Patents

Literature

68results about How to "Improve pulling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

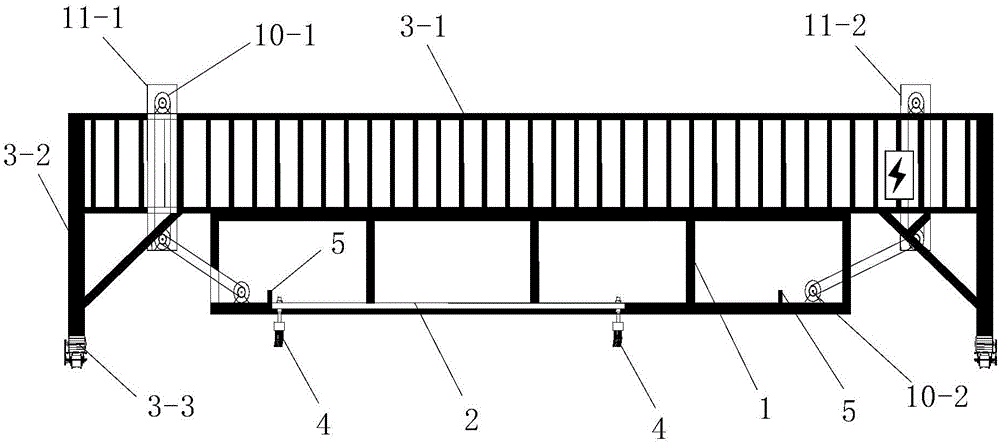

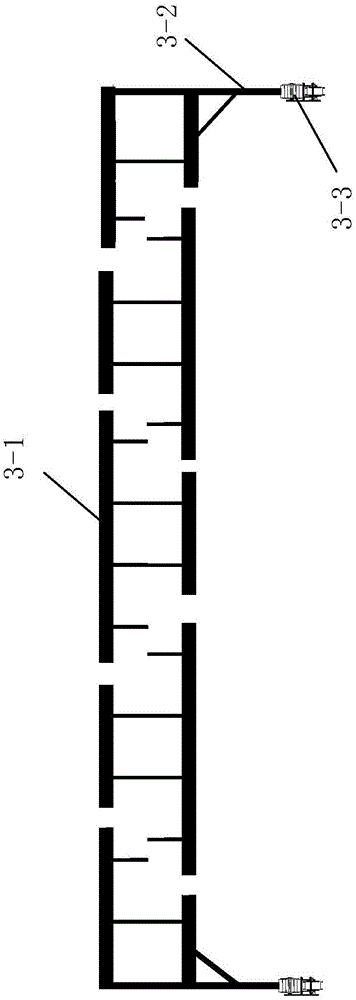

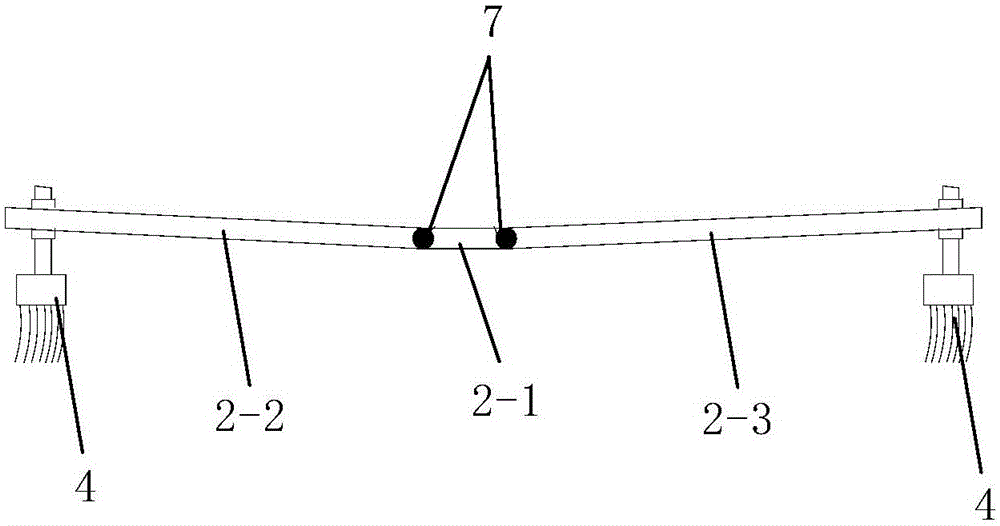

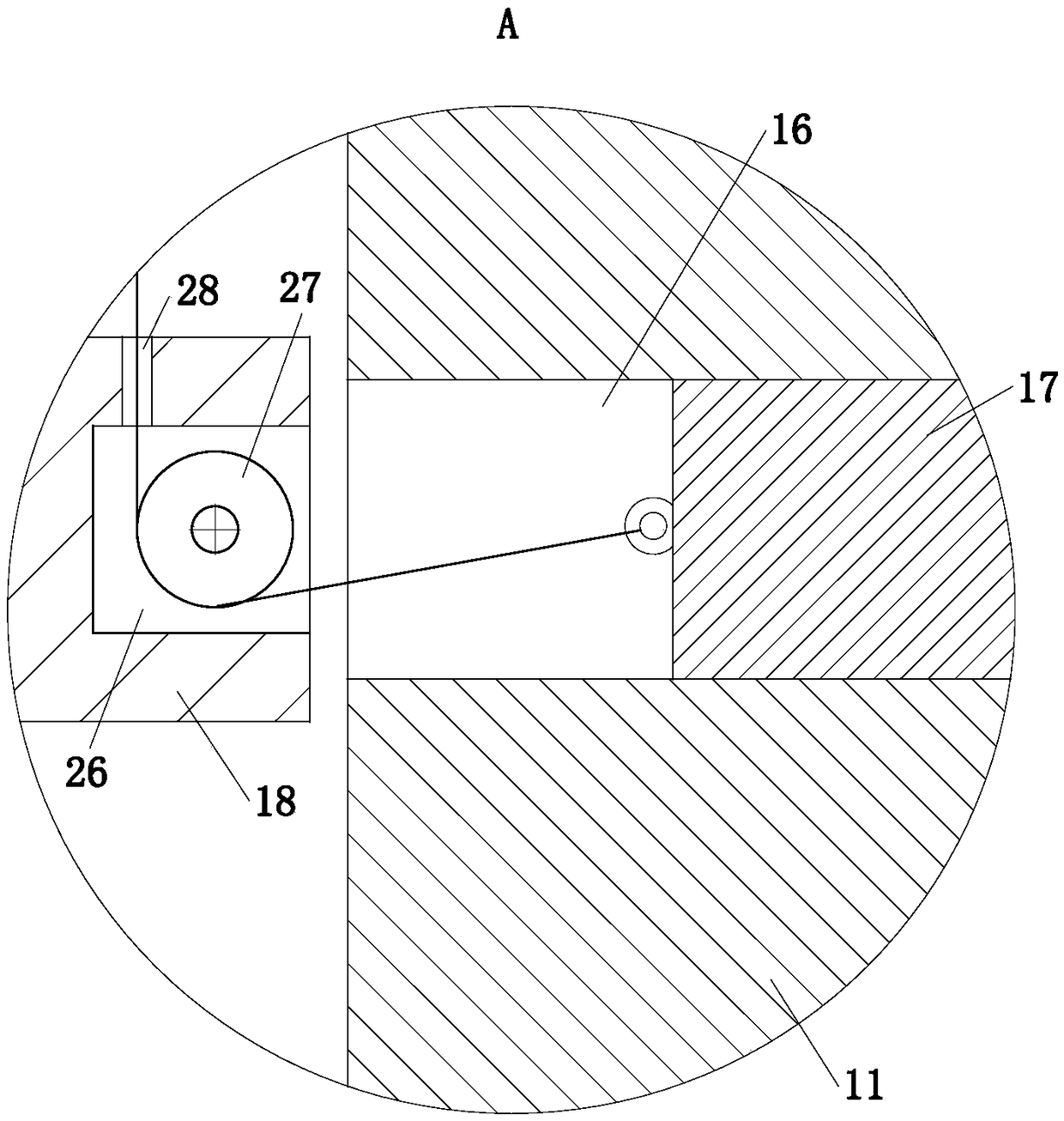

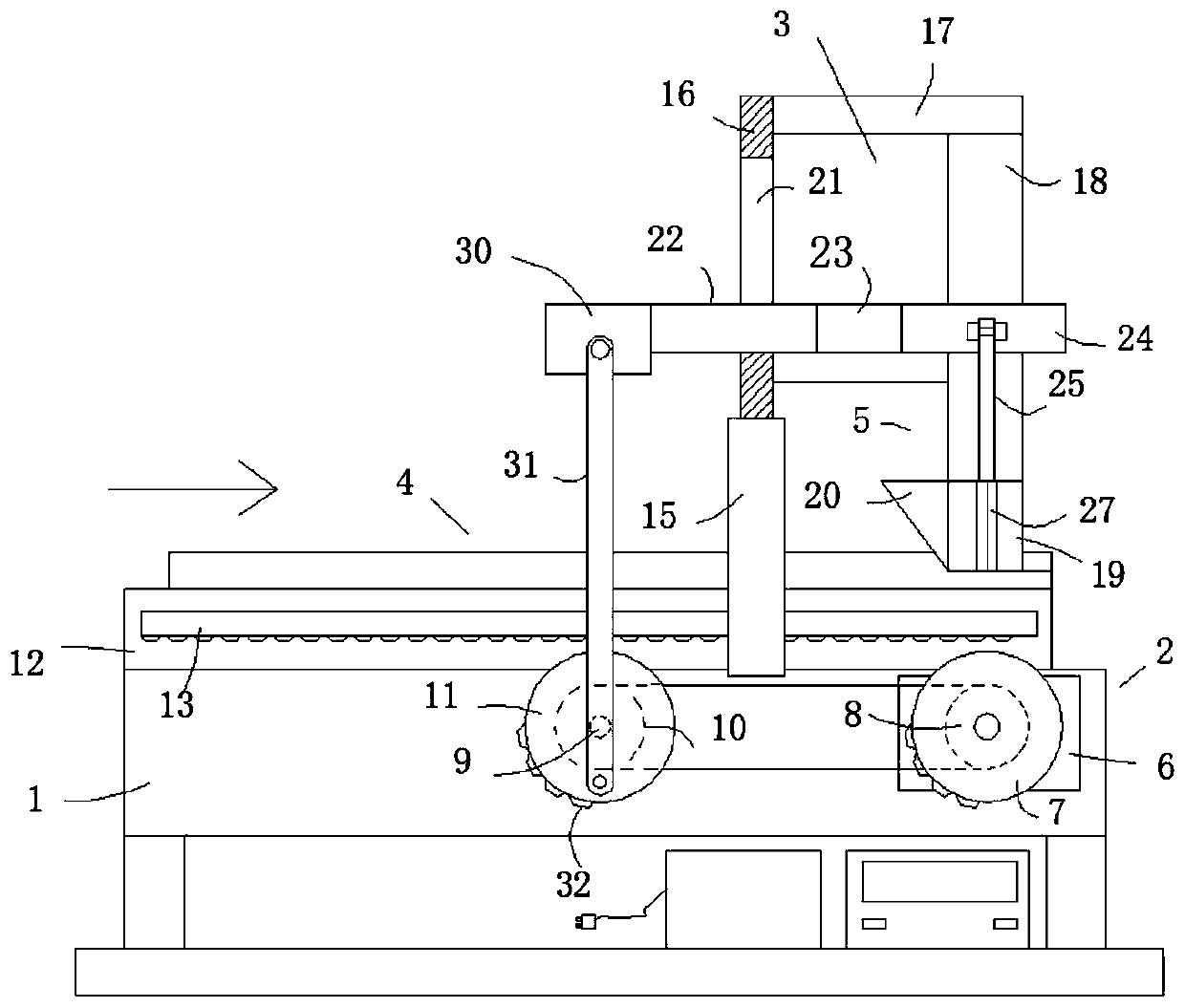

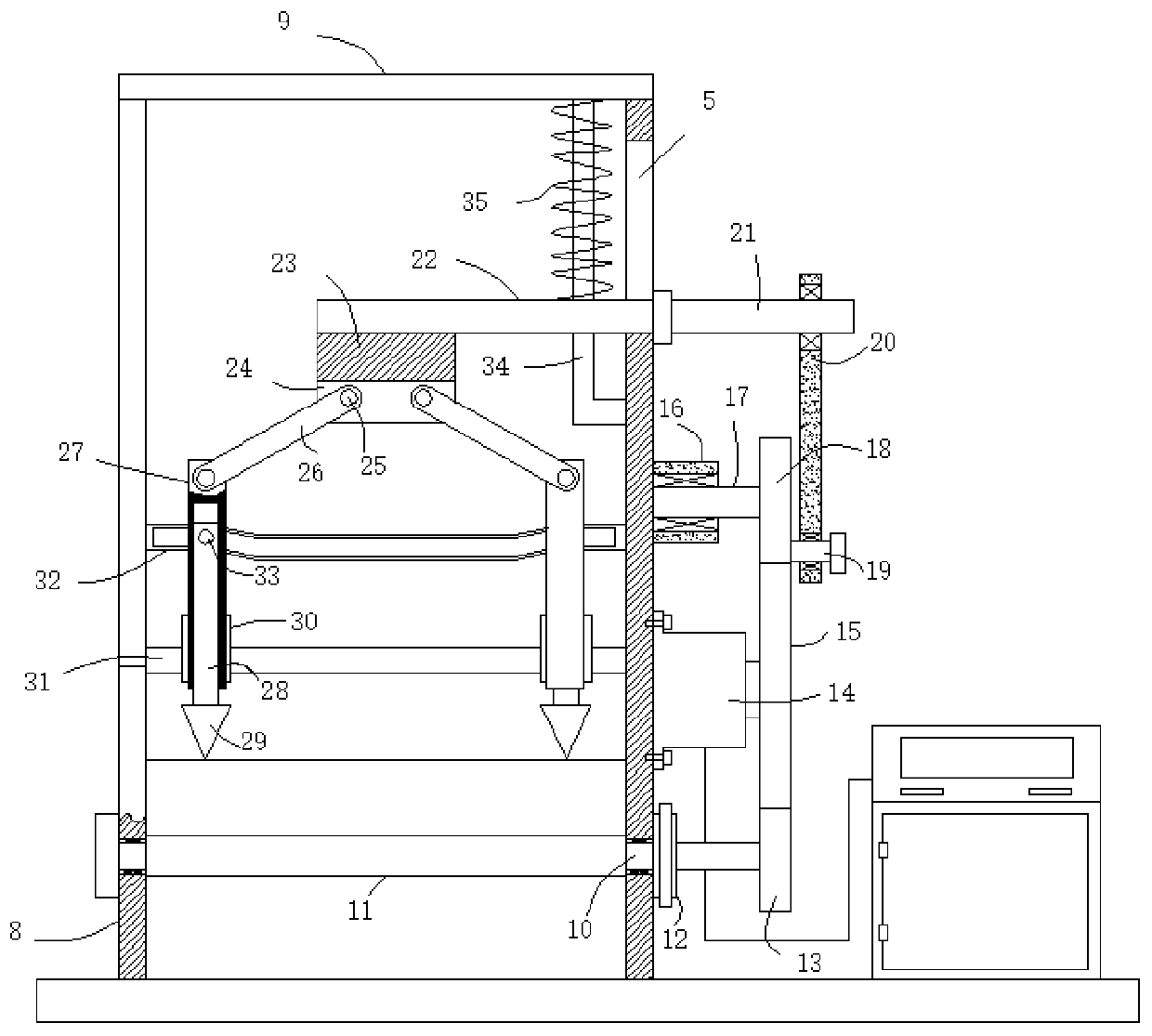

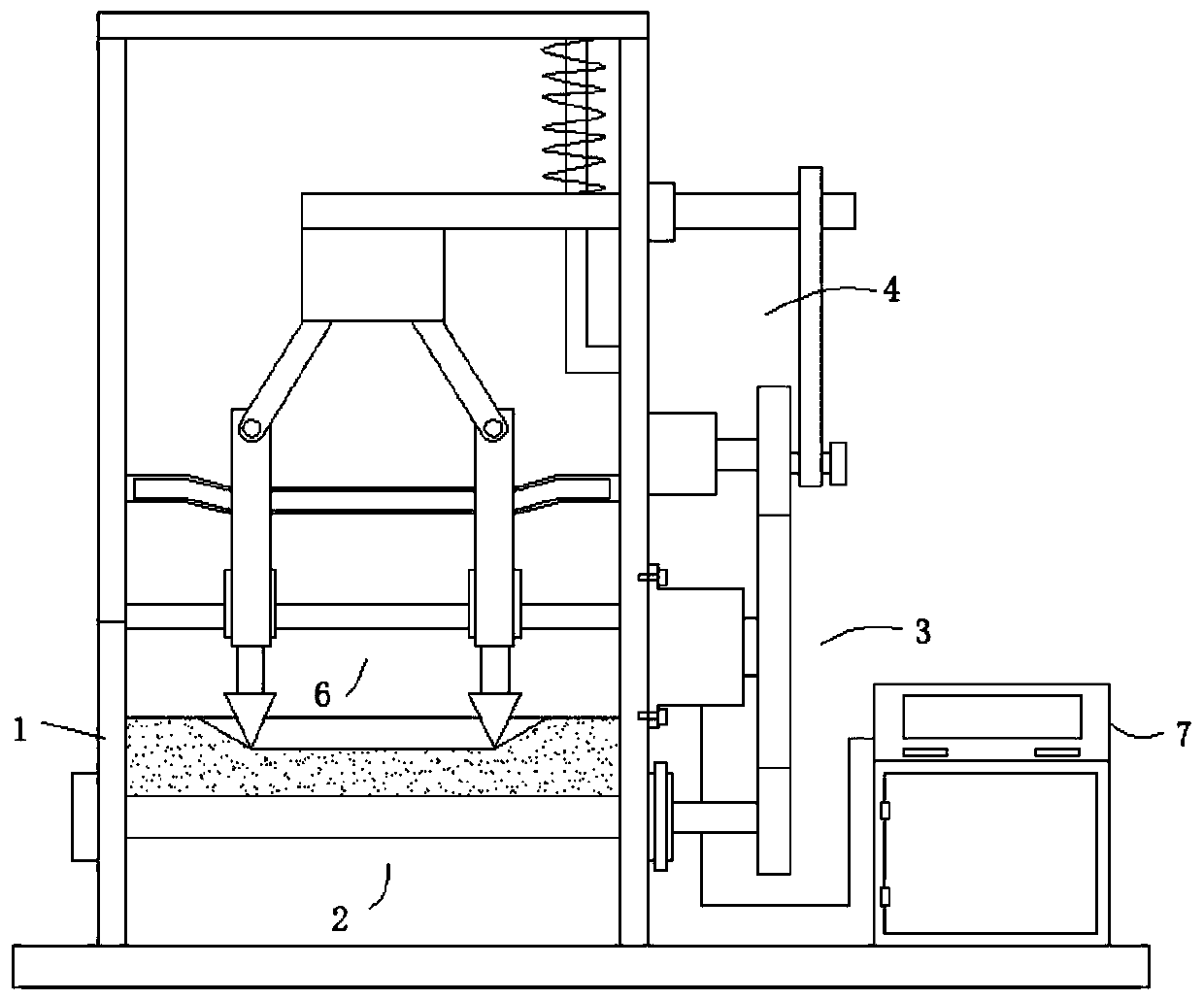

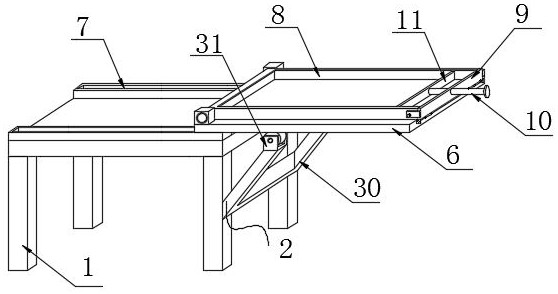

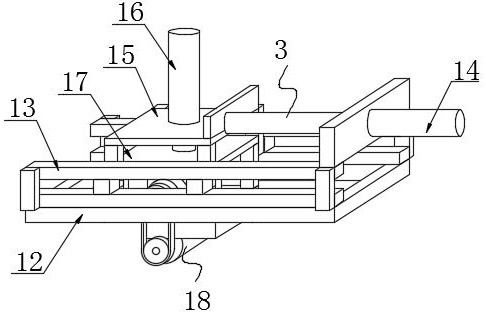

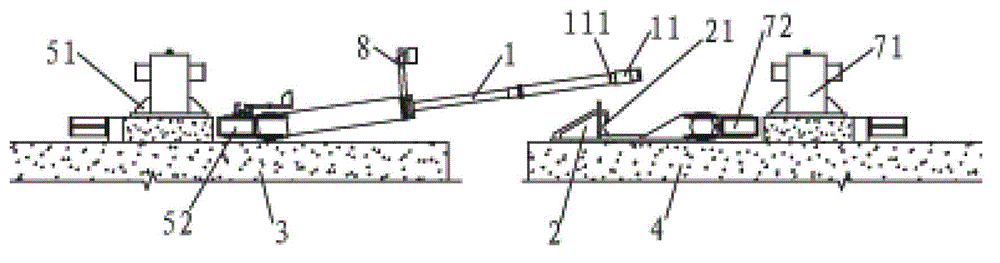

Transverse galling machine and galling treatment method

The invention discloses a transverse galling machine and a galling treatment method. The transverse galling machine comprises a walking frame moving the back forward along the longitudinal length direction of a to-be-galled area, a work rack mounted on the walking frame, a transverse move frame that is laid on the work rack and can make leftward and rightward transverse movement on the work rack, a transverse move driving mechanism driving the transverse move frame to do leftward and rightward transverse movement, and a galling tool that is driven by the transverse move frame to do leftward and rightward transverse movement synchronously and conducts transverse galling treatment on a to-be-galled area in the leftward and rightward transverse movement process. The galling treatment method includes: 1. determination of the galling treatment time: determining the galling treatment time of the to-be-galled area; and 2. transverse galling treatment, which consists the process of: 201. putting the transverse galling machine in place; and 202. carrying out transverse galling treatment. The transverse galling machine and the galling treatment method provided by the invention have the advantages of reasonable design, convenient realization and good use effect, can simple and rapidly complete the transverse galling treatment process of the to-be-galled area, and have good galling treatment effect.

Owner:CHINA RAILWAY FIRST GRP CO LTD

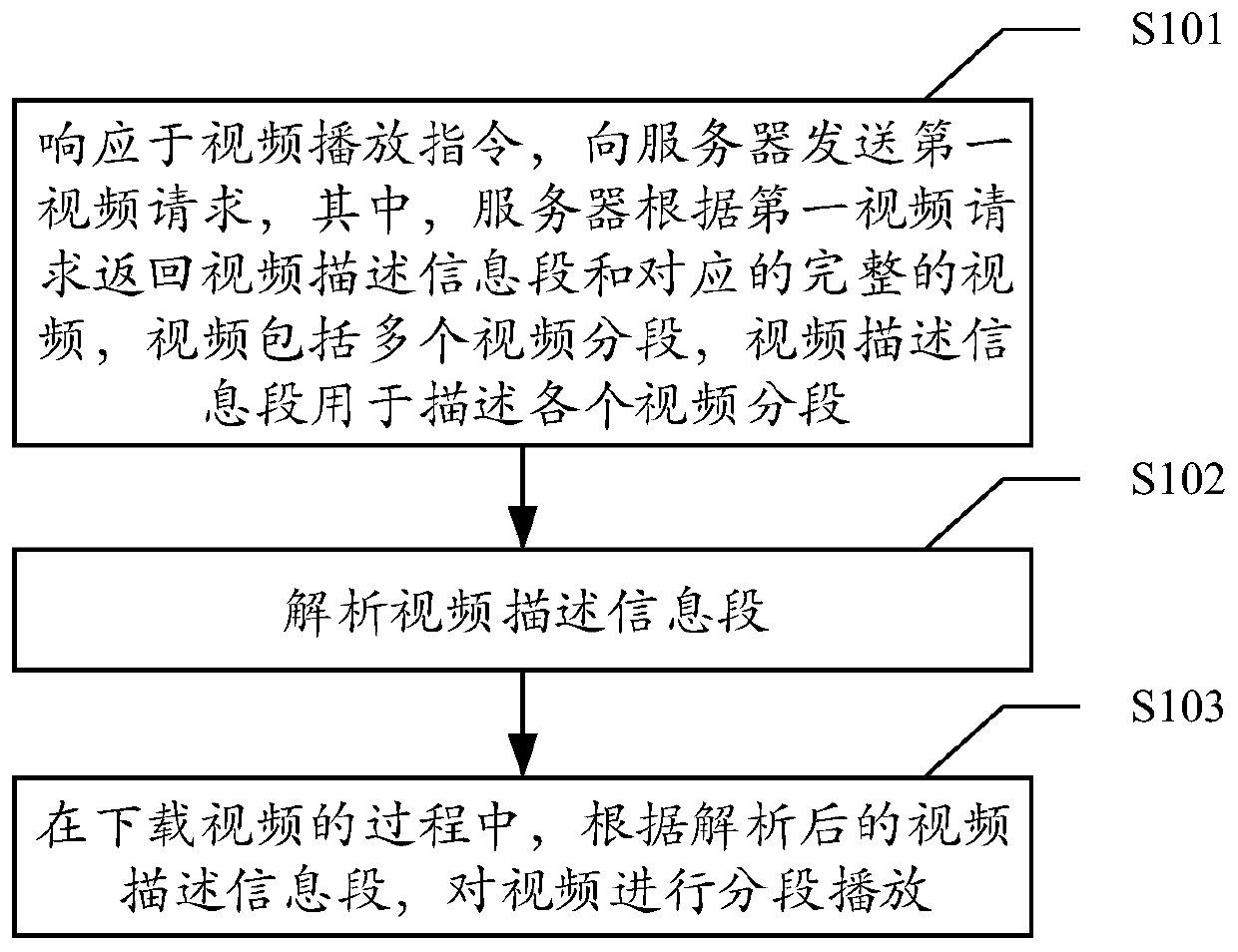

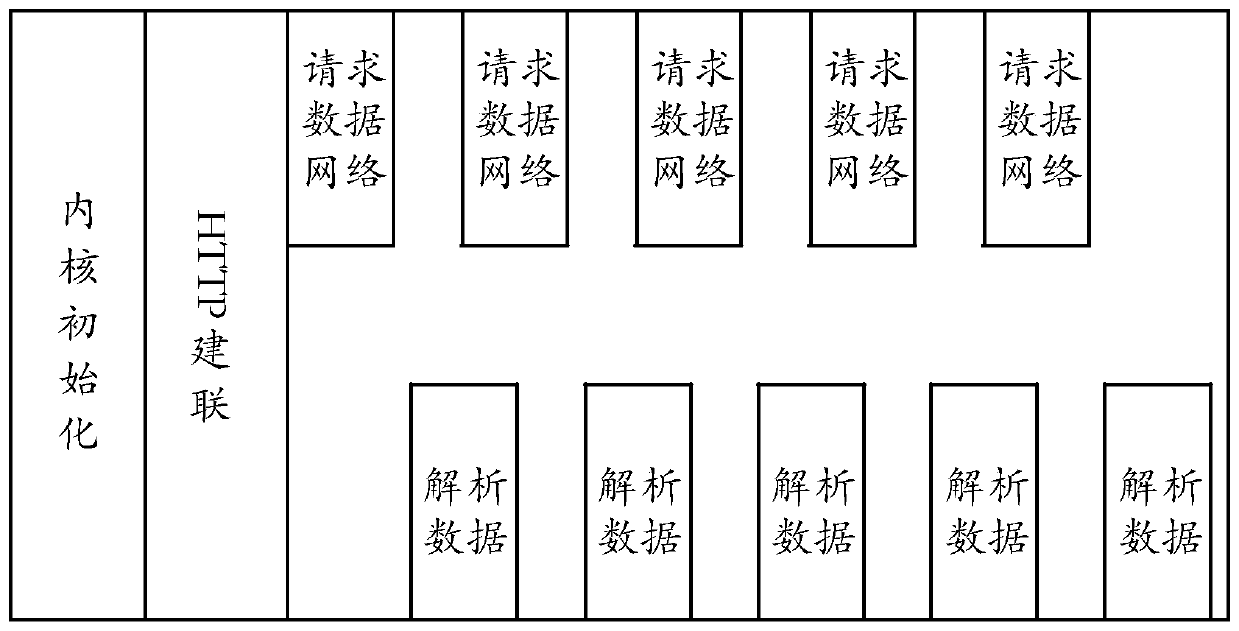

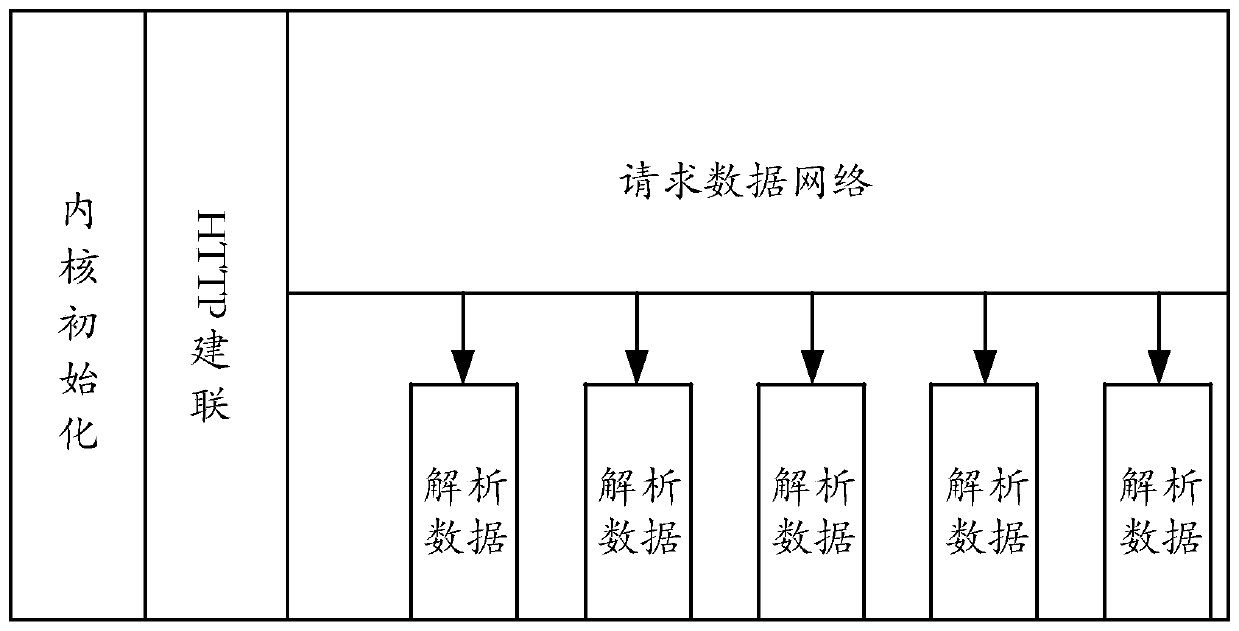

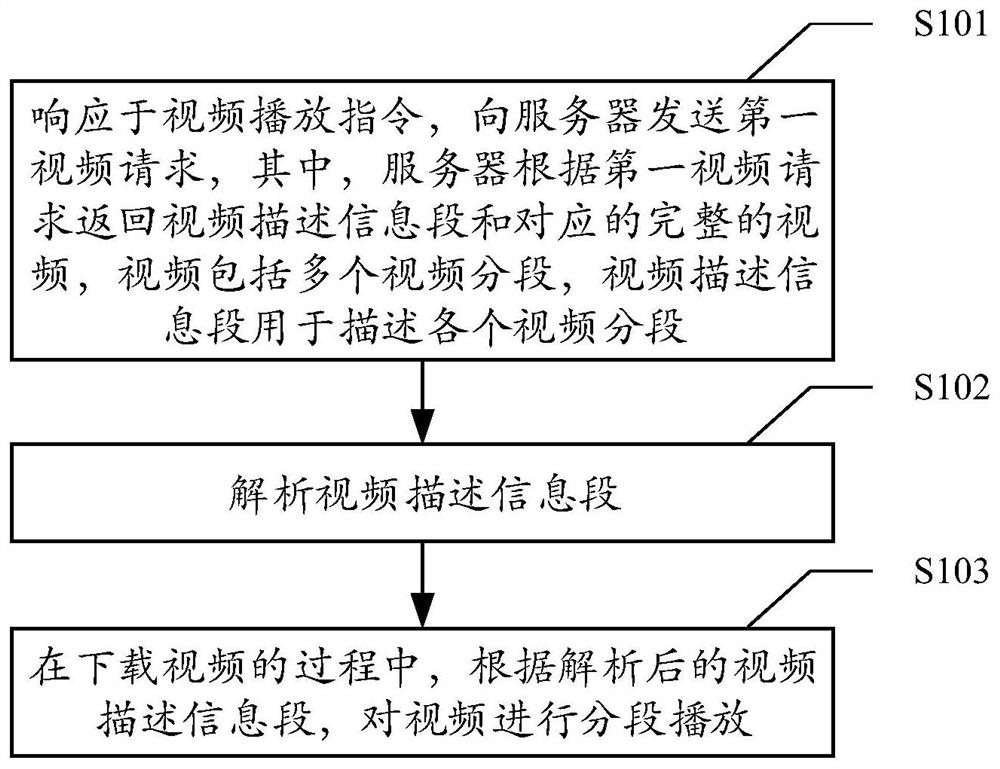

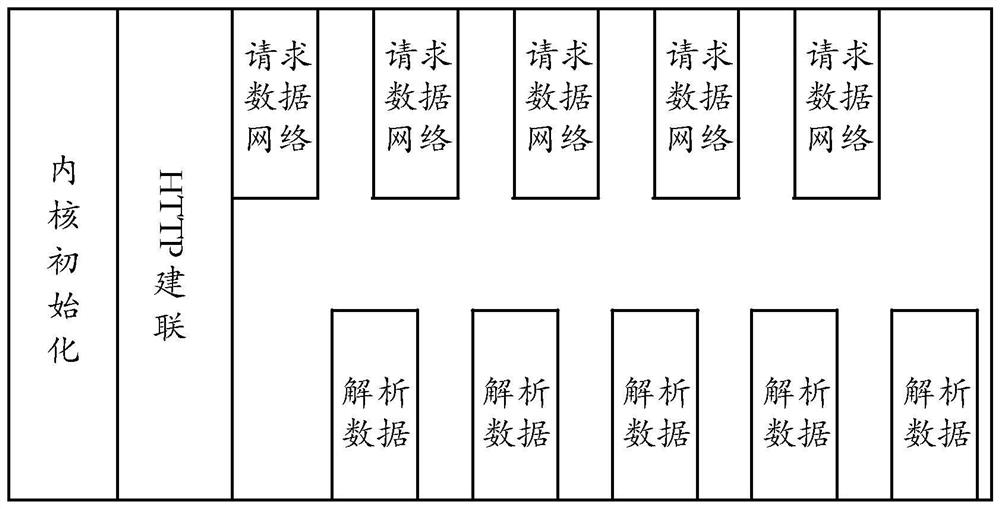

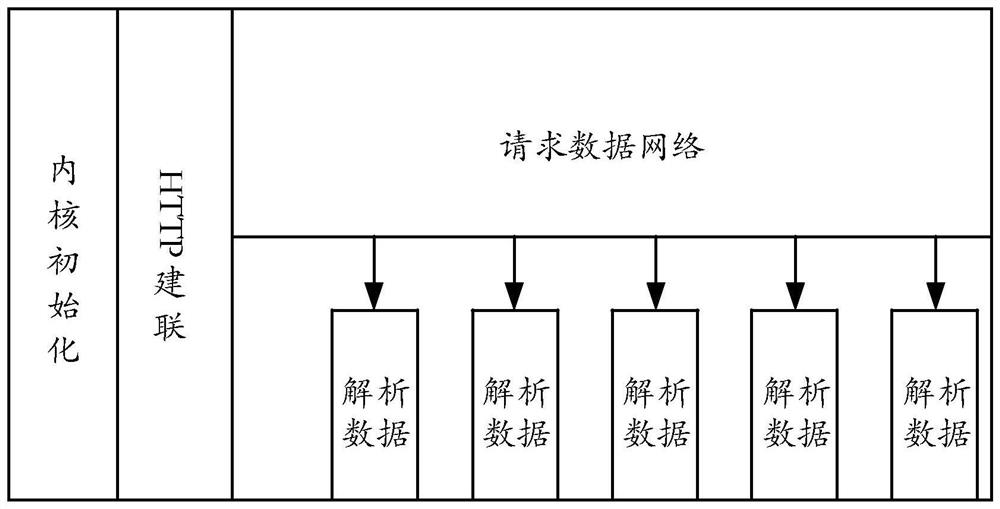

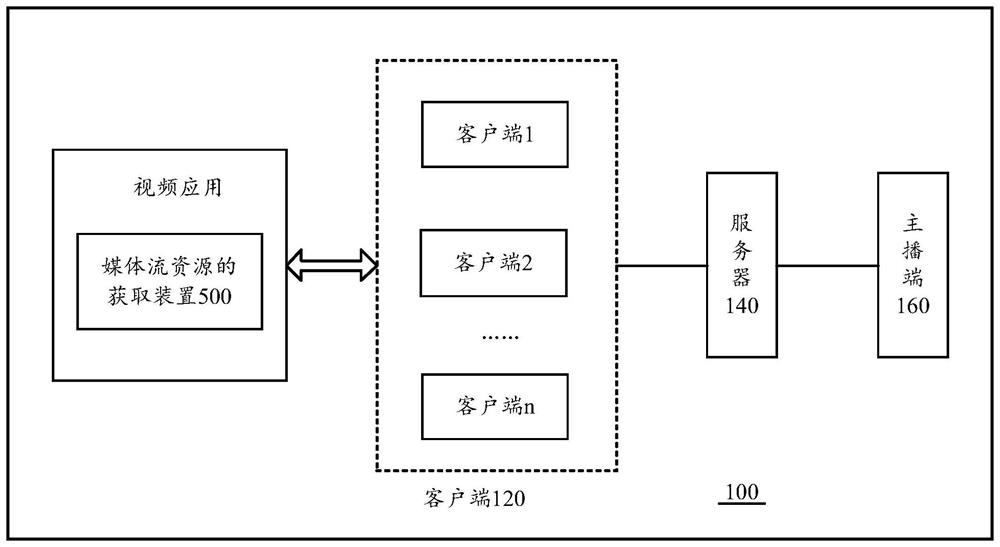

Video request method and system, computer equipment and computer readable storage medium

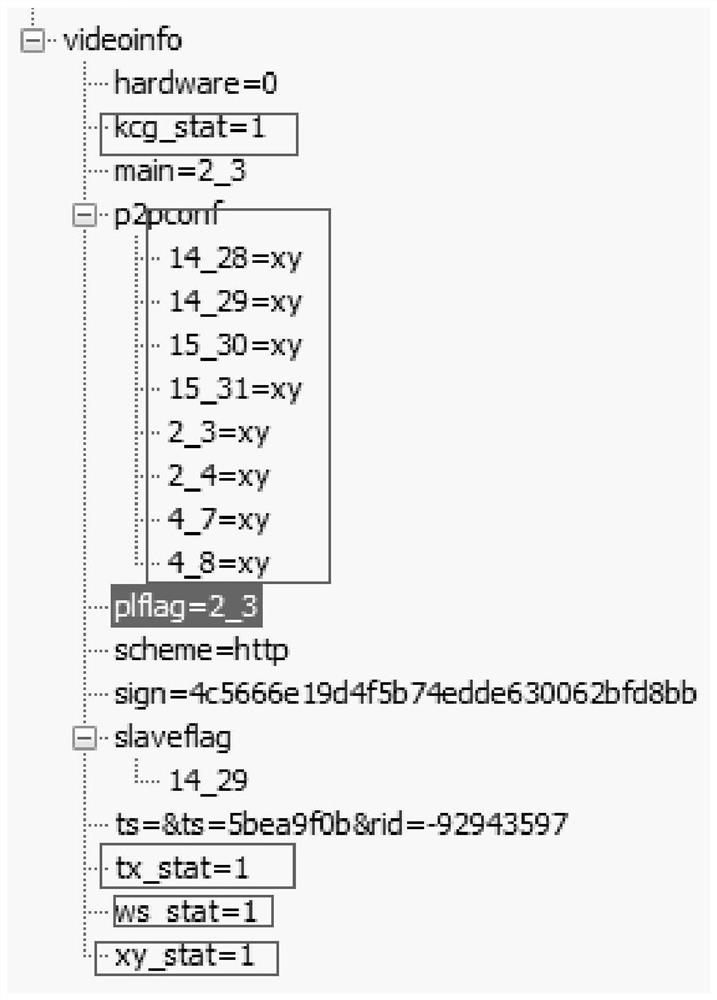

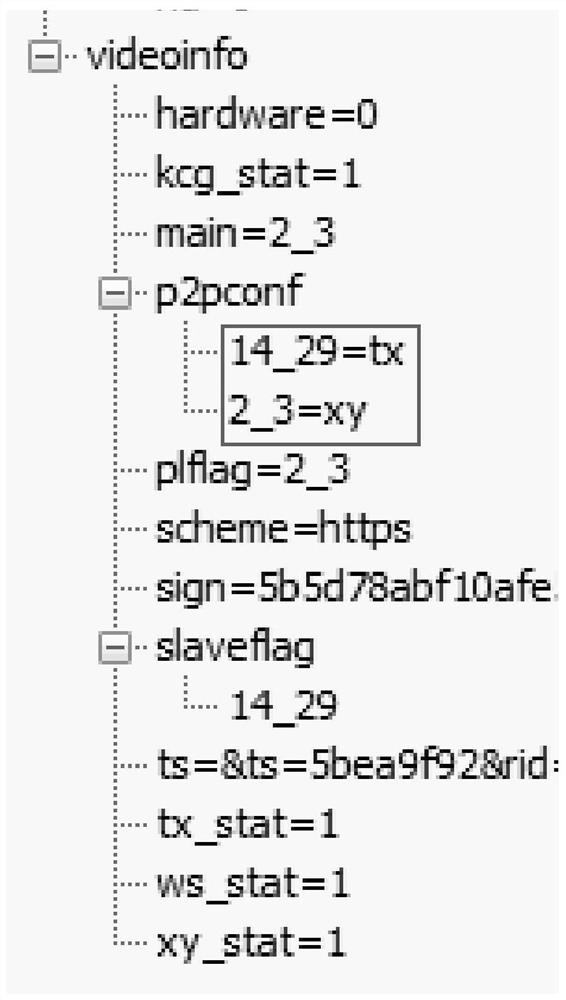

ActiveCN111510790AImprove pulling efficiencyAvoid wasting timeTransmissionSelective content distributionComputer graphics (images)Server

The invention provides a video request method characterized in that the method comprises the steps: in response to a video playing instruction, transmitting a first video request to a server, whereinthe server returns a video description information segment and a corresponding complete video according to the first video request, the video comprises a plurality of video clips, and the video description information segment is used for describing all the video clips; analyzing the video description information segment; and in the process of downloading the video, playing the video in a segmentedmanner according to the analyzed video description information segment. The invention further provides a video playing system, computer equipment and a computer readable storage medium.

Owner:SHANGHAI BILIBILI TECH CO LTD

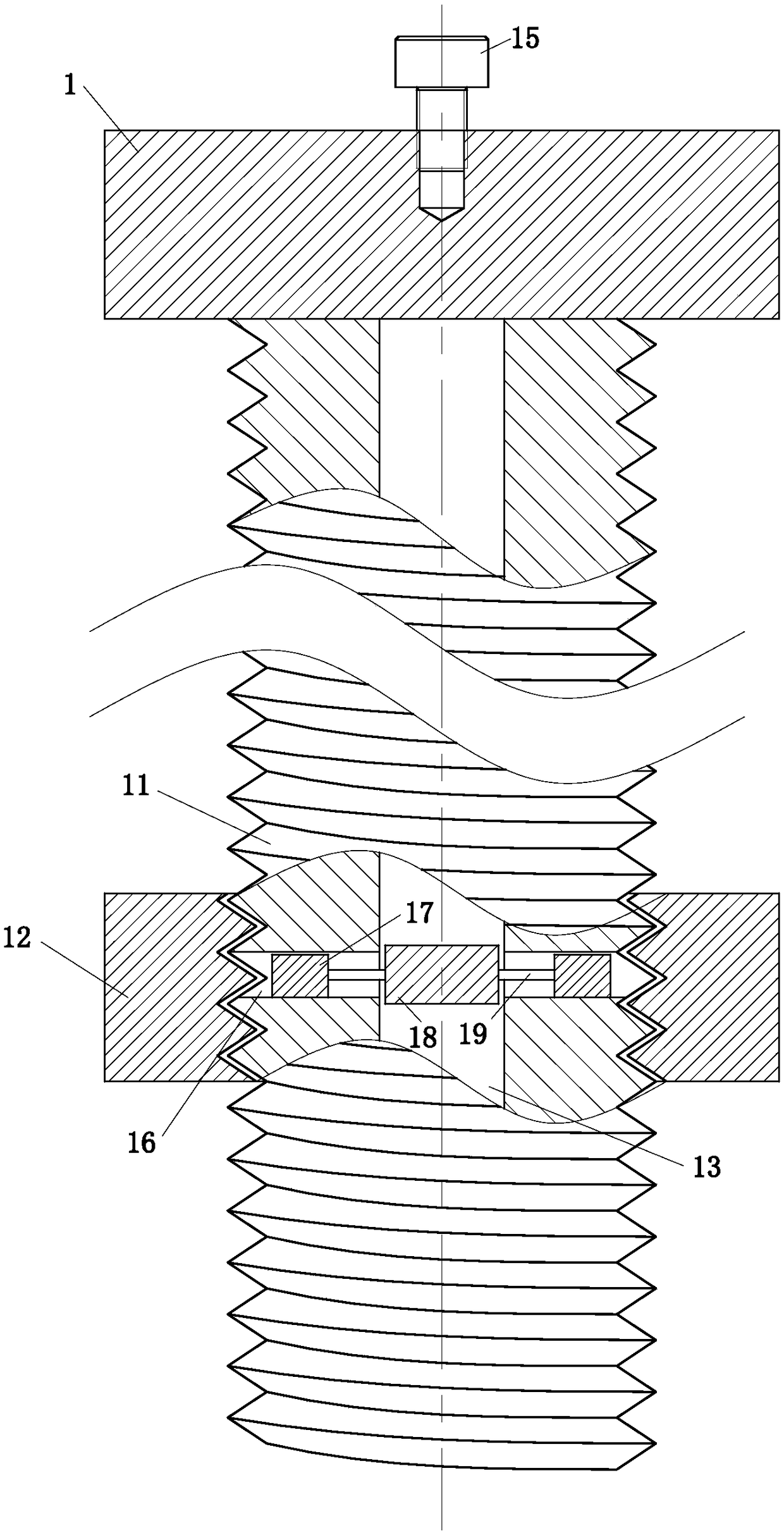

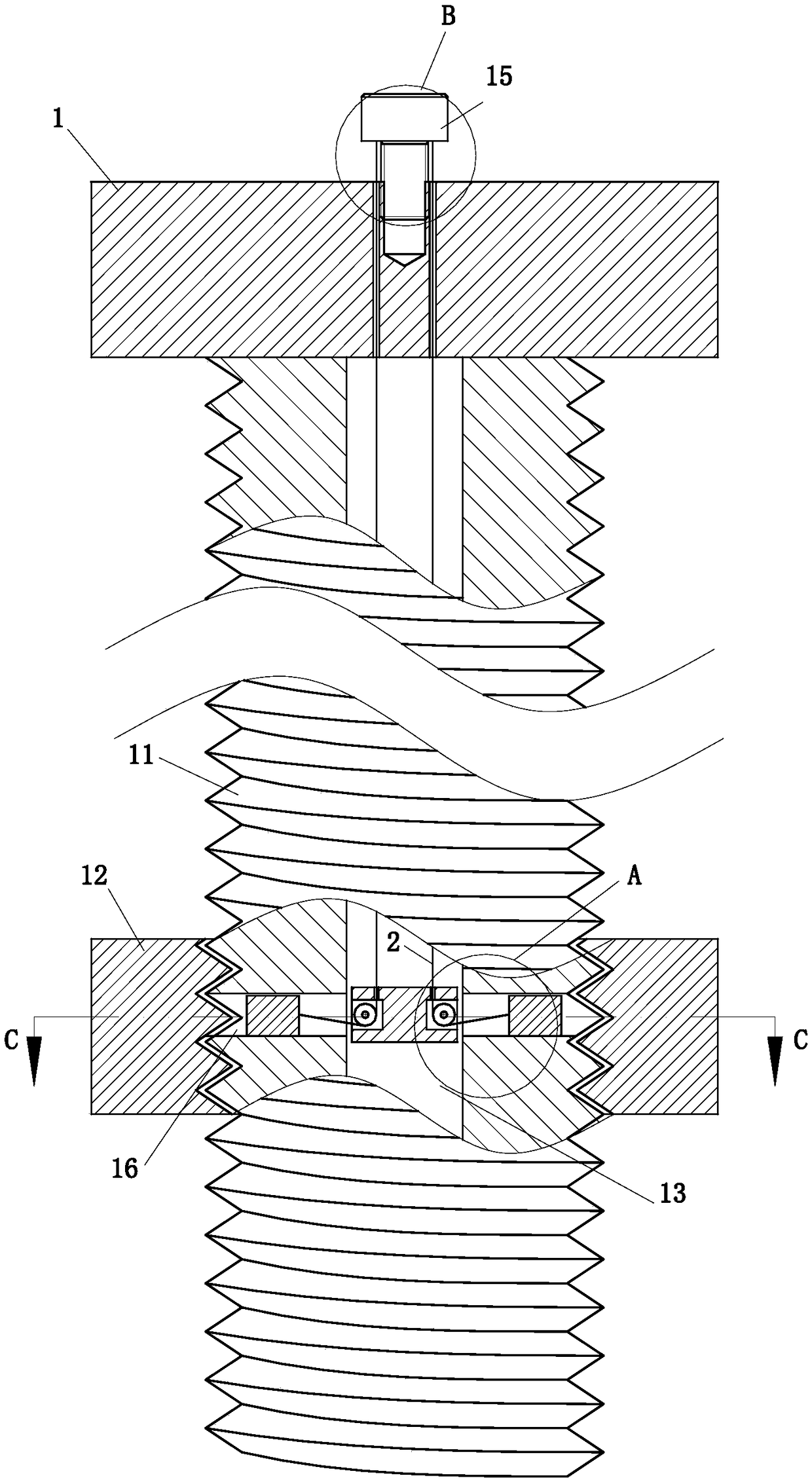

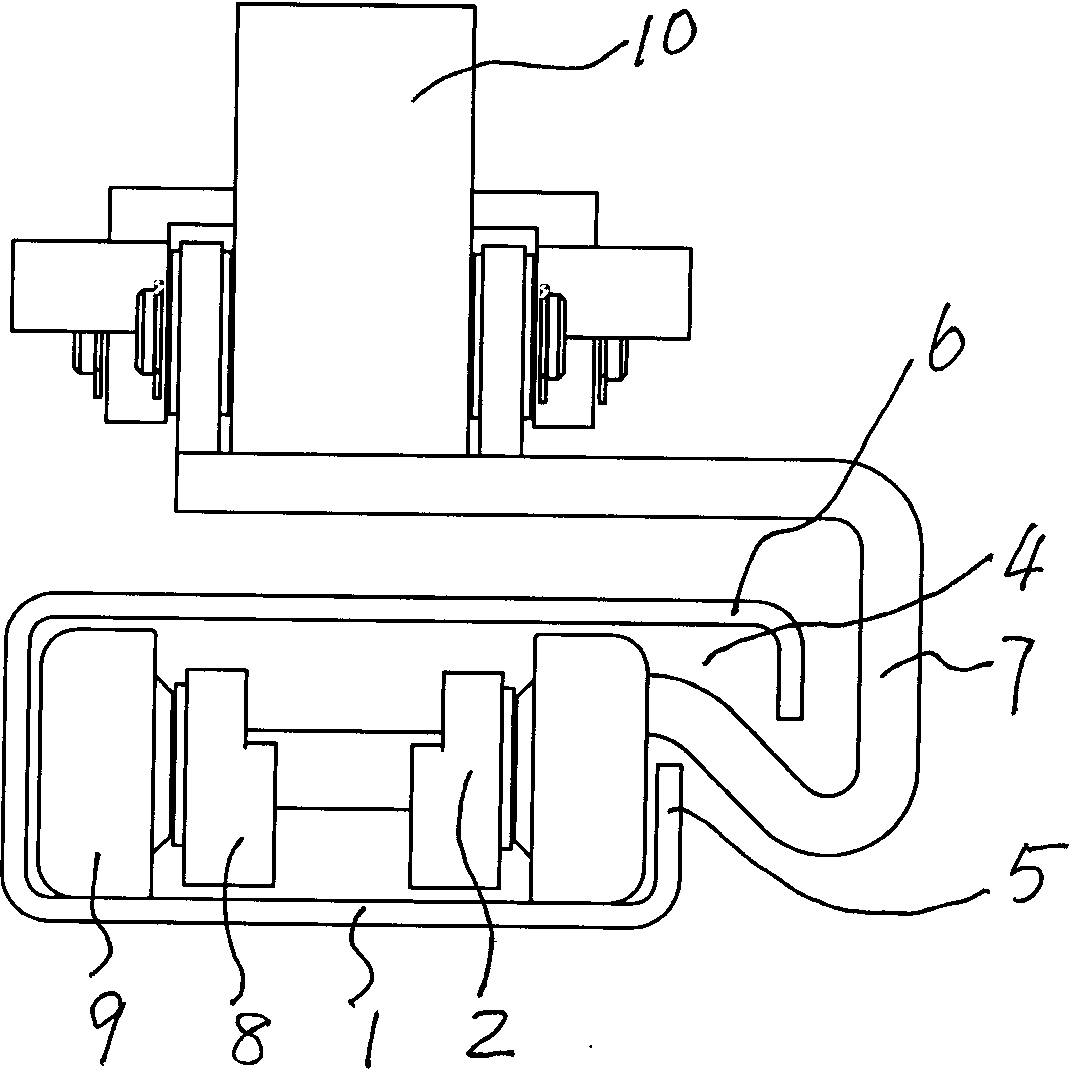

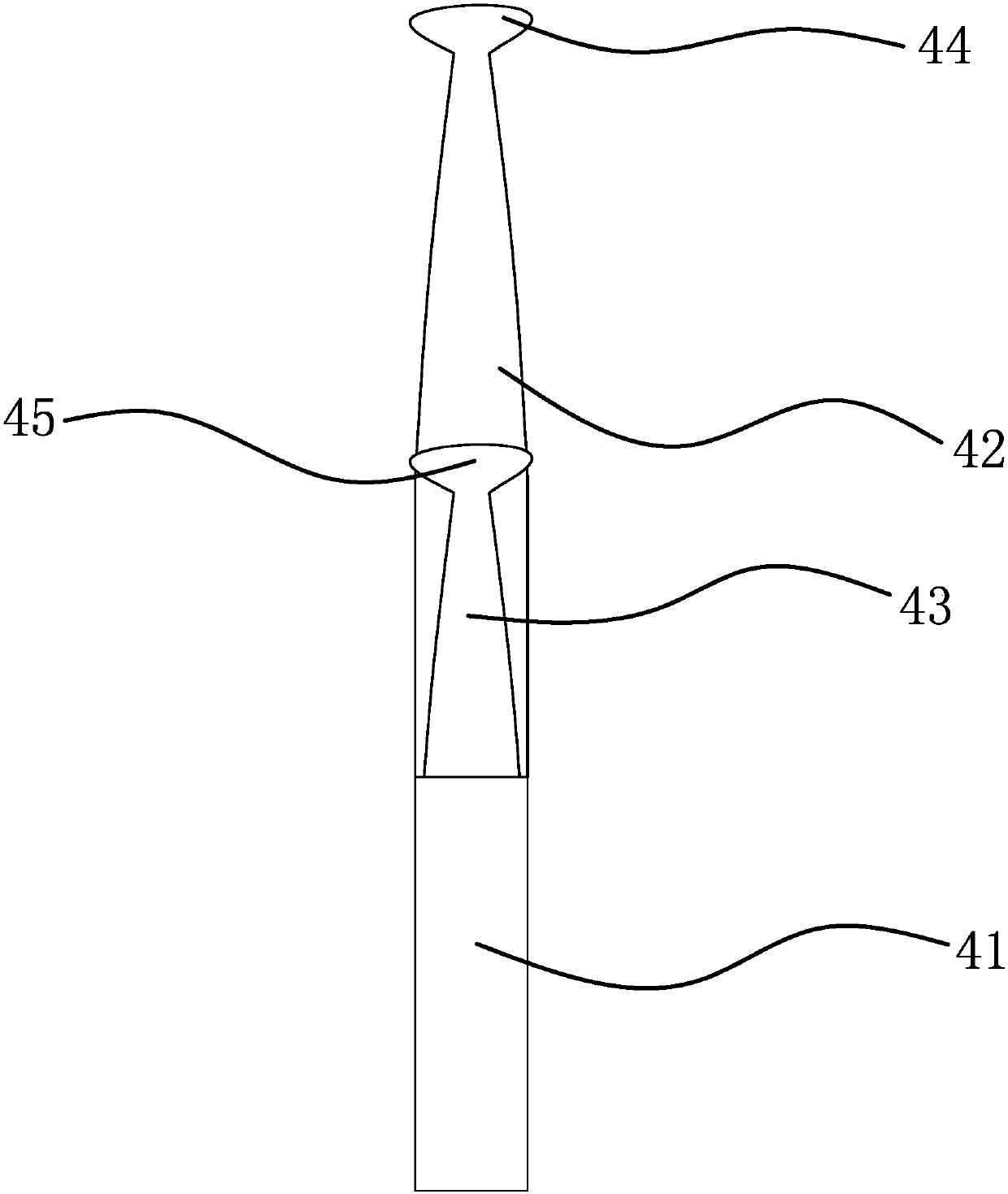

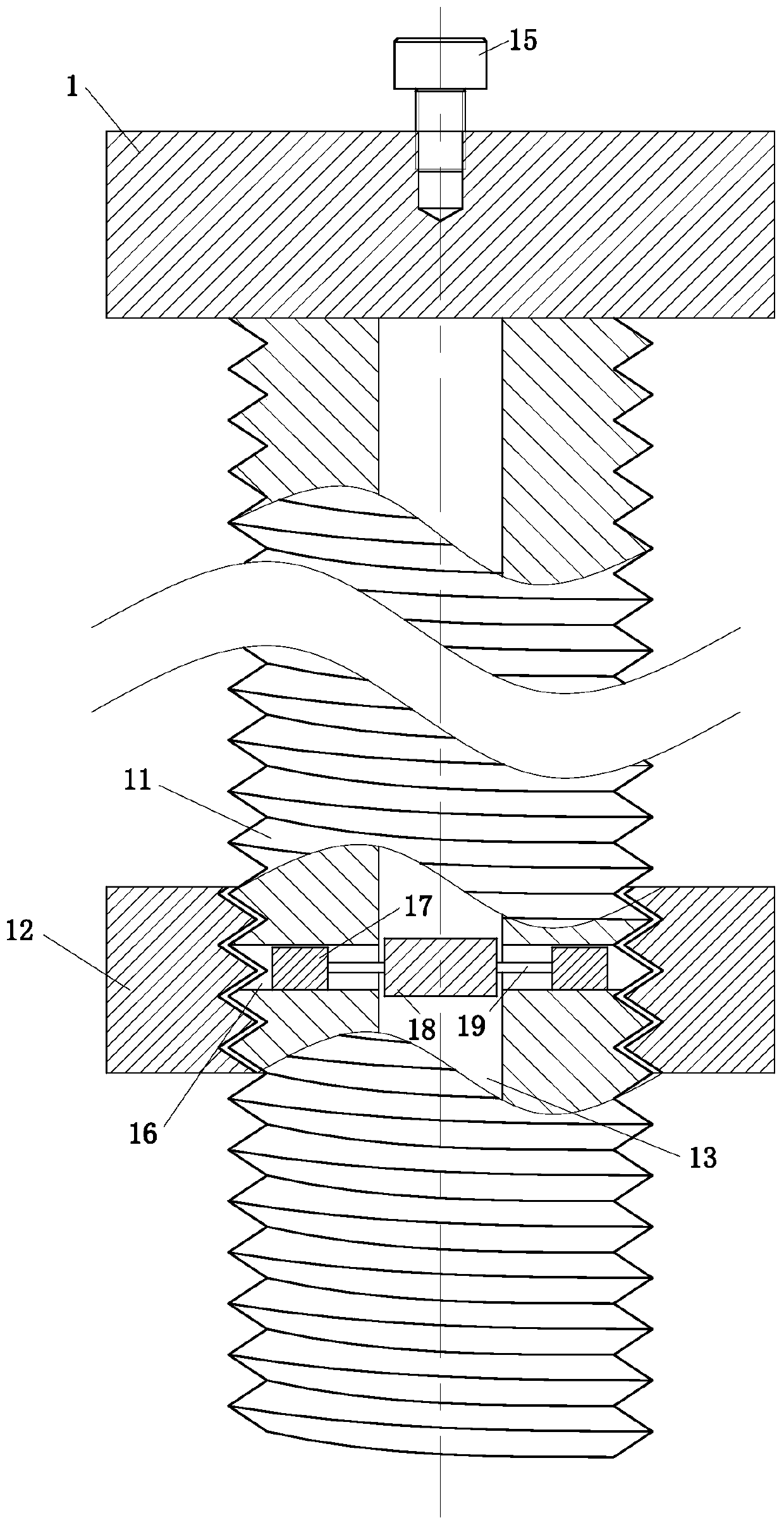

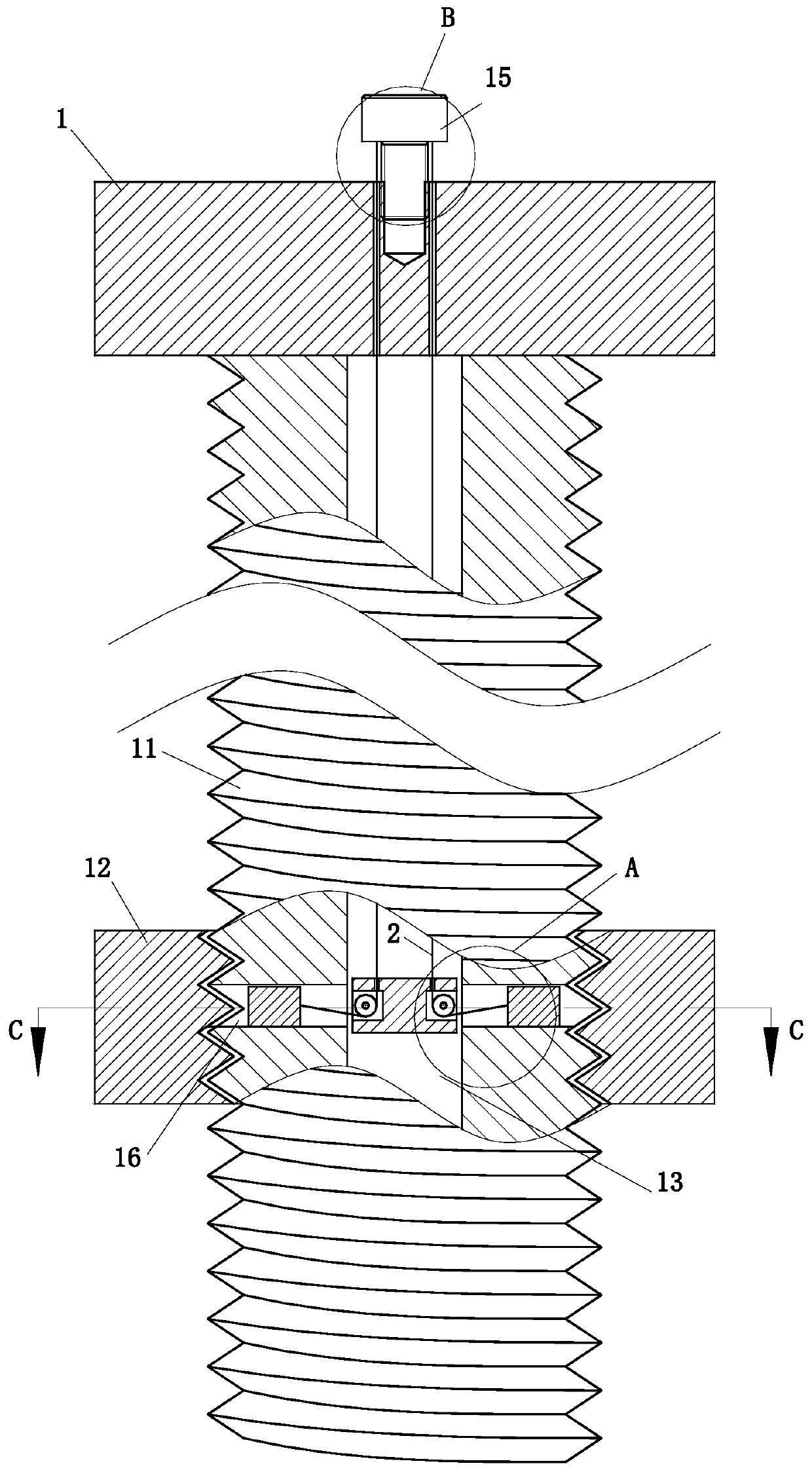

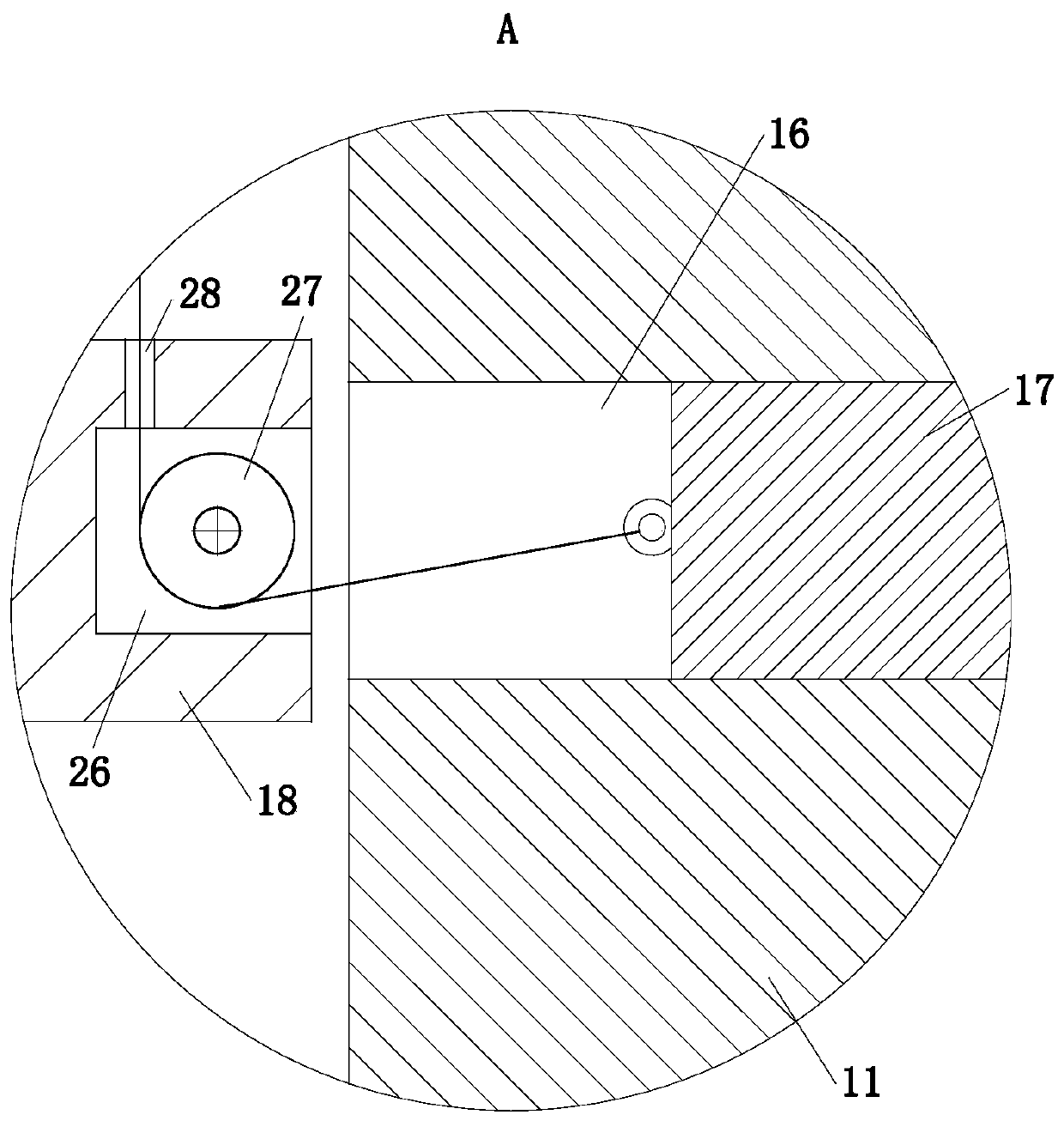

Expansion bolt convenient to disassemble

The invention belongs to the technical field of connection pieces and particularly provides an expansion bolt convenient to disassemble. The expansion bolt convenient to disassemble comprises a firstscrew cap, a first threaded rod and a first nut. The first threaded rod is fixedly installed on the bottom surface of the first screw cap and coaxial with the first screw cap. The first threaded rod is sleeved with the first nut. The bottom surface, far away from the first screw cap, of the first threaded rod is provided with a first through hole extending to the bottom surface of the first screwcap. The upper surface of the first screw cap is provided with second through holes communicating with the first through hole. A locking piece is fixedly installed on the upper surface of the first screw cap. The other end of each steel wire rope penetrates through an installation plate, the first through hole and the corresponding second through hole to be connected with the locking piece. The steel wire ropes are used for tensioning friction blocks to enable the elastic pieces to be compressed and deformed. According to the expansion bolt convenient to disassemble, through the arrangement ofthe friction blocks and the elastic pieces, the first nut is squeezed, so that locking of the bolt is achieved; a first screw is arranged to drive the steel wire ropes to move in the vertical direction so as to enable the bolt to be convenient to disassemble; and the use efficiency of the expansion bolt convenient to disassemble is improved.

Owner:瑞安市宏志钢业有限公司

Automatic folding device for disposable bed sheet production

ActiveCN113860056ARealize automatic foldingImprove folding efficiencyFolding thin materialsPackagingEngineeringLaser cutting

The invention relates to the technical field of bed sheet production and manufacturing, in particular to an automatic folding device for disposable bed sheet production. The automatic folding device for disposable bed sheet production comprises a bottom plate, a supporting frame, an unwinding unit, a limiting unit, a laser cutting unit, a pressing unit, a folding unit and an adsorption moving unit. The automatic folding device for disposable bed sheet production provided by the invention solves the problems that in the existing bed sheet folding process, due to the fact that a bed sheet is made of a flexible material, the surface of the bed sheet is prone to wrinkling due to the lack of appropriate limiting in the folding process, and the folding effect of the bed sheet is affected; and the bed sheet is made of the flexible material, so that the surface of the bed sheet is usually clamped by a clamp to pull the bed sheet in the process of pulling the bed sheet, the surface of the bed sheet is easily damaged, and the later use effect of the bed sheet is influenced. According to the automatic folding device for disposable bed sheet production provided by the invention, the folding effect of the disposable bed sheet is improved, and the surface of the bed sheet is always kept in a flat state in the folding process of the bed sheet.

Owner:徐州旅悠旅游用品有限公司

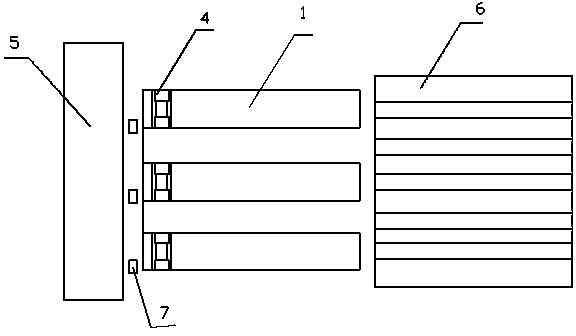

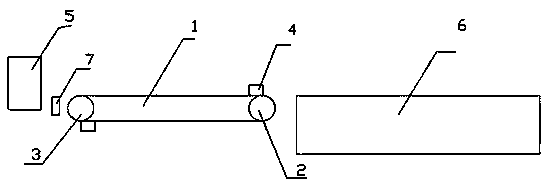

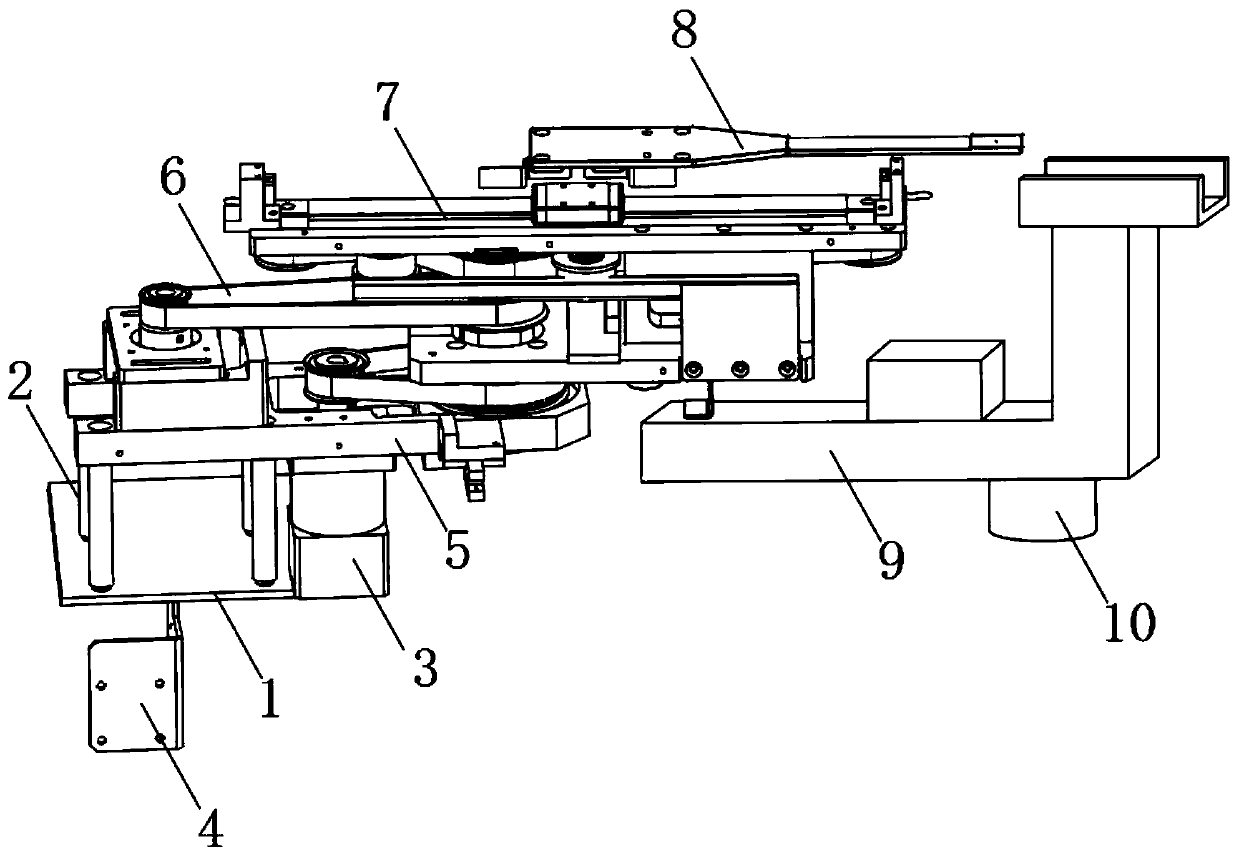

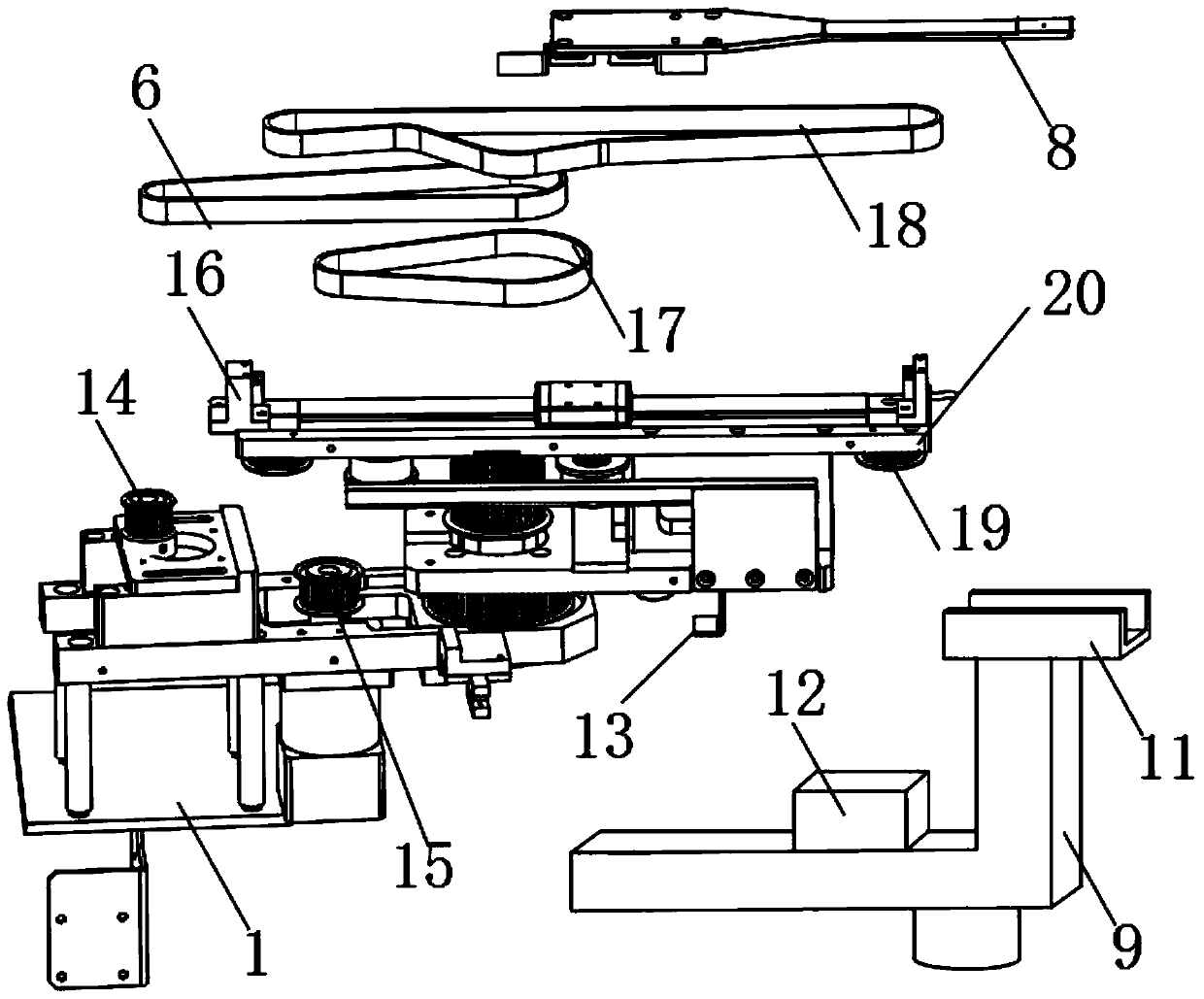

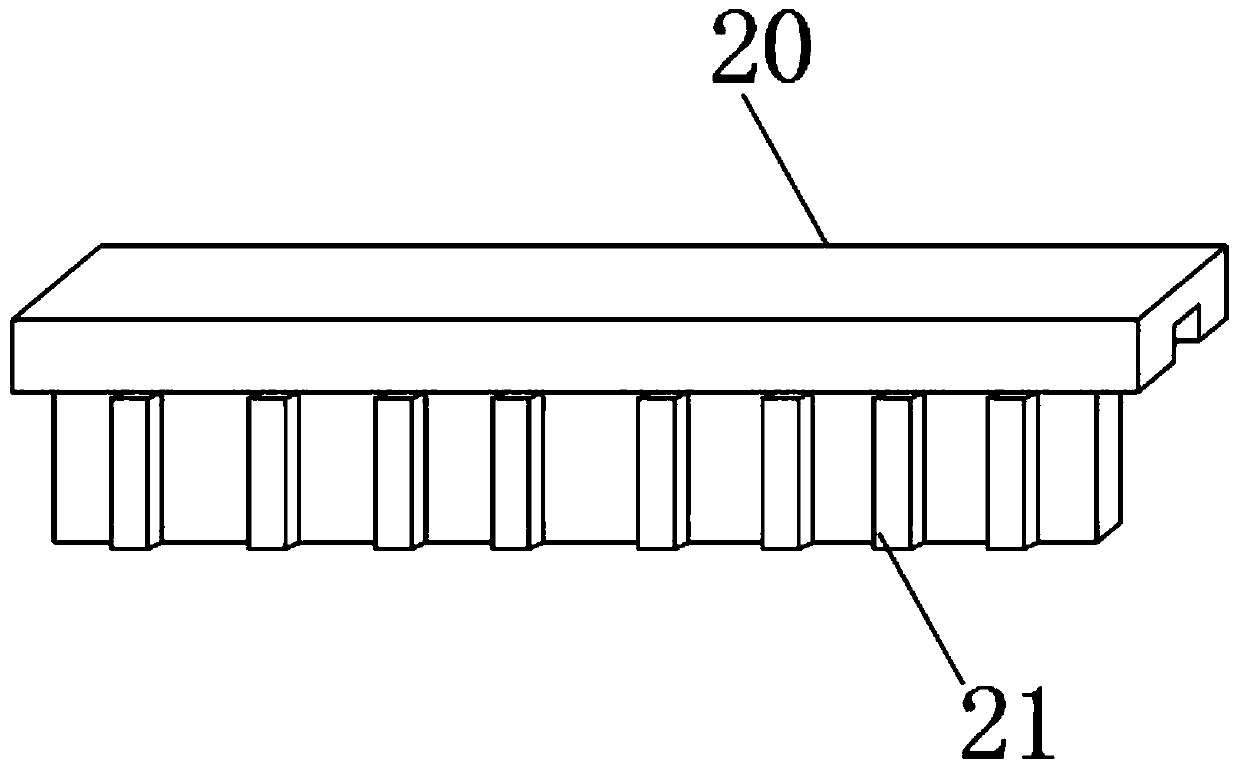

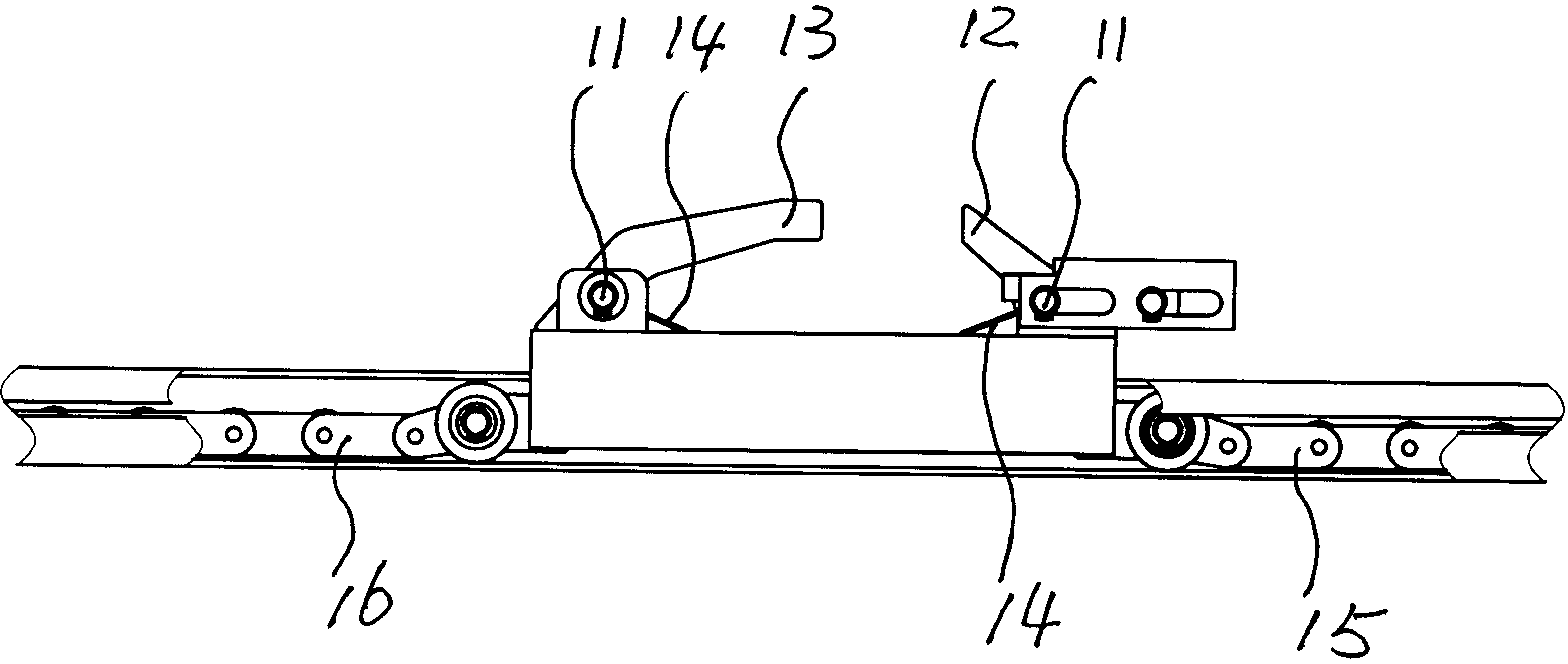

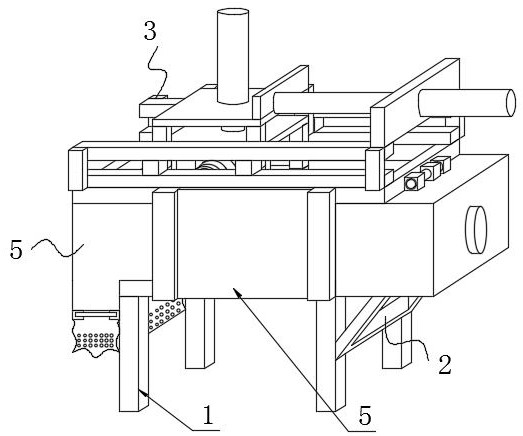

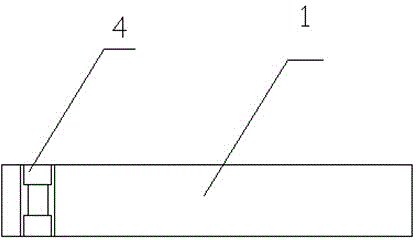

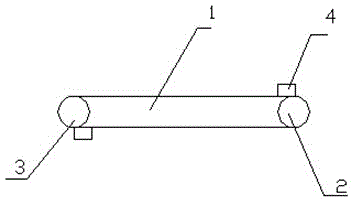

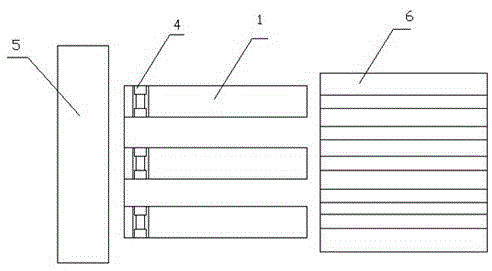

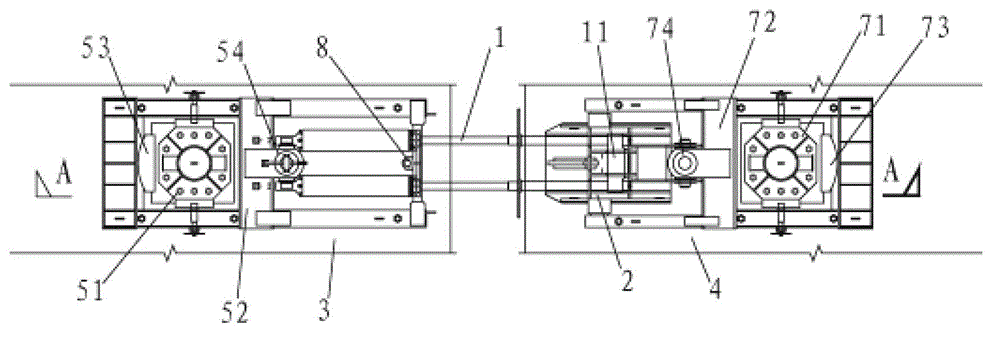

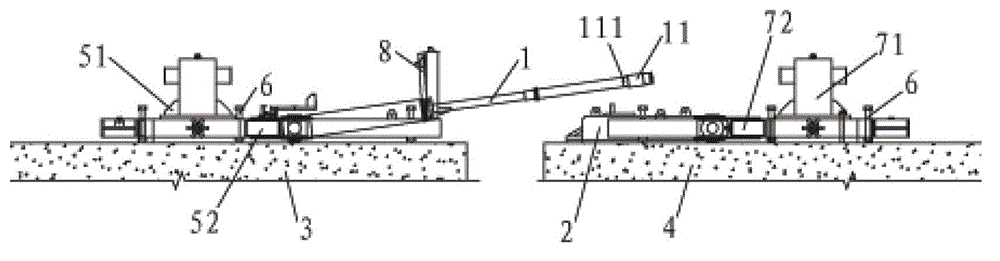

Aluminum section forming device

ActiveCN104384375AHigh degree of mechanizationReduce manual usage and laborMetal-working feeding devicesPositioning devicesMechanical engineeringElectromagnet

The invention discloses an aluminum section forming device. The aluminum section forming device comprises an extruding machine, a shearing machine, a pulling machine and a storage rack, wherein the shearing machine is positioned between the extruding machine and the pulling machine, the pulling machine is positioned behind the shearing machine, and the storage rack is positioned behind the pulling machine. The aluminum section forming device is characterized in that the pulling machine comprises a rack, a conveying belt, a driving roller, a driven roller, a driving roller driving device and two clamping heads, wherein the conveying belt is in an annular shape and sleeves the driving roller and the driven roller, the driving roller driving device is connected with the driving roller, the two clamping heads are respectively installed on both ends of the conveying belt, the clamping heads comprise two electromagnets and electromagnet fixing seats, the electromagnets are fixed in the electromagnet fixing seats, and the electromagnet fixing seats are installed on both sides of the conveying belt through sliding tracks which are vertically laid on the conveying belt. According to the aluminum section forming device, potential safety hazards are eliminated, and additionally, the pulling efficiency is greatly improved.

Owner:湖州华利铝业有限公司

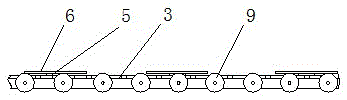

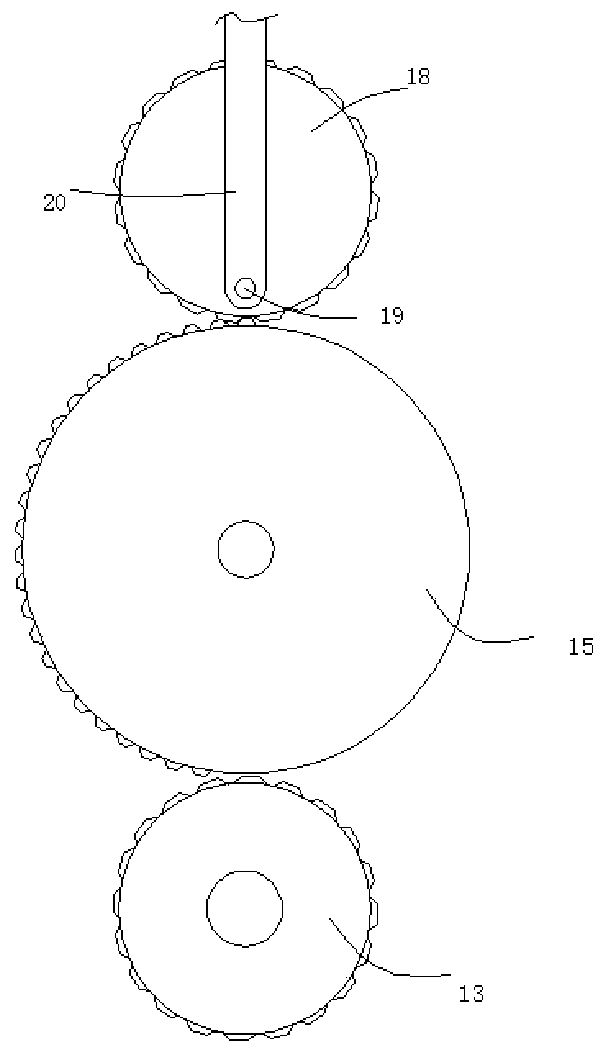

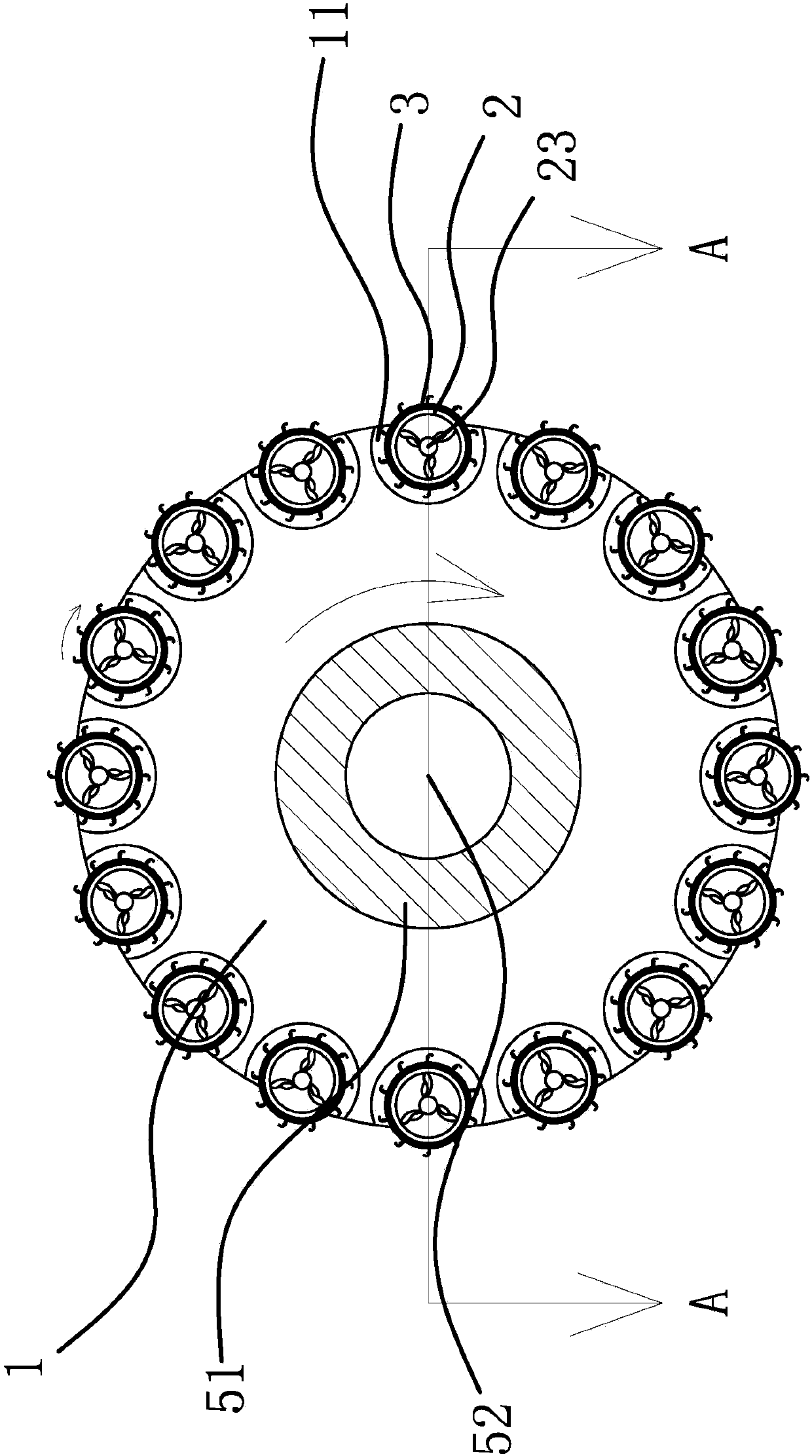

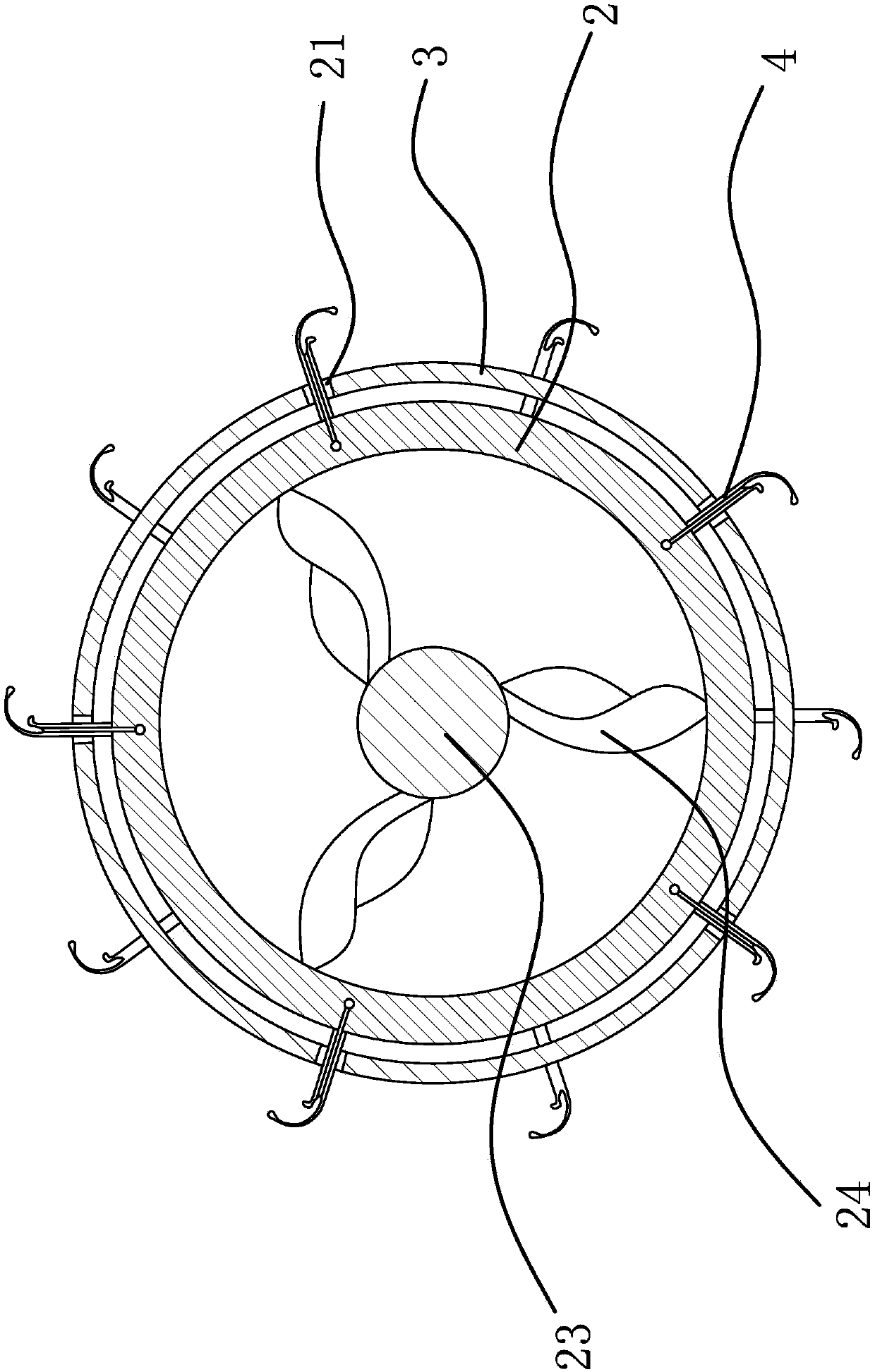

Sock napping machine

InactiveCN105624961AReasonable structureImprove pulling efficiencyRougheningBatch productionTransmission system

The invention relates to a sock napping machine which comprises a rack and a transmission system, two pairs of napping rollers, a motor and an electric cabinet which are arranged on the rack; the two pairs of napping rollers are arranged in a front-rear mode, and each pair of napping rollers are arranged up and down; the transmission system comprises a transmission chain, chain wheels and sock plates arranged on the transmission chain, and the sock plates just pass through gaps between each upper napping roller and the corresponding lower napping roller, pass through the first pair of napping rollers in the first place and then pass through the next pair of napping rollers in the conveying process of the transmission chain so as to complete preliminary napping and secondary napping. The sock napping machine is reasonable in structure, high in sock napping efficiency, good in napping quality, high in napping speed and low in napping cost and meets batch production requirements.

Owner:HAINING MENGLI KNITTING

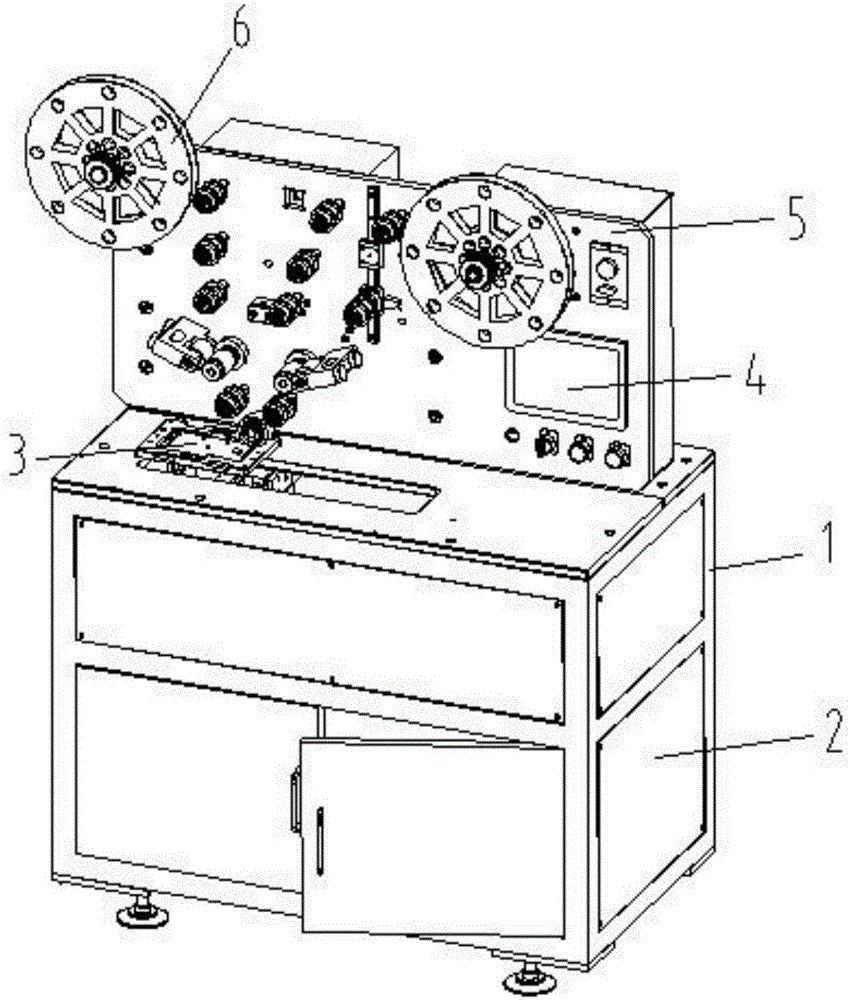

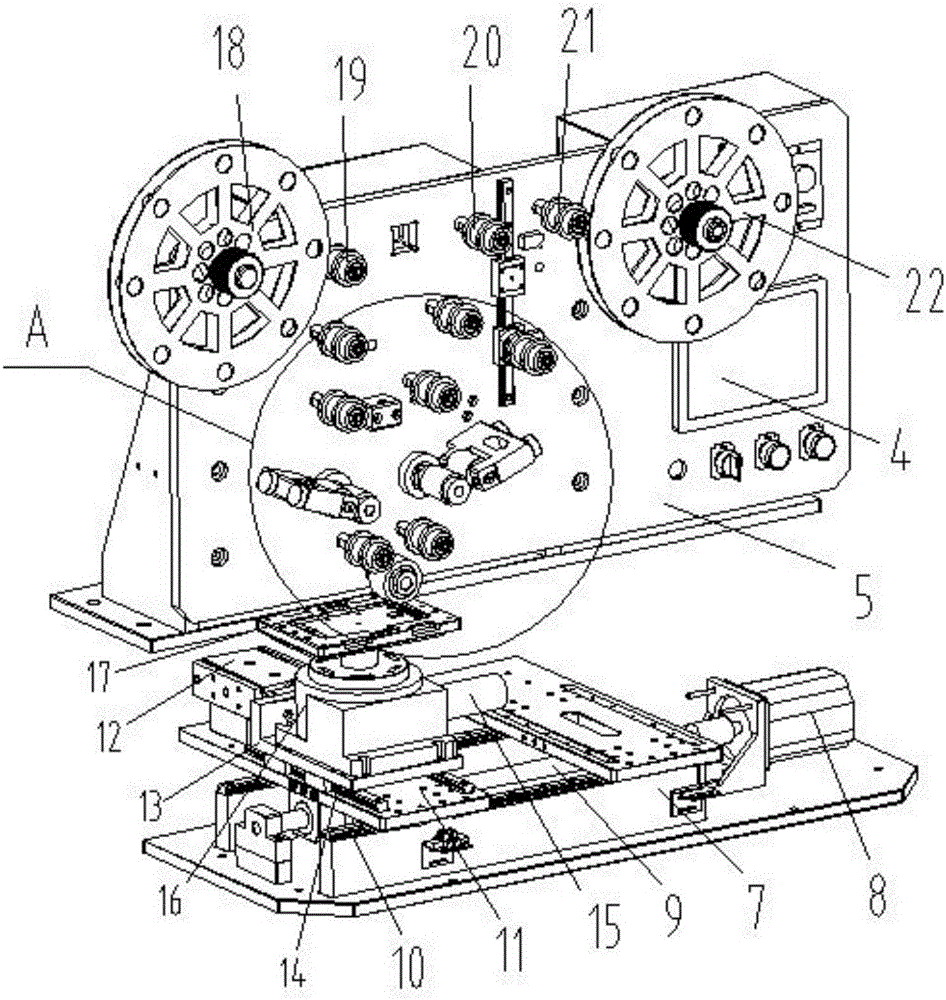

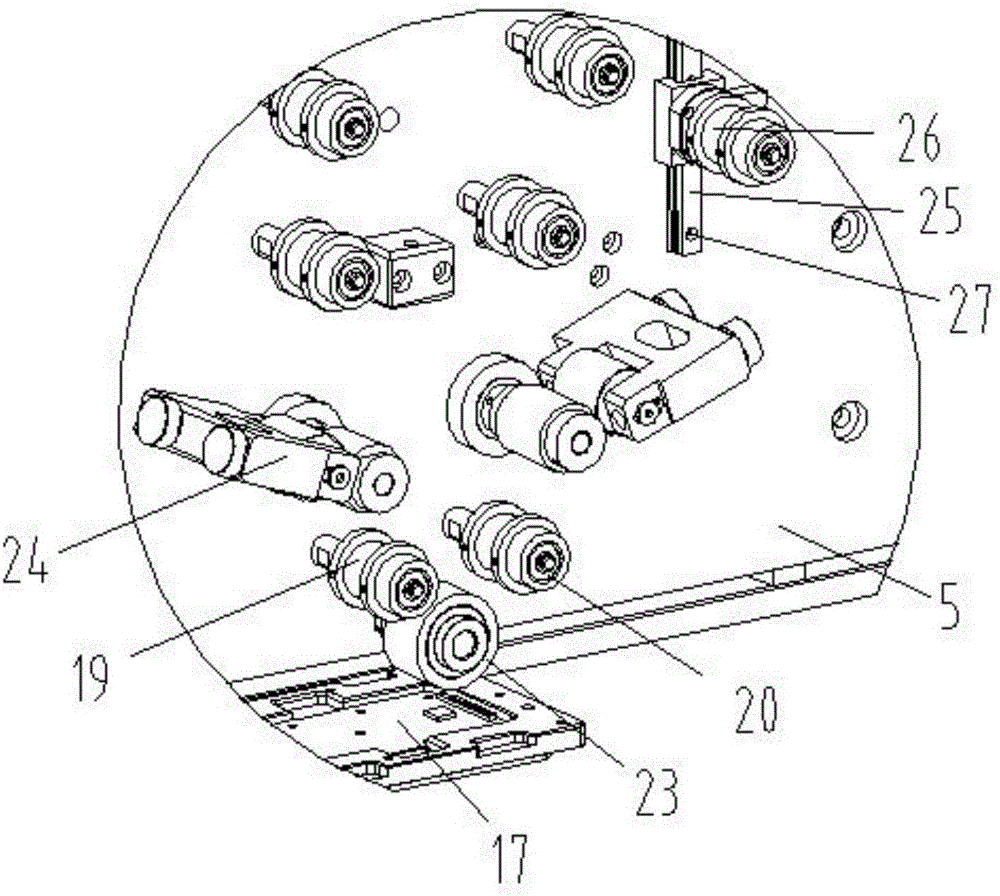

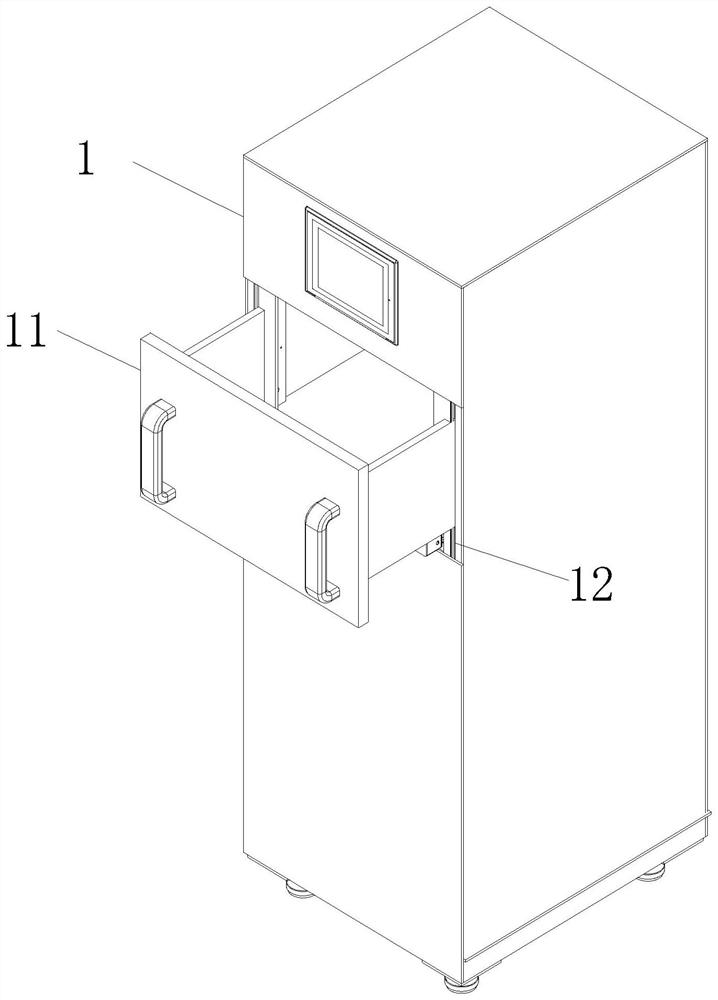

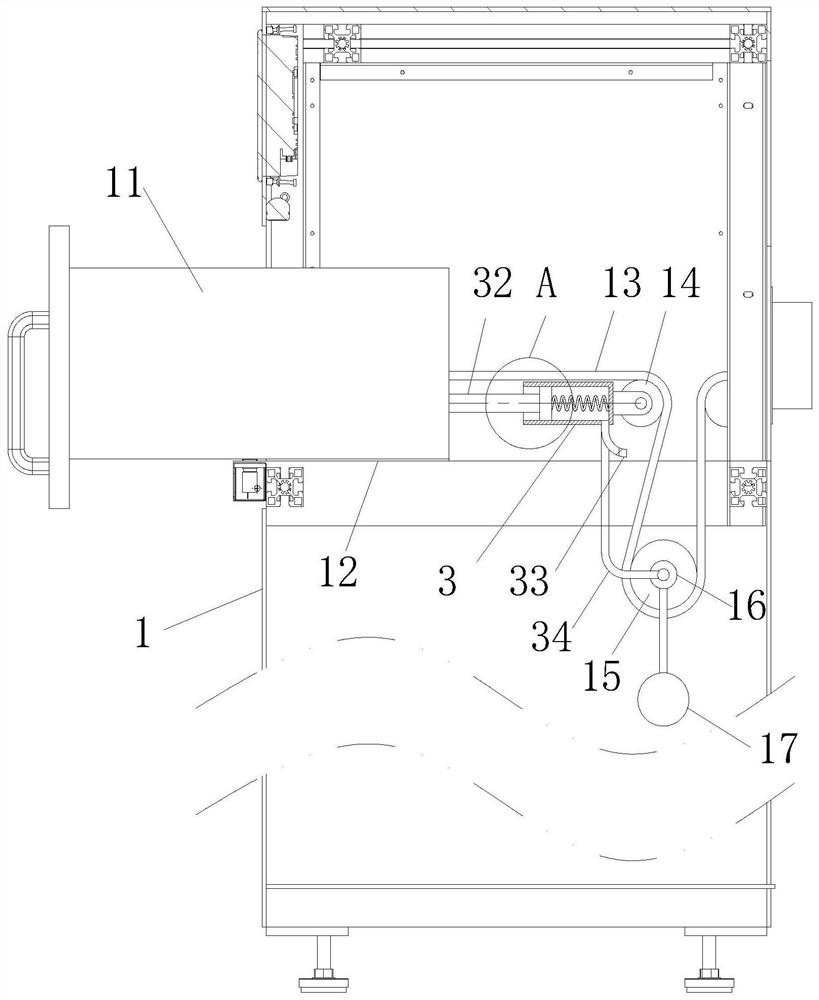

Automatic frictioning machine for panel

InactiveCN106824845ARealize the effect of wiping glueImprove glue wiping efficiencyCleaning using toolsDistribution controlEngineering

The invention relates to an automatic frictioning machine for a panel. The automatic frictioning machine comprises a rack and a power distribution control cabinet, wherein a material carrying mechanism matched with the panel is arranged on the rack; a vertical mounting plate is arranged on the rack; an operation display matched with the power distribution control cabinet and a frictioning mechanism matched with the material carrying mechanism are arranged on the mounting plate; the frictioning mechanism comprises an unwinding drum, a winding drum and a frictioning drum matched with the unwinding drum and the winding drum; the unwinding drum, the winding drum and the frictioning drum are arranged on the mounting plate; the frictioning drum is matched with the material carrying mechanism; the winding drum is connected with a winding motor through a synchronizing wheel; and the winding motor and the material carrying mechanism are connected to the power distribution control cabinet. According to the automatic frictioning machine for the panel provided by the invention, the unwinding drum and the winding drum of a frictioning strip are arranged, the frictioning drum matched with the unwinding drum and the winding drum is arranged, a panel carrier is arranged below the frictioning drum, the frictioning strip and the panel are in contact through the frictioning drum, the frictioning effect is achieved, the frictioning efficiency is high, the frictioning strip continuously moves, the frictioning effect is not affected by too large viscose glue, and good frictioning precision can be guaranteed.

Owner:DONGGUAN RONGGONG AUTOMATION TECH CO LTD

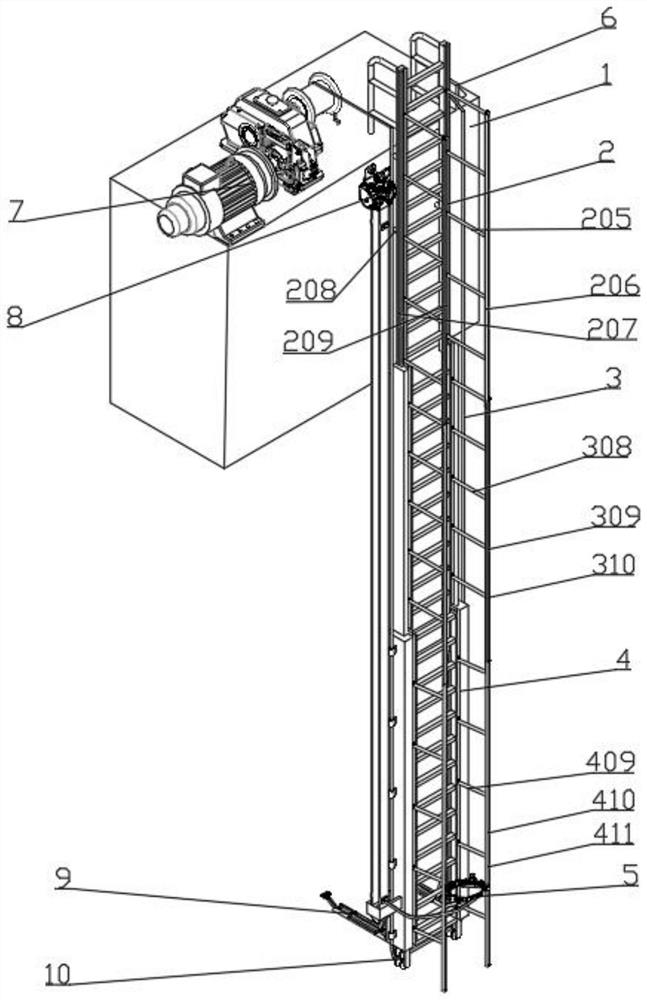

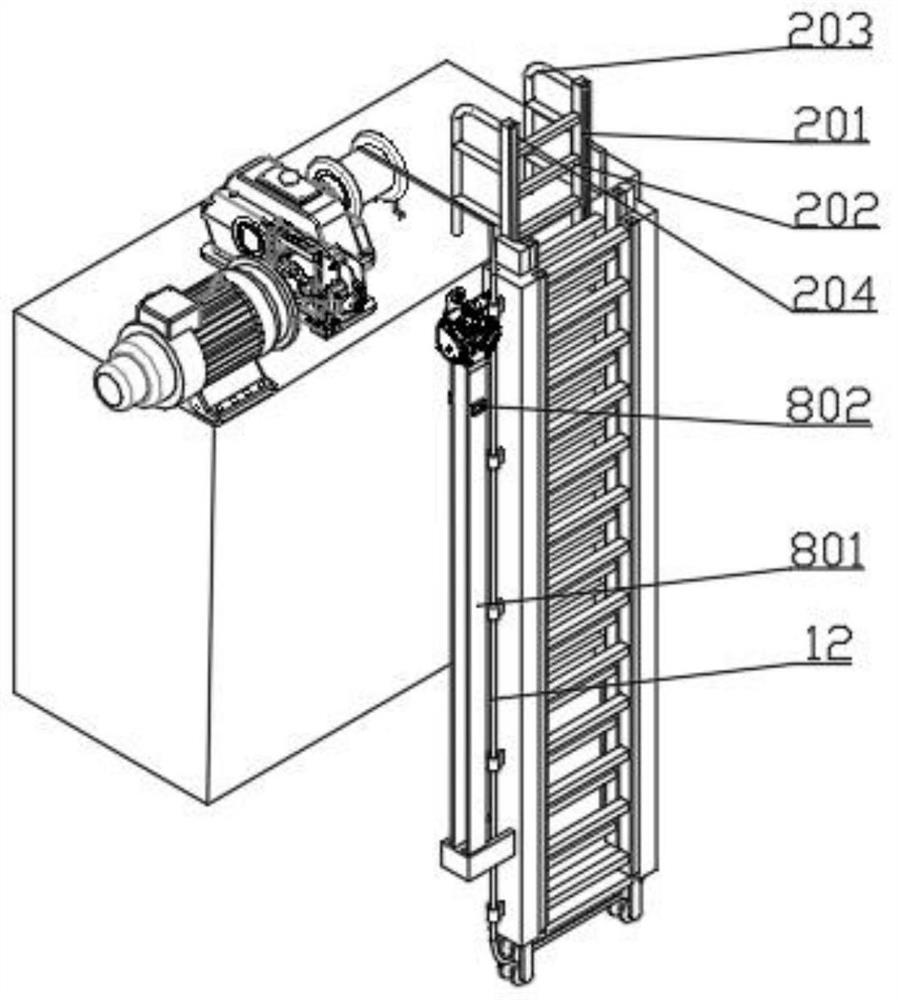

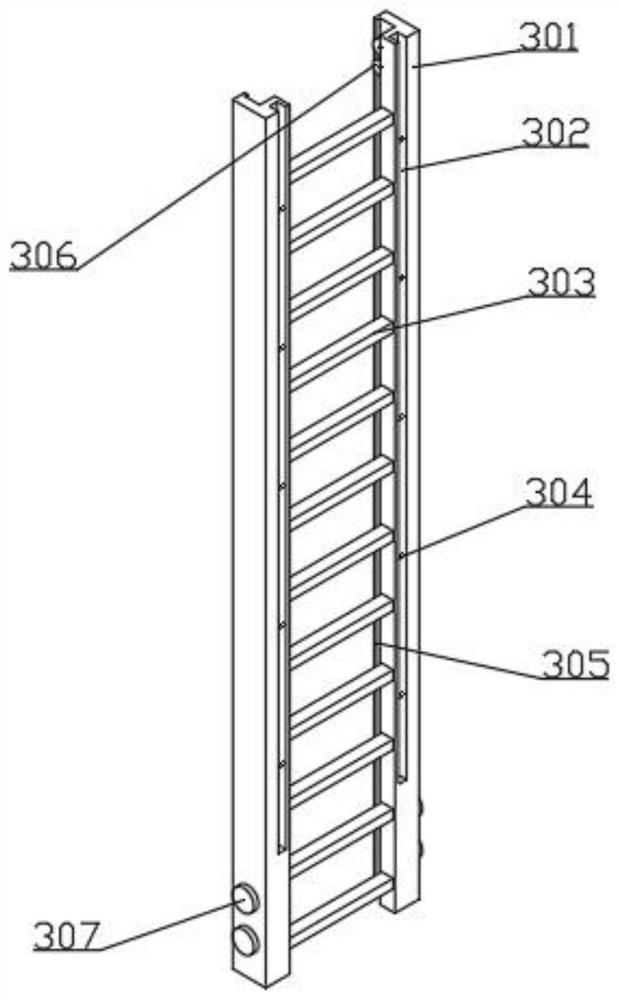

Telescopic device and use method thereof

InactiveCN113562124AIncrease flexibilityReduce wearCargo handling apparatusPassenger handling apparatusFixed ladderEngineering

The invention relates to the technical field of ship lifesaving equipment, in particular to a telescopic device and a use method thereof. The telescopic device comprises a platform, a fixed ladder, a first slide, a second slide, a safety waistband assembly, a pull rope fixing assembly, a pull-up assembly, a safety pull belt assembly, a plurality of bottom end fixing assemblies and a pull rope; the telescopic device is provided with the fixed ladder, the first slide and the second slide, the telescopic sliding function is provided for the telescopic device, the flexibility of the telescopic device is improved, the pulling efficiency of the first slide and the second slide is improved through the pulling-up assembly and the pull rope, the situation that the pull rope is abraded or wound and twisted in the pulling-up process is reduced, the safety waistband assembly and the safety pull belt assembly are arranged, climbing protection is provided for embarkation personnel, the risk of midway falling is reduced, the bottom end fixing assembly is arranged at the bottom of the second slide, violent shaking of the device in the using process is reduced, and the invention further provides a use method of the telescopic device.

Owner:重庆鑫思胜联科技有限公司

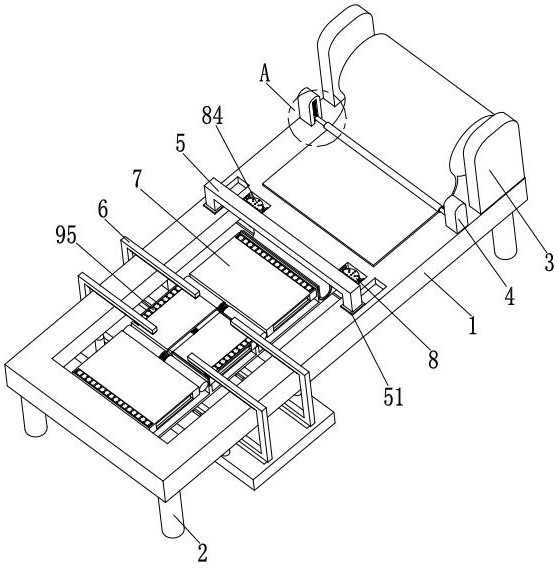

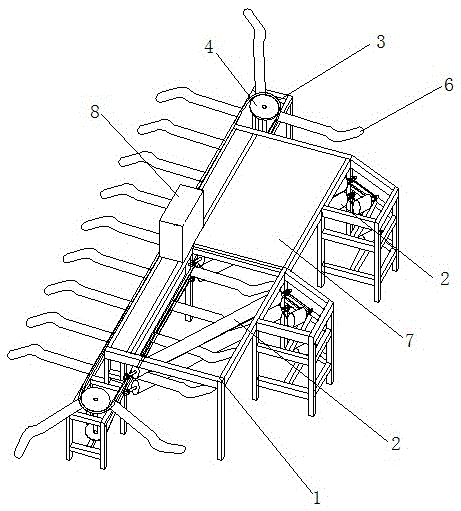

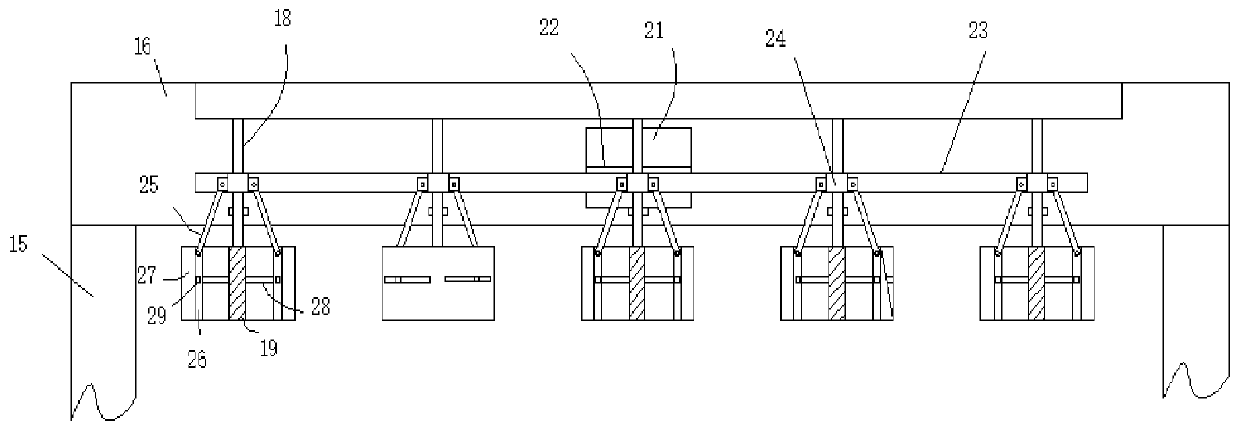

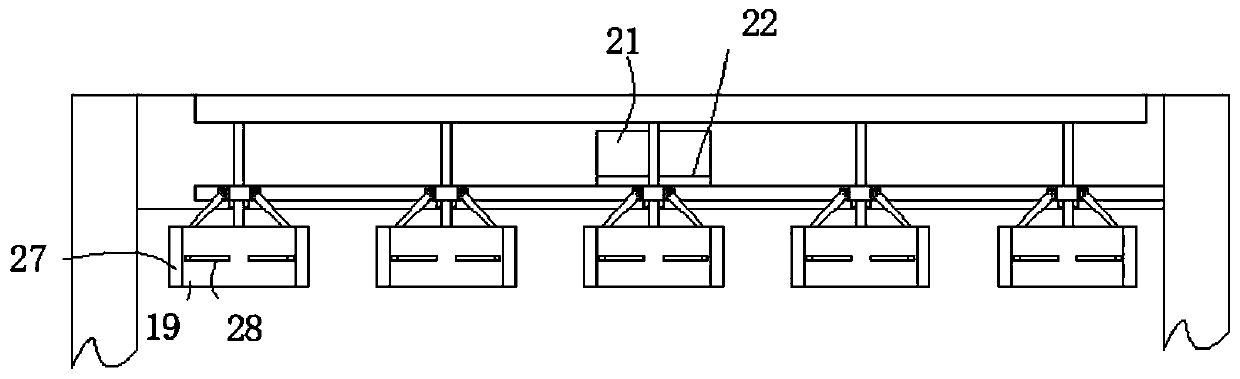

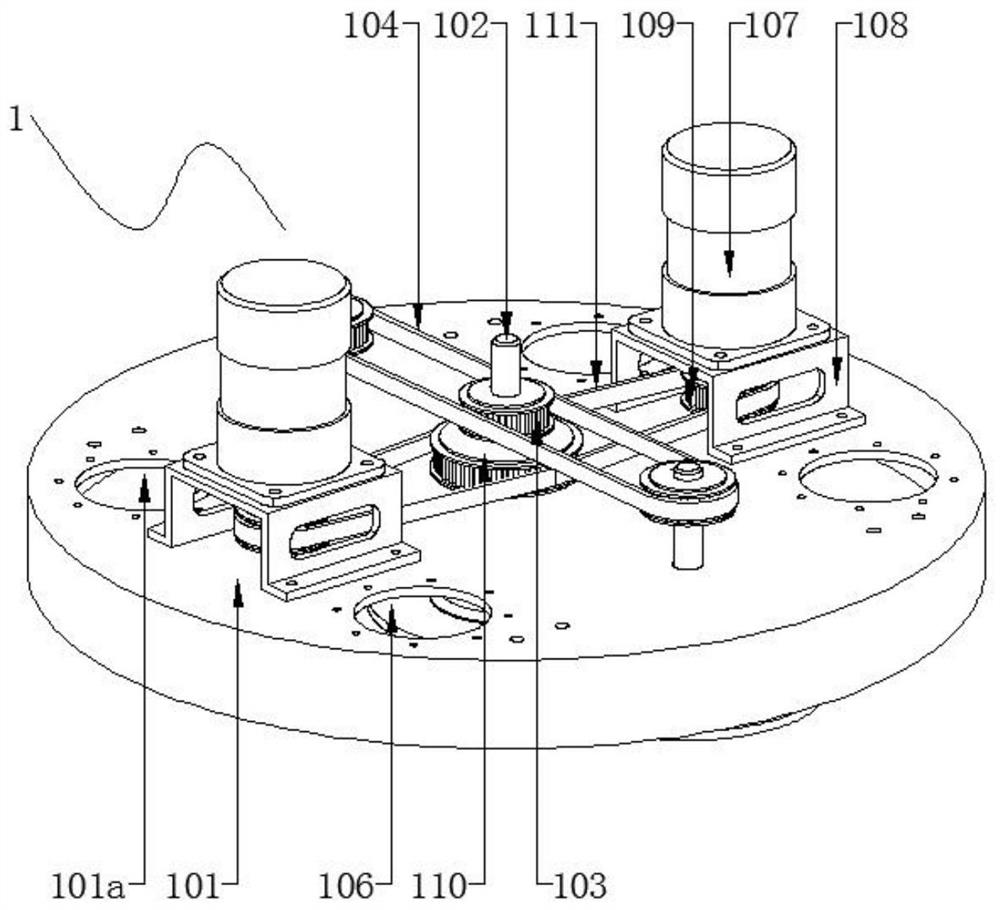

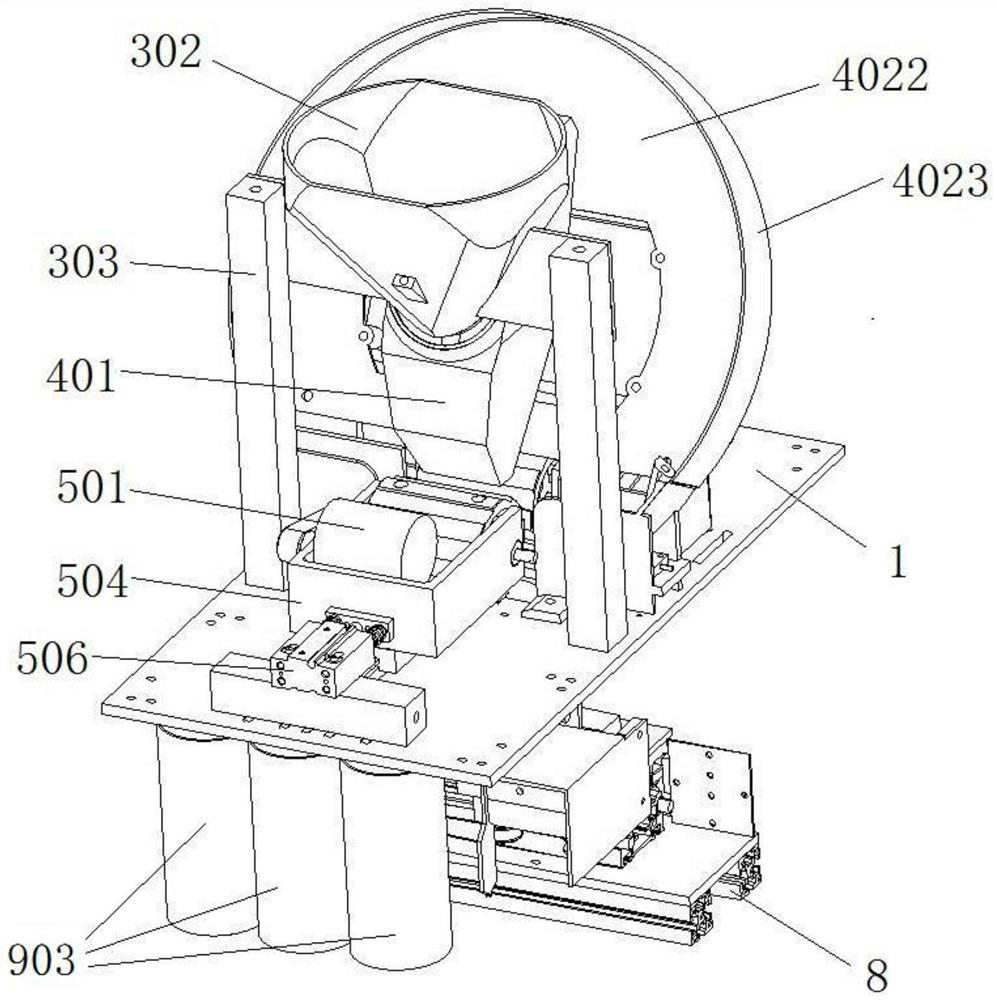

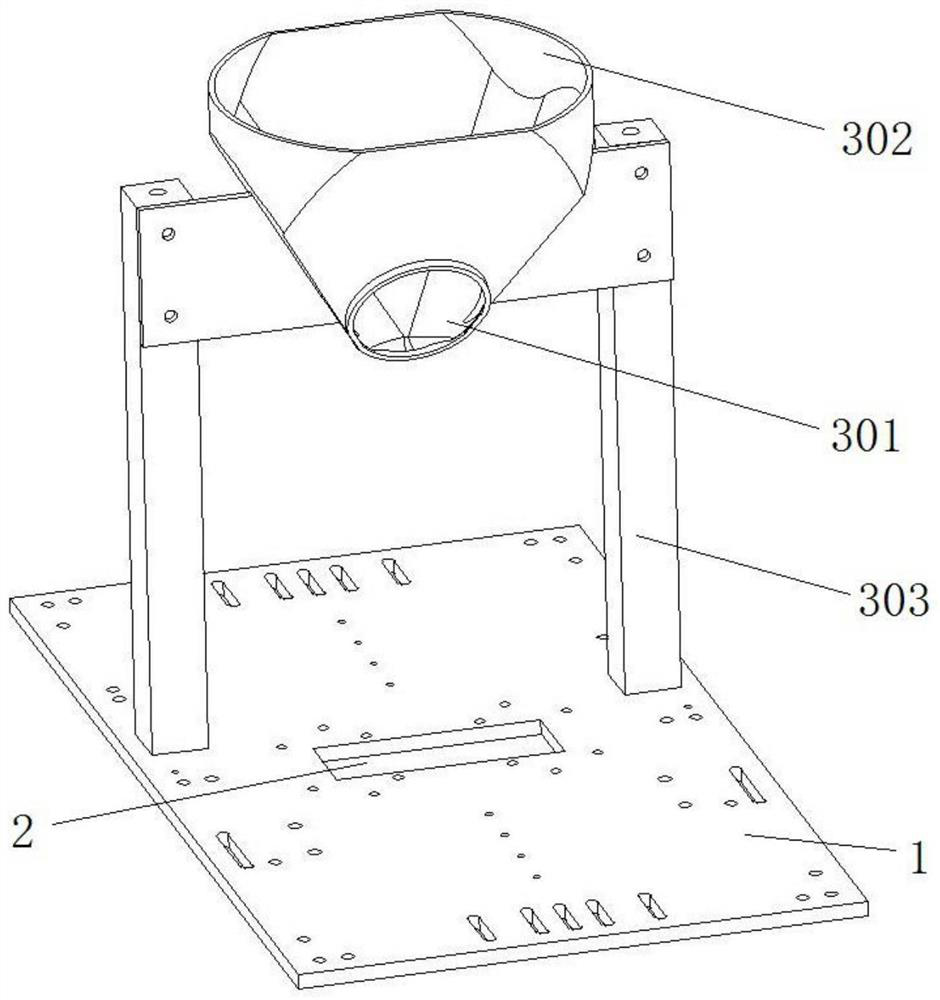

Automatic feeding and roughening device for composite board processing

ActiveCN111070394ARealize automatic feedingImproved ability to resist sideways movementAuxillary shaping apparatusElectric machineryDrive motor

The invention discloses an automatic feeding and roughening device for composite board processing, and relates to the field of composite board processing. The automatic feeding and roughening device comprises a working table fixed to a base; a driving assembly, a main cutting assembly, a feeding assembly and an assistant cutting assembly are installed on the working table, the assistant cutting assembly is installed on the main cutting assembly and located above the feeding assembly, the driving assembly is in transmission connection with the feeding assembly, and the driving assembly is in linkage connection with the assistant cutting assembly; and the driving assembly comprises a driving motor fixed to the front side of the working table. According to the scheme, main roughening groovesand assistant roughening grooves formed after roughening are perpendicular to each other to form zigzag roughening grooves, which is beneficial to enhancing the attachment effect in subsequent composite board processing, so that the lateral sway resistance of boards is high, and the boards are composited more firmly; and besides, processing of the roughening grooves is automatically completed, manual roughening processing is not needed, the roughening forming effect is good, and the roughening efficiency is high.

Owner:湖州互融新材料科技有限公司

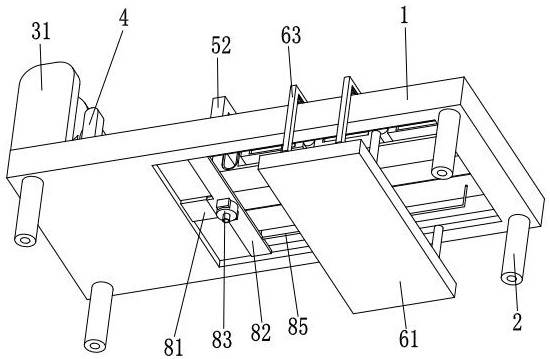

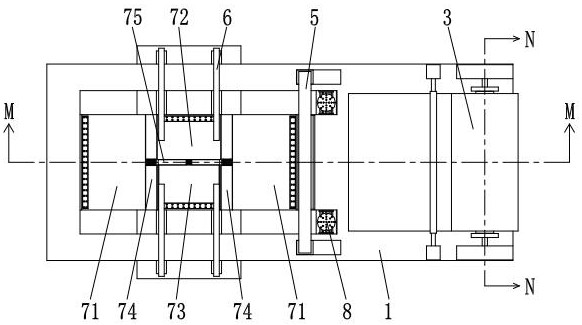

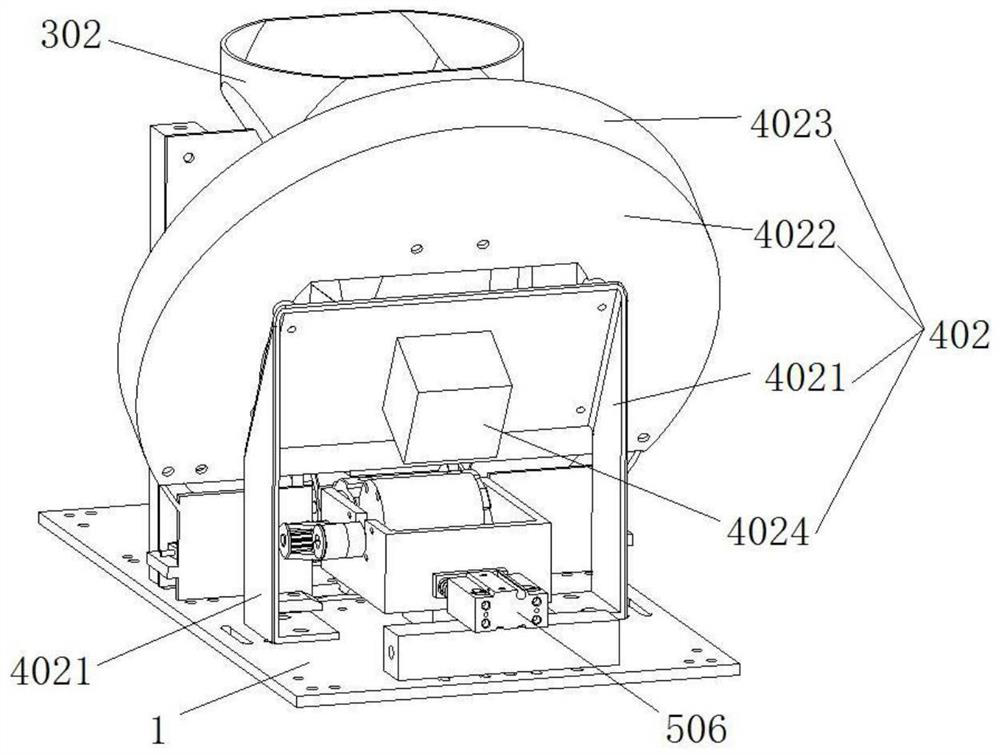

Galling equipment for composite plate machining

The invention discloses galling equipment for composite plate machining, and relates to the field of galling devices. The galling equipment comprises an installing frame. The installing frame is provided with a feeding assembly, a power assembly, a linkage assembly and a galling assembly, the linkage assembly is located above the power assembly, and the galling assembly is located above the feeding assembly and is in linkage connection with the linkage assembly. The installing frame comprises two vertical supporting plates fixed to the base, a top plate is fixed between the upper ends of the two supporting plates, and a vertical rectangular sliding groove is formed in the upper end of the supporting plate located on the right side. The power assembly comprises a drive motor fixed to the corresponding supporting plate, and an incomplete gear is fixed to the output end of the drive motor. According to the scheme, continuous galling work can be automatically conducted, the galling efficiency is high, a galling groove is in a trapezoid shape after galling, the adhesion force of a bonding layer can be enhanced after composite plate machining, the fixing effect is good after composite plate compounding, and lateral movement is not likely to happen.

Owner:江苏杰辉新材料有限公司

Cable installation safety protection structure for power transmission tower and use method of cable installation safety protection structure

ActiveCN109936103AImprove stabilityEasy to fixAdjusting/maintaining mechanical tensionDrive wheelElectricity delivery

The invention discloses a cable installation safety protection structure for a power transmission tower. The structure comprises a transverse plate, a wiring cavity and a rack. A fixed plate is horizontally mounted at the top of the transverse plate; a first driving wheel and a second driving wheel are rotationally mounted at the two ends of the fixed plate correspondingly; the bottoms of the first driving wheel and the second driving wheel are rotationally connected with a first motor, and the first motor is fixedly connected with the fixed plate; a vertical rod is longitudinally and rotationally installed at the end, close to the second driving wheel, of the fixed plate; a second driven wheel is horizontally installed at the bottom of the vertical rod, and two first driven wheels are sequentially and horizontally installed at the top of the vertical rod. After the cable is stretched, external ice blocks can be conveniently removed, and the tension of a cable can be increased. In windy weather, the tension of the cable is improved, so the cable can be prevented from being blown and shaken by wind, the safety of the cable is improved, and the cable is prevented from being broken. Ice and snow outside the cable in rainy and snowy days can be timely and comprehensively removed, and the cable can maintain normal work and is not easy to damage.

Owner:常州亚盾测控技术有限公司

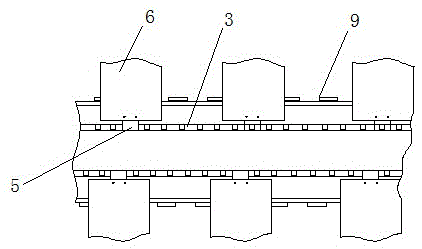

Protective automatic filter press plate dragging mechanism

InactiveCN103007598AImprove pulling efficiencyFewer raisesFiltration separationLubricationManipulator

The invention belongs to the technical field of automatic plate dragging of a filter press, and in particular discloses a protective automatic filter press plate dragging mechanism. The mechanism structurally comprises a plate dragging trolley track and a plate dragging trolley, wherein the plate dragging trolley can slide in the track; the cross section of the plate dragging trolley track is in a rectangular structure; an opening is formed in the left or right side wall of the track; a connecting arm connected with the plate dragging trolley stretches out from the opening and is fixedly connected with plate dragging manipulators installed above plate dragging trolley wheels in the track; and the front and rear ends of the plate dragging trolley are connected through chains so as to be dragged in a reciprocation movement manner. When the protective automatic filter press plate dragging mechanism is used, the defects of easiness in pollution and difficulty in lubrication are overcome, the cleaning of the inner chamber of the track is facilitated, the traction chains are better lubricated, and the dragging efficiency of an automatic plate dragging machine to filtering plates is improved.

Owner:HENGSHUI HAIJIANG FILTER PRESS GRP

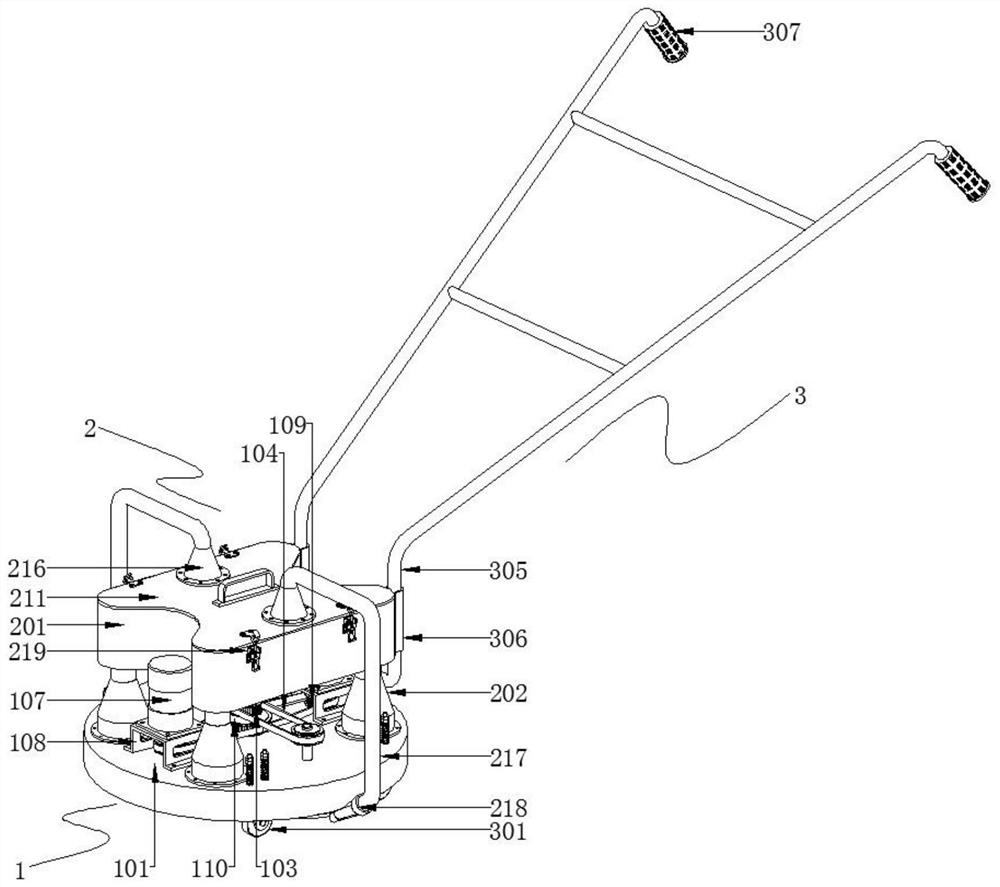

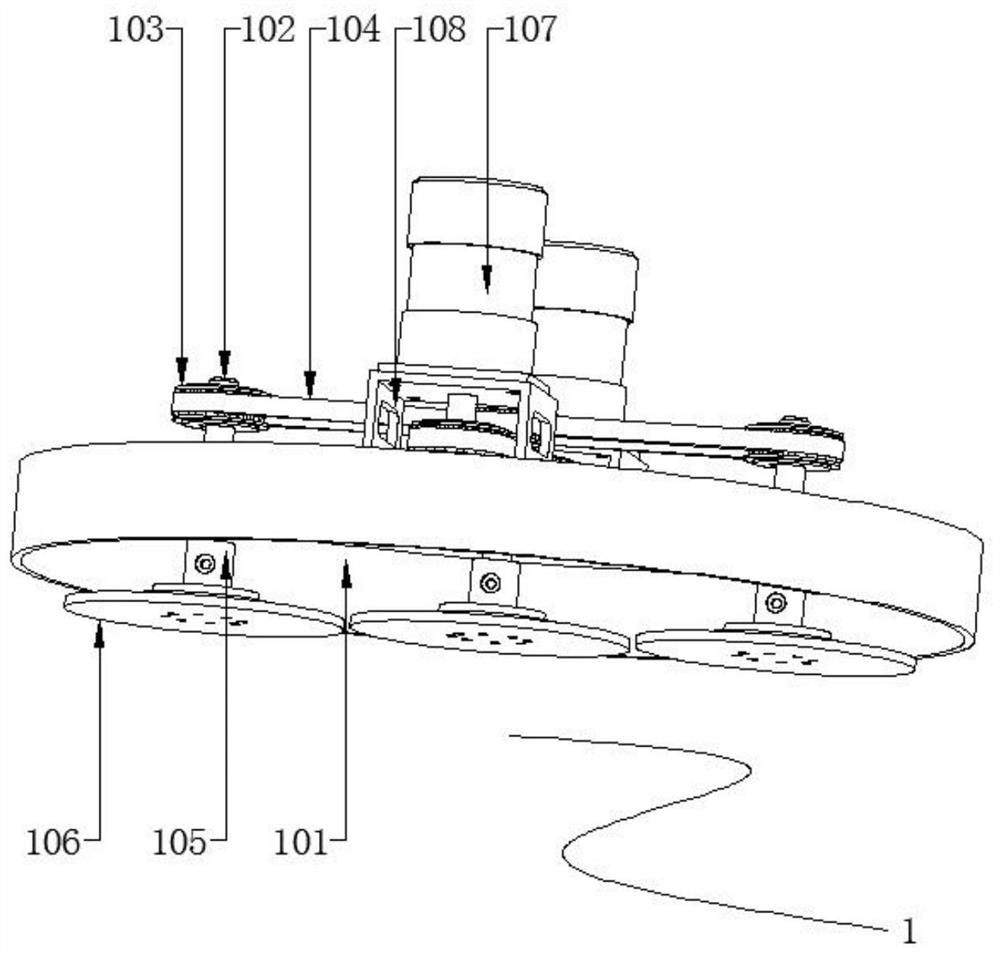

Napping device with dust removal function for steel structure coating

ActiveCN111604781AWith dust removal functionMobile made easyGrinding machinesGrinding/polishing safety devicesDust controlElectric machinery

The invention discloses a napping device with a dust removal function for steel structure coating, and relates to the technical field of steel structure coating. The napping device comprises a nappingassembly, a dust removal assembly and a moving assembly; the napping assembly is used for napping the surface of an object in contact with the napping assembly; the dust removal assembly is arrangedabove the napping assembly and is used for sucking and removing dust and chippings generated during napping operation of the napping assembly; and the moving assembly is arranged below the napping assembly and used for achieving movement of the napping assembly during non-napping operation. According to the napping device, movement can be achieved through moving wheels and pushing rods; a drivingmotor drives a napping disc to rotate through belt transmission, and the napping disc rotates to perform napping operation on the surface of an object in contact with the napping disc; and through driving dust collection fan blades to rotate, the dust collection fan blades rotate to suck dust and chippings below a mounting cover into a dust collection box. Therefore, the napping device with the dust removal function has the characteristics of being good in portability, high in napping efficiency and good in dust removal effect.

Owner:NANTONG INST OF TECH

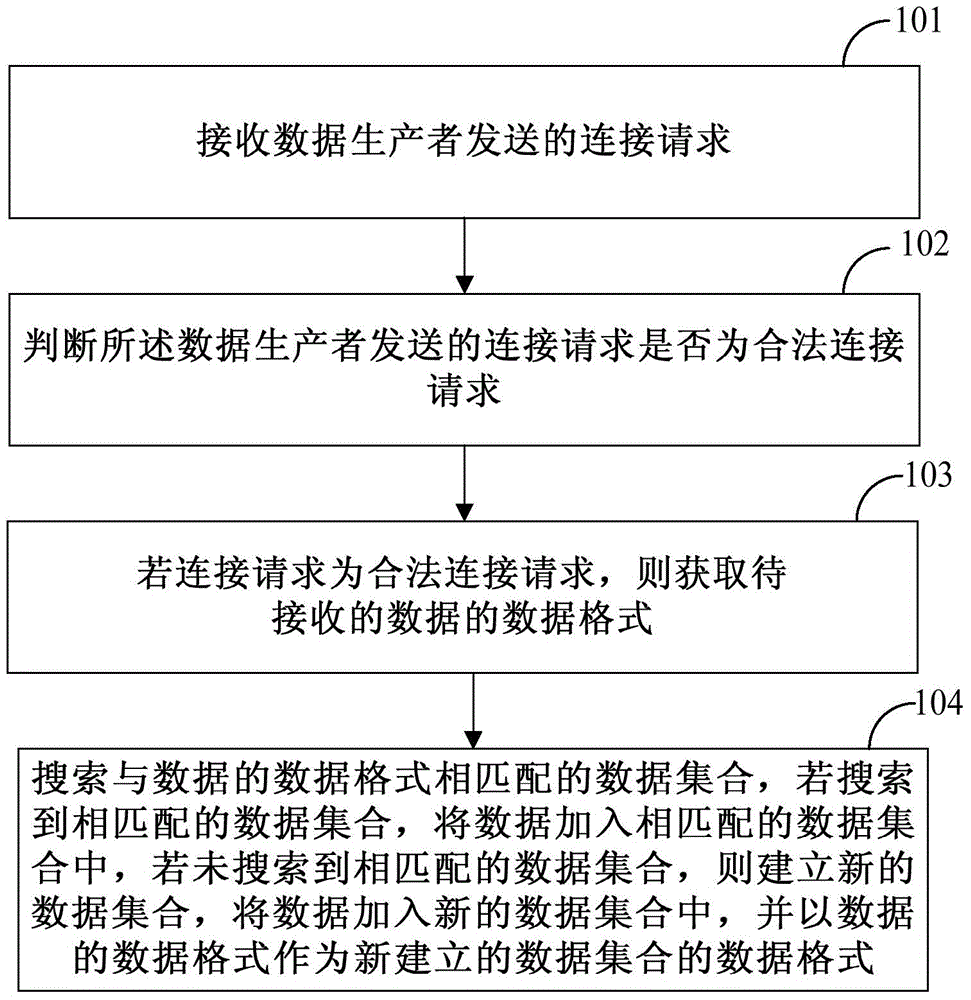

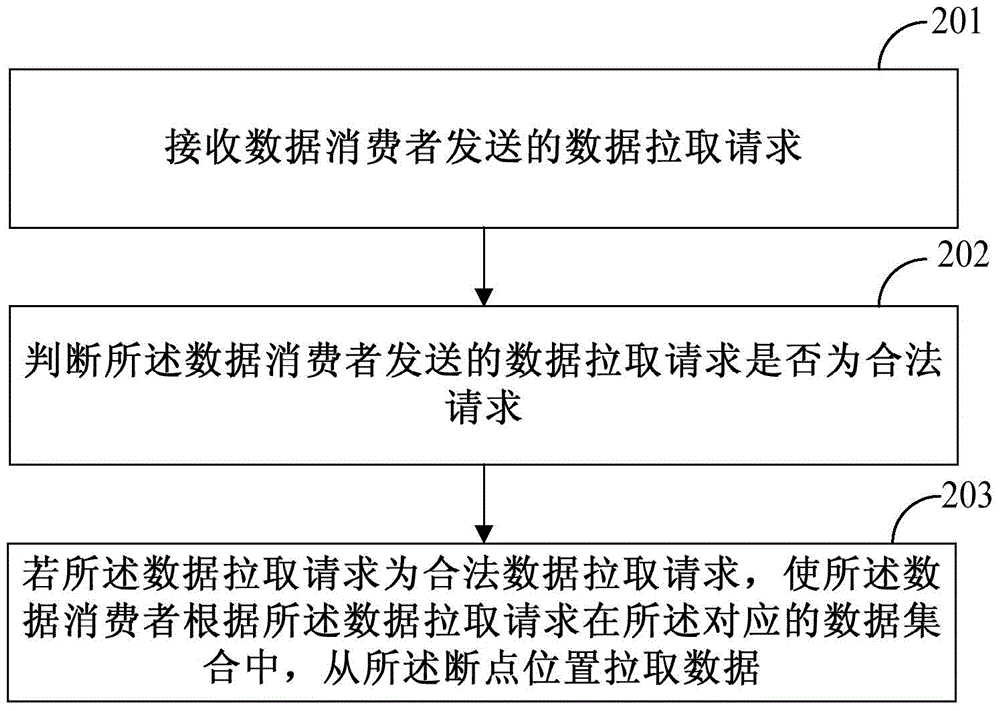

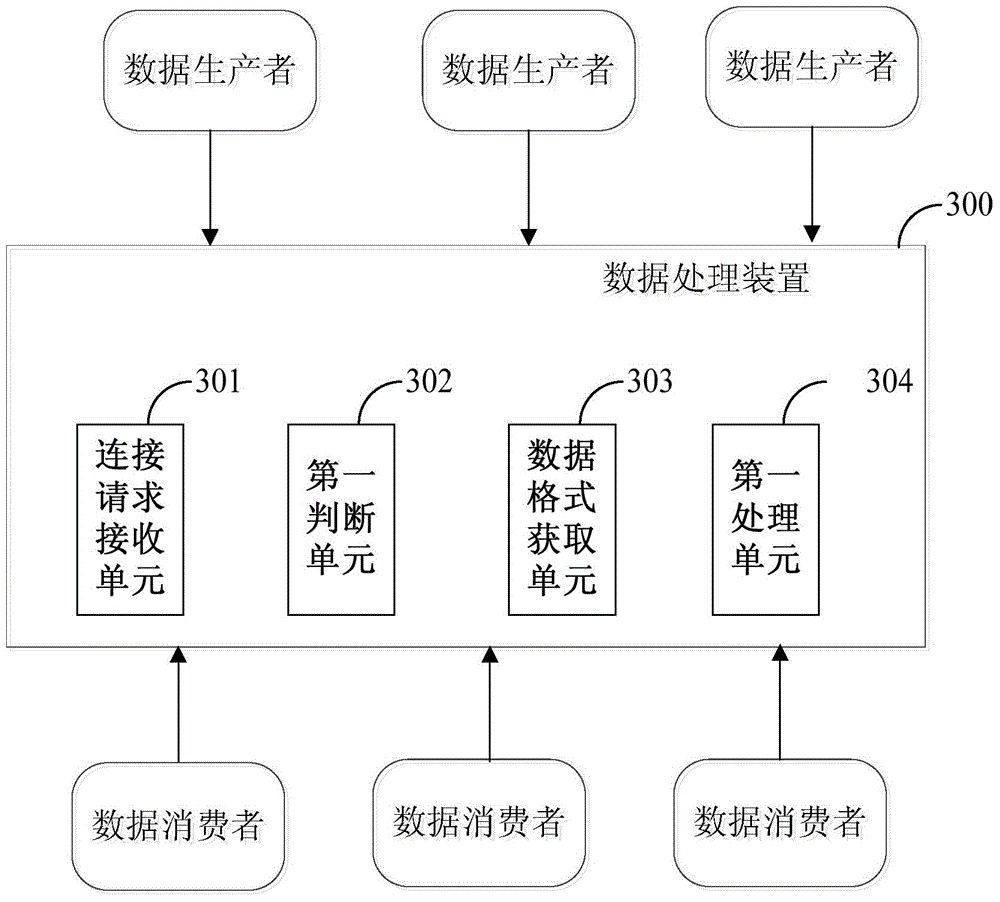

Data processing method and device

The embodiments of the invention disclose a data processing method and device. The processing method includes: receiving a connection request sent by a data producer; judging whether the connection request sent by the data producer is a legal connection request or not; if the connection request is legal, obtaining the format of data to be received; searching for a data set matching the format of the data to be received, and if a matched data set is obtained, adding the data to be received to the matched data set, and if no matched data set is obtained, establishing a new data set, adding the data to be received to this new data set and using the format of the data as the data format of the new data set. The method can improve the big data processing efficiency with high security.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD +1

Pneumatic apparatus on vehicle socket sleeve fabric napping machine

The invention provides a pneumatic apparatus on a vehicle socket sleeve fabric napping machine, and belongs to the technical field of textile. In the prior art, the existing napping machine has the low efficiency so as to easily cause damage on cloths and the like. A purpose of the present invention is to solve the technical problems in the prior art. According to the pneumatic apparatus, a plurality of napping needles are uniformly arranged on napping drums, guide sleeves are provided with a plurality of guide grooves arranged on the circumferential surfaces of the guide sleeves, the guide grooves are corrugated, the guide sleeves are fixedly connected to a main drum, the napping needles are arranged in the guide grooves, ventilation cavities are arranged in the napping drums, a rotationshaft is arranged in the ventilation cavity, and is provided with a blade wheel, the blade wheel is connected to the interior of the napping drum, the rotation shaft is rotatably to the main drum, a transmission shaft is provided with a gas flow inlet, the main drum is provided with wind inlet holes corresponding to avoidance ports one by one, and the wind inlet holes are communicated to the gas flow inlet, and are communicated to the corresponding ventilation cavities. The pneumatic apparatus of the present invention has advantages of high napping efficiency, fabric protection and the like.

Owner:求法问律(菏泽)法律咨询服务有限公司

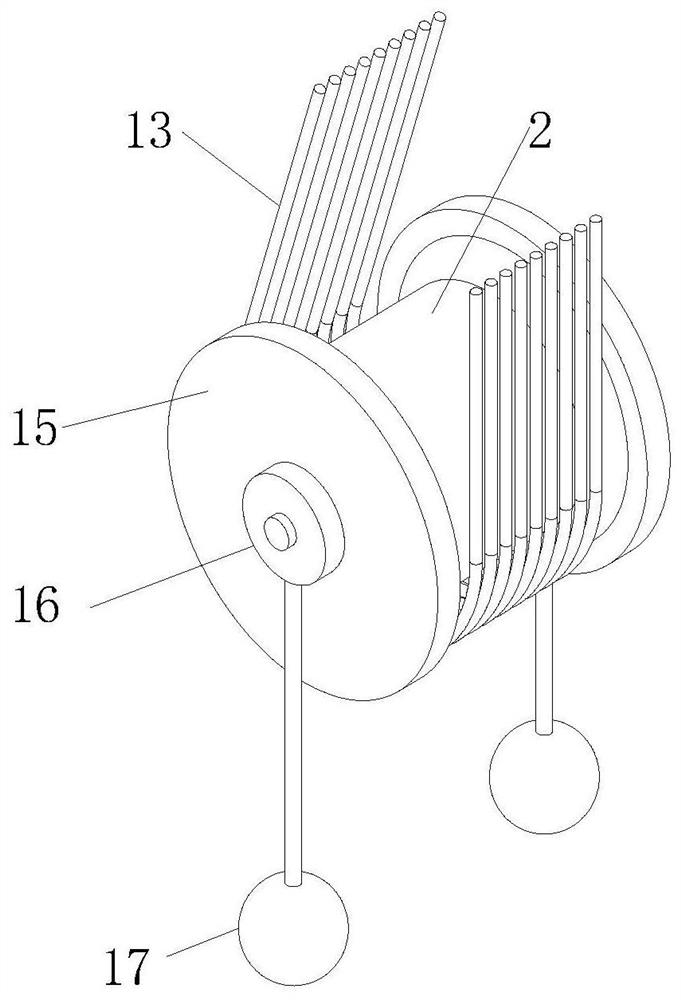

Switch cabinet for electrical engineering

PendingCN113394703AGuaranteed uptimeAvoid knotsBus-bar/wiring layoutsSwitchgear with horizontal withdrawalClassical mechanicsElectric power equipment

The invention belongs to the technical field of power equipment, and particularly relates to a switch cabinet for electrical engineering, which comprises a cabinet body and a drawer cabinet, the drawer cabinet is slidably connected to a sliding rail in an open groove in one side of the cabinet body, the tail of the drawer cabinet is connected with a group of flexible wire rows, the wire rows naturally droop and are folded to be electrically connected with the cabinet body, guide wheels are rotatably connected to the positions, corresponding to the wire rows, in the cabinet body, and the guide wheels are arranged below the wire rows. A counterweight wheel is arranged at the tops of the wire rows between the guide wheels and the cabinet body, and the counterweight wheel is in rolling connection with the wire rows; and shaft sleeves are rotationally connected to the two sides of the balance weight wheel and fixedly connected with balance weight balls through pull rods. The guide wheels are used for carding and supporting the wire rows, and the counter weight wheel and the counter weight ball are matched for downward constant pulling force on the wire rows, so that the wire rows are tidily and orderly bent and straightened during winding and unwinding, and knotting and winding between the wire rows are avoided.

Owner:北京建企动力科技工程有限公司

Layout galling mechanism of autoclaved aerated concrete slab

PendingCN113715141APull fastImprove cleaning efficiencyAuxillary shaping apparatusAutoclaved aerated concreteStructural engineering

The invention discloses a layout galling mechanism of an autoclaved aerated concrete slab, and relates to the technical field of autoclaved aerated concrete slabs. The layout galling mechanism comprises a supporting base. According to the layout galling mechanism of the autoclaved aerated concrete slab, a supporting plate is pulled out of the top of the supporting base, a baffle and a clamping frame are rotated, the autoclaved aerated concrete slab is placed on the top of the supporting plate, then the baffle and the clamping frame are clamped outside the autoclaved aerated concrete slab, and the clamping frame and the baffle are fixed together by rotating bolts on the front side and the rear side of the baffle, the autoclaved aerated concrete slab is clamped inside the clamping frame, a push rod is rotated, an extrusion plate moves inside the clamping frame, and the autoclaved aerated concrete slab is tightly clamped inside the clamping frame, so that galling of the autoclaved aerated concrete slab is quickly conducted conveniently, a fan is started, and galling chippings at the top of the autoclaved aerated concrete slab are blown into a storage bag by the fan, so that the clearing efficiency of galling equipment for the autoclaved aerated concrete slab is improved.

Owner:江苏宝鹏建筑工业化材料有限公司

Aluminum profile drawing device

The invention discloses an aluminum profile drawing device. The aluminum profile drawing device comprises a machine frame, a conveyor belt, a driving roll, a driven roll, a driving roll driving device and chucks, wherein the conveyor belt is an annular conveyor belt; the conveyor belt sleeves the driving roll and the driven roll; the driving roll driving device is connected with the driving roll; two chucks are provided, and are mounted at the two ends of the conveyor belt respectively; each chuck comprises two electromagnets and an electromagnet fixing seat; the electromagnets are fixed inside the electromagnet fixing seat; the electromagnet fixing seats are mounted on the two sides of the conveyor belt though sliding rails; the sliding rails are vertically laid on the conveyor belt. The aluminum profile drawing device eliminates potential safety hazards, and greatly improves the drawing efficiency.

Owner:湖州华利铝业有限公司

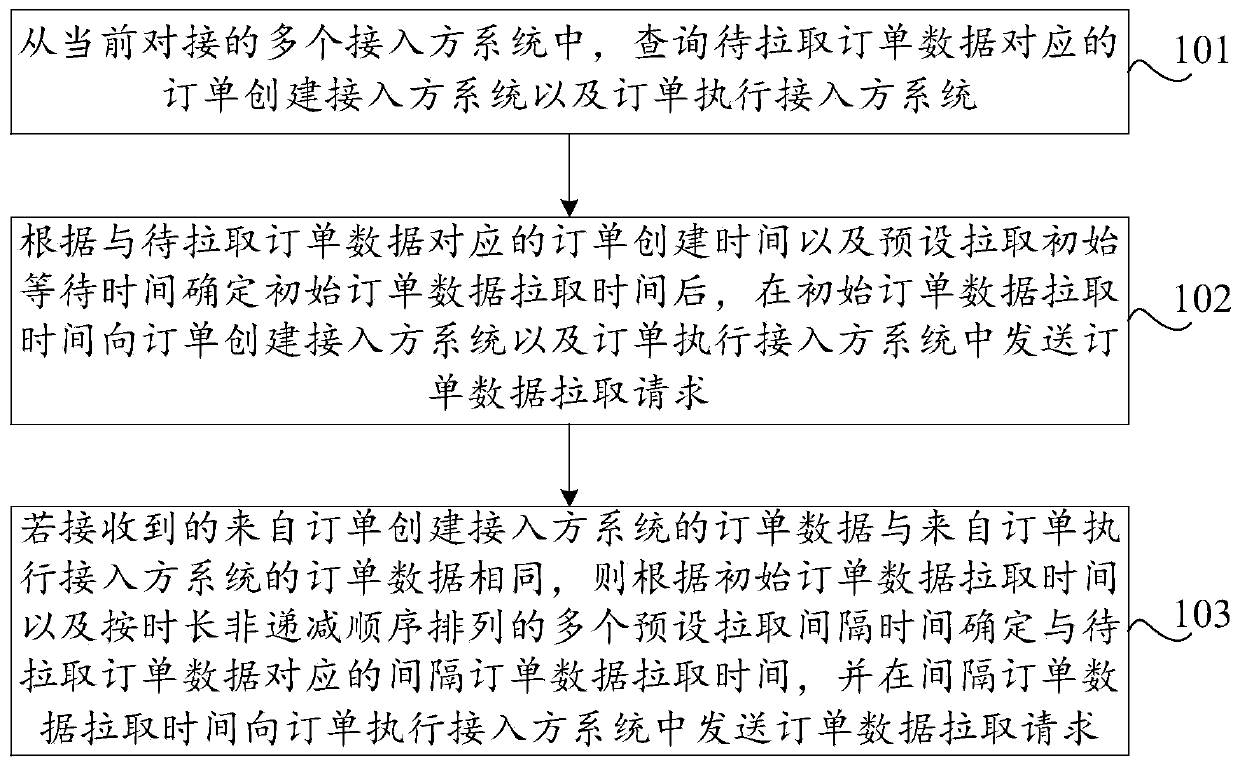

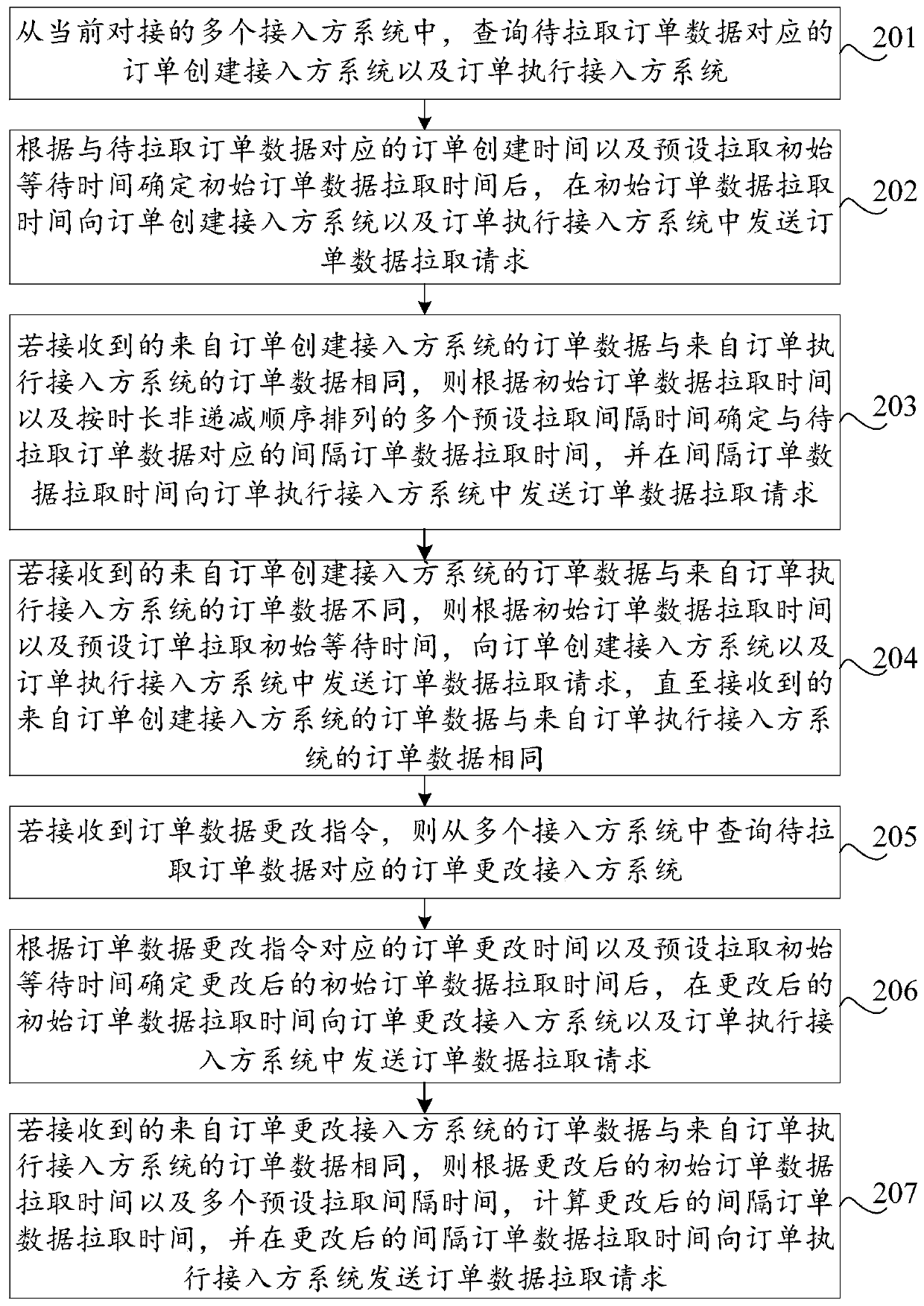

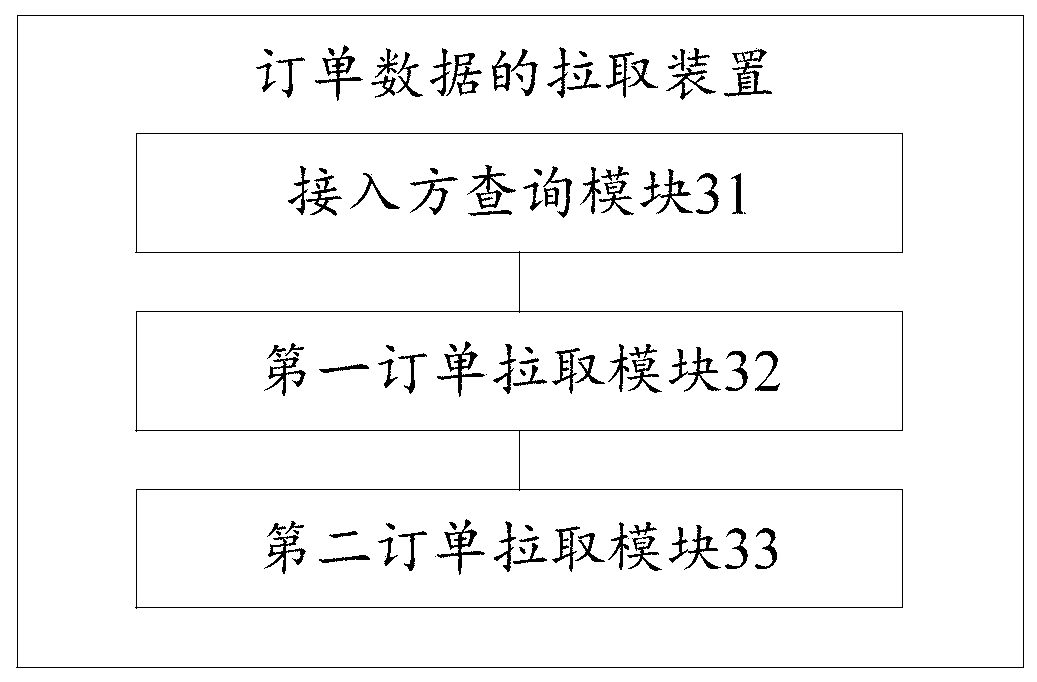

Order data pulling method and device, storage medium and computer device

ActiveCN110443674AImprove pulling efficiencyAvoid the problem of excessive resource consumptionBuying/selling/leasing transactionsTransmissionOrder formComputer science

The invention discloses an order data pulling method and device, a storage medium and a computer device. The method comprises the steps of querying an order creation access party system and an order execution access party system corresponding to to-be-pulled order data; determining initial order data pulling time according to order creation time corresponding to the to-be-pulled order data and preset pulling initial waiting time, and sending an order data pulling request to an order creation access party system and an order execution access party system at the initial order data pulling time;if the received order data from the order creation access party system is the same as the order data from the order execution access party system, sending the order data to the server, determining interval order data pulling time corresponding to the to-be-pulled order data according to the initial order data pulling time and a plurality of preset pulling interval time arranged according to a duration non-decreasing sequence, and sending an order data pulling request to an order execution access party system at the interval order data pulling time.

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

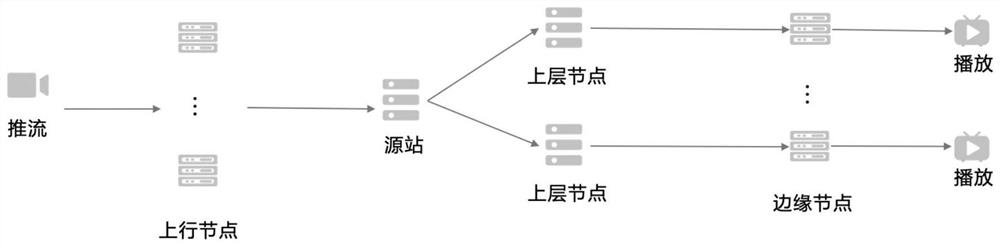

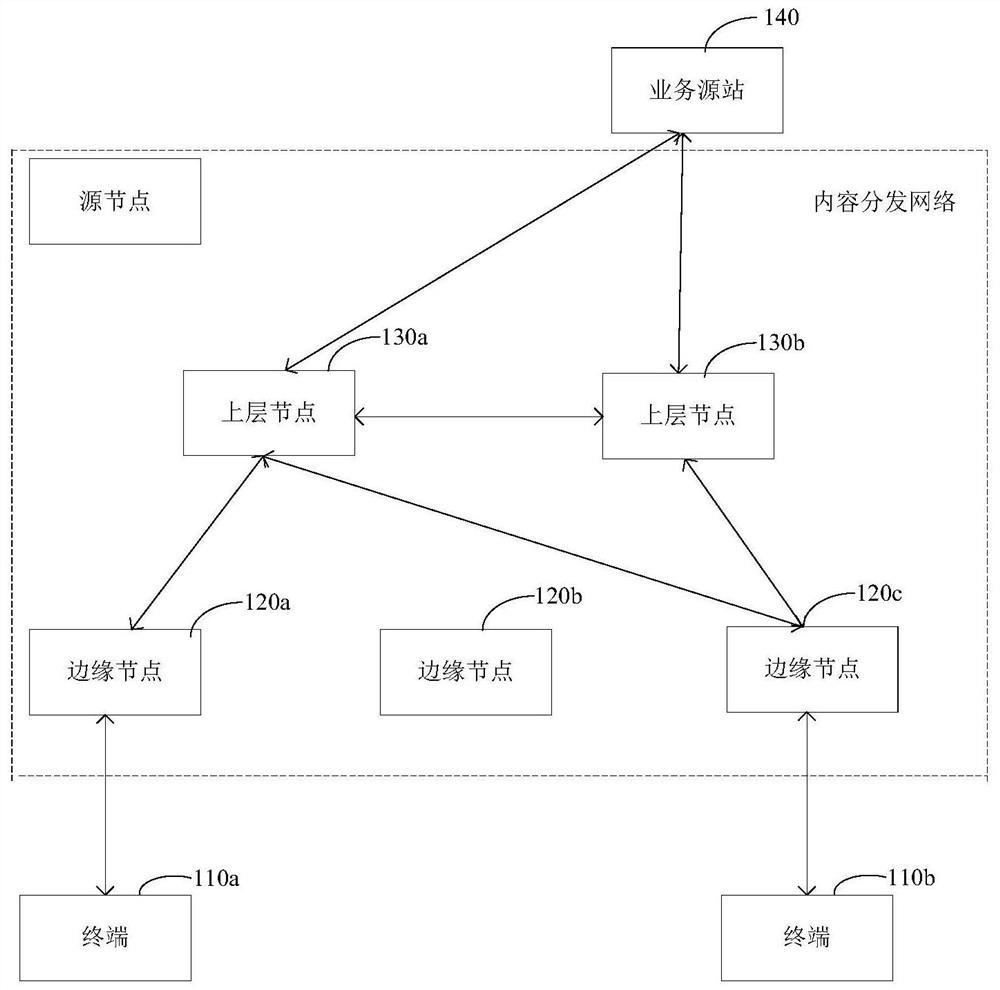

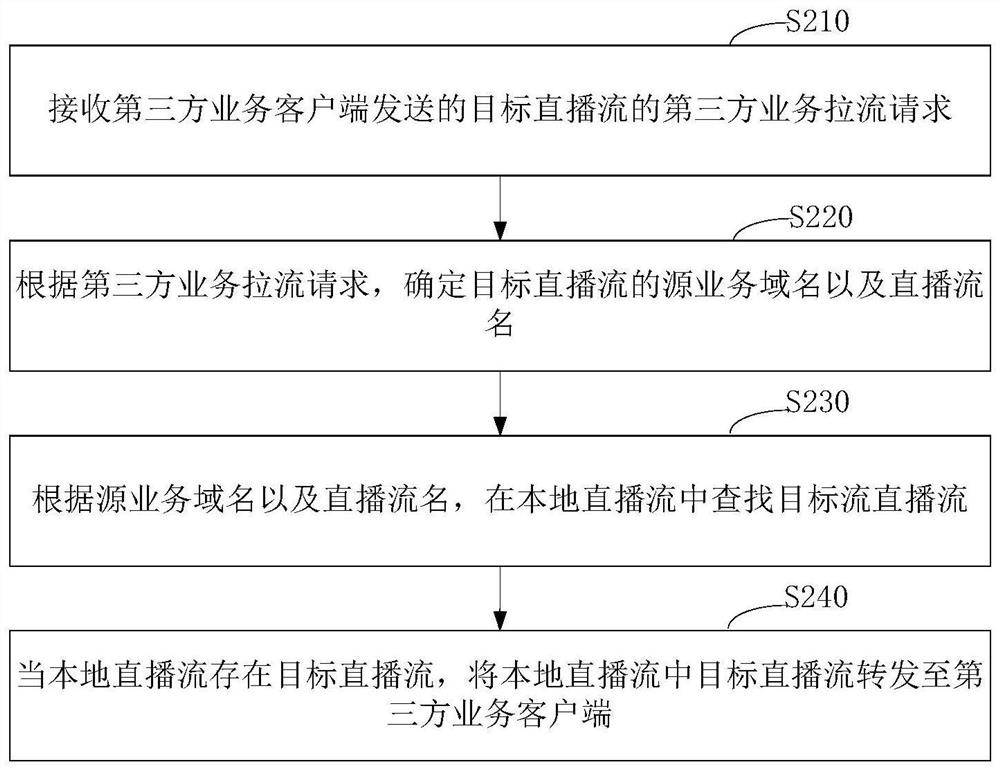

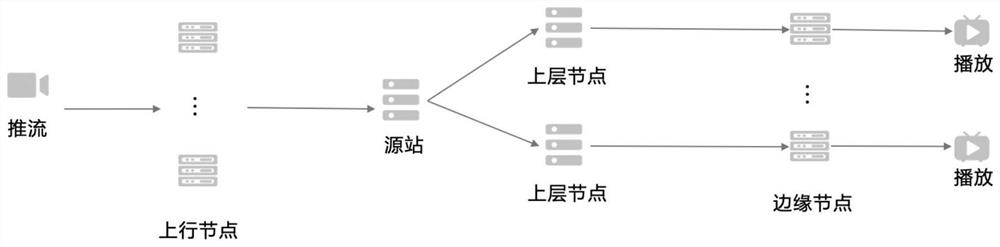

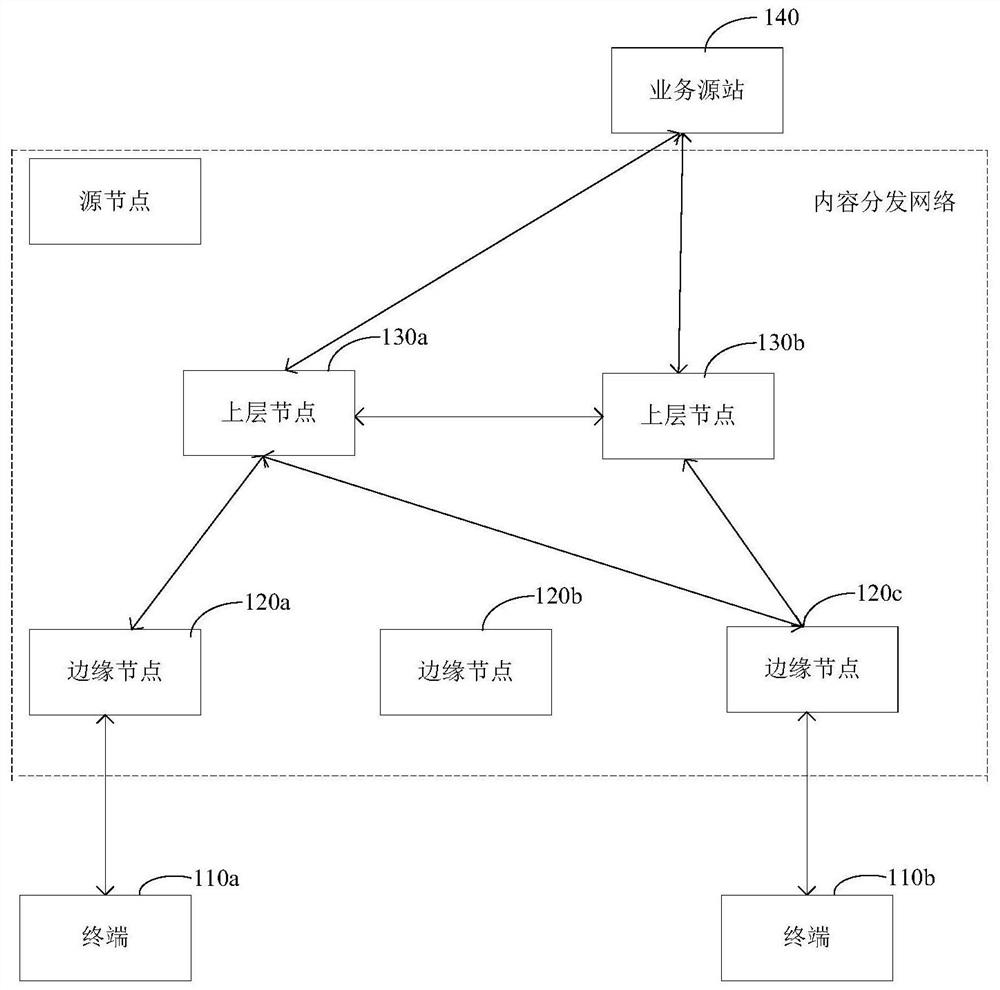

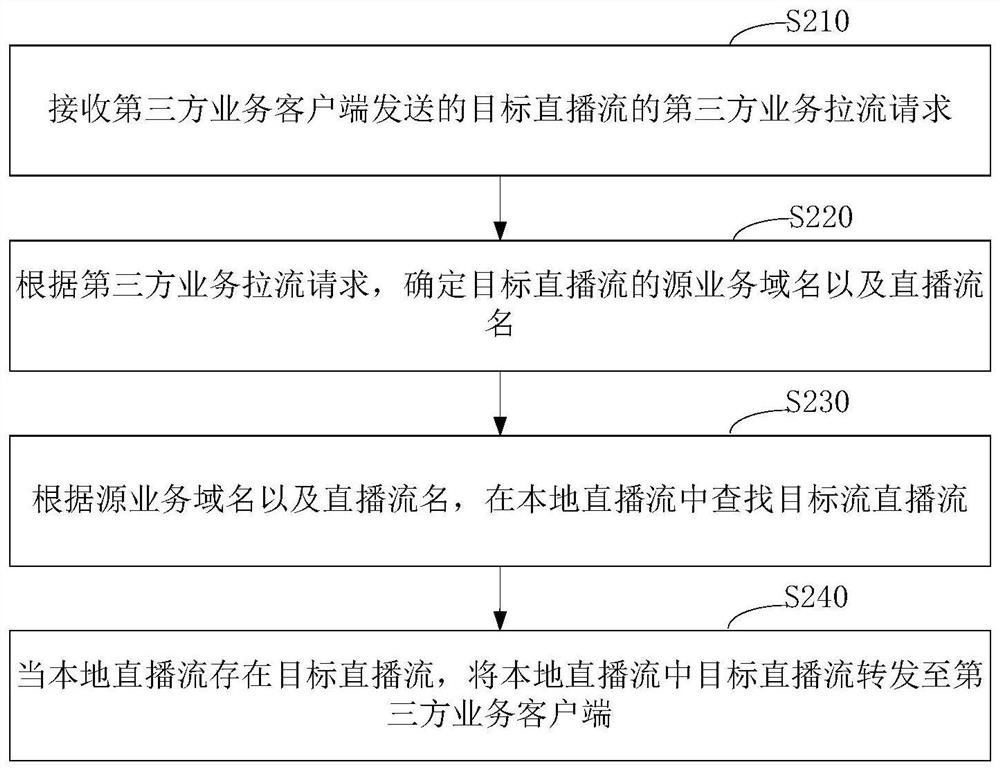

Live streaming stream pulling method and device, electronic equipment and storage medium

ActiveCN113141513AReduce streaming timeImprove pulling efficiencySelective content distributionTransmissionContent distributionDomain name

The invention relates to a live streaming stream pulling method and device, electronic equipment and a storage medium, and the method comprises the steps: receiving a third-party service pulling stream request of a target live streaming stream sent by a third-party service client, determining a source service domain name and a live streaming stream name of the target live streaming stream according to the third-party service pulling stream request, and sending the source service domain name and the live streaming stream name to a server; according to the source service domain name and the live streaming stream name, searching a target live streaming stream in the local live streaming streams, and when the target live streaming stream exists in the local live streaming streams, forwarding the pulled target live streaming stream to a third-party service client. According to the invention, when the third-party service platform adds the live streaming service, the live streaming stream produced by the source service platform does not need to be stored in the source station of the third-party service platform and shared with the source service platform, so the live streaming stream does not need to be produced; the live stream in the live stream source station of the source service platform pulled by the edge node of the content distribution network is directly obtained, the existing live stream of the source service platform is multiplexed, the live stream pulling time is shortened, and the stream pulling efficiency is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

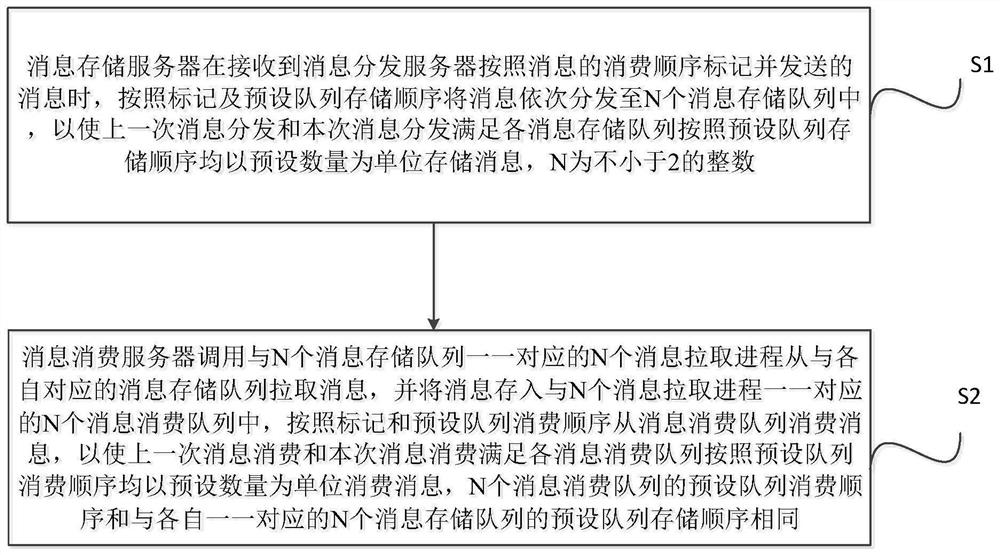

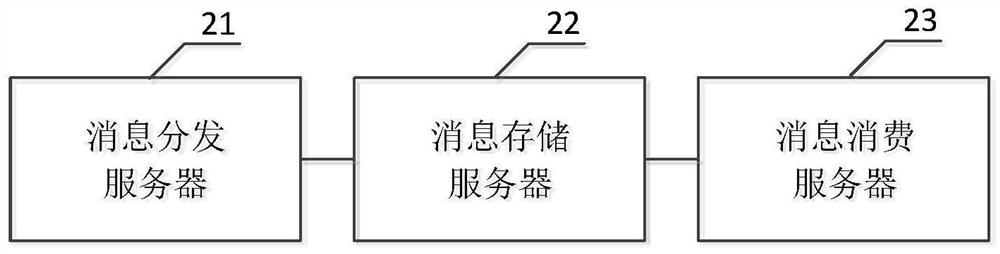

Message consumption method and message system

PendingCN114356609AGuaranteed orderImprove pulling efficiencyInterprogram communicationEngineeringThroughput

The invention discloses a message consumption method and a message system, and the method comprises the steps: setting N message storage queues and message consumption queues in one-to-one correspondence at a message consumption server and a message storage server respectively, storing the messages in a message storage queue according to a preset queue storage sequence and the marks of the messages by the message distribution server, and consuming the messages from a message consumption queue according to a preset queue consumption sequence and the marks of the messages by the message distribution server, therefore, the last message consumption and the current message consumption meet the requirement that the message consumption queues consume the messages according to the preset queue consumption sequence by taking the preset number as the unit, and the sequential performance when the messages are consumed is ensured. In addition, N message pulling processes are set in the message consumption server and pull the messages from the message storage server at the same time, so that compared with a single message pulling process, the message pulling efficiency and the message consumption efficiency and the message throughput in a high-concurrency scene are improved.

Owner:政采云有限公司

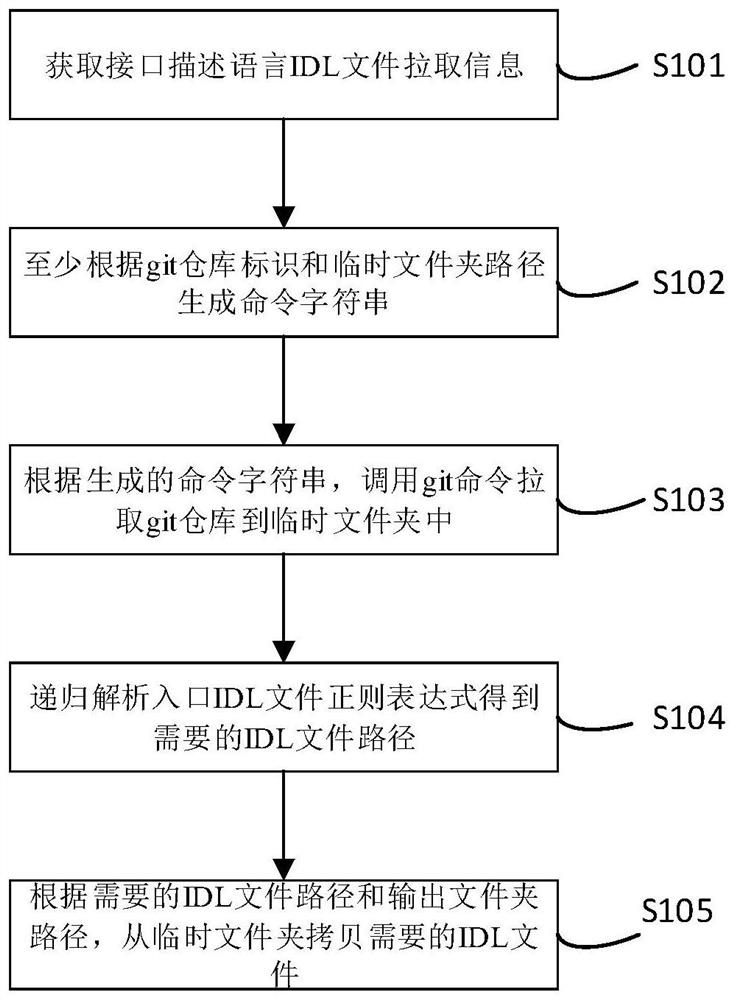

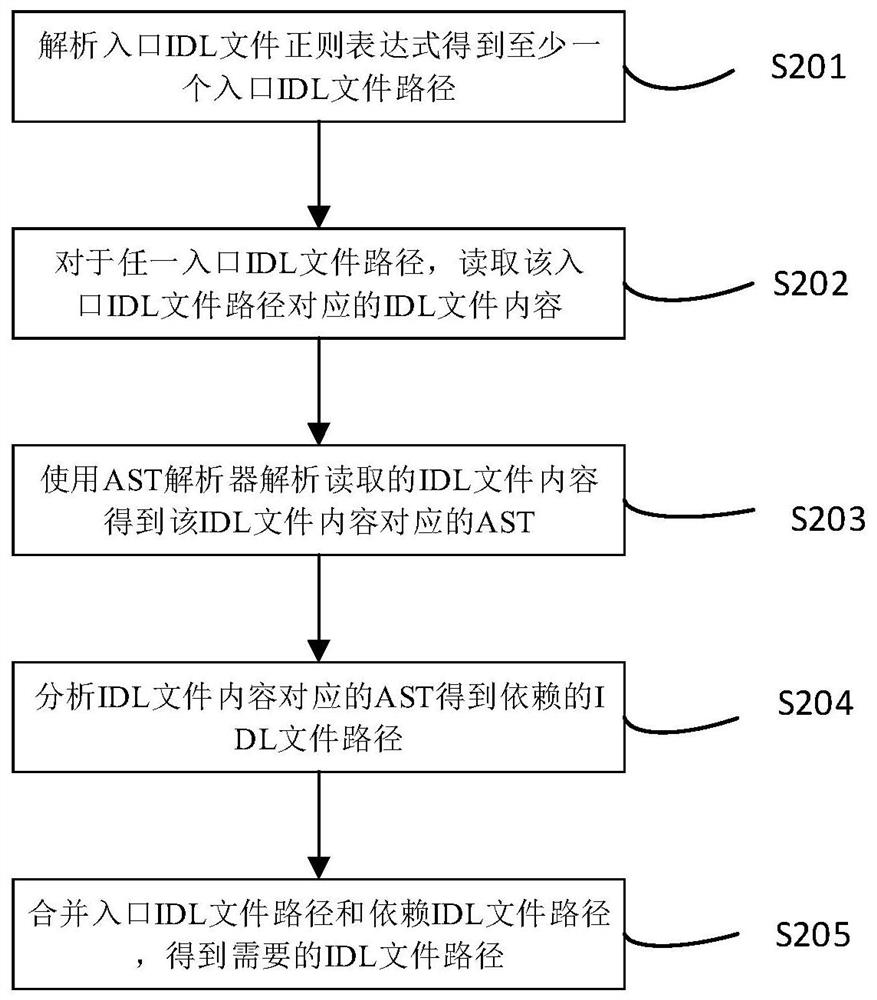

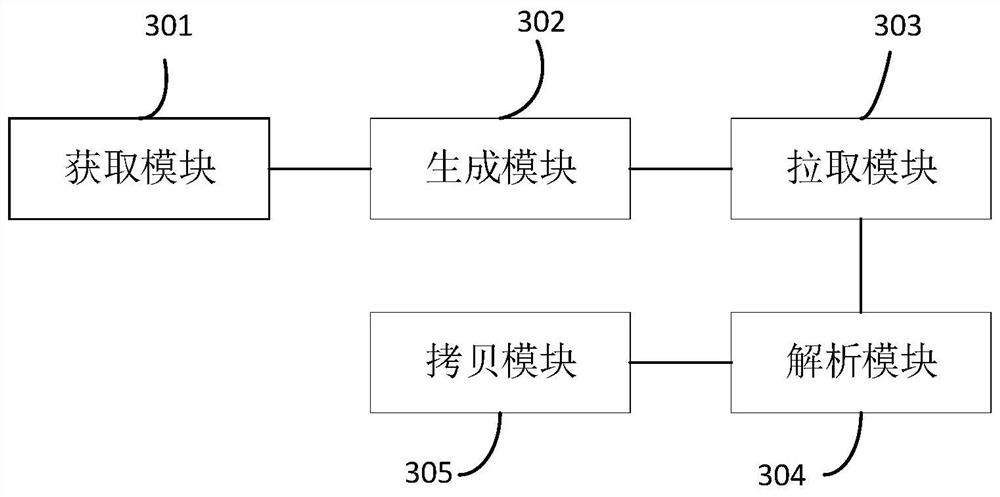

IDL file pulling method and device, computer equipment and storage medium

PendingCN111949309AShorten the timeImprove pulling efficiencyVersion controlExecution paradigmsPathPingControl system

The invention provides an IDL file pulling method and device, computer equipment and a storage medium, and the method comprises the steps: obtaining IDL file pulling information which at least comprises a distributed version control system git warehouse identification, an entry IDL file regular expression and an output folder path; generating a command character string at least according to the git warehouse identifier and a temporary folder path, the temporary folder being pre-created; according to the generated command character string, calling a git command to pull a git warehouse into a temporary folder; recursively analyzing the regular expression of the entry IDL file to obtain a required IDL file path; and copying the required IDL file from the temporary folder according to the required IDL file path and the output folder path. According to the embodiment of the invention, the IDL file is pulled as required, and the IDL file pulling efficiency is improved.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Streaming method, device, electronic equipment and storage medium for live streaming

ActiveCN113141513BReduce streaming timeImprove pulling efficiencySelective content distributionTransmissionThird partyEdge node

The present disclosure relates to a method, device, electronic device and storage medium for pulling live streams. The method includes: receiving a third-party service pull request for a target live stream sent by a third-party business client, and according to the third-party service pull request , determine the source business domain name and live stream name of the target live stream, and search the target live stream in the local live stream according to the source business domain name and live stream name. The stream is forwarded to a third-party business client. This disclosure realizes that when a third-party business platform adds a live broadcast service, there is no need to save the live stream produced by the source business platform to the source station of the third-party business platform, share the live stream with the source business platform, and directly obtain the content without producing the live stream The edge node of the distribution network pulls the live stream of the source service platform from the source station, and reuses the existing live stream of the source service platform to reduce the duration of the live stream and improve the efficiency of the stream.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

Dispersive copper alloy drawing process

ActiveCN111957755ANot brittleHigh tensile strengthExtrusion cleaning devicesAC - Alternating currentGraphite

The invention discloses a dispersive copper alloy drawing process. The dispersive copper alloy drawing process comprises the following step: step 1, substrate softening: placing an alloy body in a cobalt chloride solution firstly, then treating the mixture with alternating current, and then washing the treated mixture with boiling water 1-3 times. According to the drawing process, substrate softening is first performed before drawing, and a substrate is first placed in the cobalt chloride solution and then treated with alternating current, which is aimed to disperse the internal structure of the substrate and enable the substrate to be more easily infiltrated by a wetting agent. Raw materials such as sodium dodecyl polyoxyethylene ether sulfate and triethanolamine of the wetting agent cansoften the internal structure of the substrate, and graphene can enhance the toughness and drawability of the substrate, so that the substrate is easier to be drawn.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Tube Pulling System

ActiveCN103912015BImprove pulling efficiencyAvoid destructionArtificial islandsUnderwater structuresPull forceLap joint

Owner:CCCC FIRST HARBOR ENG +1

Video request method, system, computer device and computer readable storage medium

ActiveCN111510790BImprove pulling efficiencyAvoid wasting timeTransmissionSelective content distributionComputer graphics (images)Server

Owner:SHANGHAI BILIBILI TECH CO LTD

Method, device and mobile terminal for acquiring media stream resources

ActiveCN111479123BSave bandwidthLow costSelective content distributionComputer networkTelecommunications

Owner:玉环智寻信息技术有限公司

A detachable expansion bolt

The invention belongs to the technical field of connection pieces and particularly provides an expansion bolt convenient to disassemble. The expansion bolt convenient to disassemble comprises a firstscrew cap, a first threaded rod and a first nut. The first threaded rod is fixedly installed on the bottom surface of the first screw cap and coaxial with the first screw cap. The first threaded rod is sleeved with the first nut. The bottom surface, far away from the first screw cap, of the first threaded rod is provided with a first through hole extending to the bottom surface of the first screwcap. The upper surface of the first screw cap is provided with second through holes communicating with the first through hole. A locking piece is fixedly installed on the upper surface of the first screw cap. The other end of each steel wire rope penetrates through an installation plate, the first through hole and the corresponding second through hole to be connected with the locking piece. The steel wire ropes are used for tensioning friction blocks to enable the elastic pieces to be compressed and deformed. According to the expansion bolt convenient to disassemble, through the arrangement ofthe friction blocks and the elastic pieces, the first nut is squeezed, so that locking of the bolt is achieved; a first screw is arranged to drive the steel wire ropes to move in the vertical direction so as to enable the bolt to be convenient to disassemble; and the use efficiency of the expansion bolt convenient to disassemble is improved.

Owner:瑞安市宏志钢业有限公司

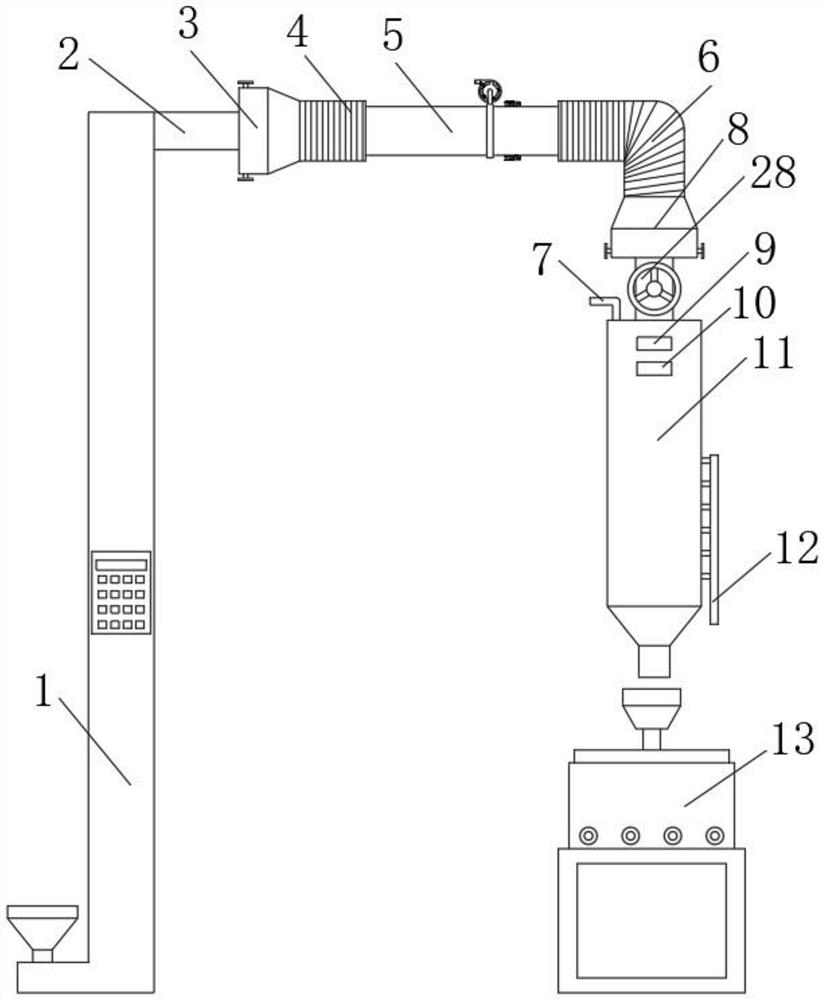

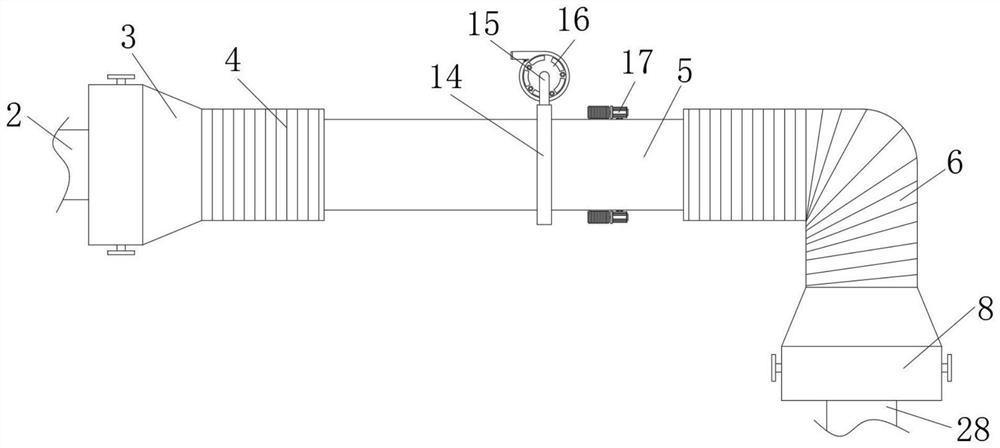

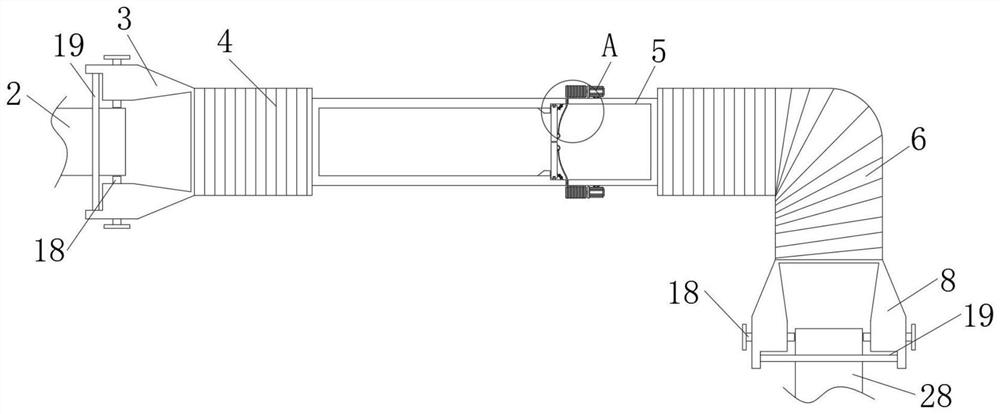

Discharging device of digester for preventing blockage of lifting conveying pipe

ActiveCN113397087APrevent overflowDoes not hinder lifting transportFood shapingStructural engineeringProcess engineering

The invention belongs to the technical field of steam grain tabletting, and discloses a discharging device of a digester for preventing blockage of a lifting conveying pipeline. The discharging device comprises a conveying pipe, the discharging end of the conveying pipe is provided with a digester assembly, the feeding end of the conveying pipe is provided with a feeding assembly, a second connecting assembly is installed between the digester assembly and the conveying pipe, and a first connecting assembly is mounted between the feeding assembly and the conveying pipe. A valve plate is pushed through a spring, one side of the valve plate is blocked through a limiting block, the valve plate can only rotate in one direction, when grains enter the conveying pipe, the valve plate is pushed through the grains, the valve plate can only rotate in one direction, and after the grains pass through the valve plate, the valve plate is automatically closed under the action of the spring; hot steam is prevented from overflowing a cooking pot and entering a hopper elevator through the conveying pipe, the steam cannot be condensed into water drops or ice on hoppers on the four walls of the hopper elevator, lifting and conveying of the hopper elevator cannot be hindered, and the feeding efficiency of the device is improved.

Owner:石嘴山市惠农区保石面粉厂

Feather piece automatic righting device

PendingCN114194862APrevent throwingAvoid cloggingControl devices for conveyorsBall sportsStructural engineeringWorkbench

The invention relates to an automatic feather piece righting device. A feeding port is formed in a workbench; the feeding mechanism is fixedly arranged on the workbench, a feeding port is formed in the top of the feeding mechanism, and a discharging port is formed in the bottom of the feeding mechanism. The righting mechanism comprises a rotating box and a driving assembly, one end of the driving assembly is fixed to the workbench, the other end of the driving assembly is in transmission connection with the center of the bottom of the rotating box, a hair inlet is formed in the position, corresponding to the transmission connection position of the bottom of the rotating box, of the top of the rotating box, and multiple hair outlet holes are formed in the two end faces in the rotating circumferential direction of the rotating box. The pore outlet hole can correspond to the feeding hole; the galling mechanism is positioned below the rotating box; the controller is electrically connected with the feeding mechanism, the driving assembly and the galling mechanism. According to the automatic feather piece righting device, a large number of feather pieces can be automatically righting and loaded, and the success rate is high.

Owner:汪锐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com