A Bidirectional Pull Fiber Bragg Grating Humidity Sensor

A technology of humidity sensor and optical fiber grating, which is applied in the field of sensors, can solve the problem of point-by-point detection of the lack of optical fiber grating humidity sensor, and can not solve the problem of prestressed loading of optical fiber grating well, so as to solve the problem of prestressed loading and environmental humidity Point-by-point detection of problems, improvement of internal stress variation and humidity detection accuracy, and improvement of moisture absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

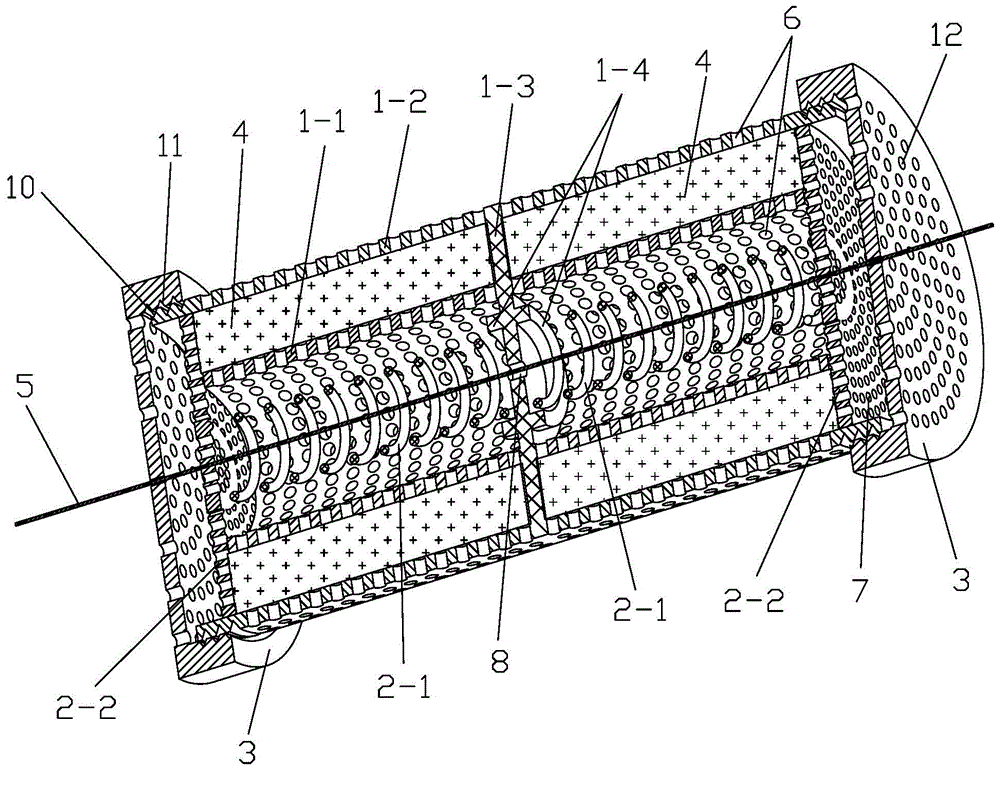

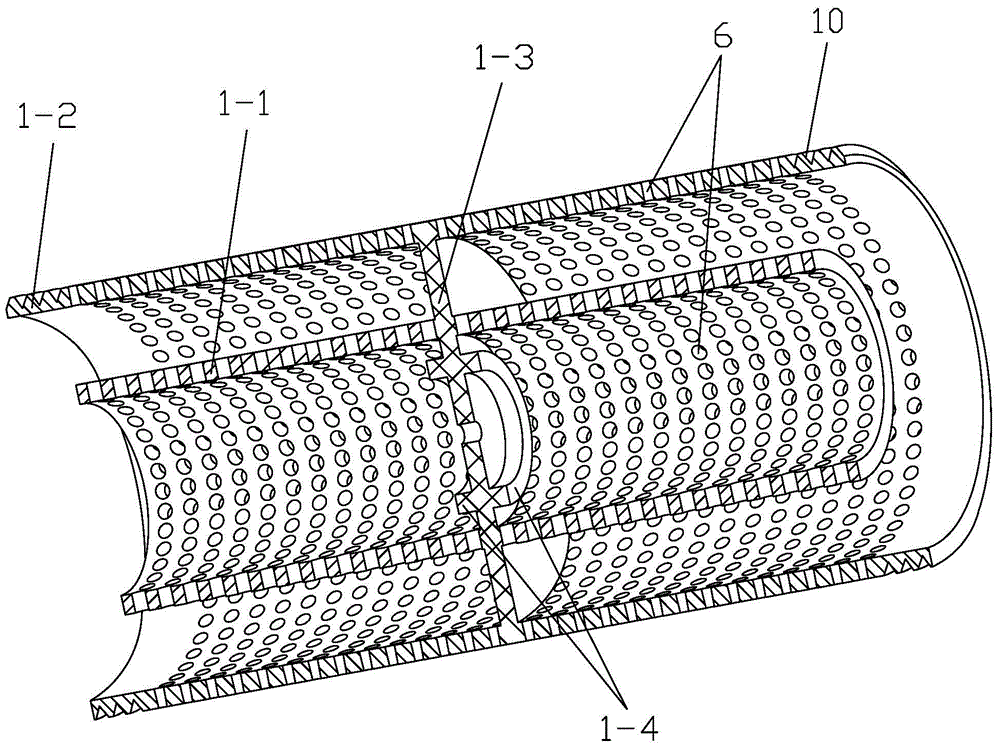

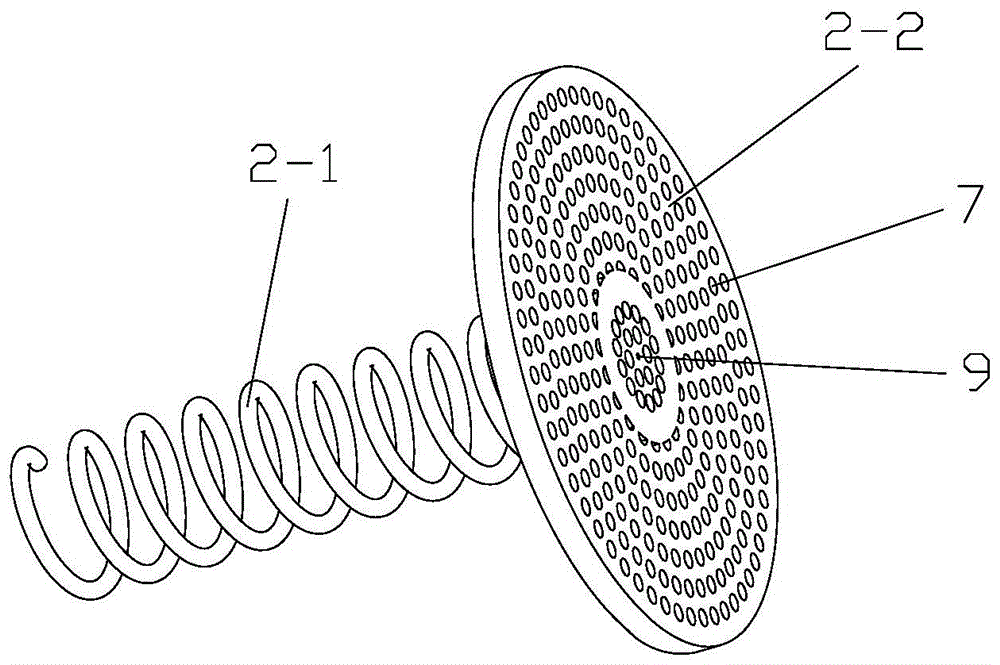

[0033] like Figure 1 to Figure 5 As shown, the present invention includes a double-layer cylindrical shell and a fiber grating 5. The double-layer cylindrical shell includes an outer shell 1-2, an inner shell 1-1 and a partition 1-3, and the outer shell 1-2 and the inner shell 1- 1 are open at both ends, the partition 1-3 is fixed in the middle of the outer casing 1-2, the partition 1-3 passes through the middle of the inner casing 1-1 and divides the double-layer cylindrical shell into equal first The cavity and the second cavity, the partition 1-3 is fixedly connected with the inner shell 1-1, both ends of the outer shell 1-2 protrude from both ends of the inner shell 1-1, and the outer shell 1-2 2 and the inner shell 1-1 are provided with a plurality of first through holes 6, and the middle parts of both sides of the partition 1-3 are fixed with a spring fixing table 1-4, and the first cavity and the second cavity A spring top plate is arranged symmetrically in the body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com