Method for determining furnace heat by using blast furnace slag iron heat index

A blast furnace slag and index technology, applied in blast furnace, blast furnace details, steel manufacturing process and other directions, can solve the problems of blast furnace production technical indicators and the adverse impact of molten iron quality, poor practicability, relying on historical data reasoning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The specific embodiment of the present invention is further described below by way of example.

[0072] A method for determining the heat level of the furnace by using the heat index of blast furnace slag and iron, comprising the following steps:

[0073] Step 1: Calculate the validity of the parameters

[0074] (1) Collection of furnace thermal parameters

[0075] This paper adopts the parameters of the company's 6# blast furnace under actual production conditions in a certain period of 2020, as shown in Table 1:

[0076] Table 1 Blast furnace operating parameters

[0077]

[0078]

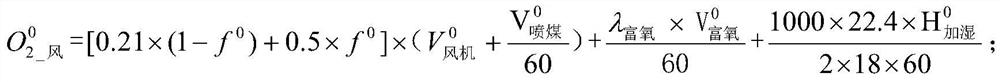

[0079] (2) into the furnace every minute O 2 Volume (Nm 3 / min)

[0080]

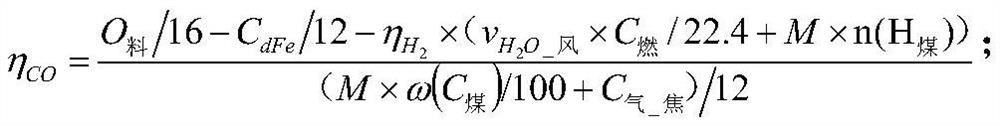

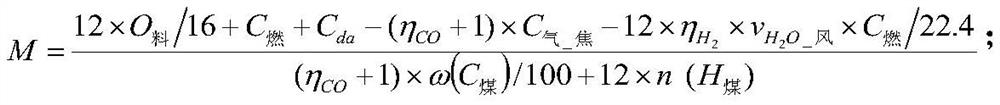

[0081] Where: f is the air percentage humidity, %;H 空气 is air humidity, g / m 3 ;V 风机 is the air volume of the fan, Nm 3 / min; V 喷煤 is the coal injection air volume, Nm3 / min; λ 富氧 O in enriched oxygen 2 The mass percentage, %; V 富氧 is the oxygen-enriched flow rate, Nm 3 / h; H 加湿 is the humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com