Waste air recycling device of hot blast stove with waste air buffer tank

A recovery device and hot blast stove technology, applied in the field of hot blast stove in the metallurgical industry, can solve the problems of failure of pressure recovery and utilization, simplicity, etc., and achieve the effect of reducing peak value and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

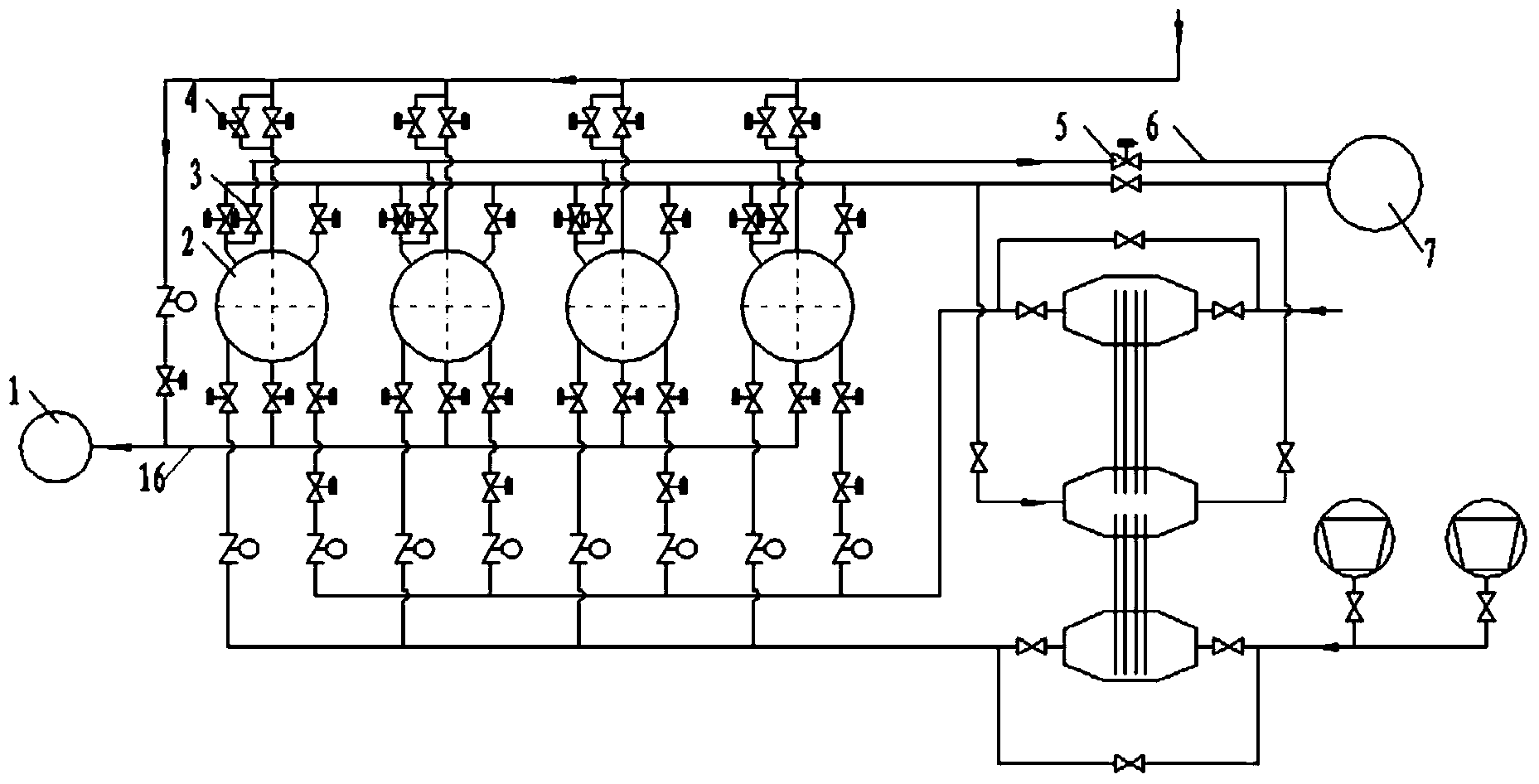

Image

Examples

Embodiment Construction

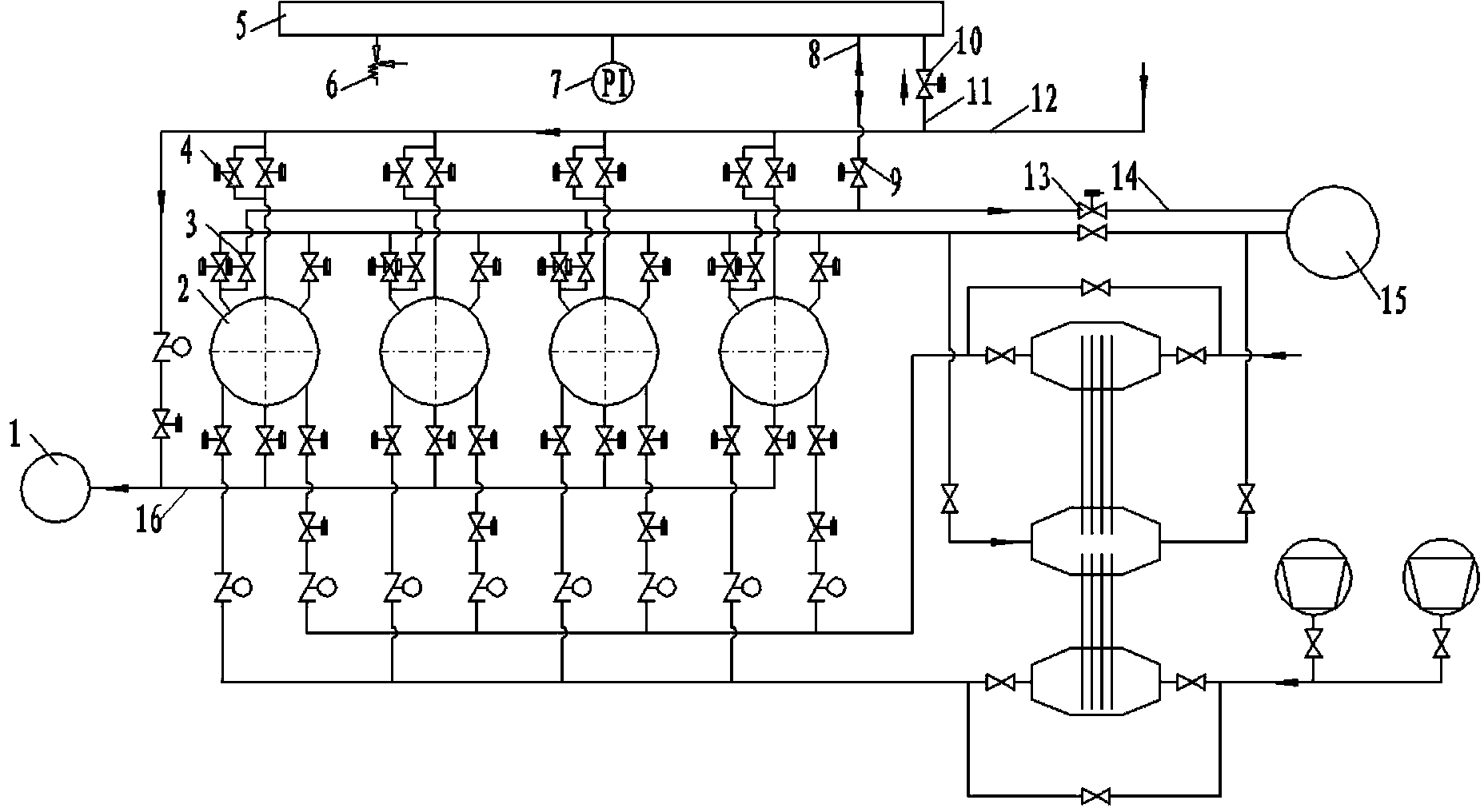

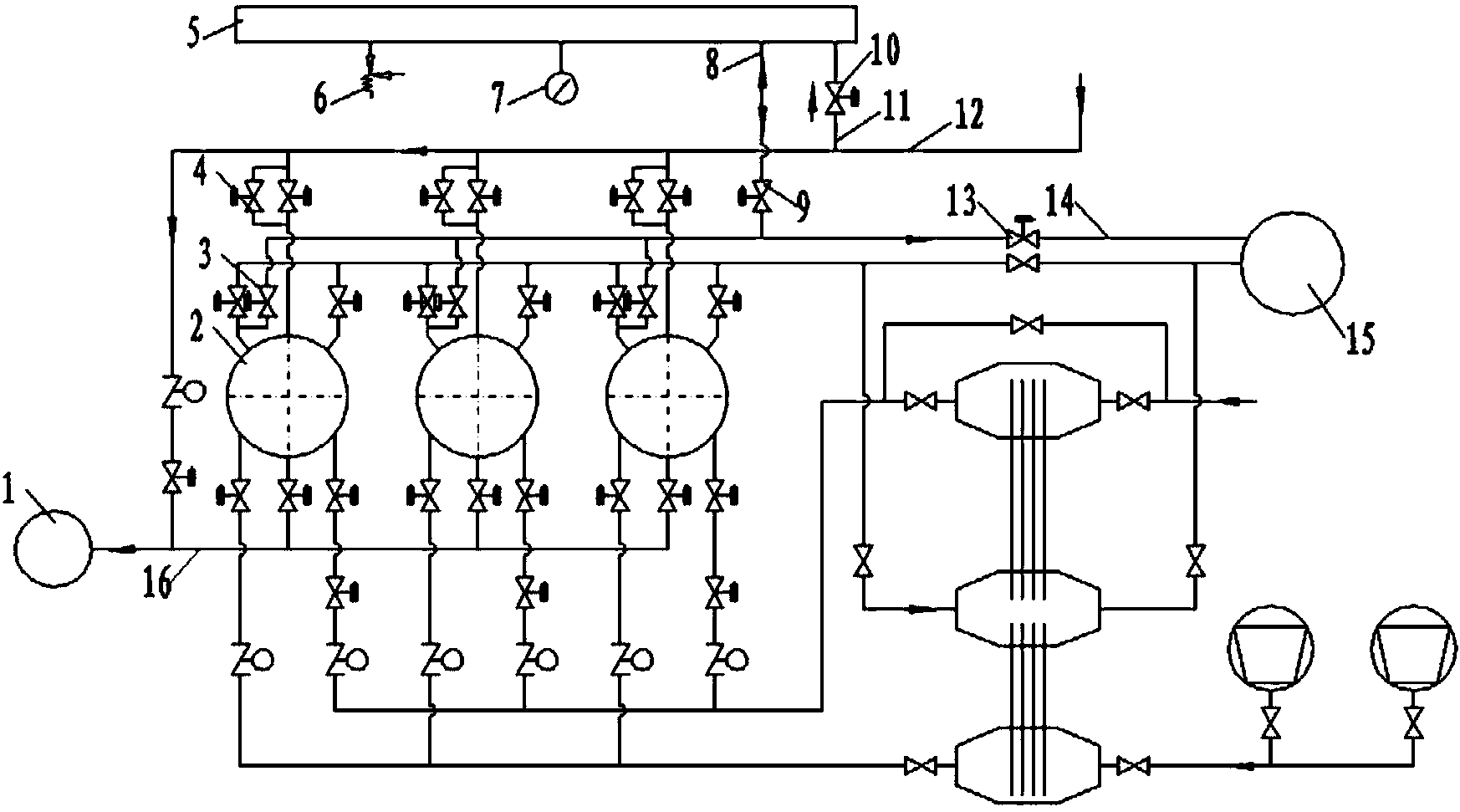

[0029] The present invention includes: blast furnace 1, hot blast stove 2, waste air valve 3, cold air equalizing valve 4, waste air buffer tank 5, safety valve 6, pressure gauge 7, waste air connecting pipe 8, waste air connecting pipe control valve 9, Cold air equalizing slow filling valve 10, slow equalizing connecting pipe 11, cold air pipe 12, waste air main control valve 13, waste air main 14, hot blast stove chimney 15, hot air pipe 16.

[0030] image 3 It is a concrete implementation of the present invention (taking 3 hot blast stoves as an example).

[0031] The waste air ducts of the three hot blast stoves merge into a waste wind main pipe 14, which is connected to the hot blast stove chimney 15, and a waste wind main control valve 13 is arranged on the waste wind main pipe. A waste air buffer tank 5 is set in the system, its working pressure is equal to the cold air pressure, and its working temperature is the highest temperature of the hot blast stove waste air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com