Molecular sieve spacing bar, manufacturing method and equipment

A spacer and molecular sieve technology, which is applied in construction, building components, building structures, etc., can solve the problems of small spacer investment, hollow glass pollution, and good thermal conductivity, so as to reduce production costs, prolong service life, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

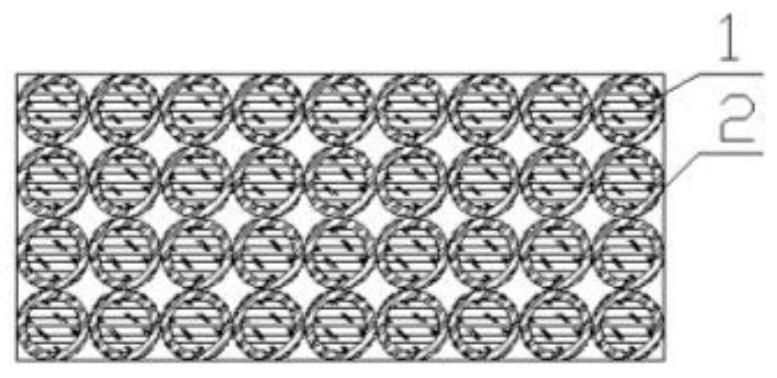

[0075] Example 1: Reference figure 1 and Figure 9 , a molecular sieve spacer, comprising a molecular sieve 1 and an adhesive 2, the molecular sieve 1 is a 3A molecular sieve with a particle size of 1.4-2.0mm, and the adhesive 2 can be selected from commonly used plastics such as PE, PP, PA, PS, PVC, ABS, PU, TPS, etc., you can also choose hot melt adhesives such as EVA, TPR, PA, PES, PEA, TPE, PUR, TPU, etc., you can also choose hot melt pressure sensitive adhesive or hot melt butyl adhesive, so that the spacer has a Self-adhesive, there is no need to apply glue when bonding with glass; since the adhesive 2 is mainly used for bonding, conventional raw materials with wide sources and low prices can be preferred. In order to prevent the deformation and cracking of the spacer, fiber materials such as glass fiber and polyester fiber can be added to the adhesive 2; Burning agent, etc.; in order to improve the service life of the spacer, an anti-aging agent, an anti-ultraviolet...

Embodiment 2

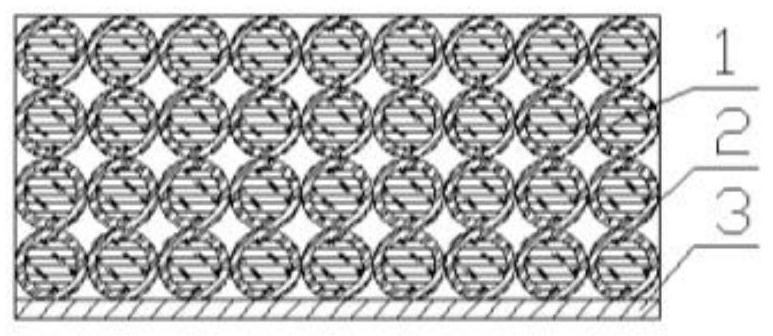

[0076] Example 2: Reference figure 2 and Figure 10 , a molecular sieve spacer bar, comprising a molecular sieve 1, an adhesive 2 and a dense layer 3, which is basically the same as in Example 1, except that a dense layer 3 is added, and the dense layer 3 has one or two layers, which can be arranged in the interval The outer surface or inside of the strip, the dense layer 3 can play a sealing and supporting role; the dense layer 3 can choose metal foil strips such as stainless steel strips with a thickness of about 0.1mm, aluminum alloy strips with a thickness of 0.1-0.2mm, etc., or metal foil strips. Plastic composite tapes such as aluminum-plastic composite tapes, etc., plastic tapes such as PET tapes with better water vapor barrier properties can also be selected; the dense layer 3 can be placed at the bottom or middle of the mold, together with the uniformly mixed molecular sieve 1 and adhesive 2 Extrude, cool down and solidify to form a spacer; in order to facilitate th...

Embodiment 3

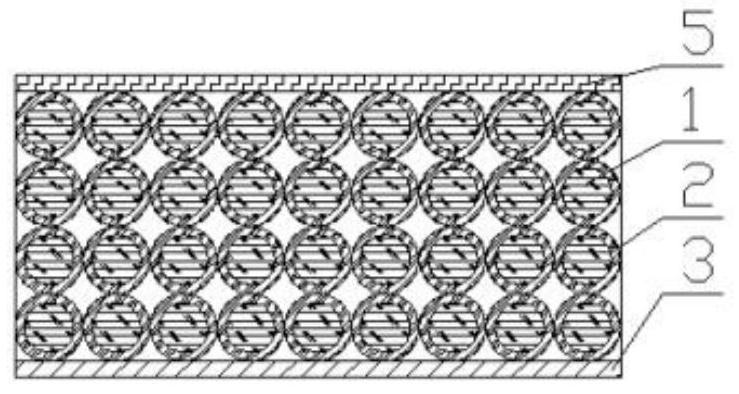

[0077] Example 3: Reference image 3 and Figure 11 , a molecular sieve spacer, comprising a molecular sieve 1, an adhesive 2, a dense layer 3 and a decorative layer 5, which is basically the same as in Example 2, except that a decorative layer 5 is added, and the decorative layer 5 can optionally have moisture absorption holes Metal foil strips such as stainless steel strips with a thickness of about 0.1mm, aluminum alloy strips with a thickness of 0.1-0.2mm, etc. You can also choose metal-plastic composite strips with moisture absorption holes such as aluminum-plastic composite strips, etc., and you can also choose breathable plastic cloth Belts such as non-woven fabrics and polyester fiber cloths with relatively good water vapor permeability, glass fiber cloths, mesh cloths, etc. can also be selected; the decorative layer 5 can be placed on the top of the mold, together with the uniformly mixed molecular sieve 1 and adhesive Adhesive 2 is extruded together, forms spacer ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com