Patents

Literature

45results about How to "Improve moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester fiber with functions of wetting, moisture transmitting and quick drying and fabric thereof

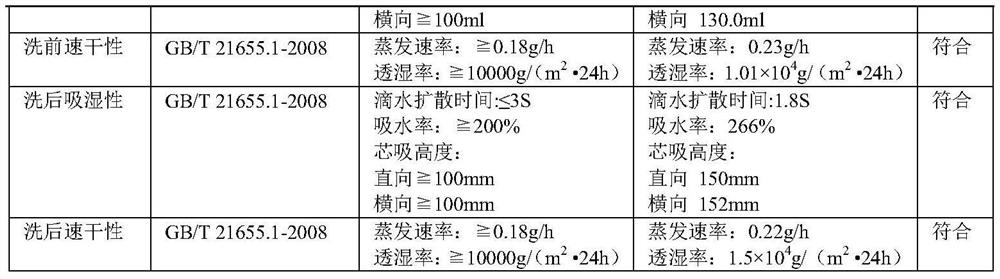

InactiveCN101792578AImprove moisture absorptionDiffusion fastConjugated synthetic polymer artificial filamentsCopolyesterNatural fiber

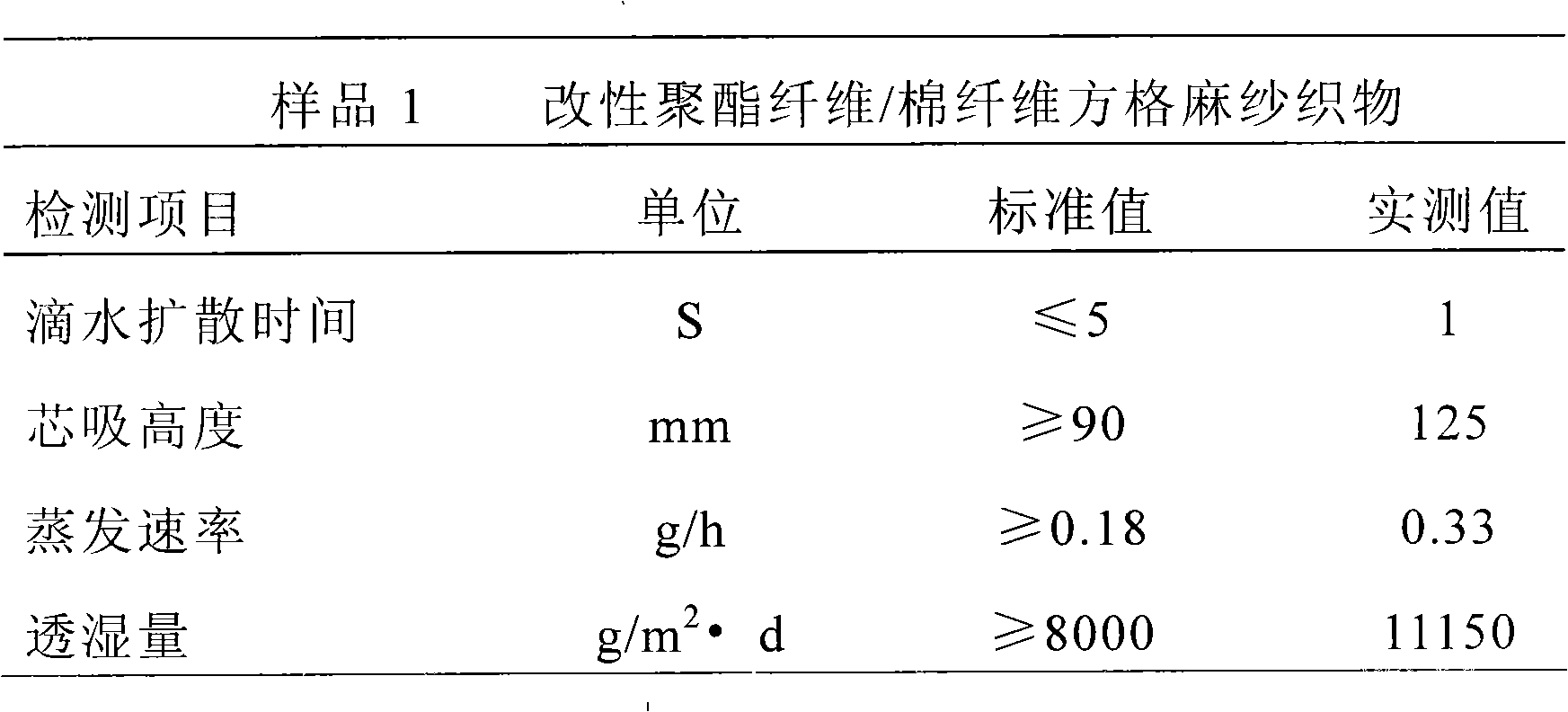

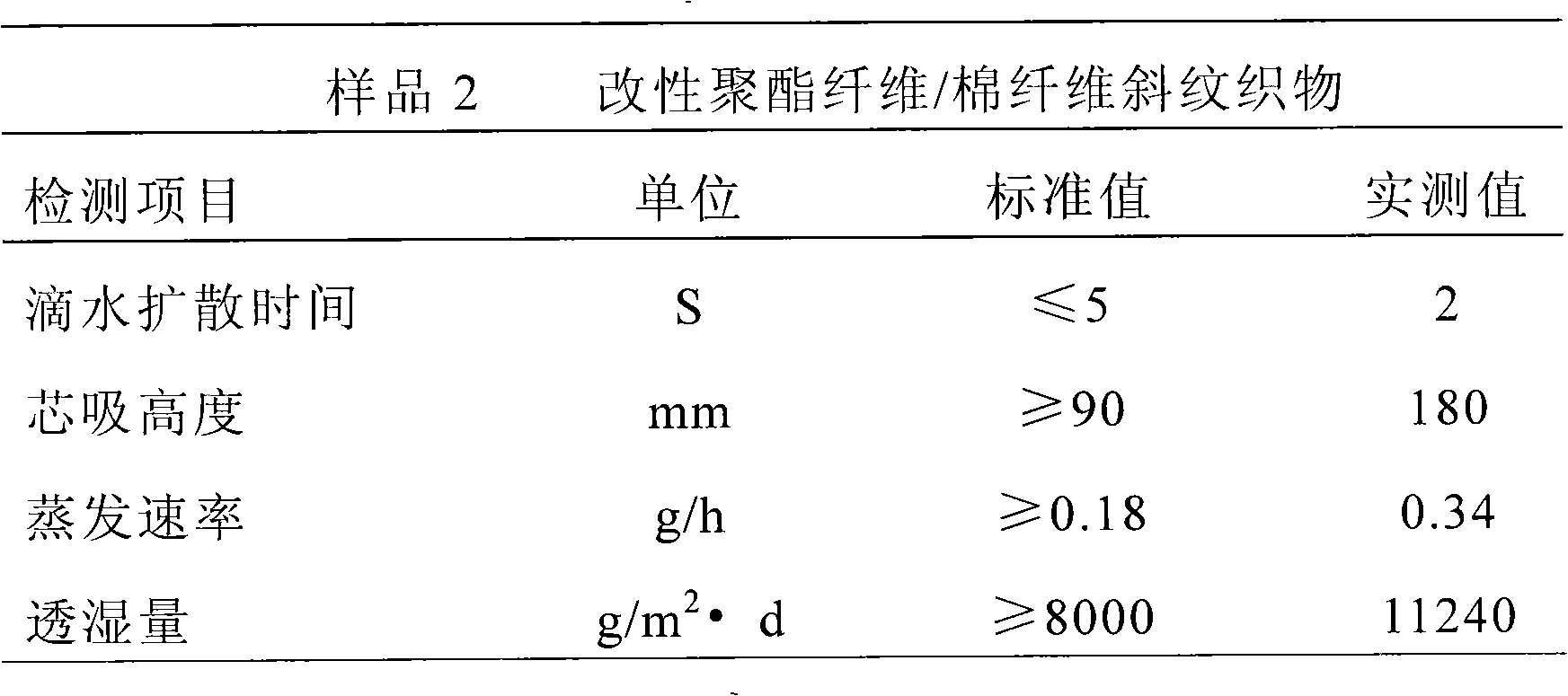

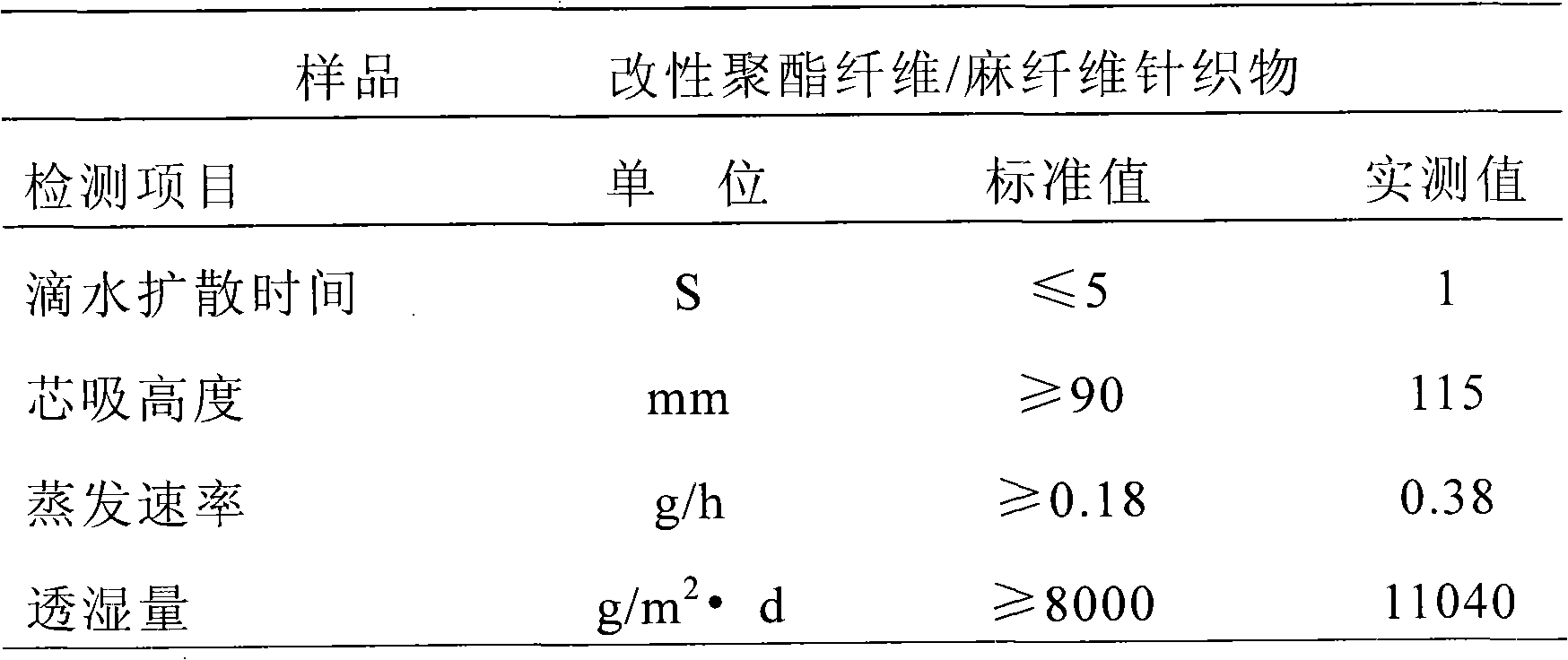

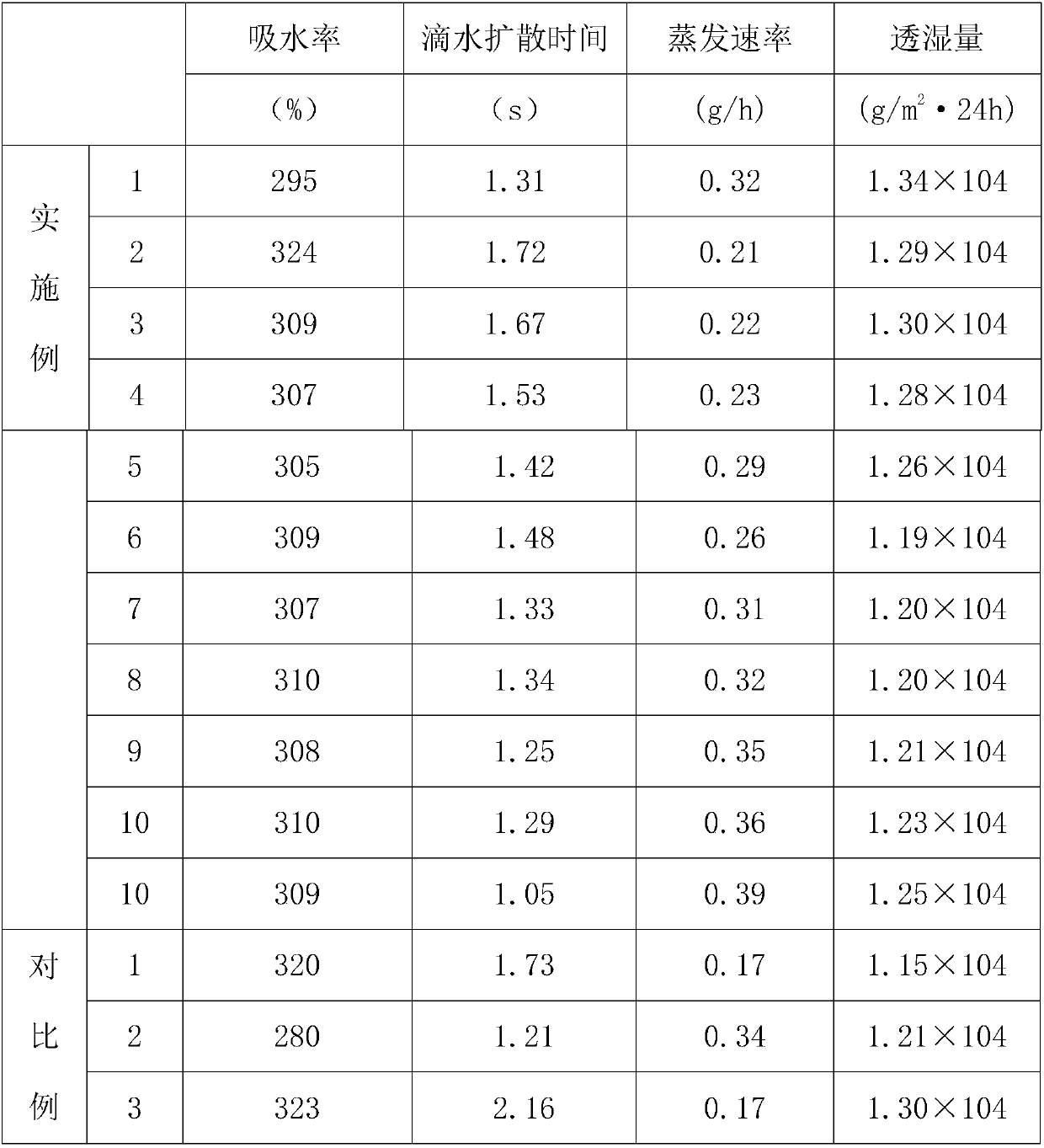

The invention discloses a modified polyester fiber prepared by carrying out blended spinning on functional copolyester master-batches containing moisture-absorbing radicals and inorganic nano-powder and conventional polyester chips, the section of the fiber is special-shaped and comprises micropores, the side surface of the fiber comprises a structure of longitudinal grooves and micro-pits, and a variety of fabric can be prepared by carrying out the blended spinning on the modified polyester fiber and natural fiber according to weight proportion. The fabric has the excellent functions of wetting by sweat, moisture transmitting and quick drying, thereby greatly improving the wearing comfort of the polyester fiber fabric.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Process for preparing activated carbon from bamboo

An activated bamboo carbon is prepared from choosing raw material, loading raw material in kiln, smoking for dewatering, dry distilling for charring it, refining, spraying steam and sealing kiln. Itsadvantages are physically activating it thoroughly, high adsorbability and electric conductivity, high output rate and no environmental pollution.

Owner:陈文照 +2

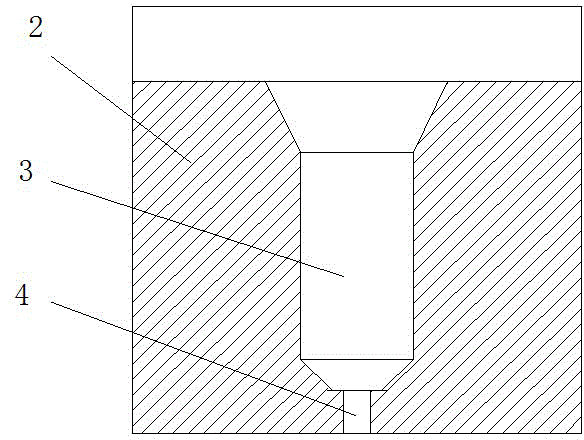

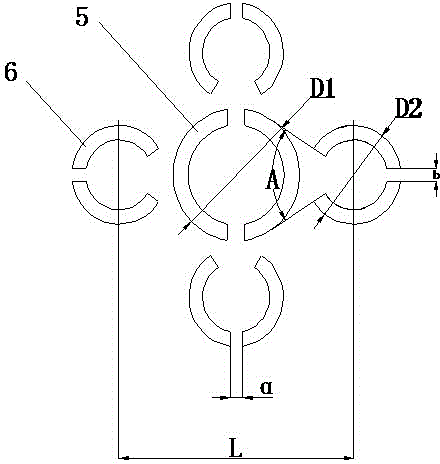

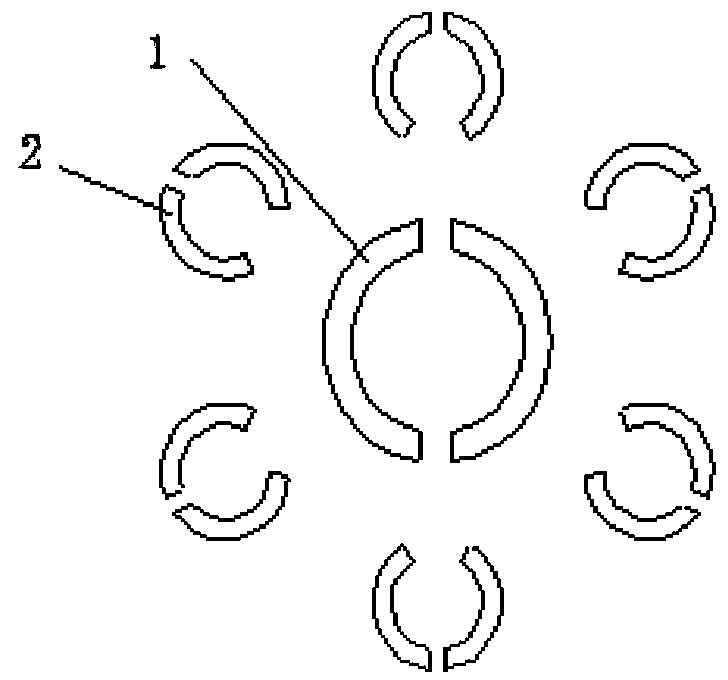

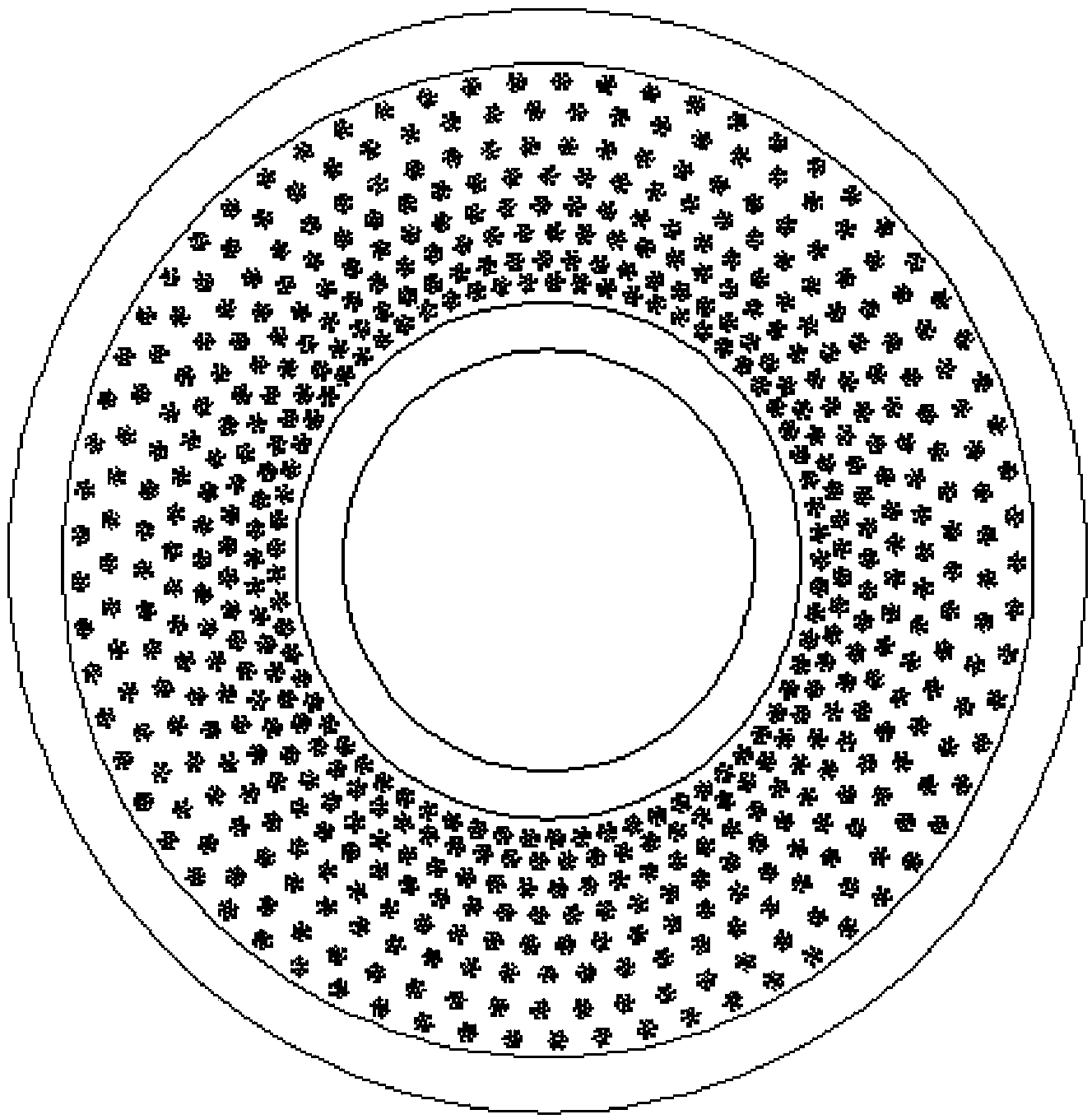

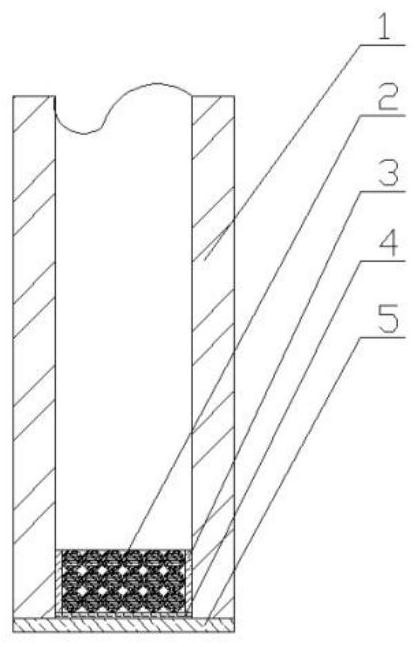

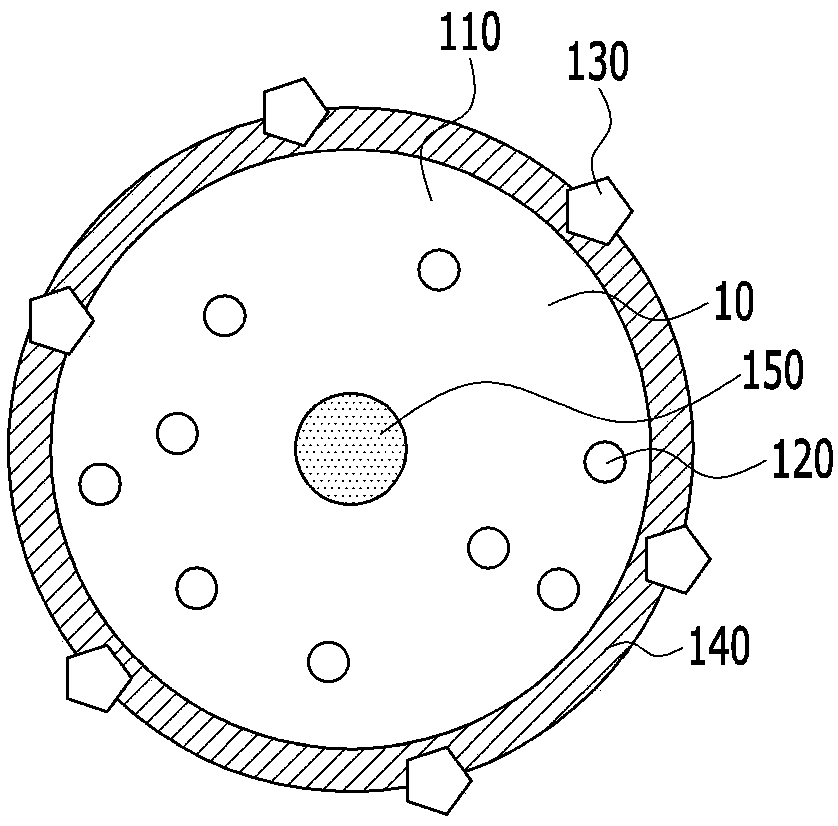

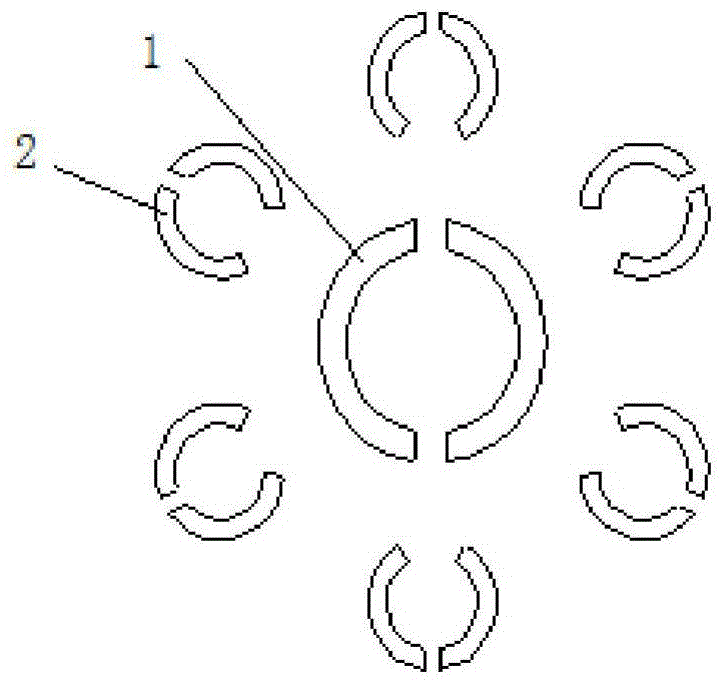

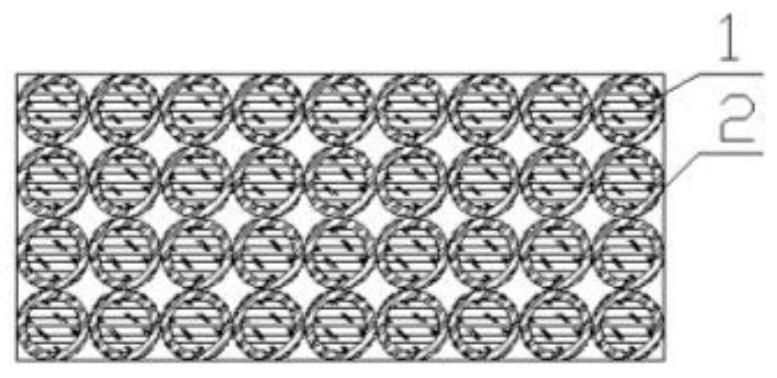

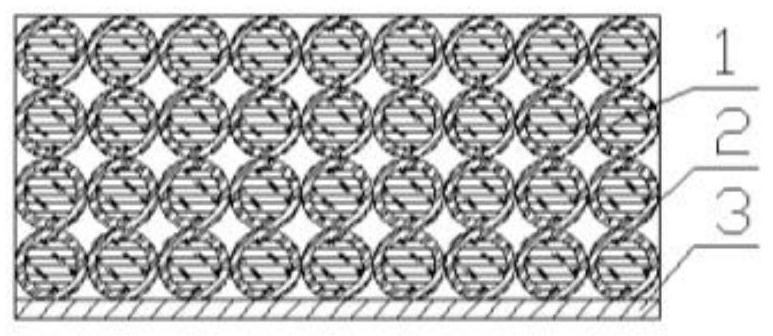

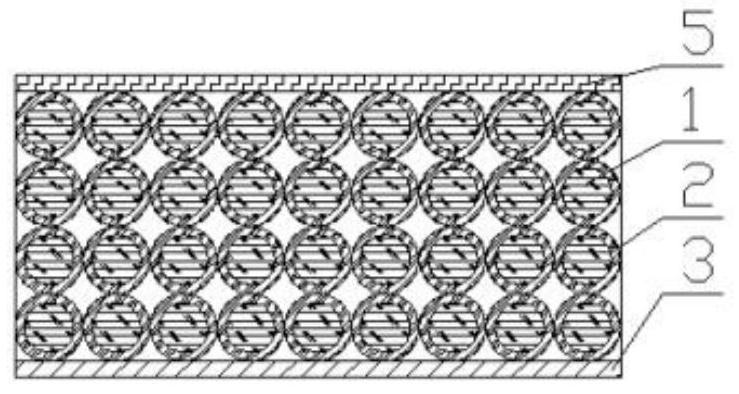

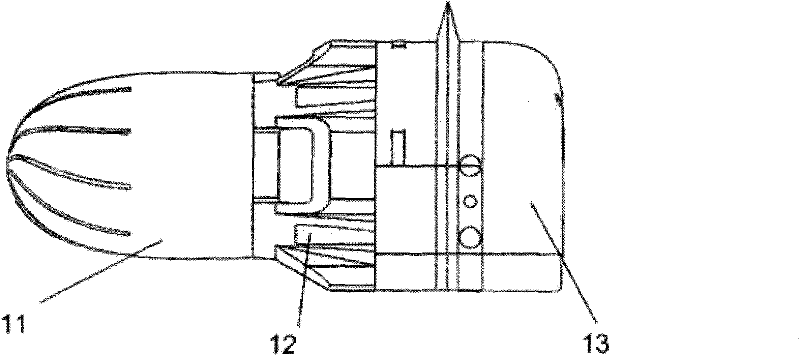

Method for spinning cross-shaped multi-hole hollow short fibers with recycle polyester bottle chip

InactiveCN104088026AEasy to shapeOptimization parametersFilament forming substance formingHollow filament manufacturePolyesterPolymer science

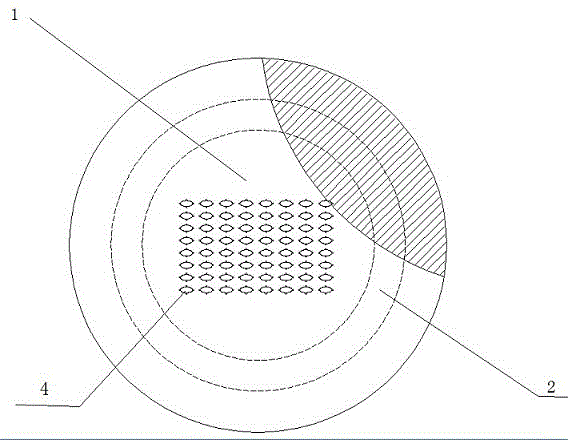

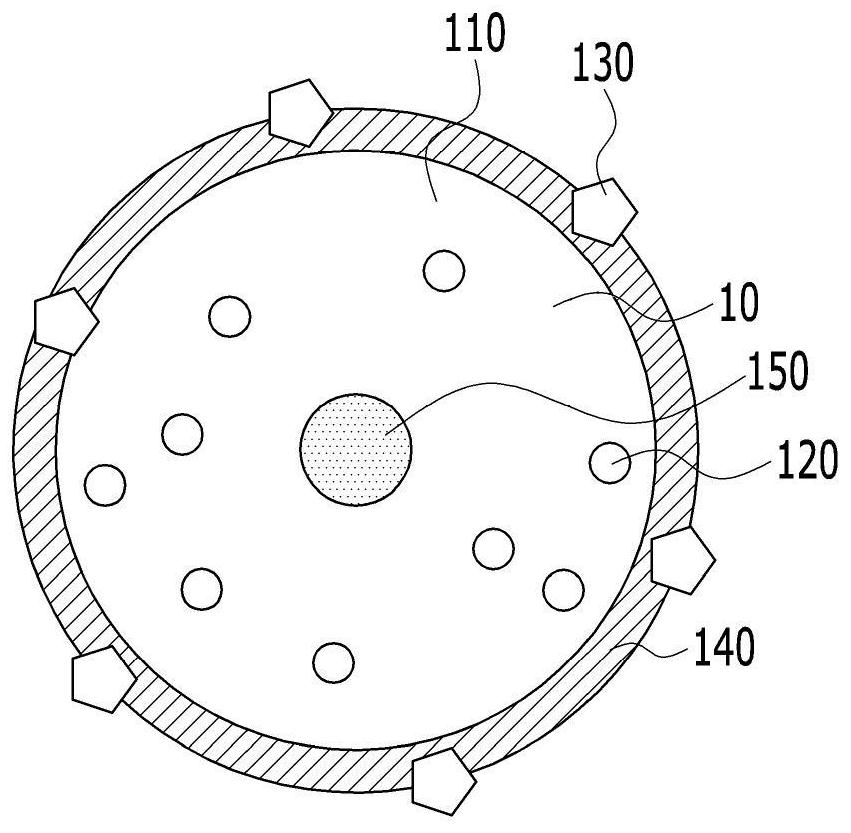

Provided is a method for spinning cross-shaped multi-hole hollow short fibers with a recycle polyester bottle chip. The recycle polyester bottle chip is dried by a vacuum drum and then is subjected to melt spinning. The recycle polyester bottle chip enters a spinning box body by screw squeezing and is sprayed out from spinneret orifices of a cross-shaped multi-hole hollow spinneret plate, nascent fibers are obtained, then the processes such as cross air blow cooling forming, winding, bundling, drafting, curling, oiling, relaxation heat setting and cutting are carried out, and the cross-shaped multi-hole hollow short fibers with the fineness of 6.67-14.44 dtex are obtained. The spinneret orifices are formed in the cross-shaped multi-hole hollow spinneret plate, the spinneret orifices are distributed in an array mode, spinneret orifice inlets are guiding holes, and spinneret orifice outlets are spinneret capillary pores. A center arc hole group and four outer periphery arc hole groups are formed in the spinneret capillary pores. The four outer periphery arc hole groups and the center arc hole group form a cross-shaped structure. A spinning technology is improved, the spinneret plate is designed in an innovative mode, and the prepared cross-shaped multi-hole hollow short fibers have the advantages of being high in hollowness degree, good in rebound resilience, large in specific surface area, soft in hand feel, good in moisture absorbing and breathing performance and the like.

Owner:JIANGSU FEILIN FIBER TECH

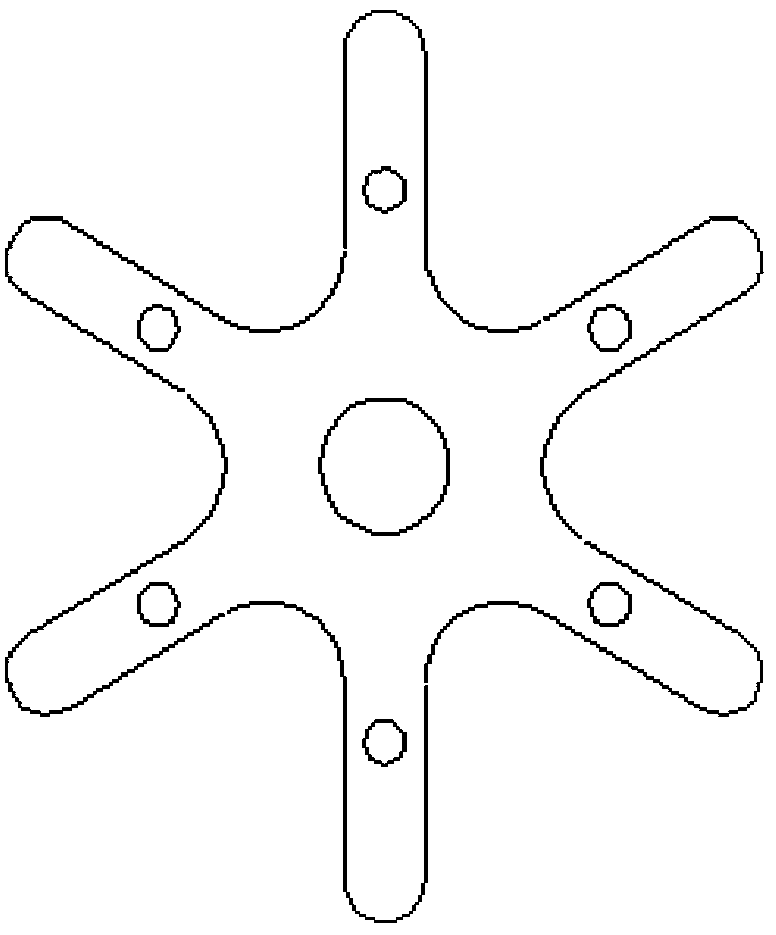

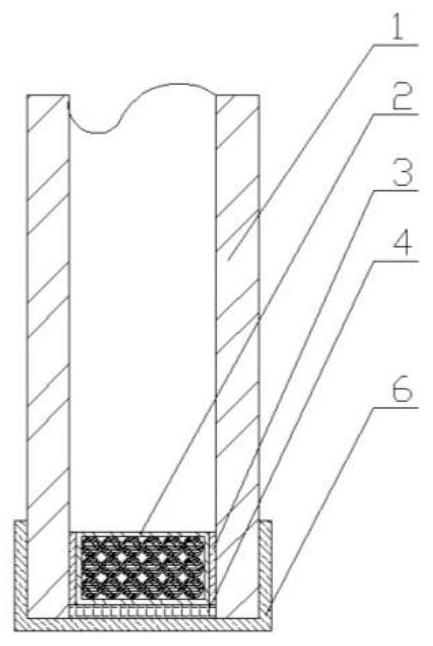

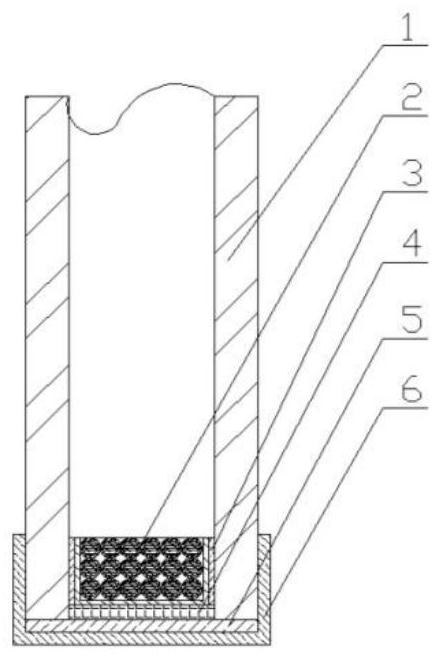

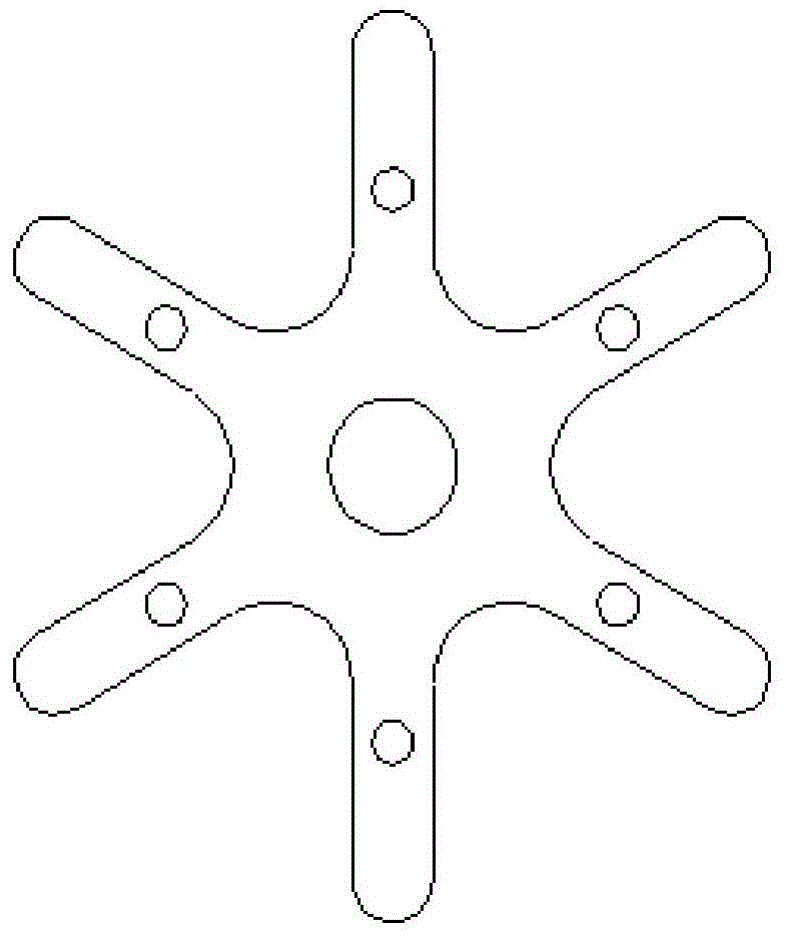

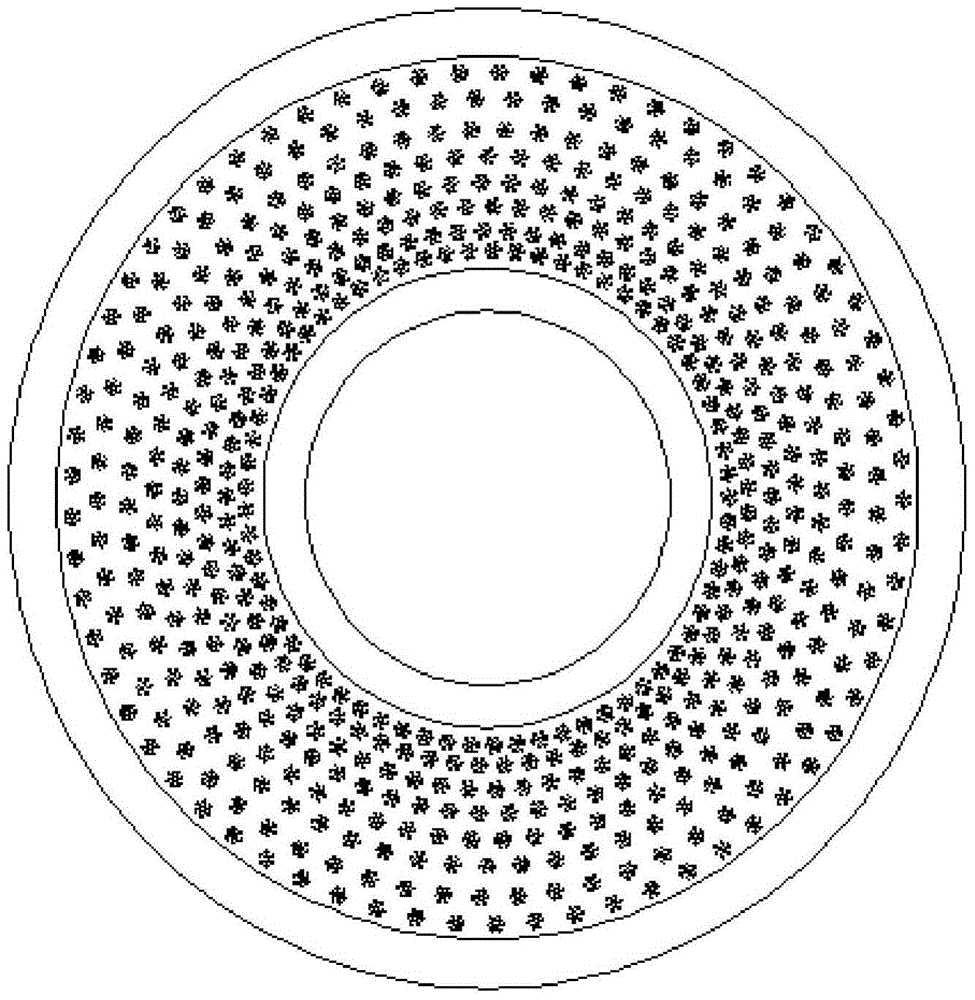

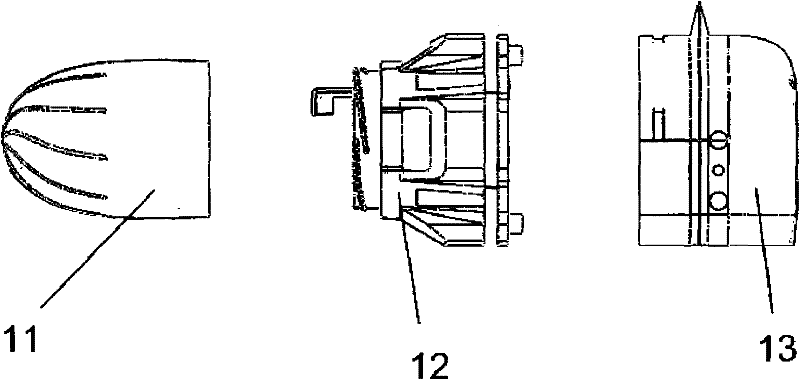

Preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes

ActiveCN104389036AEasy to shapeHigh degree of abnormalityHollow filament manufactureArtificial filament heat treatmentPolyesterPolymer science

The invention provides a preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes. The preparation method comprises the following steps: performing melt spinning on the renewable polyester bottle flakes after vacuum drum drying, enabling the renewable polyester bottle flakes to enter a spinning box body through screw extrusion, spinning out of spinneret orifices of a six-leaf porous hollow spinneret plate to obtain nascent fibers, cooling and forming through circulating air blowing, winding, bundling, drafting, crimping, oiling, loosening and heat setting, and cutting to obtain the six-leaf porous hollow staple fibers, wherein the spinneret orifices are formed in the six-leaf porous hollow spinneret plate and are arranged in arrays; inlets of the spinneret orifices are guide holes, and outlets of the spinneret orifices are spinning capillary holes; each spinning capillary hole comprises one central arc-shaped hole group and six peripheral arc-shaped hole groups; the six peripheral arc-shaped hole groups and the central arc-shaped hole group form a six-leaf structure. Through improvement of a spinning process and innovative design of the spinneret plate, the prepared six-leaf porous hollow staple fibers have the characteristics of high hollow degree, high rebound resilience, large specific surface area, good moisture-absorbing and breathable effect and the like.

Owner:江苏省科学技术情报研究所

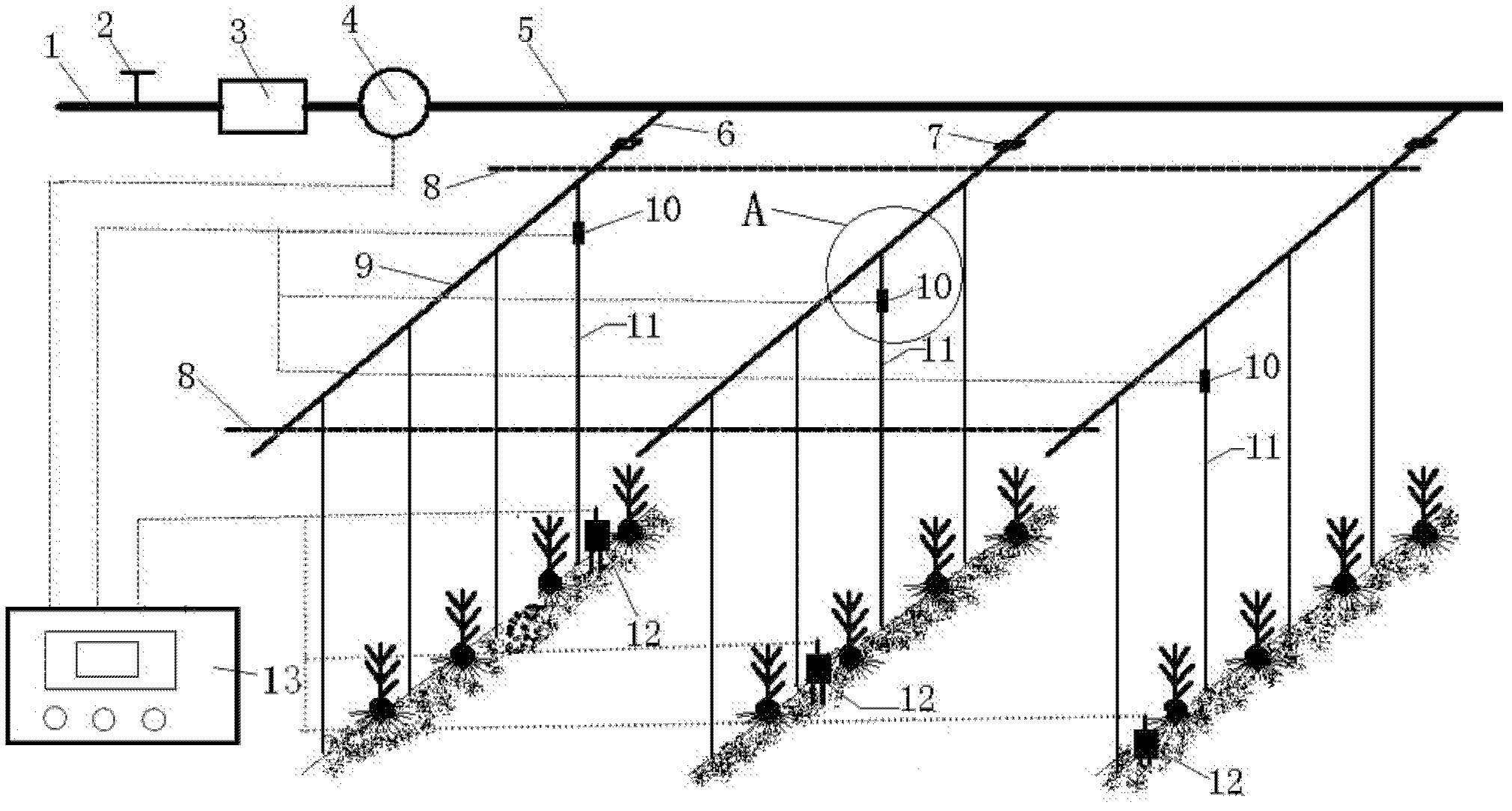

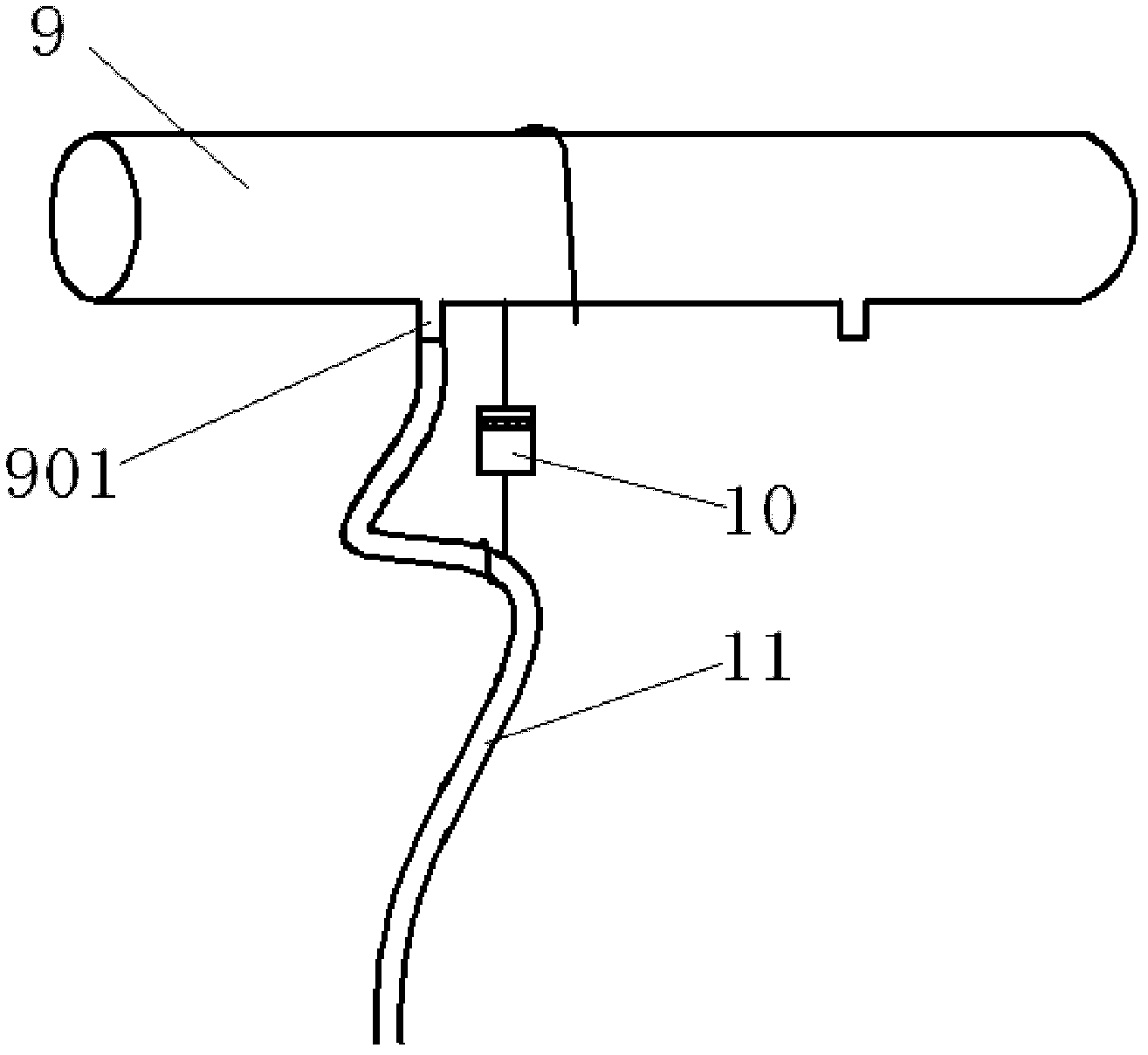

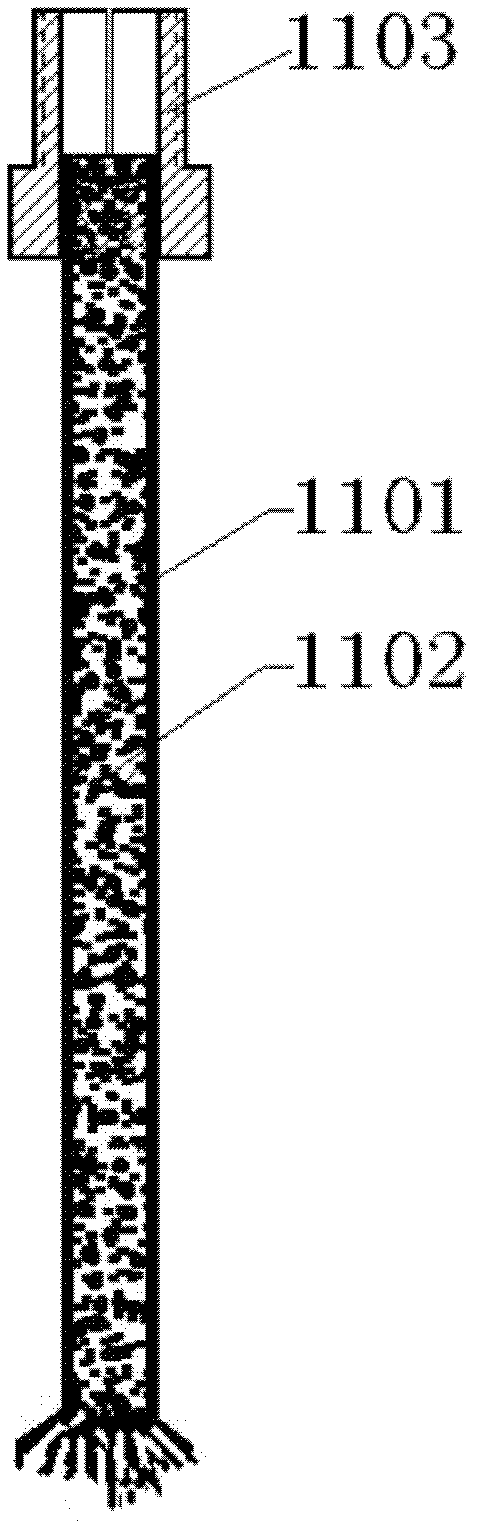

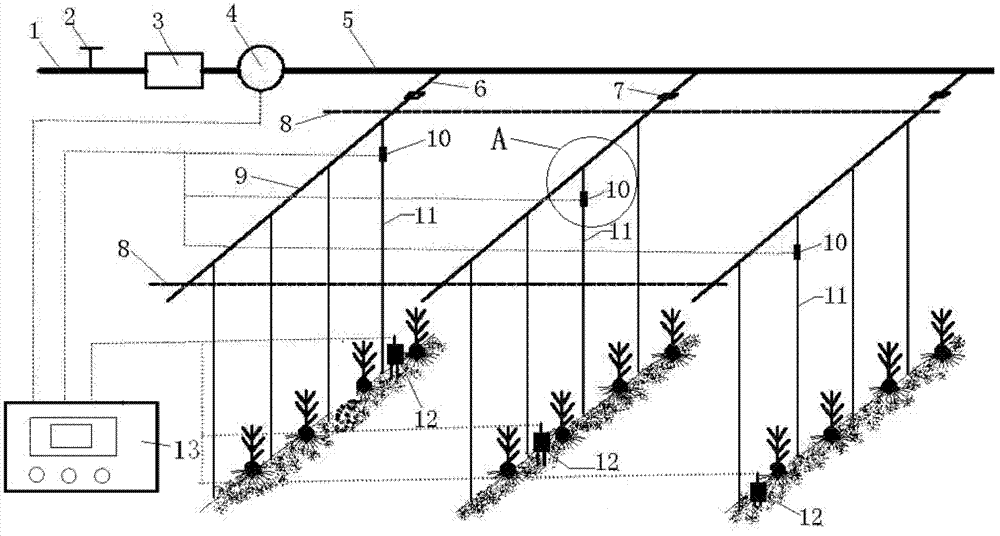

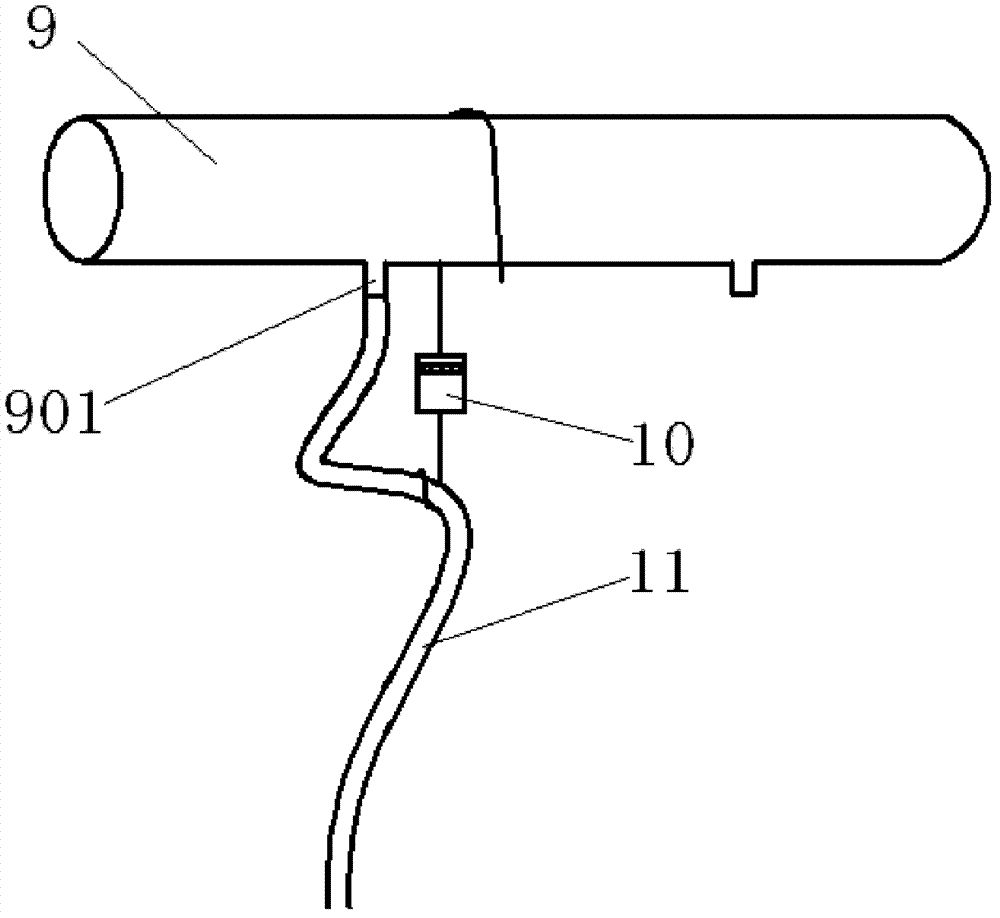

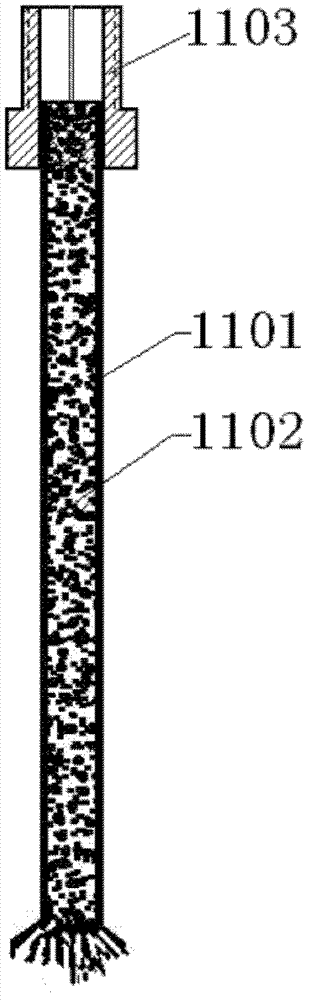

Cored micro pipe irrigation system for greenhouse climbing crops

InactiveCN102487760AReduce volatilityAvoid cloggingClimate change adaptationGreenhouse cultivationSiphonWater source

The invention belongs to the technical field of irrigation, and relates to a cored micro pipe irrigation system for greenhouse climbing crops. The system mainly comprises a main water source inlet pipe, a main water source valve, a filter, an electromagnetic valve, a main pipe, hoses, switchover joints, a branch pipe support frame, branch pipes, stress meters, cored micro pipe irrigators, soil moisture sensors and a controller. According to the system, each cored micro pipe is used as an irrigator for delivering water from each branch pipe to the roots of crops; the irrigation water from a water source is filtered by the filter, flows to the main pipe and each branch pipe and enters each cored micro pipe irrigator from the water outlet of each branch pipe; the water entering each cored micro pipe is uniformly delivered to irrigate the crops under the coaction of gravity, capillary force and siphon force of a core layer; under the control of the controller, intelligent automatic irrigation is realized in the whole crop growth period; and for the climbing crops, climbing ropes are substituted by the cored micro pipes, so the climbing ropes are not required to be built any more. The system is suitable for water-saving irrigation of the greenhouse climbing crops.

Owner:CHINA AGRI UNIV

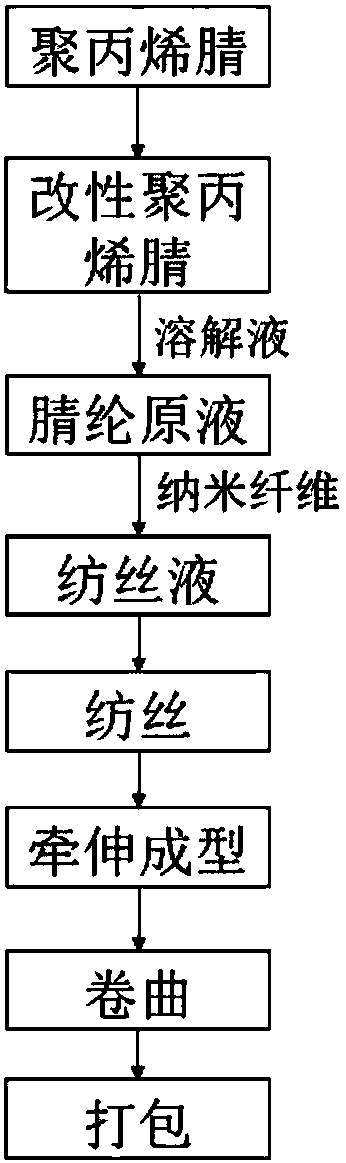

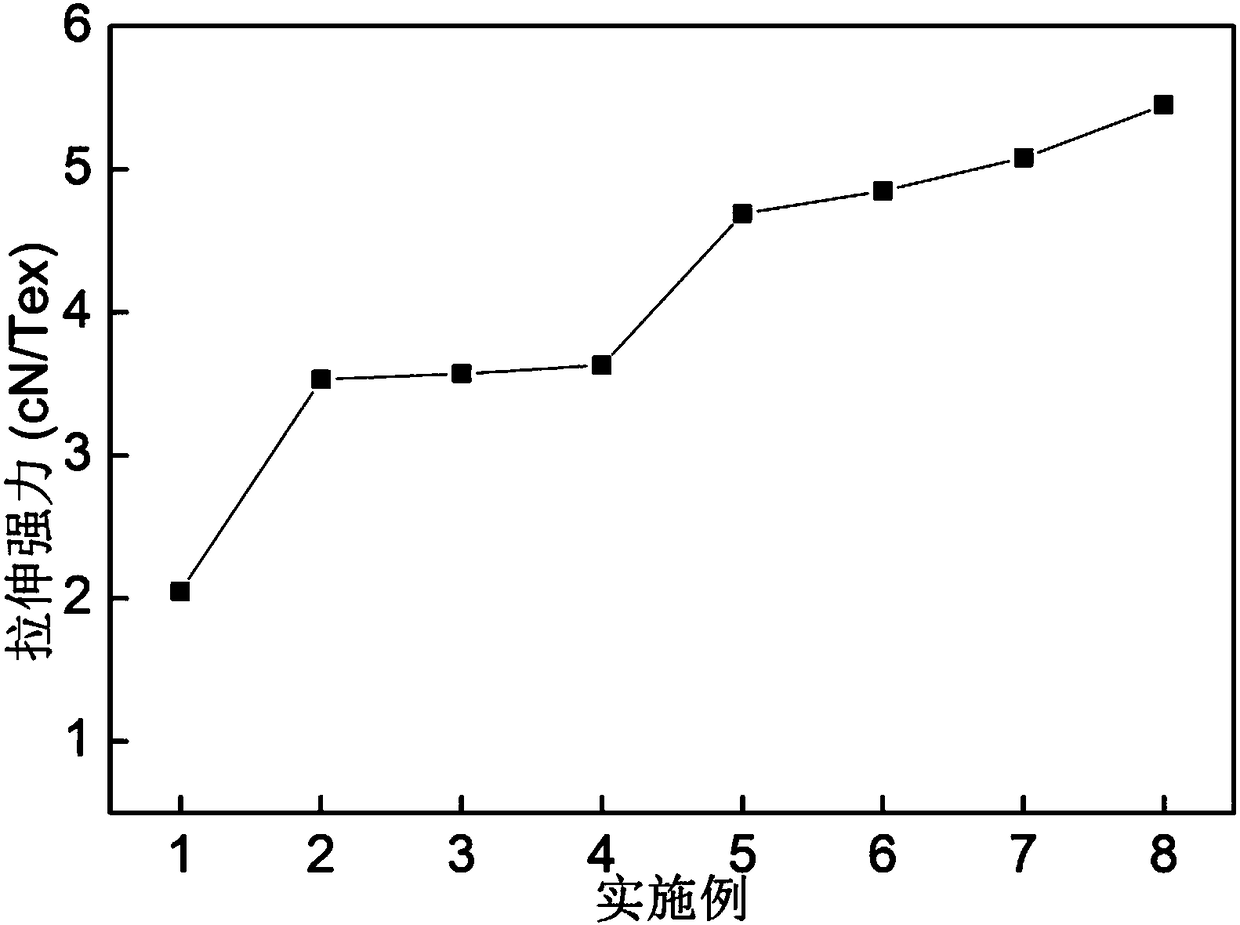

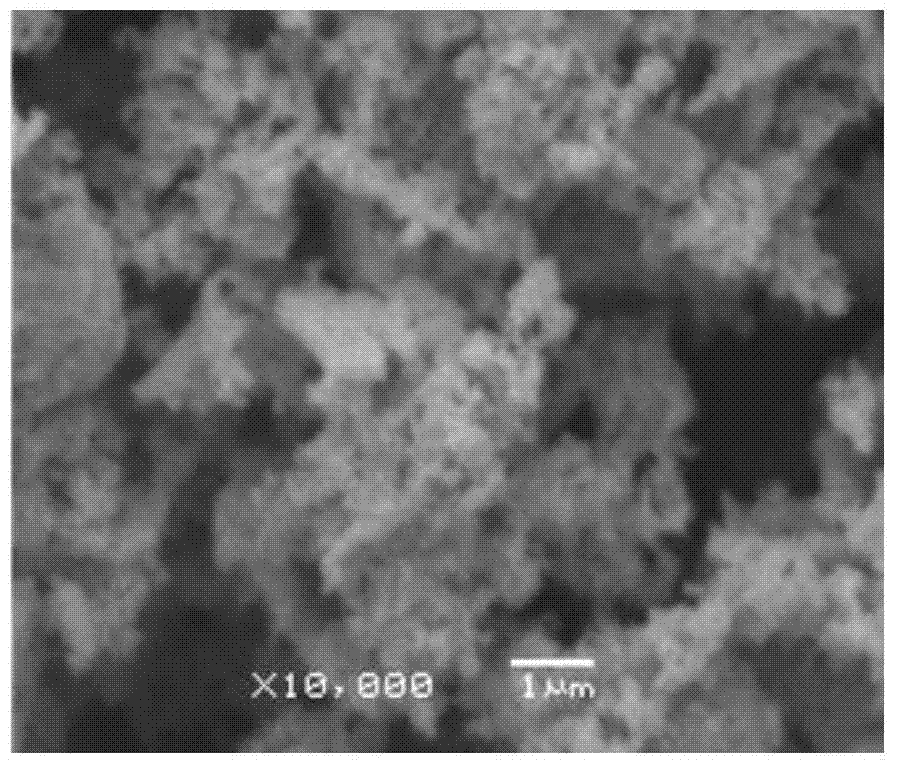

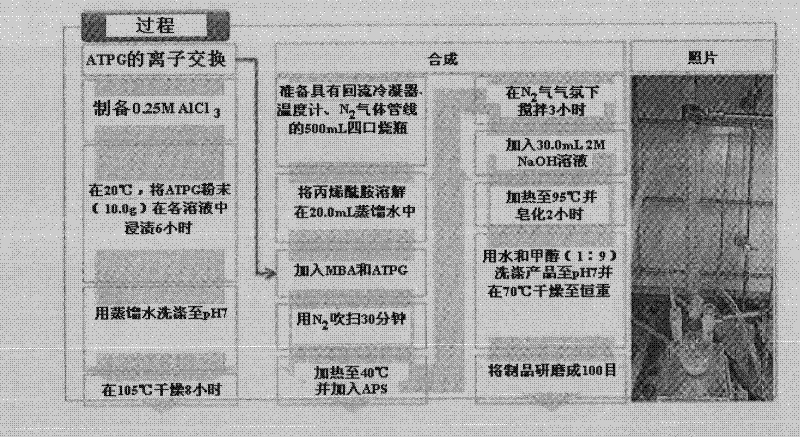

Cellulose nanofibril reinforced acrylic fiber as well as preparation method and application thereof

ActiveCN108085766AReinforced acrylic fiberImprove moisture absorptionConjugated cellulose/protein artificial filamentsMonocomponent synthetic polymer artificial filamentSolventPre treatment

The invention belongs to the technical field of polymer molding and discloses a cellulose nanofibril reinforced acrylic fiber as well as a preparation method and application thereof. The preparation method of the cellulose nanofibril reinforced acrylic fiber is divided into two steps that: in a first step, polyacrylonitrile is pretreated and dissolved in a solvent as an acrylic fiber raw solution,and then the cellulose nanofibrils are added into the acrylic fiber raw solution, after dispersing evenly, a spinning solution is obtained; in a second step, the spinning solution is spun on a spinning machine, and after a coagulation bath, the spinning solution is drafted according to a certain drafting ratio, and then finally rolled and packaged. The cellulose nanofibril reinforced acrylic fiber not only has good tensile strength, but also has a great improvement in dyeing performance compared to a traditional acrylic fiber, and can be used for making fabrics such as blankets and carpets, as well as outdoor fabrics such as ski coats, sails, military canvas, tents and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for producing health-care polyprophylene bulked continuous filament

ActiveCN102965756AImprove strength and elongationImprove moisture absorptionMonocomponent polyolefin artificial filamentArtifical filament manufactureVacuum furnaceMaleic anhydride

A method for producing a health-care polyprophylene bulked continuous filament (BCF) adopts the following steps: A, magnesium borate whisker, sepiolite and palygorskite fiber are mixed uniformly to be sintered in a vacuum furnace, are cooled and stirred in absolute ethyl alcohol through sodium hexametaphosphate to be dispersed, are subjected to plasma treatment at normal pressure and then are ultrasonically dispersed, cleaned, filtered and dried in deionized water which contains calcium stearate dispersion liquid; B, talcum powder and aluminic acid ester coupling agent are mixed and stirred; then, nanoscale tourmaline composite powder, calcium stearate propene polymer (PP)-g-maleic anhydride (MAH) bulking agent and the modified whisker mixture which is obtained in step A are added to be mixed and stirred, and polypropylene is added to be stirred at a high speed so as to obtain a modified polypropylene mixture; and C, the modified polypropylene mixture is dried and is subjected to melt extrusion in an extruding machine to spin the comfortable health-care polyprophylene bulked continuous filament which has the functions of well absorbing moisture, releasing moisture, resisting static electricity and naturally releasing negative oxygen ions.

Owner:ZHEJIANG SCI-TECH UNIV

Polyester having moisture absorption, fire retardation and ultraviolet resistance composite function

ActiveCN104725625AIncrease the amorphous spaceImprove moisture absorptionMelt spinning methodsMonocomponent polyesters artificial filamentChemistryChemical structure

The present invention discloses a polyester having moisture absorption, fire retardation and ultraviolet resistance composite function. According to the present invention, a fire retardation agent, inorganic nanometer anti-ultraviolet powder, a moisture absorption modification monomer and the like are added to the polymerization raw material, wherein the fire retardation agent and the moisture absorption modification monomer have the synergy effect so as to improve the moisture absorption property of the polyester, such that the chemical structure of the polyester is modified so as to make the polyester concurrently have functions of strong moisture absorption, strong fire retardation and strong ultraviolet resistance.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Cored micro pipe irrigation system for greenhouse climbing crops

InactiveCN102487760BImprove moisture absorptionIncrease mobilityClimate change adaptationGreenhouse cultivationSiphonWater source

The invention belongs to the technical field of irrigation, and relates to a cored micro pipe irrigation system for greenhouse climbing crops. The system mainly comprises a main water source inlet pipe, a main water source valve, a filter, an electromagnetic valve, a main pipe, hoses, switchover joints, a branch pipe support frame, branch pipes, stress meters, cored micro pipe irrigators, soil moisture sensors and a controller. According to the system, each cored micro pipe is used as an irrigator for delivering water from each branch pipe to the roots of crops; the irrigation water from a water source is filtered by the filter, flows to the main pipe and each branch pipe and enters each cored micro pipe irrigator from the water outlet of each branch pipe; the water entering each cored micro pipe is uniformly delivered to irrigate the crops under the coaction of gravity, capillary force and siphon force of a core layer; under the control of the controller, intelligent automatic irrigation is realized in the whole crop growth period; and for the climbing crops, climbing ropes are substituted by the cored micro pipes, so the climbing ropes are not required to be built any more. The system is suitable for water-saving irrigation of the greenhouse climbing crops.

Owner:CHINA AGRI UNIV

Hollow glass with edge sealed by PUR glue and manufacturing method thereof

PendingCN112983204AExtended service lifeImprove initial tackClimate change adaptationWindows/door improvementMolecular sieveMoisture absorption

The invention belongs to the technical field of production of hollow glass, and discloses hollow glass with the edge sealed by PUR glue and a manufacturing method thereof. The hollow glass with the edge sealed by the PUR glue comprises glass, spacing bars, a bonding seal between the glass and the spacing bars and a bonding seal on the periphery of the glass, wherein the bonding seal between the glass and the spacing bars and the bonding seal on the periphery of the glass adopt PUR glue, and the bonding force and the sealing performance are improved by utilizing the chemical reaction between the PUR glue and water adsorbed on the surfaces of the glass and the spacing bars, so that the service life of the hollow glass is prolonged; small-specification hollow glass with a large glue proportion is used, moisture in the hollow cavity is absorbed by utilizing a moisture absorption effect generated by a wet reaction curing mechanism of the PUR glue, and no molecular sieve is arranged in the spacing bars; and large-specification hollow glass with a small glue proportion is used, molecular sieves are arranged in spacing bars, and preferably, the molecular sieves with a slow absorption function are adopted. The method is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality.

Owner:温州前瞻玻璃科技有限公司

Environment-friendly textile size and preparation method thereof

InactiveCN111335037AImprove permeabilityImprove sizing effectFibre typesPolymer scienceMoisture absorption

The invention discloses environment-friendly textile size and a preparation method thereof. The environment-friendly textile size comprises the following effective components in parts by weight: 32-40parts of modified starch, 5-8 parts of plant starch, 3-8 parts of nano particles, 10-18 parts of glue, 3-5 parts of ethylene glycol, 10-16 parts of acrylamide, 26-50 parts of deionized water and 5-15parts of an auxiliary agent. The modified starch, acrylamide and the auxiliary agent are used as matrix components, and the plant starch, nano particles, glue and ethylene glycol are used for preparing the textile size with an environment-friendly function, so that the problem that a conventional size film is brittle is solved, and the problems that the conventional size is poor in wear resistance, serious in moisture absorption and poor in glue solution permeability are effectively relieved; and meanwhile, the nano particles, glue and ethylene glycol are added, so that the prepared textile size is good in permeability, good in sizing effect, low in moisture absorption re-viscosity, stable in quality, easy to desize, green and environment-friendly, and has a good application prospect.

Owner:荆门市诺维英新材料科技有限公司

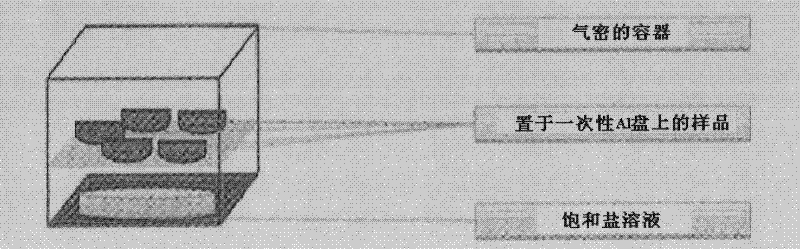

Resin composition for water absorbing film, water absorbing film for packing, and manufacturing method thereof

InactiveCN102675708AEasy to operateImprove moisture absorptionFlexible coversWrappersGrain shapeChemistry

The invention relates to a resin composition for a water absorbing film, the water absorbing film for packing, and a manufacturing method of the water absorbing film, in particular to a resin composition for the water absorbing film, which contains polyethylene system resin and a sodium meta-polyacrylate or an acrylamide synthetic attapulgite as water absorbents. According to the invention, the water absorbing film with excellent water adsorptive power and physical property can be manufactured. Flowers are packed with silica gels and moisture absorbing papers to export in order to keep color of flowers when flowers are exported generally; the silica gels and moisture absorbing papers can be replaced by the water absorbing film with convenient operation and high moisture absorption effect so as to increase quality and effect of products; especially, the water absorbing film can be used for dried foods which are sensitive to water, such as powder grain-shaped flours, frying powder, dried seafood and so on, and further can be used for dehumidifying and packing when the water absorbing film is used for storing of mechanical components or high iron productsso as to increase storage effects of the products. And the water absorbing film further can be used as dehumidifying and packing materials for storing products and taking care of interior of warehouses.

Owner:株式会社宝石葩

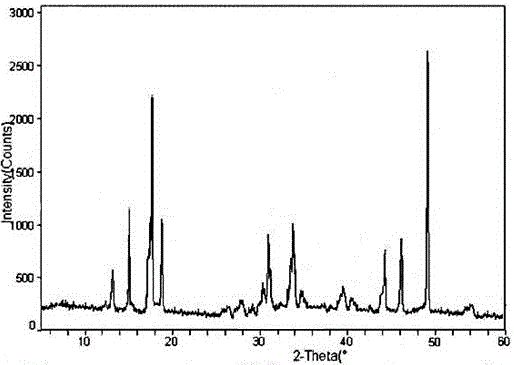

Medicinal atorvastatin calcium composition capsules for treating coronary heart disease

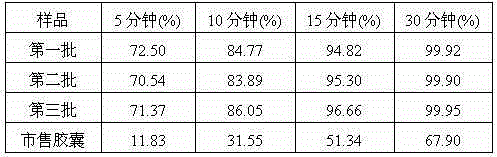

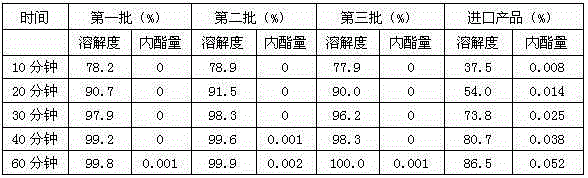

InactiveCN105030728AImprove moisture absorptionImprove solubilityOrganic chemistryMetabolism disorderSour stomachCHD - Coronary heart disease

The invention discloses medicinal atorvastatin calcium composition capsules for treating a coronary heart disease and belongs to the technical field of medicines. The capsules are prepared by atorvastatin calcium, starch, hydroxypropyl methylcellulose, dioctyl sodium sulphosuccinate, 95% of ethyl alcohol and talcum powder. The atorvastatin calcium is a novel crystal form compound, an X-ray powder diffraction diagram obtained through Cu-Ka ray measurement is shown in Figure 1 and is different from the atorvastatin calcium reported in the prior art, a test shows that the novel crystal form compound has obvious improved moisture absorption, solubility of the medicine in an acid medium and water is improved, the moisture and impurity content is low, the stability is good, the atorvastatin calcium is prevented from being destroyed in the acid environment of the stomach, the occurrence rate of the side effect of myalgia is reduced, and the prepared capsules are high in dissolution rate and good in stability.

Owner:QINGDAO HUAZHICAO PHARMA CO LTD

Heat pump clothes drying system and method for drying clothes

ActiveCN103061096BMeet drying needsGuaranteed drying qualityTextiles and paperLaundry driersEngineeringEnergy consumption

The invention relates to a heat pump clothes drying system and a clothes drying method thereof. The heat pump clothes drying system comprises a heat pump evaporator unit, a heat pump compression condensing unit and a drying chamber. A refrigerant loop of the heat pump evaporator unit is connected with a refrigerant loop of the heat pump compression condensing unit through a refrigerant pipe. An air path outlet of the heat pump evaporator unit is connected with an air path inlet of the heat pump compression condensing unit through a pipeline, an air valve A and an air valve C are sequentially disposed on the pipeline in parallel, and an air valve B is disposed on the pipeline between the air valve A and the air valve C. An air path outlet of the heat pump compression condensing unit is connected with an air path inlet of the drying chamber. An air path outlet of the drying chamber is connected with an air path inlet of the heat pump evaporator unit through a pipeline, an air valve F and an air valve D are sequentially disposed on the pipeline in parallel, and an air valve E is disposed on the pipeline between the air valve F and the air valve D. By the heat pump clothes drying system, clothes drying quality is guaranteed while energy consumption is reduced maximally, and drying speed is increased.

Owner:JINAN GOHIGH ENERGY TECH

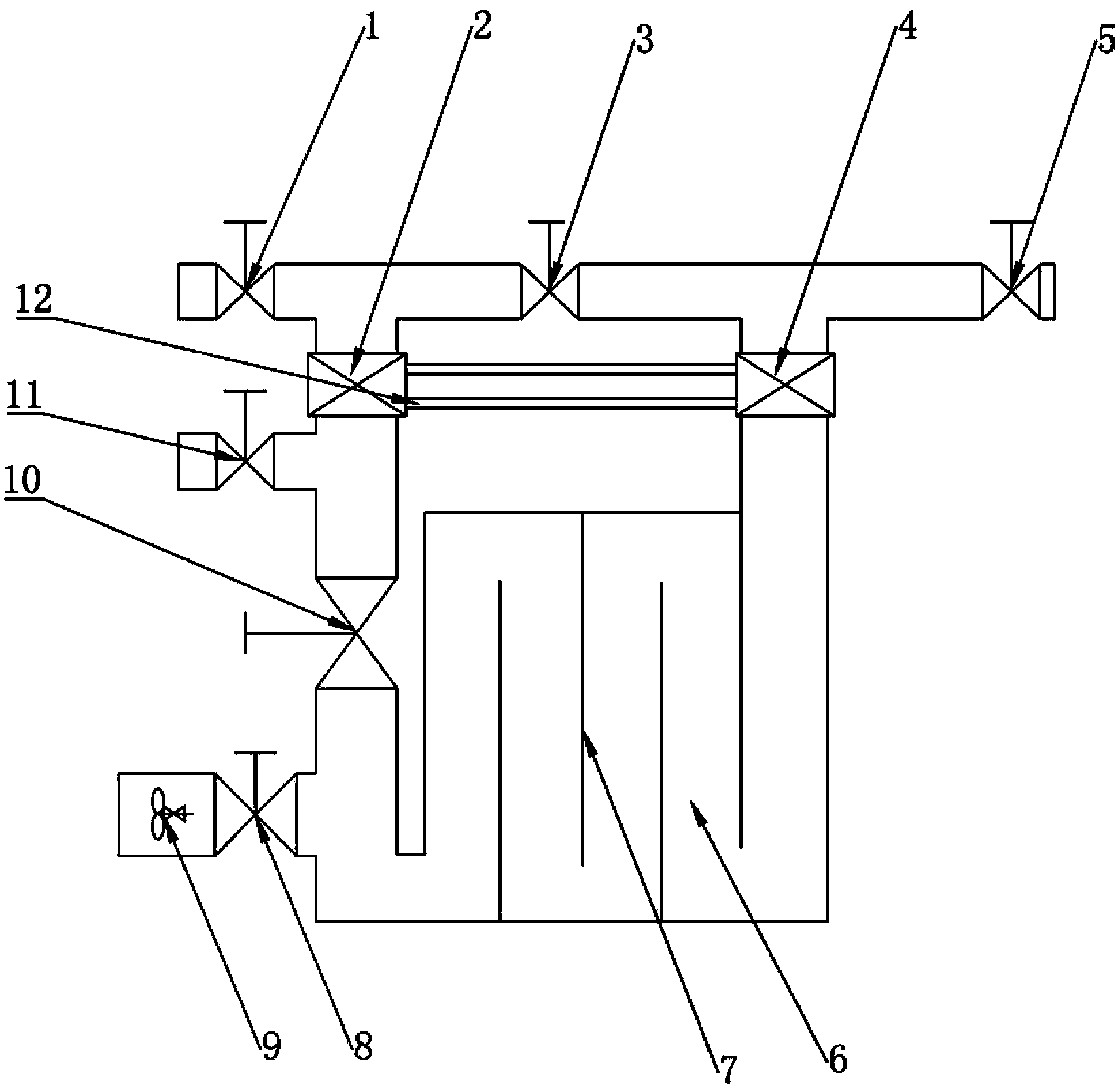

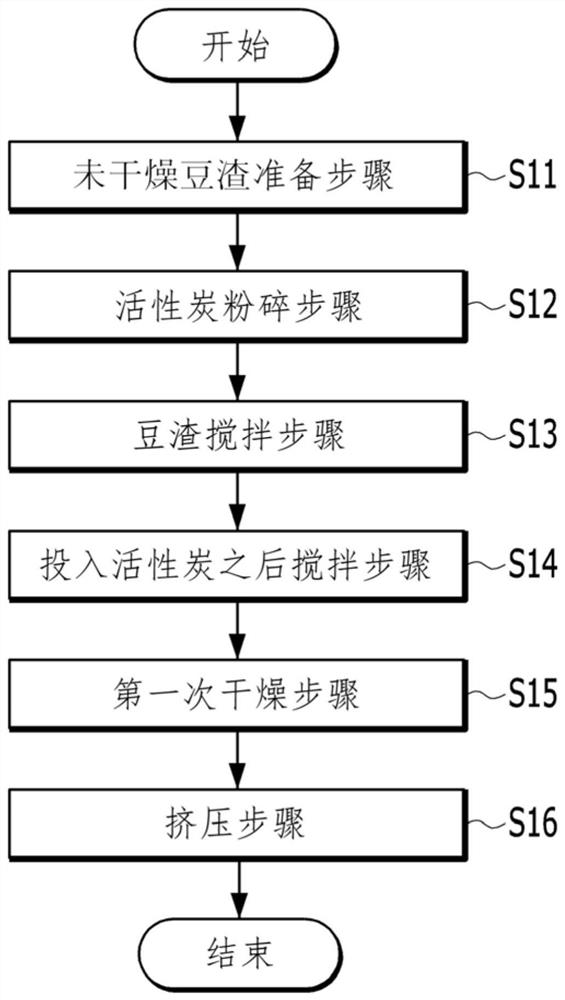

Cat litter containing tofu by-products and manufacturing method thereof

ActiveCN110384048BNo health problemsPrevent bleachingAnimal housingGrain treatmentsBiotechnologyActivated carbon

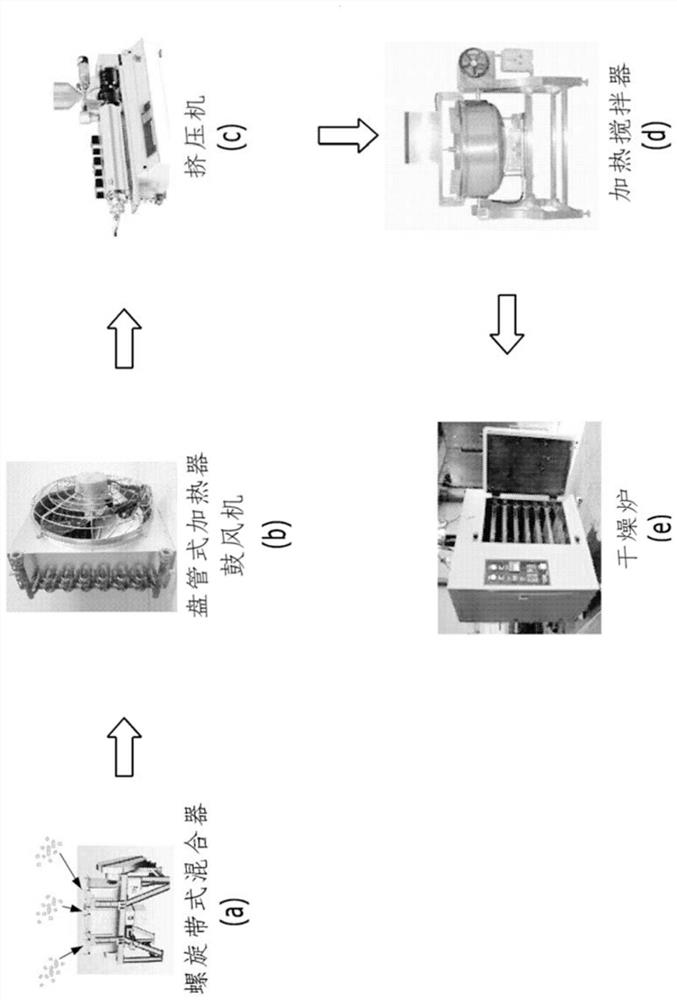

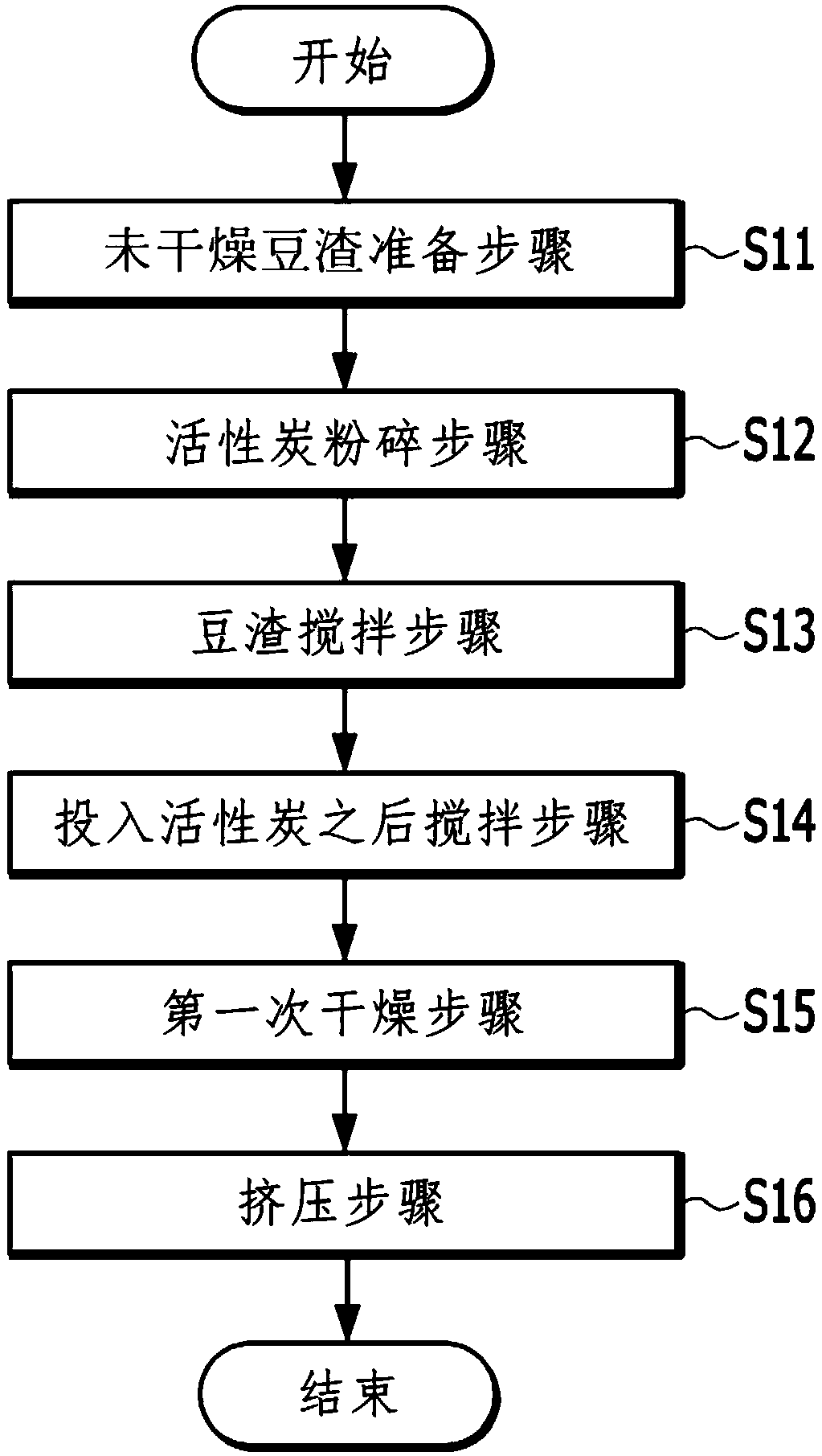

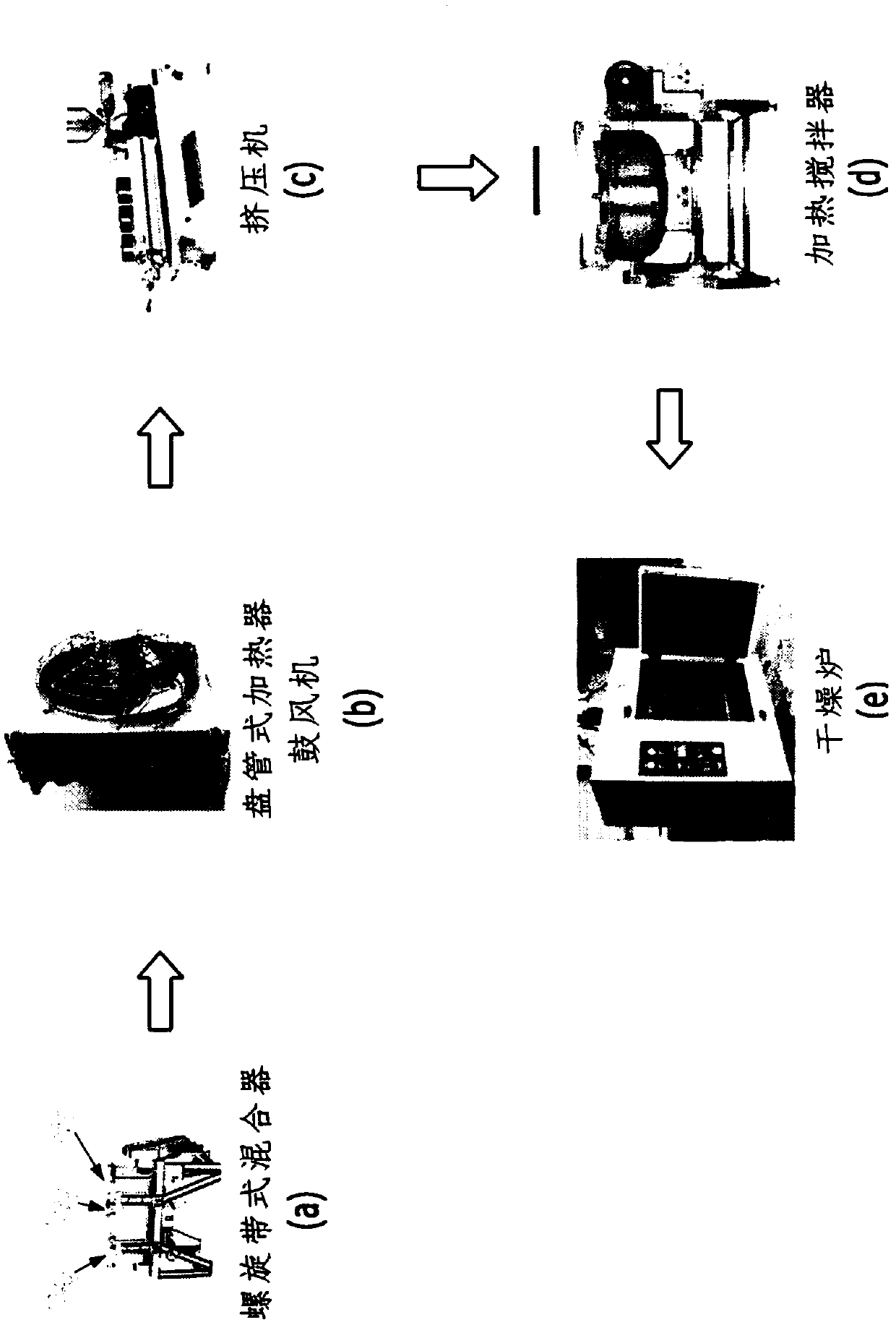

The invention relates to cat litter containing tofu by-products and a manufacturing method thereof. The manufacturing method of the present invention comprises: the step of preparing undried bean dregs; the step of pulverizing activated carbon with a mesh size of 30 to 60; putting the prepared bean dregs into a spiral ribbon mixer, and then adding water-soluble binder particles, The step of stirring at a low speed; the step of further stirring at a low speed after putting in the pulverized activated carbon; the step of blowing high-temperature air to the inside of the spiral ribbon mixer with a blower, and performing the first drying to make the moisture content reach 45% to 65%; And the step of transferring to an extruder and extruding into a predetermined shape.

Owner:郑诚训

Cat litter containing bean curd by-products and a manufacturing method thereof

ActiveCN110384048APrevent bleachingPrevent desertificationAnimal housingGrain treatmentsActivated carbonChemistry

The invention relates to cat litter containing bean curd by-products and a manufacturing method thereof. The preparation method comprises the following steps: preparing bean dregs in an undried state;crushing activated carbon to the size of 30-60 meshes; putting the prepared bean dregs into a spiral belt type mixer, then putting water-soluble adhesive particles, and carrying out low-speed stirring; adding the crushed activated carbon, and further stirring at a low speed; blowing high-temperature air into the spiral belt type mixer by using an air blower, and carrying out primary drying to enable the moisture content to reach 45%-65%; and transferring the mixture to an extruder and extruding the same into a predetermined shape.

Owner:郑诚训

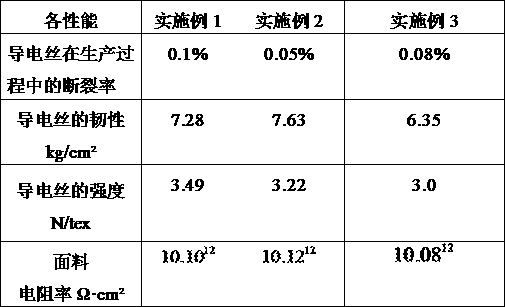

Double-sided high-strength antistatic fabric and production process

ActiveCN108930087AImprove toughnessStrong stretching abilitySynthetic resin layered productsLaminationPolyesterYarn

The invention provides a double-sided high-strength antistatic fabric. The fabric is formed by bonding two layers of fabric bodies. Each layer of fabric body is formed by weaving composite yarns, andthe fabric body is a plane three-way fabric. The composite yarn comprises a spun polyester thread and a conductive fiber winded out of the spun polyester thread in a loose manner. The spun polyester thread is a 5D-8D low-elasticity spun polyester thread. Grain size of the conductive fiber is 1.1(N / G)<1 / 2> / ZS. Cooperated with the production process provided by the invention, tenacity of the conductive fiber is relatively high, and the conductive fiber does not easily break. Production is convenient, fabric structure is meticulous, density is high, dust does not easily enter the fabric, the conductive fiber and a fabric base material combine tightly, a condition that conductive fiber drawing would not occur, and antistatic effect is lasting.

Owner:嘉兴市优泰纺织新材料有限公司

After-treatment technology of jean fabric

ActiveCN110565305AImprove moisture absorptionGood hygroscopicitySingeingLiquid/gas/vapor removalAqueous solutionYarn

The invention provides an after-treatment technology of a jean fabric. The technology comprises the following steps of 1, singeing, wherein a singeing machine is adopted for performing singeing on thejean fabric; 2, desizing, wherein a desizing machine is adopted for removing a sizing agent on the jean fabric; 3, washing, wherein a washing machine is adopted for washing the jean fabric obtained in step 2; 4, scouring, wherein a treatment solution in the step of scouring is a water solution containing 4-6 g / L of a scouring enzyme, the treatment time is 50-55 min, and the treatment temperatureis 95-98 DEG C; 5, drying, wherein a drying machine is adopted for drying the jean fabric; 6, waterproof treatment, wherein surface coating treatment, drying treatment and baking treatment are performed on the jean fabric inside a coating machine in sequence. The scouring enzyme is applied for executing the step of scouring, the sizing agent on the surface of yarn and waxiness, pectin, neps and the like in fiber can be removed, no influence is generated on the fiber body, the moisture absorption effect of the fiber is improved, and therefore the moisture absorption effect of the fabric is improved.

Owner:GUANGDONG FORWARD DENIM

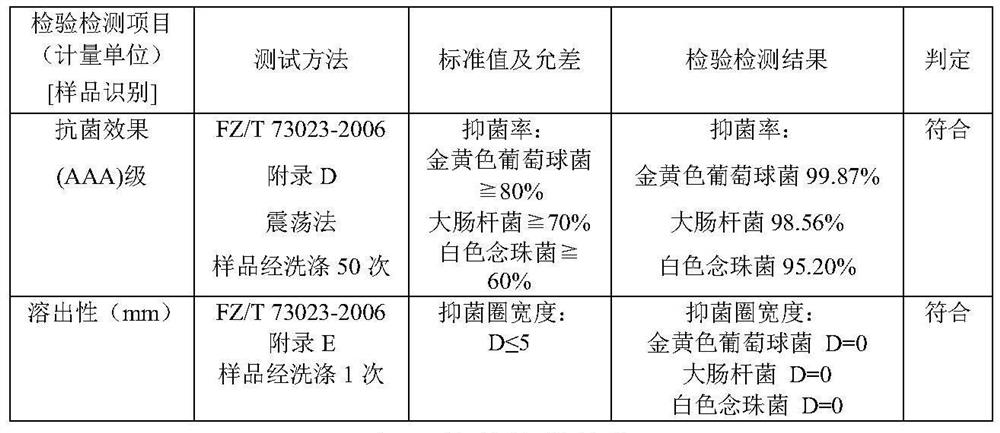

Motherwort blended yarn with moisture absorption, quick drying and antibacterial functions and fabric

PendingCN112391711AGood hygroscopicityGood skin affinityArtificial filaments from viscoseWoven fabricsHollow fibreYarn

The invention discloses a motherwort blended yarn with moisture absorption, quick drying and antibacterial functions. The motherwort blended yarn is formed by blending more than two fibers, and at least comprises motherwort viscose fibers and hollow fibers. The invention further provides a motherwort fabric with the moisture absorption, quick drying and antibacterial functions. The motherwort fabric is formed by weaving more than two kinds of yarns, and at least comprises the motherwort blended yarn with the moisture absorption, quick drying and antibacterial functions. The motherwort blendedyarn has the antibacterial property of motherwort, the hygroscopicity and skin friendliness of viscose and the quick-drying property of terylene at the same time. The fabric does not need to be held by moisture absorption quick-drying and antibacterial functional auxiliaries, achieves moisture absorption, quick-drying and lasting antibacterial effects by utilizing the characteristics of the fibers, has good antibacterial effect and comfort, has moisture absorption and quick-drying functions, is remarkable and durable in effect, is superior to the fabric prepared by after-treatment processing,and is particularly suitable for underwear.

Owner:COSMO LADY (CHINA) HOLDINGS

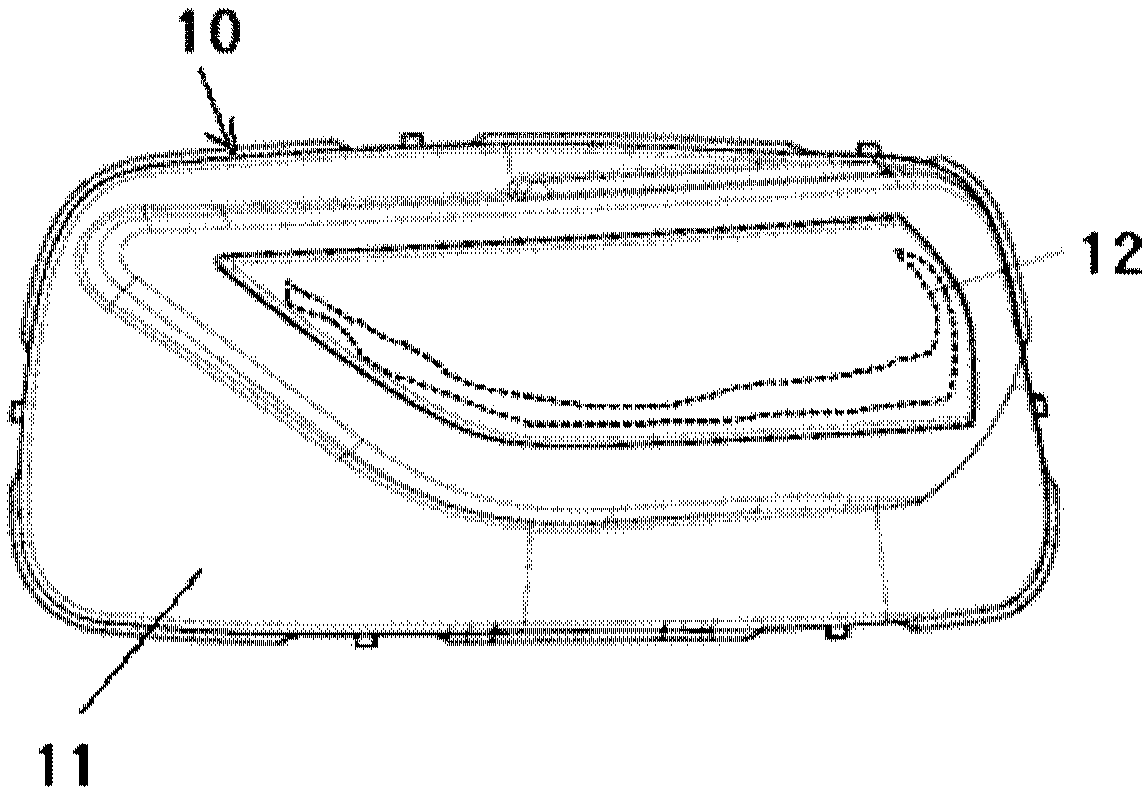

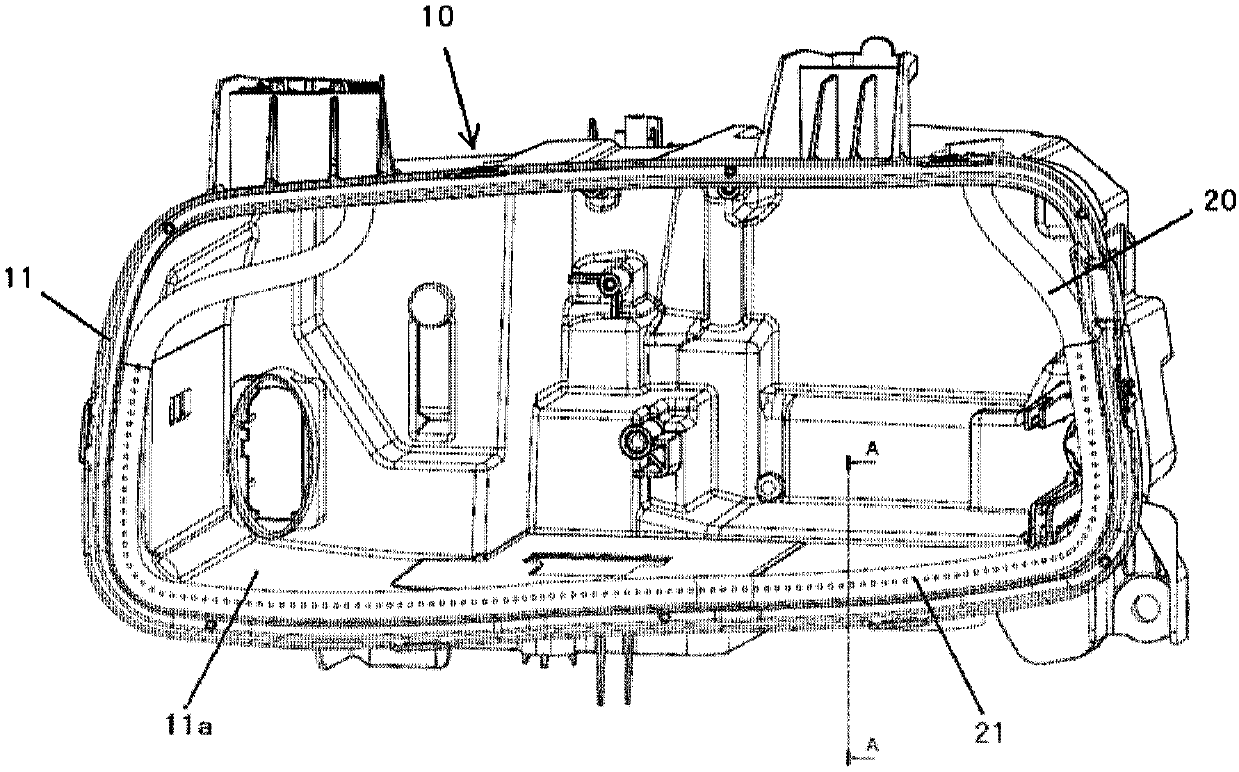

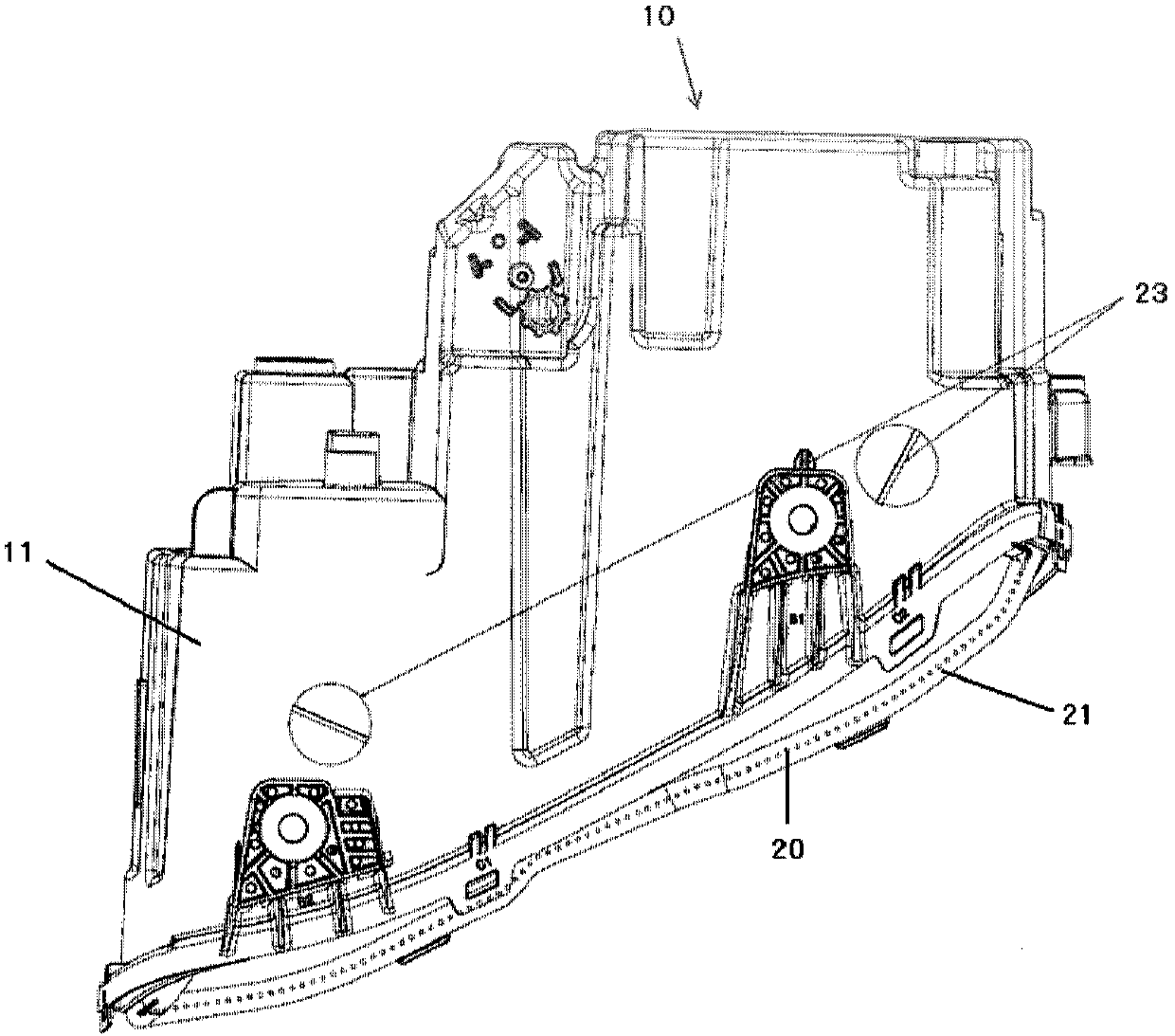

Lamp demisting structure and motor vehicle illuminating equipment with structure

ActiveCN109708074AImprove moisture absorptionMitigate and/or solve problems caused by condensationLighting and heating apparatusSignalling/lighting devicesDrying AgentsEngineering

The invention provides a lamp demisting structure which comprises a lamp body (10) and a demisting pipeline (20), wherein the lamp body (10) comprises a lamp housing (11); the lamp housing is providedwith at least one opening used for feeding and discharging; the opening of the lamp housing is provided with a sealing element which is sealed relative to external environment; a material opening ofthe demisting pipeline (20) is connected with the opening of the lamp housing (11); drying agents (30) are put inside the demisting pipeline; and ventilation holes (21) are formed in the demisting pipeline, so that the moisture absorption function of the drying agents in the demisting pipeline can be realized through the ventilation holes. Meanwhile, the invention also provides motor vehicle illuminating equipment with the lamp demisting structure. The problems caused by a mist condensation phenomenon in the lamp can be relieved and / or solved.

Owner:VALEO LIGHTING HUBEI TECHN CENT

Hollow glass and manufacturing method thereof

PendingCN113003952AReduce manufacturing costImprove performanceMolecular sieveStructural engineering

The invention discloses hollow glass with molecular sieves as spacing bars. The hollow glass comprises a plurality of pieces of glass, a plurality of spacing bars, a first seal, and at least one of a second seal, a third seal and a fourth seal, a spacing bar is arranged between every two adjacent pieces of glass; the spacing bars are arranged on the periphery of the glass in a segmented mode to form a closed spacing frame. The first seal is arranged between the glass and the spacing bar; at least one of a second seal, a third seal and a fourth seal is sequentially arranged on the outer side of the spacing frame, the second seal is located between the adjacent glass, and / or the third seal is located between the adjacent glass or on the outer side edge of the adjacent glass, and / or the fourth seal is located on the outer side edge of the adjacent glass. The fourth seals are located on the outer side edge and the edge portion of the outer surface of the adjacent glass, and the spacing bars are made of molecular sieves. The hollow glass is simple in technological process, high in mechanization and automation degree, short in production period, high in production efficiency and good in product quality, and the service life of the hollow glass can be greatly prolonged.

Owner:WEIHAI RUNFENG GLASS

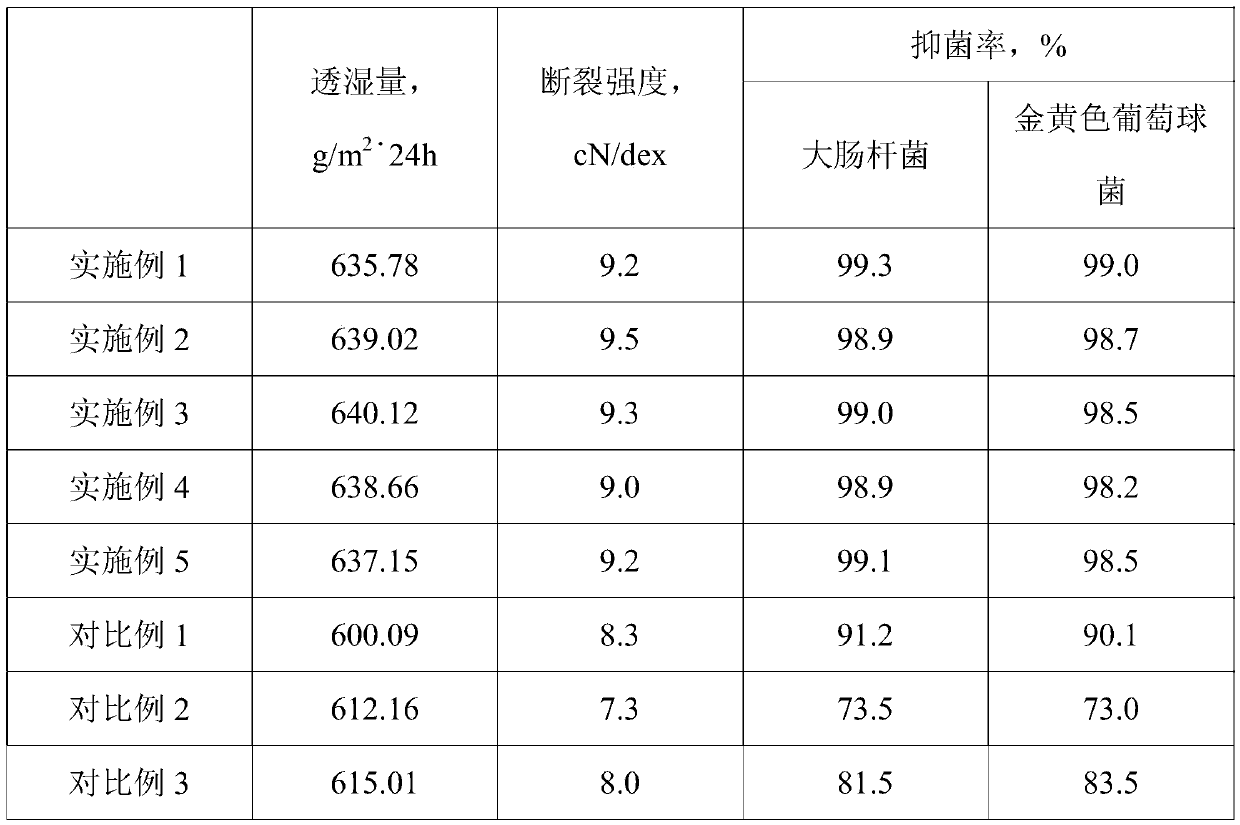

Method for preparing nano-functional fiber with moisture absorption, sweat releasing and bacterial resistance

ActiveCN110257951AImprove mechanical propertiesImprove moisture absorptionFilament/thread formingConjugated synthetic polymer artificial filamentsPolyamidePolyvinyl alcohol

The invention discloses a method for preparing a nano-functional fiber with moisture absorption, sweat releasing and bacterial resistance. The method specifically includes the following steps: firstly, preparing sodium alginate microspheres, intercalating and compounding the microspheres between layers of organic montmorillonite to obtain a sodium alginate / montmorillonite composite material, performing polymer modification on the surface of the material, and compounding, extruding and granulating with polyamide and polyvinyl alcohol to prepare composite particles A; preparing porous titanium oxide nanocrystals, extruding and granulating with dried PET to prepare composite particles B, and finally putting the prepared composite particles A and B through skin-core composite spinning processing equipment to prepare a core-shell fiber with polyamide as a core layer and polyester as a surface layer, and sequentially washing the core-shell fiber with anhydrous ethanol and deionized water to obtain the product. The method is simple to operate, and the prepared fiber not only has good moisture absorption and sweat releasing performance, but also has good antibacterial performance, and the mechanical property is effectively improved.

Owner:常熟市华坤针纺织有限公司

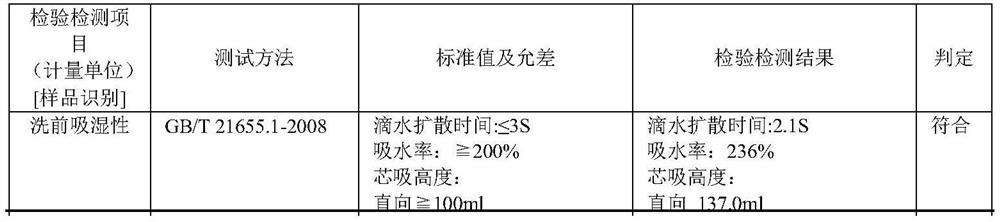

Production technology of cotton-soybean fiber-polypropylene fiber quick-to-dry fabric

InactiveCN107938128AImprove moisture regainImprove moisture absorptionWeft knittingRadio/micro wave fibre treatmentCotton fibreDyeing

The invention discloses a production technology of cotton-soybean fiber-polypropylene fiber quick-to-dry fabric. The production technology comprises the steps of preparation of raw material fiber, spinning, weaving, dyeing, shaping and softening finish, and the knitted fabric is subjected to double-faced weft-knitting by body yarn, wherein the body yarn is prepared from, by weight, 20-40% of cotton fiber, 30-40% of soybean fiber and 30-50% of micro-thin polypropylene fiber; the body yarn spinning working procedure comprises microwave treatment of the cotton fiber and the soybean fiber in the raw material fiber. The microwave treatment can change the crystal structure of cellulose, therefore the moisture regain of the cotton fiber and the soybean fiber is increased, the moisture absorptionof the fabric is optimized, subsequent treatment can further increase the number of holes in the surface of the raw material fiber, the moisture drainage performance of the fabric is improved throughthe capillary effect of the holes, the absorption and diffusing efficiency of moisture on the fabric is improved, finally, the moisture absorption and moisture drainage performance of the fabric is excellent, and the cotton-soybean fiber-polypropylene fiber quick-to-dry fabric has the quick-to-dry performance and is particularly applicable to preparing summer clothes.

Owner:JIANGSU SHENGLAN CLOTHING CREATIVE

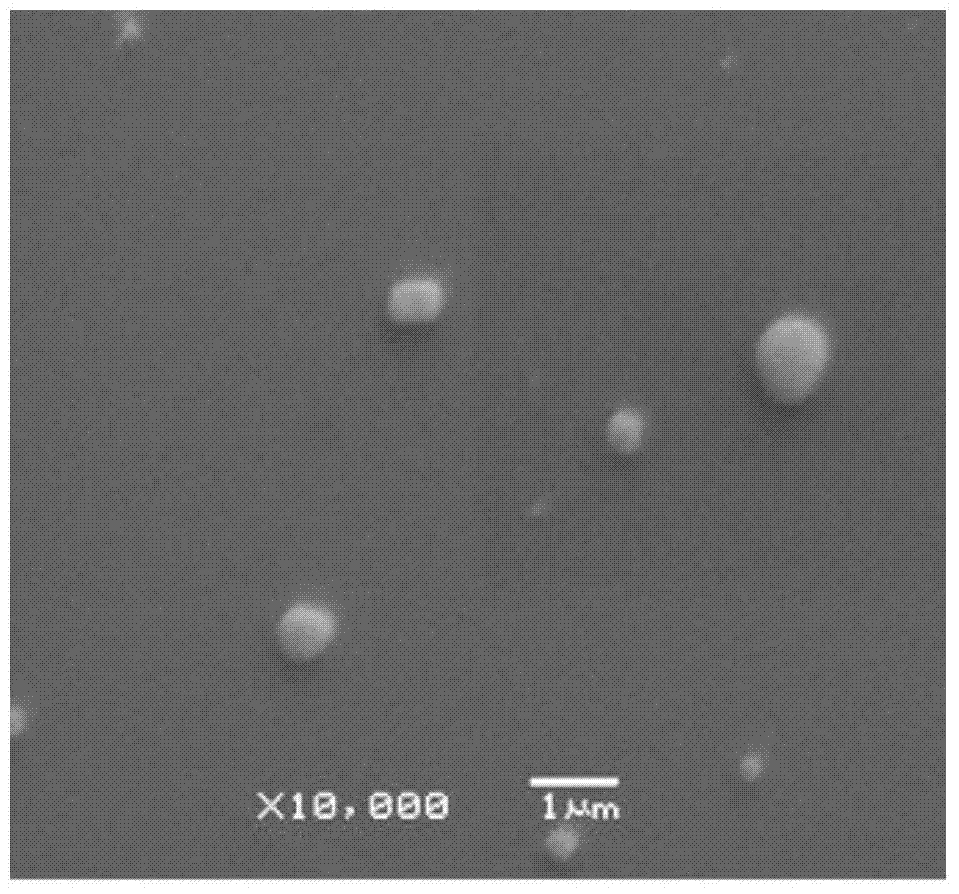

Water-borne polyurethane coating agent containing superfine down fiber-polylactic acid microspheres

InactiveCN105803793AImprove moisture absorptionImprove moisture and breathabilityFibre treatmentSolventChemistry

The invention discloses a water-borne polyurethane coating agent containing superfine down fiber-polylactic acid microspheres. The superfine down fiber-polylactic acid microspheres are prepared by the following steps of treating down fibers into superfine fibers with high surface activity and high thermal stability; mixing the superfine fibers with a polylactic acid solution, wherein the superfine fibers can adsorb the polylactic acid solution by using good adsorbability of the superfine fibers; subsequently, separating out the polylactic acid by using absolute ethyl alcohol serving as a poor solvent, thus obtaining composite microspheres. The composite microspheres have air and moisture permeability of the down fibers and biocompatibility of the polylactic acid; by using the composite microspheres, the defect that superfine down fibers easily absorb moisture is overcome, the moisture and air permeability of a traditional polyurethane coating can be effectively improved, a coating with flexibility, skin friendliness, and bacteria and mildew resistance is obtained, and use experience of fabric is remarkably improved; in addition, the coating can be biodegraded and recycled.

Owner:ANHUI WANLING DOWN & FEATHER PROD

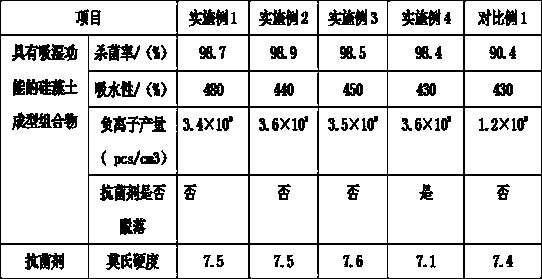

Diatomite forming composition with moisture absorption function and preparing method thereof

The invention discloses a diatomite forming composition with the moisture absorption function and a preparing method thereof. The diatomite forming composition is prepared from diatomite, tourmaline powder, zeolite powder, bamboo charcoal, antibacterial agent, acrylic resin adhesive and gypsum powder. The added antibacterial agent is an inorganic antibacterial agent obtained in the mode that a silver ion is attached to glass, and the inorganic antibacterial agent is high in safety, free of resistant bacteria and remarkable in antibacterial effect; when the antibacterial agent is prepared, metallic silver and the glass are mixed evenly under the high-temperature oxygen-free condition, and it can be avoided that the metallic silver is oxidized; when the antibacterial agent is prepared, a molten mixture is put into the low-temperature oxygen-free environment and cooled to the room temperature, the hardness of the antibacterial agent prepared with the method can be improved, the roughnessof the surface of the antibacterial agent is increased, and the falling-off phenomenon of the antibacterial agent is reduced; the tourmaline powder with the proper ratio and the zeolite powder with the proper ratio are added and can effectively excite negative oxygen ions in the room environment.

Owner:桂林良物造环境科技有限公司

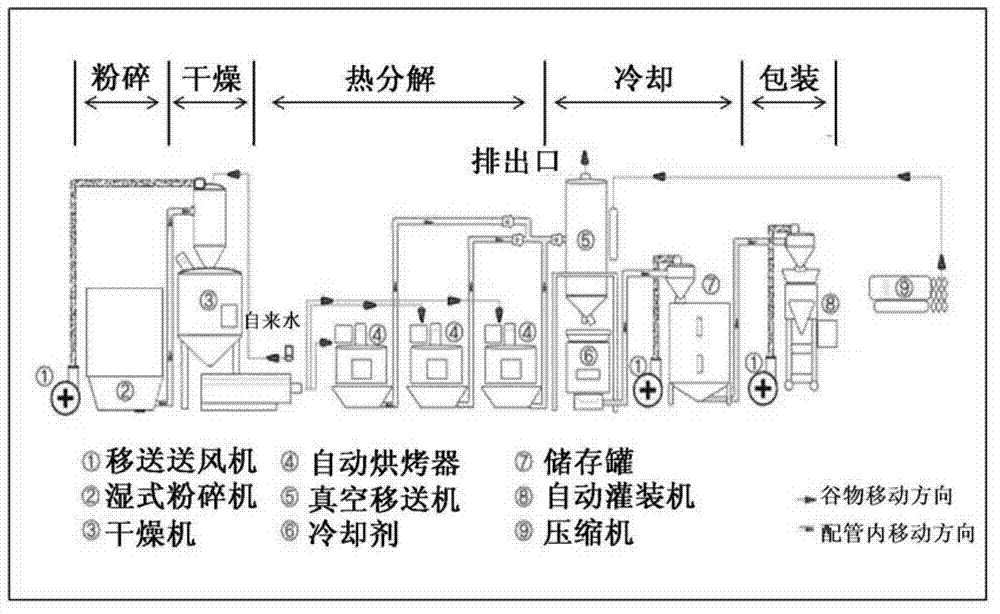

Method of manufacturing powdered coal for low absorbent fuel using coffee waste

InactiveCN103773538AImprove moisture absorptionImprove storageTransportation and packagingBiofuelsPulverizerCoal

The invention relates to a method for manufacturing powdered coal for low absorbent fuel using coffee waste. A dry-type pulverizer is used to re-decompose the coffee waste collected in a compressed form with an aqueous ratio of 50 to 60% into powder, and an air flow-type dryer is used in a pulverization step to dry the powdered coffee waste until the aqueous ratio of the coffee waste is 10% or below. Then, the dried coffee waste powder is inputted into a stirring type roaster, a heating plate of which is heated to a temperature between 225 and 320 DEG C, and then the powder is stirred for 10 to 40 minutes while being thermally decomposed so as to decompose hemicellulose as a moisture absorption ingredient contained in the coffee waste, thereby inhibiting the moisture absorption property. At the same time, a vacuum conveyor is used to convey the thermally-decomposed coffee waste in the stirring type roaster to a cooling port by an enclosed conveying line and a power packaging machine sold on the market is used to seal the coffee waste in units of specified amount, thereby blocking moisture and making the transport easy.

Owner:ALLIED BIO CORPROATION

Preparation method of six-lobed porous hollow fiber by spinning recycled polyester bottle flakes

ActiveCN104389036BEasy to shapeHigh degree of abnormalityHollow filament manufactureArtificial filament heat treatmentPolyesterSpin out

The invention provides a preparation method of six-leaf porous hollow staple fibers spun from renewable polyester bottle flakes. The preparation method comprises the following steps: performing melt spinning on the renewable polyester bottle flakes after vacuum drum drying, enabling the renewable polyester bottle flakes to enter a spinning box body through screw extrusion, spinning out of spinneret orifices of a six-leaf porous hollow spinneret plate to obtain nascent fibers, cooling and forming through circulating air blowing, winding, bundling, drafting, crimping, oiling, loosening and heat setting, and cutting to obtain the six-leaf porous hollow staple fibers, wherein the spinneret orifices are formed in the six-leaf porous hollow spinneret plate and are arranged in arrays; inlets of the spinneret orifices are guide holes, and outlets of the spinneret orifices are spinning capillary holes; each spinning capillary hole comprises one central arc-shaped hole group and six peripheral arc-shaped hole groups; the six peripheral arc-shaped hole groups and the central arc-shaped hole group form a six-leaf structure. Through improvement of a spinning process and innovative design of the spinneret plate, the prepared six-leaf porous hollow staple fibers have the characteristics of high hollow degree, high rebound resilience, large specific surface area, good moisture-absorbing and breathable effect and the like.

Owner:江苏省科学技术情报研究所

Molecular sieve spacing bar, manufacturing method and equipment

PendingCN113006652AImprove moisture absorptionAdd support functionDoors/windowsMolecular sieveAdhesive

The invention belongs to the technical field of glass deep processing, and discloses a molecular sieve spacing bar, a manufacturing method and equipment. A molecular sieve in the molecular sieve spacing bar is bonded into a strip-shaped object through an adhesive; the outer surface of the molecular sieve is wrapped with a layer of adhesive, and the spacing bar which takes the molecular sieve as a supporting framework and has a certain porosity is formed through mutual bonding of the adhesive; and the spacing bar is directly bonded on glass in an online manufacturing and online placing mode to form a spacing frame. According to the molecular sieve spacing bar, the moisture absorption function is added to the spacing bar, the supporting function is added to the molecular sieve, the molecular sieve and the spacing bar are combined into a whole, the existing molecular sieve filling process is omitted, and therefore the production cost is reduced; various additives can be added into the spacing bar, and various functional strips can be compounded, so that the performance of the spacing bar is improved; and the cost of the spacing bar is not higher than that of an existing lowest aluminum alloy strip, and the performance of the spacing bar is not lower than that of an existing highest-end TPS strip and TSS strip.

Owner:温州前瞻玻璃科技有限公司

Plastic defoaming master batch and preparation method thereof

The invention discloses a plastic defoaming master batch and a preparation method thereof, and belongs to the technical field of defoaming master batches. The plastic defoaming master batch is prepared from the following raw materials in parts by weight: 55-65 parts of superfine calcium oxide, 1-2 parts of oxidized polyethylene wax, 6-8 parts of ascorbyl stearate, 11-13 parts of polymethyl acrylate, 18-20 parts of a carrier resin and 4-6 parts of a dispersing aid, wherein the average particle size range of the superfine calcium oxide is 600-1250 meshes. The plastic defoaming master batch prepared by the invention has the advantages of long storage time and lasting moisture absorption effect.

Owner:东莞市赛美塑胶制品有限公司

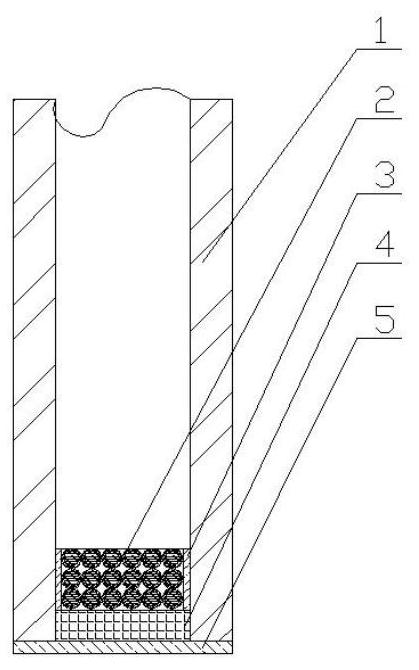

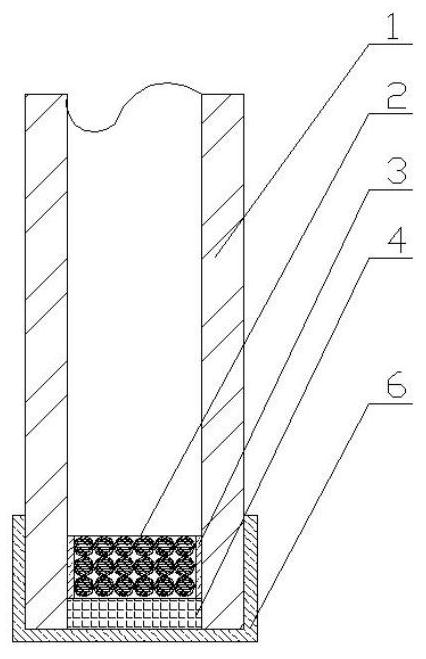

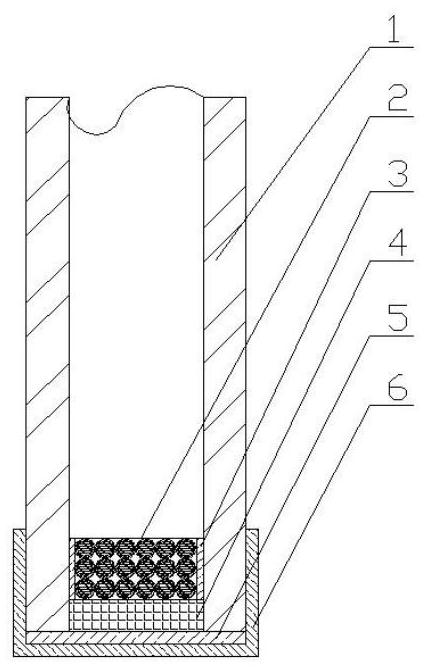

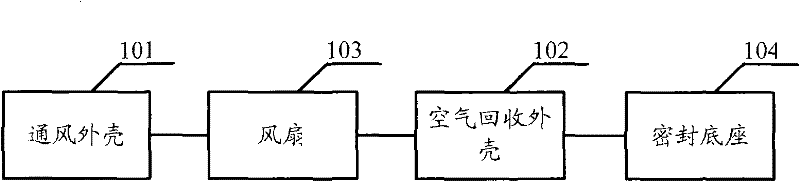

Dehumidifier

InactiveCN101732022BFast moisture absorptionImprove moisture absorptionFootwear cleanersDesiccantEngineering

The embodiment of the invention discloses a dehumidifier which comprises a ventilation shell, a fan and a sealing base, wherein the ventilation shell can bear a desiccant, and the desiccant can absorb moisture in air; the ventilation shell is connected with one end of an air recovery shell, and a fan which drives the air to flow to contact the desiccant borne by the ventilation shell when operating is installed on the air recovery shell; and the sealing base is connected with the other end of the air recovery shell and is provided with a soft edge which can cling to the inner wall of a shoe and seal the shoe. In the embodiment, by adding the fan in the dehumidifier, peripheral air is driven to fully contact the desiccant, thereby accelerating the moisture absorption speed of the desiccantand enhancing the moisture absorption function. In addition, by adding the sealing base, the shoe is sealed and a sealed space is formed, and therefore, a range of dry air can be shortened within thespace of the shoe, and the dehumidification efficiency is enhanced. Further, because the shoe is sealed with the sealing base, the dehumidification range of the dehumidifier is limited within the range of a shoe frame, and the dehumidification efficiency is enhanced.

Owner:徐弘 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com