Corrosion-resistant hygroscopic coat and preparation method thereof

A coating and corrosion-resistant technology, used in the field of corrosion-resistant and moisture-absorbing coatings and their preparation, can solve the problems of uneven chromaticity, easy pulverization, and poor hygroscopicity, and achieve a simple preparation process, good hygroscopicity, and poor mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The water-based anti-corrosion primer coating A component is: the phenolic resin (molecular weight one million) of 25% by weight concentration, the amino crosslinking agent of 3% by weight percent concentration, the isopropanol of 5% by weight percent concentration, the rest is deionized water;

[0053] The composition B of the water-based hygroscopic surface coating is: silica gel (powder) with a concentration of 20% by weight, polyacrylic acid (100,000 molecular weight) with a concentration of 5% by weight, and the rest is deionized water.

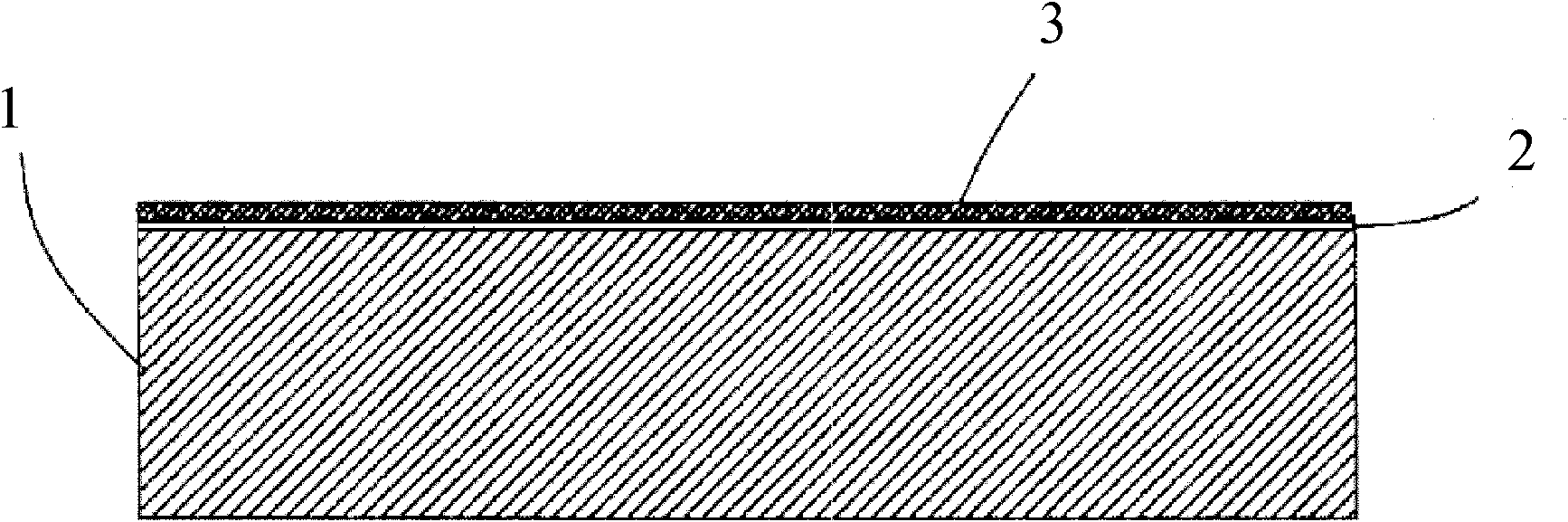

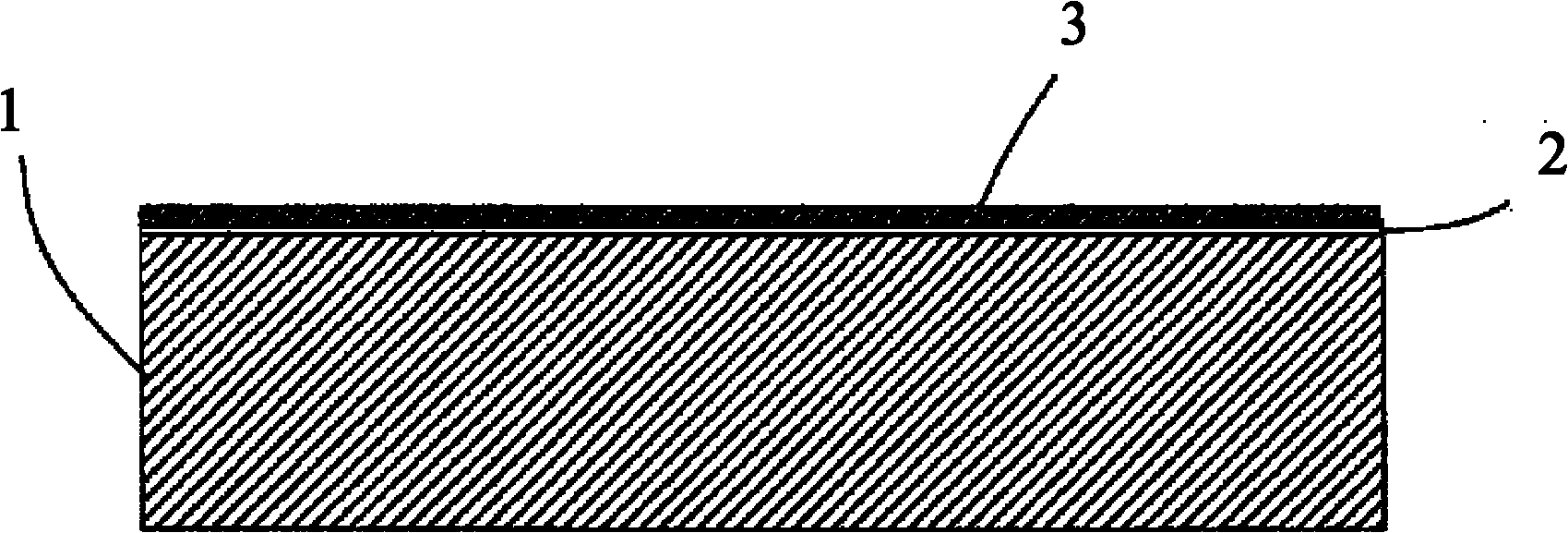

[0054] Apply the water-based anti-corrosion primer A on the aluminum foil by roller coating, and bake it at 300°C for 10 seconds to form a thickness of 0.8g / m 2 After cooling, apply water-based moisture-absorbing top coat B by roller coating, and bake at 400°C for 5 seconds to form a thickness of 8g / m 2 The moisture-absorbing top coating of the coating is obtained to obtain a corrosion-resistant moisture-absorbing coating, and th...

Embodiment 2

[0056] The water-based anti-corrosion primer A component is: the acrylic resin (molecular weight ten thousand) that the weight percent concentration is 12%, the silane coupling agent that the weight percent concentration is 1%, the ethylene glycol monobutyl ether that the weight percent concentration is 2% , and the rest is deionized water;

[0057] Water-based moisture-absorbing surface coating B component is: the molecular sieve (powder shape, particle diameter of 1000mm) of 40% by weight concentration, the polyacrylamide (molecular weight 20 million) of 5% by weight concentration, and the rest is deionized water.

[0058] Apply the water-based corrosion-resistant primer A on the aluminum foil by brushing, and bake it at 250°C for 25 seconds to form a thickness of 1.0g / m 2 After cooling, apply water-based moisture-absorbing topcoat B by brush, and bake at 300°C for 10 seconds to form a thickness of 12g / m 2 The moisture-absorbing top coating is used to obtain a corrosion-res...

Embodiment 3

[0060] The water-based anti-corrosion primer coating A component is: the epoxy resin (molecular weight five hundred) that the weight percent concentration is 18%, the isocyanate cross-linking agent that the weight percent concentration is 2%, the ethylene glycol that the weight percent concentration is 1%, the rest is deionized water;

[0061] The water-based hygroscopic surface coating B component is: the molecular sieve (powder) of 10% by weight concentration, the silica gel (sol-like) of 30% by weight concentration, the polyoxyethylene (molecular weight two million) of 7% by weight concentration ), and the rest was deionized water.

[0062] First coat the water-based anti-corrosion primer A on the aluminum foil by dip coating, and bake it at 200°C for 50 seconds to form a thickness of 0.9g / m 2 After cooling, apply water-based moisture-absorbing topcoat B by dip coating, and bake at 80°C for 10 minutes to form a thickness of 10g / m 2 The moisture-absorbing top coating can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hygroscopicity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com