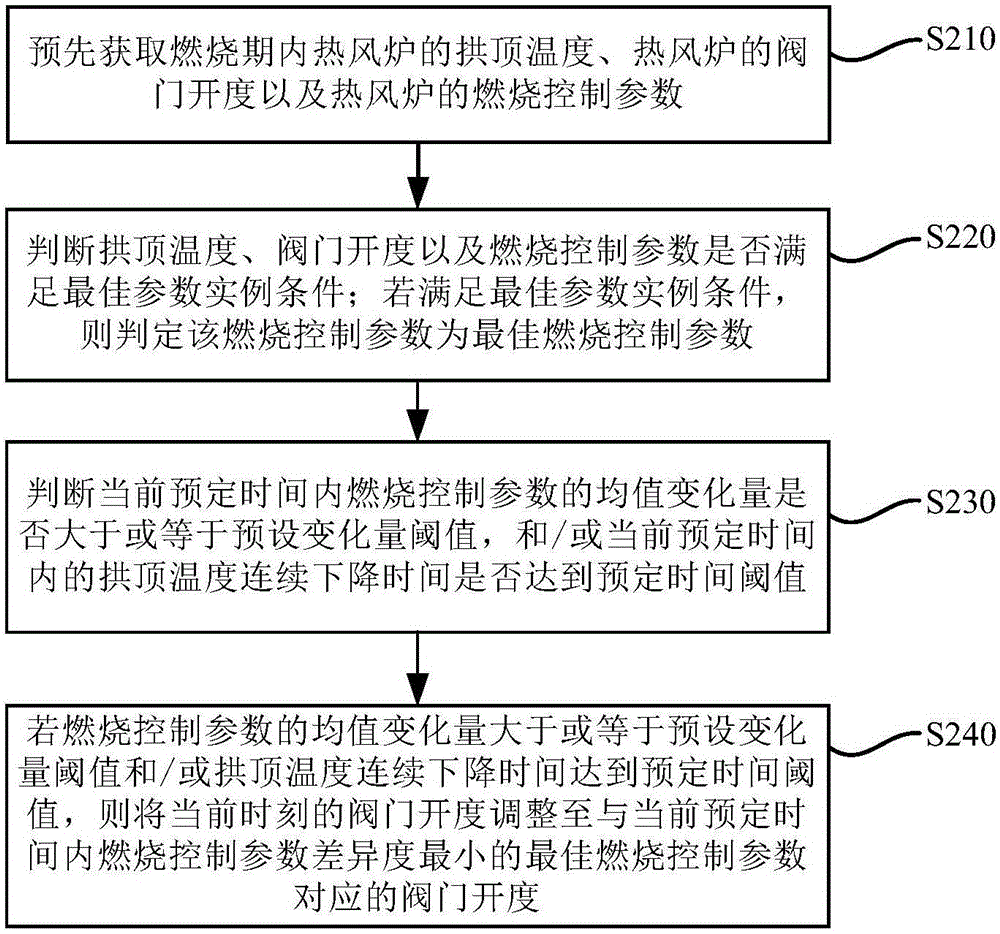

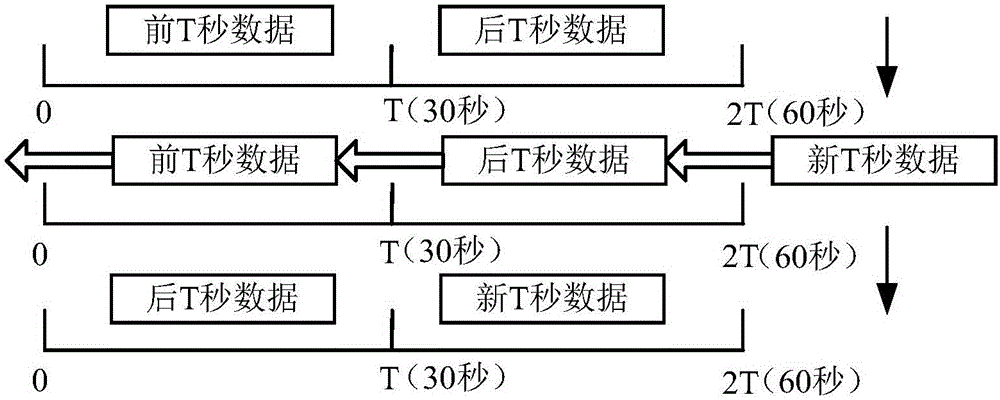

Combustion control method and system for hot blast heater

ActiveCN105157057AVault temperature stabilizationAdjust the air-fuel ratioFluid heatersCombustion regulationAir temperatureAir–fuel ratio

The embodiment of the invention discloses a combustion control method and system for a hot blast heater. The control method comprises the steps of obtaining the dome temperature, the valve openness and the combustion control parameters of a hot blast heater in a combusting period in advance; judging whether the dome temperature, the valve openness and the combustion control parameters meet the optimal parameter example conditions; judging the combustion control parameters are the optimal combustion control parameters if the optimal parameter example conditions are met; judging whether the mean value variation of the combustion control parameters in the current preset time is larger than or equal to a preset variation threshold value and / or whether the continuous descending time of the dome temperature in the current preset time reaches a preset time threshold value; and adjusting the valve openness to the valve openness corresponding to the optimal combustion control parameters with the minimum difference of the combustion control parameters in the current preset time if the mean value variation is larger than or equal to the preset variation threshold value and / or the continuous descending time reaches the preset time threshold value. According to the technical scheme, the air-fuel ratio of the hot blast heater can be accurately adjusted in time, fuel gas of the hot blast heater can be fully combusted, the dome temperature of the hot blast heater is stabilized, and the utilizing level of the blast furnace air temperature is improved.

Owner:ELECTRON CO LTD

Banking method for damping down of large blast furnace

InactiveCN103436646AImprove liquidityGood for opening the furnaceBlast furnace detailsProcess efficiency improvementSlagCoke

The invention relates to a banking method for damping down of a large blast furnace. The method comprises the follow steps: adding manganese ore into the blast furnace within 24-48 hours before damping down; within 5-8 hours before damping down, first, loading coke to the upper edge of the hearth, then, adding manganese ore, limestone and serpentine into the bosh and filling bosh by coke, and finally loading empty packing fully in batches to the bosh; loading normal packing and empty packing from the furnace stack to the furnace throat, and uniformly dividing the effective volume from the furnace stack to the furnace throat into a lower section, a middle section and an upper section so as to load, namely, the lower section: adding the normal packing and the empty packing in batches; the middle section: adding the normal packing and the empty packing in batches; and the upper section: fully adding the normal packing in batches; at 50-70 minutes before loading, thoroughly removing scrap iron in slag, and then, immediately damping down and banking. According to the method provided by the invention, the addition proportion of sinter is improved by adding silica and serpentine, so that not only is iron residue in the blow-on period good in mobility and is furnace practice stable, but also the time from blow-on to production capability is shortened to 3-5 days from original 15 days.

Owner:武汉钢铁有限公司

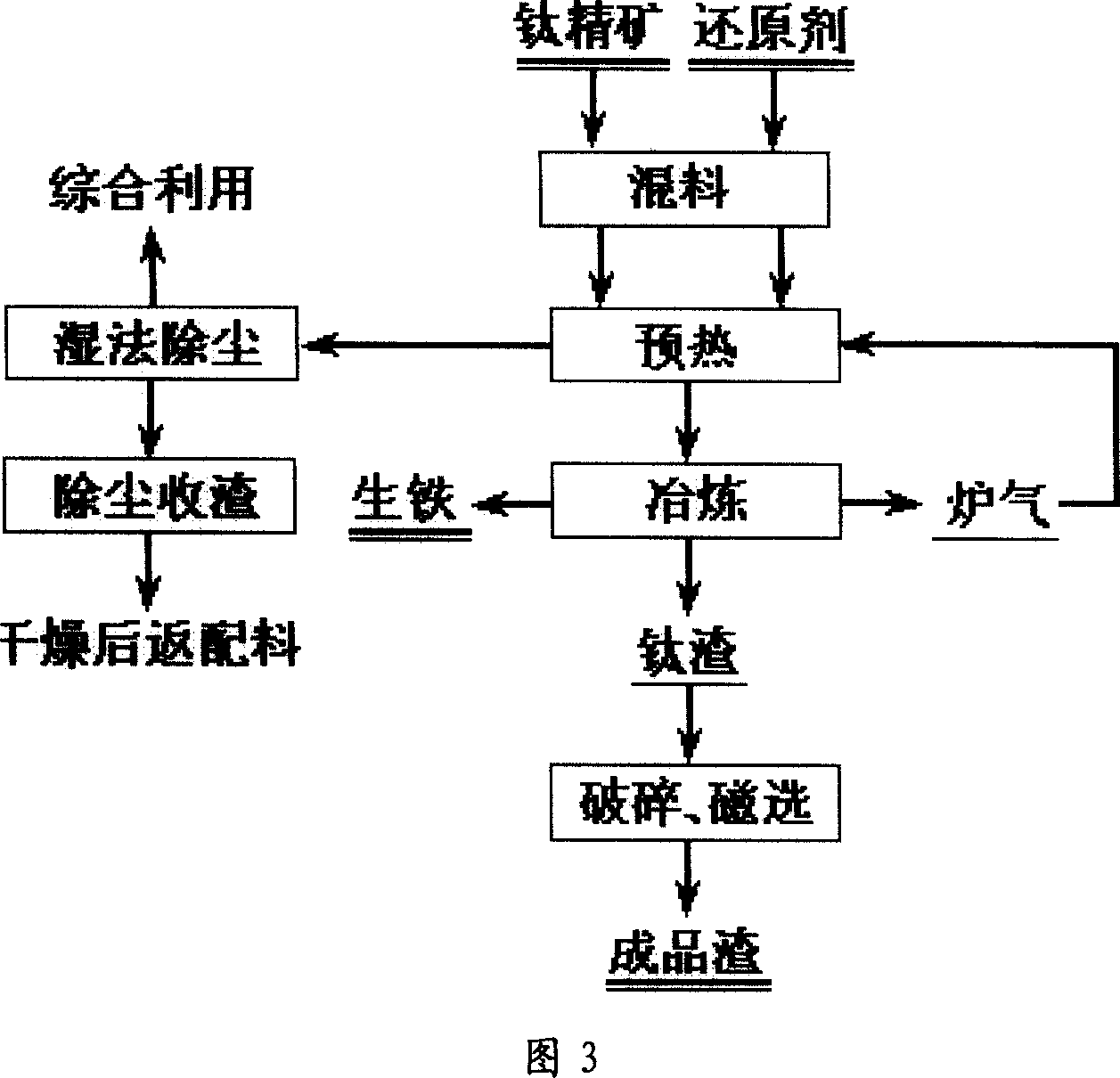

Method for reducing and smelting titania slag by utilizing vanadium-titanium-iron ore concentrates in molten state

The invention provides a method for reducing and smelting titania slag by utilizing vanadium-titanium-iron ore concentrates in a molten state. The method comprises the following steps: mixing the vanadium-titanium-iron ore concentrates with titanium ore concentrates and adding a carbonaceous reducing agent and a binder, thus forming a mixture; reducing the mixture and then performing slag-iron separation treatment, thus obtaining semisteel and titanium slag; and spraying water to the surface of the titanium slag obtained through slag-iron separation treatment so as to rapidly cool the titanium slag to 600-850 DEG C in a cooling process, thus forming the acidsoluble titania slag. The method provided by the invention can be used for efficiently utilizing the Fe and TiO2 in the vanadium-titanium-iron ore concentrates and has the advantages of stable molten-state reduction process, good effect in smelting and separating process, stable furnace condition, short smelting period, low power consumption level, low production cost and the like.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

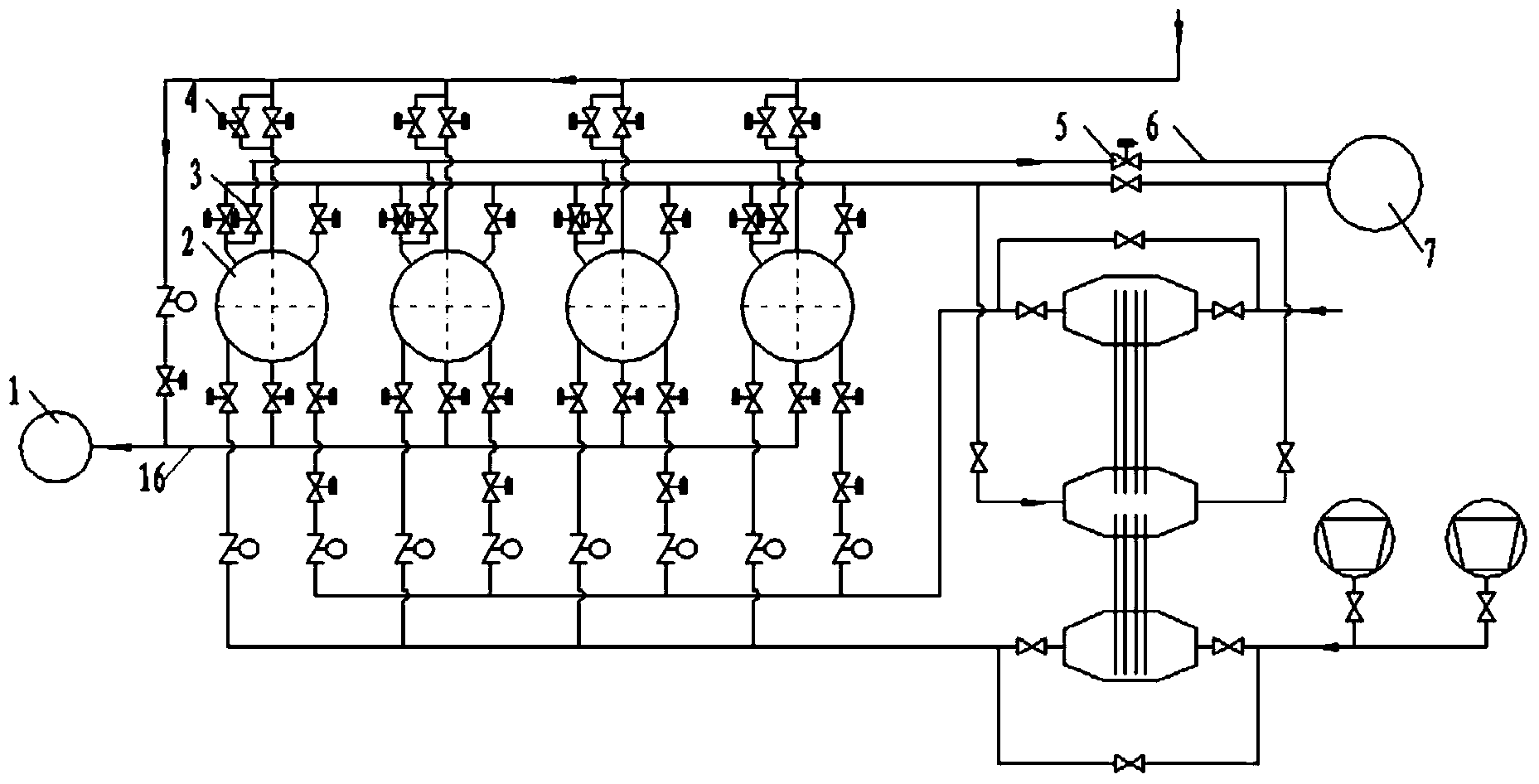

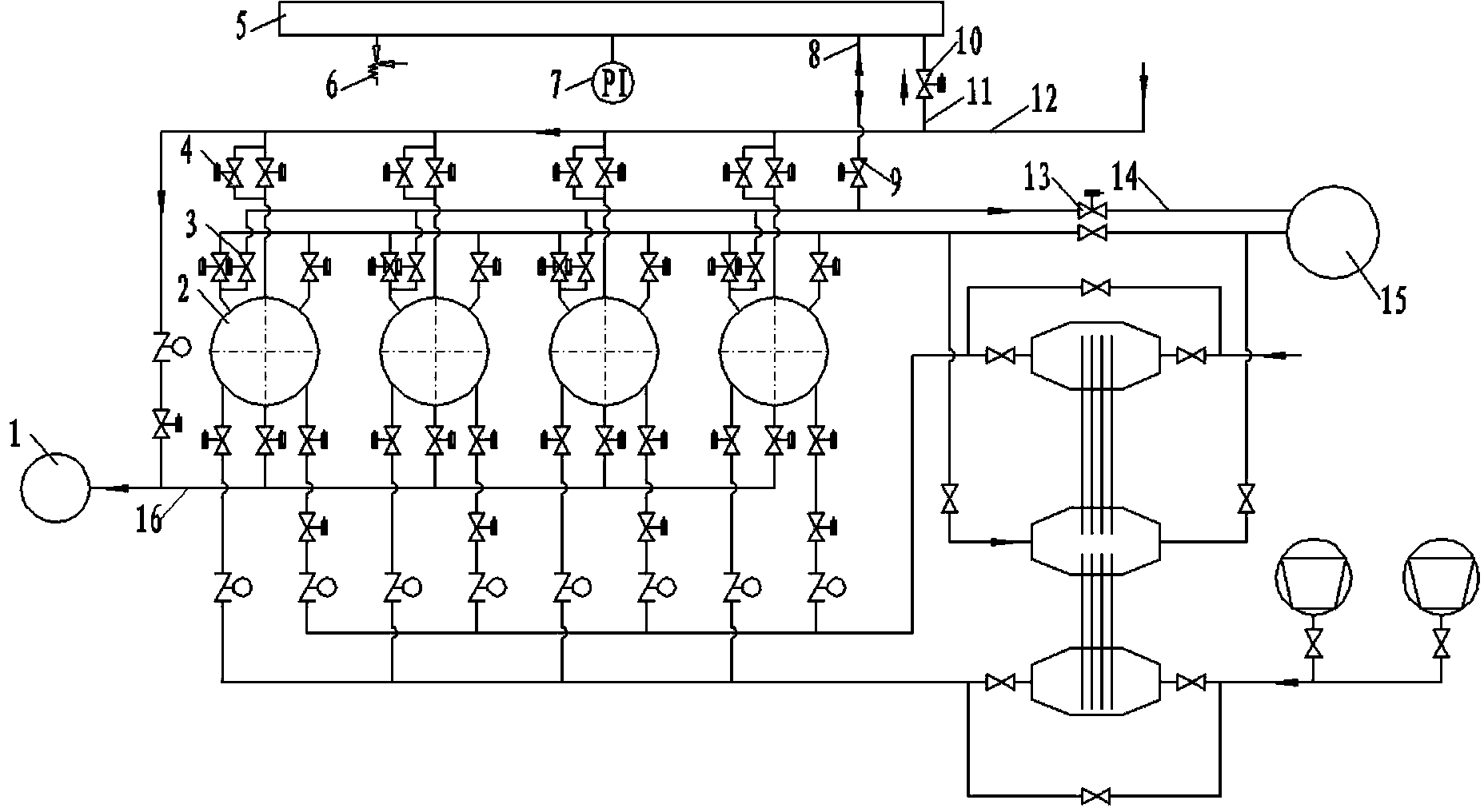

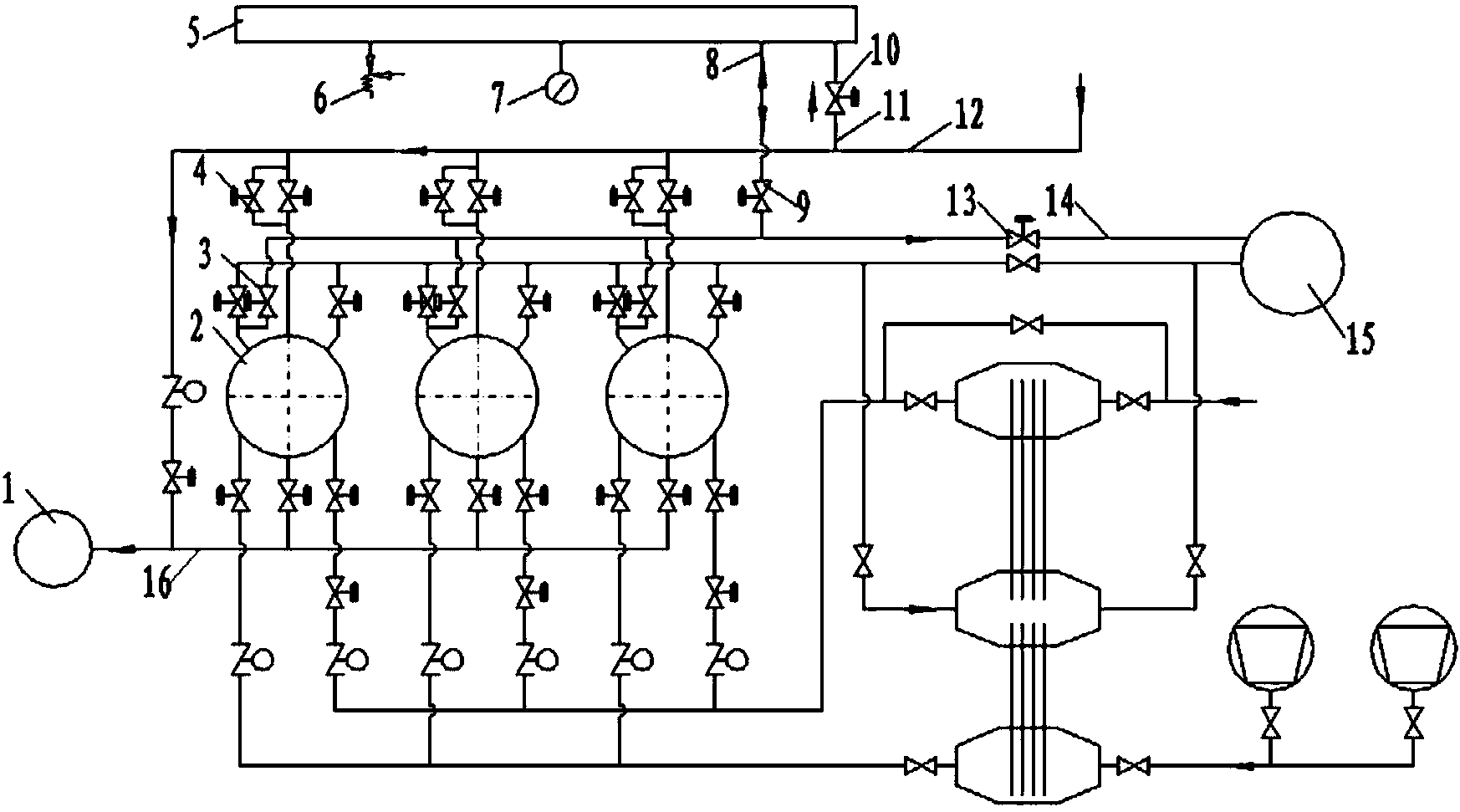

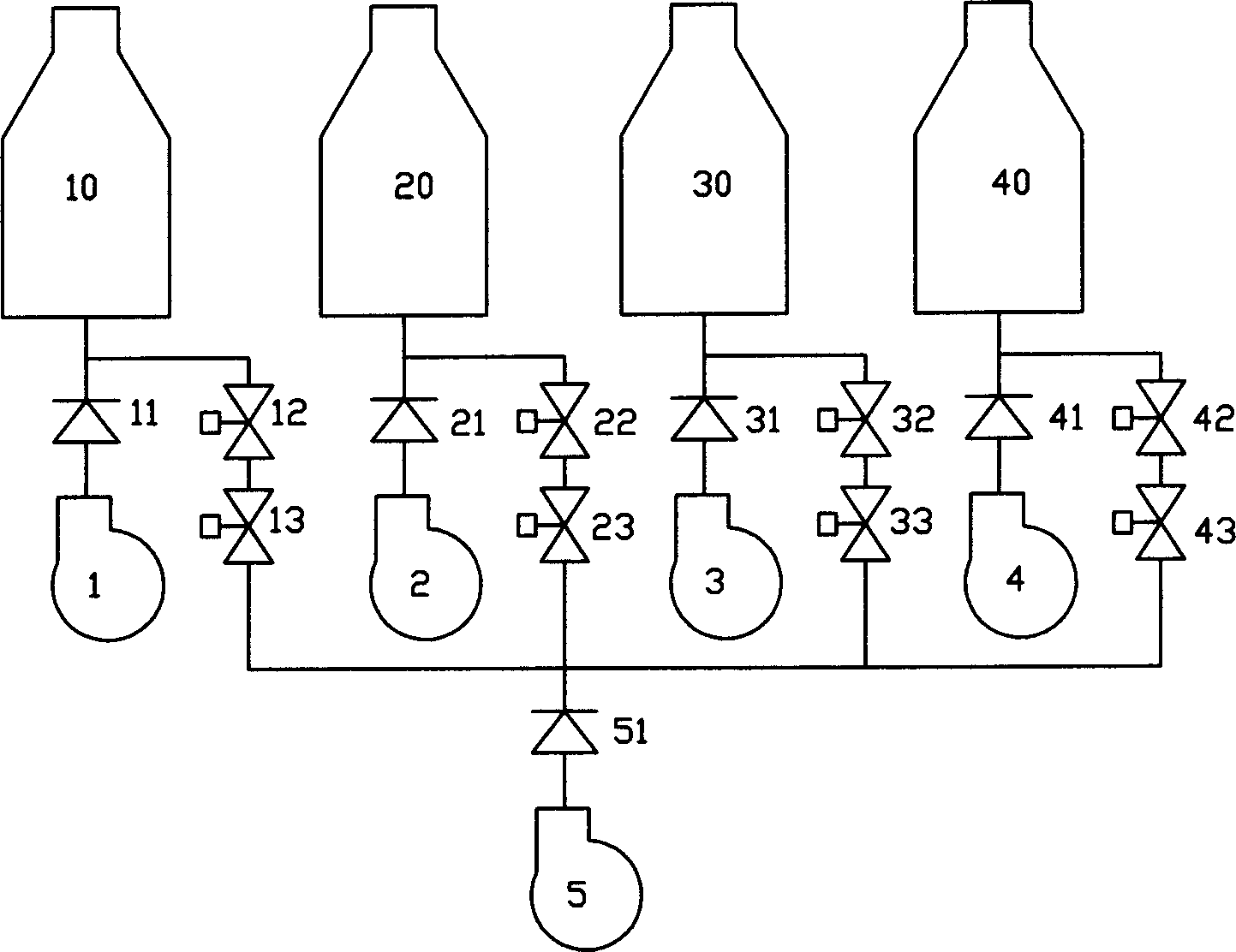

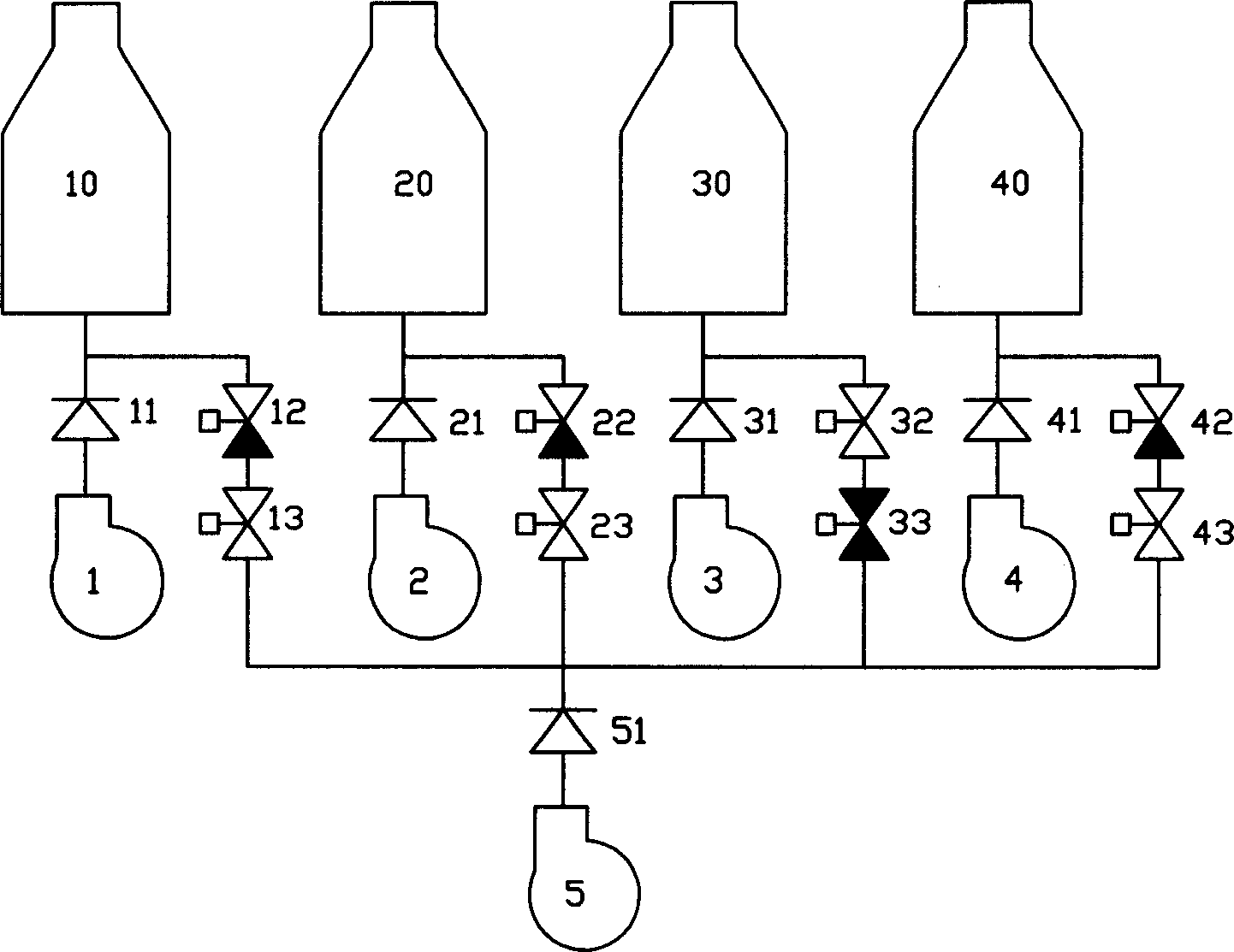

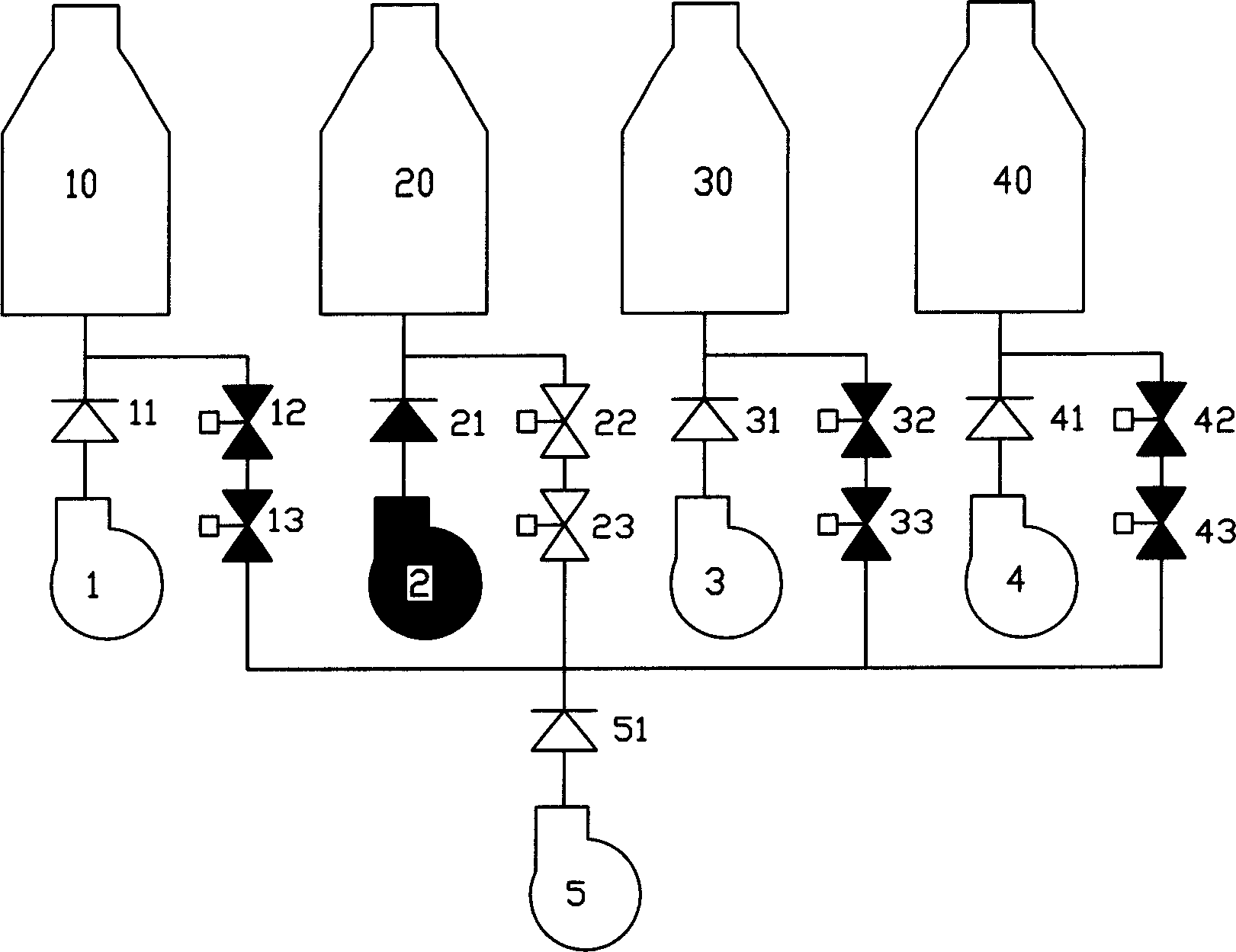

Waste air recycling device of hot blast stove with waste air buffer tank

ActiveCN103966379AStable and reliable recycling operationAchieve the effect of saving energy and reducing consumptionBlast furnace detailsHeating stovesCold airBuffer tank

The invention discloses a waste air recycling device of a hot blast stove with a waste air buffer tank, and belongs to the technical field of the hot blast stove in the metallurgical industry. The waste air recycling device comprises a blast furnace, a hot blast stove, a waste air valve, a cold air pressure-equalizing valve, a waste air buffer tank, a safety valve, a pressure meter, a waste air communicating tube, a waste air communicating tube control valve, a cold air pressure-equalizing slow charging valve, a slow pressure-equalizing communicating tube, a cold air pipeline, a waste air header tube control valve, a waste air header tube, a hot blast stove chimney and a hot air pipeline, wherein a blast furnace air blower is connected with the hot blast stove (2) by a cold air pipeline (12); the hot blast stove (2) and the blast furnace (1) are connected by the hot air pipeline (16); the cold air pressure-equalizing valve (4) is arranged on a pressure-equalizing pipeline of each hot blast stove; the waste air valve (3) is arranged on the waste air pipeline of each hot blast stove; the waste air buffer tank (5) is arranged near the hot blast stove; the waste air communicating tube (8) is arranged for connecting the waste air header tube (14) with the waste air buffer tank (5). The waste air recycling device disclosed by the invention has the advantages that furnace condition fluctuation, which is brought by pressure-equalizing operation of the hot blast stove, of the blast furnace can be relieved; and requirements of the blast furnace air blower on air charging capacity are further lowered due to buffer effect.

Owner:BEIJING SHOUGANG INT ENG TECH

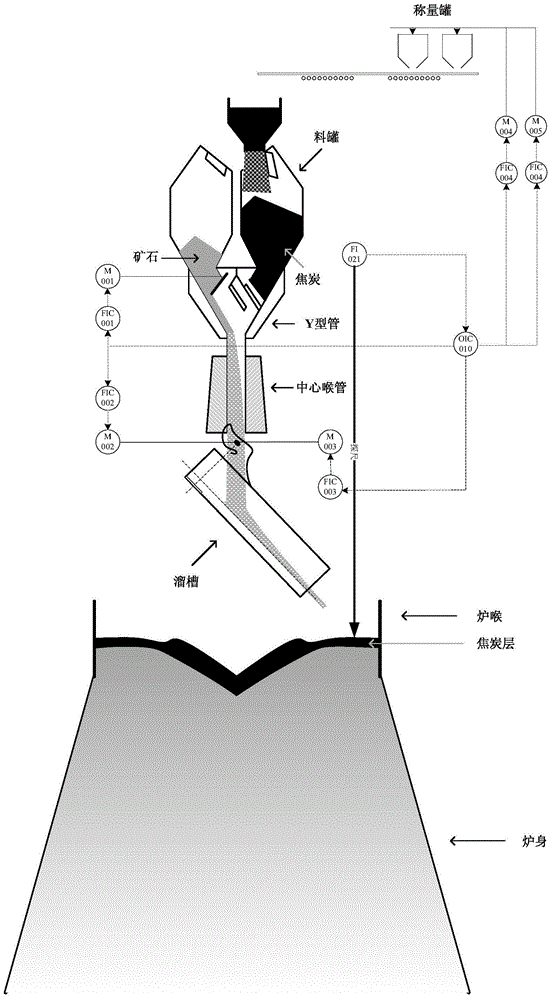

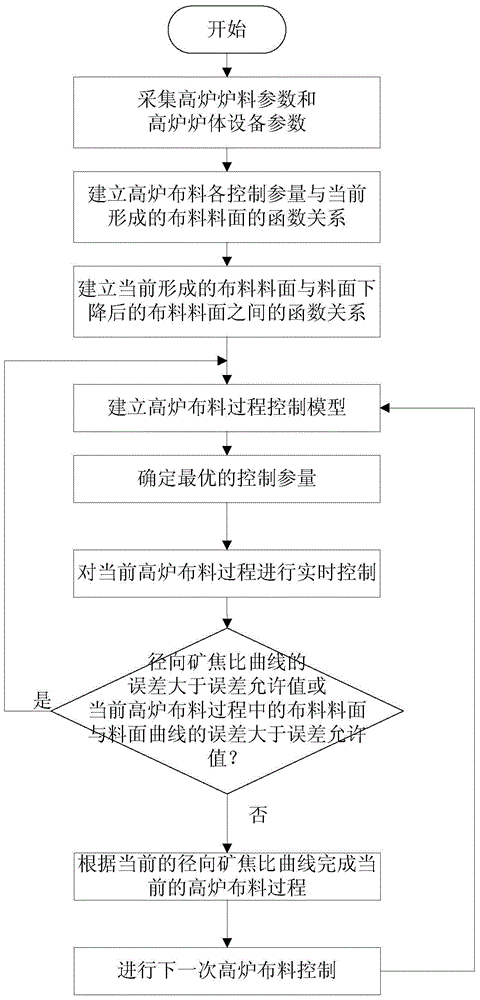

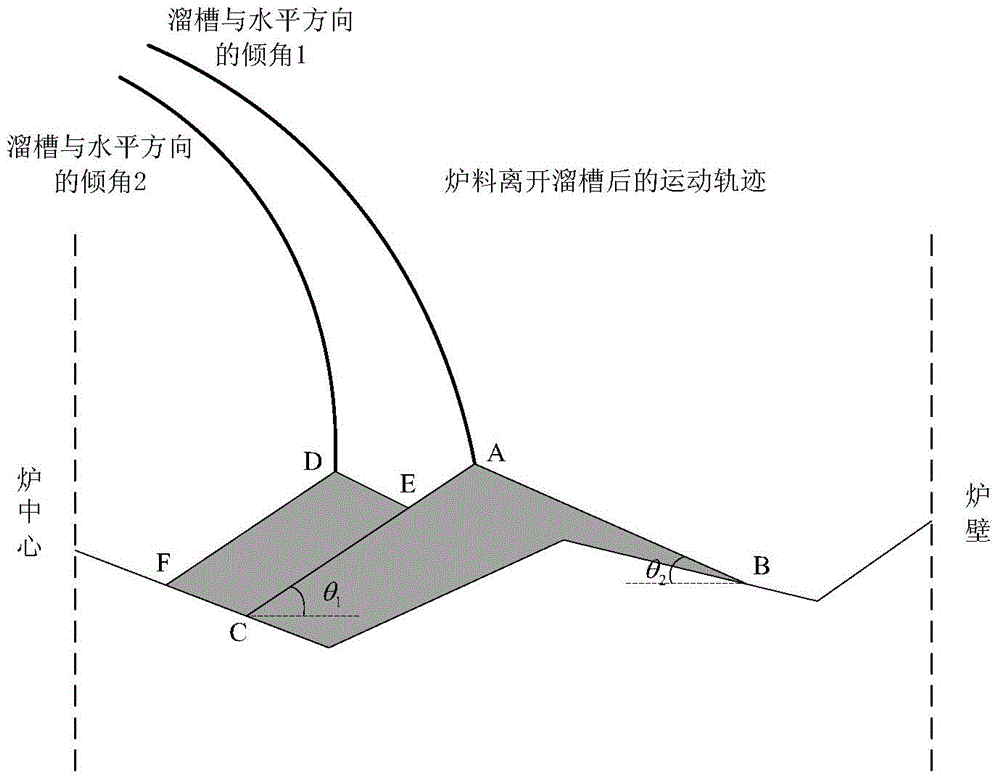

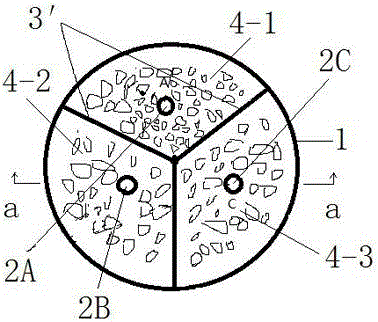

Method for controlling radial ore to coke ratio in blast furnace burden distribution process

ActiveCN104133945AIncrease productionStable furnace conditionSpecial data processing applicationsDistribution matrixTime control

The invention provides a method for controlling the radial ore to coke ratio in a blast furnace burden distribution process. The method comprises the following steps that: a blast furnace burden parameter and a blast furnace body equipment parameter are collected; the function relationship between each control parameter in the blast furnace burden distribution process and the current formed burden distribution burden level is built; the function relationship between the current formed burden distribution burden level and the burden distribution burden level after the burden level reduction is built; a blast furnace burden distribution process control model is built and is used for describing the relationship between a blast furnace burden distribution radial ore to coke ratio curve and each control parameter; the optimum control parameter is determined by using the blast furnace burden distribution process control model, and the current blast furnace burden distribution process is controlled in real time; and when the error of the radial ore to coke ratio curve in the real-time control process of the current blast furnace burden distribution process is greater than an error allowable value, the blast furnace burden distribution process control model is rebuilt, and otherwise, the current blast furnace burden distribution process is completed according to the current ore to coke ratio curve. The method provided by the invention has the advantages that the real-time burden level shape can be provided, so that operators can be effectively guided for improving a charging system, modifying a burden distribution matrix and regulating the furnace burden distribution.

Owner:NORTHEASTERN UNIV

Batching method for banking up large-scale blast furnace

A batching method for banking up a large-scale blast furnace comprises the following steps: adding manganese ore within 72 hours before damping-down and banking-up of the blast furnace; charging materials layer by layer within 6-8 hours before damping-down, wherein a hearth, a bosh and all parts above a furnace stack are full of the materials respectively at the time of damping-down; opening a tap hole 65-70 minutes before all the damping-down and banking-up materials are charged, discharging all iron slag so that the whole furnace is filled with the banking-up materials, and performing damping-down and banking-up. According to the method, under the premise of guaranteeing the total coke ratio, the slag-coke ratio, the furnace slag alkalinity, the furnace slag Al2O3 and MgO content and the like of blow-in burden, the Al2O3 weight concentration in furnace slag is controlled below 14.5, the reducibility is good, powder in materials entering the furnace is reduced, the air permeability is improved, and the furnace condition is stable, so that blowing-in after damping-down is facilitated.

Owner:武汉钢铁有限公司

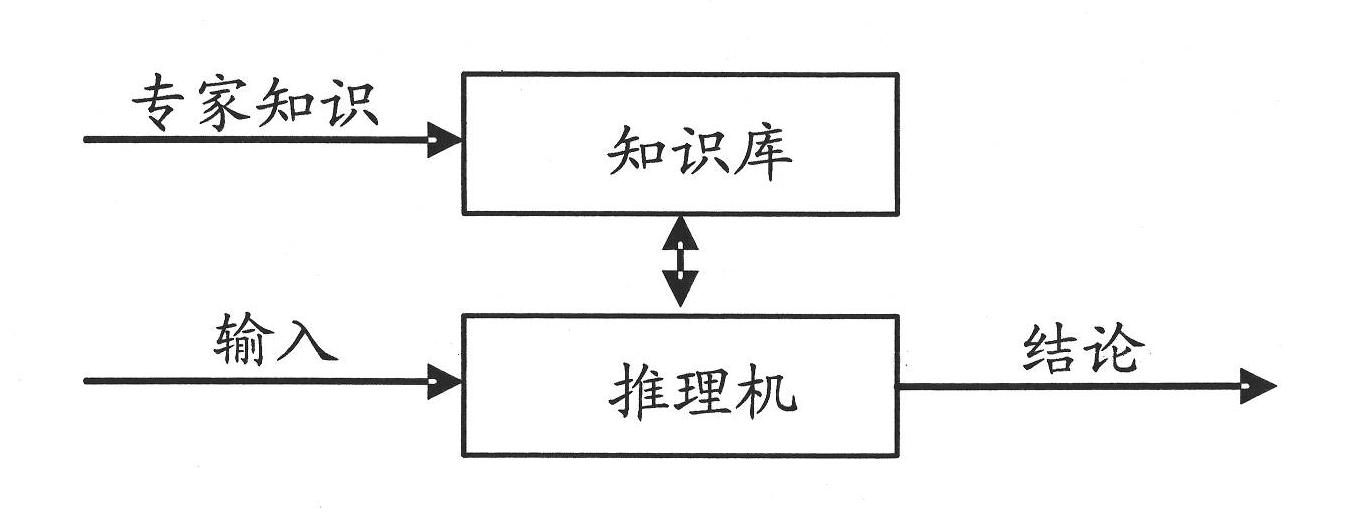

Intelligent control system of industrial furnace

InactiveCN104819650AAutomatic temperature controlHigh control precisionControl devices for furnacesCoalIntelligent control system

The invention discloses an intelligent control system of an industrial furnace. The intelligent control system comprises a cement furnace body, and a decomposition furnace online smoke analyzer, a rotary kiln smoke chamber online smoke analyzer, a high-temperature fan, a tertiary air valve, a raw material detecting analyzer, a coal quality detecting analyzer, a kiln head coal scale and a kiln tail coal scale connected with the body; the intelligent control system of the industrial furnace is characterized by being connected with the cement furnace body, transmits control and sampling signals of a traditional cement furnace control system in a communication manner, and sends the control and sampling signals to the traditional cement furnace control system; and the traditional cement furnace control system sends signals needed by the intelligent control system of the industrial furnace to the intelligent control system of the industrial furnace.

Owner:CHONGQING HUACHENG YUANZHI ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

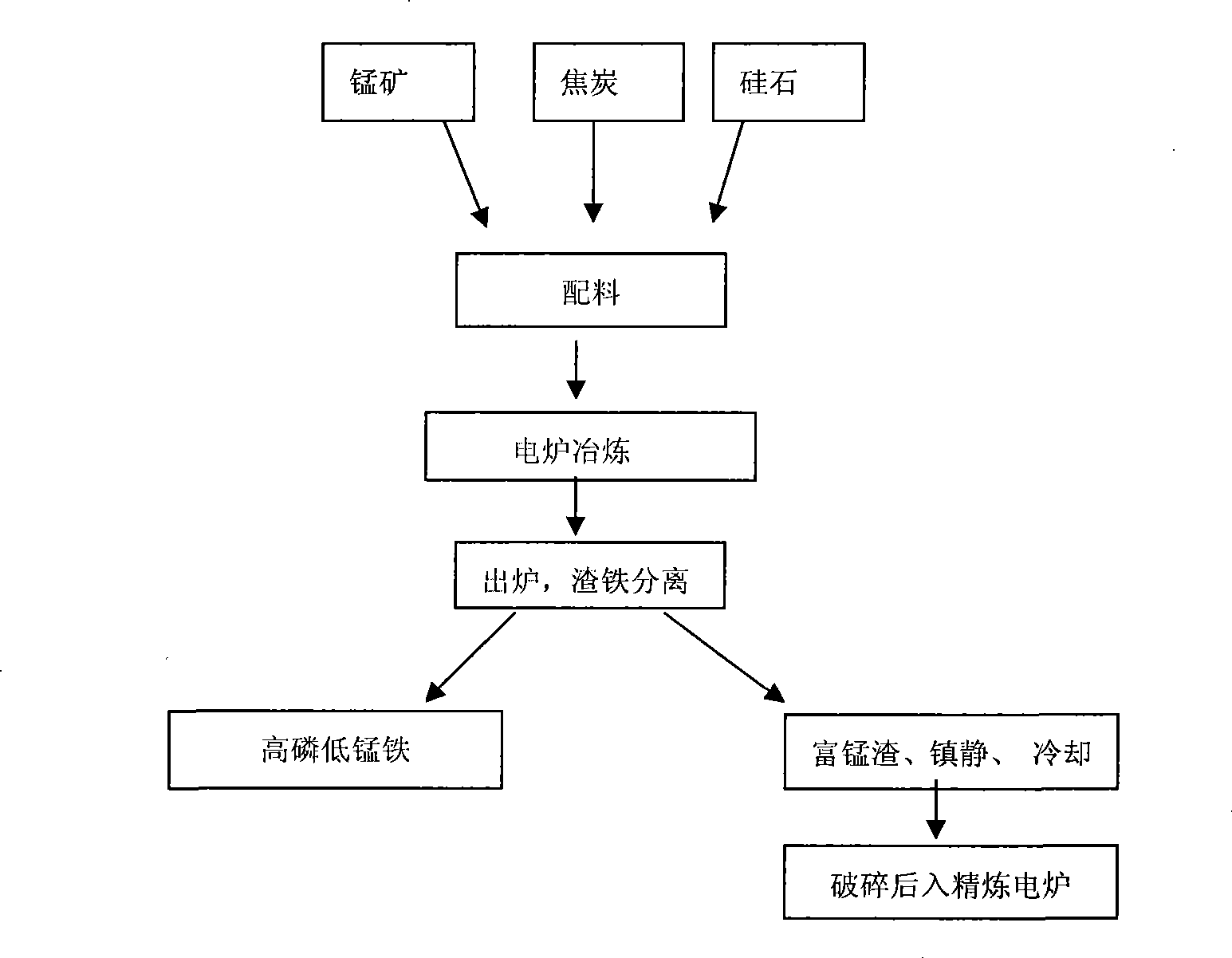

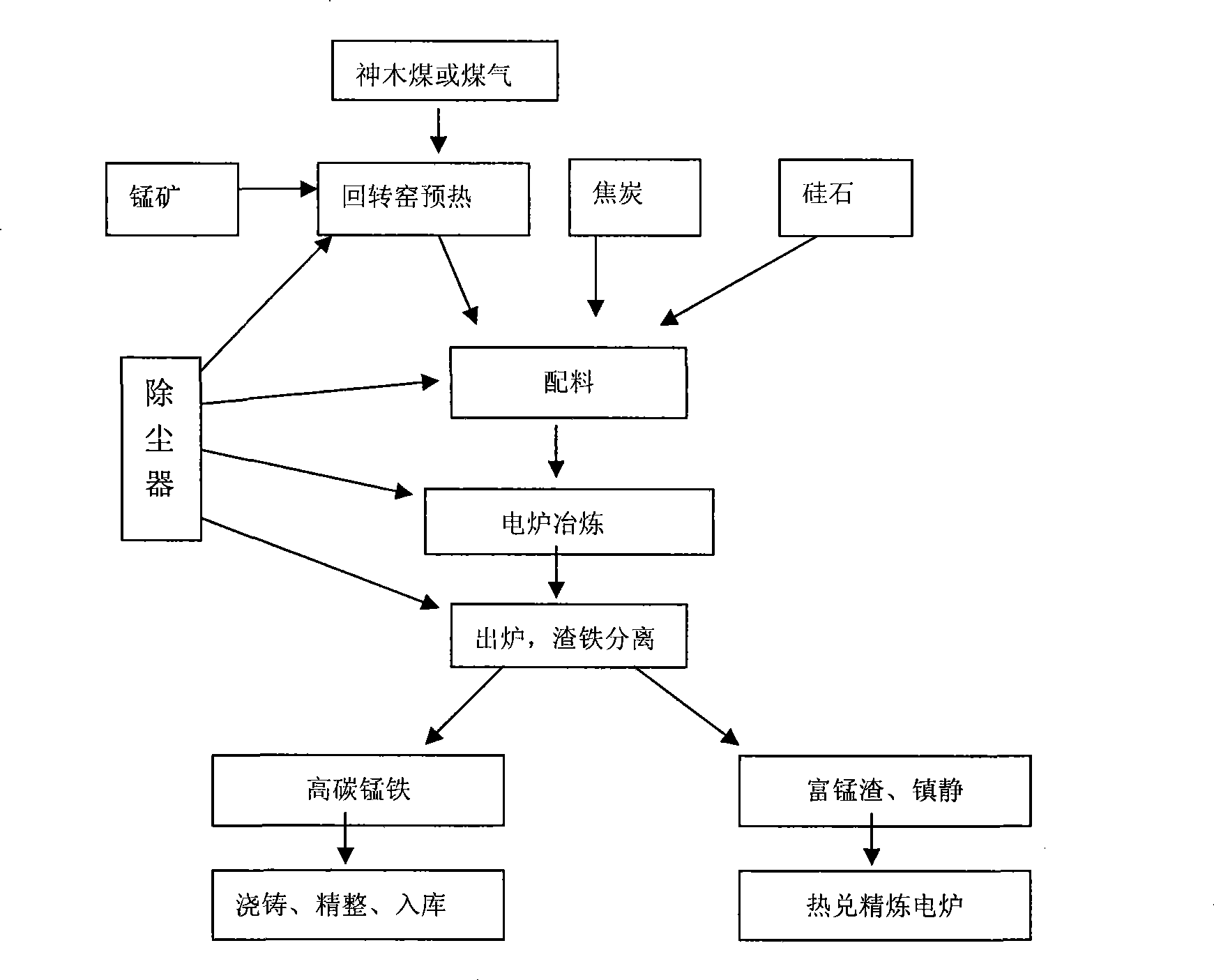

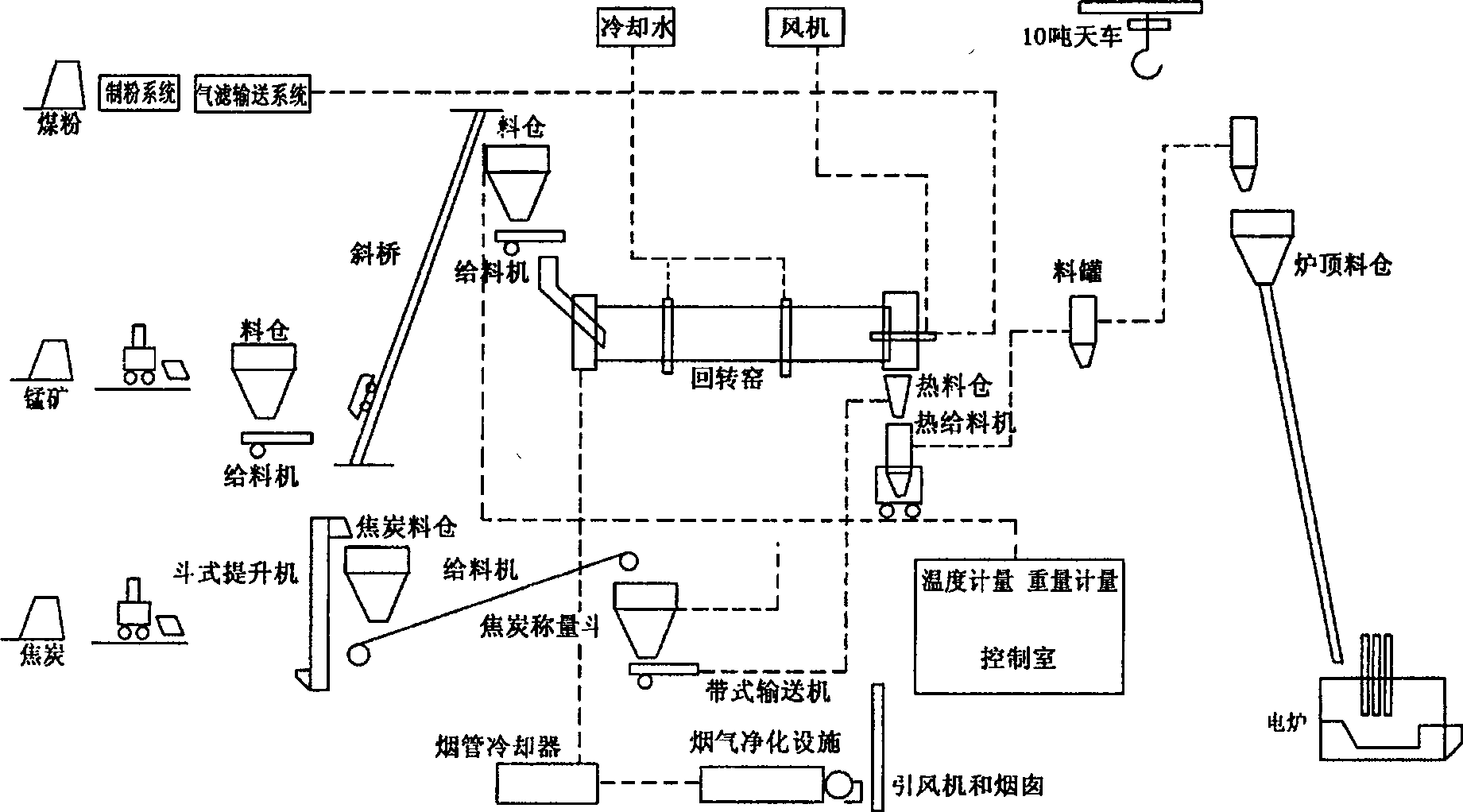

Electric furnace smelting process for manganese-rich slag

ActiveCN101481757AReduce smelting power consumptionReduce consumptionTemperature controlSmelting process

The invention belongs to the process for smelting manganese-rich slag, and particularly relates to the process for smelting the manganese-rich slag using an electric furnace. The invention, which solves the problems that the process for smelting the manganese-rich slag is energy-intensive, operationally dangerous and consumptive, is characterized in that manganese ore is pre-heated by a rotary kiln, wherein, the temperature, at which the manganese ore is pre-heated in the rotary kiln, is controlled within 900 to 1,100 DEG C; and the charging temperature of the manganese ore to be pre-heated is controlled above 600 DEG C. Compared with the prior art, the invention has the following beneficial effects: the power consumption for smelting is remarkably reduced; the production capacity of the electric furnace is expanded; the operating rate thereof is increased; the working condition is improved; and the labor productivity and the labor safety are improved.

Owner:JIAOCHENG YIWANG FERROALLOY

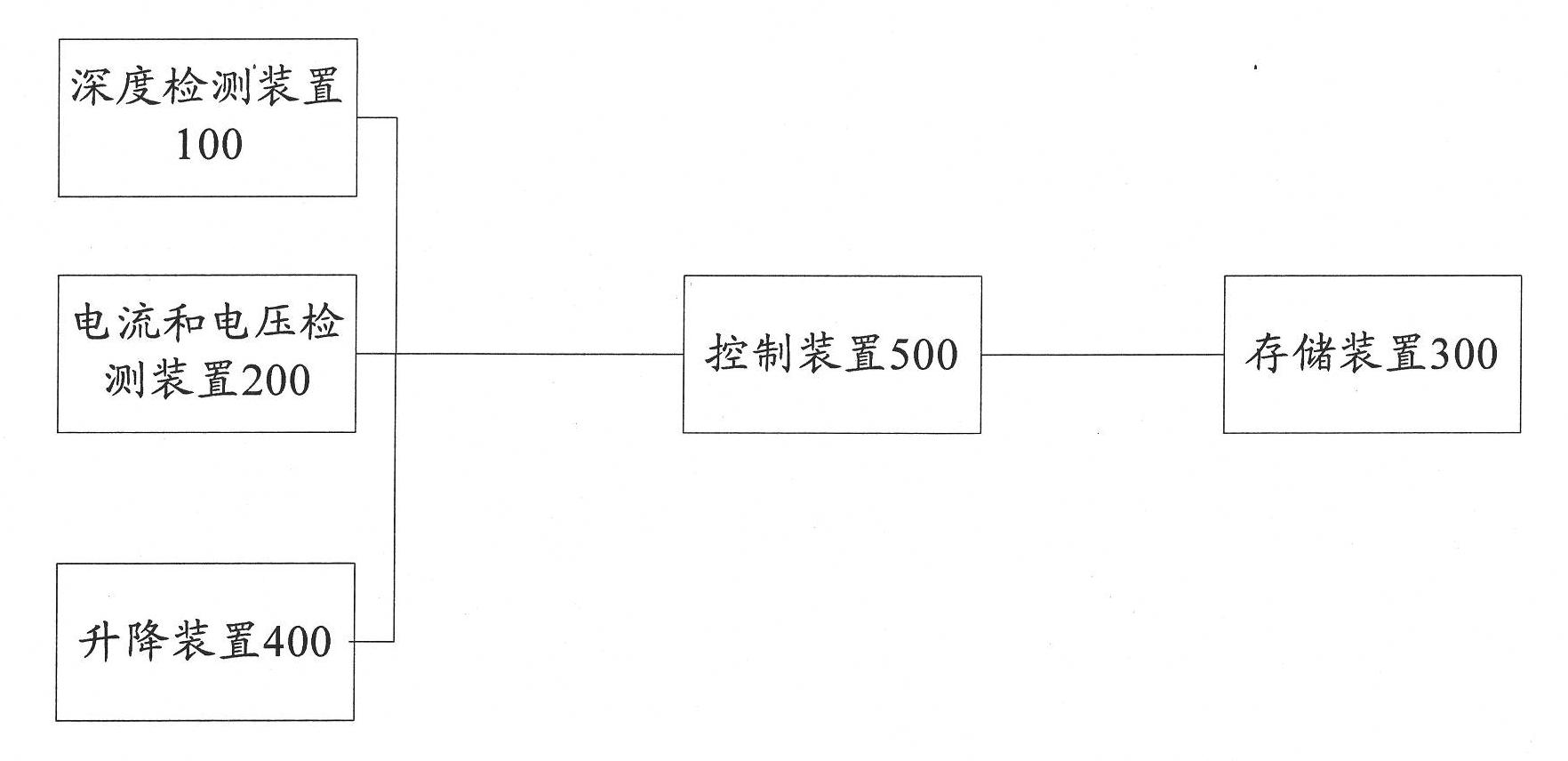

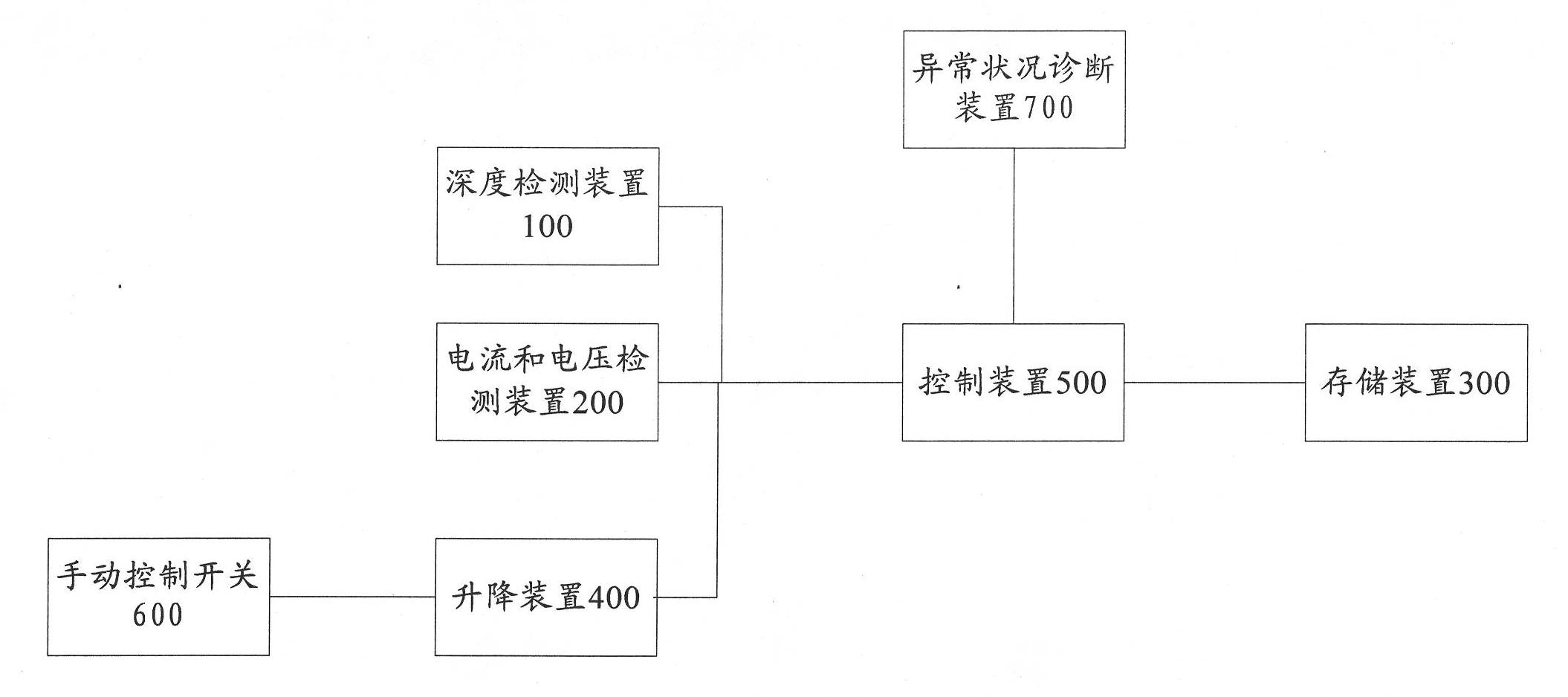

Automatic power control system of electric furnace

ActiveCN101968319ASolve complex modeling and difficult to control problemsReduce shockControl devices for furnacesElectrical resistance and conductanceElectric arc furnace

The invention provides an automatic power control system of an electric furnace, comprising a depth detection device, a current and voltage detection device, a storage device, an elevating device, and a control device, wherein the storage device is used for storing a preset expert reasoning table and a resistance set value, the elevating device is used for controlling insertion depth of three electrodes into the electric furnace, and the controlling device is used for calculating the current resistance valve of each electrode according to the current value and the current voltage value of each electrode, searching the preset expert reasoning table according to the current resistance value of each electrode and the resistance set value so as to confirm the adjustment range values of the three electrodes, and controlling the elevating device to adjust the insertion depths of the three electrodes into the electric furnace according to the current depth values and the adjustment range values of the three electrodes. Aiming at the characteristics of nonlinearity, time invariance and multivariable coupling of an electric furnace controlled object, the invention effectively solves the problems of complicated modeling and difficult control of the electric furnace object through integrating excellent field operation experience into algorithms via the design to an expert rule and a reasoning mechanism.

Owner:CHINA ENFI ENGINEERING CORPORATION

Blast furnace coal injection accelerant as well as preparation method and application thereof

The invention claims a blast furnace coal injection accelerant as well as a preparation method and application thereof. The blast furnace coal injection accelerant is composed of 0-100wt% of roasting siderite, 0-100wt% of light burned dolomite and 0-100wt% of fly ash, and the weight percentage of the above compositions totals 100%. The preparation method comprises pretreatment and preparation steps, and comprises the following specific steps: preparing the material based on the formula of the accelerant, weighing the pulverized roasting siderite, light burned dolomite and the fly ash based on the formula proportions, and mixing and stirring the compound uniformly to obtain the target accelerant. The application of the blast furnace coal injection accelerant is as follows: applying the blast furnace coal injection accelerant to the blast furnace anthracite or mixed pulverized coal injection. According to the preparation method, the invention adopts calcium-based, magnesium-based, ferrum-based and partial modified substances are adopted as the main components of the accelerant, so that the accelerant has the advantages of easily available material, low cost and effects of well reducing the coke ratio, stabilizing furnace conditions and increasing the yield; according to the method, the partial industrial wastes are used as the raw materials, so that the method has the functions of protecting the environment and recycling resources.

Owner:WUKUN STEEL

Method for utilizing vanadium-titanium-secondary iron concentrate to smelt acid-soluble titanium slag by way of smelting reduction

ActiveCN102417944AOptimize charge structureReduce the temperature of the smelting reduction processFluidised-bed furnacesSemi-steelSeparation process

The invention provides a method for utilizing vanadium-titanium-secondary iron concentrate to smelt acid-soluble titanium slag by way of smelting reduction. The method includes the following steps: the vanadium-titanium-secondary iron concentrate and titanium concentrate are mixed and added with carbonaceous reducing agent and binder to form mixture; the mixture is reduced, and slag-iron separation is then carried out in order to obtain semisteel and titanium slag; water is sprayed on the surface of the titanium slag obtained in slag-iron separation, so that the temperature of the titanium slag can rapidly cross a temperature range between 600 DEG C and 850 DEG C in the process of cooling, and thereby the acid-soluble titanium slag is formed. The method can efficiently utilize Fe and TiO2 in the vanadium-titanium-secondary iron concentrate, and has the advantages of smooth reaction in the smelting reduction process, good effect in the smelting and separation processes, stable furnace state, short smelting period, low electricity consumption level, low product cost and the like.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

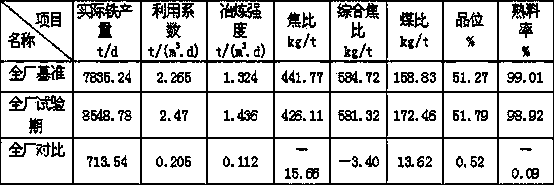

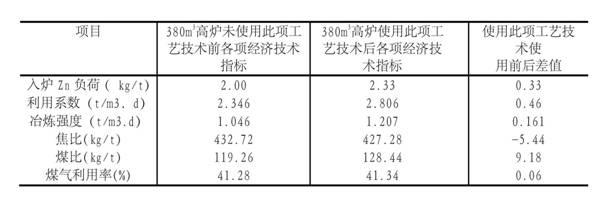

Method for distributing raw materials with high zinc content in blast furnace with bell-less top

InactiveCN102010922APrevent escapeAvoid cloggingBlast furnace componentsBlast furnace detailsThroatMaterial distribution

The invention discloses a method for distributing raw materials with high zinc content in a blast furnace with a bell-less top, which comprises the following steps of: (1) controlling ore batch weight to be greater than a critical value, and ensuring that the average thickness of ore at the furnace throat is 8 to 10 percent of the diameter of the furnace throat; (2) adopting a material distribution mode from a small angle to a large angle increasingly at distributor chutes on the furnace top, and ensuring that small particle burden and powder caused by mass flow particle segregation are distributed from the center of the blast furnace to a part 1 / 3 away from the edge of the furnace wall when a material tank discharges materials; (3) selecting double-ring single pile top large-angle distribution for ore and coke gears, distributing outer-ring ore according to the maximum angle, ensuring that the ore and coke angular difference is -2 degrees and the angular difference of the inner and outer rings of the ore and the coke is 6 degrees, controlling the materials distributed in the inner ring to account for 50 to 60 percent of the total burden, making the ring number of the outer ring distribution at least two, and ensuring that the outer-ring distribution pipe top covers the inner-ring distribution pipe top; (4) adopting a positive packaging and ore-coke unequal line packaging method; and (5) regularly performing tank turning operation on tank-combined blast furnace with the bell-less top, and controlling 4 to 5 tank turning cycle periods in a material column.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Slag-back prevention and parallel aeration process for blast furnace

InactiveCN1837377AIncrease air volumeImprove utilization factorBlast furnace detailsProcess efficiency improvementSlagControl system

This invention provides the residue-proof and parallel connection air feed process of the high furnace, it can solve such problems as the disbalanceable hardware configuration in high furnace air feed system, the efficiency of air feed systerm isn't high, and damping down and residue-proof in the high furnace caused by air feed system fault. This invention offers a parallel connection air feed technology in the air feed systerm, installing auxiliary air supply duct on main air supply duct of high furnace fan, install auxiliary one and main one in parallel to form air-supply network, monitor the air supply condition of every high furnace with control system,in order to adjust corresponding parameters, to change-over between main air supply duct and auxiliary one and control them, to make other fans of high furnaces supply air for the high furnace whose air supply is insufficient and the one whose fan is damaged.

Owner:燕永存

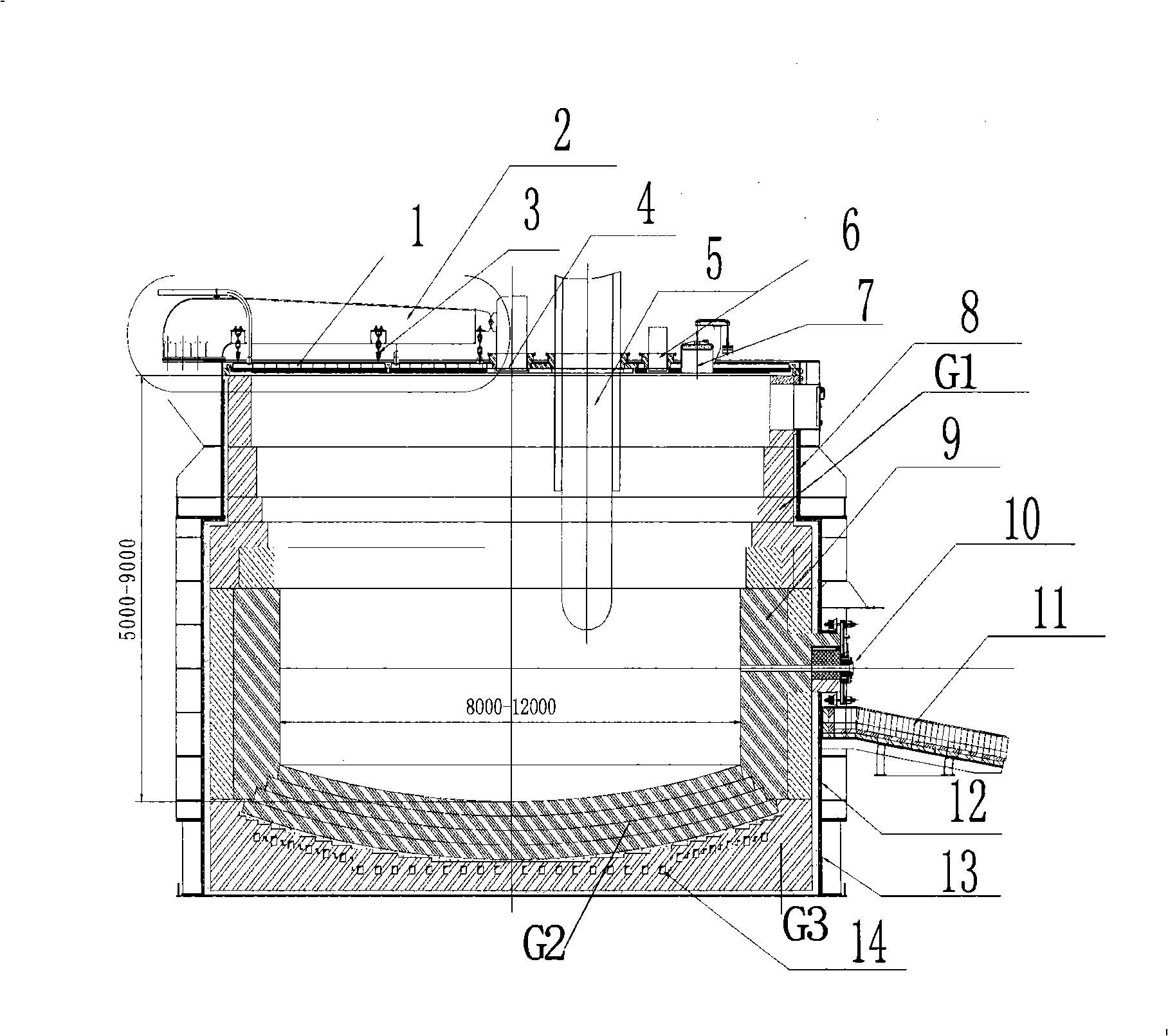

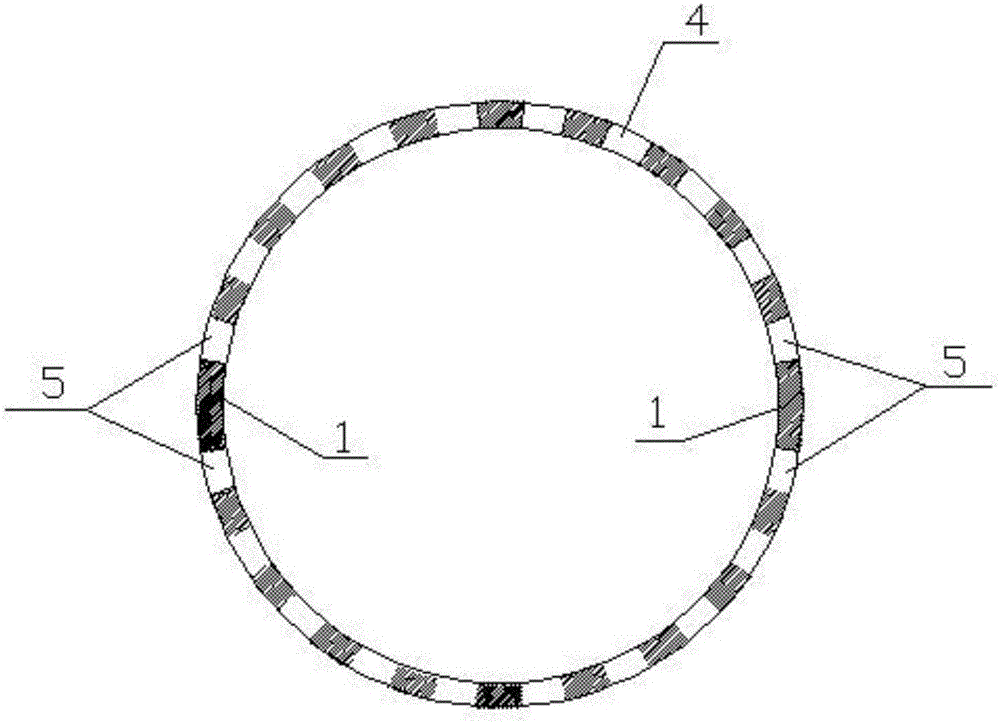

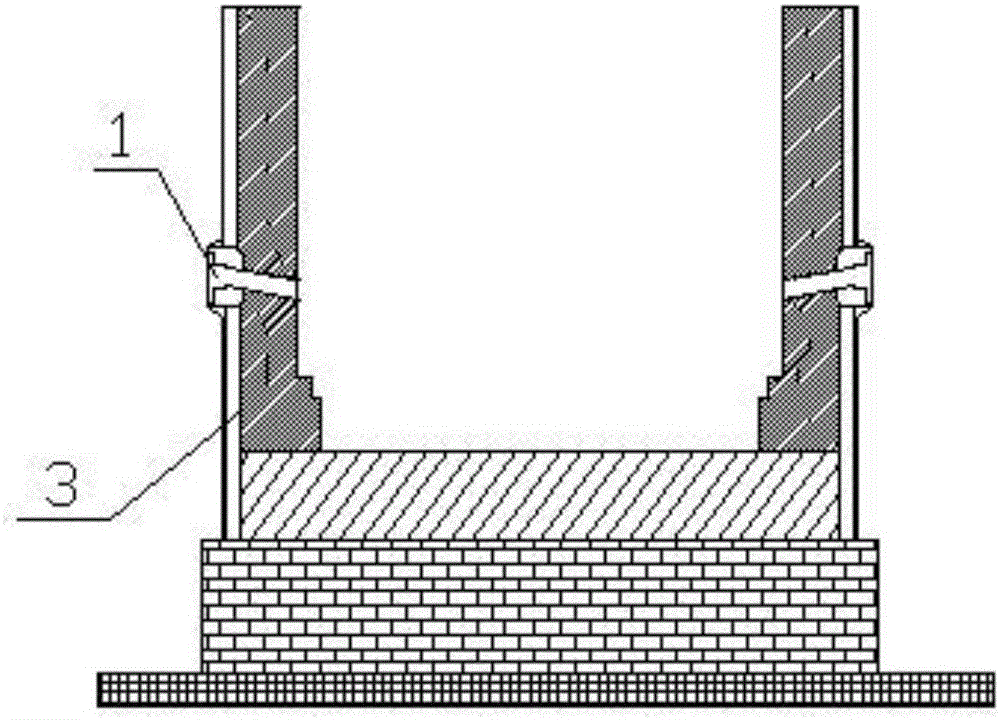

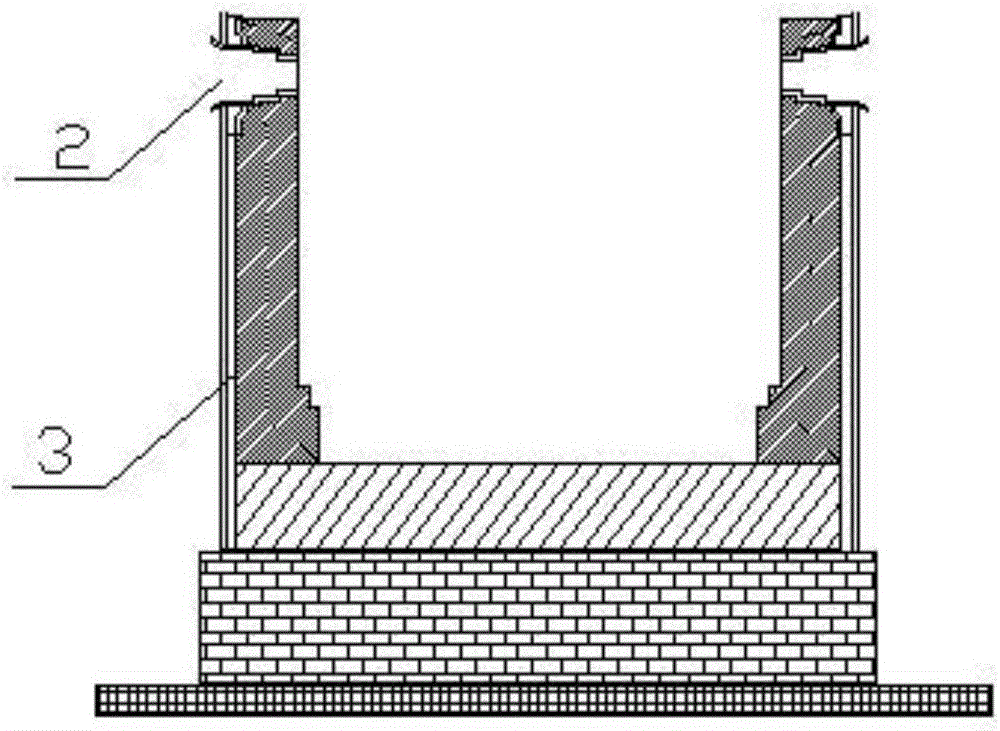

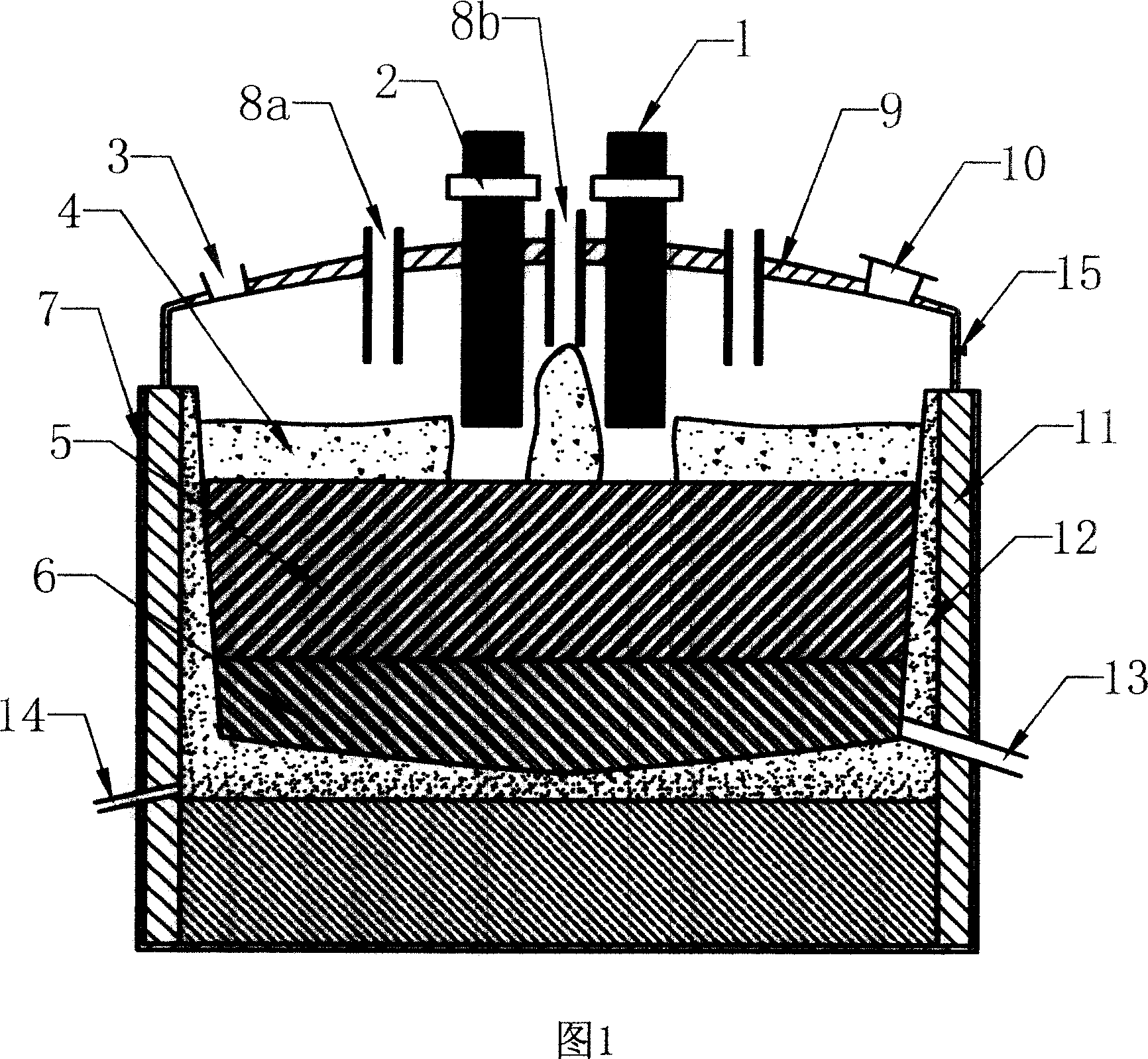

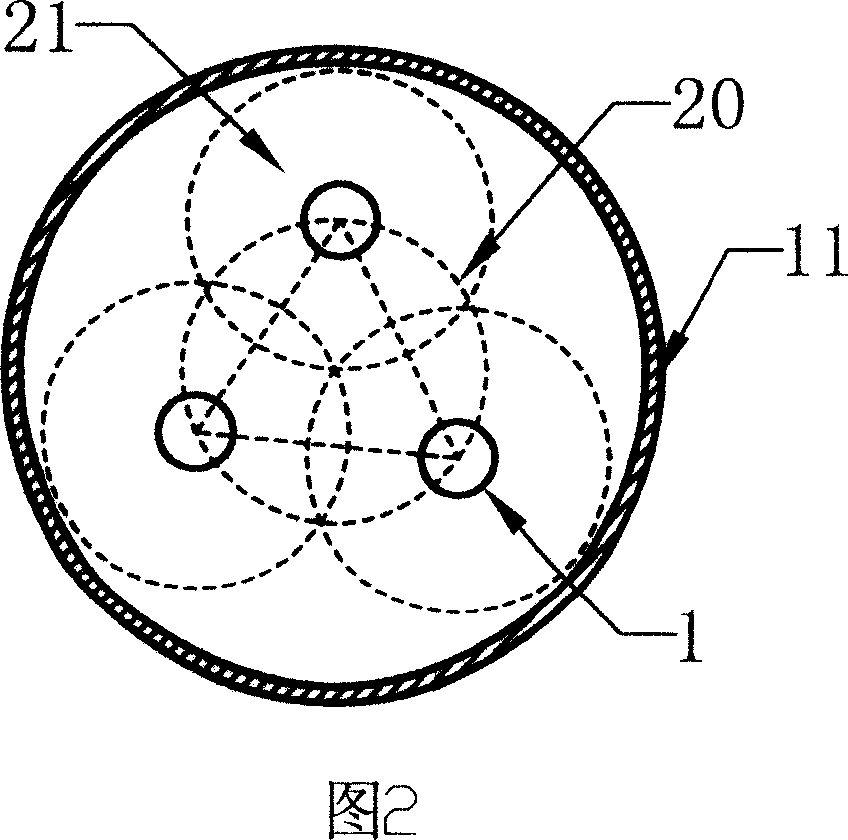

Electric stove for smelting titanium slag

ActiveCN101349503AStable furnace conditionImprove thermal efficiencyCrucible furnacesElectric furnaceElectric arc furnaceThermal efficiency

The invention provides an electric furnace for melting titanium slag, which comprises a furnace lid, a furnace mantle, a furnace lining, a feed opening, electrodes, a slag hole, a slag notch and a taphole, and is characterized in that the diameter of the pole circle of the electric furnace is 2500mm-3500mm, the operation power of the electric furnace is 15000kVA-30000kVA, the hearth height of the electric furnace is 5000mm-9000mm, and the diameter of a molten pool of the electric furnace is 8000mm-12000mm. According to the embodiment of the invention, the electric furnace for melting titanium slag has stable furnace condition and high heat efficiency when smelting titanium slag.

Owner:PANGANG GROUP TITANIUM INDAL +1

Smelting technique of brown corundum

InactiveCN102815731AReduce smelting power consumptionImprove securityEnergy inputAluminium oxides/hydroxidesThermal insulationElectricity

The invention discloses a smelting technique of brown corundum, which comprises the following steps: 1. adding pulverized raw alumina, which satisfies the particle size requirement, into a rotary kiln or shaft kiln, and roasting to 1200 DEG C by using heat from coal gas generated by a generating furnace; 2. sending the roasted alumina material into a thermal insulation charging basket, proportionally adding a carbon material and iron chips, and transferring into a thermal insulation storage bin; and 3. sending the material in the thermal insulation storage bin in the step 2 into an electric furnace by using a feeder, continuing heating for smelting until the reaction is complete, inspecting, cooling and grading to obtain the finished product. The smelting can also be carried out after pulverizing, mixing, granulating and roasting the three raw materials. The invention can lower the power consumption for smelting and enhance the safety of the smelting technique. The smelting technique does not need to use cured alumina, but only uses raw alumina, thereby greatly lowering the raw material cost; and the material is roasted in the rotary kiln or shaft kiln, and added into the electric furnace for smelting while the material is hot, thereby utilizing the waste heat of roasting and saving the electric power.

Owner:王洪仁

Method for synthesizing calcium carbide smelting raw material by extruding blue coke and lime powder

The invention relates to a method for synthesizing a calcium carbide smelting raw material by extruding blue coke and lime powder. The method comprises the following steps: evenly mixing blue coke powder, lime powder and middle-temperature coal tar pitch based on the weight ratio of (42-48%):(42-48%):(8-12%); then stirring the mixed powder at constant temperature of 200-220 DEG C for 10-15 minutes; and finally extruding the powder into elliptical pellets by utilizing a mixture extrusion molding machine, and naturally cooling to finally obtain the calcium carbide smelting raw material. By utilizing the method, the blue coke and the lime can be fully utilized in a calcium carbide smelting process in the case of low cost and low technical requirements, thus achieving the purposes of lowering cost, saving resource and protecting environment.

Owner:宁夏兴平精细化工股份有限公司

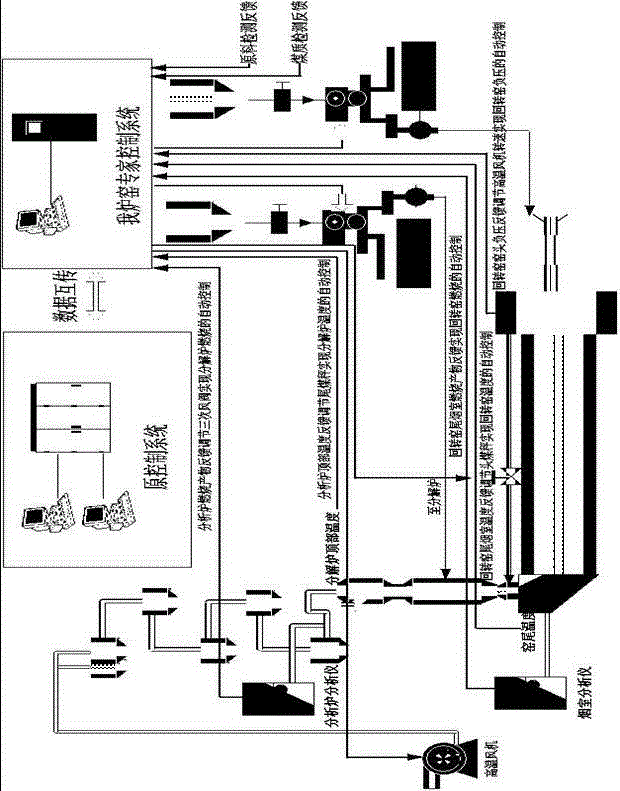

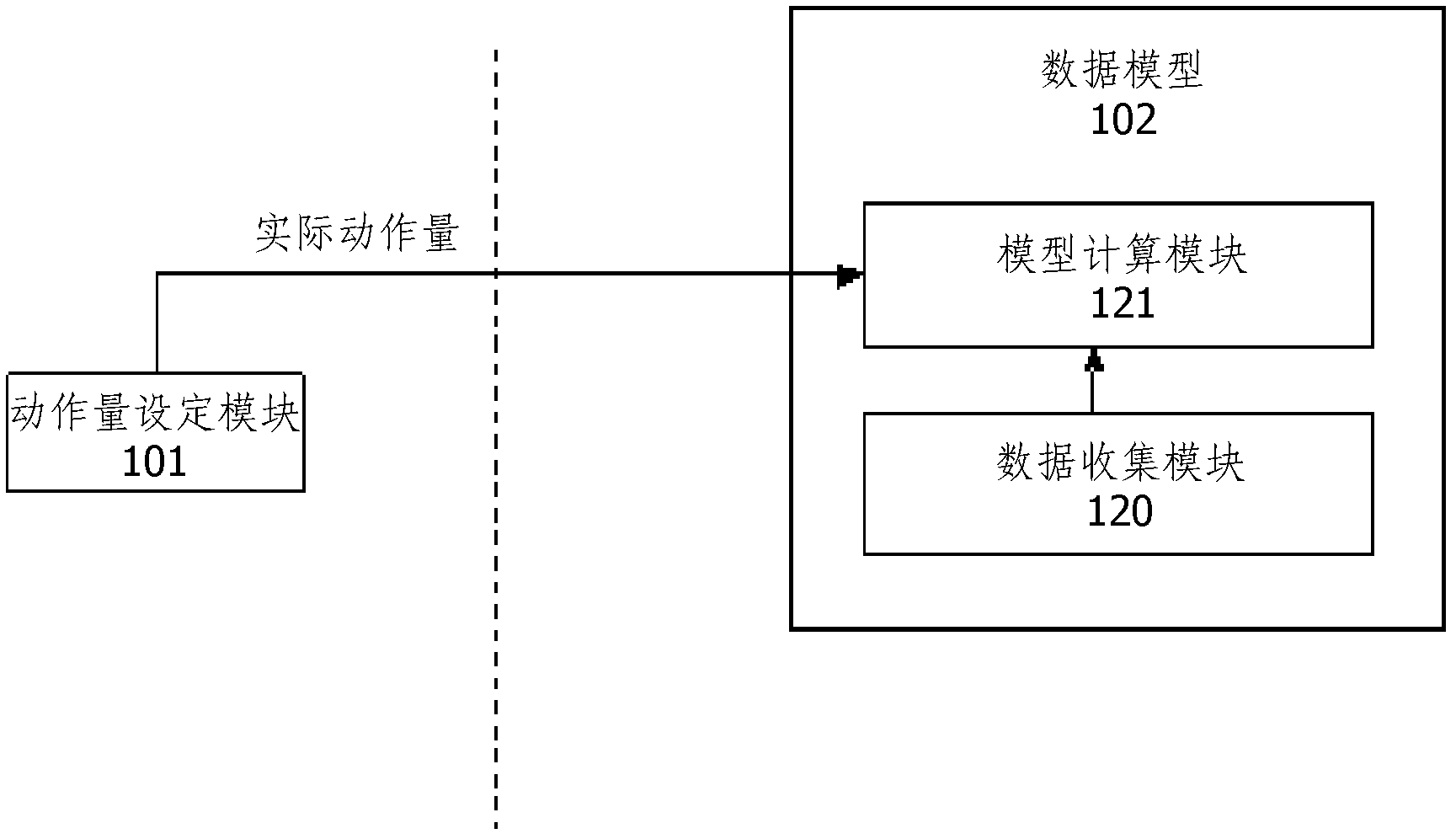

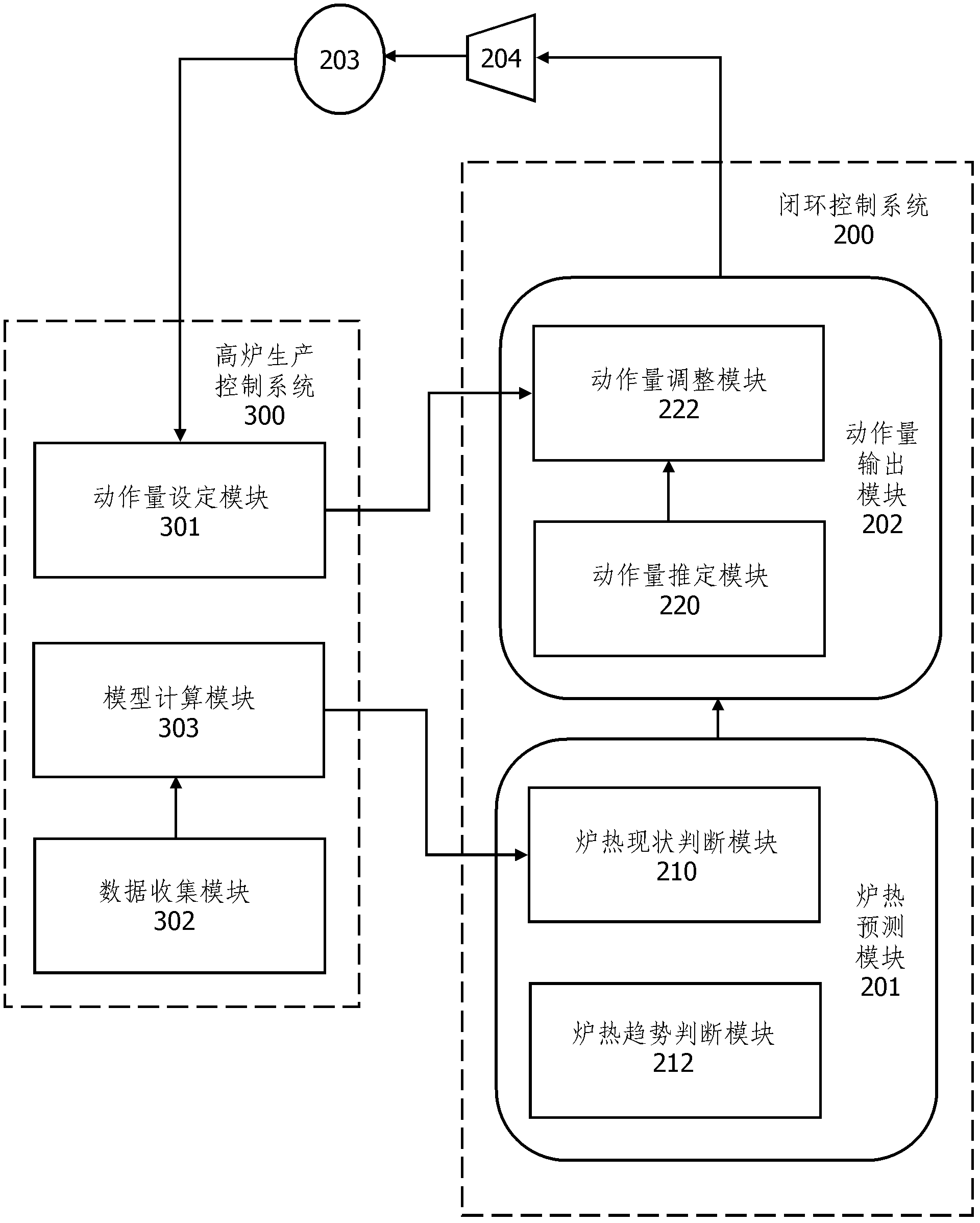

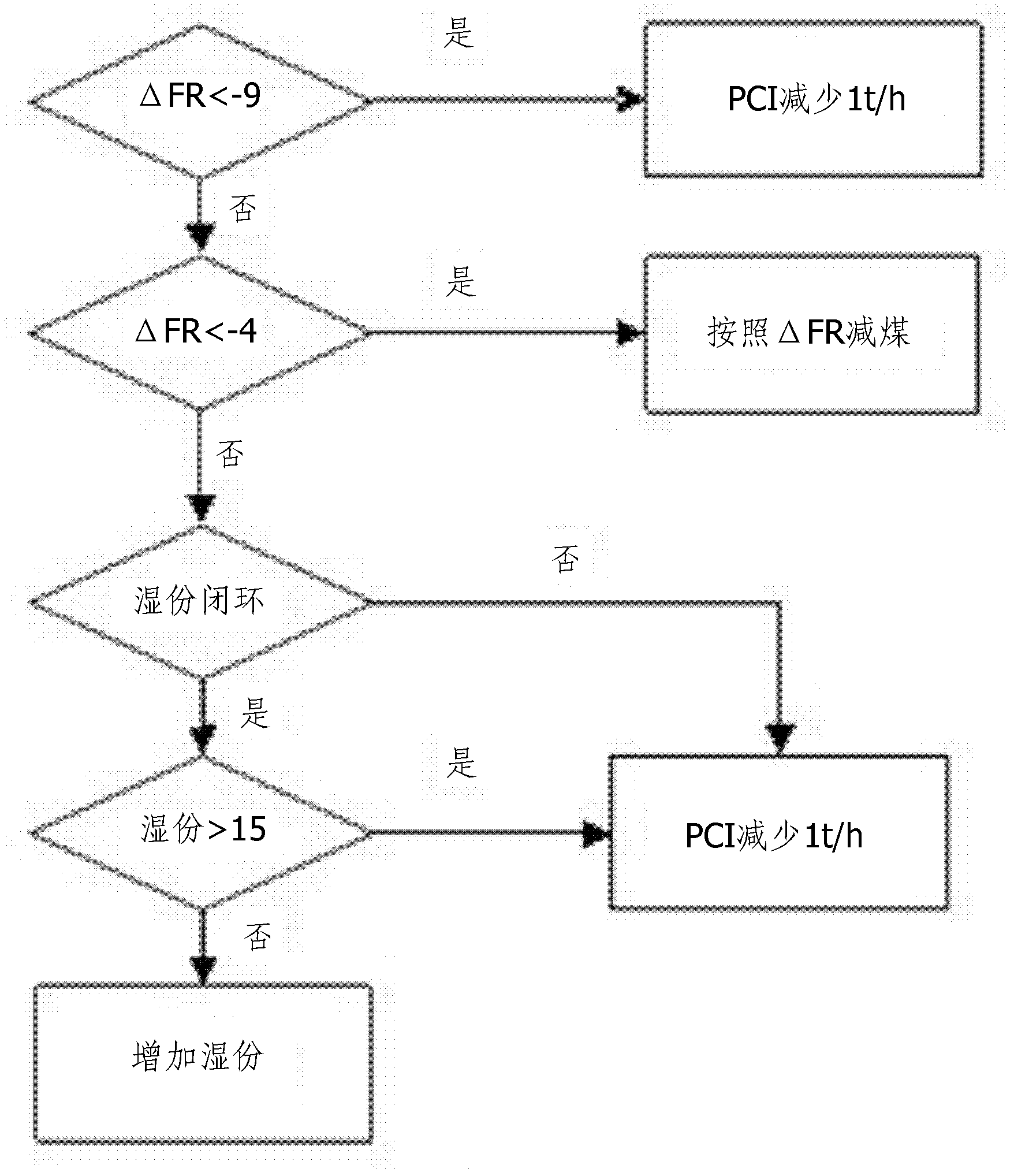

Blast furnace operation closed-loop control system

ActiveCN102876822AImprove the level ofStable furnace conditionBlast furnace detailsTotal factory controlLoop controlControl system

The invention discloses a blast furnace operation closed-loop control system. The closed-loop control system is connected to a blast furnace production control system and comprises a furnace heat prediction module and an actuating quantity output module. The furnace heat prediction module is connected to the blast furnace production control system, acquires blast furnace running data, and generates current furnace heat parameters and trend furnace heat parameters based on the blast furnace running data. The actuating quantity output module is connected to the furnace heat prediction module, acquires the feed data of a practical actuating quantity, and adjusts the feed data of the practical actuating quantity according to the current furnace heat parameters and the trend furnace heat parameters generated by the furnace heat prediction module to generate actuating quantity adjustment parameters. The blast furnace operation closed-loop control system can realize automatic closed-loop blast furnace operation control without manpower, so it is in favor of improving the whole level of the blast furnace operation, stabilizing the blast furnace condition, and eliminating individual operation differences.

Owner:BAOSHAN IRON & STEEL CO LTD

Skimming tool for blast-furnace casting

InactiveCN104045355AImprove plasticityGood thermal stabilityDischarge devicesSodium triacetoxyborohydrideSilicone resin

The invention discloses a skimming tool for blast-furnace casting, and belongs to the technical field of refractory materials for blast furnace. The skimming tool consists of a refractory aggregate and a binder. The refractory aggregate comprises waste high-aluminum brick, mullite, quartz sand, chromite, bentonite, kaolin, coke, fly ash, silicon carbide, ceramic waste, magnesium oxide, lanthanum oxide, titanium boride, thorium oxide, Suzhou soil, clay, aluminium powder and zirconia; and the binder is composed of asphalt, silicone resin, melamine formaldehyde resin, butadiene nitrile rubber, 2-imidazolidinone, starch, sodium triacetoxyborohydride, salt, Cetyl trimethyl ammonium chloride and chloroprene rubber. The skimming tool provided by the invention through specific component ratio greatly prolongs the service life of the skimming tool to 60 days without repair, does not require supplementary material in the use process, greatly reduces the stokehold labor intensity, and guarantees the stable, secure and smooth conditions of the high furnace.

Owner:WUHU WATER PUMP MFG

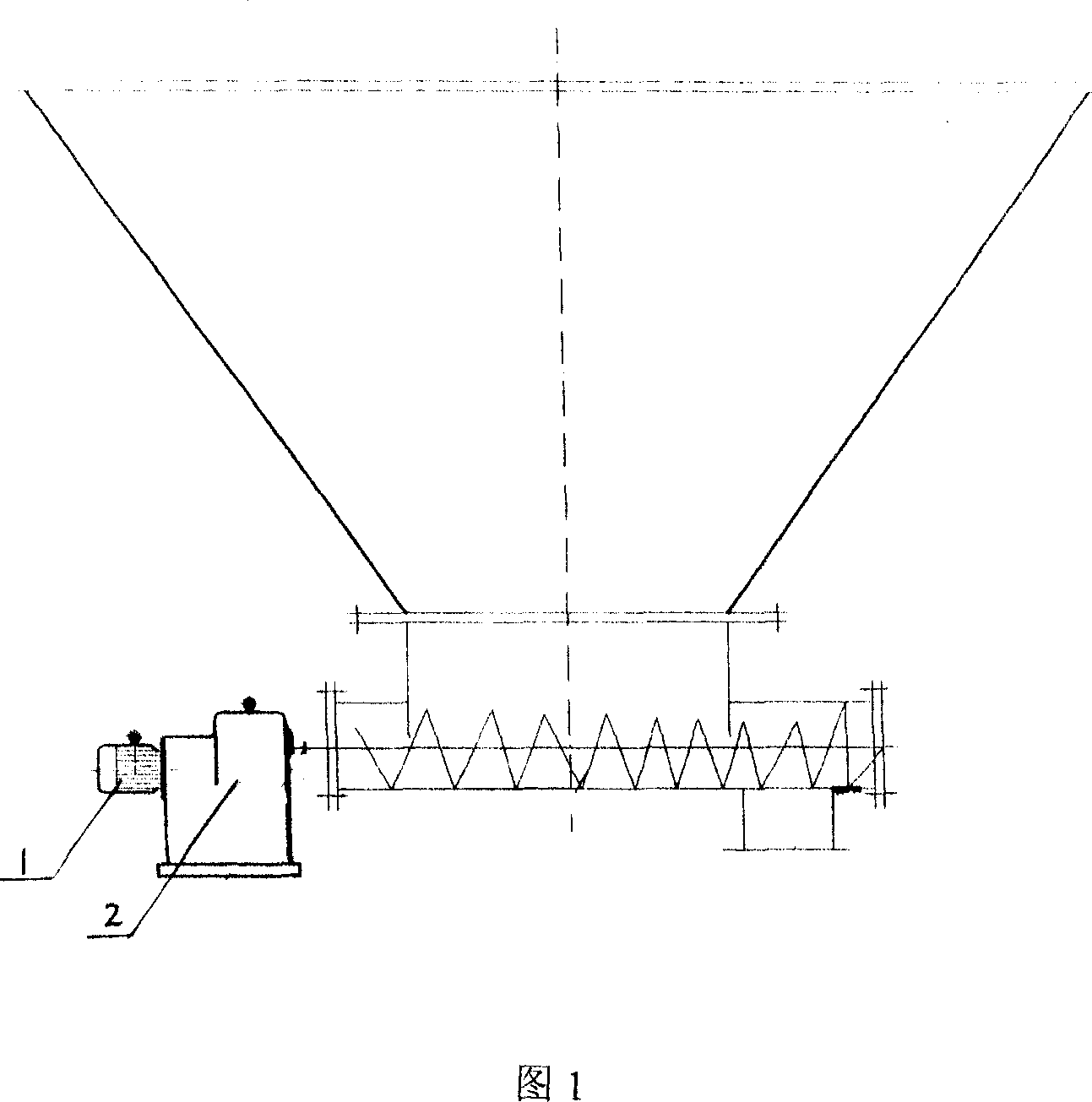

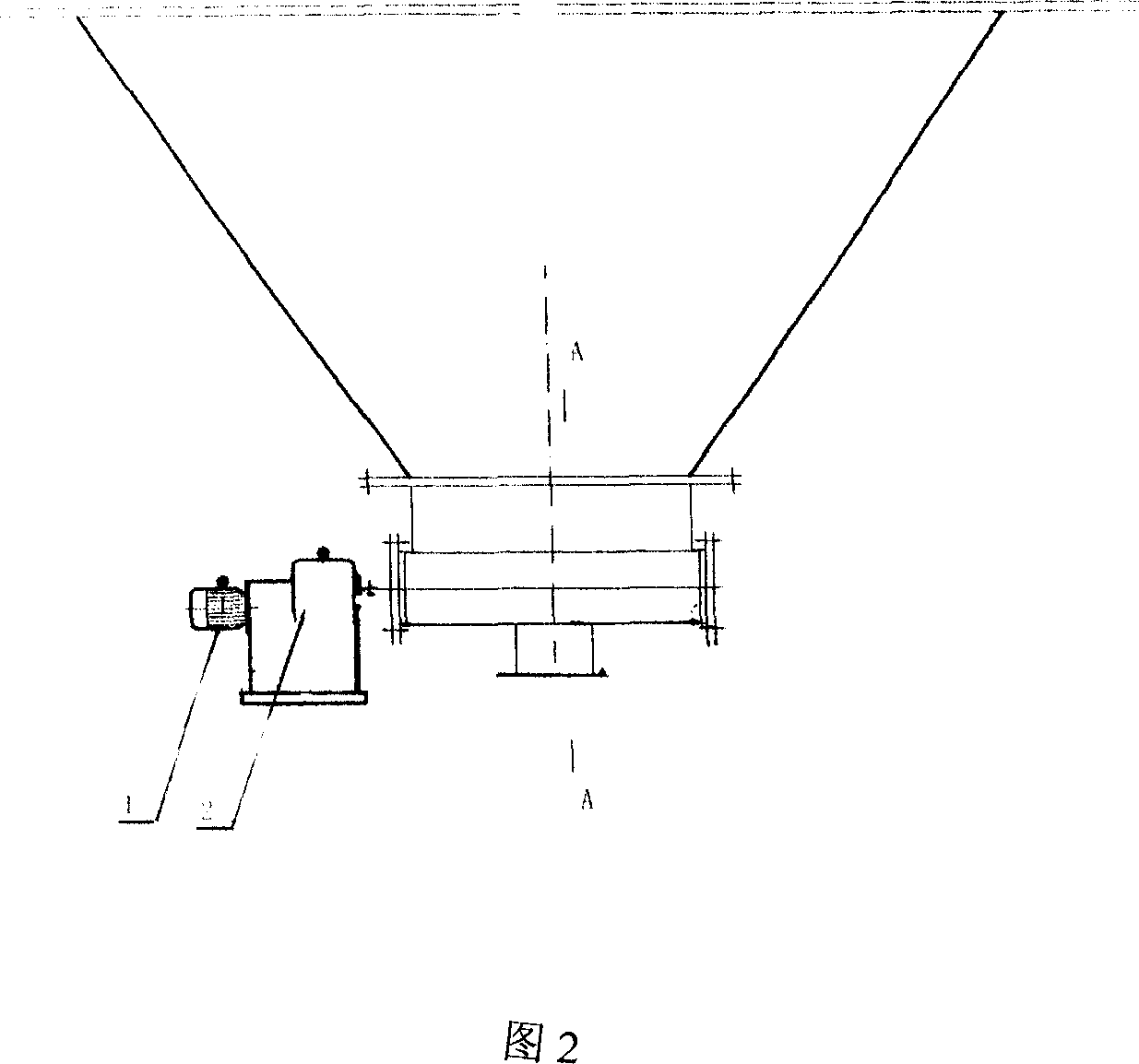

Slag discharging device for dust collector

InactiveCN1919415AAvoid sticking equipmentSmooth dischargeDispersed particle filtrationDrive shaftTransmitted power

The invention discloses a preparing method of titanic chloride, which is characterized by the following: the discharge device of cleaner is set under the cleaner (15), which consists of cleaner floor (10) and scraper discharge machine, the cleaner floor (10) connects flannel (12) of cleaner (15) through bolt, which is sealed by sealing pad (11), the cleaner floor possesses slag gathering hopper (13), when the discharge machine works, the motor (1) anchors conical gear couple (5) and (6) through reducer (2), which transmits power to scraping board (9) through driving shaft (8), the scraping board (9) winds shaft (8), which gathers dust in the slag gathering hopper (13), the discharge door is opened timely, which drains the dust in the slag pouring pool.

Owner:ZUNYI TITANIUM

Method for smelting low-silicon pig iron by using iron ore with complex mineral structure

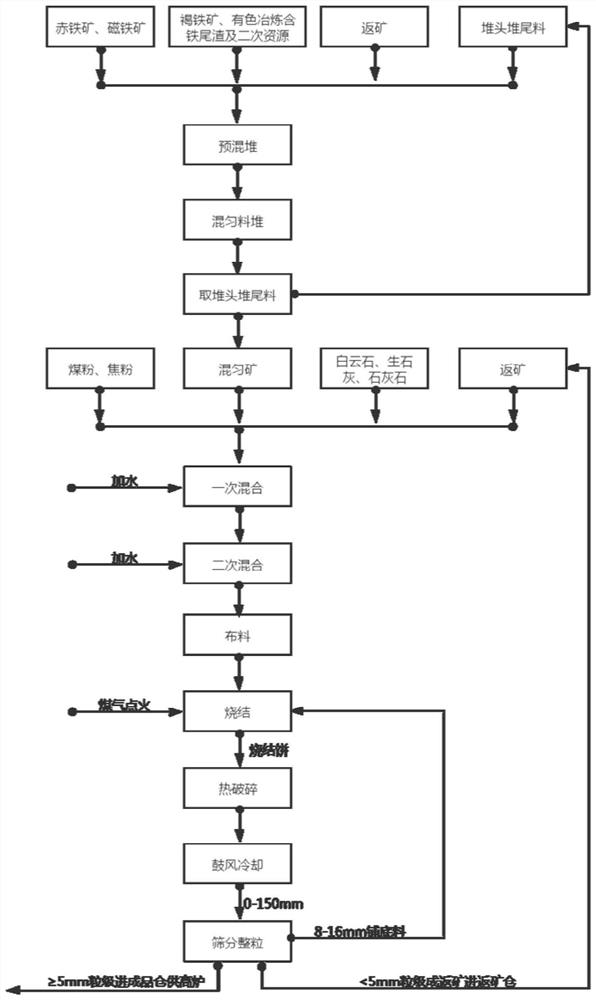

ActiveCN111748666AGuaranteed continuityOptimize the mine structureBlast furnace detailsIronstoneBlast furnace smelting

The invention relates to a method for smelting low-silicon pig iron by using iron ore with a complex mineral structure, and belongs to the technical field of ironmaking. The method comprises the following steps of uniformly mixing limonite, nonferrous smelting iron-containing tailings, secondary resources, fine-grained magnetite concentrate, fine-grained vanadium-titanium magnetite concentrate andhematite, piling, taking the uniformly mixed ore in the middle of a material pile, mixing the uniformly mixed ore with SYP synergist, dolomite, limestone, quicklime and coke powder, pelletizing, sintering the obtained pellets to obtain a finished product sinter, crushing, spraying a CaCl2 solution, screening, and blending the sintered ore with the particle size of more than 5mm, the pellet ore and the lump brown iron ore into a blast furnace for blast furnace smelting to obtain a low-silicon qualified pig iron. According to the method, secondary resource reutilization is achieved, on one hand, environmental pollution is reduced, meanwhile, the production cost can be saved, and application and popularization are easy.

Owner:红河钢铁有限公司

Remaining slag single-slag smelting operation method in converter low-iron-consumption mode

ActiveCN113201621AHigh yieldReduce consumptionManufacturing convertersProcess efficiency improvementSlagMaterial consumption

The invention relates to a remaining slag single-slag smelting operation method in a converter low-iron-consumption mode. The method comprises the following steps that S1, smelting raw materials are prepared; S2, after last charge of slag is subjected to slag splashing treatment, the slag is solidified, all final slag is left in a converter, and then the raw materials are added into the converter to be prepared for smelting; S3, during smelting, in the blowing starting stage, lime and magnesium balls are started to be added, the adding mass of the lime is 10-15 in a thousand of the steel tapping amount of the converter, the adding mass of the magnesium balls is 6.5-10 in a thousand of the steel tapping amount of the converter, and the lance position of an oxygen lance refers to the distance between a spray head of the oxygen lance and the liquid level of a molten pool; S4, when the slag jumps at a converter mouth, the flow of the oxygen lance is adjusted to 26000-35000 m3 / h, the oxygen lance is moved upwards to 1350-1450 mm, and lime is added in batches according to 400-600 kg / batch; and S5, slag splashing is performed, wherein after slag splashing, all slag in the converter is left in the converter for smelting of the next charge; and the operation method solves the problems of high steel material consumption and insufficient phosphorus hit rate at the blowing end point caused by converter blowing splashing after slag remaining.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

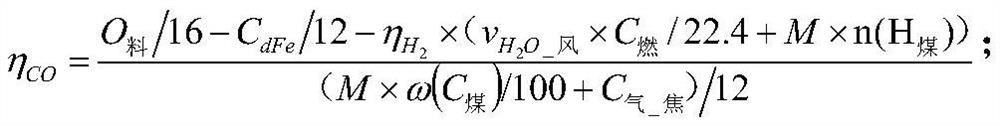

Method for determining furnace heat by using blast furnace slag iron heat index

ActiveCN112593030AImproved furnace heat controlQuality improvedSteel manufacturing process aspectsBlast furnace detailsSlagHeat balance

The invention relates to a method for determining furnace heat by using a blast furnace slag iron heat index, belongs to the technical field of blast furnace operation control, and solves the technical problem about making correct judgment on the furnace heat of a blast furnace. The method has the main principles that a slag-iron heat index capable of reflecting the heat states of slag and molteniron is solved by using a blast furnace high-temperature zone heat balance and carbon-oxygen balance equation, then a blast furnace heat storage index is constructed according to historical data, thetotal heat level in the furnace is determined, and a furnace heat index of the blast furnace is constructed by combining chemical heat and physical heat parameters of the blast furnace, then the furnace heat level of the blast furnace can be determined, and blast furnace heat judgment and adjustment are guided, so that the molten iron quality is improved, and the furnace condition is stabilized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

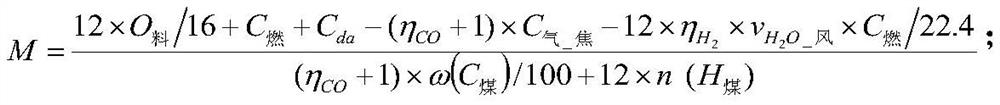

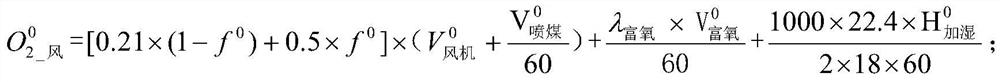

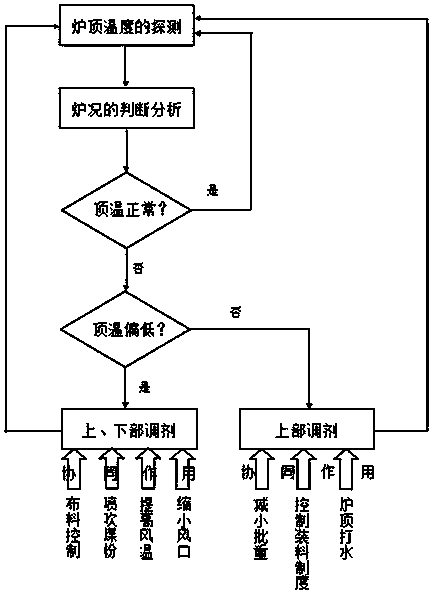

Method for regulating and controlling temperature of furnace top through upper part and lower part of blast furnace under oxygen-enriched condition

ActiveCN108611456AImproves responsivenessImprove furnace conditionBlast furnace detailsTime informationFurnace temperature

The invention relates to a method for regulating and controlling a temperature of a furnace top through the upper part and the lower part of a blast furnace under the oxygen-enriched condition. The method is characterized by comprising the following steps of step 1, real-time detection of the temperature of the furnace top: dividing the furnace top of the blast furnace into a plurality of regionswith an equal interval in a radial direction, and acquiring real-time data of the temperature of the furnace top in each region through a temperature detection device installed in each region; step 2,judgement analysis of the furnace condition; step 3, regulation with the upper part and the lower part of the blast furnace: according to judgement analysis on the real-time furnace condition, when the furnace temperature is abnormal, starting regulation; and step 4, real-time information feedback: judging a change of the temperature of the furnace top in each region in real time, entering the step 2, and forming a system of regulating the temperature of the furnace top in real time.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

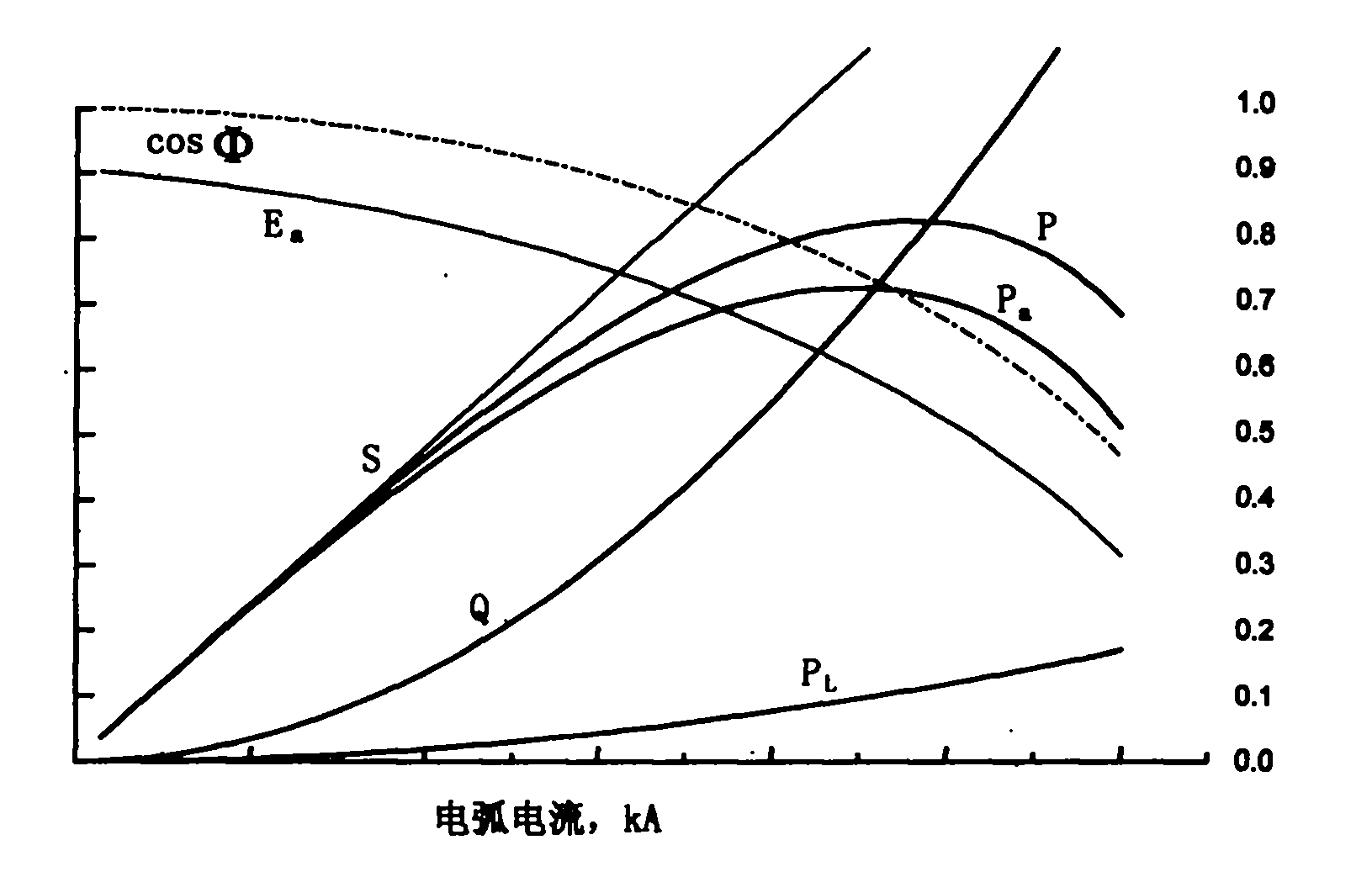

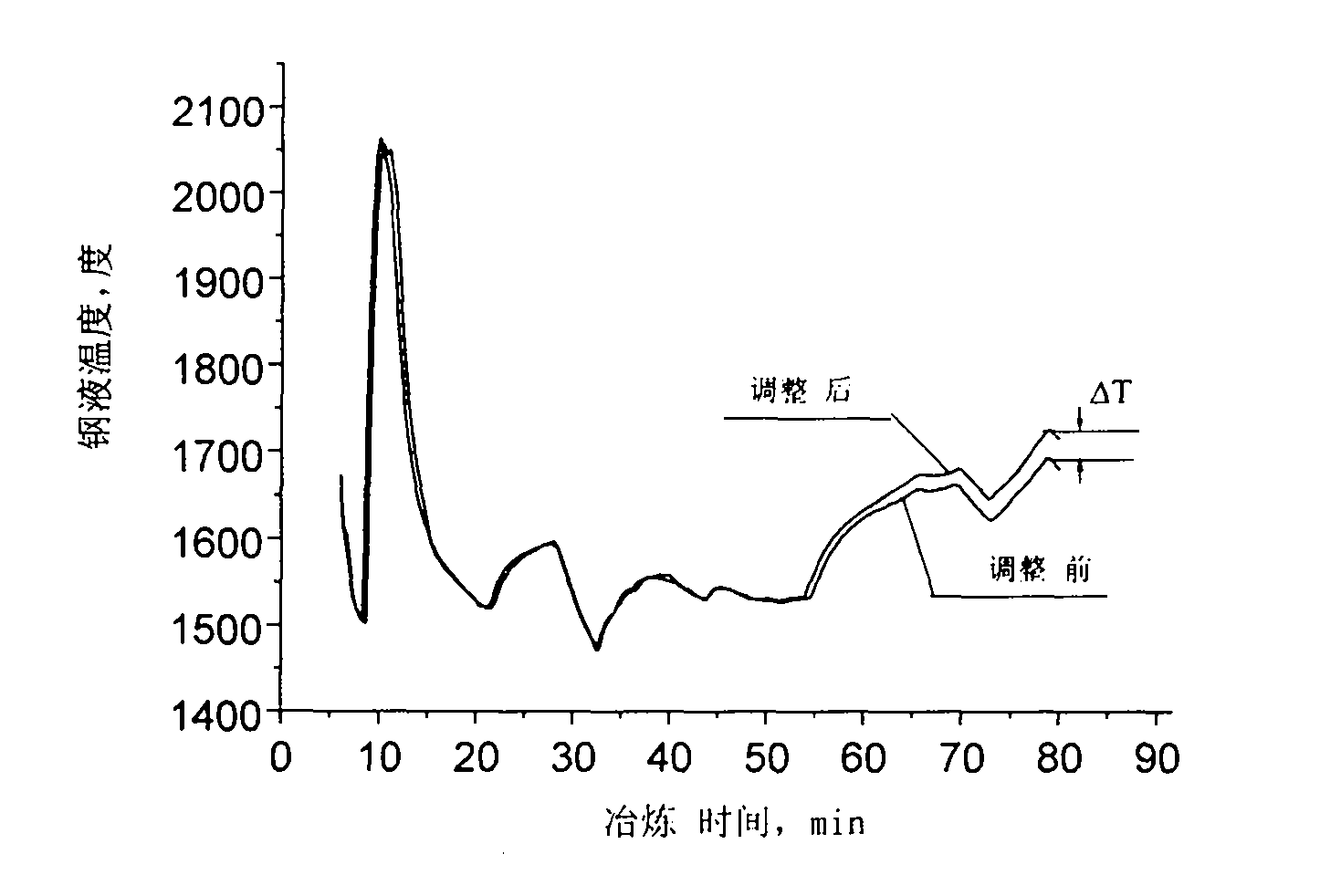

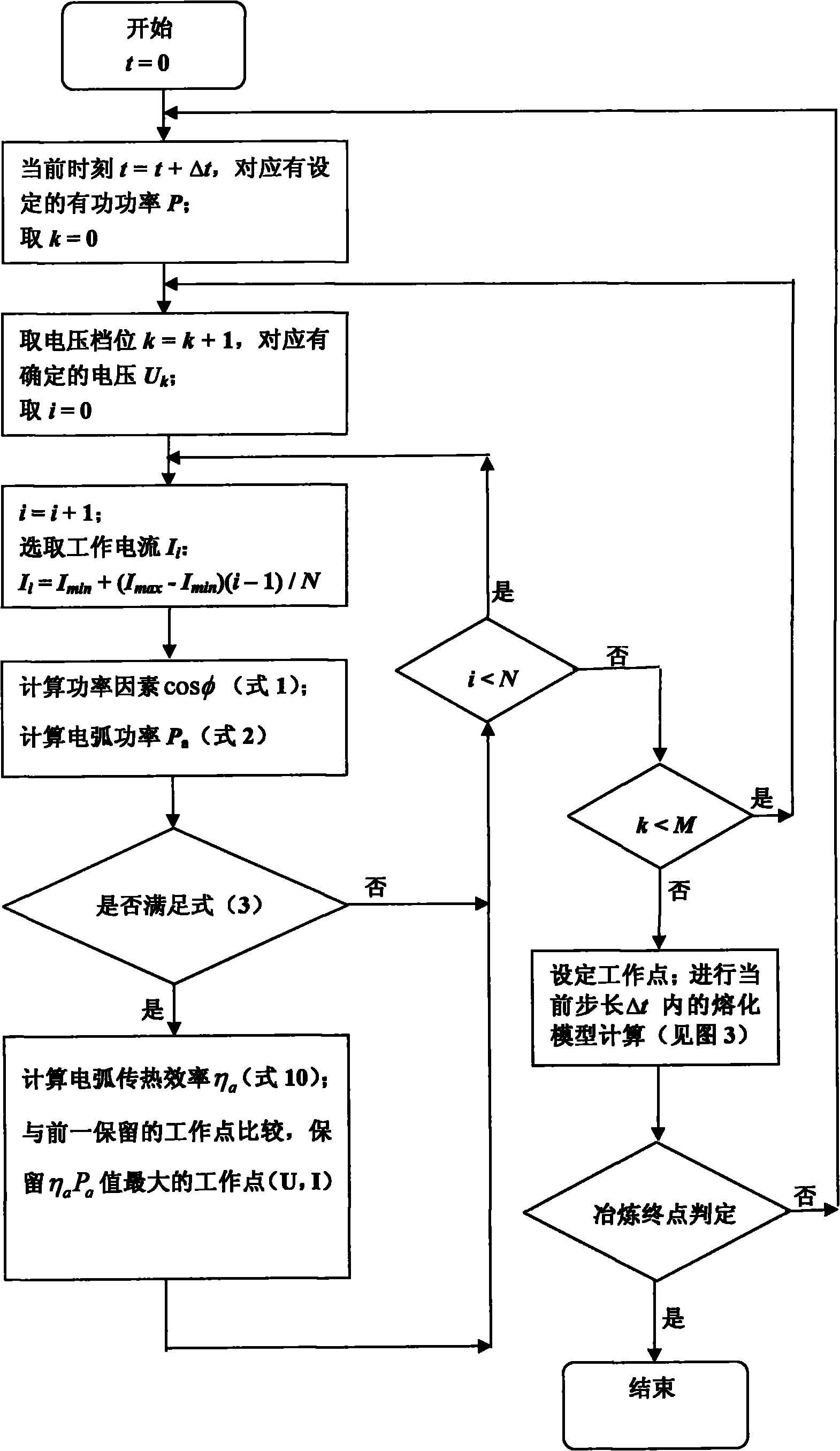

Material melting model-based power supply control method for arc furnace

ActiveCN101833288AImprove accuracyStable furnace conditionElectric discharge heatingIncreasing energy efficiencyElectric arc furnaceSmelting process

The invention discloses a material melting model-based power supply control method for an arc furnace. The method combines furnace condition information which represents various scrap steel melting characteristics and is provided by the material melting model with electrical characteristics of the arc furnace; a power supply parameter in the smelting process of the arc furnace is dynamically regulated on line; and a working point with the maximum etaaPa value or the minimum active power is selected from a plurality of current calculated working points based on a material melting model to carry out smelting process so as to accurately judge the smelting end-point of the arc furnace. Through the adoption of the power supply control method of the invention, the change of the furnace condition can be continuously quantificationally tracked and forecast so as to fulfill the aims of improving electric energy efficiency, reducing electric energy consumption, reducing temperature fluctuation of molten steel and preventing overheated molten steel; and the method shortens the smelting time on the premise of guaranteeing to realize a smelting task and can improve the capacity of controlling the smelting end-point and accuracy of judging the smelting end-point.

Owner:BAOSHAN IRON & STEEL CO LTD

Industrial carbon-containing powder resource utilization method

ActiveCN104787741AImprove breathabilityStable furnace conditionSilicon compoundsUtilization factorCarbon particle

The present invention discloses an industrial carbon-containing powder resource utilization method, wherein industrial carbon-containing powder is added with a molding binder, and automation production processes such as material preparing, transporting, stirring, molding, and drying are performed to process and mold into the carbon particle reducing agent, the steelmaking particle recarburizer or the auxiliary material meeting the smelting application requirements in metallurgy, calcium carbide, industrial silicon, carbon and other industries. The method of the present invention has characteristics of solving of the problem of difficult carbon-containing dust utilization, high carbon-containing powder resource utilization rate, production cost reducing, significant economic benefits, significant social benefits, and the like.

Owner:河南普绿环保科技有限公司 +1

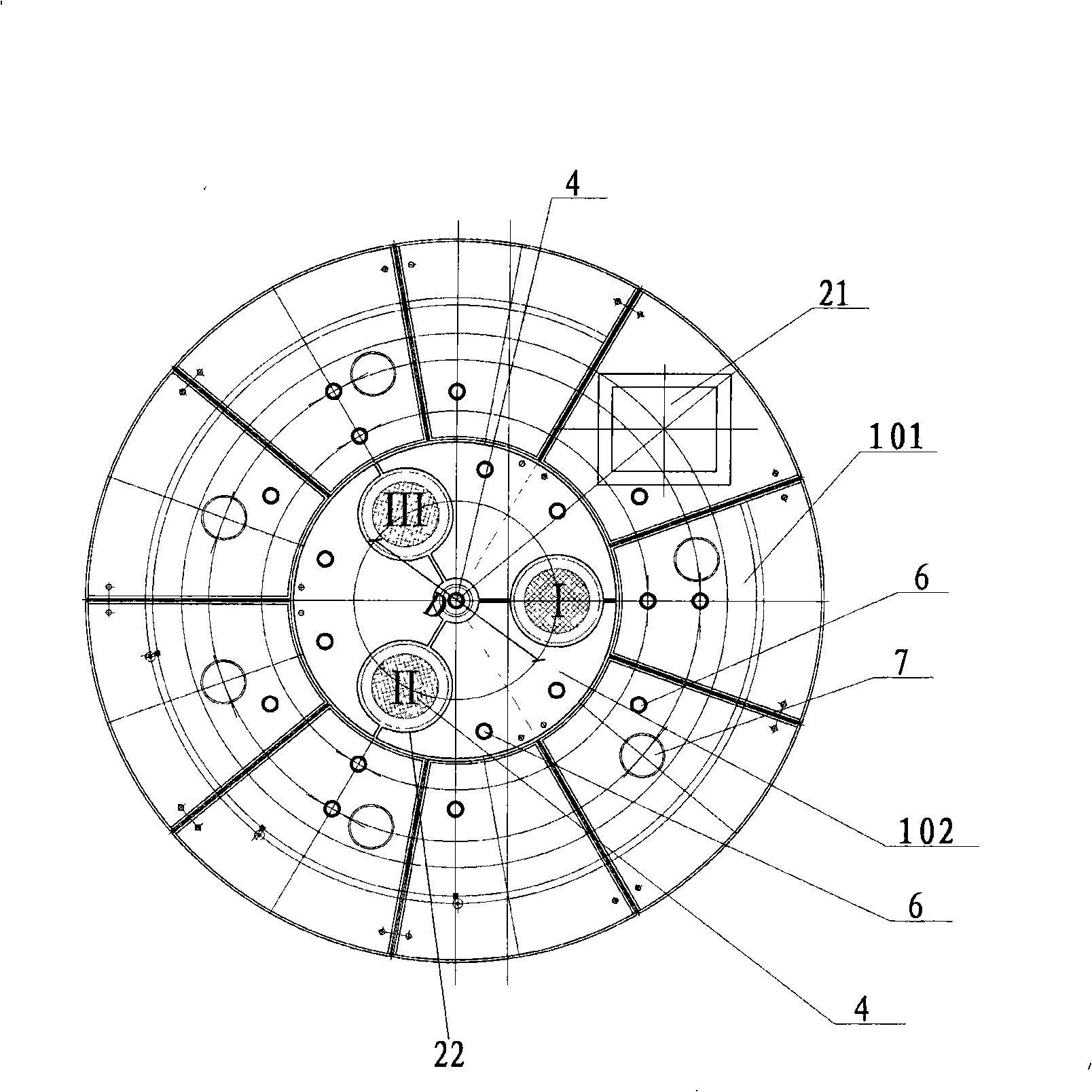

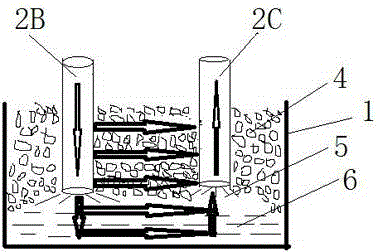

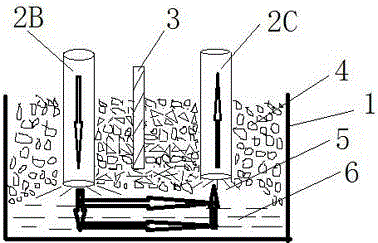

Three-phase alternating-current ore smelting furnace and method for controlling furnace condition thereof

ActiveCN103604292AImprove electricity efficiencyImprove power factorLighting and heating apparatusThree-phaseReaction zone

The invention discloses a method for controlling a furnace condition of a three-phase alternating-current ore smelting furnace. Electrodes are vertically arranged in a hearth of the three-phase alternating-current ore smelting furnace, a burden layer in the hearth is longitudinally divided into a plurality of smelting zones, the smelting zones are insulated from one another, and each smelting zone corresponds to one electrode. The invention further discloses the three-phase alternating-current ore smelting furnace which comprises the electrodes and high-temperature-resistant insulation devices. The electrodes are vertically arranged in the hearth of the three-phase alternating-current ore smelting furnace, the high-temperature-resistant insulation devices are arranged in the hearth, the corresponding burden layer of the hearth is longitudinally divided into the multiple smelting zones by the high-temperature-resistant insulation devices, accordingly, the smelting zones are insulated from one another, and each smelting zone corresponds to the corresponding single electrode. The method and the three-phase alternating-current ore smelting furnace have the advantages that the problem of influence of branch currents of a burden layer on running of an existing three-phase alternating-current ore smelting furnace can be solved by the method and the three-phase alternating-current ore smelting furnace, the stability of the furnace condition can be improved, secondary running voltages of the three-phase alternating-current ore smelting furnace can be increased, electric energy of reaction zones of lower ends of the electrodes can be greatly increased, unit energy consumption of products can be reduced, and the yield of the products can be increased.

Owner:勾武

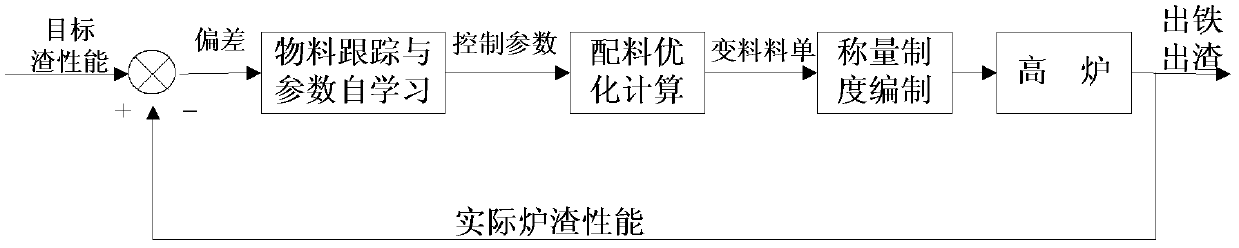

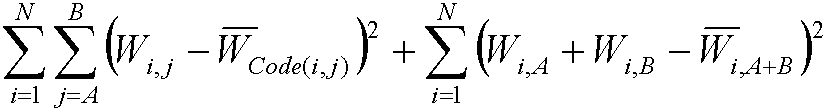

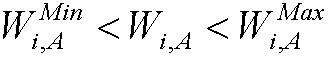

Closed-loop control method for burdening of blast furnace

ActiveCN103374638ASmall fluctuations in performanceStable furnace conditionBlast furnace detailsProduction rateSlag

The invention provides a closed-loop control method for burdening of a blast furnace. The closed-loop control method comprises the steps of: presetting a control target of reasonable slag performance of a blast furnace; carrying out material tracking and parameter self-learning of the blast furnace; acquiring analytic component values of materials loaded in the blast furnace; acquiring loading calculating information and loading time of each batch of material at the top of the blast furnace; acquiring actual molten iron analytic components and actual slag analytic component values; acquiring actual iron discharging time and the like; determining whether the materials need to be changed or not according to preparation information to generate a material changing list of the blast furnace; acquiring a use status and the like of each trough of the blast furnace; and calculating a cutout quantity of materials in each trough according to the material changing list of the blast furnace, as well as the status of each trough and the like, and issuing the cutout quantity to a basic automatic system for being executed. The closed-loop control method is capable of specifying the slag performance control operation, plays positive roles in reducing slag performance fluctuation, stabilizing furnace condition, reducing labor intensity, increasing production efficiency and the like, and has a large actual value and a wide application prospect for medium and large blast furnaces with more perfect devices.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

Low-cost blast furnace smelting method

InactiveCN106591524AQuality improvementAvoid pollutionTuyeresBlast furnace detailsGranularityBlast furnace smelting

The invention discloses a low-cost blast furnace smelting method. The low-cost blast furnace smelting method comprises the steps that coke nut with the particle sizes ranging from 8 mm to 20 mm is added to sintered vanadium-titanium ores, small sintered vanadium-titanium ore cubes, vanadium-titanium pellets and pig iron, and an ore layer is formed through uniform mixing; and the coke and the ore layers are alternately fed into a blast furnace, so that an alternate layering structure of the ore layers and the coke layers is formed, wherein the coke is composed of high-strength coke and low-strength coke, and the high-strength coke comprises dry quenched coke. A hearth of the blast furnace comprises multiple tuyeres and two iron notches, wherein the two iron notches are symmetrical about the center axis of the hearth, the tuyeres are arranged above the iron notches and distributed circumferentially, the diameters of the tuyeres which are symmetrical about the center axis of the hearth are identical, and the diameters of the tuyeres located on the two sides of the iron notches are smaller than or equal to the diameters of the other tuyeres on the circumference. By the adoption of the low-cost blast furnace smelting method, the ventilation performance of blast furnace smelting is improved, the intensity of blast furnace smelting is improved, the fuel ratio is lowered, and the cost is lowered.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Closed electric furnace and titanium slag smelting process

This invention relates to a sealed electrical furnace and technology of sealed furnace smelt titanium slag. The electrode hole of the sealed furnace adopt the flexible dry seal; the operate power of electrical furnace is 3200 to 8400kVA; the pole heart circle of the electrical furnace is 1500 to 2350mm; each feed pipe 8a, 8b is independently controlled. The technology of sealed furnace smelt titanium slag provided by the invention; adopt special mixture making ingredient and smelting technology when run a new furnace, so that the furnace wall is articulated with high melting point substance with thickness of 100 to 150mm to form furnace slag, protect the flame-proof material. The technology of sealed furnace smelt titanium slag provided by the invention, compared with the flow of open furnace or petticoat pipe accessible furnace: (1) no dust, no noise in smelting process; (2) the furnace condition is stable, no collapse of materials, no slag turning over, not need to tamp trace furnace; (3) no consumption of binding admixture such as asphalt and pulp; furnace gas is mainly fuel gas without toxic and malodorous substance as decomposition of asphalt; (4) The gas is not directly discharged, the sensible heat can be used to preheat furnace charge, and can be used as industrial fuel or reducing gas after purification.

Owner:PANZHIHUA CITY YONGXING TITANIUM IND

Method for producing artificial rich iron ore from copper smelting waste slag by using new sintering technology

The invention relates to a method for producing artificial rich iron ore for ironmaking from copper smelting waste slag, in particular to a method for producing the artificial rich iron ore from the copper smelting waste slag by using new sintering technology. The method is characterized by comprising the following steps: a, pouring copper smelting waste slag at 1100-1300 DEG C into a hot slag ladle, shaking the ladle for 5-15 minutes, and standing for 10-20 minutes; b, transferring the rest of the waste slag in the hot slag ladle into another hot slag ladle; c, adding a ferrous raw material into the hot slag ladle filled with most of the waste slag, wherein the ferrous raw material accounts for 30-100 wt% of the waste slag in the hot slag ladle; and d, pouring out the waste slag with the ferrous raw material, and cooling. By fully utilizing the sensible heat produced by the emission of the copper smelting waste slag, the method removes the impurities to purify the waste slag, recycles the ferrous metals and saves the heat energy, thereby obtaining the novel artificial rich iron ore product.

Owner:牛庆君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com