Cloth drying device of circular screen printing machine

A cloth drying and rotary screen printing technology, which is applied to screen printing machines, general parts of printing machinery, printing machines, etc., can solve the problems of fabric surface temperature field disorder, large space occupation, and low utilization rate, and achieve guaranteed Drying effect, reduced ventilation area, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

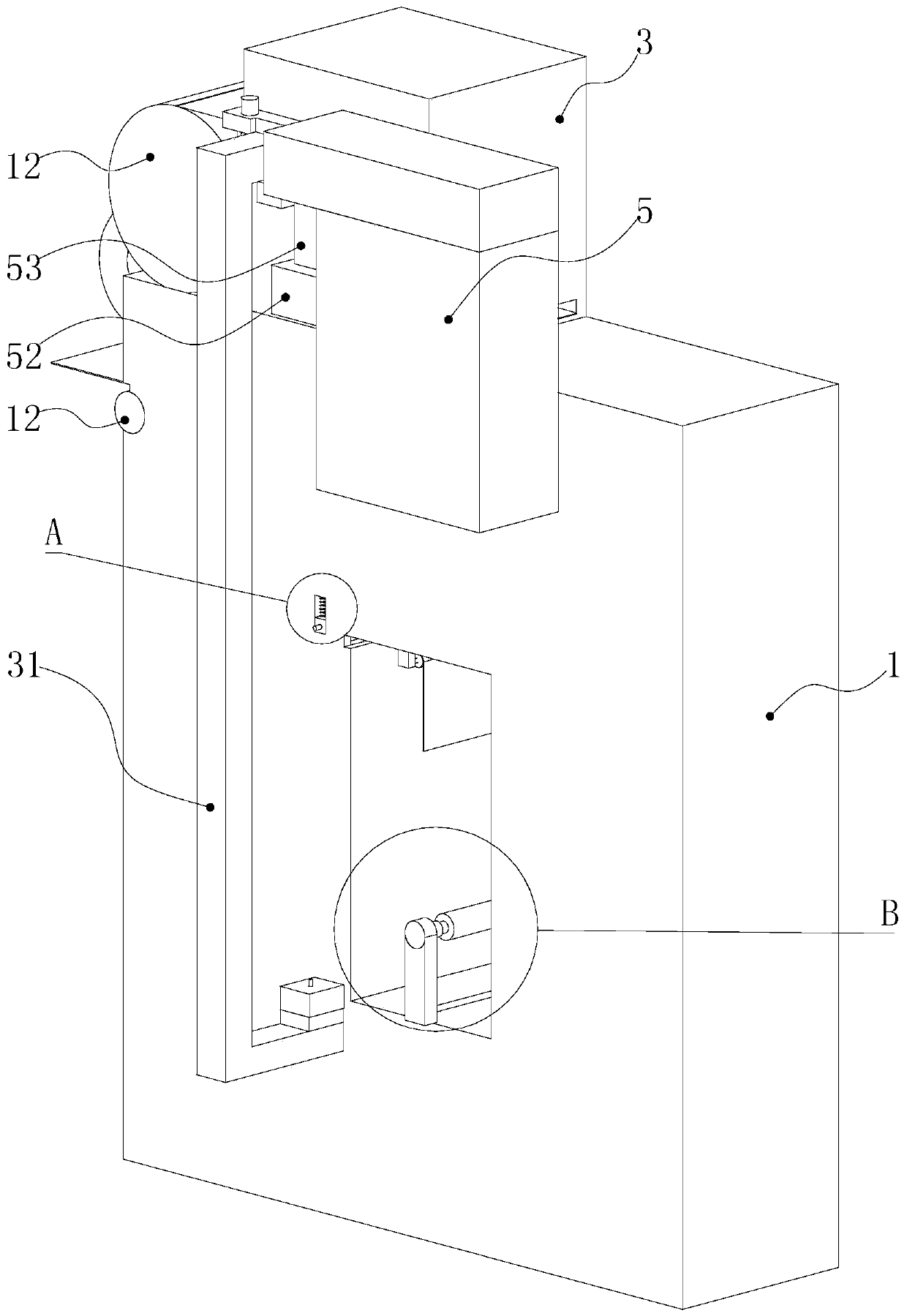

[0021] Such as Figure 1-7 As shown, a cloth drying device of a rotary screen printing machine includes an oven 1, a feeding mechanism, a drying mechanism, a hot air recovery mechanism and a collecting mechanism, and the material collecting mechanism includes a feeding port 11 and a feeding roller 12, The feed inlet 11 is provided on the side wall top of the oven 1, and the feed roller 12 is a conventional round roller, which is arranged in the feed inlet, and the two ends are respectively connected to the inner wall of the oven by rotation. The cloth can be flattened into the oven for drying.

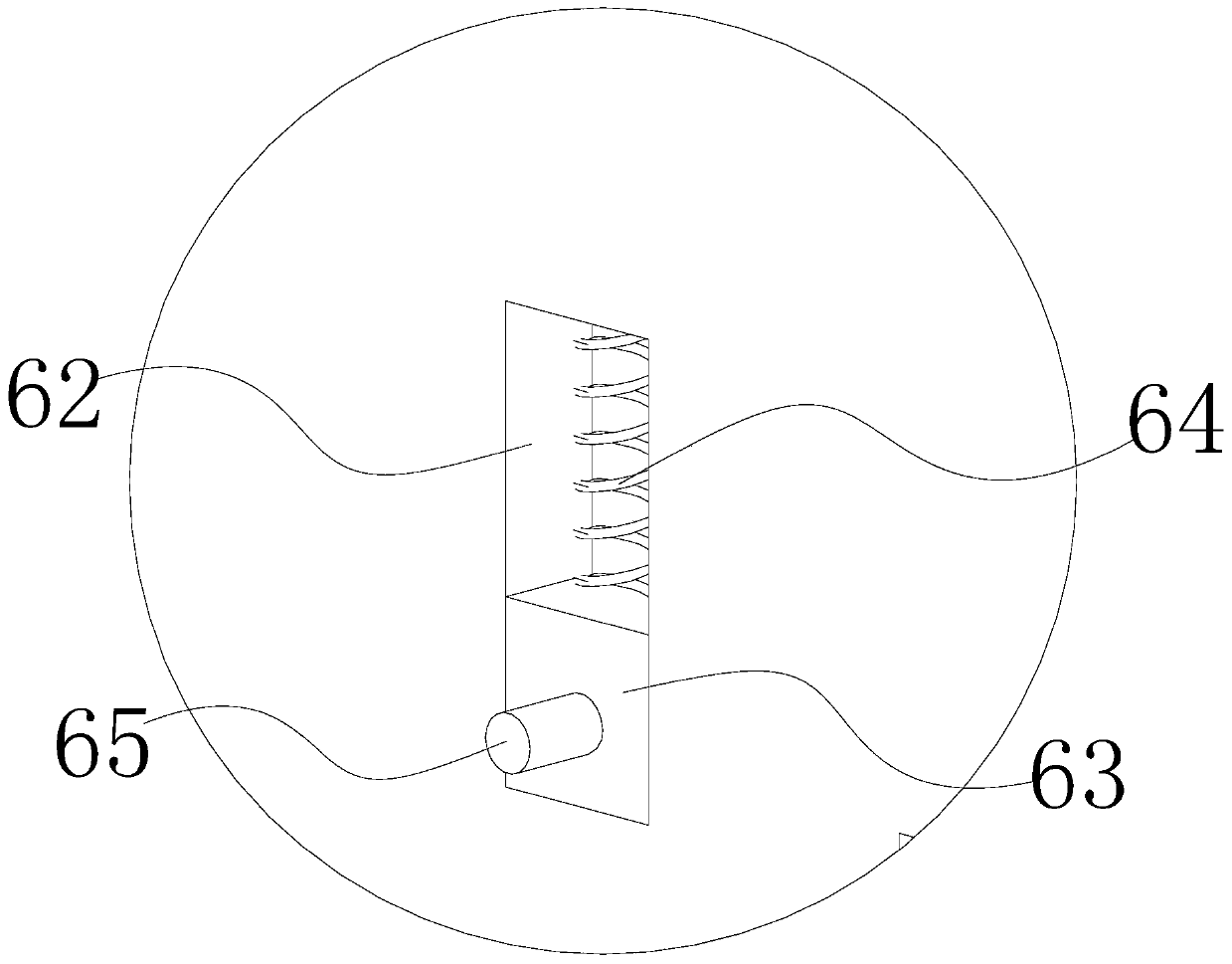

[0022] Described drying mechanism comprises guide roller 2, hot air blower 21, air inlet 22, air inlet pipe 23, heating plate 28 and air guide member, and described hot air blower 21 selects conventional hot air blower for use, is fixed on the oven top, and described air inlet The tuyere 22 is opened on the side wall of the oven, positioned at the top of the feed inlet. The air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com