Aluminum profile drawing device

An aluminum profile and driving device technology is applied in the field of aluminum profile pulling devices, which can solve the problems of low material pulling efficiency and potential safety hazards, and achieve the effects of improving the degree of mechanization and reducing the amount of labor and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

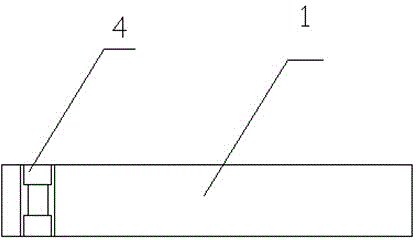

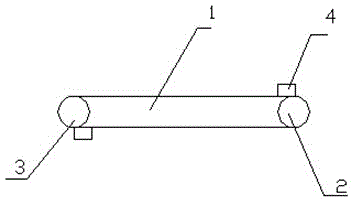

[0030] This embodiment includes a frame, a conveyor belt 1, a driving roller 2, a driven roller 3, a driving roller driving device and a collet 4, the conveyor belt 1 is an endless conveyor belt, and the conveyor belt 1 is sleeved on the driving roller 2 and the driven roller 3, the driving roller driving device is connected with the driving roller, and there are two chucks 4, which are respectively installed at both ends of the conveyor belt 1. The chuck 4 includes two electromagnets and electromagnet fixing seats, and the electromagnet is fixed on the electromagnetic In the iron fixed seat, the electromagnet fixed seat is installed on both sides of the conveyor belt through the slide rail, and the slide rail is vertically laid on the conveyor belt.

[0031] The drive roller driving device includes a motor, a frequency converter and a reducer, the output shaft of the motor is connected to the reducer, the output shaft of the reducer is connected to the drive roller, and the fr...

Embodiment 2

[0033]This embodiment includes a frame, a conveyor belt 1, a driving roller 2, a driven roller 3, a driving roller driving device and a collet 4, the conveyor belt 1 is an endless conveyor belt, and the conveyor belt 1 is sleeved on the driving roller 2 and the driven roller 3, the driving roller driving device is connected with the driving roller, and there are two chucks 4, which are respectively installed at both ends of the conveyor belt 1. The chuck 4 includes two electromagnets and electromagnet fixing seats, and the electromagnet is fixed on the electromagnetic In the iron fixed seat, the electromagnet fixed seat is installed on both sides of the conveyor belt through the slide rail, and the slide rail is vertically laid on the conveyor belt.

[0034] The drive roller driving device includes a motor, a frequency converter and a reducer, the output shaft of the motor is connected to the reducer, the output shaft of the reducer is connected to the drive roller, and the fre...

Embodiment 3

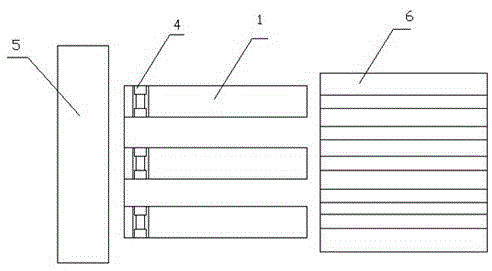

[0037] In this embodiment, three pulling devices are installed between the press 5 and the storage rack 6. The pulling device in this embodiment includes a frame, a conveyor belt 1, a driving roller 2, a driven roller 3, and a driving roller driving device. And chuck 4, the conveyor belt 1 is an endless conveyor belt, the conveyor belt 1 is sleeved on the driving roller 2 and the driven roller 3, the driving roller driving device is connected with the driving roller, there are two chucks 4, which are respectively installed on the conveyor belt 1, the chuck 4 includes two electromagnets and an electromagnet fixing seat, the electromagnet is fixed in the electromagnet fixing seat, and the electromagnet fixing seat is installed on both sides of the conveyor belt through a slide rail, and the slide rail is laid vertically on the conveyor belt.

[0038] The drive roller driving device includes a motor, a frequency converter and a reducer, the output shaft of the motor is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com