Double-component composite melt-blown nonwoven fabric

A technology of melt-blown non-woven fabric and matrix layer, applied in the direction of layered products, etc., can solve the problems of user inconvenience, unfavorable production, process obstacles, etc., and achieve the effects of improving moisture absorption, fast moisture absorption, and increasing performance strength.

Active Publication Date: 2013-06-19

JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, this kind of fiber or filament will generate static electricity due to friction during processing, which will bring obstacles and troubles to the subsequent process, which is not conducive to production. At the same time, it will also bring many problems to users due to static electricity during use. inconvenient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

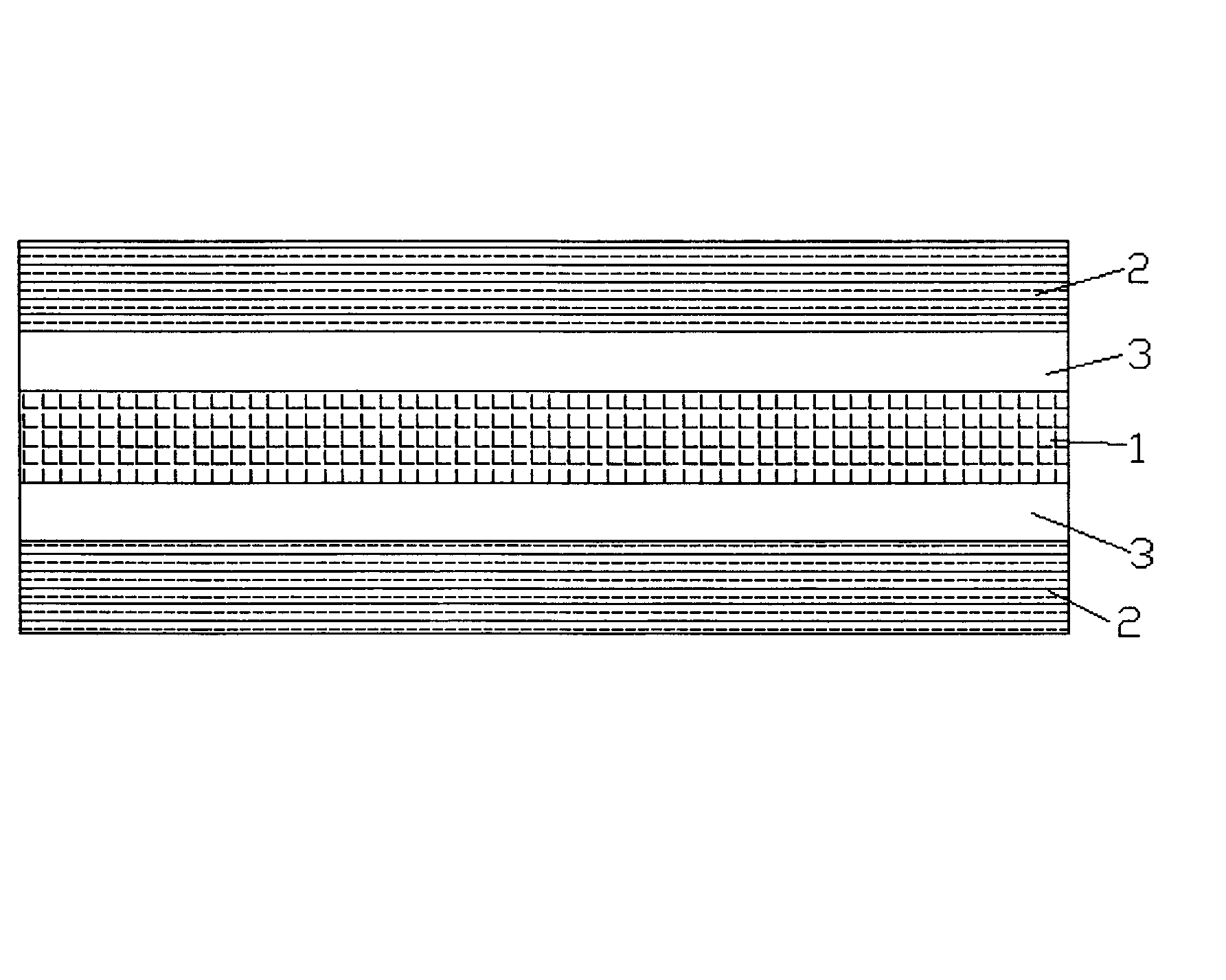

[0011] A two-component composite melt-blown non-woven fabric includes a matrix layer 1, the matrix layer has two upper and lower sides, and a layer of intersecting microfiber layers 2 are respectively arranged on the upper and lower sides of the matrix layer.

[0012] Preferably, a hydrophilic layer 3 is respectively provided between the upper and lower side surfaces of the matrix layer and the obliquely intersecting superfine fiber layer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a double-component composite melt-blown nonwoven fabric comprising a substrate layer with an upper side and a lower side. A layer of oblique crossed microfiber layer is respectively arranged on each of the upper side and the lower side of the substrate layer. The nonwoven fabric has the advantages of reasonable structure, good uniformity, good hydrophilic effect, good anti-aging effect, and good anti-static effect.

Description

technical field [0001] The invention relates to a two-component composite melt blown nonwoven fabric. Background technique [0002] Non-woven fabric is a kind of fabric formed without spinning and weaving. It is formed by orienting or randomly arranging short textile fibers or filaments to form a web structure, which is then reinforced by mechanical, thermal bonding or chemical methods. become. Compared with the traditional process, it has the characteristics of short process flow, fast production speed, high output, low cost and wide application. At present, non-woven fabrics are widely used in medical and sanitary cloths, home decoration cloths, agricultural cloths, etc. However, this kind of fiber or filament will generate static electricity due to friction during processing, which will bring obstacles and troubles to the subsequent process, which is not conducive to production. At the same time, it will also bring many problems to users due to static electricity during...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B32B5/26

Inventor 邱邦胜

Owner JIANGSU SHENGFANG NANO MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com