Patents

Literature

168 results about "Air recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laundry lint filter cleaning machine

ActiveUS9027256B2Improve efficiencyPromote repairDrying gas arrangementsOther washing machinesWaste managementAir recovery

Owner:LG ELECTRONICS INC

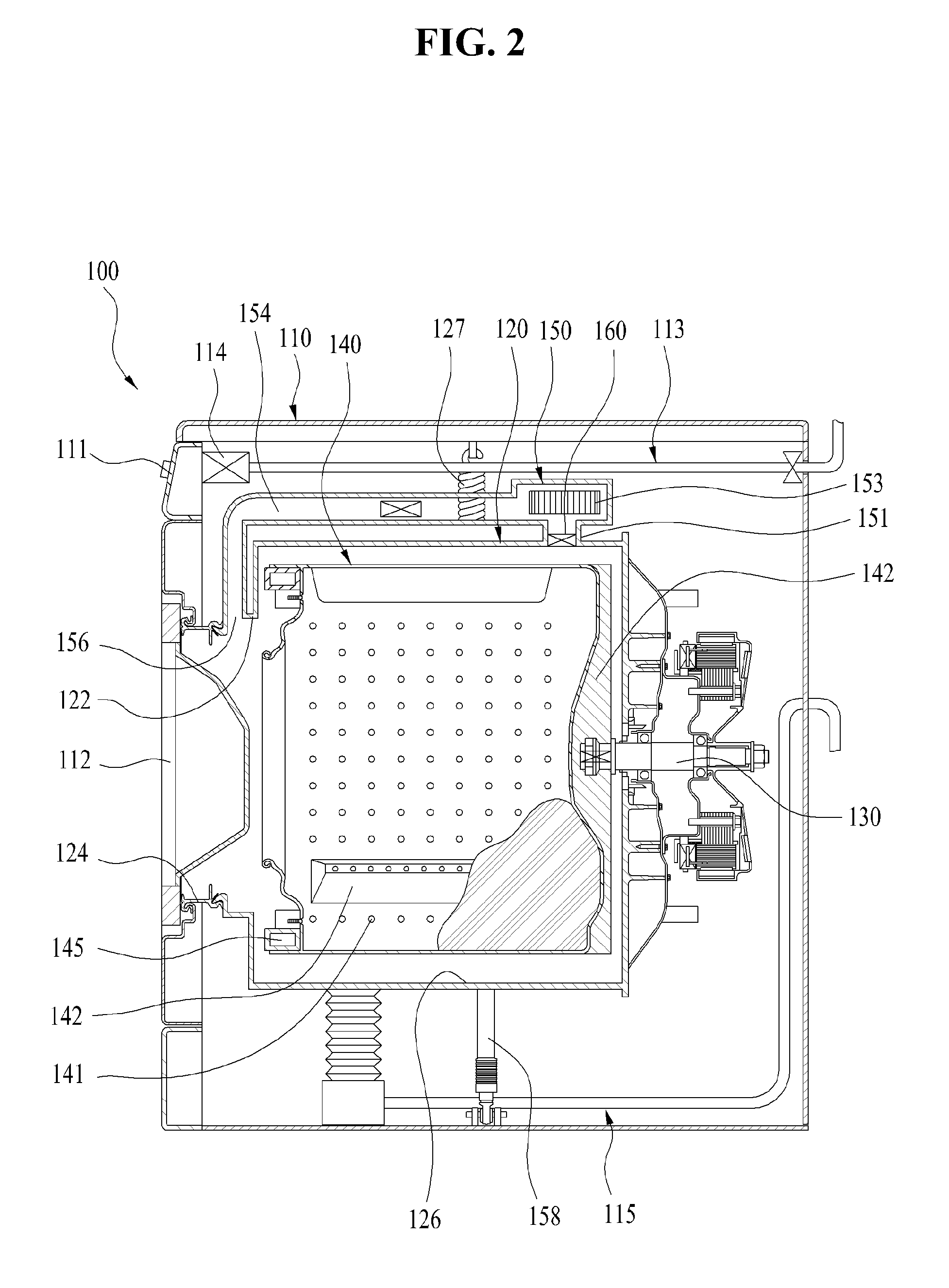

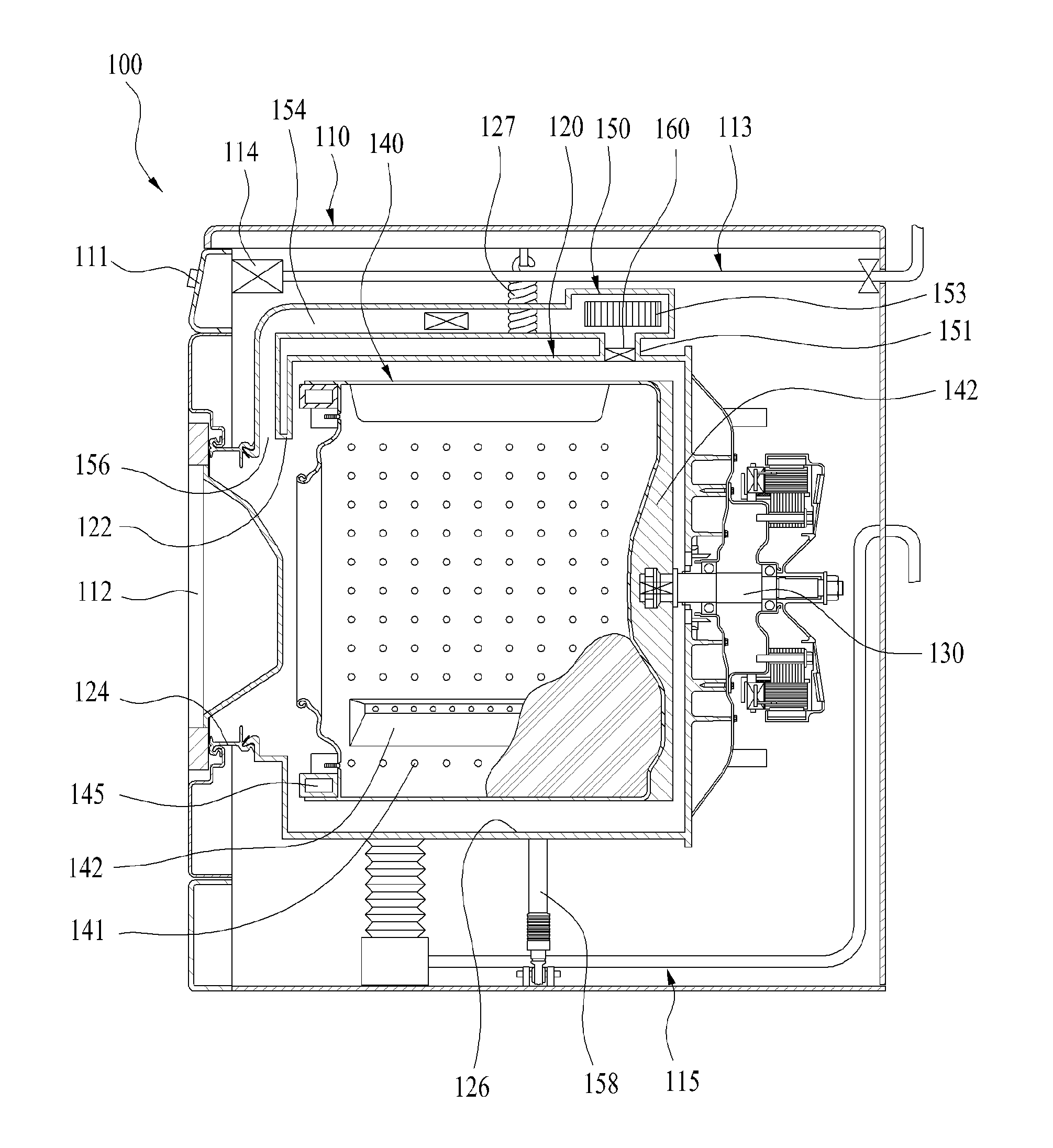

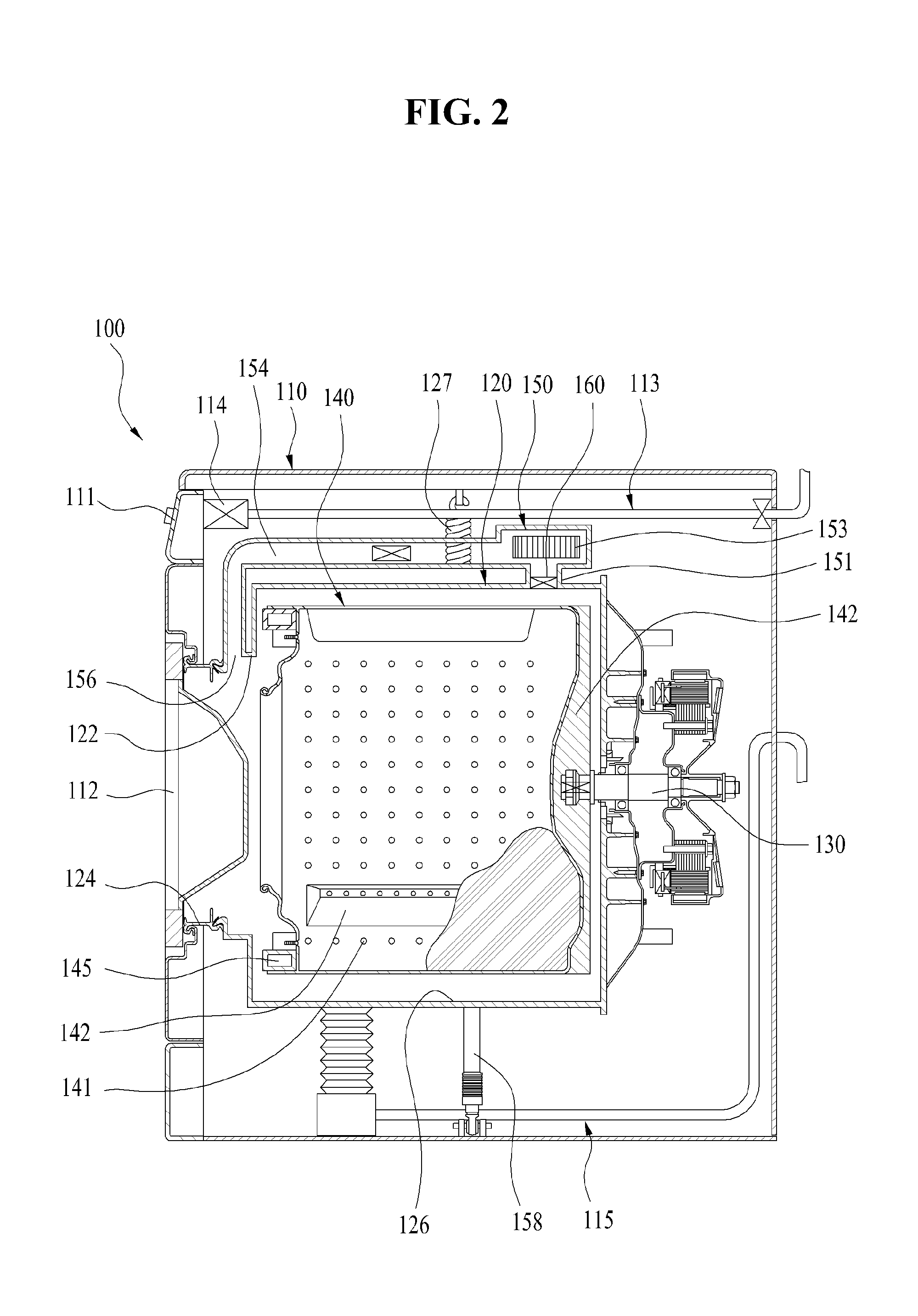

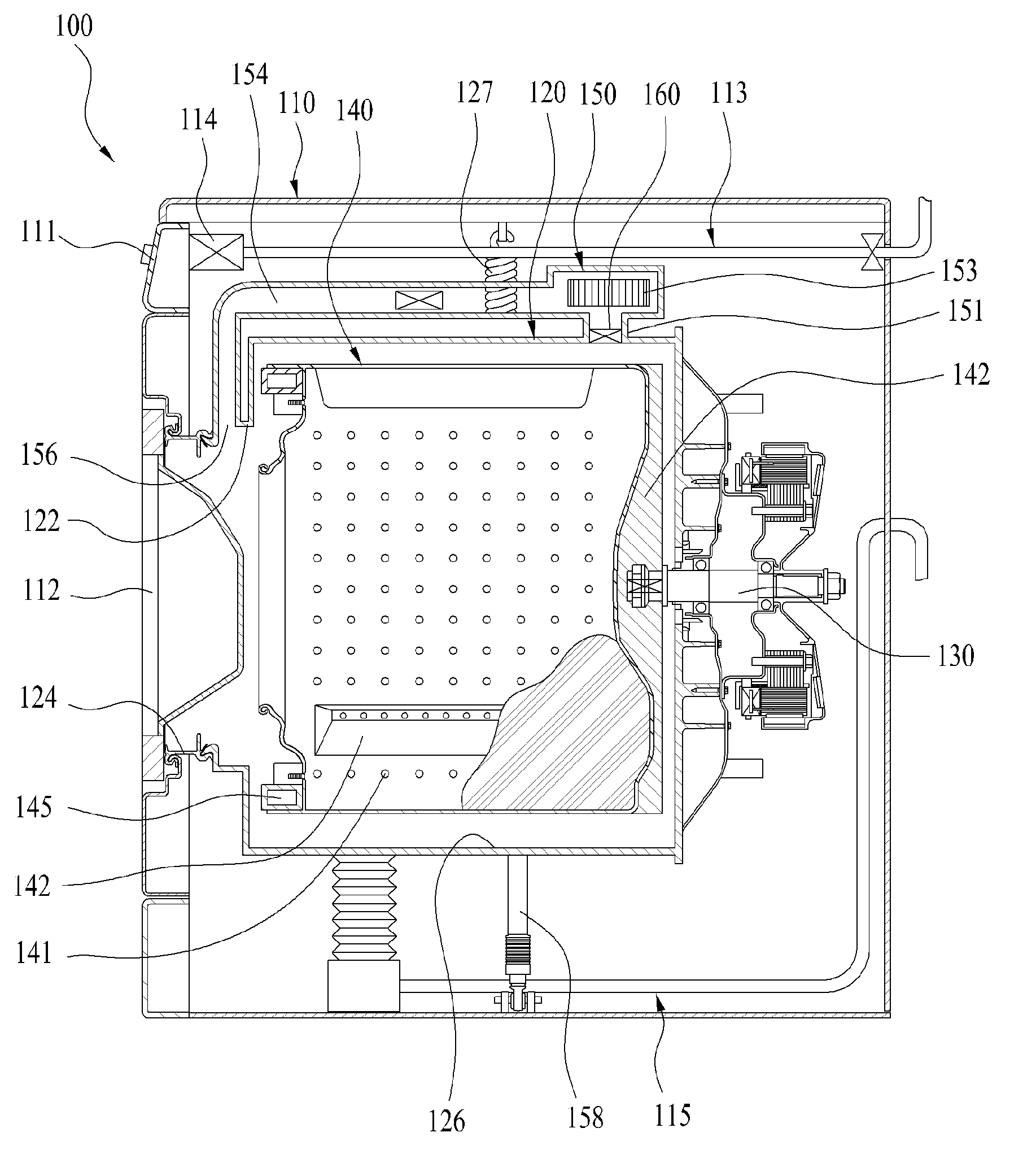

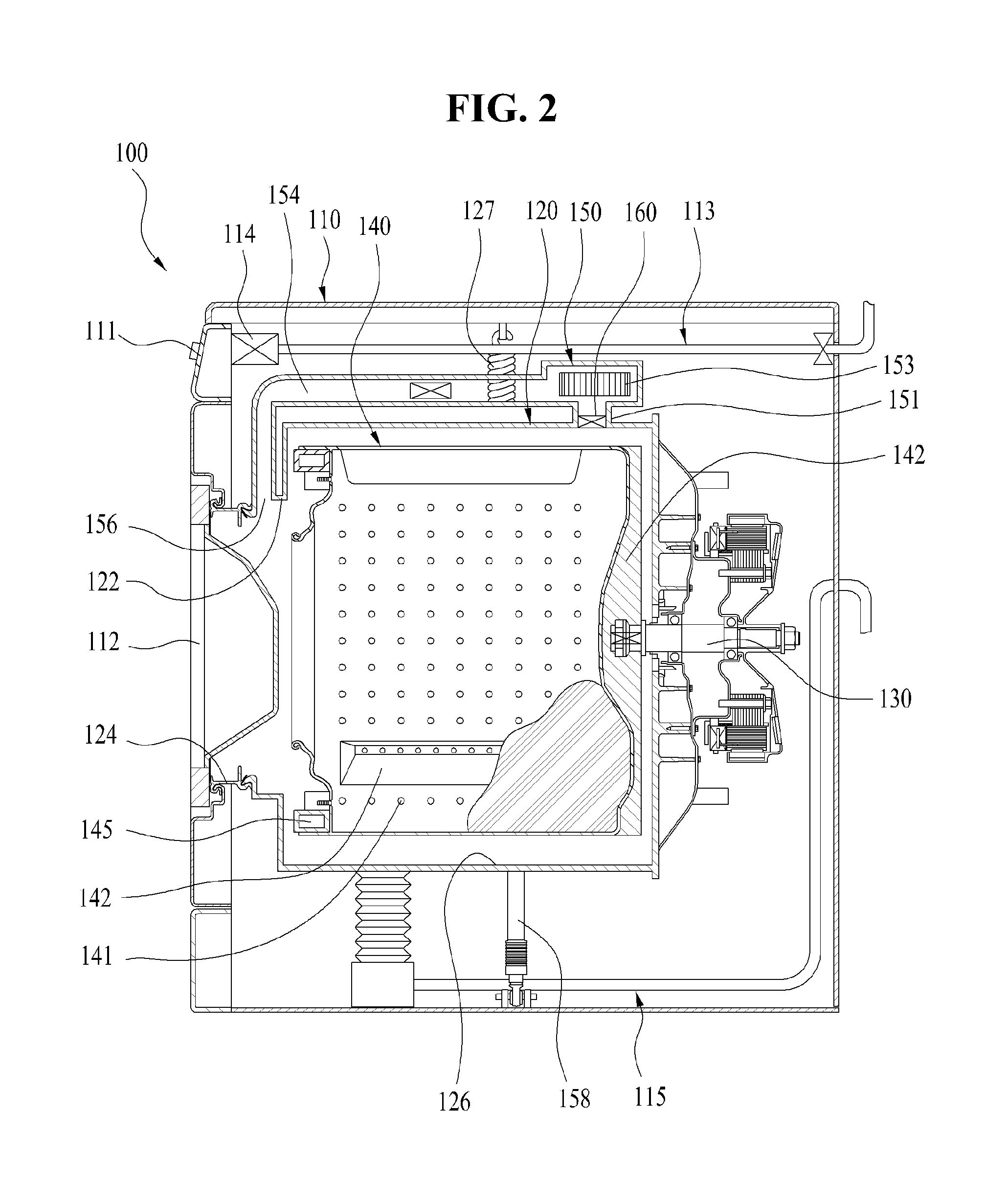

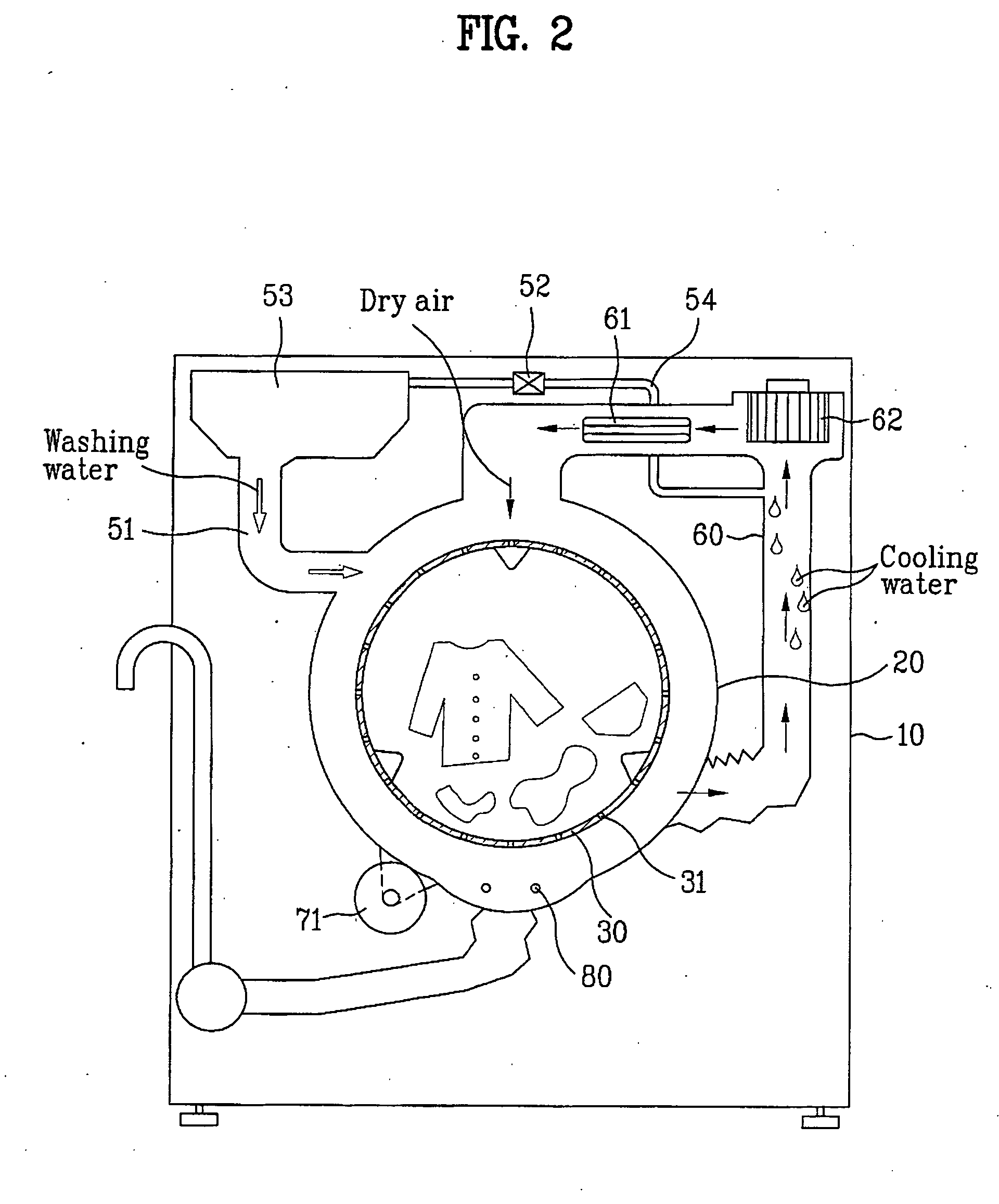

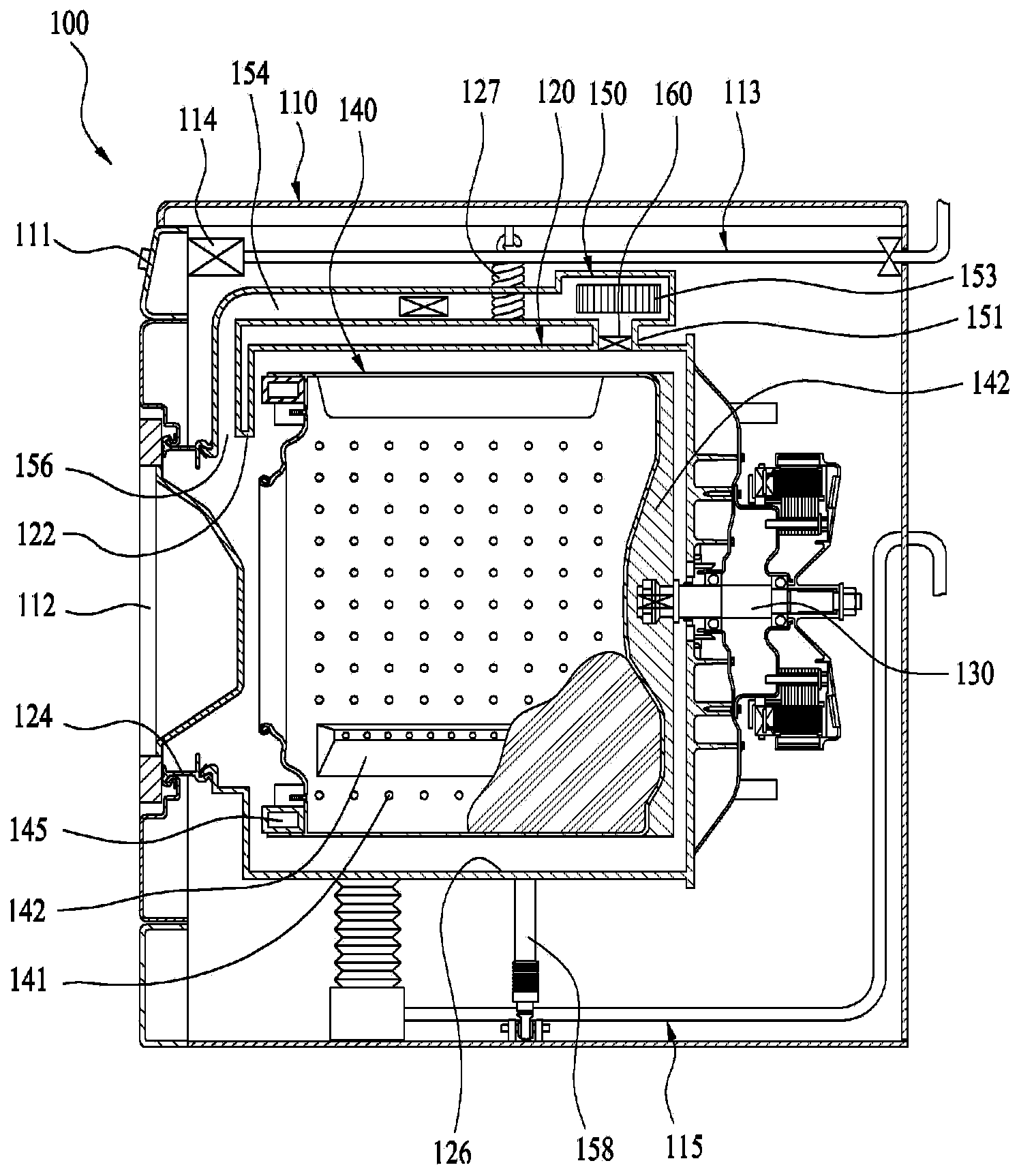

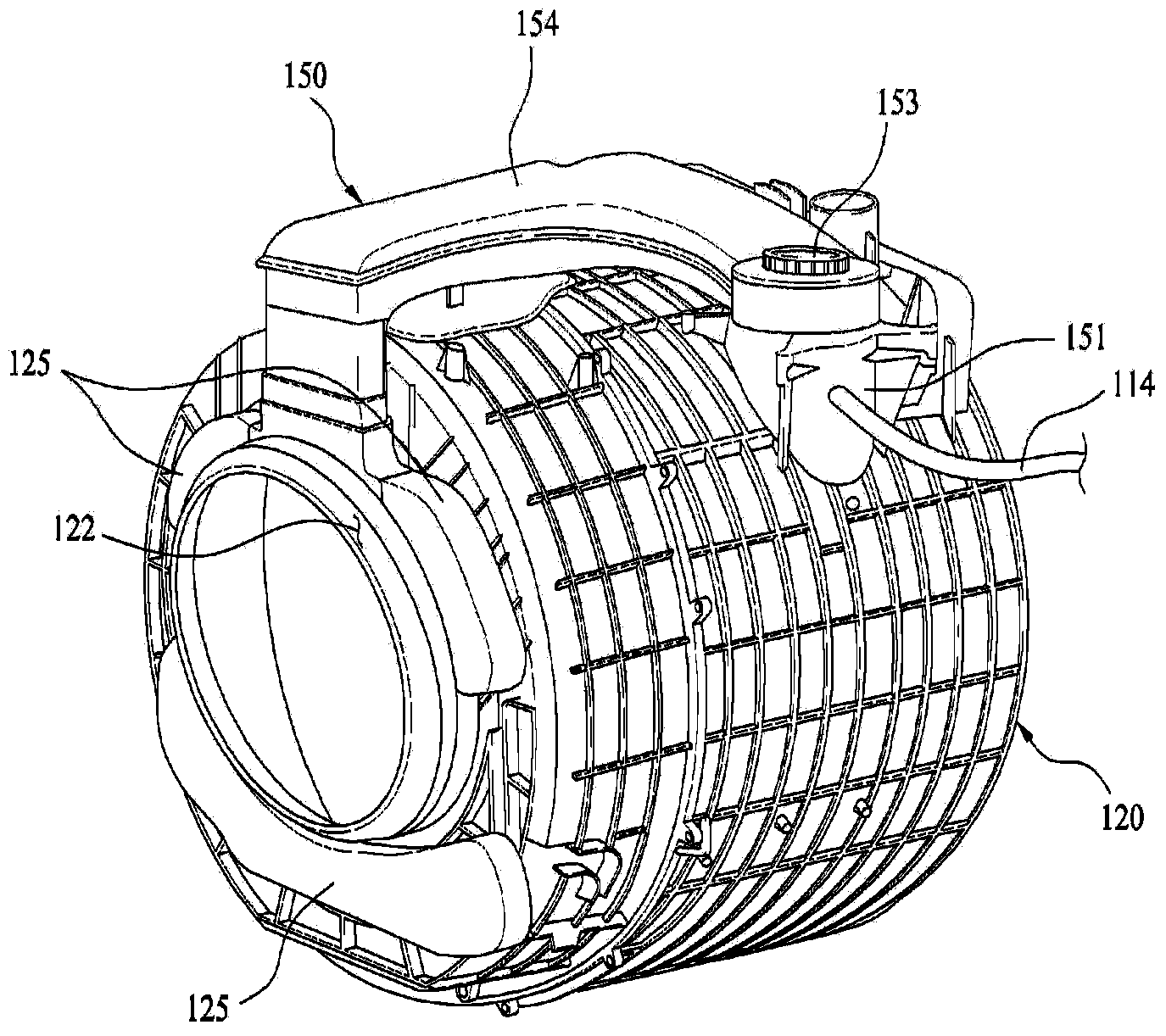

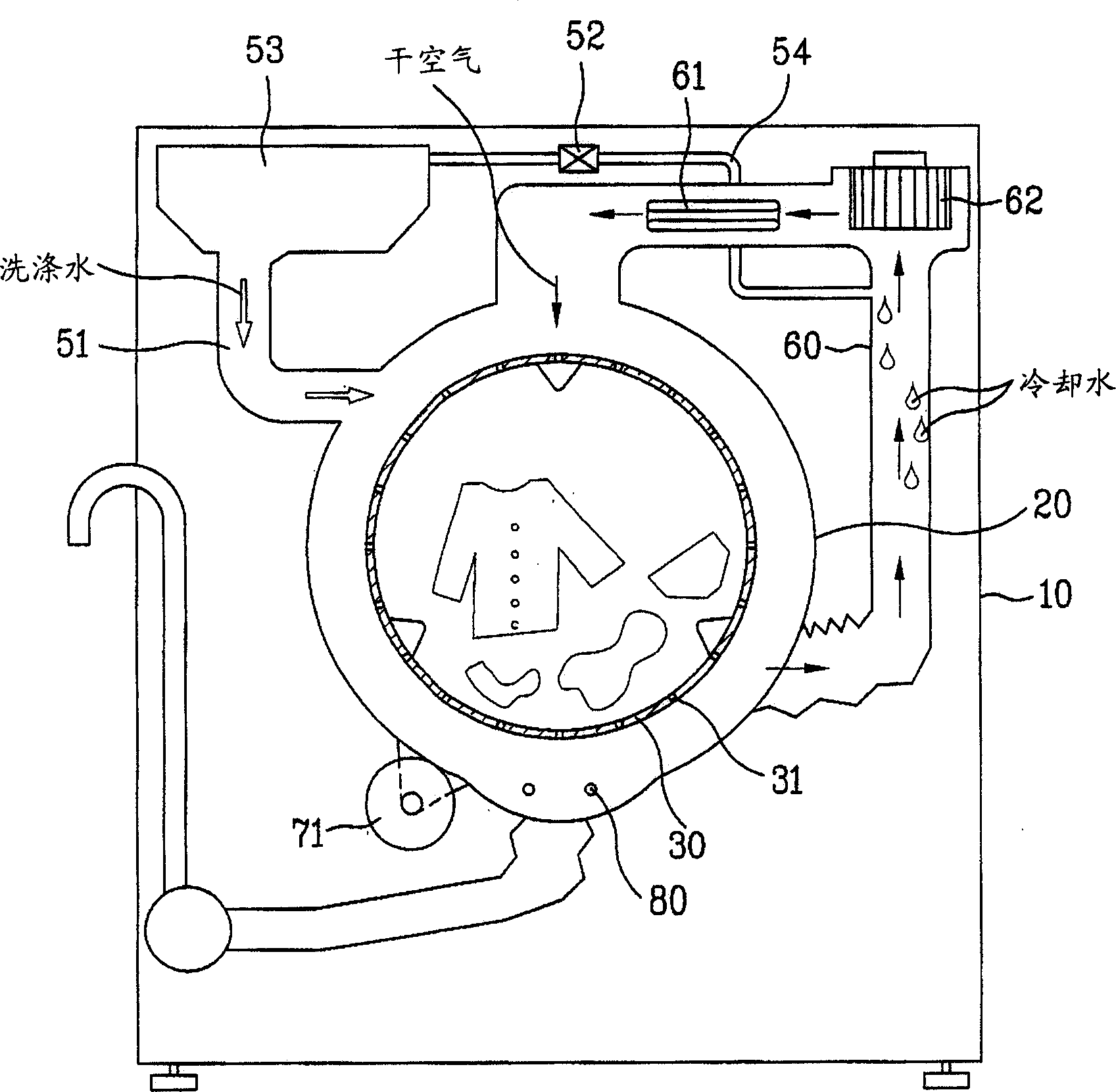

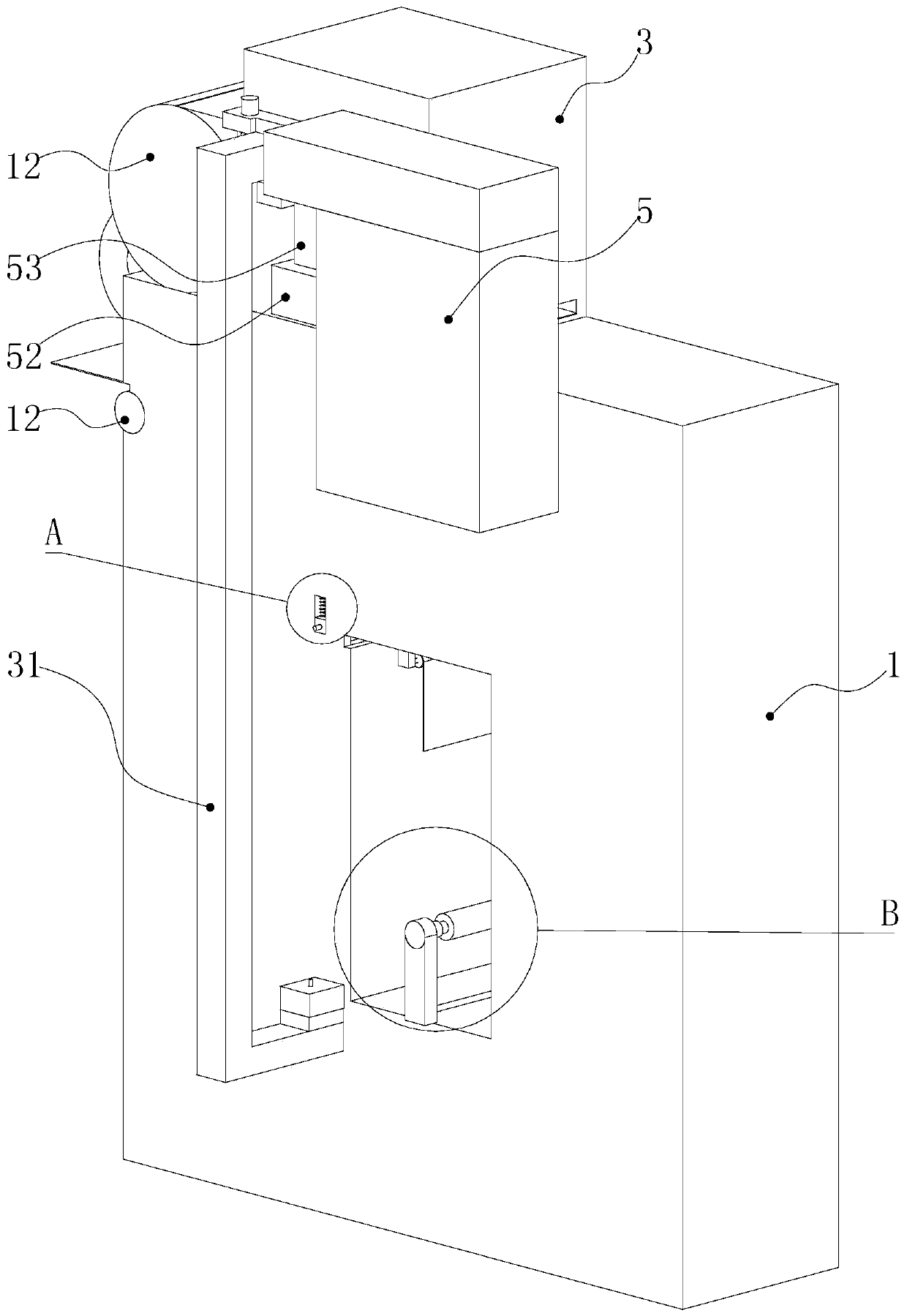

Laundry treating machine

ActiveUS20130219734A1Condensing efficiency can be improvedImprove efficiencyDrying gas arrangementsOther washing machinesLaundryAir recovery

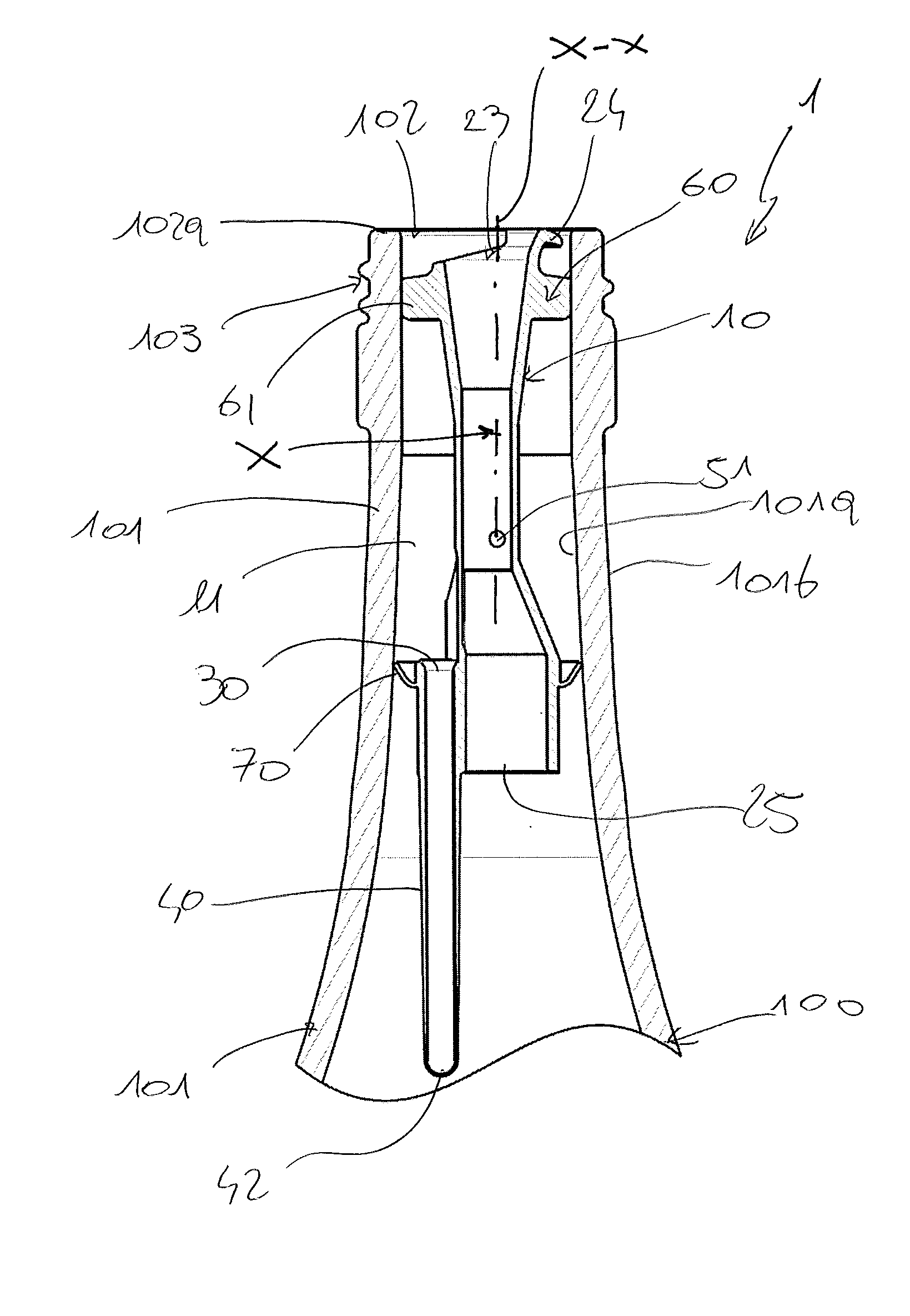

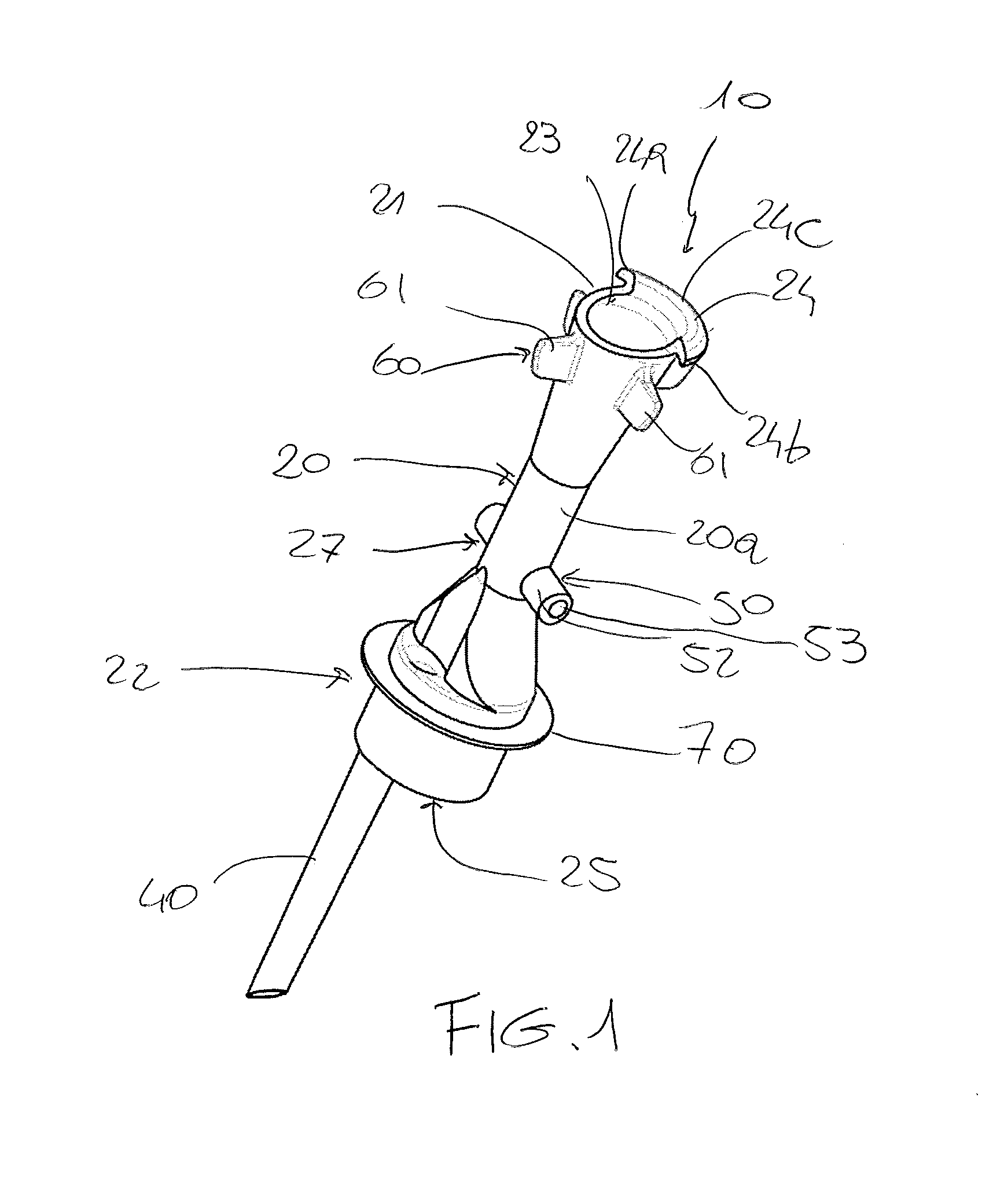

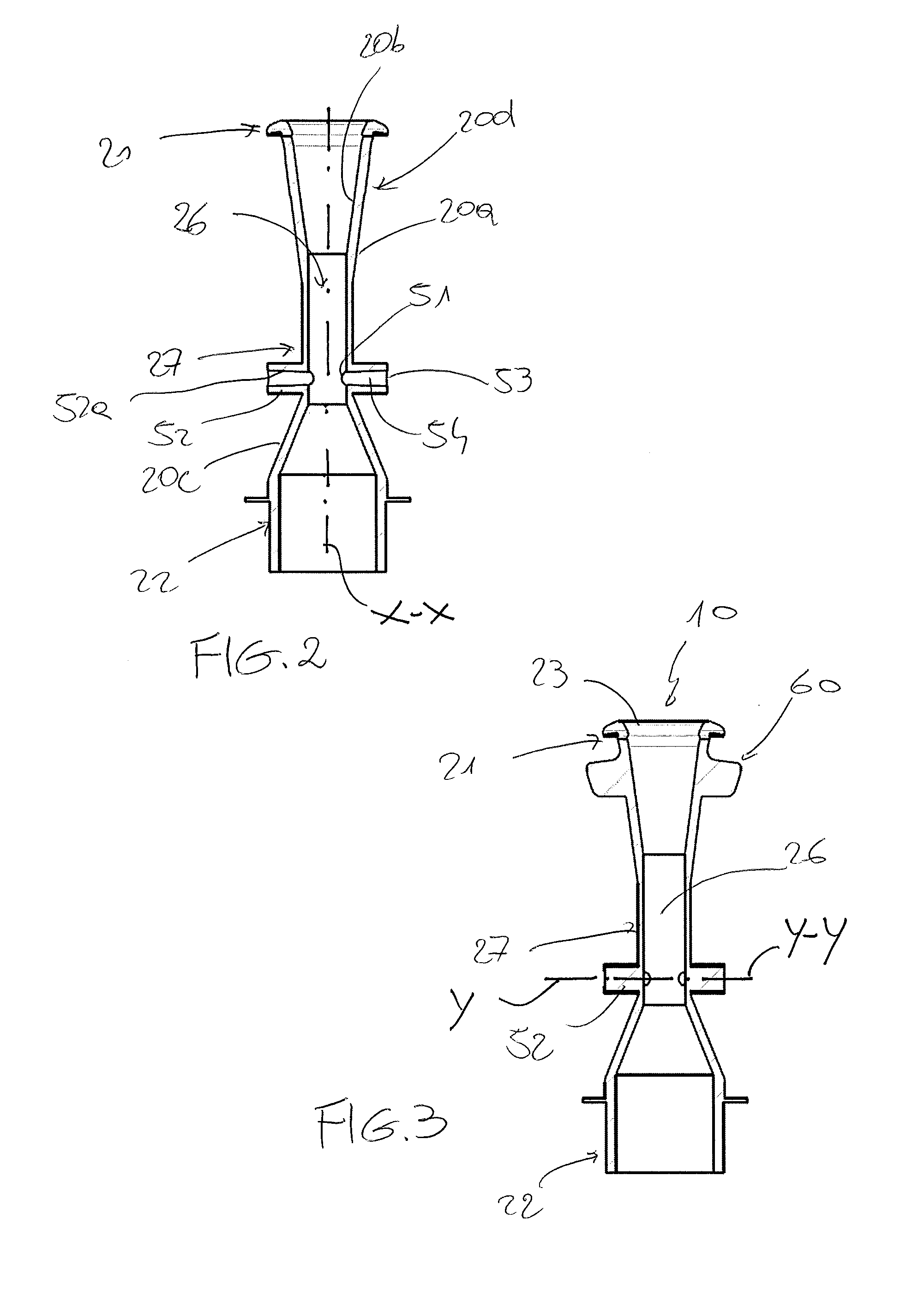

The present invention relates to a laundry treating machine, including an air supply unit for supplying air, a tub for having the air supplied thereto from the air supply unit to treat the laundry, the tub having an air recovery opening formed in an outside circumferential surface thereof for recovery of the air to the air supply unit, a lint filter mounted to an inside of the air recovery opening for filtering the lint from the air, a filter cleaning unit for spraying cleaning water to separate the lint from the lint filter, and a flow passage member for guiding the cleaning water dropping from the lint filter to an inside of the tub to an inside surface of the tub.

Owner:LG ELECTRONICS INC

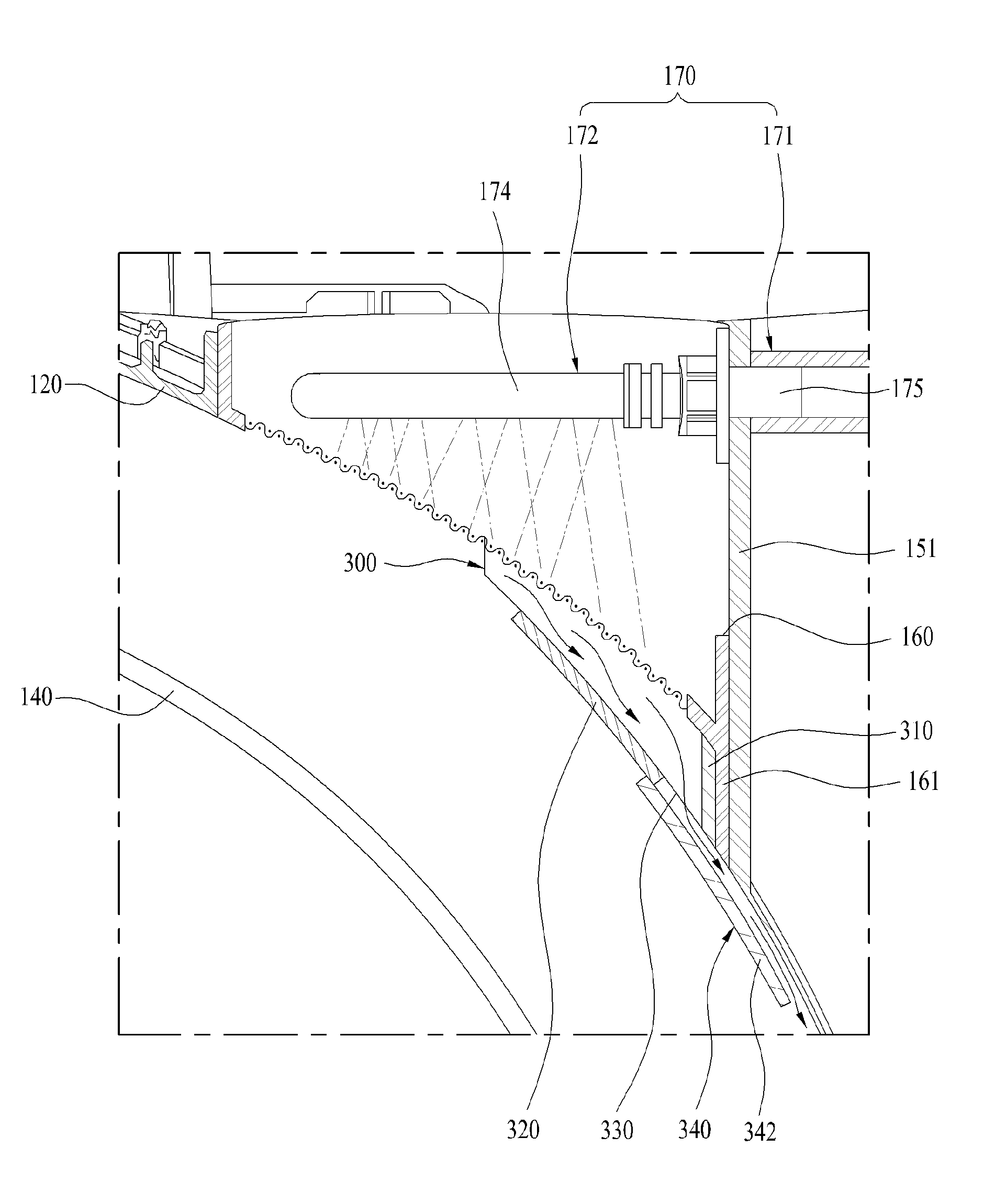

Laundry treating machine

ActiveUS20130212894A1Condensing efficiency can be improvedImprove efficiencyDrying gas arrangementsOther washing machinesLaundryAir recovery

The present invention relates to a laundry treating machine, and more particularly, a laundry treating machine including an air supply unit for supplying air, a tub for having the air supplied thereto from the air supply unit to treat the laundry, the tub having an air recovery opening formed in an outside circumferential surface thereof for recovery of the air to the air supply unit, a lint filter mounted to an inside of the air recovery opening for filtering the lint from the air, and a filter cleaning unit for spraying cleaning water toward the lint filter to separate the lint from the lint filter, wherein the filter cleaning unit is extended and branched to the inside of the air recovery opening for spraying the cleaning water to the lint filter.

Owner:LG ELECTRONICS INC

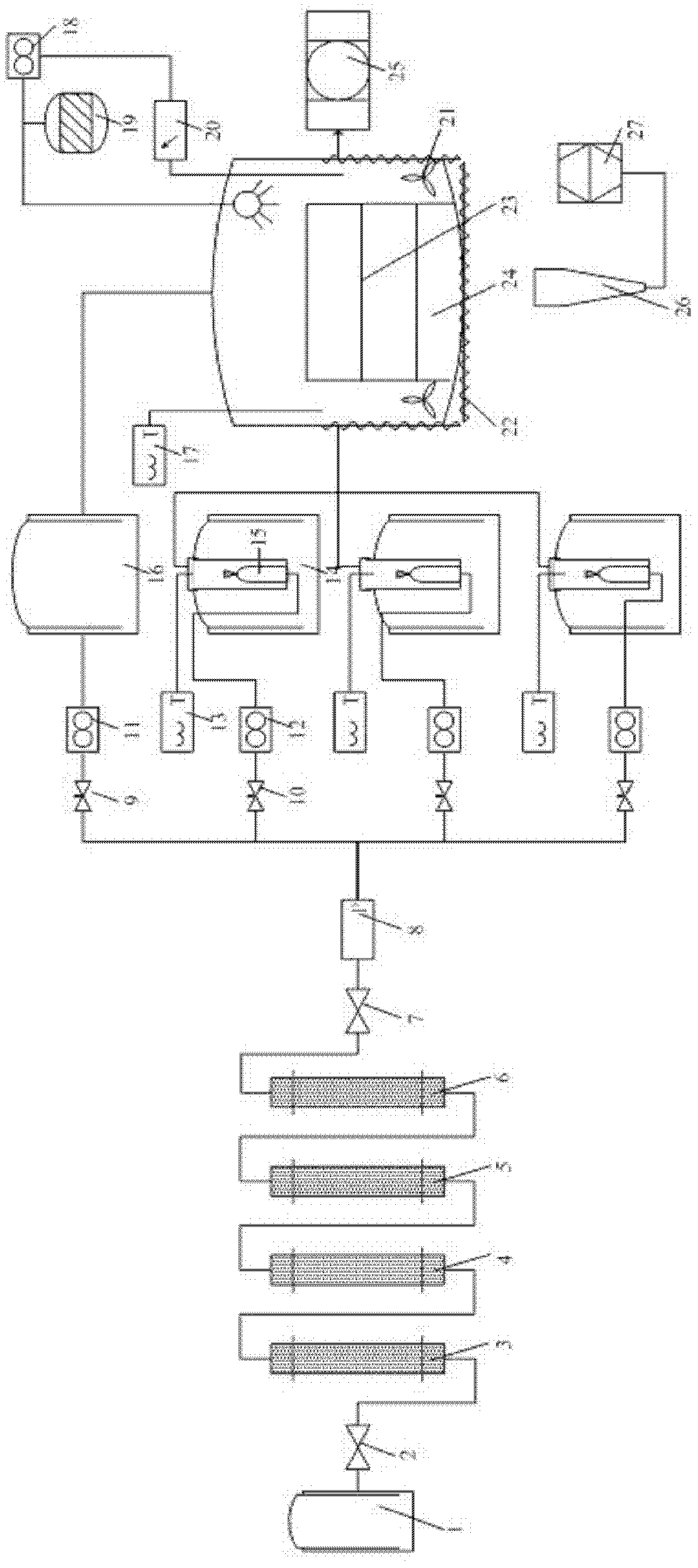

Trace corrosive gas environmental test box

ActiveCN102539311AMultiple gas pathsWith humidity controlWeather/light/corrosion resistanceExperimental researchLight pollution

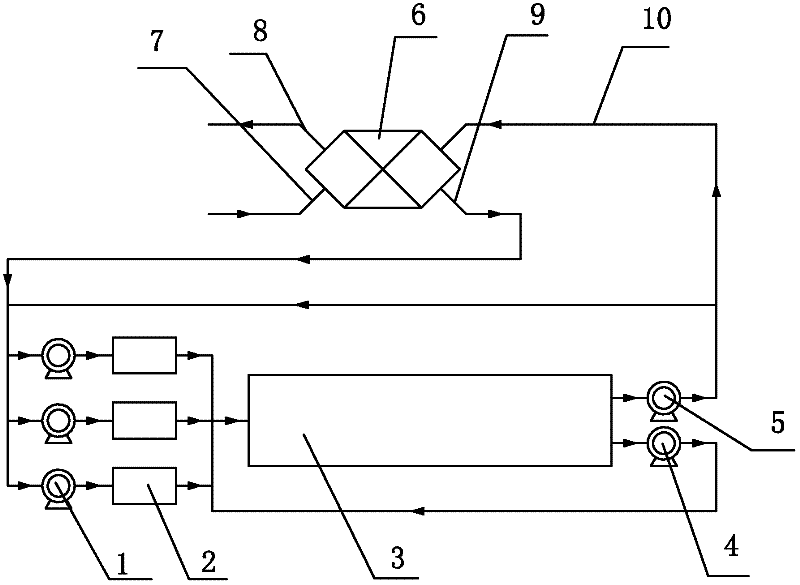

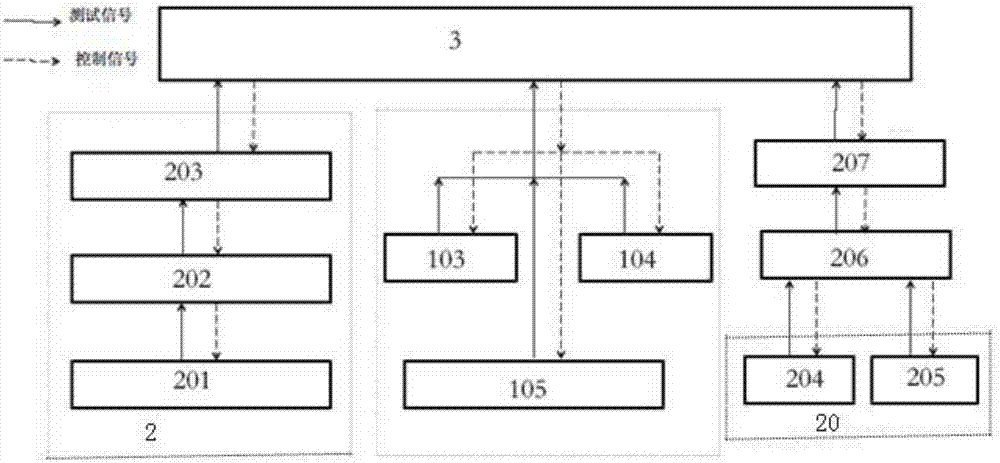

The invention discloses a trace corrosive gas environmental test box and belongs to the technical field of environment friendliness and material corrosion research. The trace corrosive gas environmental test box comprises a clean air supply module, a trace corrosive gas generation module, a sample corrosion test reaction module, an air recovery module and an in-situ image acquisition system. A multi-gas-path trace corrosive gas environmental test box which can perform in-situ observation on the surface state of a sample and control temperature to be 25 to 80 DEG C, humidity to be 40 to 97 percent and the concentration of the trace corrosive gas to be 10 to 10,000ppb is implemented. The trace corrosive gas environmental test box has the advantages of occupying small floor, along with simple structure, convenience in operation, light pollution, high accuracy, capacity of controlling temperature, humidity and the concentration of polluted air simultaneously and acquiring images of a sample state in real time, and can be applied to scientific research and engineering experimental research.

Owner:UNIV OF SCI & TECH BEIJING

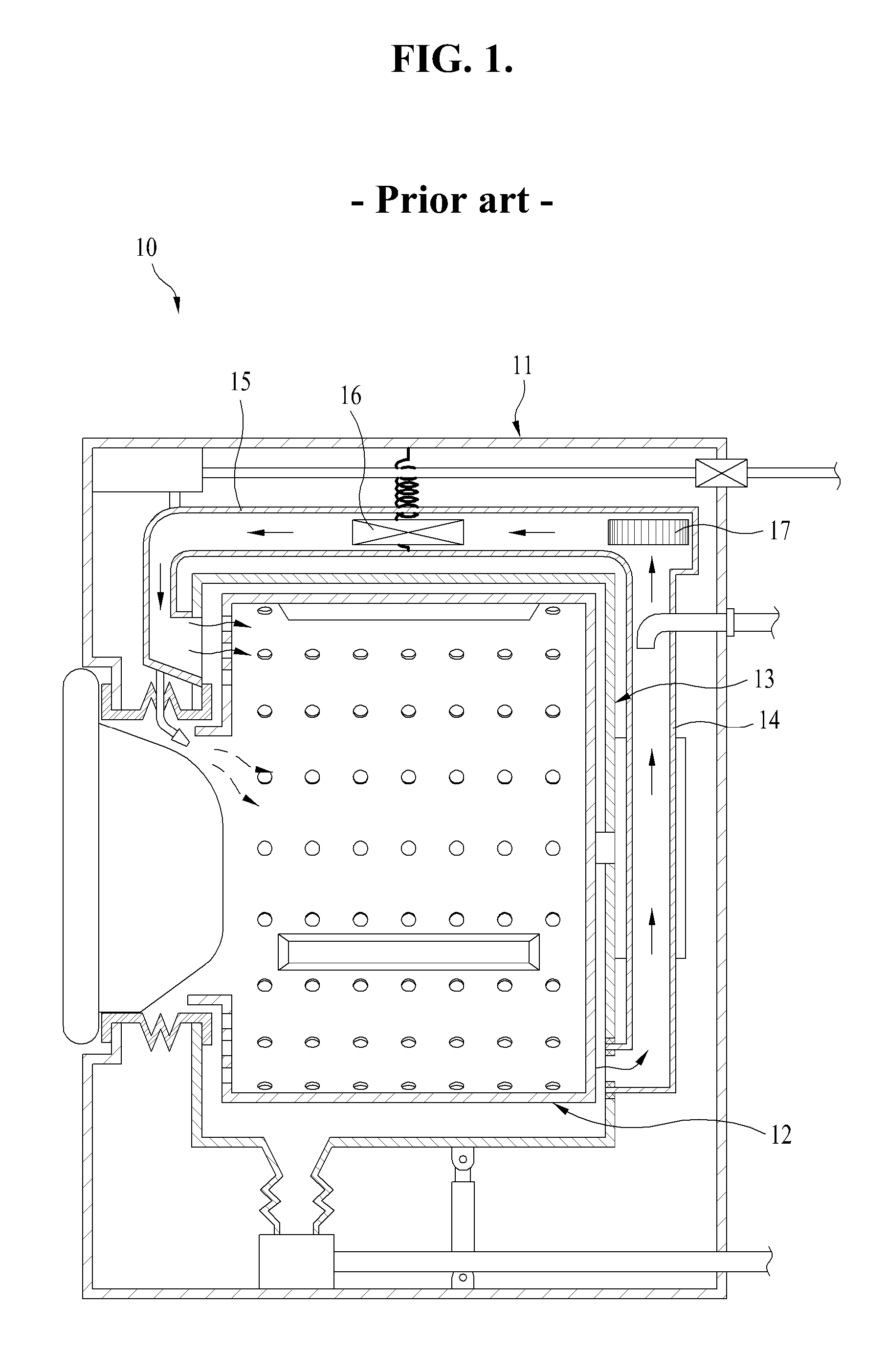

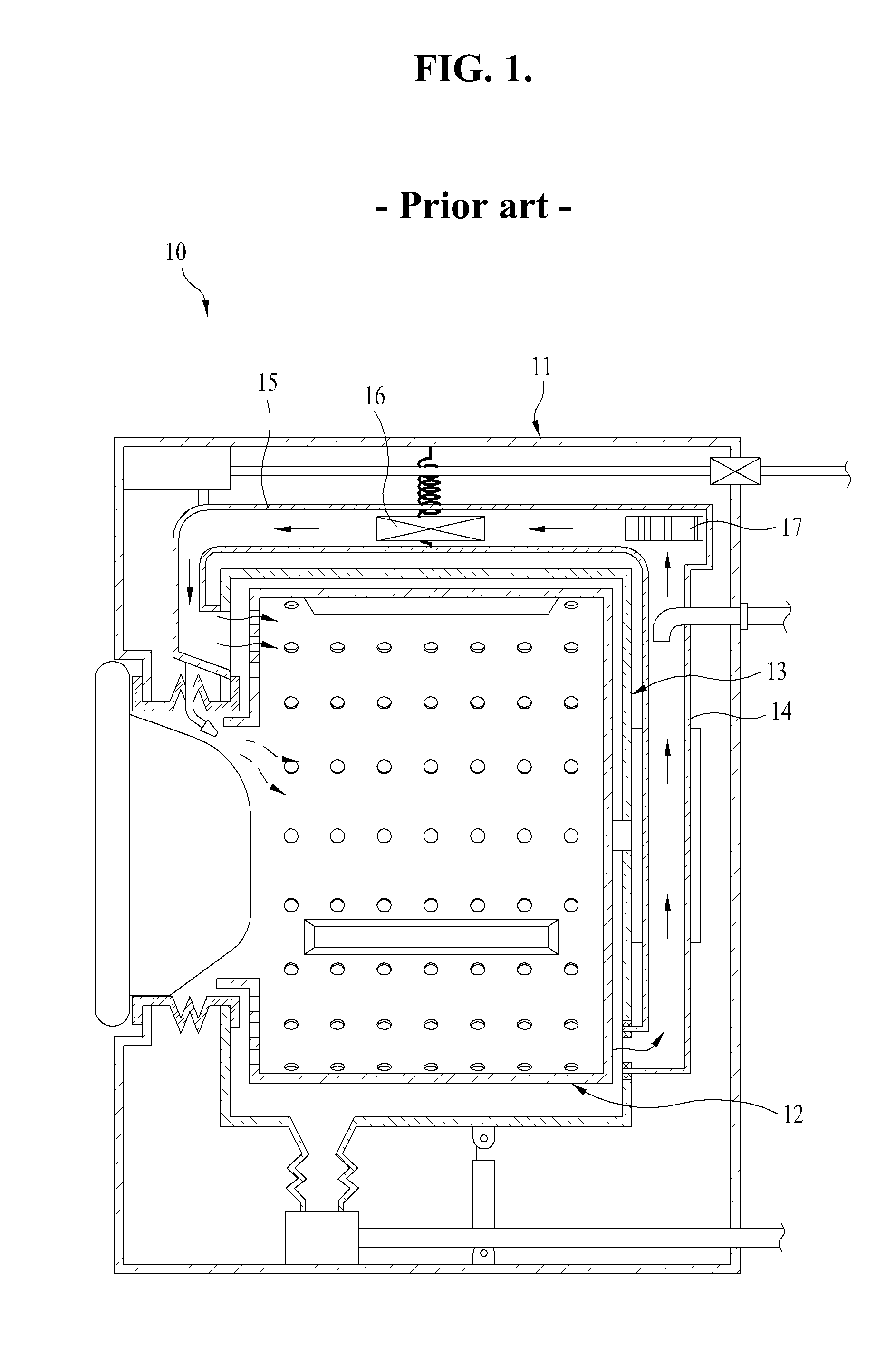

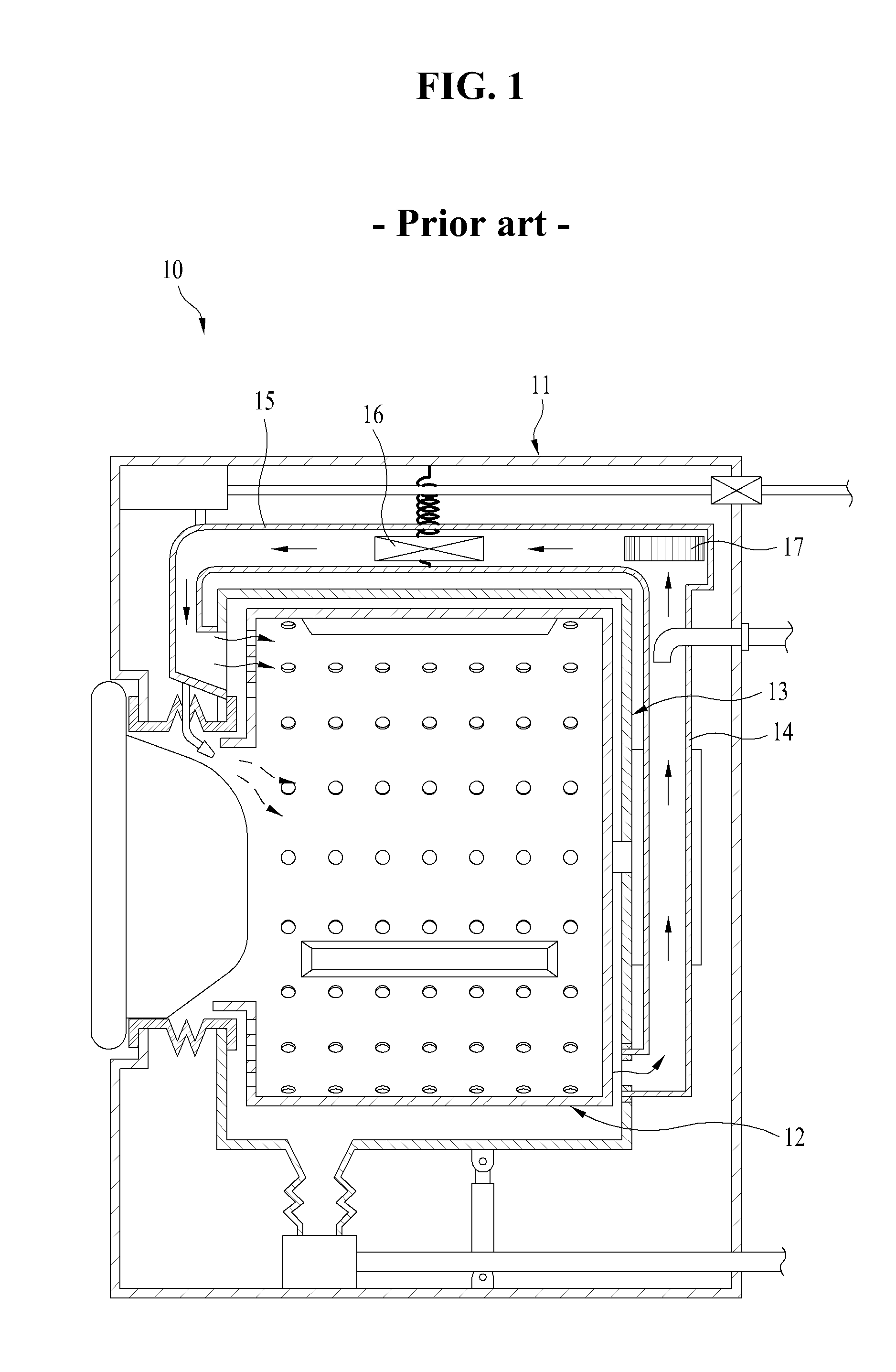

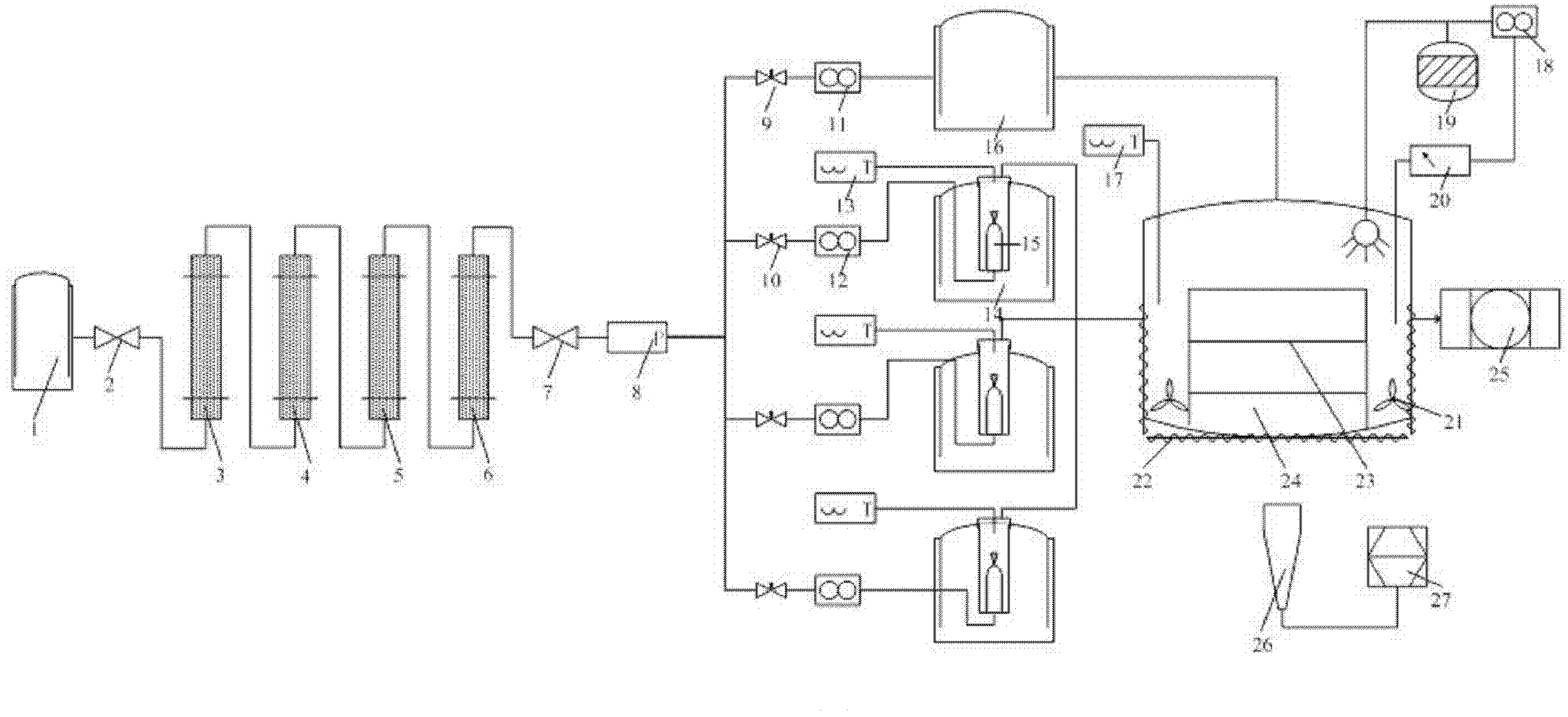

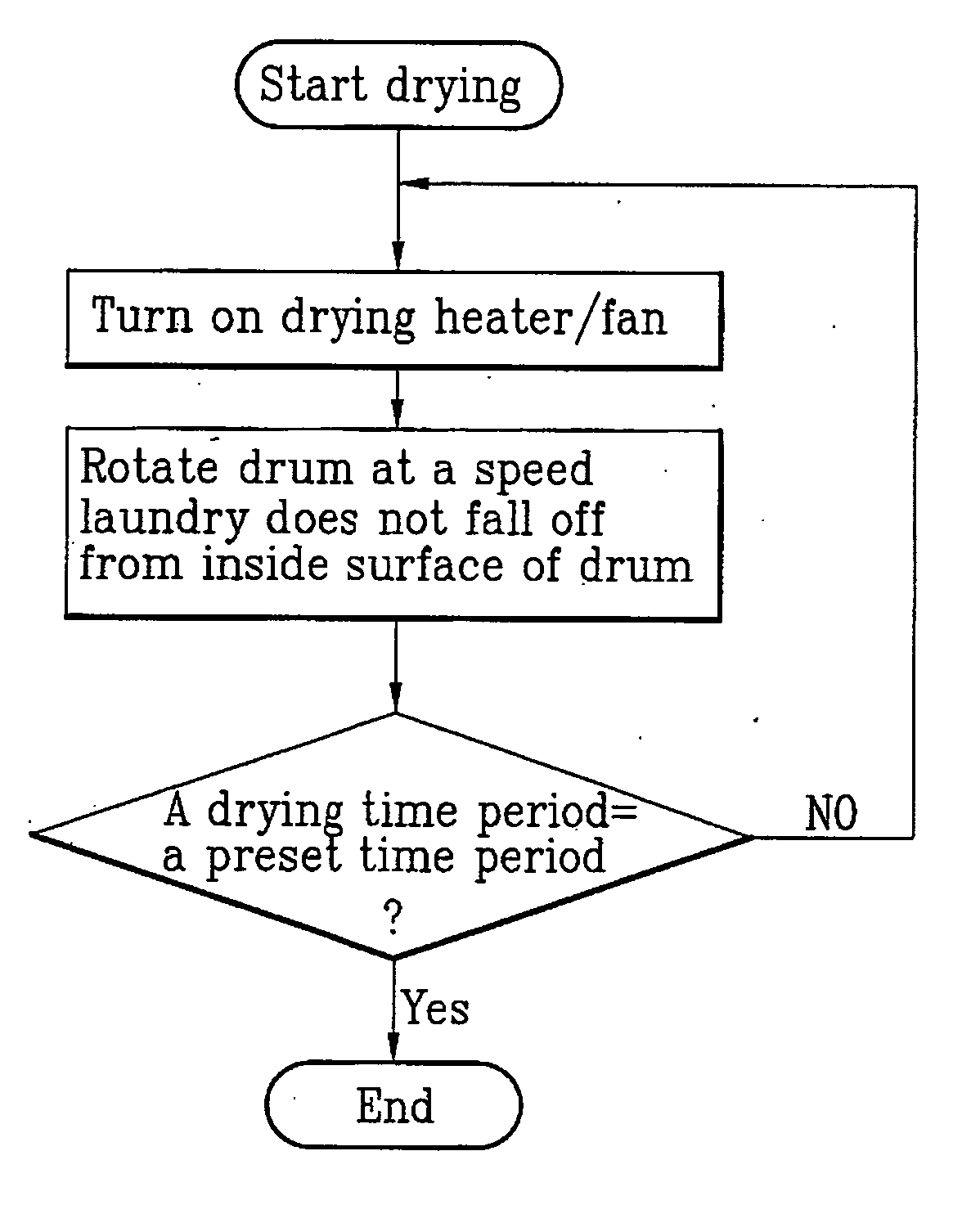

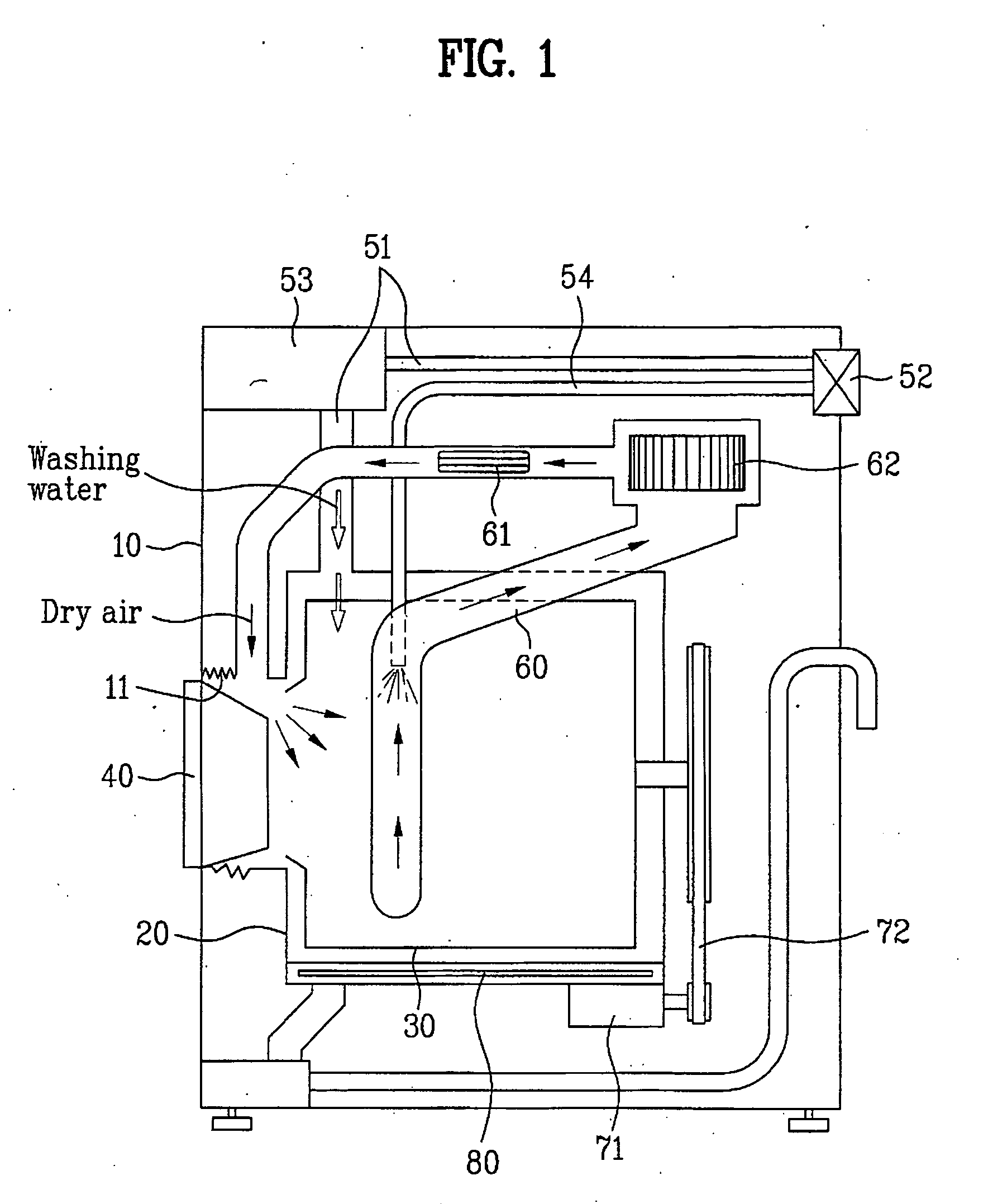

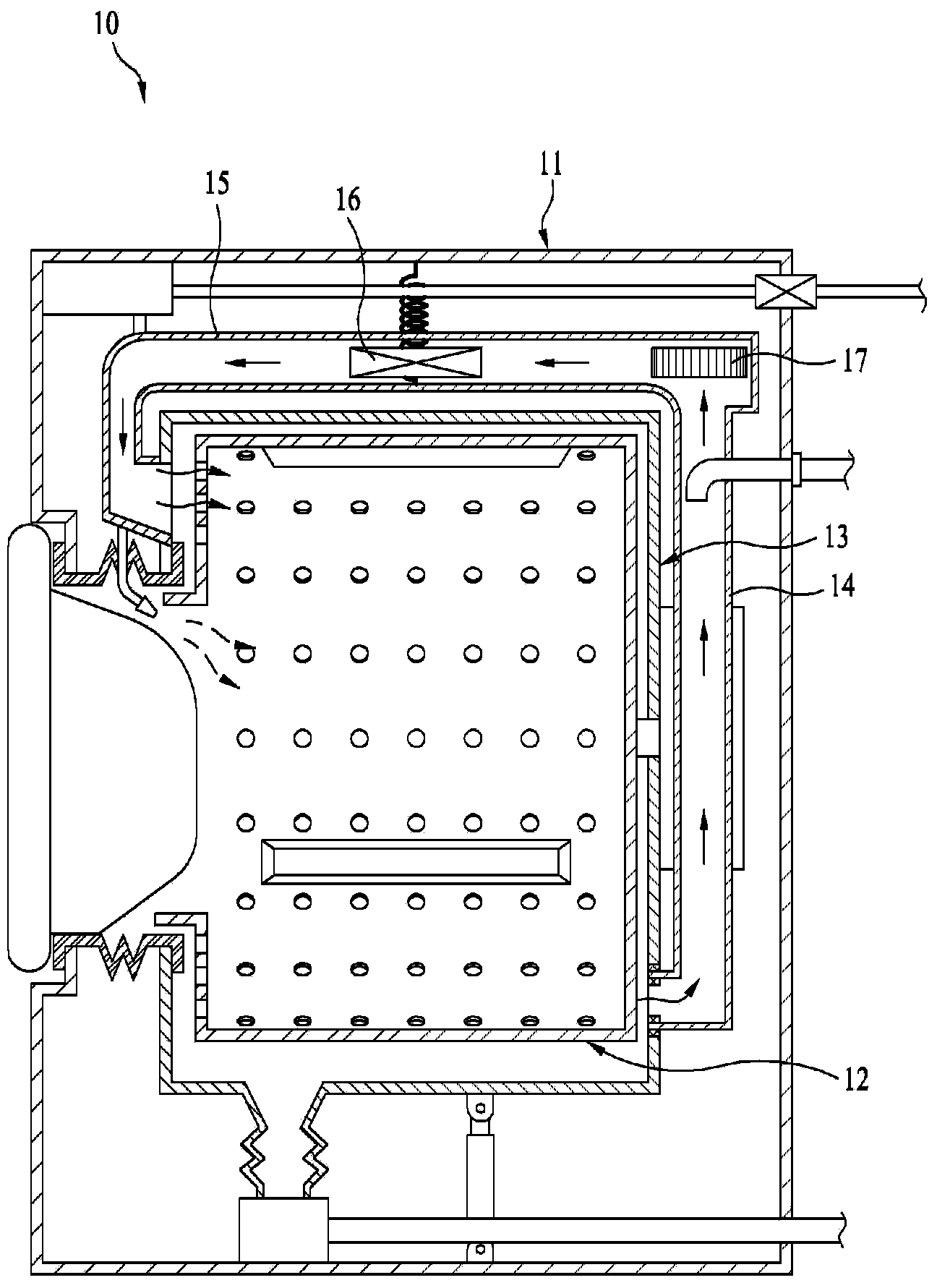

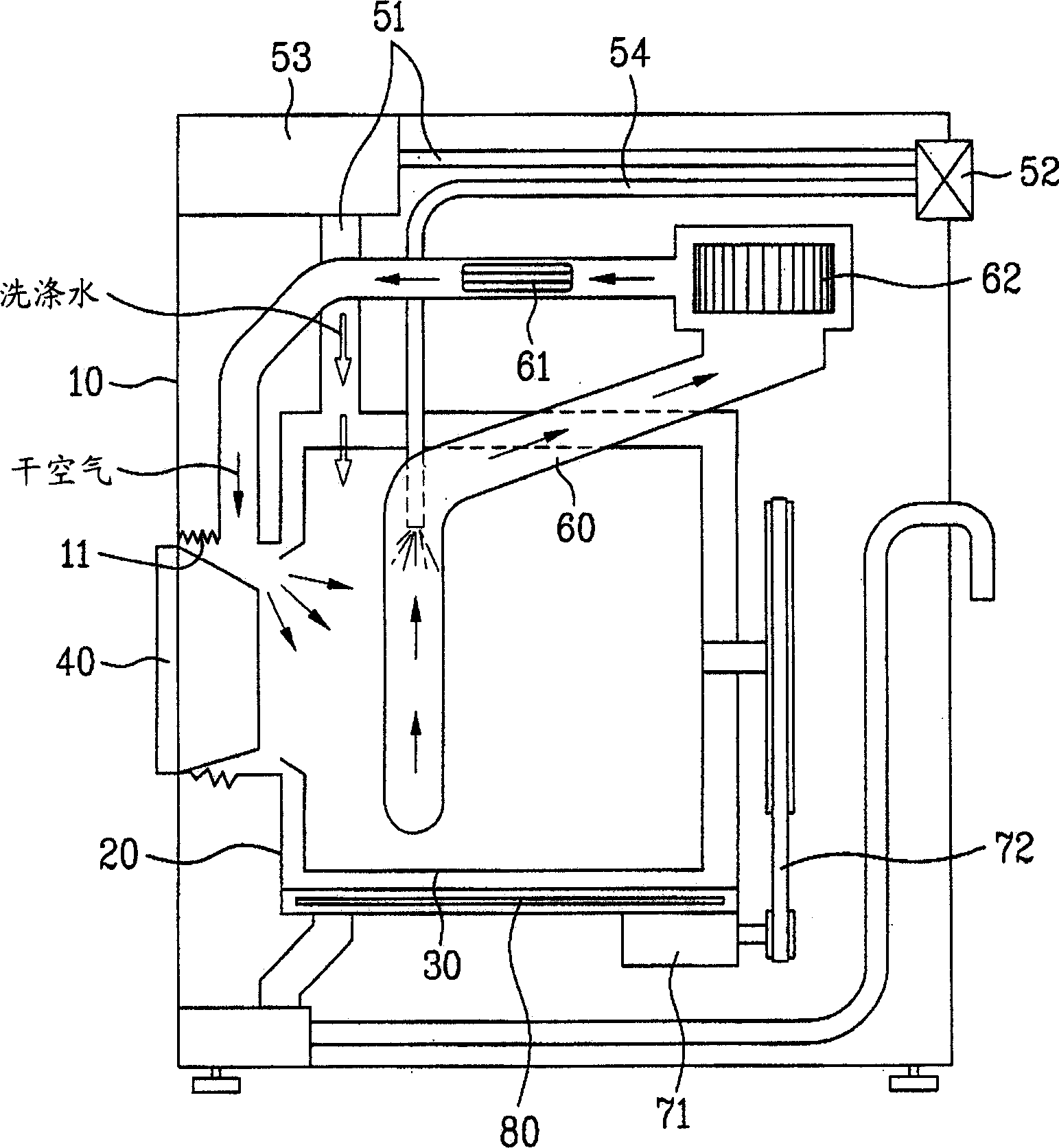

Structure for supplying hot air for drying clothes in drum type washing machine and operation control method thereof

InactiveUS20050188471A1Improve efficiencyImprove performanceOther washing machinesWashing machine with receptaclesEngineeringHot blast

Structure for supplying hot air to a drum washing machine, and operation control method thereof, in which uniform introduction of hot air deep into an inside of a drum is made possible for enhancing drying capability and efficiency. For this, a drum washing machine includes a tub for holding washing water, a drum rotatably mounted in the tub, for introducing laundry therein, a drying heater for heating air being supplied to an inside of the drum, a drying duct forming a flow passage for supplying hot air heated by the drying heater to the inside of the drum, a fan for forced supply of the hot air heated by the drying heater to the inside of the drum, a hot air inlet at a front side of the drum for supplying the hot air to the inside of the drum, and a humid air recovery opening at a rear side of the drum for recovering humid air from the inside of the drum, and the operation control method of a drum washing machine includes the step of supplying hot air to an inside of the drum while rotating the drum at a speed equal to, or higher than a speed enough to keep the laundry in the drum attached to, and not fall off from, the inside surface of the drum in progressing a drying cycle.

Owner:LG ELECTRONICS INC

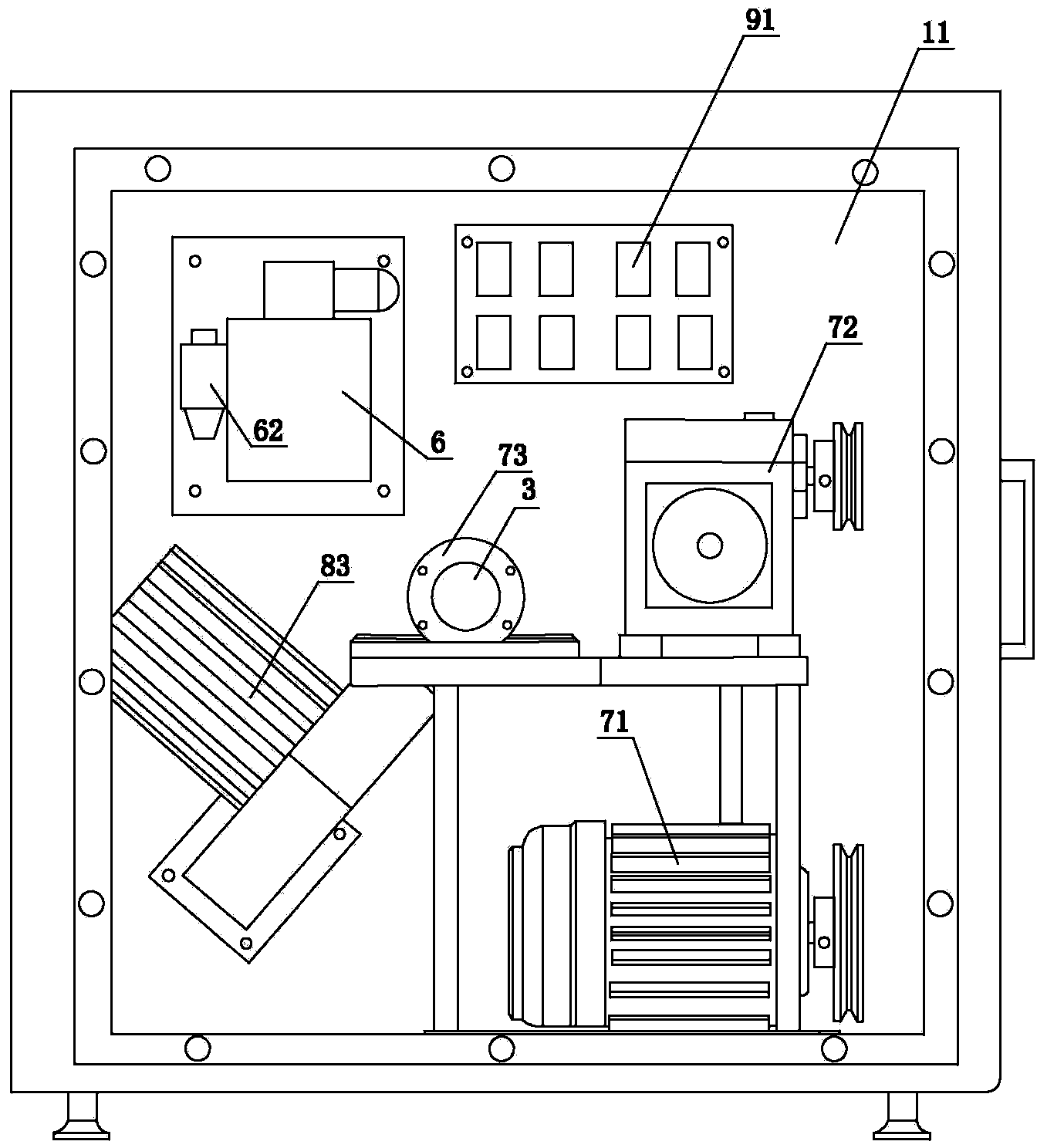

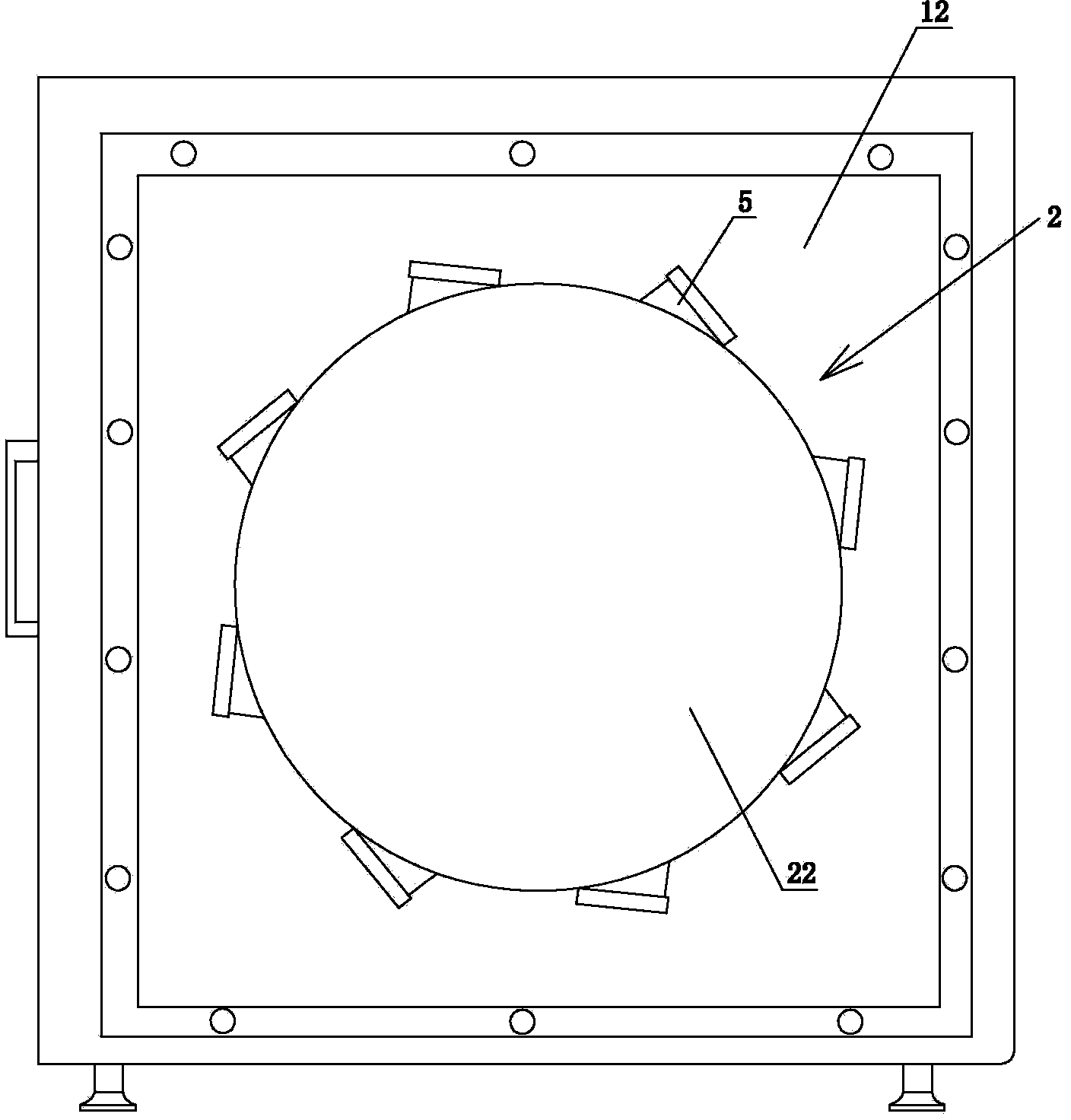

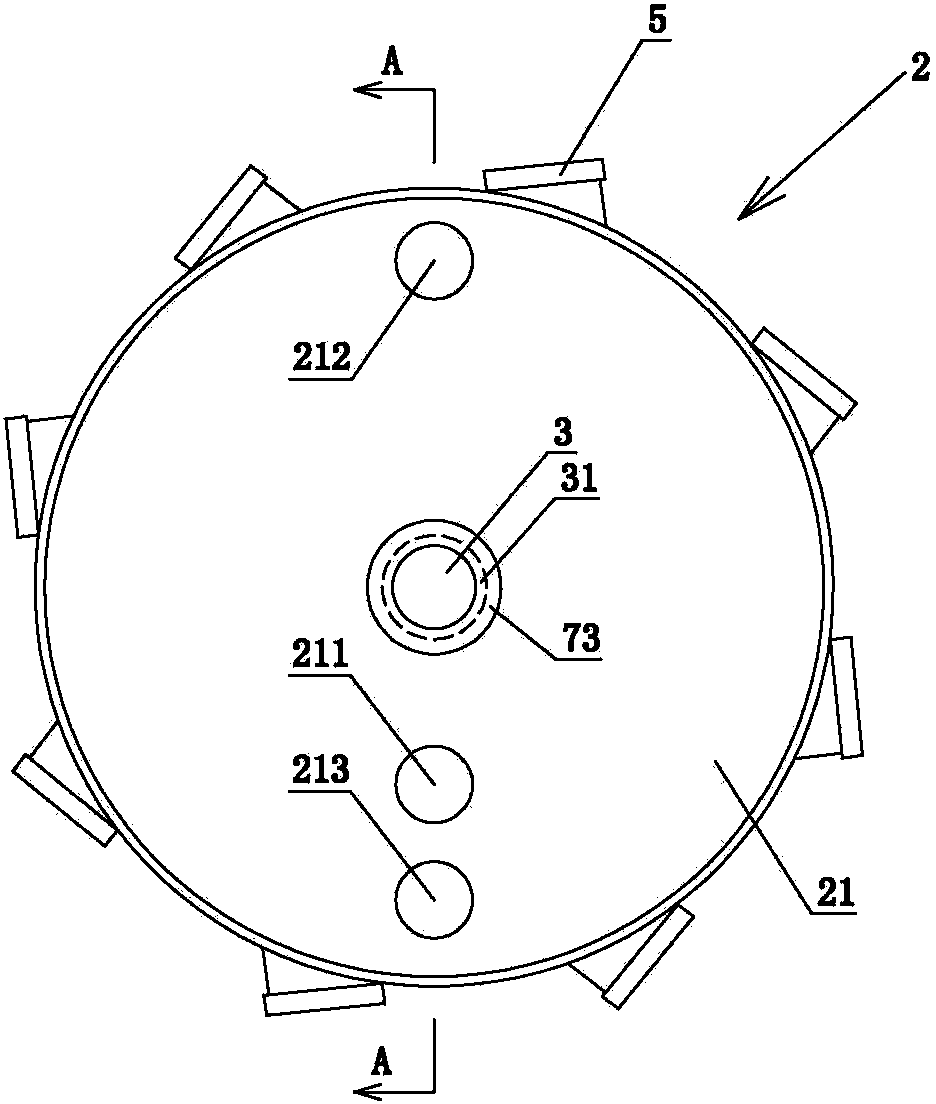

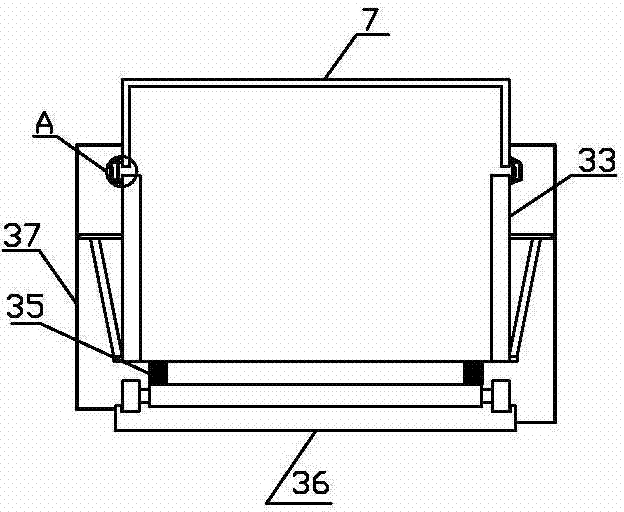

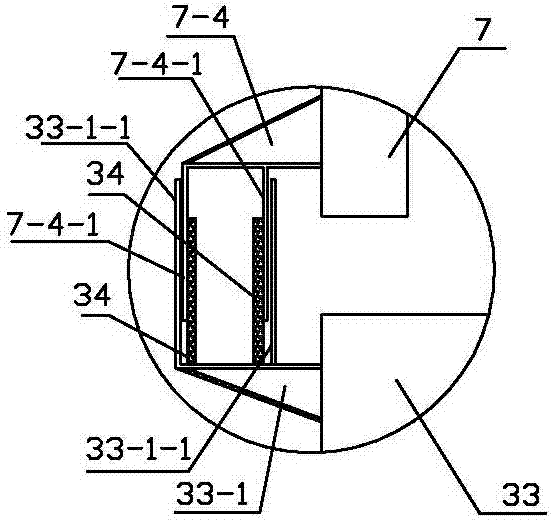

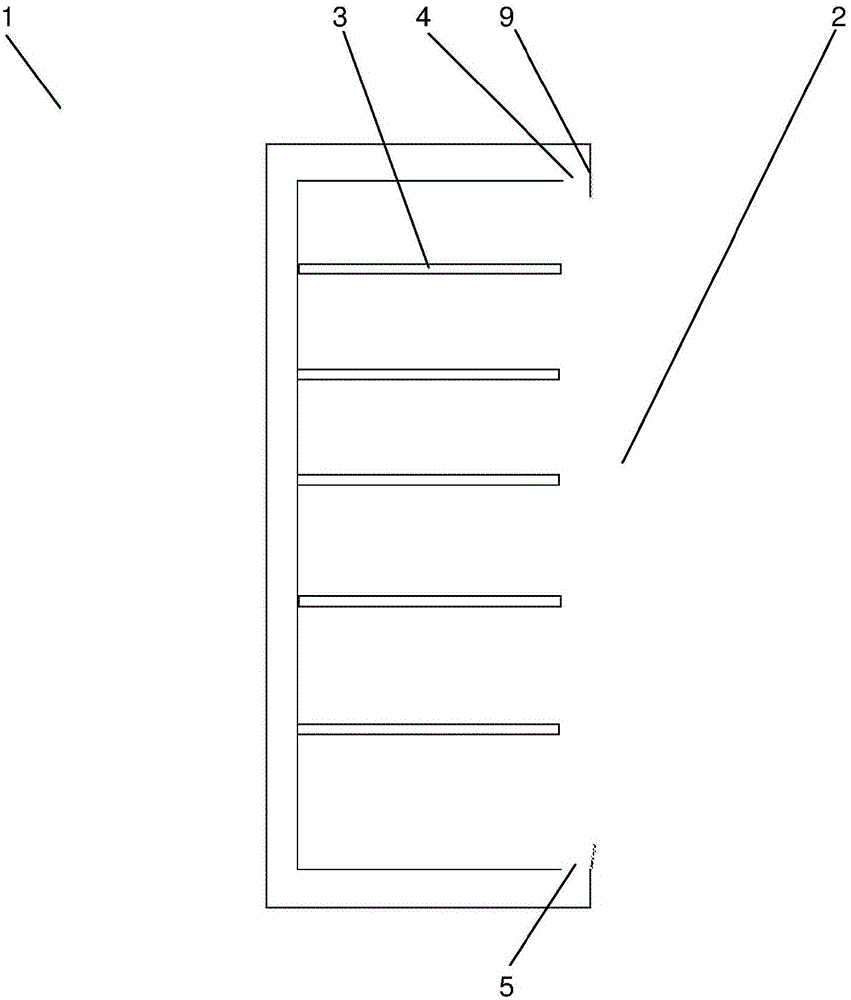

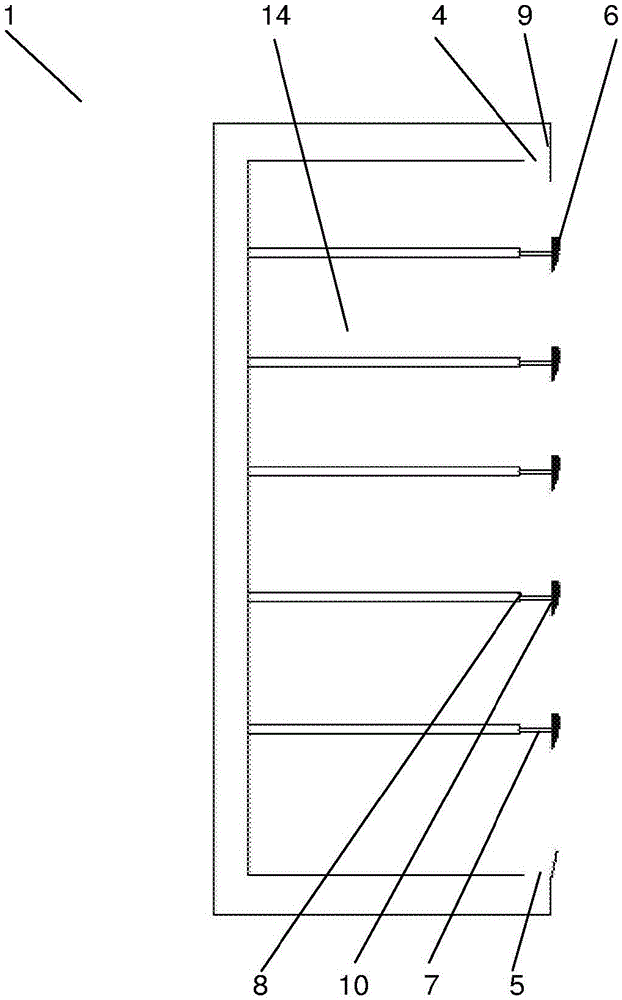

Recirculating air heating type laboratory color dyeing machine

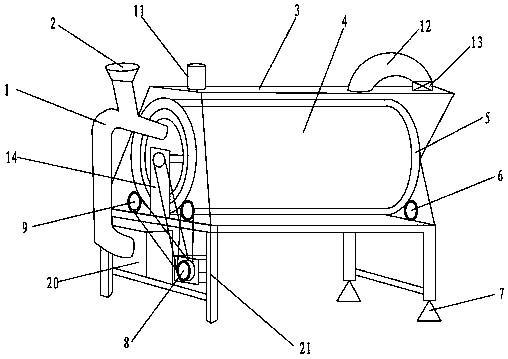

ActiveCN103757848AReduce manufacturing costReduce consumptionTextile treatment dyeing devicesTextile treatment machine arrangementsEngineeringLaboratory facility

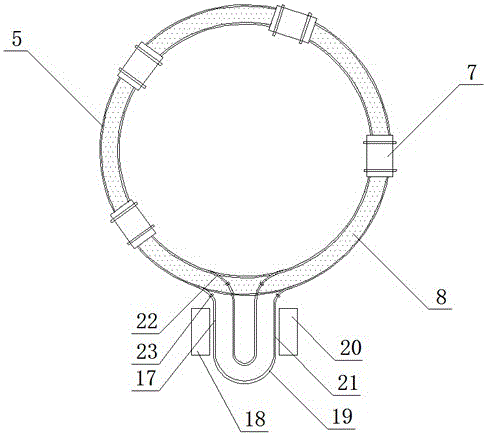

A recirculating air heating type laboratory color dyeing machine comprises a box body, a hollow rotating disc arranged in the box body and a rotating shaft connected with the rotating disc. A plurality of dyeing cup sleeves are evenly distributed on the outer peripheral face of the rotating disc, a dyeing cup is sleeved with each dyeing cup sleeve, a left end cover is arranged on the left end face of the rotating disc, a right end cover is arranged on the right end face of the rotating disc, one end of the rotating shaft penetrates through the left end cover to be fixedly connected with the right end cover, and the other end of the rotating shaft is connected with a transmission mechanism, a bearing is arranged on the rotating shaft, the left end cover is fixedly connected to an outer ring of the bearing, an air heater is arranged on the left side of the rotating disc, an air outlet of the air heater is connected with a hot air pipe, an air input hole is formed in the lower portion of the left end cover, one end of the hot air pipe penetrates into the air input hole and faces to the lateral wall of a corresponding dyeing cup sleeve, a hot air recovery device is arranged on the air heater, and an air inlet of the hot air recovery device is connected with a recovery pipe, a recovery hole is formed in the upper portion of the left end cover, and the other end of the recovery pipe penetrates through the recovery hole to be located in the rotary disc.

Owner:SHISHI TAIRUI PRECISION MACHINERY

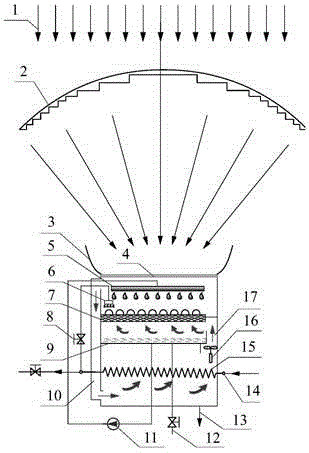

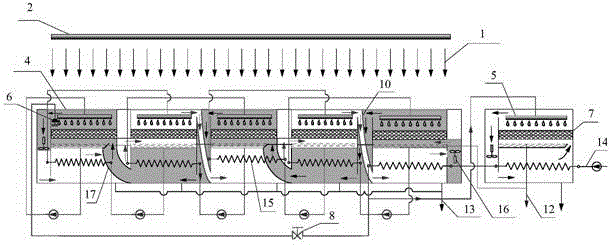

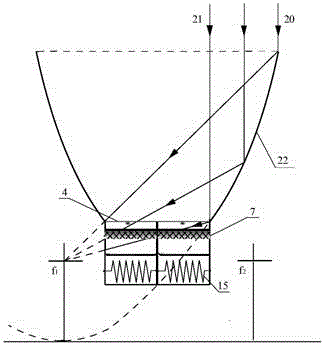

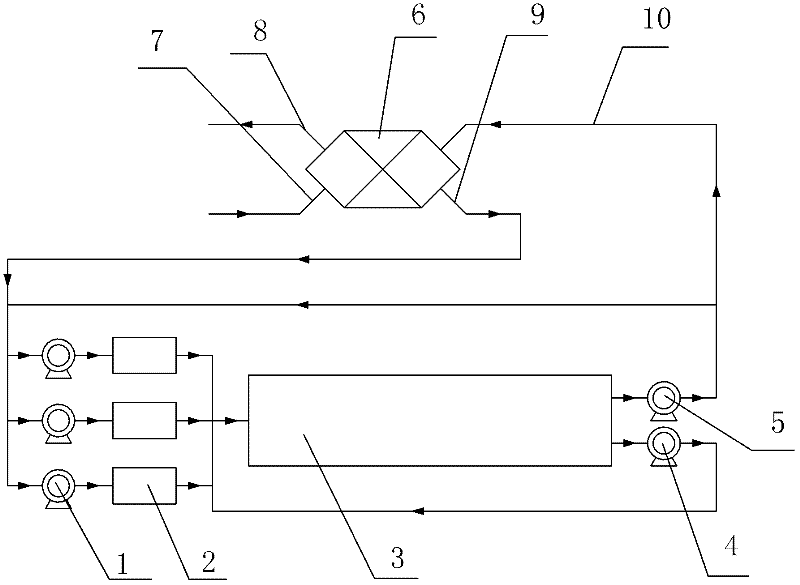

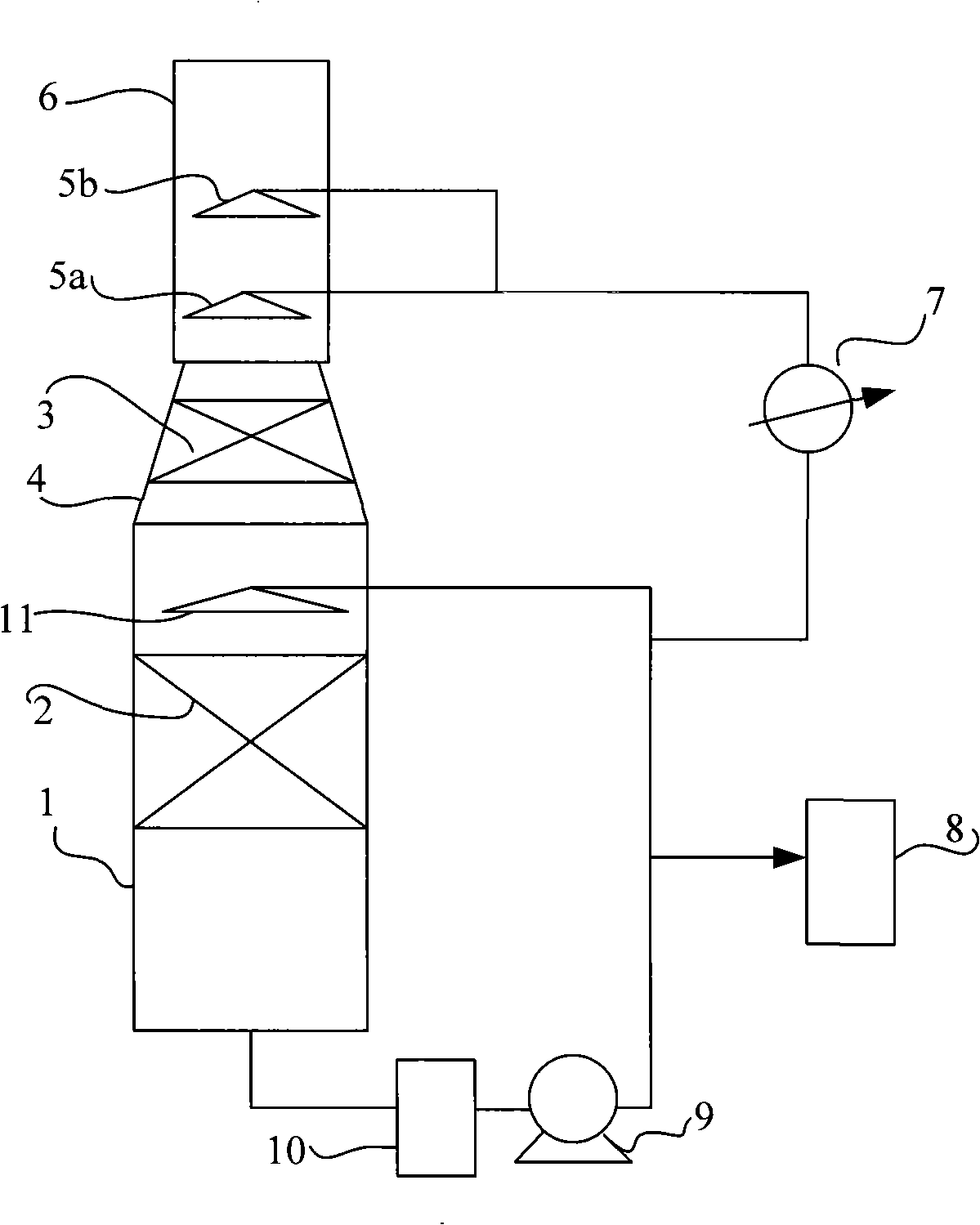

Forward-condensing multiple-effect back-heating array type humidification and dehumidification solar-powered seawater desalination device

InactiveCN105174339AReduce heat transferImprove heat collection efficiencyGeneral water supply conservationSeawater treatmentGlass coverSolar light

The invention discloses a forward-condensing multiple-effect back-heating array type humidification and dehumidification solar-powered seawater desalination device which comprises condensers, humidifiers, condensing apparatuses and air channels. Solar light incident from the upper side is condensed through the condensers, penetrates through glass cover plates to reach the surfaces of the humidifiers and is converted into heat energy. Seawater is sprayed on the humidifiers, absorbs vapor of the solar heat energy and performs heat and humidity exchange with air to form saturated wet air, and the high-temperature wet air enters condensation cavities under driving of fans and performs heat exchange with cold seawater to produce fresh water. After the seawater flows out of the condensers, a part of seawater is supplemented and sprayed on the humidifiers, and the residual seawater is discharged out of a system. Non-evaporated saline water drops on saline water plates to be recycled, and redundant saline water is discharged out of the device through the bottoms of the plates. The device can form the multiple-effect system in an arrayed mode, multiple effect structures are identical, the high-temperature high-humidity air and the saline water in one saline water plate are respectively delivered to another effect structure to heat the saline water in the corresponding condenser and cool the wet air, and latent heat discharged during vapor condensation is recovered to achieve the purpose of efficient seawater desalination.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Laundry treating machine

ActiveCN104204336AAvoid wastingIncrease condensation areaDrying gas arrangementsOther washing machinesLaundryAir recovery

The present invention relates to a laundry treating machine, including an air supply unit for supplying air, a tub for having the air supplied thereto from the air supply unit to treat the laundry, the tub having an air recovery opening formed in an outside circumferential surface thereof for recovery of the air to the air supply unit, a lint filter mounted to an inside of the air recovery opening for filtering the lint from the air, a filter cleaning unit for spraying cleaning water to separate the lint from the lint filter, and a flow passage member for guiding the cleaning water dropping from the lint filter to an inside of the tub to an inside surface of the tub.

Owner:LG ELECTRONICS INC

Tape casting machine drying oven with heat recovery function and drying method

The invention discloses a tape casting machine drying oven with a heat recovery function and a drying method. According to the invention, heat of damp-hot air in the tape casting machine drying oven can be recycled, energy consumption can be reduced and the effect of energy saving is further achieved. An air outlet of an air supply fan is connected with an air inlet of a drying tunnel through a heating box, a return air port of the drying tunnel is connected with an air inlet of a return air fan through a return air channel, an air outlet of the return air fan is connected with the air inlet of the drying tunnel; an air exhaust port of the drying tunnel is connected with an air inlet of an air exhaust fan through an air exhaust channel, one path of an air outlet of the air exhaust fan is connected with the air inlet of the air supply fan through a first air valve, the other path of an air outlet of the air exhaust fan is connected with an air exhaust inlet of a hot air recovery heat exchanger through a second air valve, and a fresh air outlet of the hot air recovery heat exchanger is connected with the air inlet of the air supply fan through a third air valve. The drying oven can send the damp-hot air to the air supply fan through the air exhaust fan and directly send the exhausted damp-hot air to the drying tunnel, thus reaching the purposes of hot air heat recovery and energy saving.

Owner:TIANJIN UNIV OF COMMERCE

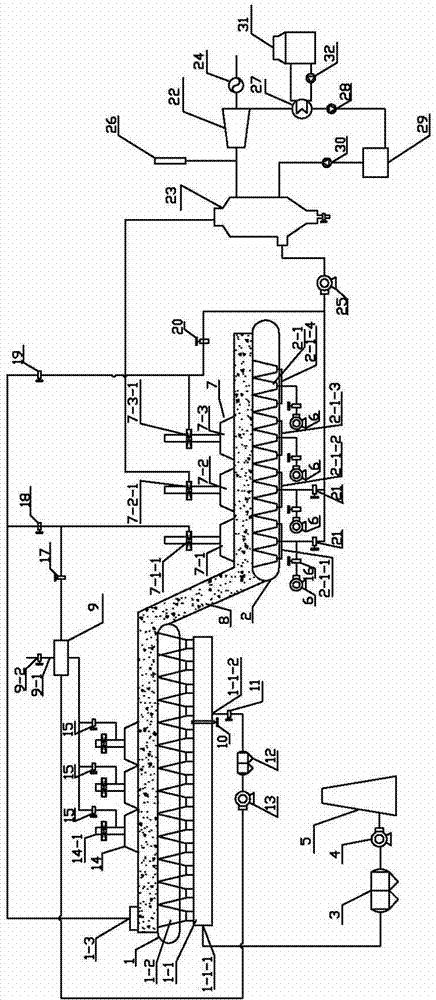

Hot air circulation sintering and sintering double-pressure waste heat utilizing system and method

ActiveCN103615909ARaise the sintering temperatureIncrease the amount of liquid phaseIncreasing energy efficiencyWaste heat treatmentSolid fuelHeat losses

The invention discloses a hot air circulation sintering and sintering double-pressure waste heat utilizing system and method. The hot air circulation sintering and sintering double-pressure waste heat utilizing system comprises a sintering machine and an annular cooler, wherein the sintering machine and the annular cooler are arranged in a head-tail longitudinal fall mode, a hot air circulation mixer is connected with a sintering machine hot air recovery mechanism and an annular cooler hot air recovery mechanism to collect hot air, and the hot air circulation mixer sends the collected hot air into a sintering bed of the sintering machine. The hot air circulation sintering and sintering double-pressure waste heat utilizing system and method adopt the hot air circulation and sintering technology, the sintering temperature of the upper portion of a material layer is improved, the liquid phase amount is increased, liquid phase viscosity is lowered at the same time, minerals are fully crystallized, the glass phase content is reduced, and therefore the rate of finished products of the whole sintering body and the strength of sintering ores are improved. The 300-500 DEG C hot air circulation technology is adopted to improve the quality of the sintering ores, solid fuel can be saved by 5%-10%, the total heat loss is reduced by 5-8%, dust exhaust amount is reduced by 20%-30%, the high-pressure steam generated by waste heat is supplied to an air-supplementation condensing type turbine generator unit, and the waste heat is fully used.

Owner:BEIJING ZHINENG XIANGYING ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH CO LTD

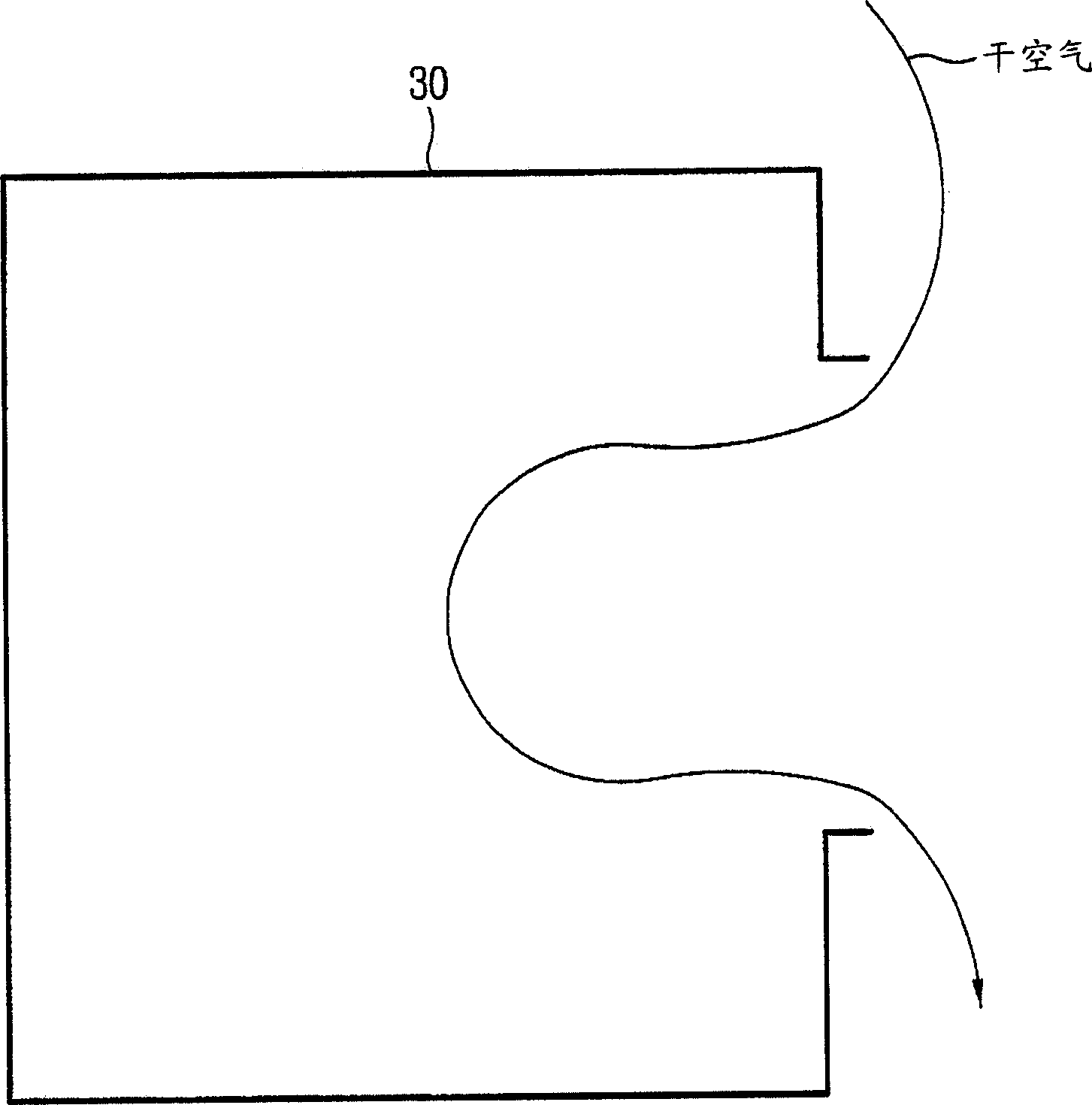

Structure for supplying hot air in drum type washing machine and operation control method thereof

InactiveCN1657683ATake advantage ofKeep dryOther washing machinesWashing machine with receptaclesEngineeringAir recovery

Structure for supplying hot air to a drum washing machine, and operation control method thereof, in which uniform introduction of hot air deep into an inside of a drum is made possible for enhancing drying capability and efficiency. For this, a drum washing machine includes a tub for holding washing water, a drum rotatably mounted in the tub, for introducing laundry therein, a drying heater for heating air being supplied to an inside of the drum, a drying duct forming a flow passage for supplying hot air heated by the drying heater to the inside of the drum, a fan for forced supply of the hot air heated by the drying heater to the inside of the drum, a hot air inlet at a front side of the drum for supplying the hot air to the inside of the drum, and a humid air recovery opening at a rear side of the drum for recovering humid air from the inside of the drum, and the operation control method of a drum washing machine includes the step of supplying hot air to an inside of the drum while rotating the drum at a speed equal to, or higher than a speed enough to keep the laundry in the drum attached to, and not fall off from, the inside surface of the drum in progressing a drying cycle.

Owner:LG ELECTRONICS INC

Cloth drying device of circular screen printing machine

ActiveCN110406252ASmall footprintContact freeScreen printersPrinting press partsScreen printingEngineering

The invention discloses a cloth drying device of a circular screen printing machine. The device comprises a feeding mechanism, a drying mechanism, a hot air recovery mechanism and a collecting mechanism, wherein the drying mechanism comprises a drying oven, a plurality of guide rollers and a blowing assembly, the guide rollers and the blowing assembly are arranged in the drying oven, and the guiderollers are distributed on the inner wall of the drying oven in a vortex shape. Through the guide rollers which are arranged in the drying oven in the vortex shape, cloth can be spirally wound in thedrying oven, the effective space in the drying oven is fully utilized, and the occupied space of the drying oven is saved. The guide rollers are distributed in the vortex shape, and it can be ensuredthat each guide roller is only in contact with the bottom surface of the cloth, so that the printing surface is prevented from being in contact with the guide rollers, and a printed pattern is prevented from being damaged.

Owner:台州智子科技有限公司

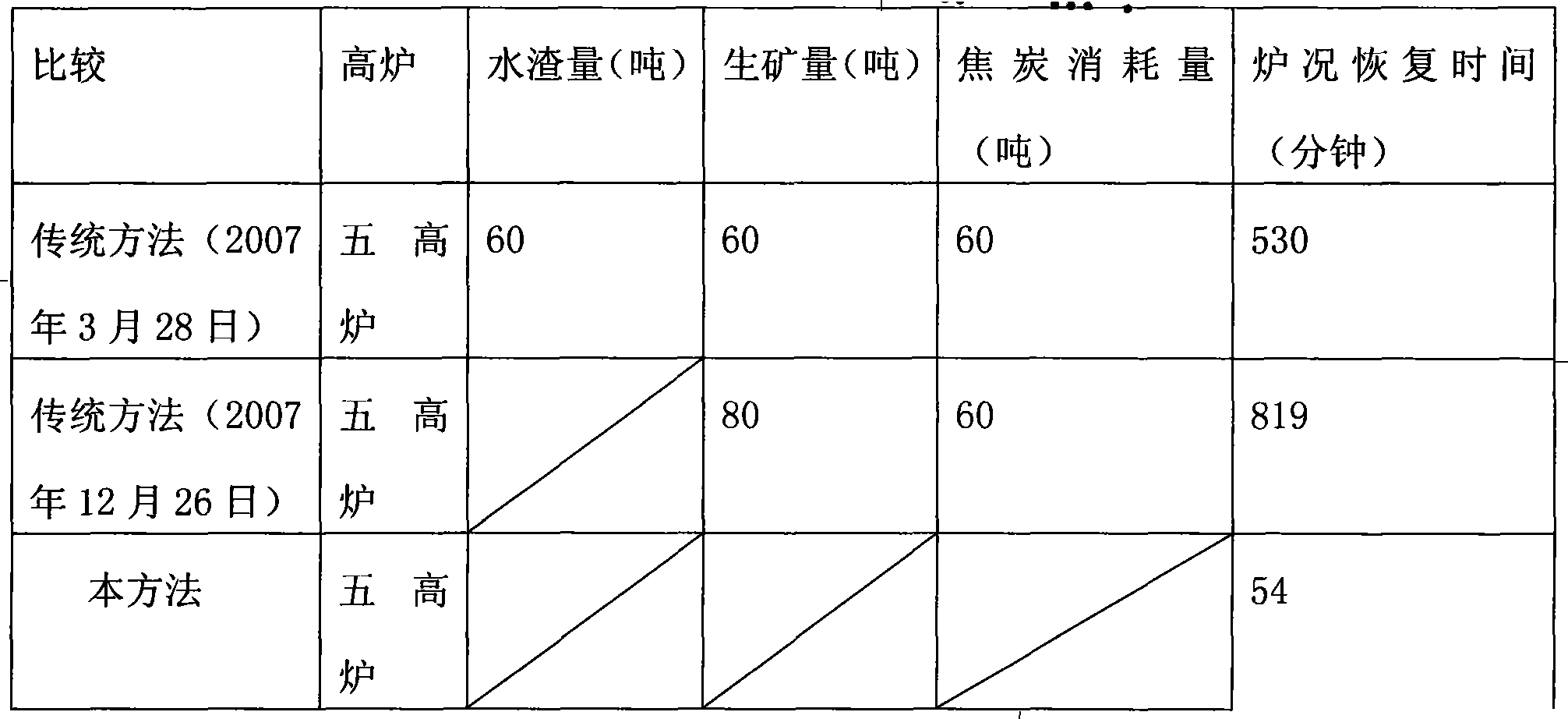

Blast furnace banking method

InactiveCN101250599AStew oven effect is goodConducive to increasing production and maintaining qualityBlast furnace componentsBlast furnace detailsSlagWater quality

The invention discloses a blast furnace stewing process, which comprises the following steps that adding blowing-down burden material in a blast furnace, damping down when blowing-down burden material reaches to the upper edges of a furnace hearth, gradually descending stock-line to the several meters under a furnace throat, adopting the way of watering on the furnace top portion and appropriate reducing blast, controlling the temperature of the furnace top portion within 300 DEG C, instantly opening a blast pipe cover plate, plugging an air inlet with water-stem, then covering on the cover plate, starting to press coke free positive material and positive material into the blast furnace after plugged the air inlet, controlling the temperature of the furnace top portion about at 200 DEG C, wherein the furnace top portion temperature can gradually descended to 100 DEG C in 3 hours after stewing material is finished to fill. The process has excellent stewing effect, has stable temperature in the blast furnace, can shortens blow-in process after stewing, can fast recover the furnace situations after air recovery in the blast furnace, can generate iron in large amount, has stable slag basicity after stewing burden discharged, can guarantee the iron water quality, can save large amount of coke and grain slag, can improve blast furnace technical economical index and create favorable economical benefits.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

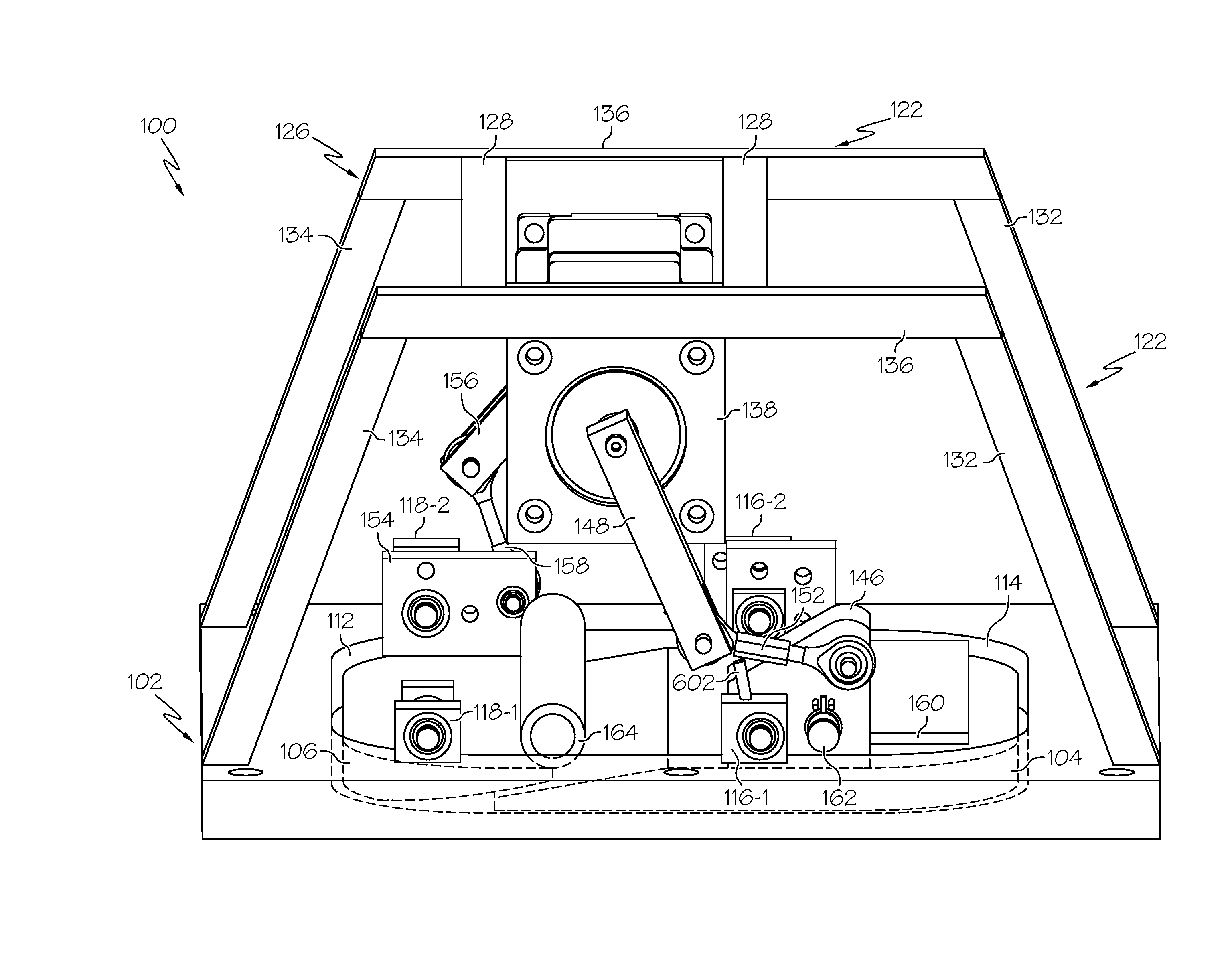

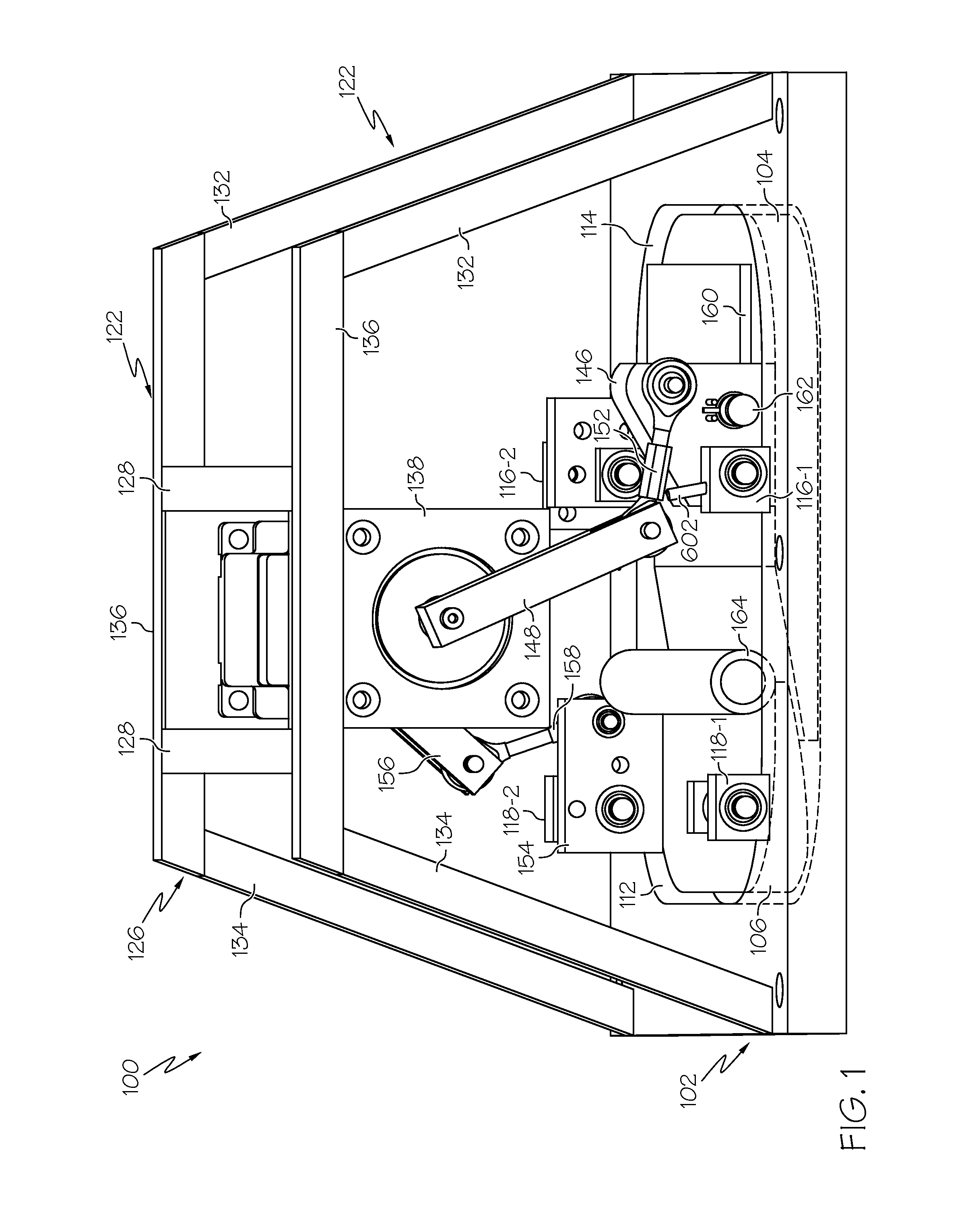

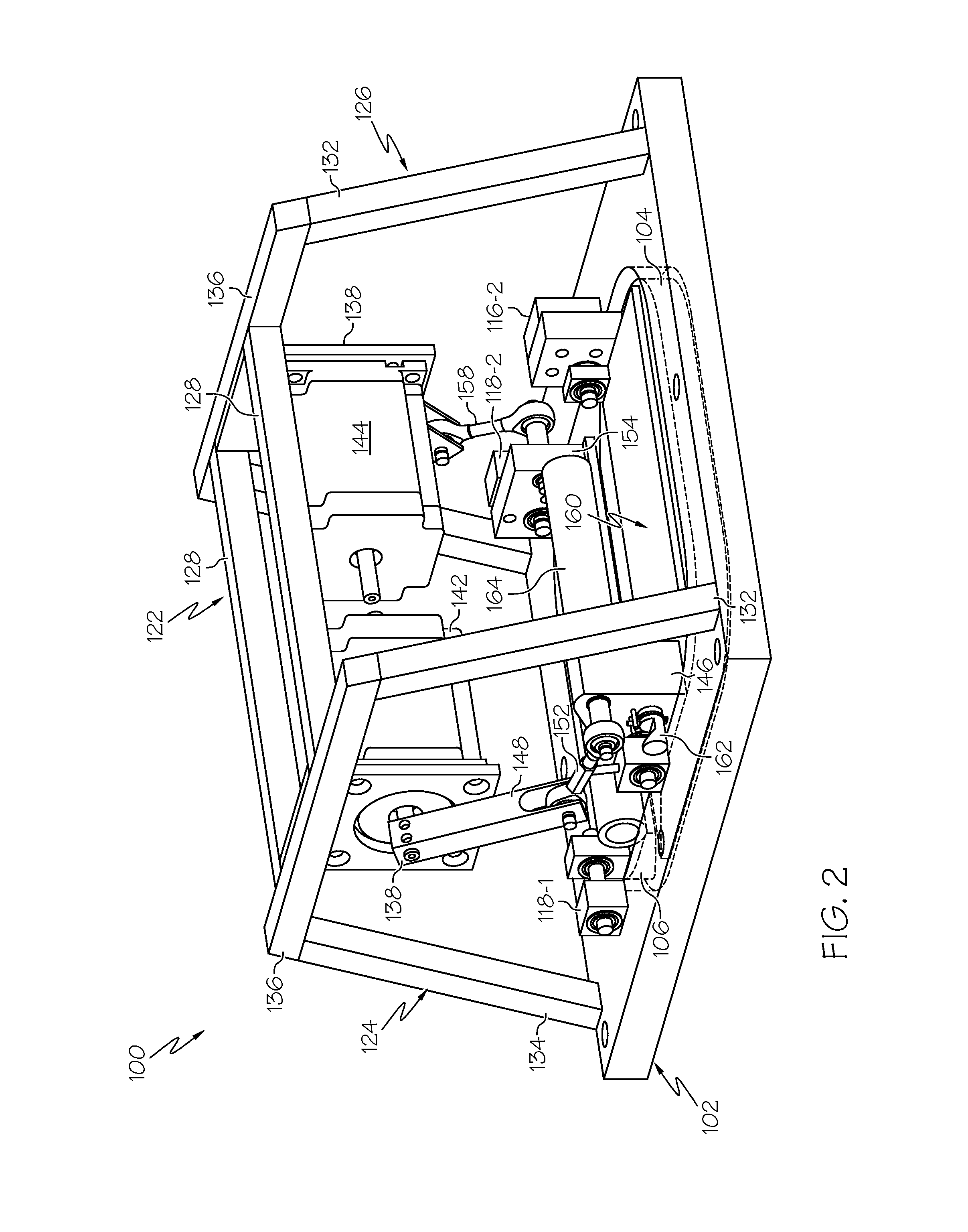

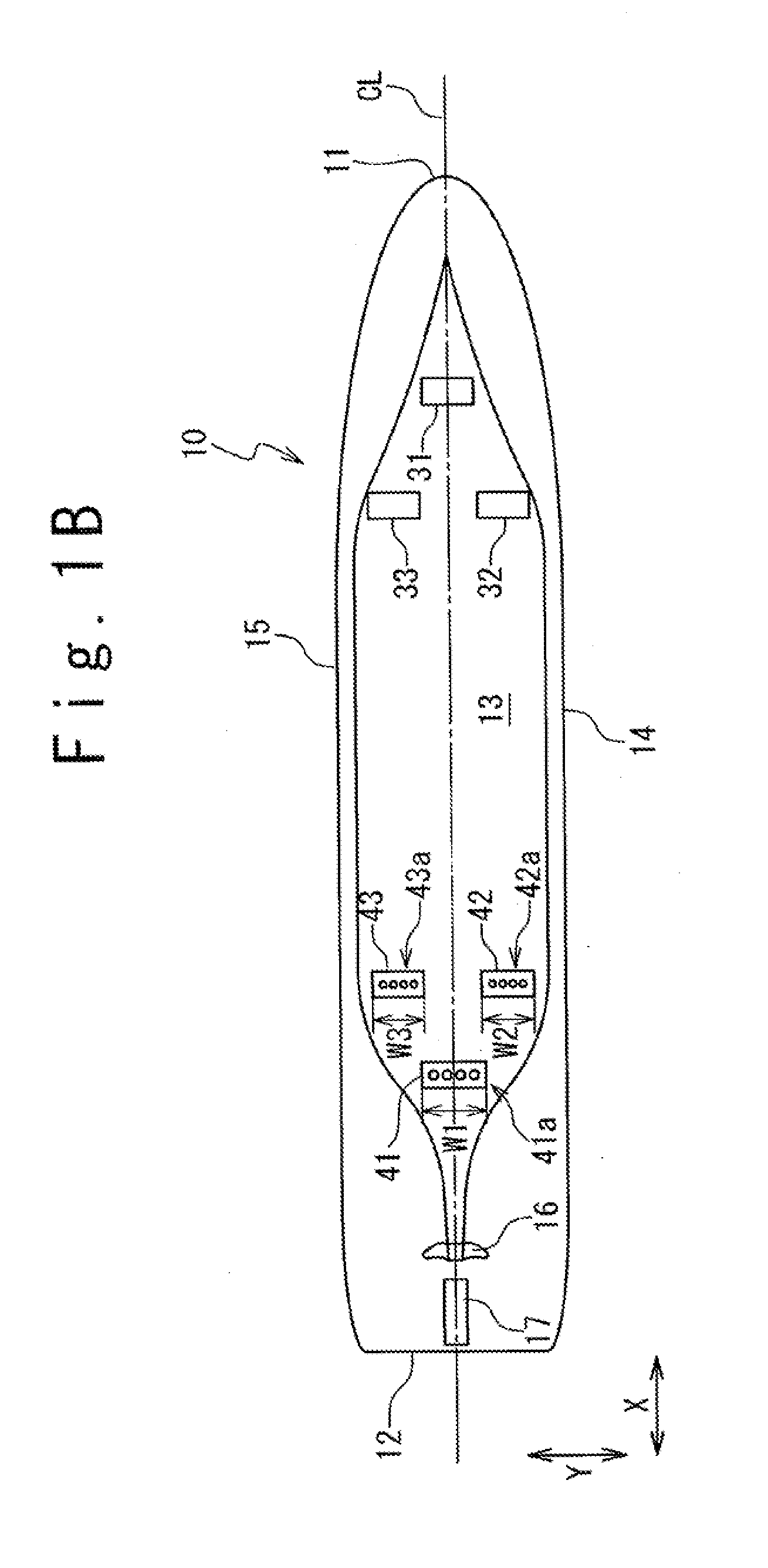

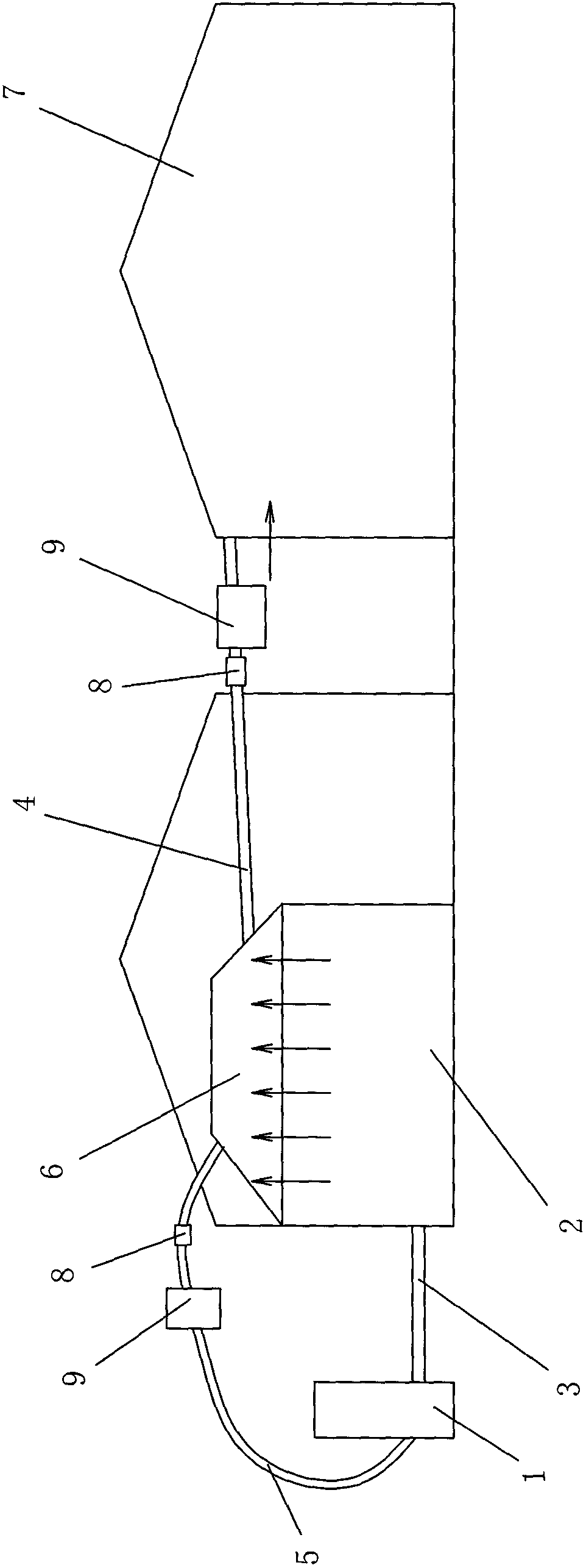

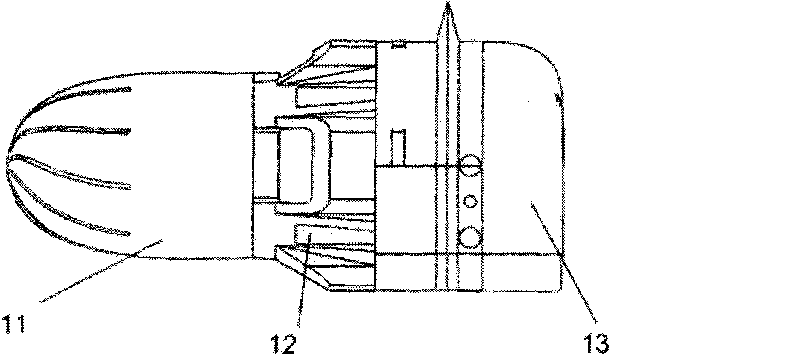

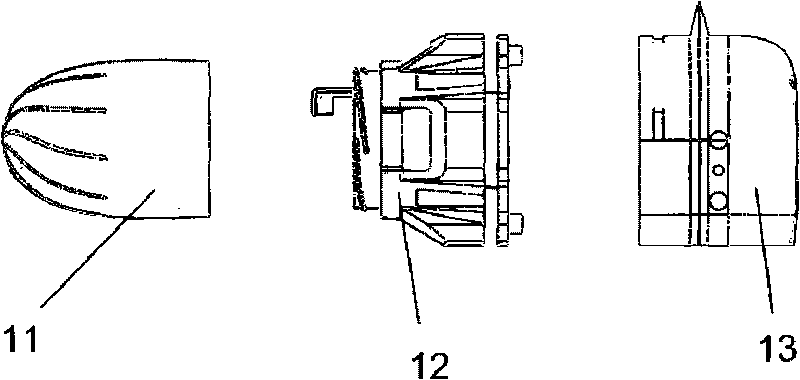

Cabin pressure control system thrust recovery outflow valve and method that enable ram air recovery

A thrust recovery outflow valve and method for controlling the transfer of air between a cabin in an aircraft and atmosphere outside of the aircraft are provided. An outflow valve is mounted on the aircraft that includes a valve frame, a first valve door, and a second valve door. The first valve door is rotated to a first predetermined open position while the second valve door is in the second door closed position to thereby open first and second flow passages that place the aircraft cabin in fluid communication with the atmosphere. When the first valve door is at a first predetermined open position, a flap is rotated, relative to the first valve door, to at least partially cover the second flow passage and thereby at least inhibit flow through the second flow passage.

Owner:HONEYWELL INT INC

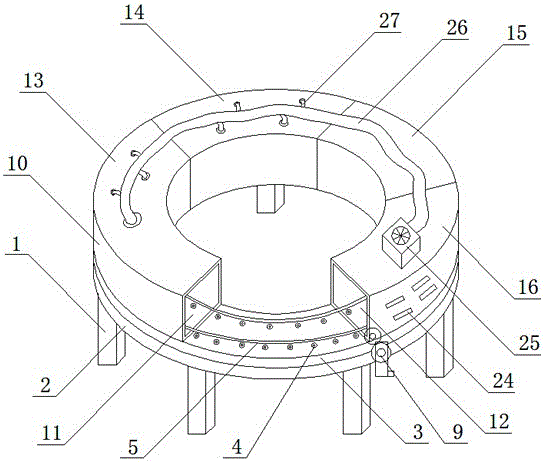

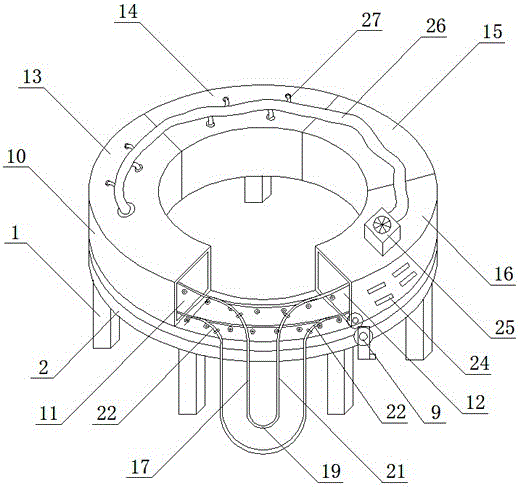

Multifunctional environmental protecting and energy saving rotary kiln

ActiveCN105737597AAvoid lostImprove cooling effectFurnace typesWaste heat treatmentProduction lineThermal insulation

The invention discloses a multifunctional environmental protecting and energy saving rotary kiln. The multifunctional environmental protecting and energy saving rotary kiln comprises a kiln support frame (1), and is characterized in that a kiln body base (3) is fixed on an annular base (2); an annular rotating rail (5) is arranged on the annular upper surface of the kiln body base (3); an annular kiln body (10) is arranged above the kiln body base (3); and a preheating section (13), a roasting section (14), an insulation section (15) and a cooling section (16) are arranged in the annular kiln body (10) between a feed gap (11) and a discharge gap (12) in sequence. The multifunctional environmental protecting and energy saving rotary kiln adopts an annular rail type production line to greatly improve the automation degree and the production efficiency, is provided with transition gap sections among the preheating section, the roasting section, the insulation section and the cooling section and provided with thermal insulation fans or hot air recovery mechanisms in the transition gap sections to prevent the heat loss to the greatest extent, and replenishes hot air, extracted by an exhaust fan, into the preheating section and the roasting section through an air supply pipe to realize the recycling of heat energy.

Owner:WUHAN TAIKANGXIANG TECH CO LTD

Calcium carbide sensible heat recovery device

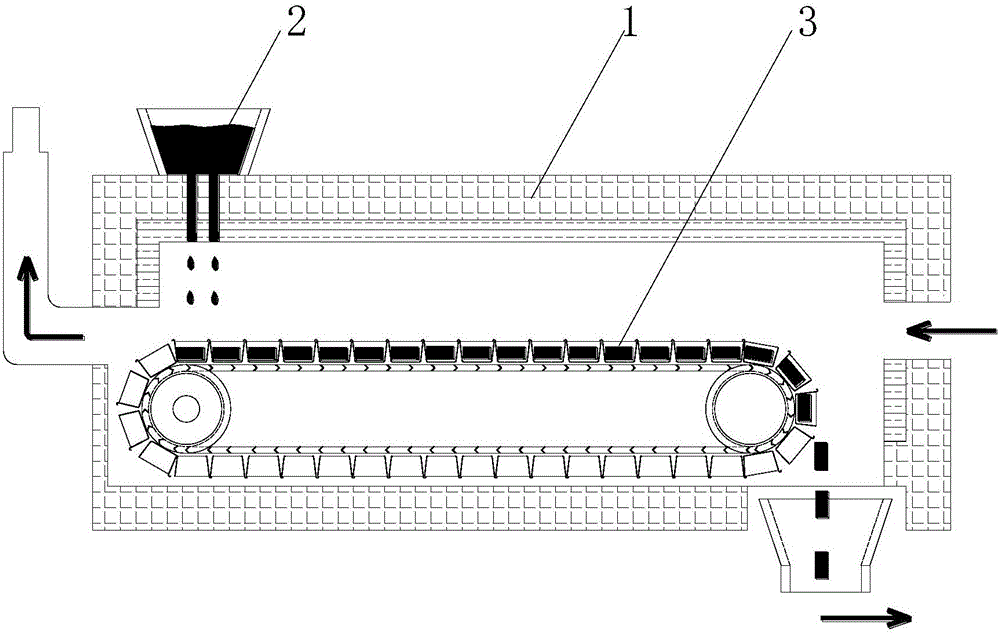

InactiveCN105858662AAchieve recyclingSave manpower and material resourcesRecuperative heat exchangersChemical industryMolten stateCalcium carbide

The invention provides a calcium carbide sensible heat recovery device. The device comprises a recuperative furnace, wherein a forming mold capable of carrying out cycle operation is arranged in a chamber of the recuperative furnace and is provided with a feed end and a discharge end; a plurality of air cooling devices are arranged above the part between the feed end and discharge end of the forming mold to cool calcium carbide in a molten state at the feed end in the forming mold to form solid calcium carbide at the discharge end; and a hot air recovery channel is arranged on the side wall of the recuperative furnace to recover the heat generated when calcium carbide on the forming mold is converted from the molten state to a solid state. The calcium carbide sensible heat recovery and non-crushing device has the advantages that by arranging the forming mold capable of carrying out cycle operation inside the recuperative furnace, calcium carbide is converted from the molten state to the solid state via the effects of the air cooling devices at the top of the recuperative furnace in the process of conveying calcium carbide by the forming mold, and the heat generated in the conversion process is recovered and utilized by the hot air recovery channel of the recuperative furnace, thus achieving recovery of the calcium carbide sensible heat.

Owner:SHANGHAI TAIXU ENERGY SAVING SCI & TECHCO

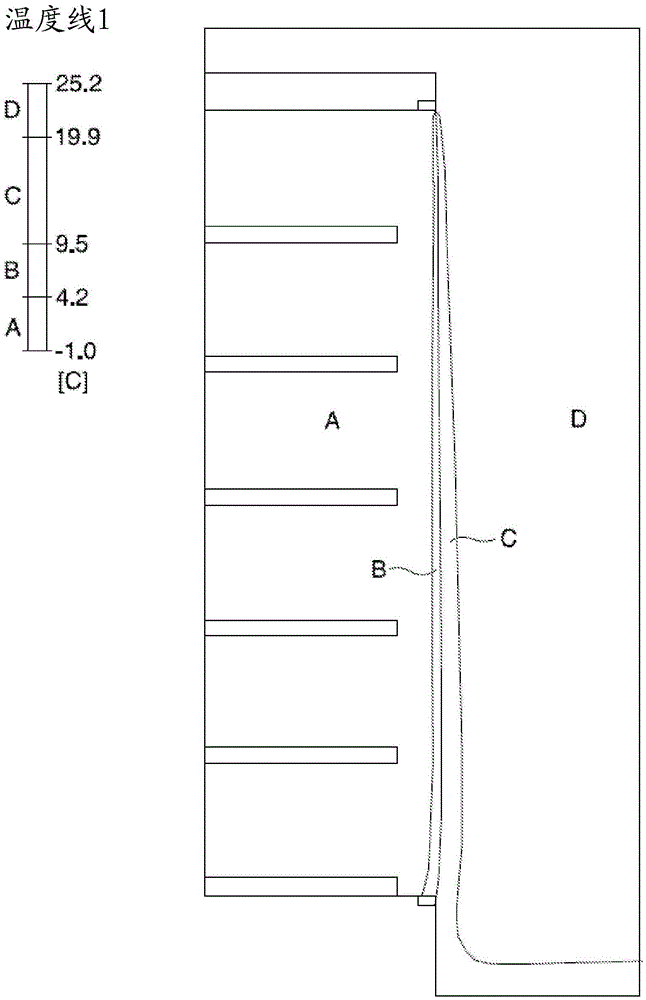

Improvements in refrigerators

A refrigerator has an open front and an air curtain system having at least one upper air egress with an outer edge and at least one lower air-recovery ingress. The air curtain system is adapted to produce a substantially vertical air curtain over at least part of the open front of the refrigerator. The refrigerator comprises at least one shelf between the egress and the ingress, the shelf having a front edge, and at least one elongate air-guiding strip extending across at least part of the open front of the fridge. The strip is located substantially in the plane of the shelf and spaced from the front edge of the shelf. The strip is located substantially vertically beneath the outer edge of the upper air egress.

Owner:AEROFOIL ENERGY LTD

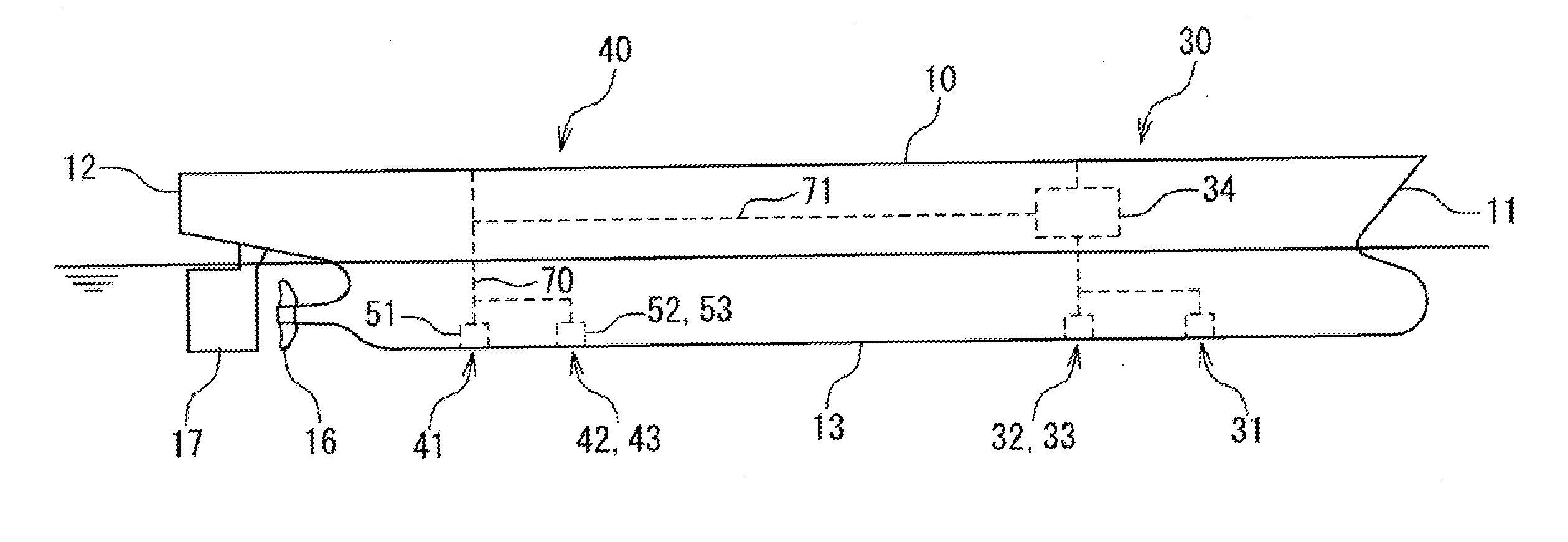

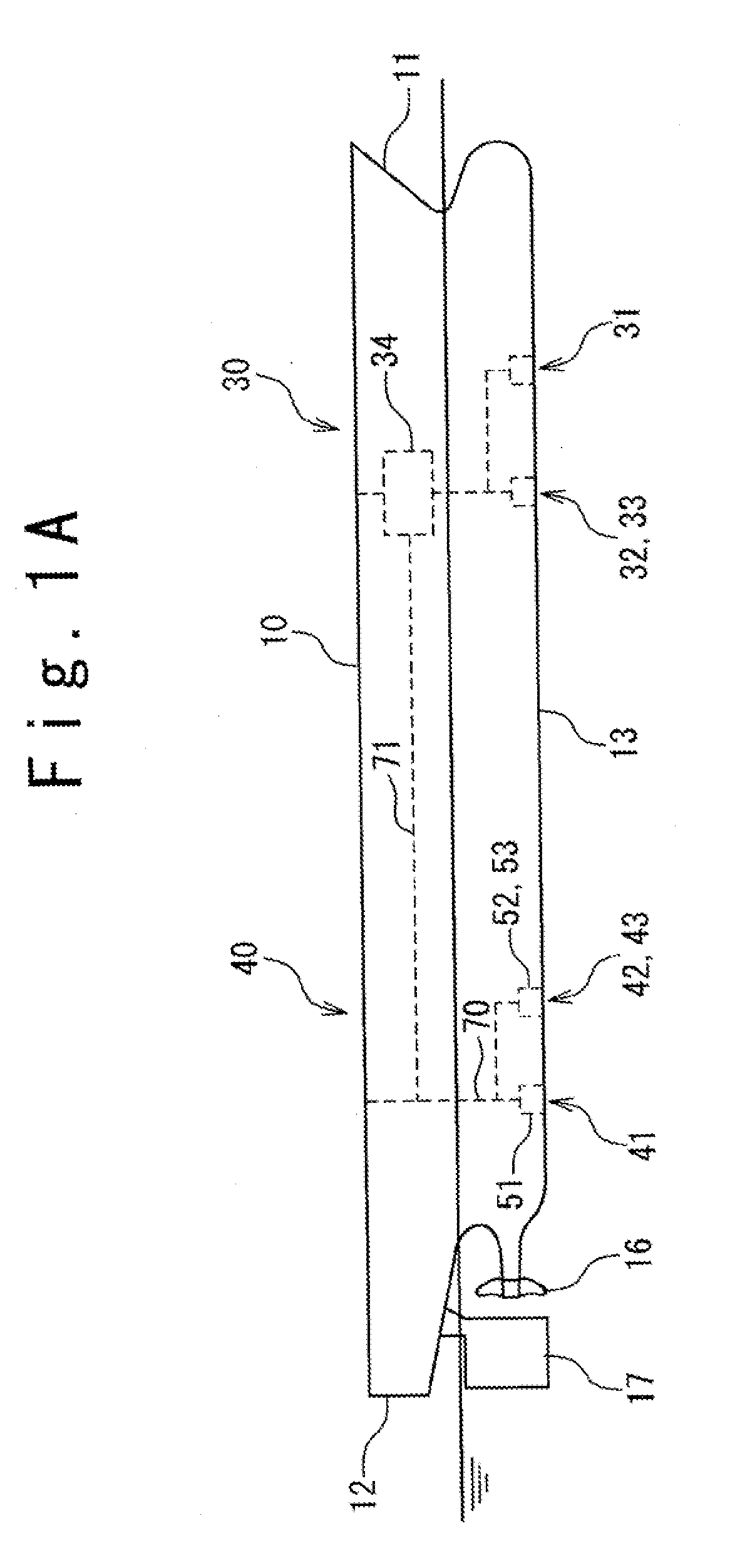

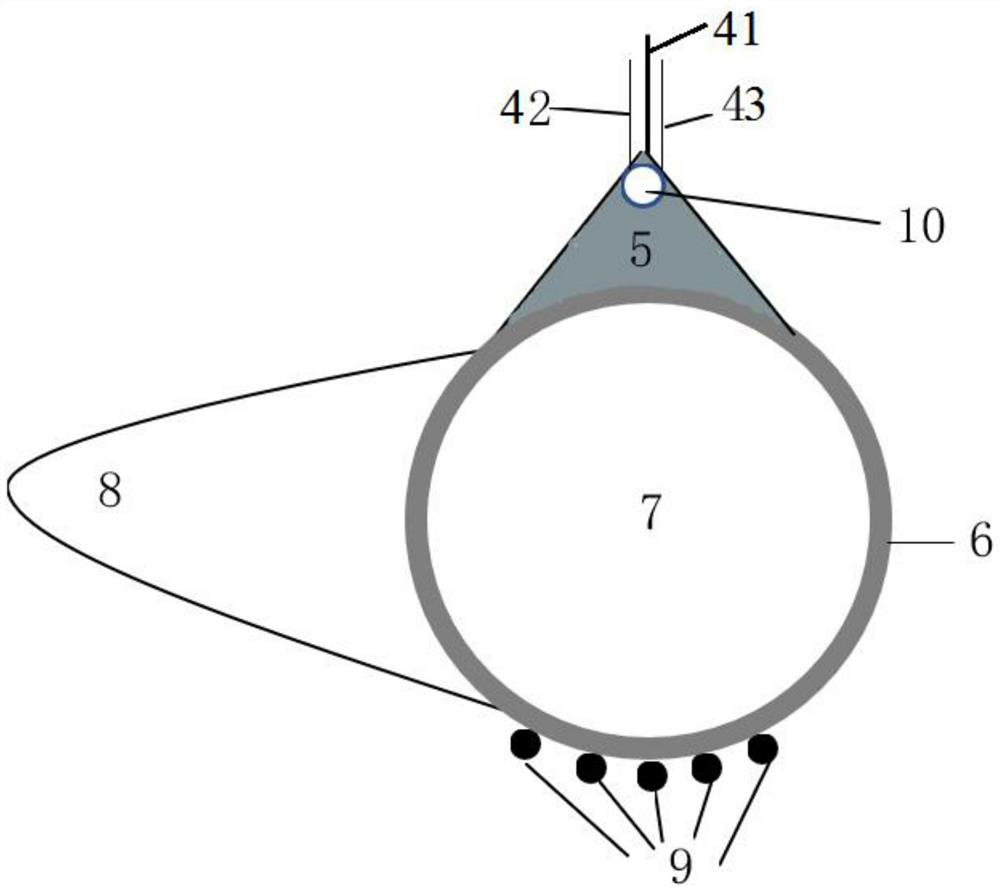

Air bubble recovery device of ship

ActiveUS20110239927A1Reduce frictional resistanceAvoid problemsWatercraft hull designFloating buildingsMarine engineeringCircular segment

An air ejecting unit is configured to eject air into water from an air ejecting outlet provided in a ship bottom of a ship body. An air recovery device is configured to recover the air into the ship body from first to third air recovery inlets provided in the ship bottom. The first air recovery inlet is provided to cross the center line. The second air recovery inlet is provided to project on a port side from the first air recovery inlet. The third air recovery inlet is provided to project on a starboard side from the first air recovery inlet. The second and third air recovery inlets are arranged on a bow side from the first air recovery inlet. Each of the first to third air recovery inlets includes a plurality of air recovery holes.

Owner:MITSUBISHI SHIPBUILDING CO LTD

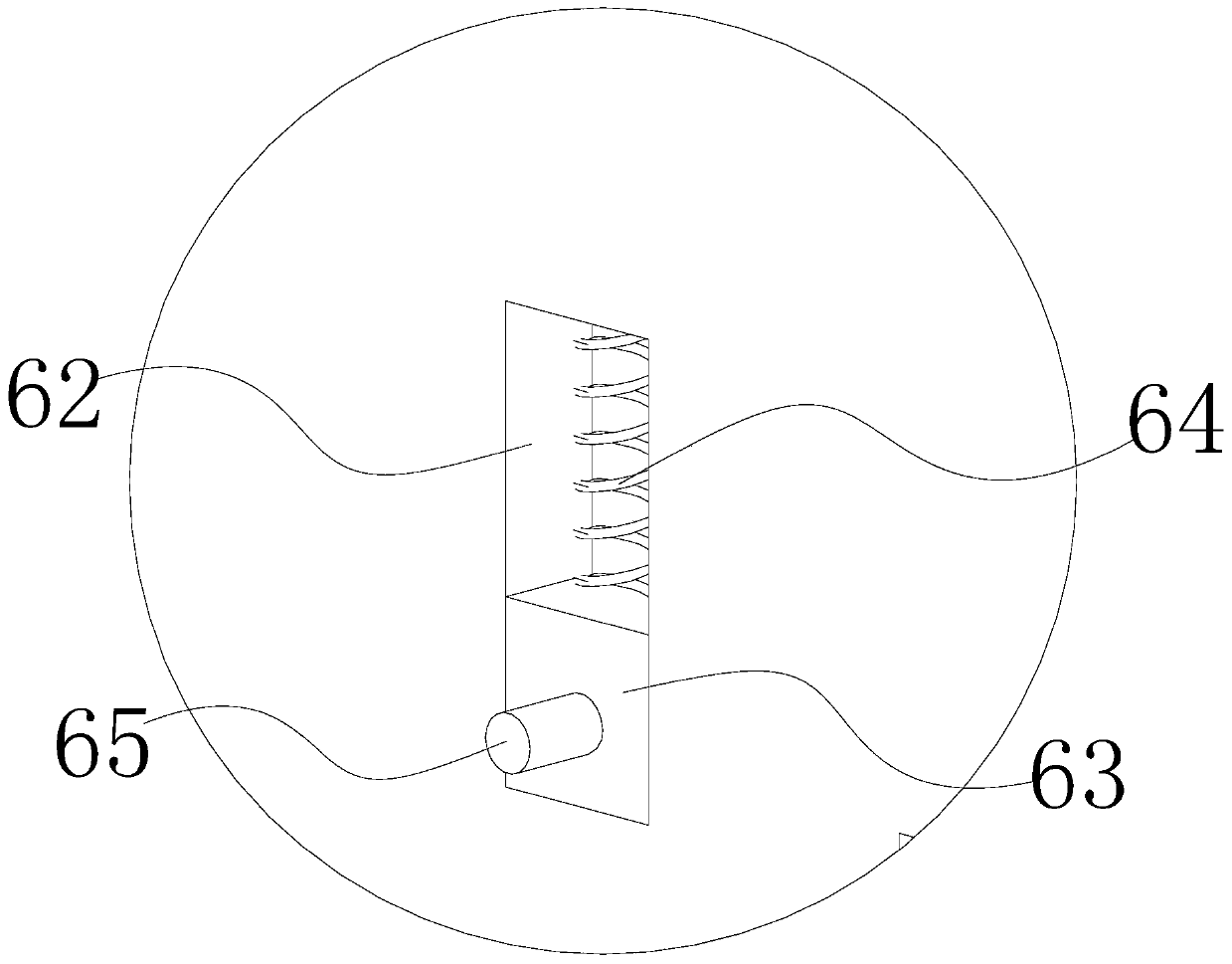

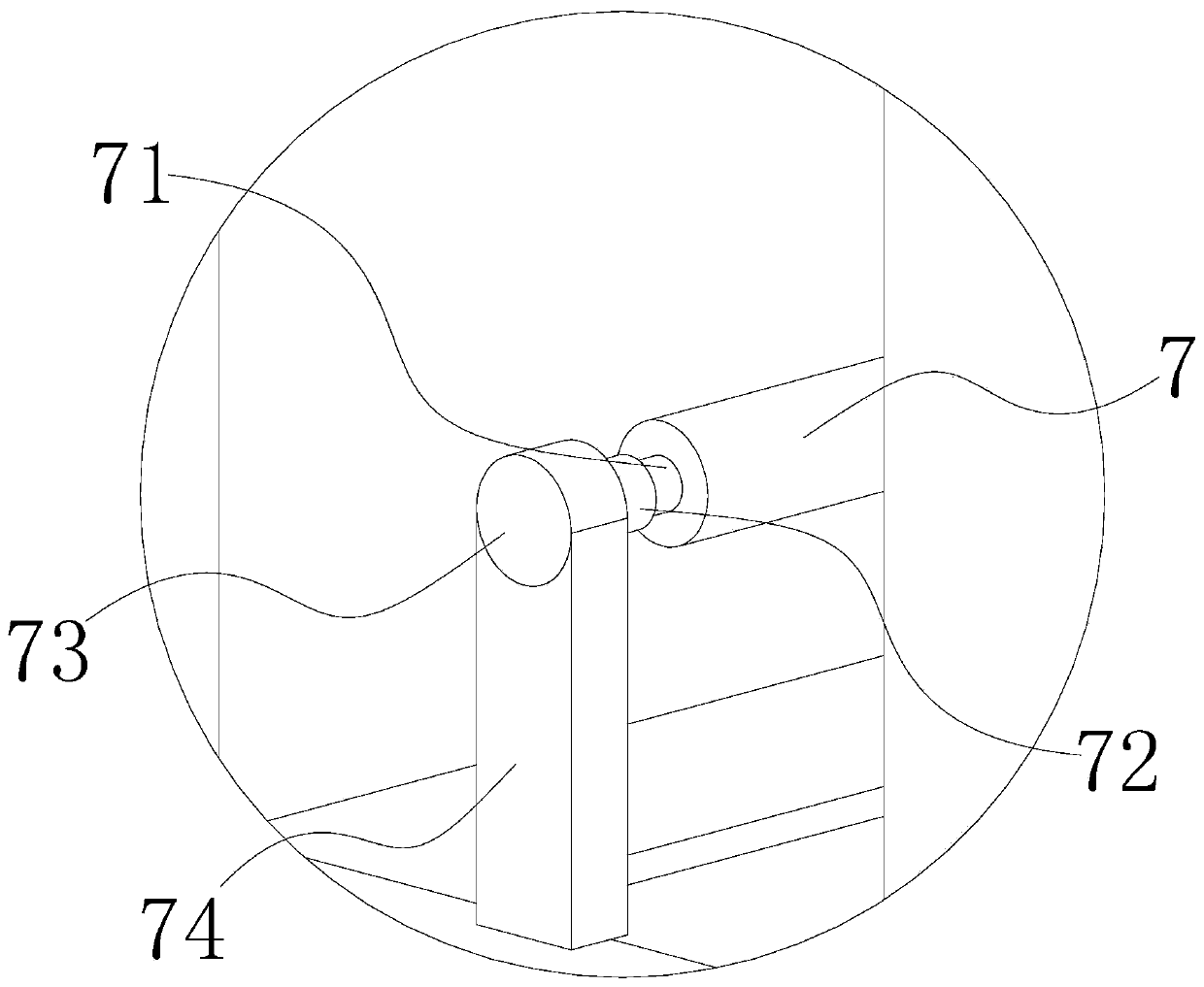

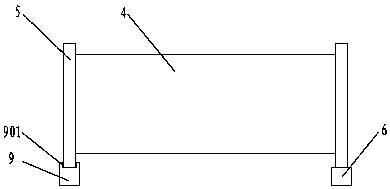

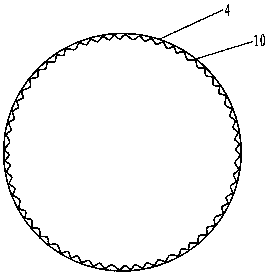

Molding sand drum dryer

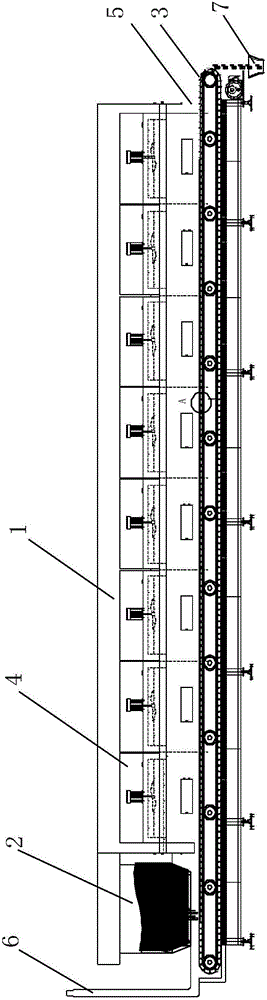

InactiveCN104236271AIncrease temperatureStable temperatureDrying chambers/containersDrying machines with non-progressive movementsPulp and paper industryAir recovery

The invention relates to a molding sand drum dryer. The molding sand drum dryer comprises a drum, wherein the drum is obliquely arranged relative to the horizontal plane, the upper end of the drum is a feed end, the lower end of the drum is a discharge end, a baffle which is spirally coiled from the feed end to the discharge end is arranged on the inner wall of the drum, the baffle comprises an inclined section and a perpendicular section, and the perpendicular section is perpendicular to the drum. A steam pipe is arranged on the surface of the drum, a gap is reserved between the steam pipe and the outer surface of the drum, one end of the steam pipe is connected with a hot air supply system and is close to the feed end of the drum, the other end of the steam pipe is connected with a hot air recovery system and is close to the discharge end of the drum, the feed end of the drum is connected with the hot air supply system and the discharge end of the drum is connected with the hot air recovery system. The molding sand drum dryer can guarantee more stable drying environment and drying efficiency and can guarantee molding sand drying uniformity and consistency.

Owner:赵勇辉

Air well technological testing system during full life cycle

PendingCN106869863ASimple processOptimize job parametersConstructionsFluid removalFull life cycleAir compressor

The invention belongs to the technical field of air well technological testing and particularly provides an air well technological testing system during a full life cycle. The air well technological testing system during the full life cycle comprises an air compressor, a water tank, an air storage well, a plunger pump, an air-liquid mixed accurately-control injecting system, an input manifold, a technological testing well, a throttling manifold, an automatic separating and metering system, a sound eliminating and filtering recycling system, a waste water collector, a down hole multipoint parameter direct reading test and interpreting system and a visualization monitoring and operating integrated system. According to the air well technological testing system during the full life cycle, the problem that parameter optimization and effect verification cannot be achieved due to the fact that the operation technologies such as spray induction and liquor drainage, drainage air recovery, down hole throttle and air well repair lack necessary testing platforms all the time in the down hole operation process is solved, air well technological simulating and testing during the full life cycle can be conducted, wherein the air well technological simulating and testing during the full life cycle comprises construction technological verification tests and operation parameter optimization such as air well liquor drainage after pressing, low-pressure air well spray induction and liquor drainage, drainage air recovery, down hole throttle and the well repair technology and operation parameter optimization as well as technological simulating and testing of operation under the pressure and coiled-tubing operation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Energy-saving needle-shaped tea stir-frying machine and method for processing needle-shaped tea by using energy-saving needle-shaped tea stir-frying machine

PendingCN108541780AKeep it green and brightStraight and beautifulPre-extraction tea treatmentBlack teaAgricultural engineering

The invention discloses an energy-saving needle-shaped tea stir-frying machine and a method for processing needle-shaped tea by using the energy-saving needle-shaped tea stir-frying machine. Accordingto the energy-saving needle-shaped tea stir-frying machine, a roller is arranged, in rotating coordination, in a shell; a material inlet and a material outlet of the roller reveal outside the shell;a sealed space is formed between an outer wall of the roller and the shell; a stir-frying paddle rotating shaft is arranged in the roller; a set of stir-frying paddles are arranged on the stir-fryingpaddle rotating shaft; two ends of the stir-frying paddle rotating shaft are supported by a first stir-frying paddle mounting base and a second stir-frying paddle mounting base; the stir-frying paddlerotating shaft and the roller are both driven by a variable-speed gear motor, wherein rotation directions of the stir-frying paddle rotating shaft and the roller are opposite; a hot air pipe is arranged at a material inlet of the roller; a fixed leaf feeding port is arranged on the hot air pipe; the hot air pipe is connected with an electrically-heated blast furnace; a hot air recovery fan is arranged at a material outlet end of the roller; and a hot air recovery pipe is connected with the hot air recovery fan. Green tea stir-fried by using the energy-saving needle-shaped tea stir-frying machine is tight, straight and beautiful in strip shape, and very well preserves bright green color of green tea; and straight-strip-type Congou black tea stir-fried by using the energy-saving needle-shaped tea stir-frying machine is tight, straight and beautiful in strip shape, and has golden tea color.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Aerator and container-aerator assembly

InactiveUS20170014783A1Efficient aerationSimple and cost-effective structureFlow mixersMixing methodsAerationAir recovery

An aerator comprises a tubular member, an air recovery conduit and aeration members. The aeration members comprise an aeration conduit that projects from the outer surface of the tubular member.

Owner:GUALA CLOSURES SPA

Hot air recovery system of tea drying machine

InactiveCN102669311AShorten the stall timeAlleviate problems such as labor shortagePre-extraction tea treatmentHot air ovenPulp and paper industry

The invention discloses a hot air recovery system of a tea drying machine. The hot air recovery system comprises a hot air stove and a drying machine; the drying machine is communicated with an air outlet of the hot air stove through a first guide pipe; the hot air recovery system further comprises a second guide pipe and a third guide pipe; the top of the drying machine is provided with an air suction hood communicated with the top of the drying machine; and the air suction hood is communicated with a green leaf tedding chamber through the second guide pipe and communicated with an air inlet of the hot air stove through the third guide pipe; Both the second guide pipe and the third guide pipe are provided with regulation valves and draught fans. According to the hot air recovery system of the tea drying machine, disclosed by the invention, when temperature in a green leaf tedding workshop cannot reach at the requirements, the hot air in the hot air hood is discharged to the green leaf tedding chamber through the second guide pipe, and the discharged hot air is used for rapidly tedding tea leaves and effectively speeding up moisture loss in fresh leaves (in particular rainwater-contained leaves), so that the tedding time of tea leaves is shortened, the number of workers is reduced, the problems such as manpower shortage during the traditional processing of tea leaves are solved, and the utilization rate of heat is improved.

Owner:浙江更香有机茶业开发有限公司

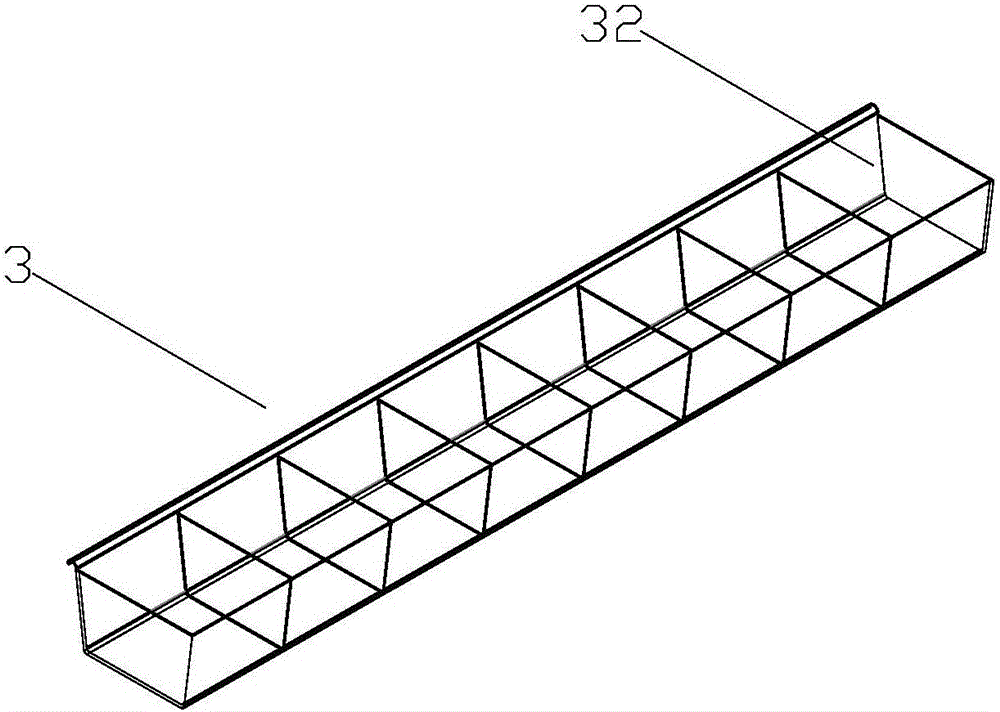

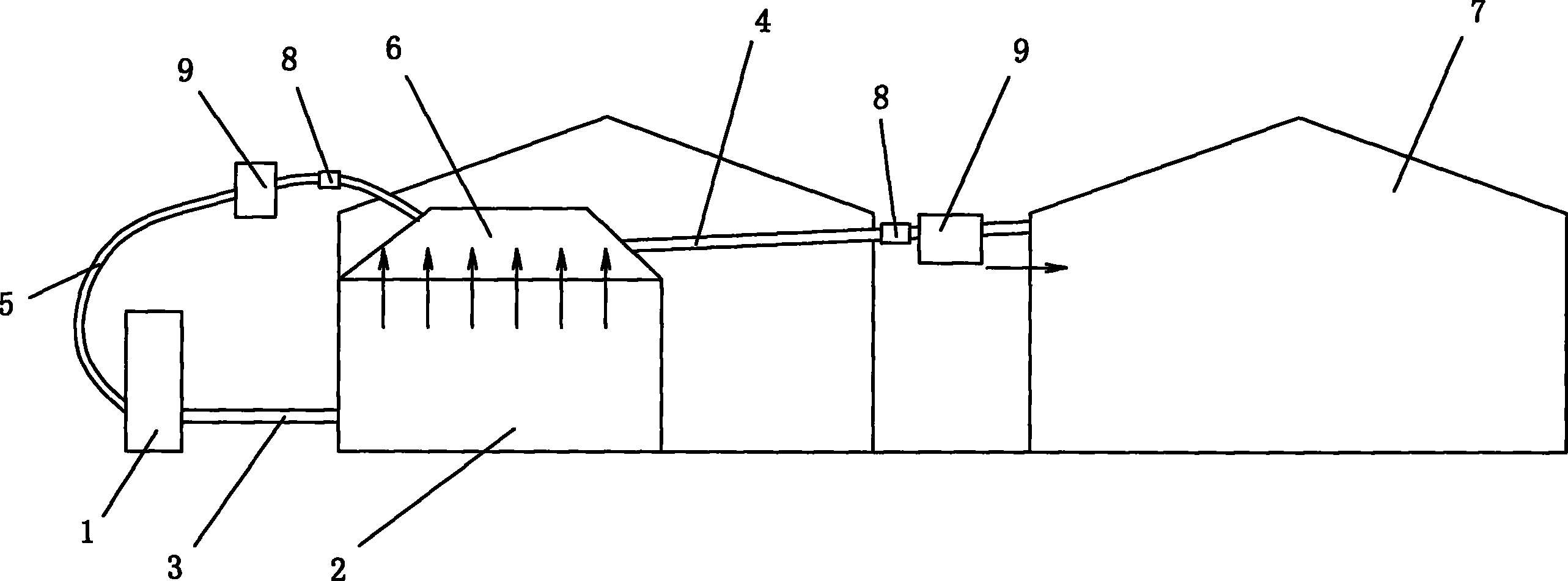

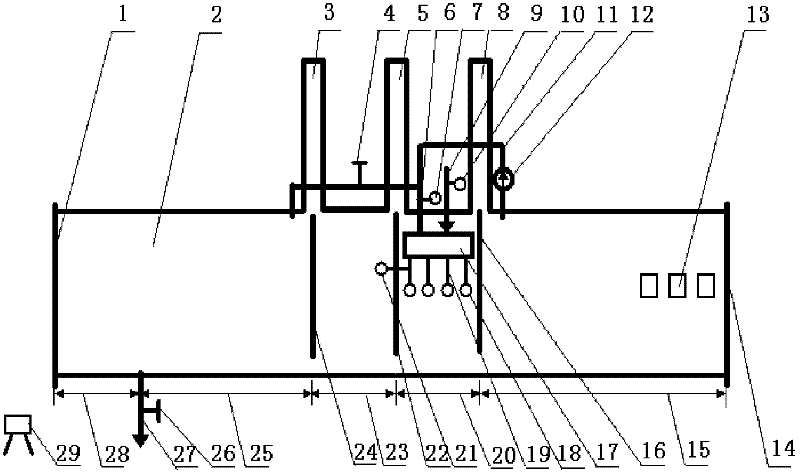

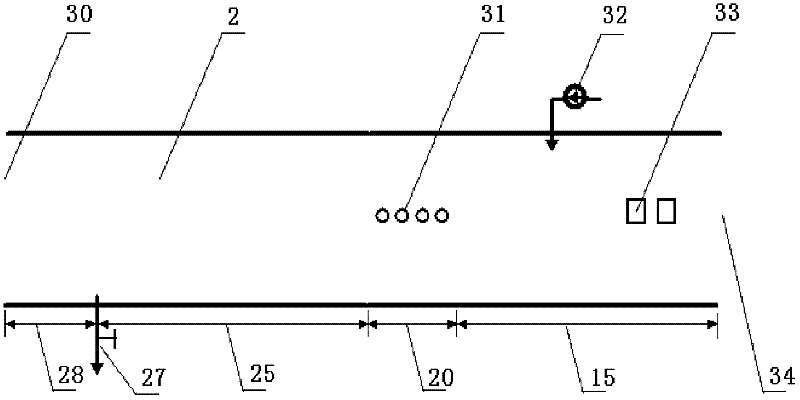

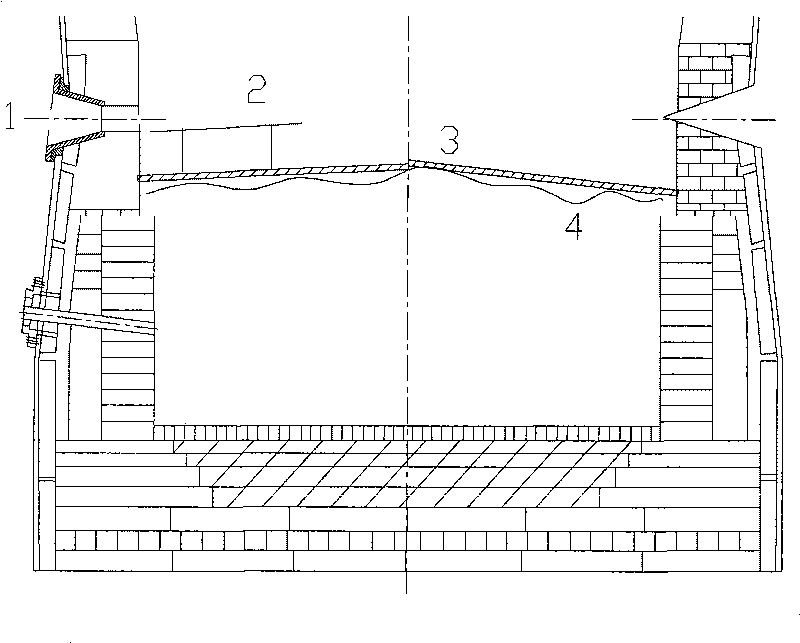

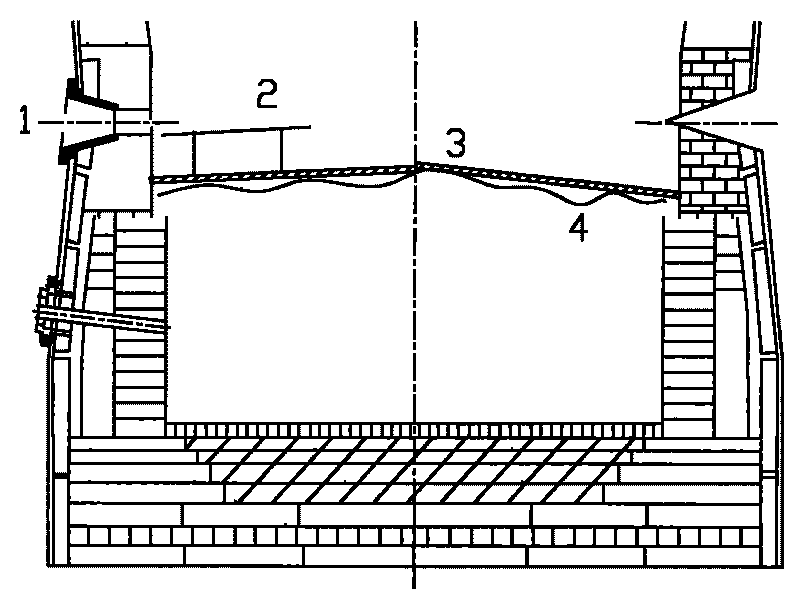

Tunnel kiln

InactiveCN102538448AReduce heat dissipationReduce energy consumptionFurnace typesWaste heat treatmentTunnel kilnCombustion chamber

The invention relates to a tunnel kiln. A kiln front door and a kiln back door are arranged to decrease external heat dissipation of two end openings of the tunnel kiln; a back heating section, a front hanging door, a middle hanging door and a rear hanging door are arranged to decrease dissipation of heat of a sintering section into the tunnel kiln or other areas and reduce energy consumption of the tunnel kiln, wherein the front hanging door, the middle hanging door and the rear hanging door are refractory, heat-insulating and controllable and are arranged at the initial end of the back heating section, at the initial end of the sintering section and at the tail end of the sintering section; a waste hot air recovery channel is arranged to recover waste hot air in a cooling section; and acombustion chamber outside the tunnel kiln is arranged and the waste hot air in the cooling section is recycled, so that the sintering section of the tunnel kiln obtains air-fuel ratio of efficient combustion, and fuels are more conveniently controlled to sufficiently combust. The sintering section of the tunnel kiln is less in energy consumption and high in temperature, and the tunnel kiln has the advantages of high waste heat utilization level, short sintering time and low energy consumption.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

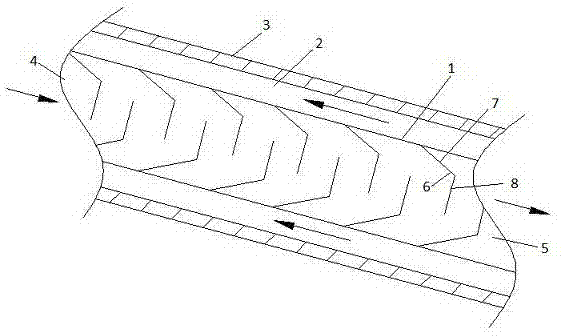

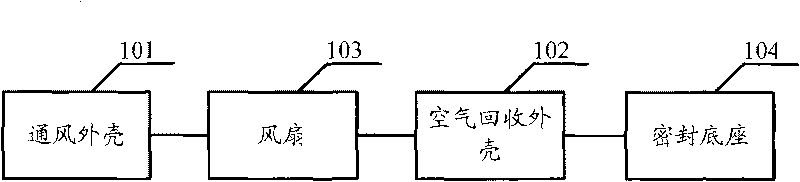

Method for improving exhaust air recovery tower efficiency and exhaust air recovery tower

InactiveCN101279180AImprove efficiencyReduce the temperatureDispersed particle separationExhaust fumesEngineering

The invention discloses a method for increasing the efficiency of a waste gas recovery tower, wherein, a packing layer is additionally arranged on the neck of the tower; at least one spraying pipeline is arranged above the packing layer arranged on the neck of the tower; and a condenser is additionally arranged. The method for increasing the efficiency of waste gas recovery tower can effectively absorb benzene, formaldehyde and other organic gases in waste gas, thus reducing the emission of organic gases in waste gas and retrieving organic composition.

Owner:中国蓝星(集团)总公司 +1

Hot air recovery device and air conditioner-water heater integration system adopting same

ActiveCN105371405AImprove heat transfer efficiencyGuaranteed uptimeEnergy recovery in ventilation and heatingMechanical apparatusWaste heat recovery unitEngineering

The invention relates to the technical field of waste heat recovery devices, in particular to a hot air recovery device and an air conditioner-water heater integration system adopting the same. The hot air recovery device comprises a guide air way, wherein a window structure is arranged on the side wall of the guide air way, and is provided with a cover plate; and the cover plate is used for opening or closing the window structure. Meanwhile, the invention further provides an air conditioner-water heater integration system adopting the hot air recovery device. Through the guide air way, the window structure arranged on the guide air way and the cover plate for opening and closing the window structure, the recovery of heat discharged from an air conditioner outdoor unit is realized, so that a water heater outdoor unit is higher in heat exchange efficiency, and the air conditioner outdoor unit and the water heater outdoor unit can be guaranteed to singly and normally operate.

Owner:GREE ELECTRIC APPLIANCES INC

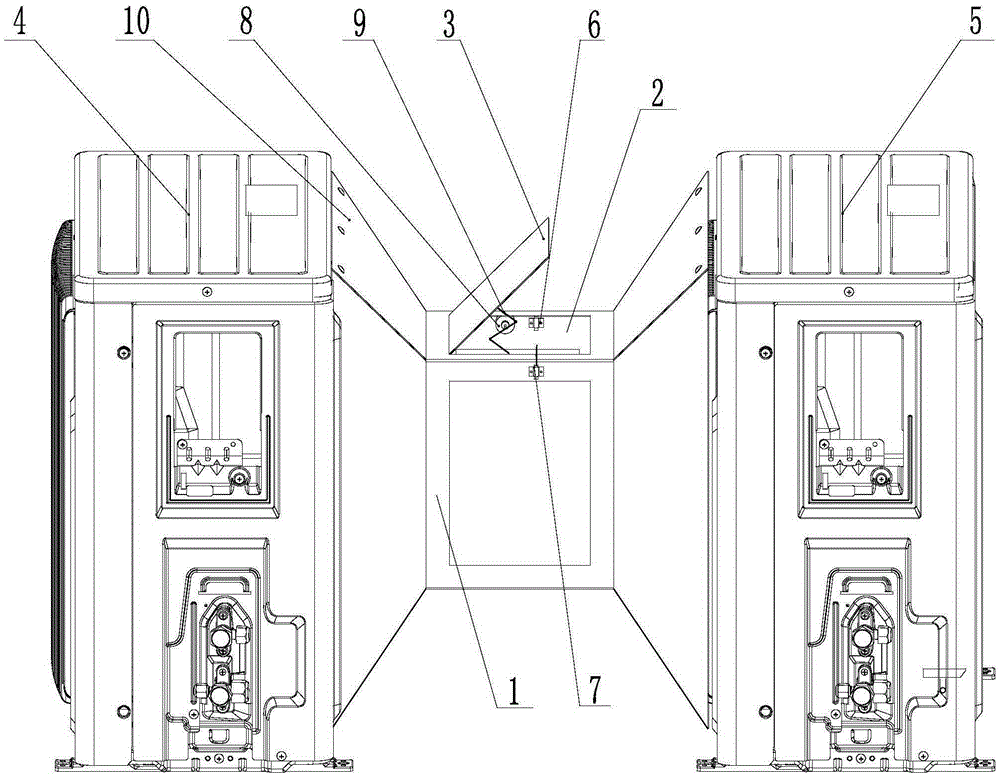

Dehumidifier

InactiveCN101732022AFast moisture absorptionImprove moisture absorptionFootwear cleanersDesiccantMoisture absorption

The embodiment of the invention discloses a dehumidifier which comprises a ventilation shell, a fan and a sealing base, wherein the ventilation shell can bear a desiccant, and the desiccant can absorb moisture in air; the ventilation shell is connected with one end of an air recovery shell, and a fan which drives the air to flow to contact the desiccant borne by the ventilation shell when operating is installed on the air recovery shell; and the sealing base is connected with the other end of the air recovery shell and is provided with a soft edge which can cling to the inner wall of a shoe and seal the shoe. In the embodiment, by adding the fan in the dehumidifier, peripheral air is driven to fully contact the desiccant, thereby accelerating the moisture absorption speed of the desiccant and enhancing the moisture absorption function. In addition, by adding the sealing base, the shoe is sealed and a sealed space is formed, and therefore, a range of dry air can be shortened within the space of the shoe, and the dehumidification efficiency is enhanced. Further, because the shoe is sealed with the sealing base, the dehumidification range of the dehumidifier is limited within the range of a shoe frame, and the dehumidification efficiency is enhanced.

Owner:徐弘 +1

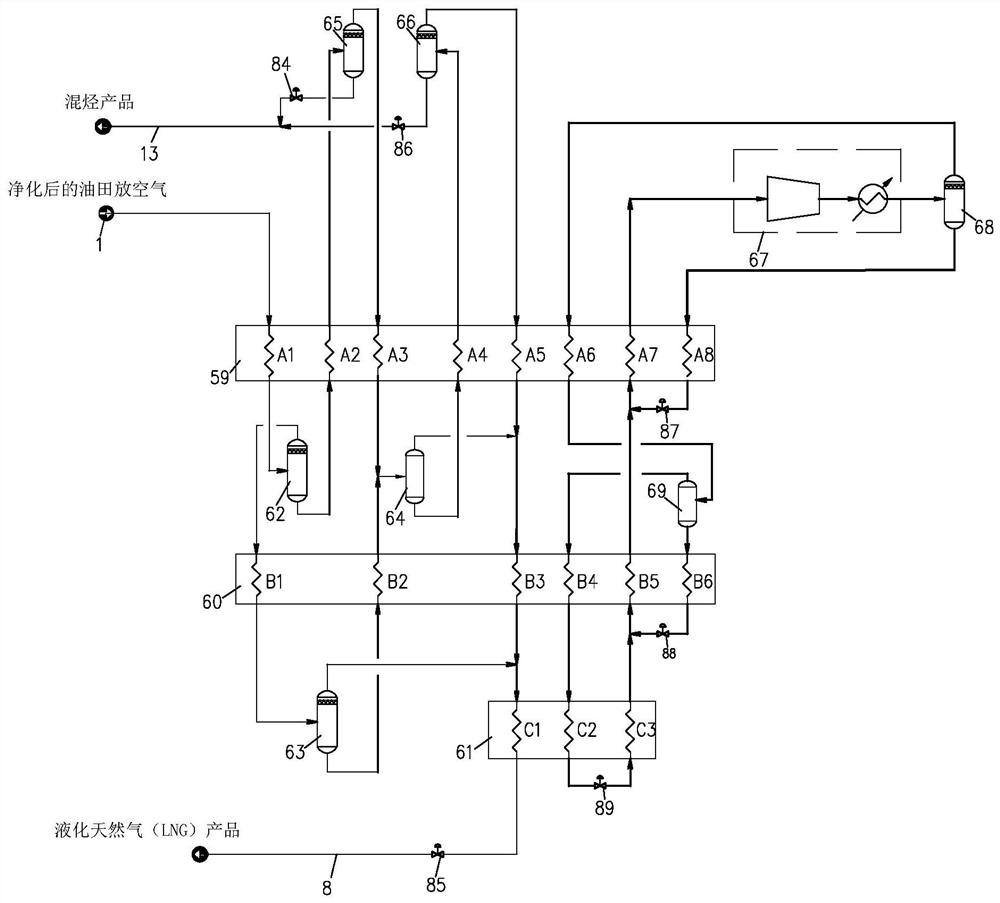

Liquefaction unit in vehicle-mounted mobile oilfield vent gas recovery system and liquefaction method thereof

ActiveCN111607423AEmission reductionLower the altitudeLiquid hydrocarbon mixture recoveryIn vehicleOil field

The invention relates to a liquefaction unit in a vehicle-mounted mobile oilfield vent gas recovery system and a liquefaction method thereof. The liquefaction unit comprises a precooling heat exchanger, a cryogenic heat exchanger, a liquefaction heat exchanger, a first-stage separator, a second-stage separator, a third-stage separator, a normal-temperature separator, a mixed hydrocarbon separatorand a closed mixed refrigerant three-stage throttling refrigeration device. A bottom liquid outlet of the mixed hydrocarbon separator is connected with a mixed hydrocarbon product conveying pipeline.The closed mixed refrigerant three-stage throttling refrigeration device provides cooling capacity for the pre-cooling heat exchanger, the cryogenic heat exchanger and the liquefaction heat exchanger.The liquefaction unit adopts the first-stage separator, the second-stage separator, the third-stage separator, the normal-temperature separator and the mixed hydrocarbon separator to separate a liquid mixed hydrocarbon product and a liquid natural gas product. The product recovery rate is increased, the emission of oilfield vent gas is reduced, a traditional mixed hydrocarbon recovery rectifyingtower is canceled, the height of low-temperature equipment is reduced, and the design, manufacturing and application of a vehicle-mounted mobile low-temperature cold box skid are realized.

Owner:WUXI HONGSHENG HEAT EXCHANGER MANUFACTURING CO LTD

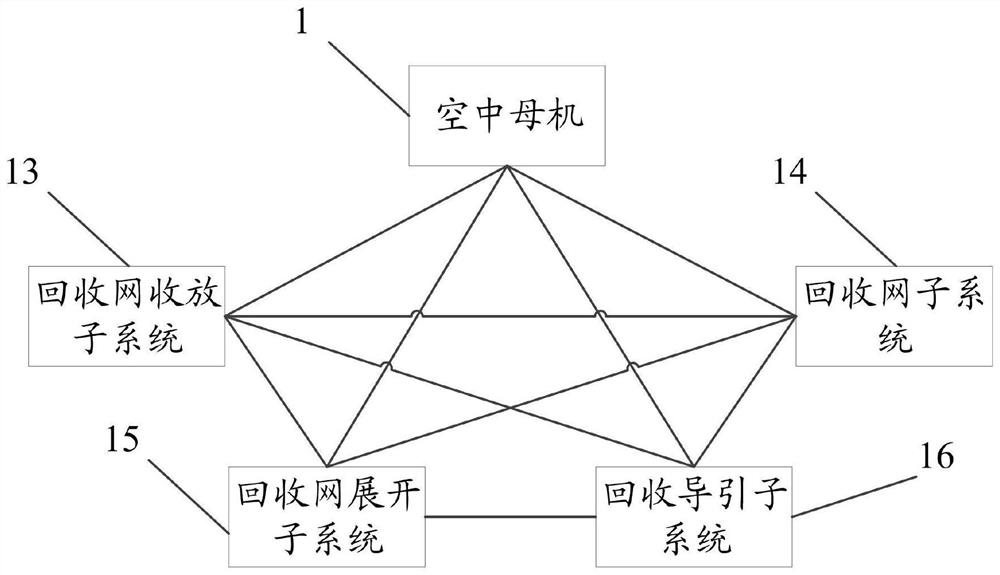

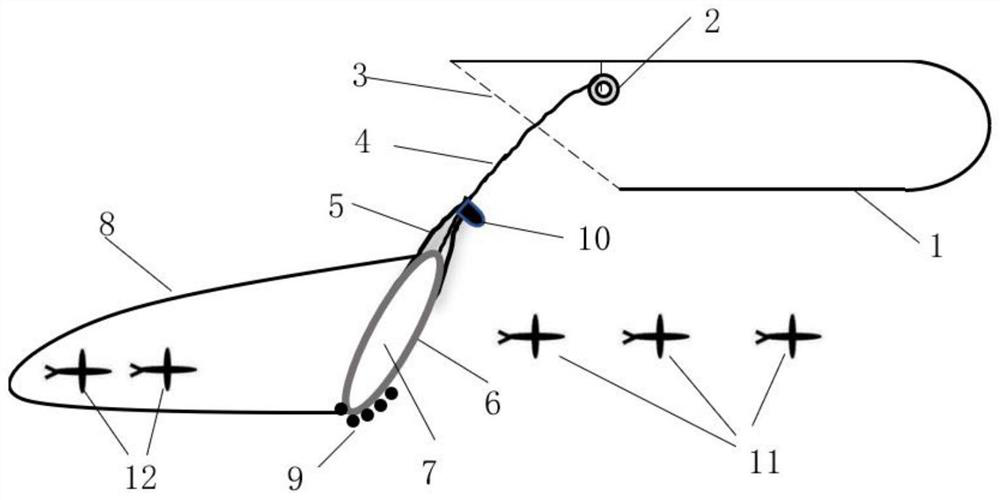

Unmanned aerial vehicle group air recovery system and method

PendingCN114237290ARealize copyingImprove recycling efficiencyPosition/course control in three dimensionsUncrewed vehicleVision sensor

The invention discloses an unmanned aerial vehicle group air recovery system and method. The system comprises a controller, an air mother machine, a recovery net folding and unfolding subsystem, a recovery net subsystem, a recovery net unfolding subsystem and a recovery guiding subsystem. The method comprises the steps that the controller sends a recovery signal; acquiring a recovery flight route of the aerial mother aircraft; sending a control instruction for releasing the recovery network subsystem; and sending a control instruction for recovering the recovery network subsystem. Through the design of the structure of the recovery net subsystem, the recovery net subsystem is released by the recovery net retracting and releasing subsystem on the aerial mother aircraft platform, the recovery net is opened by air flow, and the visual sensor transmits images of the unmanned aerial vehicle and a net port to the controller in real time; the controller controls the flight position of the aerial mother aircraft according to the images and the flight parameters of the unmanned aerial vehicles, and all the unmanned aerial vehicles are copied into the net bag; the system is simple in structural composition, safe and controllable in recycling process and high in recycling efficiency, and the aim of improving the recycling efficiency and reliability of the unmanned aerial vehicle is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for avoiding blast-furnace gunning rebound materials mixing with cokes in hearth

ActiveCN101748223AAvoid mixingReturn to normal operations as soon as possibleBlast furnace componentsBlast furnace detailsHearthBlast furnace

The invention discloses a method for avoiding blast-furnace gunning rebound materials mixing with cokes in a hearth, and belongs to the technical field of gunning a furnace wall by descending burden surface of a blast furnace and rapid recovery after maintenance. The method comprises the following steps of: descending the burden surface of the blast furnace to a tuyere zone; capping 4.5-5.5 tons of cokes to the burden surface from a furnace top of the blast furnace; enabling an operator to enter the furnace to leveling up sunk parts of the burden surface of the tuyere zone; stacking the burden surface to a tip shape and leveling up the burden surface; spraying a covering agent to keep the temperature; paving and fixing iron plates on the covering agent; inserting iron wires into round holes of the adjacent iron plates to fix to ensure that a gap is not reserved between the adjacent iron plates; placing a pre-welded angle iron stand between adjacent tuyere zones, and filling the space between the adjacent tuyere zones by the angle iron stand without gap; and fixing the iron plates on the upper side and the lateral sides of the angle iron stand to ensure that the rebound materials fall on the iron plates arranged in front of the tuyere zones. The method has the advantages of maintaining the cokes in the hearth to be clean to the maximum extent, improving the efficiency of clearing the rebound materials by the operator and creating a condition for rapid air recovery.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com