Patents

Literature

63results about How to "Fast moisture absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comfortable skin-care warming health-care hollow porous yarn, and preparation method and application thereof

The invention provides a preparation method and application of a comfortable skin-care warming health-care hollow porous yarn. The comfortable skin-care warming health-care hollow porous yarn is formed by firstly blending and then processing such six hollow fibers (one or more fibers) as fine staple cotton fibers, seashell fibers (or Amicor antibiotic fibers or Cleancool fibers), water-soluble polyvinyl short fibers (or water-soluble polyvinyl filaments), kawo kawo fibers ( or Viloft fibers or Prolivon fibers or antibiotic hollow polyester fibers or Porel hollow fibers or Poral hollow fibers or micropore polyester fibers) and the like. The product has a body temperature adjustment effect, keeps a human body to always feel comfortable, is good in stiffness, feels soft and smooth, is good in drapability, unique in appearance and good in wrinkle resistance, enables a wearer to feel comfortable and is fluffy in texture, thereby being suitable for production of high-grade knitting machine woven fabrics, cold-proof underwear, bedding articles and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

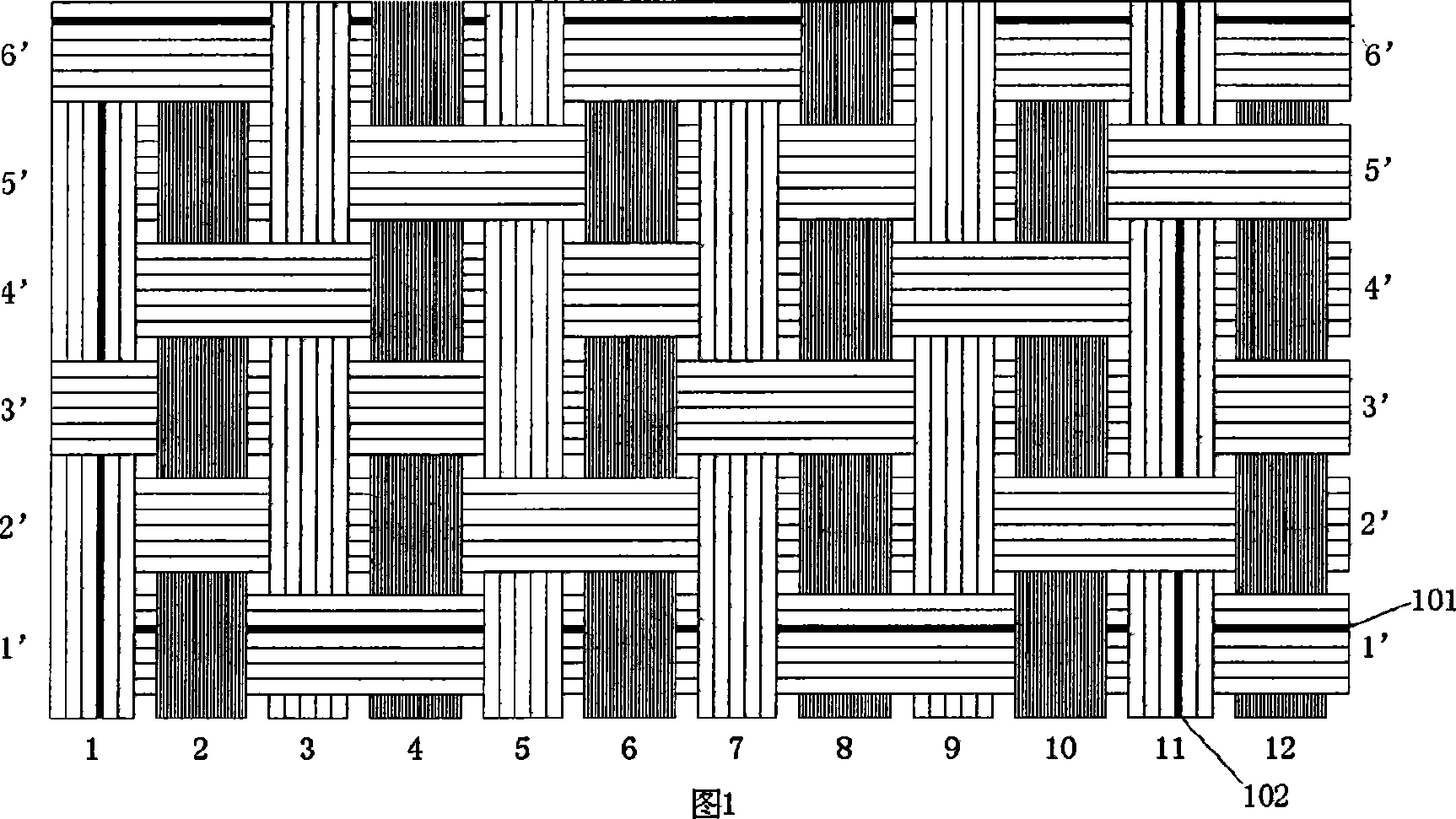

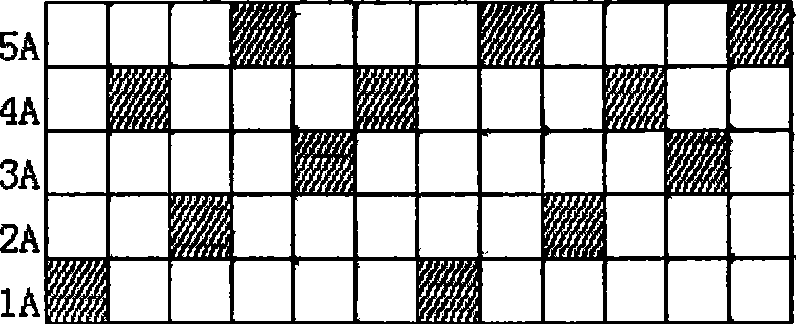

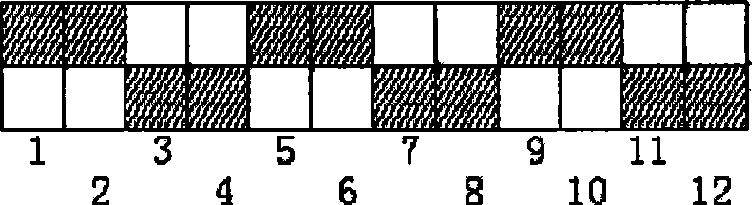

Moisture absorption and perspiration antistatic fabric

InactiveCN101413168AGood hygroscopicityLower specific resistanceWoven fabricsFiberMoisture absorption

The invention discloses an antistatic fabric for moisture absorption and sweat elimination, which is formed by interweaving warps and wefts. The fabric has rib weave consisting of back weave and face weave, wherein odd warps are back warps which are interwoven with the wefts to form the back weave, even warps are face warps which are interwoven with the wefts to form the face weave, the back warps are common fiber back warps, the face warps are superfine fiber face warps, and the fabrics are embedded into conductive yarns at intervals in the warp direction and in the weft direction respectively. The invention provides the antistatic fabric for the moisture absorption and the sweat elimination, which has good effects on moisture absorption and sweat elimination, good antistatic effect, and comfort.

Owner:苏州新纶超净技术有限公司 +1

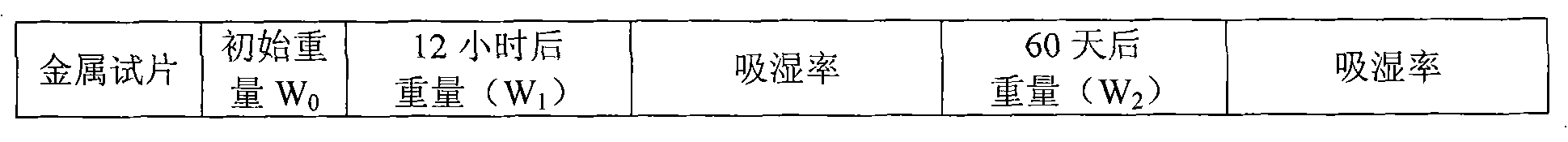

Starch-based high-efficiency moisture-absorbing desiccant

InactiveCN101862579AImprove moisture absorption efficiencyExtension of timeOther chemical processesDispersed particle separationInorganic saltsDesiccant

The invention provides a starch-based high-efficiency moisture-absorbing desiccant, which has high moisture-absorbing efficiency, long-time action and great moisture-absorbing quantity and comprises the main components of pregelatinized starch, inorganic salt and a gel reinforcing agent. The main processing technique thereof comprises the following steps of: (1) preparation of the gelatinized starch: taking starch to be mixed in cold water, stirring to form emulsus suspension, and heating to lead the starch to be changed to be doped; (2) grinding and crushing of the inorganic salt and the gel reinforcing agent; and (3) alloying of the pregelatinized starch, the inorganic salt and the gel reinforcing agent. The starch-based high-efficiency moisture-absorbing desiccant has the main advantages of: (1) long moisture-absorbing time: moisture absorption can be continuously conducted for more than 60 days under the condition of 100%RH; (2) great moisture-absorbing quantity: the total moisture-absorbing quantity can achieve more than two times of self weight; (3) formation of the gel after moisture absorption: liquid cannot be formed to overflow a package to pollute devices; (4) environmental protection and low toxicity: no harmful influence exists on a human body and the environment; and (5) by comparison with the conventional desiccating agent such as silica gel and the like: the usage is reduced by 7 times.

Owner:任风芝 +1

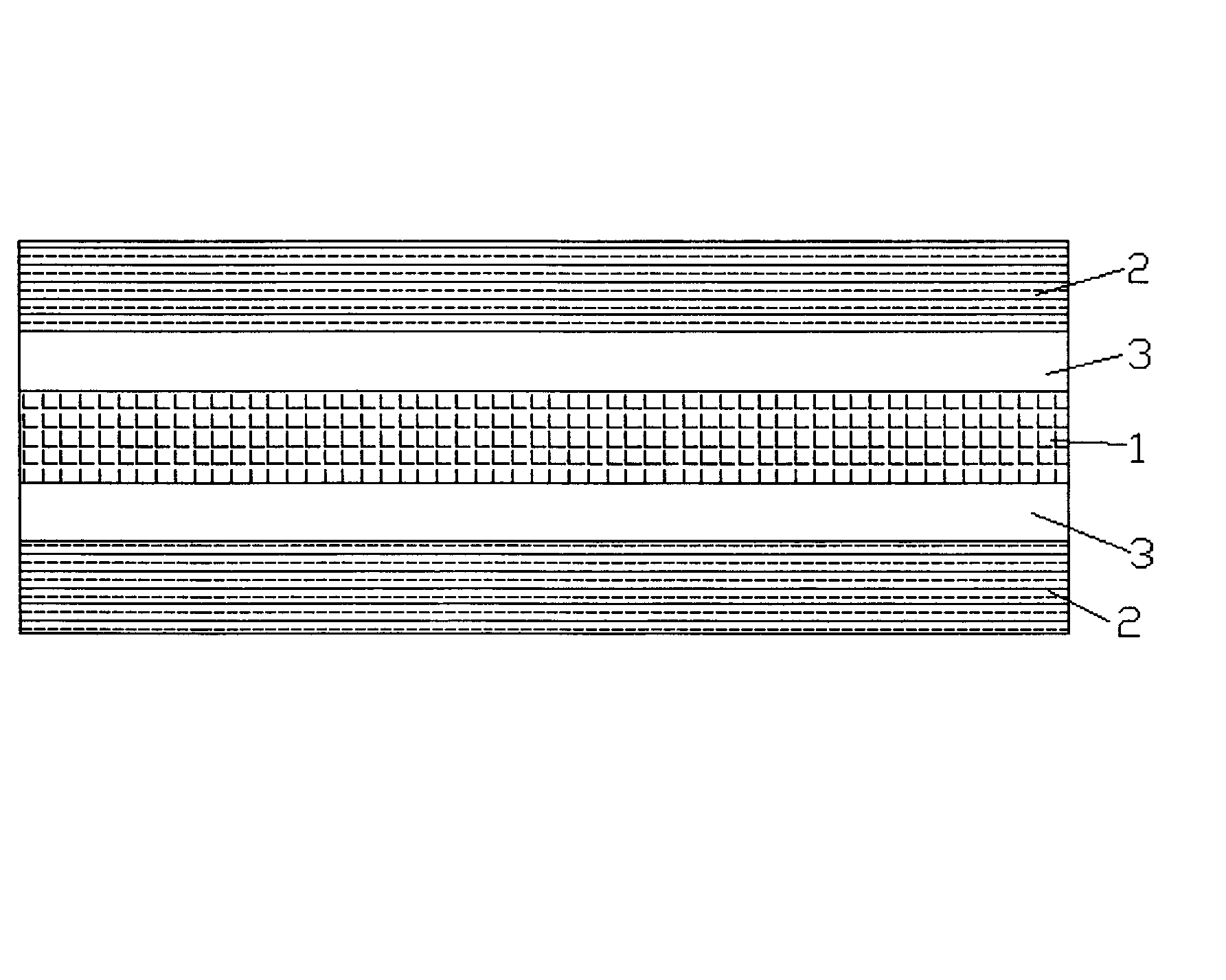

Double layer composite melt-blown non-woven fabric

The invention discloses a double layer composite melt-blown non-woven fabric, comprising a first substrate layer, a multi-layer oblique injection composite superfine staple fiber layer and a second substrate layer sequentially arranged from the top down. The double layer composite melt-blown non-woven fabric is further provided with a water storage fiber substrate layer between the two substrate layers, so that the hygroscopicity of the fiber surface is improved, the surface ratio resistance is lowered, and the surface static is reduced. Meanwhile, when the double layers are compounded, the superfine staple fiber mesh is included between the upper and lower layers, so that the performance intensity and application functions of the non-woven fabric are increased and added, and the non-woven fabric is ensured to have a soft and uniform fabric surface and has the advantages of rapid moisture absorption speed and being anti-static and flame-retardant.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

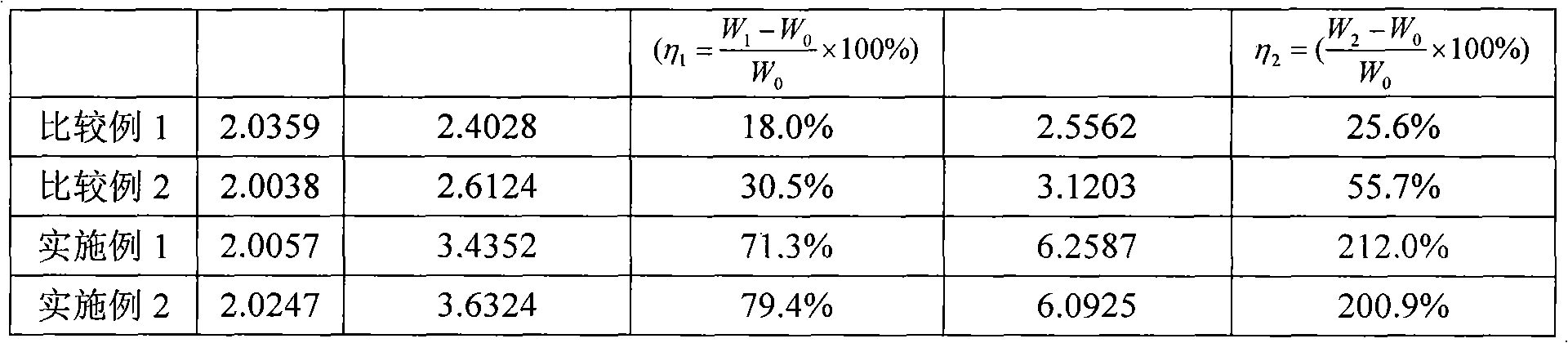

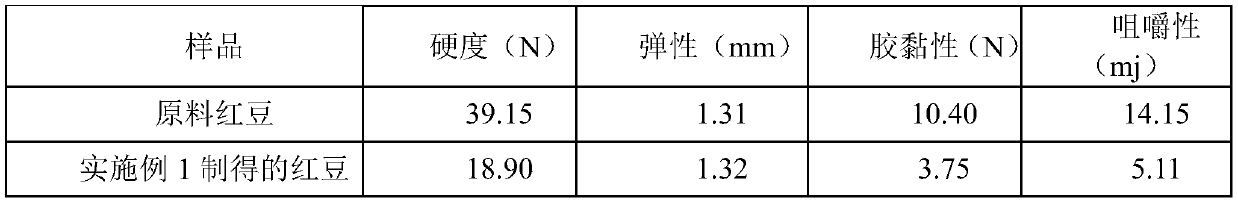

Processing method making coarse grains and millet boiled and cooked together, and coarse grains obtained by processing

The invention belongs to the technical field of food processing, and in particular, relates to a processing method making coarse grains and millet boiled and cooked together, and coarse grains obtained by processing. The processing method making coarse grains and millet boiled and cooked together includes the following steps: (1) ultrasonic assisted soaking: placing cleaned coarse grains in water,carrying out ultrasonic assisted soaking for 10-100 min, and draining for standby application; (2) pre-curing of the coarse grains: placing the coarse grains processed in the step (1) in a high-pressure cooker, and cooking for 2 min-5 min; and (3) microwave drying: drying the coarse grains properly processed in the step (3) for 3-7 min with 300 W-600 W microwaves. The coarse grains processed according to the method can be boiled and cooked together with millet, and the processing method has higher efficiency.

Owner:XUCHANG UNIV

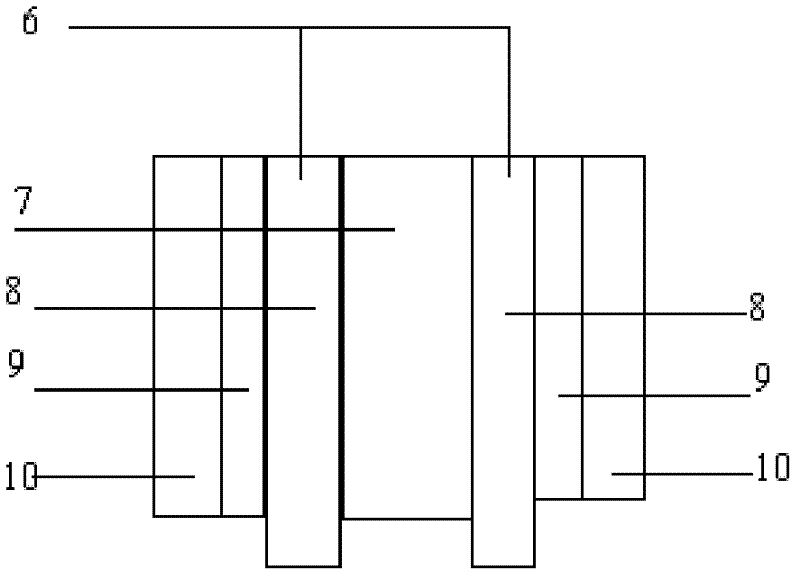

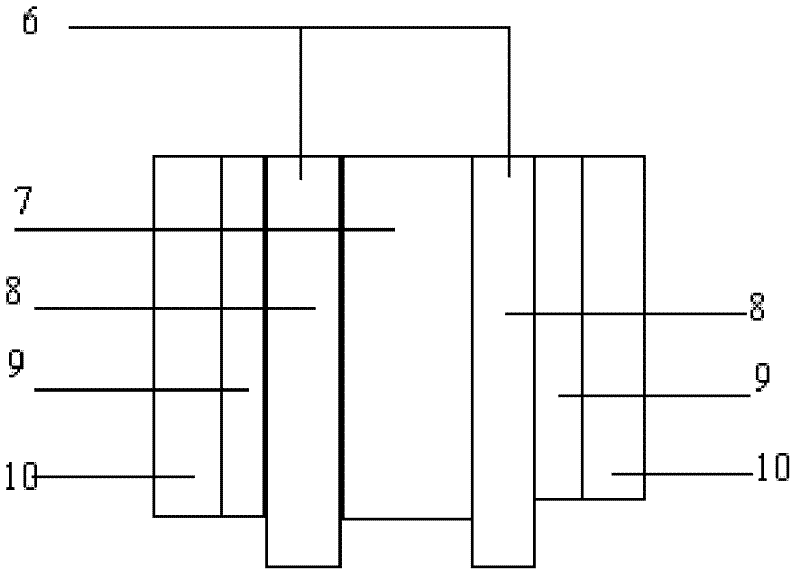

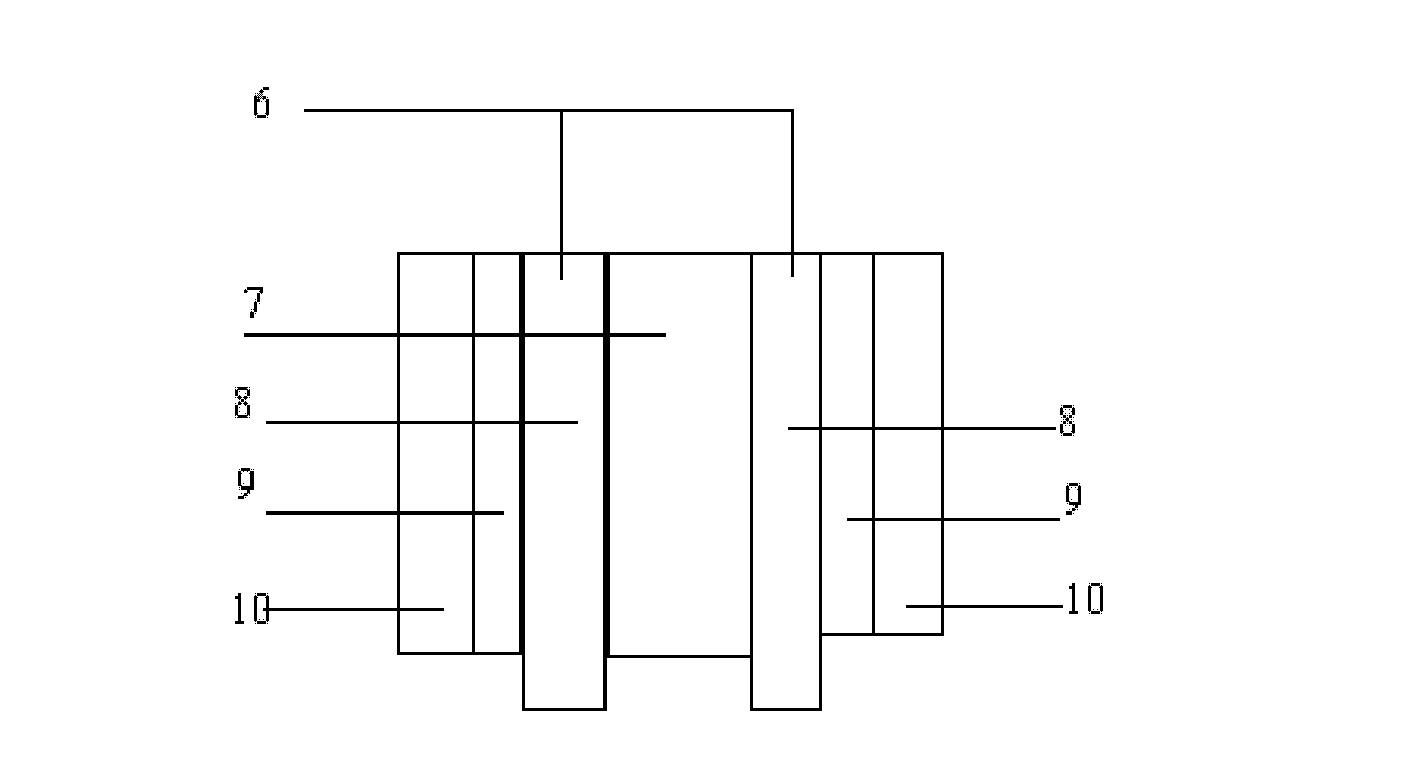

Method for processing wool and polyester blended fabric with rapid high-efficient moisture absorbable and breathable function

InactiveCN102517876AWon't breakFast moisture absorptionPhysical treatmentAnimal fibresPolyesterAlkylphosphate

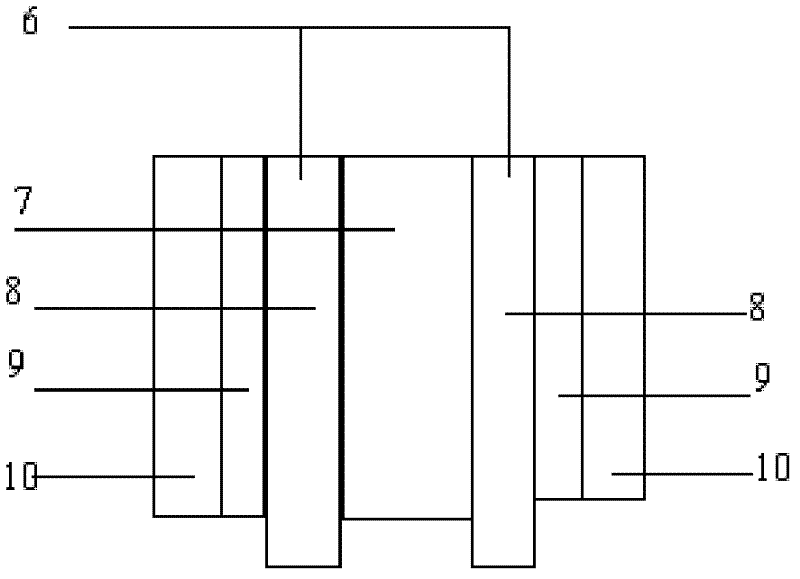

The invention relates to a method for processing textile fabric, specifically to a method for processing wool and polyester blended fabric with a rapid high-efficient moisture absorbable and breathable function. At normal pressure, the wool and polyester blended fabric undergoes radiation mutation by the use of a low temperature plasma spray gun device. After radiation, alkyl sulfonate, alkyl phosphate ester or quaternary ammonium salt is grafted onto the surface of the fabric, thus stabilizing and enhancing hydrophilic capability. The low temperature plasma spray gun device contains an earthing device. A quartz tube is arranged in the middle of the earthing device. A plasma zone is formed between the quartz tube and the earthing device. The plasma spray gun is used to modify the textile material. The method provided by the invention can effectively solve the problem of ''instant effect''. The processed fabric has advantages of fast moisture absorption speed and good effects, and can realize the moisture absorbable and breathable effect.

Owner:WUHAN TEXTILE UNIV

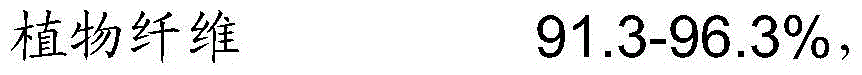

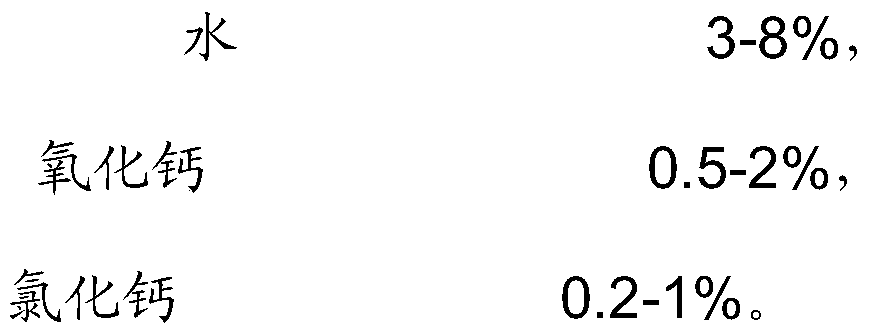

Plant fiber dryer and preparation method thereof

ActiveCN105664863AFast moisture absorptionNo spaceOther chemical processesDispersed particle separationFiberDesiccant

The invention provides a plant fiber dryer which includes the following components, by mass, 91.3-96.3% of plant fibers, 3-8% of water, 0.5-2% of calcium oxide and 0.2-1% of calcium chloride. The plant fiber dryer is prepared from the pure-natural plant fibers through a special process finely, so that the plant fiber dryer has high moisture absorption rate and moisture absorption ratio. The saturate moisture absorption ratio is 100% as the weight of the plant fiber dryer itself (25 DEG C, RH is 100%) and is three times as that of a common silica gel dryer. The dryer is convenient and practical and is free of space occupation. With the natural plant fibers as a moisture absorption carrier, the dryer can be naturally degraded by 100% and belongs to environment-friendly dryers. The plant fiber dryer looks like a thick paper piece and can be cut or chopped into different shapes, can be filled in bottle covers or other containers directly and is an excellent selection for various biological foods, health-caring foods and medicines.

Owner:DONGGUAN JIULV POLYMER MATERIALS CO LTD

Double-component composite melt-blown nonwoven fabric

ActiveCN103158285AGood hygroscopicityLower surface specific resistanceLayered productsEngineeringNonwoven fabric

The invention discloses a double-component composite melt-blown nonwoven fabric comprising a substrate layer with an upper side and a lower side. A layer of oblique crossed microfiber layer is respectively arranged on each of the upper side and the lower side of the substrate layer. The nonwoven fabric has the advantages of reasonable structure, good uniformity, good hydrophilic effect, good anti-aging effect, and good anti-static effect.

Owner:JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Technology for manufacturing water absorption soft fabrics

InactiveCN104611818ASoft textureMoisture-absorbing and breathableBiochemical fibre treatmentWoven fabricsDisperse dyeYarn

The invention discloses a technology for manufacturing water absorption soft fabrics. The technology includes steps of manufacturing woven fabrics from selected yarns or threads; carrying out dyeing and finishing processing the manufactured fabrics, to be more specific, desizing the fabrics by the aid of sodium carbonate under the condition that a PH (potential of hydrogen) value is smaller than 10, bleaching the fabrics by the aid of hydrogen peroxide for the bleach wash time of 35min-50min at the water temperatures ranging 60 DEG C to 78 DEG C, performing jig dyeing on the fabrics by the aid of disperse dye at high temperatures under high pressures or dyeing the fabrics by the aid of cationic dye, washing the fabrics under the condition that a PH value is smaller than 10, finishing the fabrics in finishing agents for 25min-60min, ironing the fabrics by the aid of steam at the temperatures ranging from 100 DEG C to 180 DEG C and setting the fabrics to obtain the water absorption soft fabrics. Cotton and polyester fibers which are of hollow structures are blended to form the selected yarns or threads. The technology has the advantages that the water absorption soft fabrics manufactured by the aid of the technology have characteristics of soft textures, moisture absorption, breathability, sweat drainage, warmth keeping and the like and are excellent in elasticity and extensibility, wearers feel comfortable when wearing the water absorption soft fabrics, are free of tightening feel, and can enjoy unprecedented skin comfort, and the body curves of the wearers can be sufficiently embodied.

Owner:NANTONG SIDEFU TEXTILE DECORATION

Processing method of polyamide and cotton blending fabric with rapid and efficient moisture absorption performance

InactiveCN102517877AFast moisture absorptionGood effectPhysical treatmentVegetal fibresAlkylphosphatePolyamide

The invention relates to a processing method of a weaving fabric and specifically provides a processing method of a polyamide and cotton blending fabric with rapid and efficient moisture absorption performance. The polyamide and cotton blending fabric is treated with irradiation mutagenesis by a low temperature plasma spray gun apparatus under normal pressure; and after irradiation, alkyl sulfonate, alkyl phosphate ester or quaternary ammonium salt is grafted to the fabric surface. The low temperature plasma spray gun apparatus comprises an earthing device; a quartz tube is arranged in the middle of the earthing device; a plasma zone is formed between the quartz tube and the earthing device; a high voltage electrode is arranged in the quartz tube; and an upper end of the quartz tube is connected with an air inlet system. The invention utilizes plasma spray gun to modify the polyamide and cotton blending fabric and a blended fabric mainly containing polyamide and cotton; the treated fabric has high moisture absorption speed and good moisture absorption effect, can realize effects of moisture absorption and perspiring and solves a problem, caused by timeliness restriction, of fast degeneration of water absorption speed of cotton / polyamide fabric or polyamide / cotton and failure to realize practical application effect.

Owner:WUHAN TEXTILE UNIV

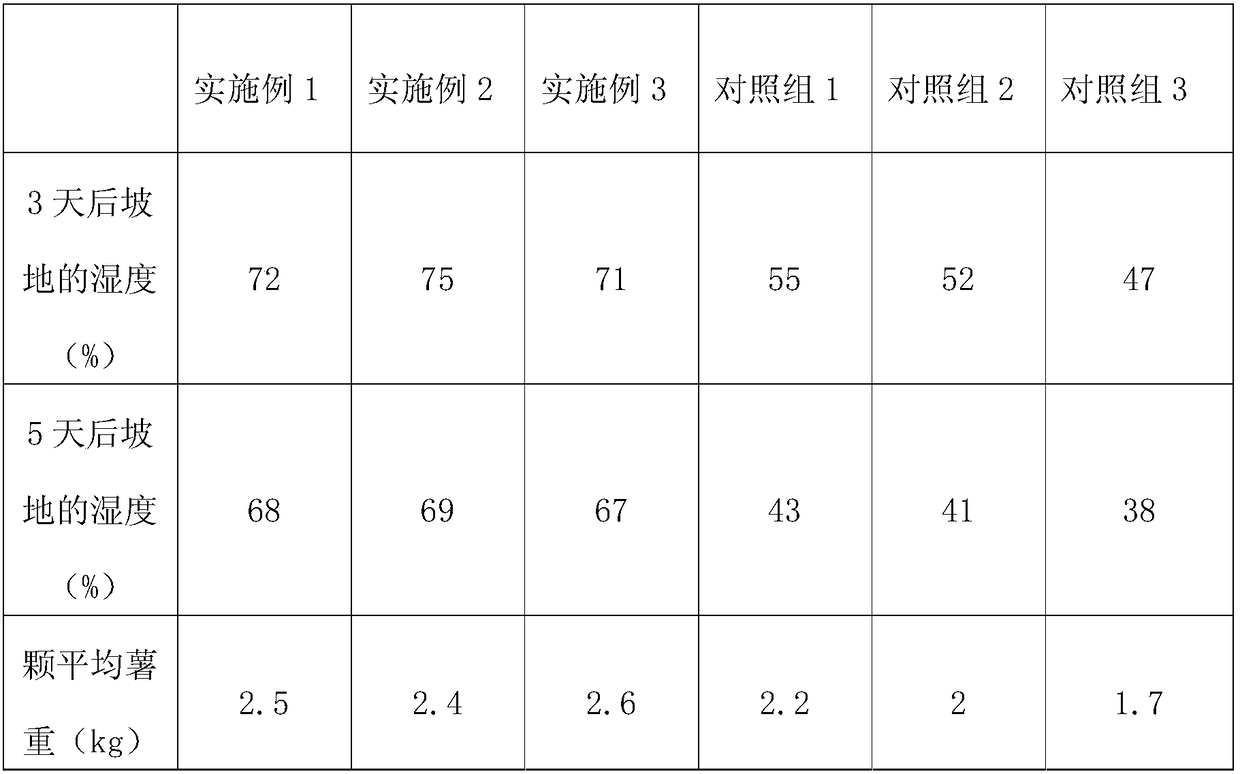

Water-retaining planting method for Millettia specisoa Champ in sloping land

InactiveCN108476896ANo pollution in the processLarge specific surface areaSuperphosphatesBioloigcal waste fertilisersBiologyBiomass

The invention belongs to the technical field of agricultural planting, and specifically relates to a water-retaining planting method for Millettia specisoa Champ in a sloping land. The water-retainingplanting method comprises the following steps: (1) preparationof the sloping land; (2) seedling raising and transplanting; and (3) water and nutrient management. The water-retaining planting method provided by the invention has the following steps: biomass charcoal and a water-retaining fertilizer are spread onto the sloping land during ploughing and buried into soil after ploughing, have good water-retaining effect, can rapidly absorb and slowly release water, realize water retention for the sloping land, and have good water-retaining effect, so the Millettia specisoa Champ can vigorously grow on the sloping land, and the yield of the Millettia specisoa Champ on the sloping land is increased.

Owner:东兰县委荣村伟造林下药材种植合作社

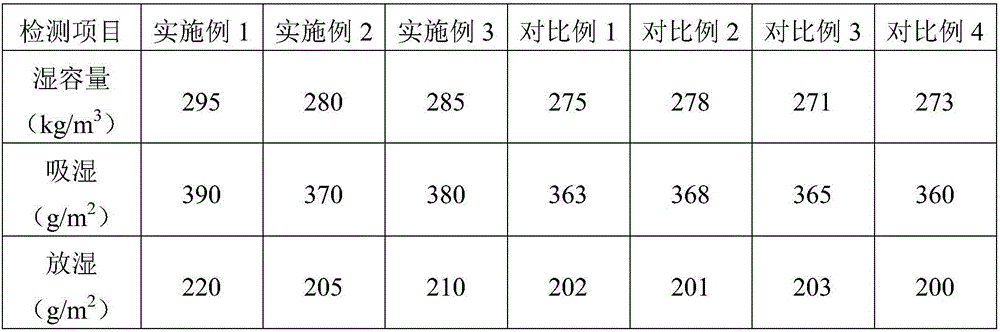

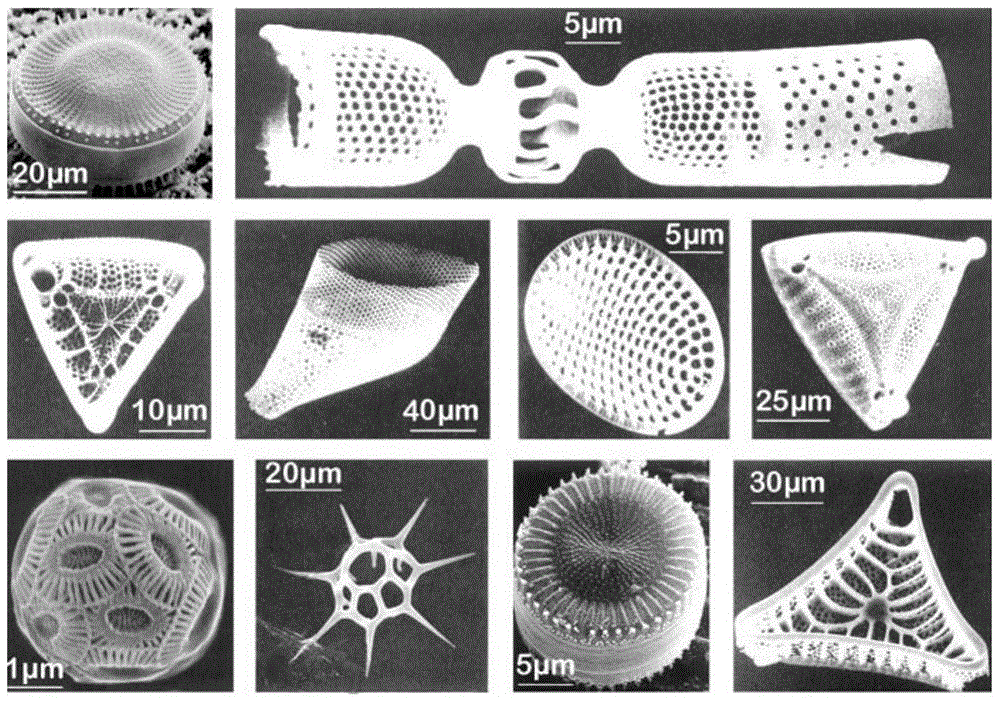

Composite humidity adjusting material

InactiveCN106117616AFast moisture absorptionLarge wet capacitySodium polyacrylateSodium carboxymethylcellulose

The invention discloses a composite humidity adjusting material. The composite humidity adjusting material is prepared from the following components in parts by weight: 7-9 parts of CaCl<2>.6H<2>O, 3-5 parts of ZnSO<4>.7H<2>O, 2-4 parts of shell powder, 1-3 parts of xonotlite, 3-6 parts of garnet, 3-6 parts of spinel, 4-6 parts of sodium carboxymethyl starch, 4-8 parts of carboxymethyl cellulose, 5-7 parts of sodium polyacrylate, 4-7 parts of chitosan, 1-3 parts of sodium lignosulfonate, 1-3 parts of sodium alginate and 0.3-0.7 part of nanometer silicon dioxide. The composite humidity adjusting material disclosed by the invention has the characteristics of being high in humidity volume and high in humidity sucking and discharging rate, and is a material with broad development prospects.

Owner:黄琳

Interior wall putty with moisture-regulating and moisture-proof function

The invention relates to an internal wall putty with humidity-regulating and moistureproof functions, which is composed of the following components in parts by weight: 0.2-0.6 part of main humidity-regulating material, 10-35 parts of auxiliary humidity-regulating material, 20-30 parts of inorganic gel material, 20-50 parts of inorganic filler, 1-5 parts of organogel material, 0.8-2 parts of functional assistant and 0.5-3.5 parts of assistant. The main humidity-regulating material is high-polymer water-absorbing resin with the fineness of greater than 200 meshes. The functional assistant is microcrystalline cellulose with the fineness of greater than 300 meshes. The internal wall putty has the decoration function, and also has the humidity-regulating and moistureproof functions. The internal wall putty can effectively adsorb moisture in indoor air to achieve the moistureproof and moldproof effects, and can also relatively regulate the indoor air humidity to enhance the residence comfort. The product has the advantages of no pollution and zero VOC (volatile organic compound) release, can be used as a rough coat of the latex paint and can also be used as an interior decoration material independently.

Owner:柳州市三的化工有限公司 +1

Honeycomb-like fabric and manufacturing technology thereof

InactiveCN109338576AHigh oil absorptionIncrease moisture contentWeft knittingBiochemical fibre treatmentYarnManufacturing technology

The invention discloses a manufacturing process of a honeycomb-like fabric. The process specifically includes the following steps that 1, materials are prepared, wherein nylon high elastic fiber, all-cotton fiber, polypropylene fiber, an antimicrobial agent, a deodorant and water as raw materials are weighed according to the corresponding weight parts; 2, spinning is performed, wherein the different fiber materials in the step 1 are spun through a spinning machine to prepare roving and spun yarn; 3, a solution is prepared, wherein the clean water, the antimicrobial agent and the deodorant areadded in a dyeing cylinder, and the mixture is stirred and mixed evenly; 4, the roving and the spun yarn are immersed, wherein the roving and the spun yarn in the step 2 are put in the solution prepared in the step 3 for immersion for 30-45 min; 5, drying, wherein the roving and the spun yarn in the step 4 are taken out and placed in a drying box for drying. According to the production process ofthe honeycomb-like fabric with good water absorption and oil absorption properties, polypropylene is processed into fiber, the oil absorption property is good, and the fiber can be specifically used for absorbing petroleum hydrocarbons, hydrocarbons and the like. The energy consumption is small, the operation is simple, the practicability is high, and the fabric is suitable for wide popularization.

Owner:迦南(福建)新材料科技有限公司

Method for processing polyester cotton with quick and high-efficient moisture absorption performance, and blended fabric mainly comprising polyester cotton

InactiveCN102493167AGood for locationGood for arranging sportsPhysical treatmentVegetal fibresPolyesterAlkylphosphate

The invention relates to a method for processing textile fabric, in particular to a method for processing polyester cotton with quick and high-efficient moisture absorption performance, and blended fabric mainly comprising the polyester cotton. According to the method, the polyester cotton or the blended fabric mainly comprising the polyester cotton is subjected to irradiation induced mutation under normal pressure by a low-temperature plasma torch device, and then alkane sulfonate, alkyl phosphate, or quaternary ammonium salt is grafted on the surface of the fabric, wherein the low-temperature plasma torch device comprises a grounding device; a quartz tube is arranged in the middle of the grounding device; a plasma area is formed between the quartz tube and the grounding device; a high voltage electrode is arranged in the quartz tube; and the upper end of the quartz tube is connected with an air inlet system. According to the method, the textile fabric is modified by using the plasma torch, and the problem about an immediate effect can be effectively solved; and the method can be widely applied in the field of treating textiles by a dry method, a dry reaction can be promoted to replace wet processing, and the treated fabric is high in moisture absorption speed, good in effect and can achieve the moisture absorption and sweat removing effects.

Owner:WUHAN TEXTILE UNIV

Preparation method of safe granular food drying agent

ActiveCN106334545ANon-falling powderFast moisture absorptionGas treatmentOther chemical processesFiberFiltration

The invention discloses a preparation method of a safe granular food drying agent, and belongs to the technical field of packing material preparation. The preparation method comprises the steps that pulp liquid is prepared by taking fresh edulis canna tuberous rhizomes as a raw material and then filtered, the obtained filtrate is washed and subjected to suction filtration to obtain crude starch, filter residues are washed and dried to obtain edulis canna crude fibers, edulis canna starch is prepared by taking the crude starch as a raw material, enzymolysis treatment is conducted on the edulis canna starch with alpha-amylase to obtain edulis canna starch enzymolysis emulsion, the edulis canna crude fibers are crushed and screened and then stirred and mixed with micro-bead silica gel in the edulis canna starch enzymolysis emulsion, the surface of the micro-bead silica gel is coated with a layer of starch fiber film, and then the safe granular food drying agent is obtained. The preparation method is simple, and the moisture adsorption rate of the prepared food drying agent is greatly increased; in addition, the natural plant fibers are taken as a moisture adsorption carrier, and therefore the food drying agent can be fully and naturally degraded, belongs to an environment-friendly drying agent and achieves the high actual application value and a wide market prospect.

Owner:苏州博展干燥剂有限公司

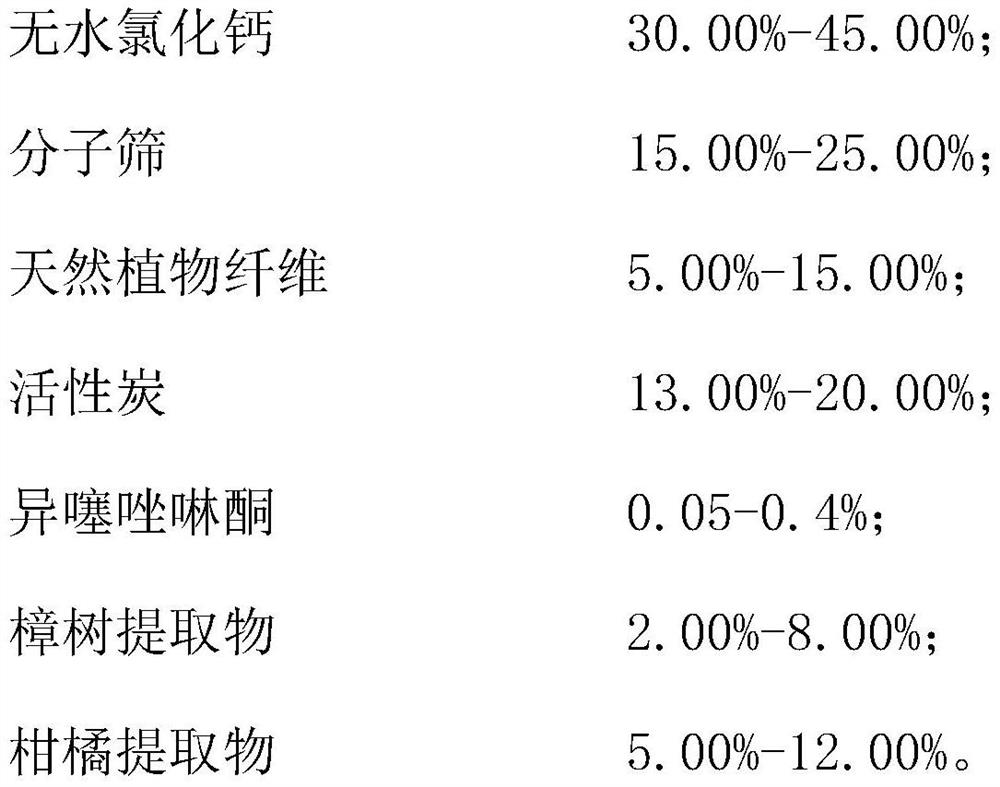

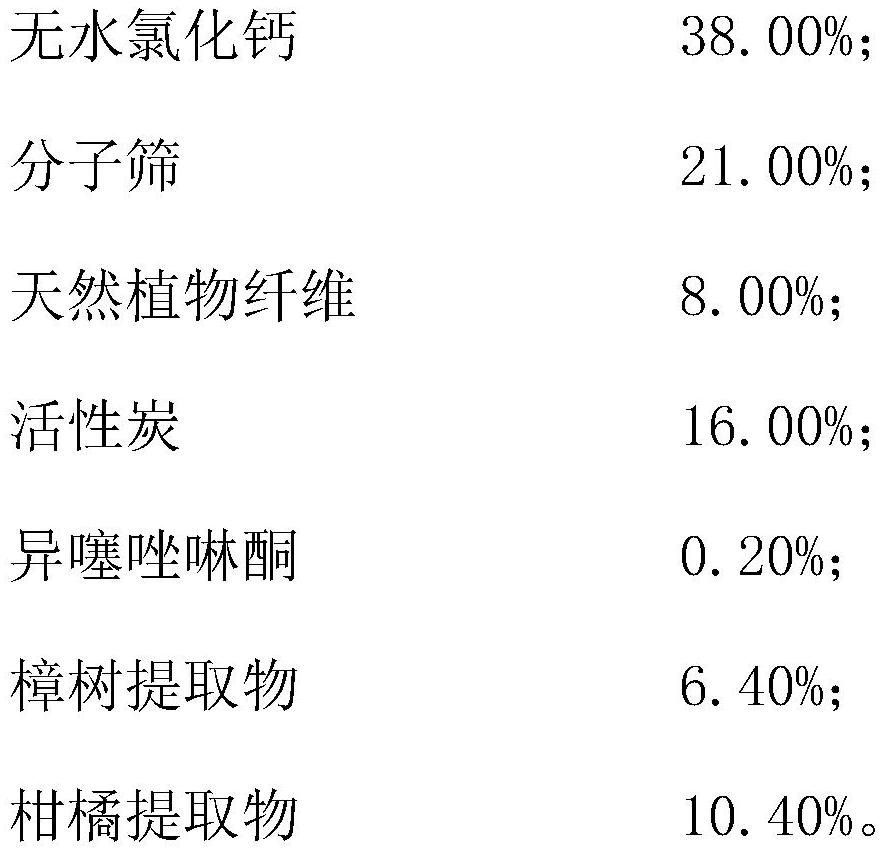

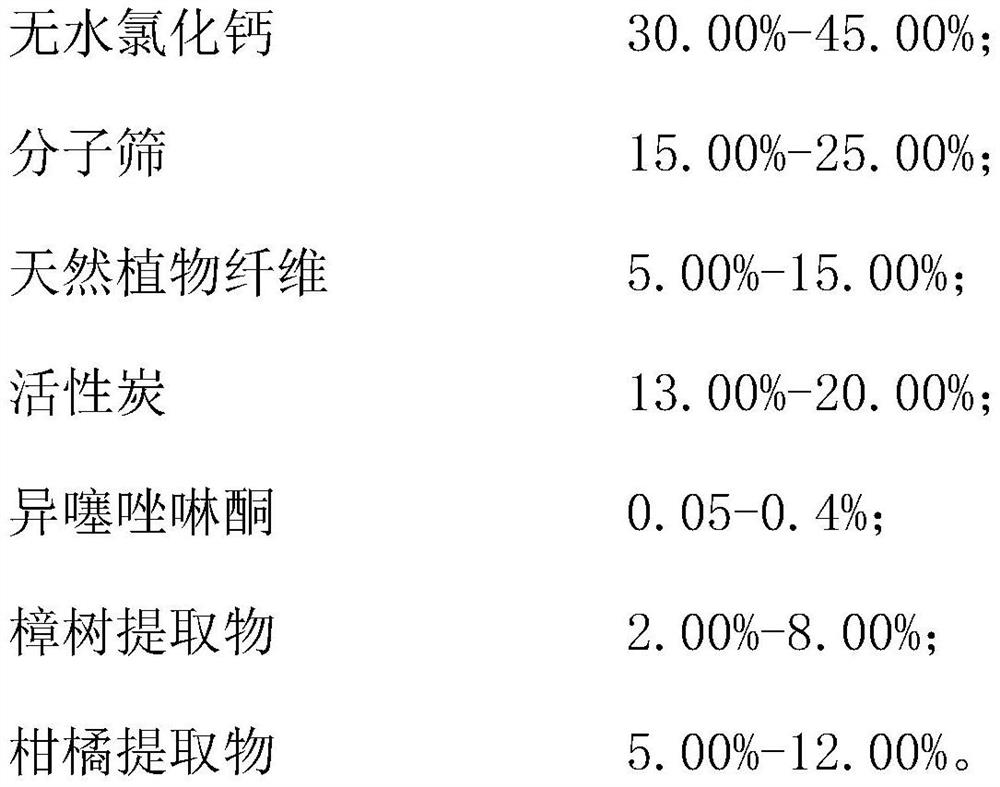

Anti-mildew drying agent and preparation method thereof

InactiveCN112495343AGrowth inhibitionImprove securityBiocideGas treatmentBiotechnologyIsothiazolinone

The invention discloses an anti-mildew drying agent and a preparation method thereof, relates to the related field of drying agents, and aims to solve the problems that after a drying agent in the prior art absorbs water and carried out dehumidification, internal moisture is not easy to evaporate, the interior is damp, and mildew is easy to generate due to good water retention. Raw materials in the drying agent comprise anhydrous calcium chloride, a molecular sieve, natural plant fibers, activated carbon, isothiazolinone, a camphor tree extract and a citrus extract. The drying agent is prepared from the following raw materials in percentage by weight: 30.00%-45.00% of anhydrous calcium chloride; 15.00%-25.00% of a molecular sieve; 5.00%-15.00% of natural plant fibers; 13.00%-20.00% of activated carbon; 0.05%-0.4% of isothiazolinone; 2.00%-8.00% of a camphor tree extract; and 5.00%-12.00% of a citrus extract. The desiccant specifically comprises the following raw materials in percentageby weight: 38.00% of anhydrous calcium chloride; 21.00% of a molecular sieve; 8.00% of natural plant fibers; 16.00% of activated carbon; 0.20% of isothiazolinone; 6.40% of a camphor tree extract; and10.40% of a citrus extract.

Owner:东莞市鼎兴实业有限公司

Preparation method of soil-loosening humectant

InactiveCN107629803AIncrease the number of hydroxyl groupsIncrease infiltration rateOrganic fertilisersSoil conditioning compositionsAlcoholSoil remediation

The invention relates to the technical field of soil remediation and particularly relates to a preparation method of a soil-loosening humectant. The preparation method comprises the steps of firstly carrying out grape fermentation so as to prepare grape fermentation liquid rich in alcohol, soaking sepiolite powder by virtue of the grape fermentation liquid, carrying out hydroxylation modificationon the surface of the sepiolite powder by virtue of alcohol so as to increase the number of hydroxide radicals on the surface of the sepiolite, extracting supernatant rich in amino acids from fermented bean curds and soybeans which are rich in amino acids, carrying out blending fermentation modification on the supernatant and the hydroxylation-modified sepiolite, introducing amino and hydroxide radicals to the sepiolite by virtue of microorganisms so as to obtain modified sepiolite, and grafting the modified sepiolite to acrylic acid, so as to finally obtain the soil-loosening humectant. According to the soil-loosening humectant, the sepiolite has the property of swelling after water absorption, and the soil-loosening humectant is applied to soil and is capable of swelling after the waterabsorption and opening soil so as to realize a soil loosening effect, so that the hardening of the soil is avoided, water molecules can relatively easily enter the soil so as to improve the moisture absorption of the humectants, and the soil-loosening humectant has wide application prospects.

Owner:常州蓝旗亚纺织品有限公司

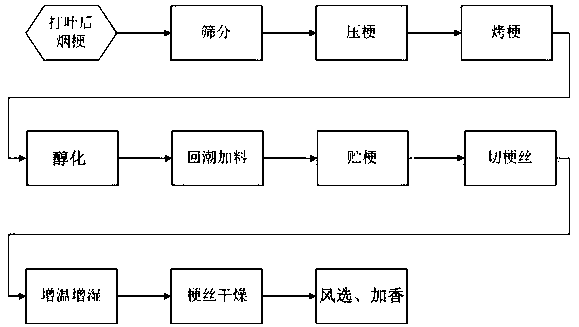

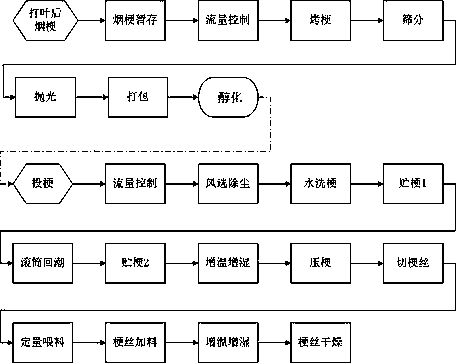

Tobacco stem processing method using stem sheets for feeding

ActiveCN109275941AGood for natural agingStem surface area increasedTobacco preparationTobacco treatmentCooking & bakingEngineering

The invention relates to a tobacco stem processing method using stem sheets for feeding, and belongs to the field of cigarette processing. The method comprises the work procedures of tobacco stem sieving, stem pressing, stem baking, alcoholization, dampening feeding, stem storage, stem shred cutting, stem shred heating and humidification, drying and winnowing perfuming. The two work procedures ofstem wetting and feeding are integrated; the conventional processing work procedures of stem washing by water, heating and humidification before stem pressing, stem pressing, stem shred feeding and the like and relevant auxiliary connection equipment are omitted; during the stem wetting, the feeding is performed; after the feeding, stem storage is performed; the moisture content of the stem sheetsis balanced; meanwhile, the stem sheets better absorb sugar materials; the internal quality of the tobacco stems is effectively improved; the tobacco stem processing work procedures are simplified; the energy consumption is reduced; and the production efficiency is improved.

Owner:HONGTA TOBACCO GRP

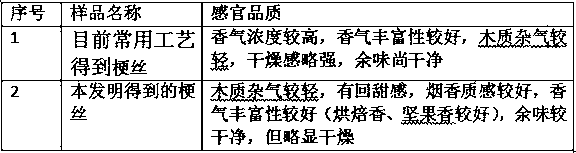

Blended dehumidifying film and preparation method thereof

ActiveCN110818931AStable structurePorous hygroscopic spaceGas treatmentDispersed particle separationPolymer scienceHydrophobic polymer

The invention provides a blended dehumidifying film and a preparation method thereof, belonging to the technical field of films. The method comprises the following steps: a) respectively drying a crystalline hydrophobic polymer and polyvinyl alcohol for later use; b) sequentially adding the polyvinyl alcohol obtained in the step a) and the crystalline hydrophobic polymer obtained in the step a) into a solvent as solutes, carrying out mixing, and adding inorganic moisture absorption particles to obtain a film casting solution; and c) performing film scraping by adopting the film casting solution obtained in the step b) so as to obtain the blended dehumidifying film. The obtained blended dehumidifying film is mainly used for air dehumidification. According to the invention, multi-component polymers are blended, a solvent evaporation induced phase separation method is improved, and the adding sequence of all the components is reasonably adjusted, so the blended dehumidifying film which isstable in structure, high in moisture absorption rate, large in moisture absorption capacity and stable in mechanical property is prepared in one step.

Owner:TIANJIN POLYTECHNIC UNIV

High-moisture-absorptivity mineral dryer and preparation method thereof

InactiveCN105983299AGood hygroscopicityHigh moisture absorptionGas treatmentDispersed particle separationHalloysiteSlag

The invention discloses a high-moisture-absorptivity mineral dryer and a preparation method thereof. The dryer is prepared from, by weight, 22-28 parts of halloysite, 30-40 parts of bauxite, 17-29 parts of turquoise, 16-24 parts of dolomite, 20-25 parts of cement slag, 10-15 parts of rock wool powder, 8-12 parts of 4A molecular sieve, 6-11 parts of aluminum potassium sulfate, 5-10 parts of quicklime, 4-8 parts of calcium chloride and 98-114 parts of modifier. The dryer prepared by the method is high in moisture absorptivity which is more than 1.5 times that of conventional dryers, and is large in moisture absorbing quantity, and total moisture absorbing quantity can reach higher than 2 times of own weight; moisture absorbing performance can be maintained stable in various temperature environments, and the dryer is high in moisture absorbing speed, suitable for being used in various places and wide in market prospect.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

Process method for preparing small ball type white tea by using finished product loose white tea and product

InactiveCN105166156AOvercome the major disadvantages of loose tea quality deteriorationImprove qualityPre-extraction tea treatmentProcess engineeringTea leaf

The invention relates to a process method for preparing small ball type white tea by using a finished product loose white tea and a product. The process method comprises: (1) humidifying and softening the finished product loose white tea; (2) feeding the humidified and softened finished product loose white tea into a moulding press for mould pressing to preset-shaped small ball type white tea; and (3) drying the small ball type white tea which is mould-pressed to the preset shape to a predetermined certain moisture content. The process method is characterized in that the specific process of humidifying and softening the finished product loose white tea comprises: (1) immersing the finished product loose white tea in a tea juice liquid prepared by the white tea to be humidified and softened in a special container; and (2) removing residual tea juice water by using a centrifugal dehydrator to obtain the softened finished product loose white tea. The process provided by the invention overcomes a major defect that the quality of tea leaves is deteriorated in an existing steam humidifying and softening process, and the prepared small ball type white tea is excellent in quality.

Owner:WUYISHAN DEBANG ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP MFG

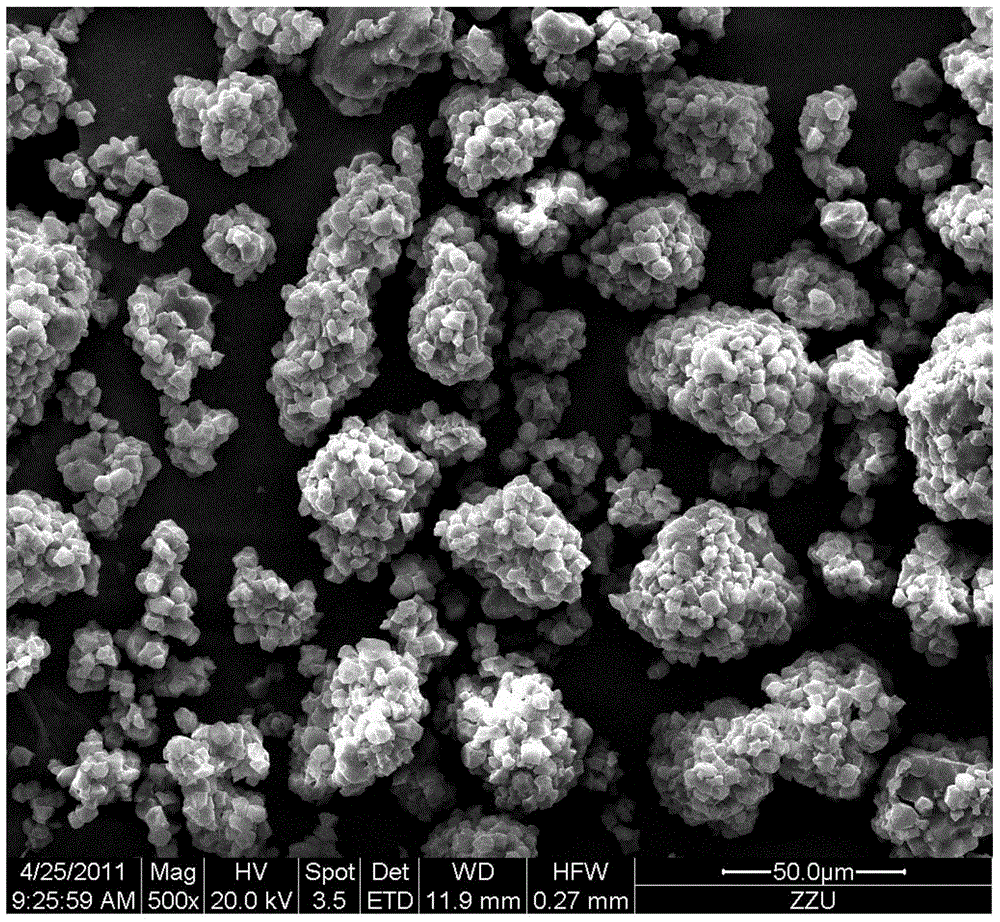

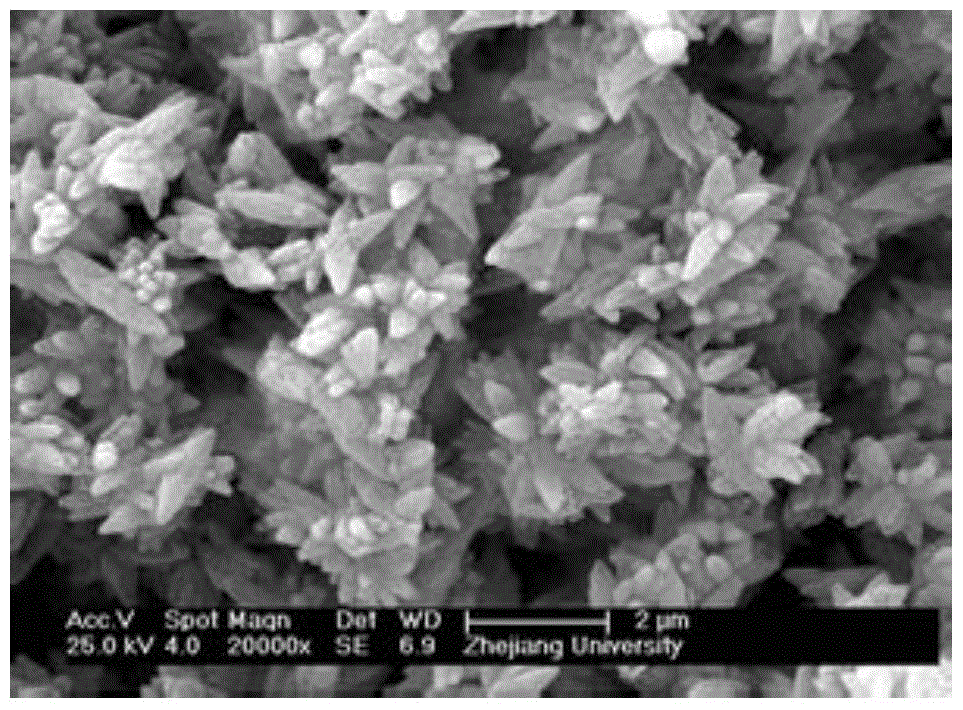

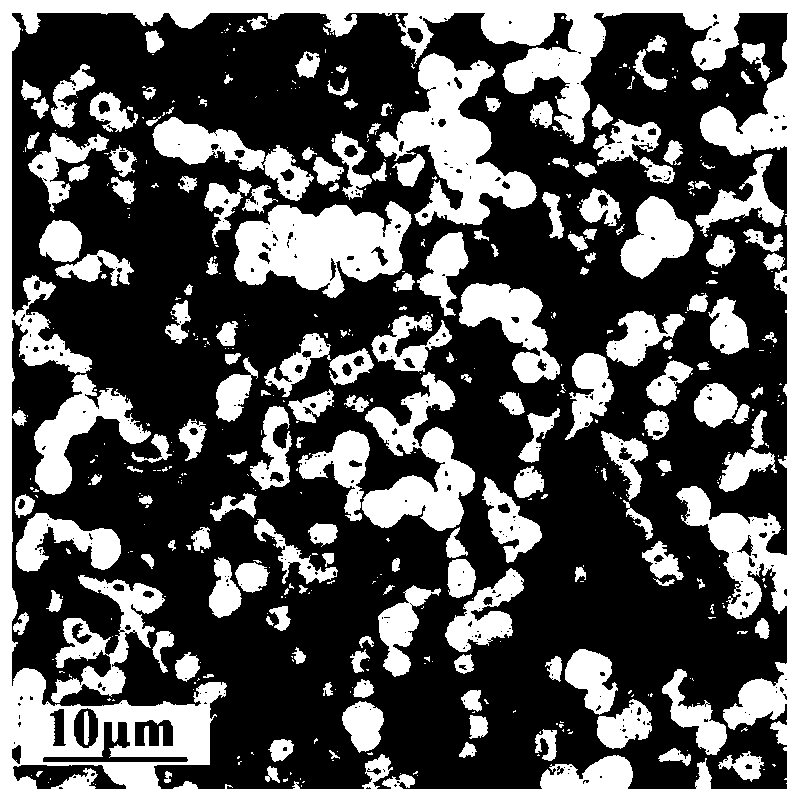

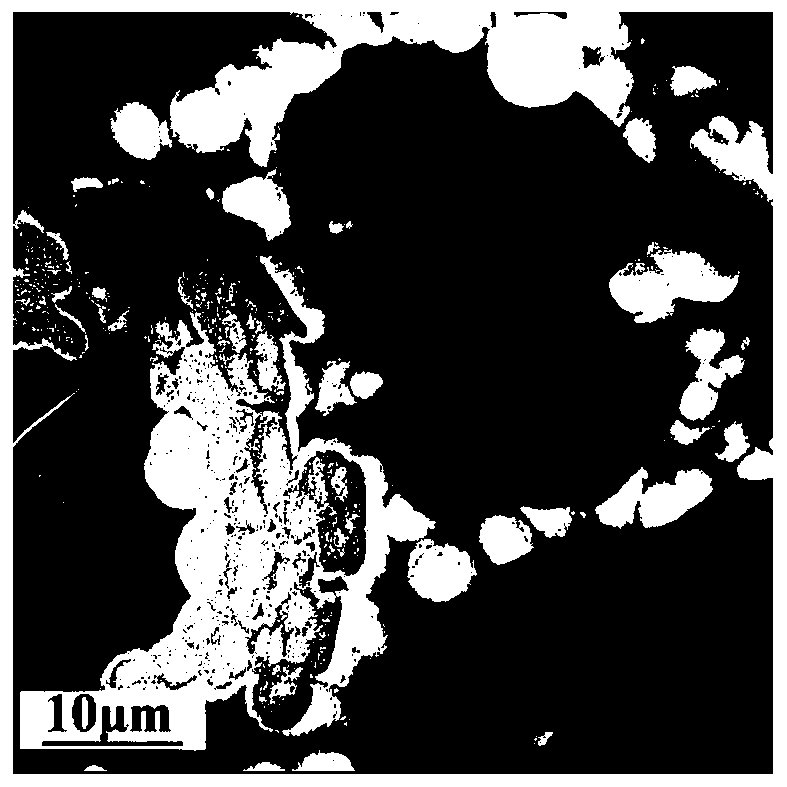

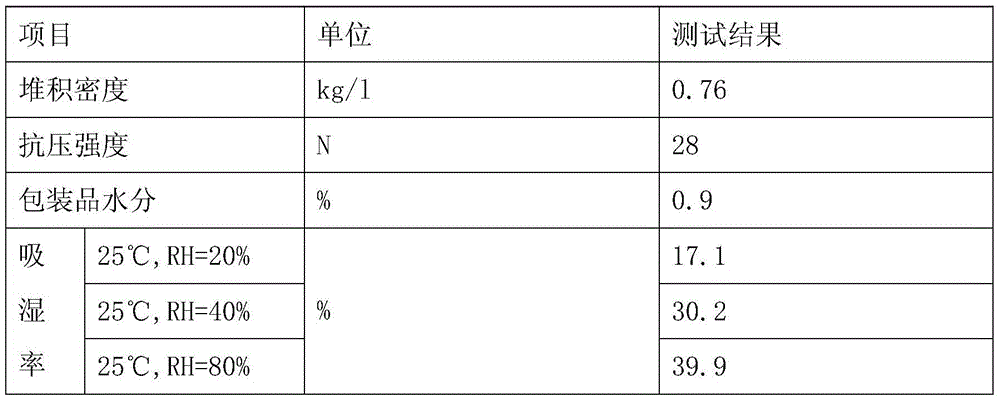

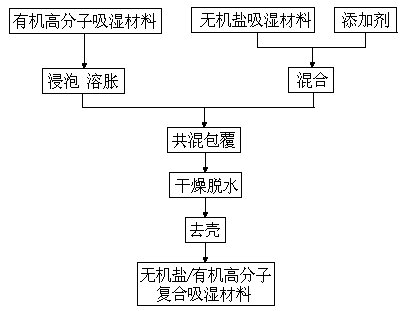

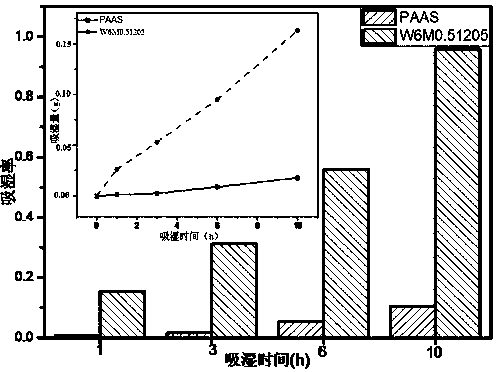

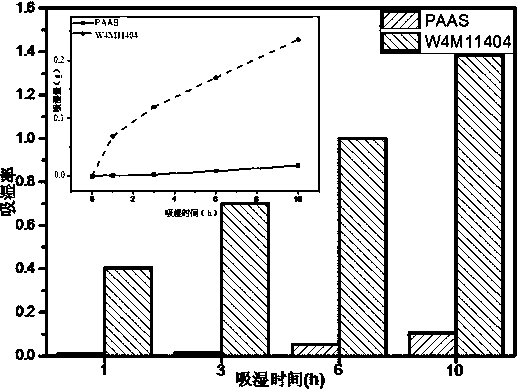

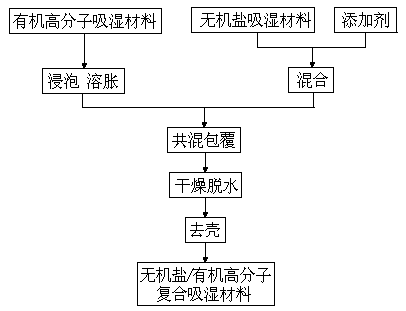

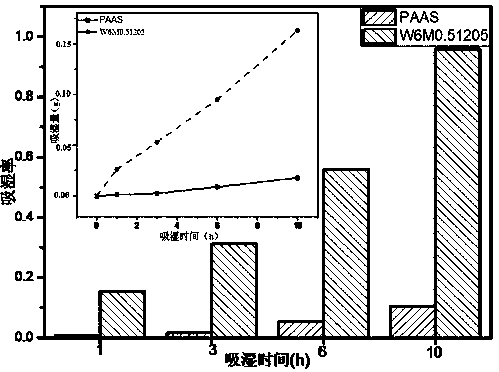

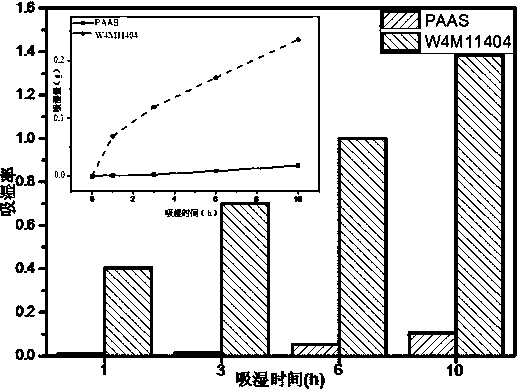

Inorganic salt/organic macromolecular composite moisture absorption material and preparation method thereof

The invention discloses an inorganic salt / organic macromolecular composite moisture absorption material and a preparation method thereof. The inorganic salt / organic macromolecular composite moisture absorption material is prepared from the following raw materials in percentage by mass: 10 to 20 percent of organic macromolecular moisture absorption materials, 0.35 to 4.5 percent of inorganic salt moisture absorption material and 75.5 to 89.65 percent of additive, wherein the additives is one or more of sodium chloride, table salt and industrial salt. The preparation method of the inorganic salt / organic macromolecular composite moisture absorption material comprises the following steps: soaking the organic macromolecular composite moisture absorption material into deionized water and performing swelling; mixing the additives with the inorganic salt moisture absorption material and then performing co-blending and coating with the swelled organic macromolecular moisture absorption materials to obtain a composite material; drying and dehydrating the composite material and removing a surface salt shell to obtain a final product. The composite moisture absorption material disclosed by theinvention simultaneously has larger moisture absorption capacity and quicker moisture absorption velocity; the preparation method is simple and convenient to operate, has no special requirement on the equipment, is low in production cost, and is applicable to industrial large-scale production.

Owner:温州温优赫科技有限公司

A functional cellulose fiber with silk and hemp characteristics and preparation method thereof

ActiveCN106012072BImprove antibacterial propertiesImprove functionalityArtificial filaments from viscoseWet spinning methodsProtein solutionCellulose fiber

The invention provides a functional cellulosic fiber with silk and linen characteristics. The functional cellulosic fiber is characterized by containing amino acid. The invention further provides a method for preparing the functional cellulosic fiber with the silk and linen characteristics. The method is characterized by comprising the step of preparation of a high-viscosity protein solution, preparation of the high-viscosity protein solution comprises the step of preparation of a urea solution, and preparation of the urea solution comprises the steps that the urea solution with the concentration of 3.0 mol / L to 6.0 mol / L is prepared and then heated to 35 DEG C to 50 DEG C. The fiber prepared through the method contains 1.12 wt%-4.96 wt% of the amino acid and 2.0 wt%-6.0 wt% of a linen extract, and therefore the prepared fiber has the more comfortable experience and the functionality.

Owner:潍坊欣龙生物材料有限公司

Process method for preparing green tea cakes by using finished product loose green tea and product

InactiveCN105166114AOvercome the major disadvantages of loose tea quality deteriorationImprove qualityPre-extraction tea treatmentGreen teasProcess engineering

The invention discloses a process method for preparing green tea cakes by using a finished product loose green tea and a product. The process method comprises: humidifying and softening the finished product loose green tea; (2) feeding the humidified and softened finished product loose green tea into a moulding press for mould pressing to preset-shaped green tea cakes; and (3) drying the green tea cakes which are mould-pressed to the preset shape to a predetermined certain moisture content. The process method is characterized in that the specific process of humidifying and softening the finished product loose green tea comprises: (1) immersing the finished product loose green tea in a tea juice liquid prepared by the green tea to be humidified and softened in a special container; and (2) removing residual tea juice water by using a centrifugal dehydrator to obtain the softened finished product loose green tea. The process provided by the invention overcomes a major defect that the quality of tea leaves is deteriorated in an existing steam humidifying and softening process, and the prepared green tea cakes are excellent in quality.

Owner:WUYISHAN DEBANG ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP MFG

Small ball-shaped flower tea processing method using finished loose flower tea and product thereof

InactiveCN105166224AOvercome the major disadvantages of loose tea quality deteriorationImprove qualityTea substituesProcess engineeringTea leaf

The present invention discloses a small ball-shaped flower tea processing method using finished loose flower tea and a product thereof. The processing method comprises the following steps: 1 humidifying and softening the finished loose flower tea; 2 loading the humidified and softened finished loose flower tea into the moulding press to be mould pressed into small ball-shaped flower tea with predetermined shapes; and 3 drying the small ball-shaped flower tea which is mould pressed into predetermined shapes to have a predetermined moisture content. The characteristics of the small ball-shaped flower tea processing method are as follows: the humidifying and softening of the finished loose flower tea has the following specific processes: 1 soaking the finished loose flower tea in a specially made container containing tea juice prepared from the flower tea to conduct humidifying and softening; and 2 removing excess water from tea juice by using a centrifugal dewatering machine to obtain the softened finished loose flower tea. The processing technology overcomes the significant drawback that the existing steam humidifying and softening process causes deterioration of the tea leaf quality, and enables the prepared small ball-shaped flower tea to have excellent quality.

Owner:WUYISHAN DEBANG ENVIRONMENTAL PROTECTION ENERGY SAVING EQUIP MFG

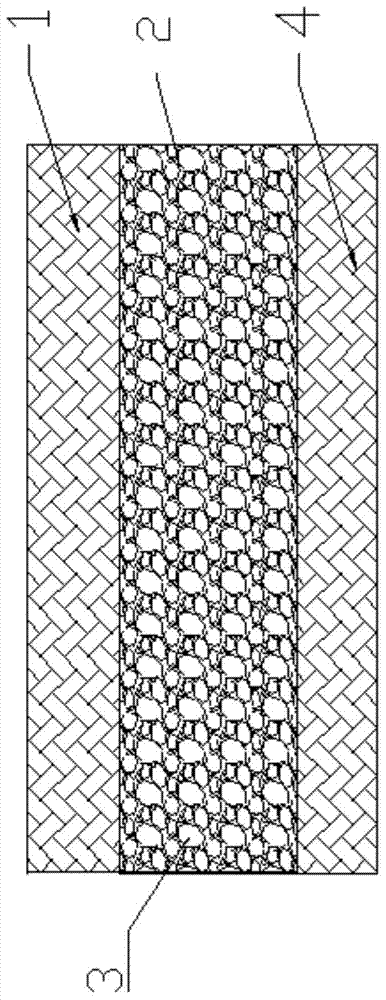

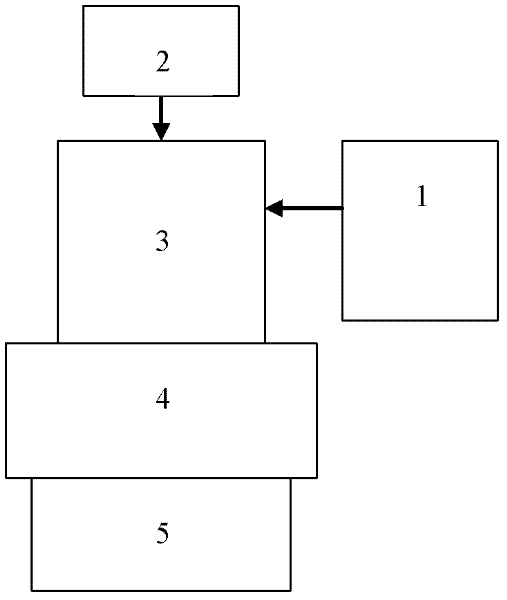

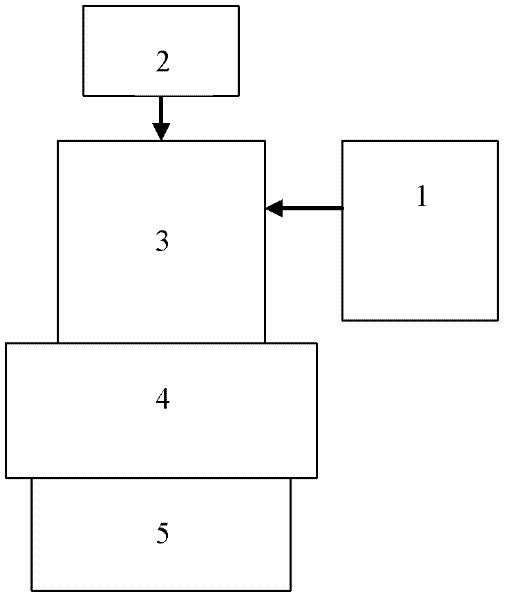

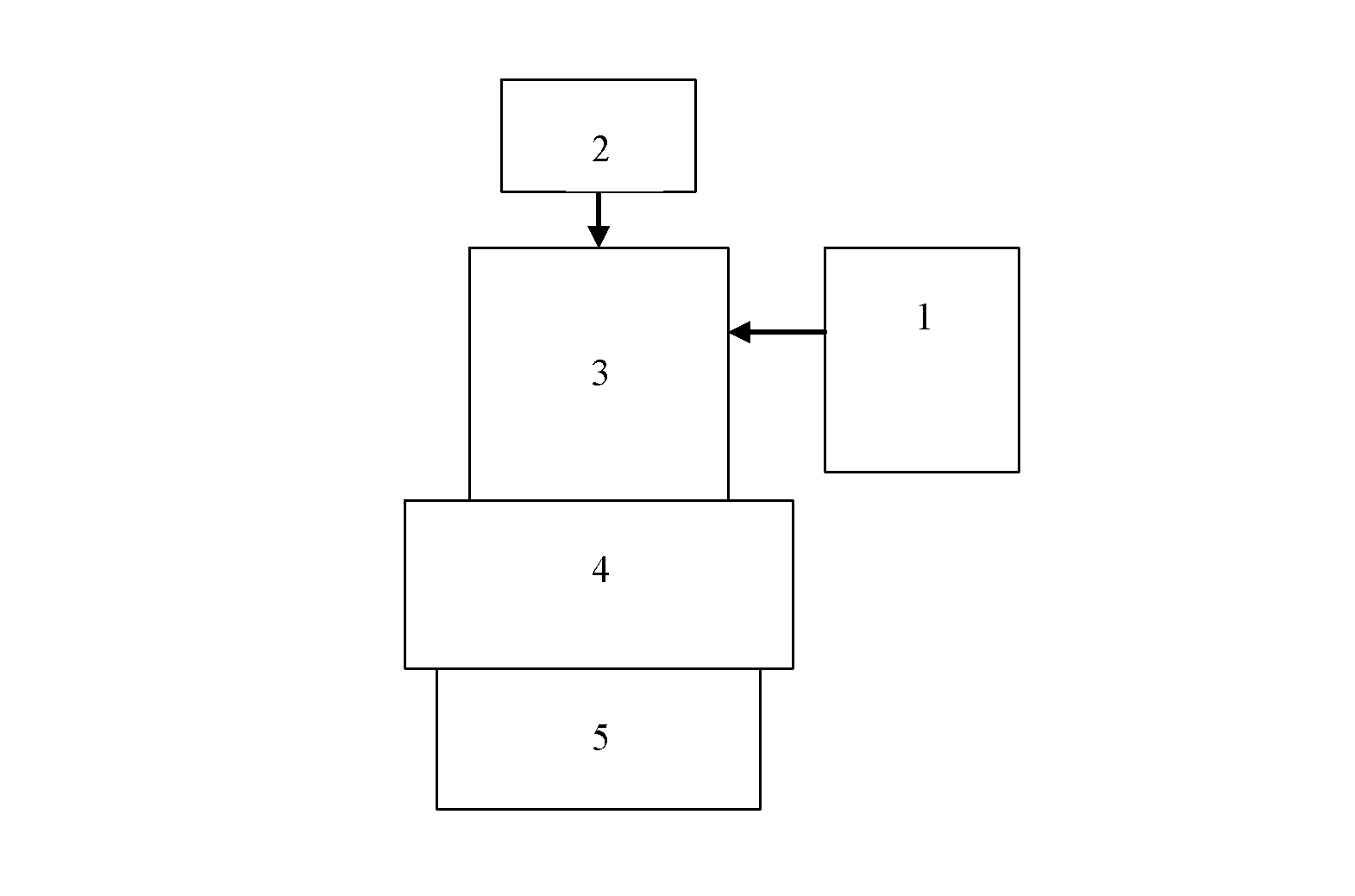

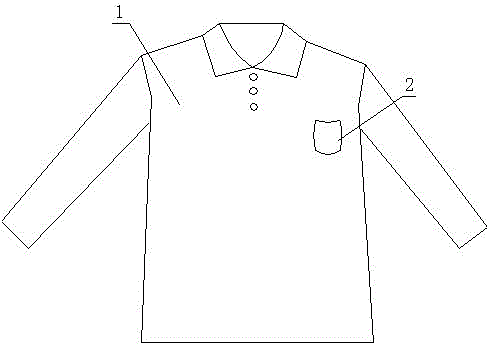

Life-saving underwear with quick moisture absorption function for the aged

InactiveCN104413557ATimely treatmentAvoid dangerHandkerchiefsBaby linensPolyesterMoisture absorption

The invention relates to life-saving underwear with quick moisture absorption function for the aged, which comprises an underwear main body (1). A chest pocket (2) is opened on the underwear main body (1). A sensor (3) is fixed inside the chest pocket (2). The sensor (3) is used to monitor the changes of heart rate. The sensor (3) is connected with a central processing unit (5) via an AD conversion module (4). The central processing unit (5) is connected with a GSM sending module (6). The underwear main body is made of fabrics. The fabrics comprise a fabric surface and an outer woven surface. The outer woven surface is woven on the outer surface of the fabric surface. The fabric surface is made of polyester silk and the outer woven surface is made of cellulosic fiber. When the central processing unit decides the great changes of the heart rate, warning signals will be delivered to children's or partners' cell phones via the GSM sending module, and thus in-time treatment will be carried out. The moisture absorption of the invention is quick.

Owner:JIANGYIN SHENYING KNITWEAR & TEXTILE

A kind of plant fiber desiccant and preparation method thereof

ActiveCN105664863BFast moisture absorptionNo spaceOther chemical processesDispersed particle separationDesiccantPlant fibre

The invention provides a plant fiber dryer which includes the following components, by mass, 91.3-96.3% of plant fibers, 3-8% of water, 0.5-2% of calcium oxide and 0.2-1% of calcium chloride. The plant fiber dryer is prepared from the pure-natural plant fibers through a special process finely, so that the plant fiber dryer has high moisture absorption rate and moisture absorption ratio. The saturate moisture absorption ratio is 100% as the weight of the plant fiber dryer itself (25 DEG C, RH is 100%) and is three times as that of a common silica gel dryer. The dryer is convenient and practical and is free of space occupation. With the natural plant fibers as a moisture absorption carrier, the dryer can be naturally degraded by 100% and belongs to environment-friendly dryers. The plant fiber dryer looks like a thick paper piece and can be cut or chopped into different shapes, can be filled in bottle covers or other containers directly and is an excellent selection for various biological foods, health-caring foods and medicines.

Owner:DONGGUAN JIULV POLYMER MATERIALS CO LTD

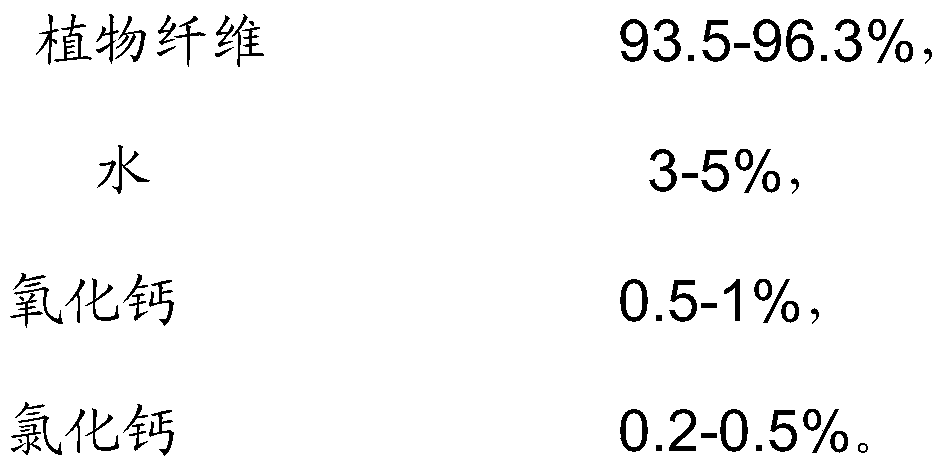

Patchwork patient clothes with high moisture absorption speed

The invention relates to patchwork patient clothes with a high moisture absorption speed. The patchwork patient clothes comprise a clothes body. The clothes body comprises a front clothes piece (1), a rear clothes piece (2) and two sleeves (3), wherein the front clothes piece (1) and the rear clothes piece (2) are connected through side pieces and zippers (4) at the collar; the two sleeves (3) are connected with the front clothes piece (1) and the rear clothes piece (2) through annular zippers (5) at the upper ends of the sleeves (3). The clothes body is made of a fabric. The fabric comprises an inner knitted surface, wherein an outer knitted surface is woven onto the outer surface of the inner knitted surface, the inner knitted surface is made of polyester yarn, and the outer knitted surface is made of cellulosic fibers. A nurse only needs to push a patient to lie on the side and then can complete splicing of the clothes when putting on the clothes for the patient. The patchwork patient clothes are high in moisture absorption speed.

Owner:王凤华

A kind of inorganic salt/organic polymer composite hygroscopic material and its preparation method

The invention discloses an inorganic salt / organic macromolecular composite moisture absorption material and a preparation method thereof. The inorganic salt / organic macromolecular composite moisture absorption material is prepared from the following raw materials in percentage by mass: 10 to 20 percent of organic macromolecular moisture absorption materials, 0.35 to 4.5 percent of inorganic salt moisture absorption material and 75.5 to 89.65 percent of additive, wherein the additives is one or more of sodium chloride, table salt and industrial salt. The preparation method of the inorganic salt / organic macromolecular composite moisture absorption material comprises the following steps: soaking the organic macromolecular composite moisture absorption material into deionized water and performing swelling; mixing the additives with the inorganic salt moisture absorption material and then performing co-blending and coating with the swelled organic macromolecular moisture absorption materials to obtain a composite material; drying and dehydrating the composite material and removing a surface salt shell to obtain a final product. The composite moisture absorption material disclosed by theinvention simultaneously has larger moisture absorption capacity and quicker moisture absorption velocity; the preparation method is simple and convenient to operate, has no special requirement on the equipment, is low in production cost, and is applicable to industrial large-scale production.

Owner:温州温优赫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com