Starch-based high-efficiency moisture-absorbing desiccant

A hygroscopic drying, starch-based technology, applied in the field of starch-based high-efficiency hygroscopic desiccant, can solve the problems of small moisture absorption, non-degradability, and large space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Take 85 parts of pregelatinized starch, 14 parts of inorganic salt, and 1 part of gel strengthening agent, and blend according to the above-mentioned production process to obtain the product.

Embodiment 2

[0027] Example 2: Take 70 parts of pregelatinized starch, 29 parts of inorganic salt, and 1 part of gel strengthening agent, and blend them according to the above-mentioned production process to obtain the product.

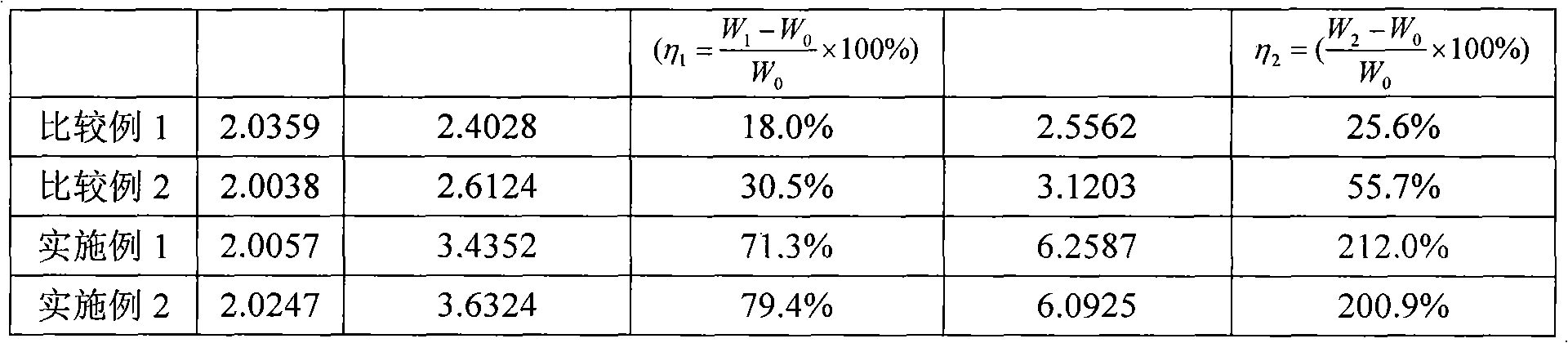

[0028] Experimental verification of the moisture absorption performance of each of the above-mentioned embodiments

[0029] 1. Moisture absorption rate test under constant humidity conditions

[0030] This test is used to verify the moisture absorption rate of Example 1-2 under static constant humidity conditions.

[0031] Adjust the high and low temperature alternating humid heat box to "fixed value test", humidity: 98%, temperature 30°C, put 2 grams of packaged examples 1 and 2 into the humid heat box respectively, measure their weight after 12 hours, and calculate Moisture absorption rate. After 60 days, measure its weight and calculate the moisture absorption rate.

[0032] The comparative example contrasted with embodiment is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com