Method for smelting low-silicon pig iron by using iron ore with complex mineral structure

A low-silicon pig iron and iron ore technology, applied in the field of ironmaking, can solve problems such as reducing the cost of ore, reducing the quality of sintered ore, and increasing the proportion of limonite, so as to reduce the cost of ore, achieve good economic benefits, and optimize the use of The effect of mine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

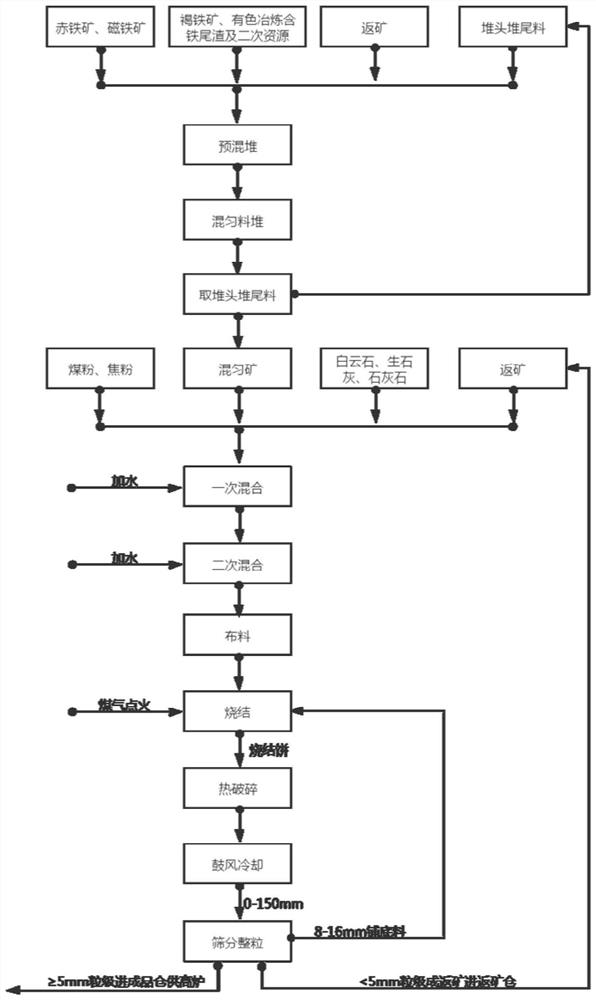

[0063] A method for smelting low-silicon pig iron using iron ore with a complex mineral structure, comprising the steps of:

[0064] Step (1), prepare the following raw materials according to the following mass percentages:

[0065] ① Limonite 40%;

[0066] ② Non-ferrous smelting iron-containing tailings and secondary resources 10%;

[0067] ③ fine-grained magnetite concentrate 23%;

[0068] ④ Fine-grained vanadium-titanium magnetite concentrate 5%;

[0069] ⑤ Hematite 5%;

[0070] ⑥SYP synergist 0.028%;

[0071] ⑦ Dolomite 3.5%;

[0072] ⑧Limestone 6%;

[0073] ⑨ quicklime 2%;

[0074] ⑩The balance of char end; total 100%;

[0075] The basicity of sintered ore is controlled by 2.2-2.5 times;

[0076] In step (2), mix the raw materials ①-⑤ prepared in step (1), then build a pile, remove the head and tail of the pile, and take the middle part of the pile to mix the ore;

[0077] Step (3), mix the middle mixed ore obtained in step (2) with the remaining raw materials p...

Embodiment 2

[0083] A method for smelting low-silicon pig iron using iron ore with a complex mineral structure, comprising the steps of:

[0084] Step (1), prepare the following raw materials according to the following mass percentages:

[0085] ① Limonite 48%;

[0086] ② Non-ferrous smelting iron-containing tailings and secondary resources 5%;

[0087] ③Fine-grained magnetite concentrate 18%;

[0088] ④ fine-grained vanadium-titanium magnetite concentrate 6%;

[0089] ⑤ Hematite 5.7%;

[0090] ⑥SYP synergist 0.030%;

[0091] ⑦ Dolomite 3.57%;

[0092] ⑧Limestone 6.1%;

[0093] ⑨Lime 2.1%;

[0094] ⑩ end of coke 5.5%;

[0095] The basicity of sintered ore is controlled by 2.2-2.5 times;

[0096] In step (2), mix the raw materials ①-⑤ prepared in step (1), then build a pile, remove the head and tail of the pile, and take the middle part of the pile to mix the ore;

[0097] Step (3), mix the middle mixed ore obtained in step (2) with the remaining raw materials prepared in step (1)...

Embodiment 3

[0110] A method for smelting low-silicon pig iron using iron ore with a complex mineral structure, comprising the steps of:

[0111] Step (1), prepare the following raw materials according to the following mass percentages:

[0112] ① Limonite 40.5%;

[0113] ② Non-ferrous smelting iron-containing tailings and secondary resources 5.5%;

[0114] ③Fine-grained magnetite concentrate 18.5%;

[0115] ④ Fine-grained vanadium-titanium magnetite concentrate 5.1%;

[0116] ⑤ Hematite 5.368%;

[0117] ⑥SYP synergist 0.032%;

[0118] ⑦ Dolomite 5.5%;

[0119] ⑧Limestone 8%;

[0120] ⑨ quicklime 4%;

[0122] The basicity of sintered ore is controlled by 2.2-2.5 times;

[0123] In step (2), mix the raw materials ①-⑤ prepared in step (1), then build a pile, remove the head and tail of the pile, and take the middle part of the pile to mix the ore;

[0124] Step (3), mix the middle mixed ore obtained in step (2) with the remaining raw materials prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com