Polyester having moisture absorption, fire retardation and ultraviolet resistance composite function

A composite function, anti-ultraviolet technology, applied in the direction of single-component polyester rayon, melt spinning, etc., can solve the problems of hygroscopic performance modification, secondary poisoning, yet to be developed, etc., to achieve increased hygroscopicity, slow down The effect of dripping, increasing amorphous space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

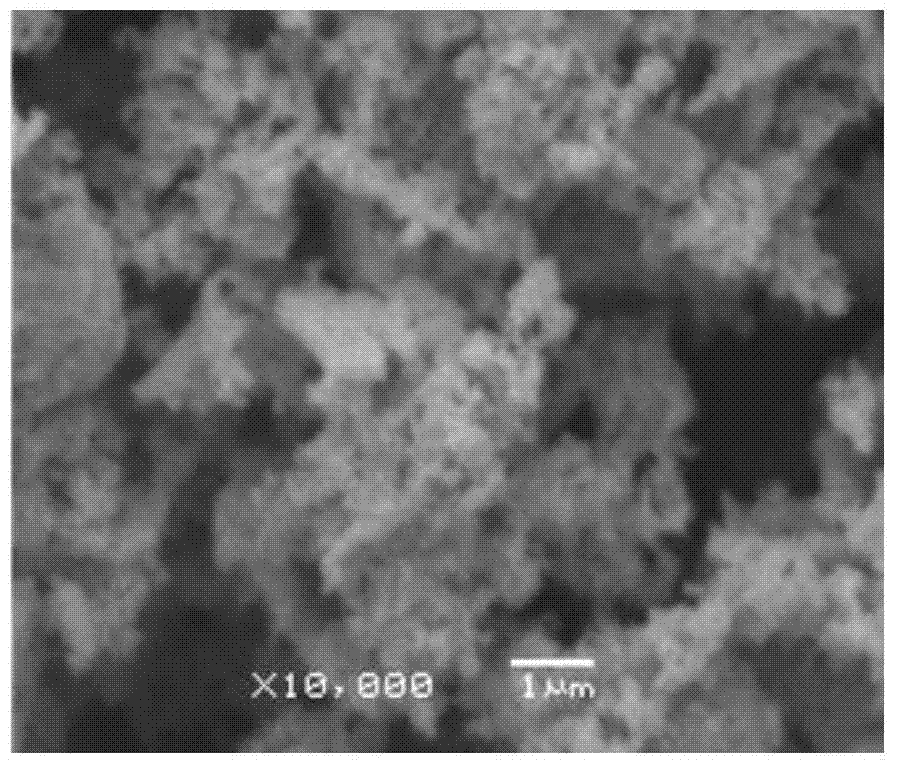

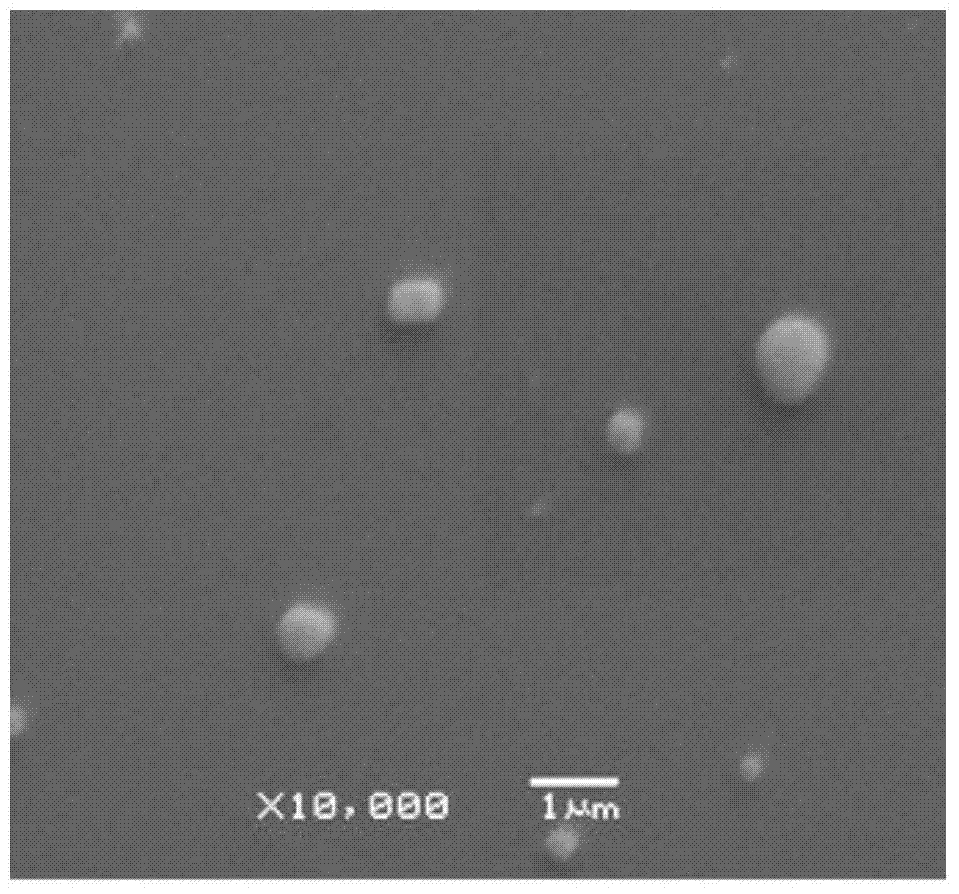

[0083] Pretreatment of inorganic nano-anti-ultraviolet powder: Weigh 50g of zinc oxide and PEG2001g, mix and stir, and then use ethylene glycol as the dispersion medium to disperse the aforementioned mixture by ball milling. Centrifuge for 30 seconds to obtain a dispersed particle size of zinc oxide of 190-280 nm.

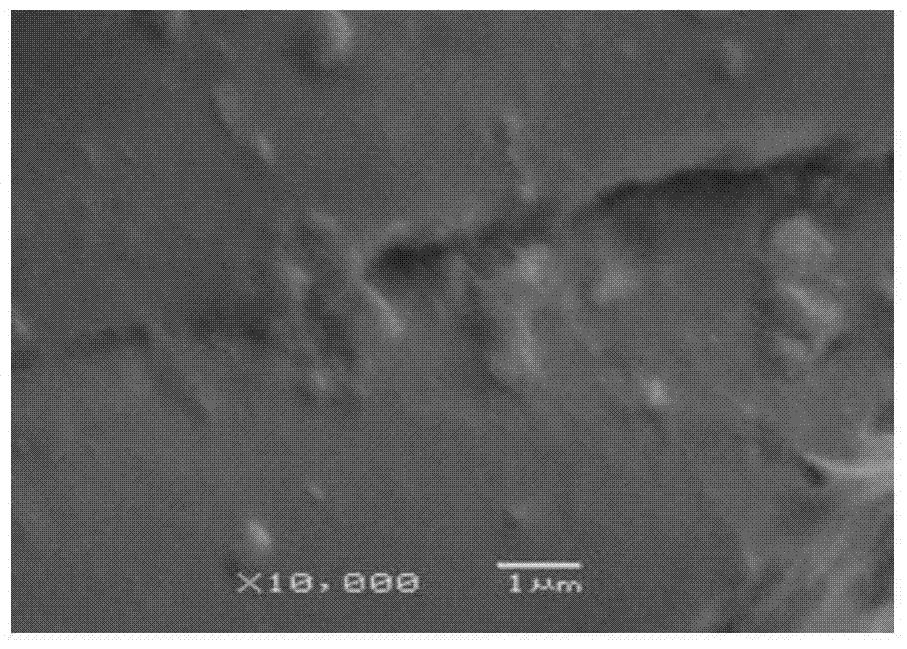

[0084] Weigh 45g of ethylene glycol (EG), 98g of terephthalic acid (PTA), 2g of isophthalic acid (IPA), flame retardant 9,10-dihydro-9-oxa-10-phosphaphenanthrene- 5.4g of 10-oxide and 0.032g of antimony trioxide were added to the first esterification reactor at the same time to carry out the esterification reaction at a temperature of 245°C. The esterification reaction was carried out for 3.5 hours, and the first esterification product was introduced into the second esterification reactor. , adding 7.5g of diethylene glycol isophthalate-5-sodium sulfonate (SIPE), 10g of polyethylene glycol and 1.7g of treated zinc oxide in sequence, and after continuing the esterif...

Embodiment 2

[0086] Pretreatment of inorganic nano-anti-ultraviolet powder: Weigh 70g of aluminum oxide, mix and stir 1g of PEG400, and then use ethylene glycol as the dispersion medium to disperse the aforementioned mixture by ball milling. The aluminum oxide powder after ball milling and dispersion is in the Centrifuge at 2600r / min for 25 seconds to obtain aluminum oxide with a particle size of 220nm-300nm.

[0087] Weigh 41g of ethylene glycol (EG), 98g of terephthalic acid (PTA), 2g of isophthalic acid (IPA), flame retardant 9,10-dihydro-9-oxa-10-phosphaphenanthrene- 10-oxide 3.0g, 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide 3.0g and antimony acetate 0.03g, add a The esterification reaction is carried out at a temperature of 258°C in the esterification reaction kettle, and the esterification reaction is carried out for 3 hours. The monoesterification product is introduced into the diesterification reaction kettle, and dimethyl isophthalate-5-sodium sulfonate...

Embodiment 3

[0089] Pre-treatment of inorganic nano-anti-ultraviolet powder: Weigh 10g of titanium dioxide, 10g of kaolin, and 10g of silicon dioxide respectively, mix and mix with 1g of PEG200 and stir, and then use ethylene glycol as the dispersion medium for titanium dioxide, kaolin, and silicon dioxide Mix the solid powders for ball milling and disperse. After ball milling, the mixed powder of titanium dioxide, kaolin and silicon dioxide is centrifuged at 2600r / min for 30 seconds to obtain titanium dioxide, kaolin and silicon dioxide with a particle size of 200-400nm.

[0090] Weigh 48g of ethylene glycol (EG), 95g of terephthalic acid (PTA), 5g of isophthalic acid (IPA), 6-oxo-6H-dibenzo-c,e-1,2-oxaphospha Hexan-6-one methyl-succinic acid 6.8g and ethylene glycol antimony 0.035g were added into the esterification reaction kettle at the same time to carry out the esterification reaction at a temperature of 250°C. The esterification reaction was carried out for 3.5 hours, and the esterif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com