Pneumatic apparatus on vehicle socket sleeve fabric napping machine

A kind of pneumatic device, the technology of hair pulling machine, which is applied in the direction of fabric surface trimming, textile and paper making, roughening, etc., can solve the problems of poor hair pulling effect, poor fabric durability and shape retention, and inability to pile and shape, so as to improve the protection. The effect of shape and durability, increase in rolling line speed, and increase in pull strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

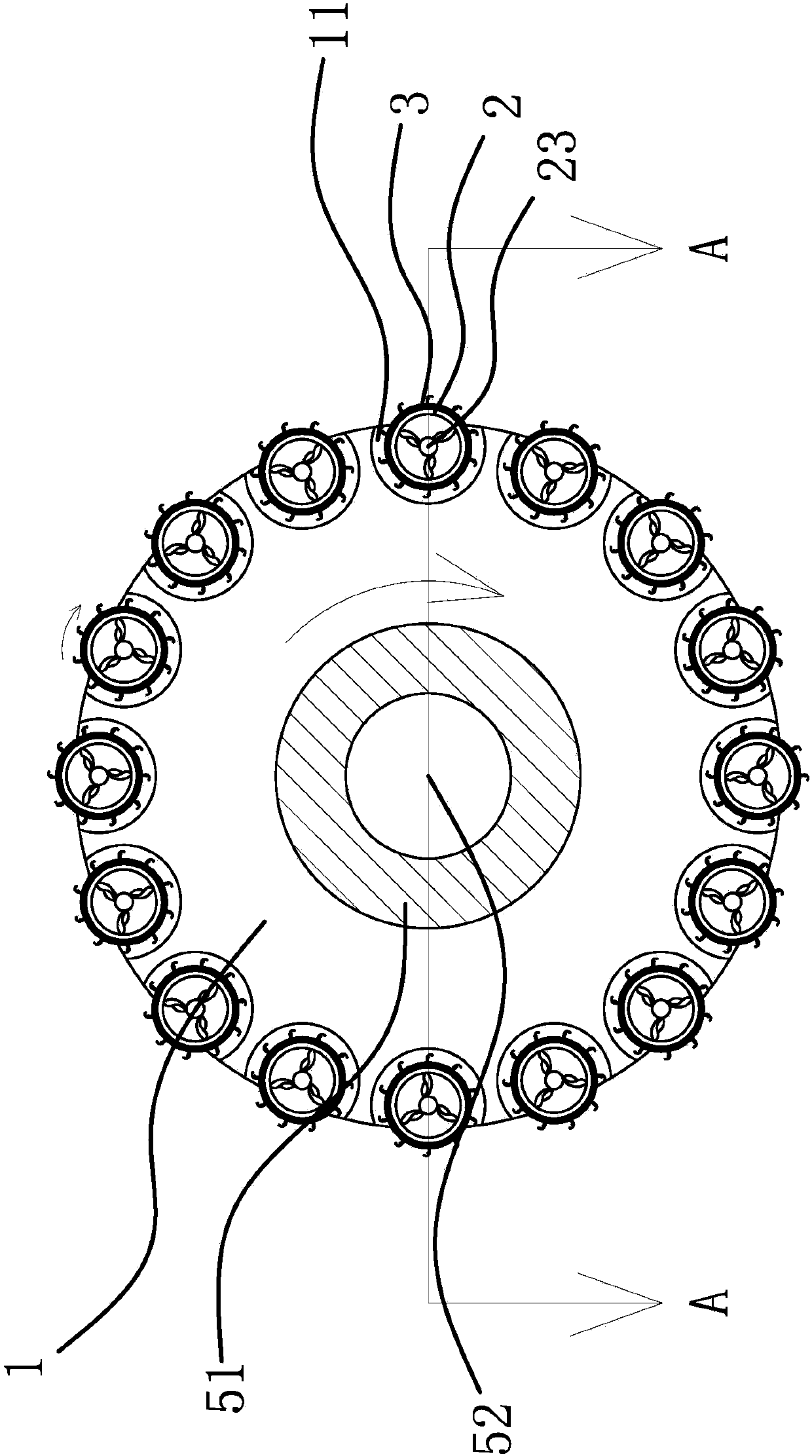

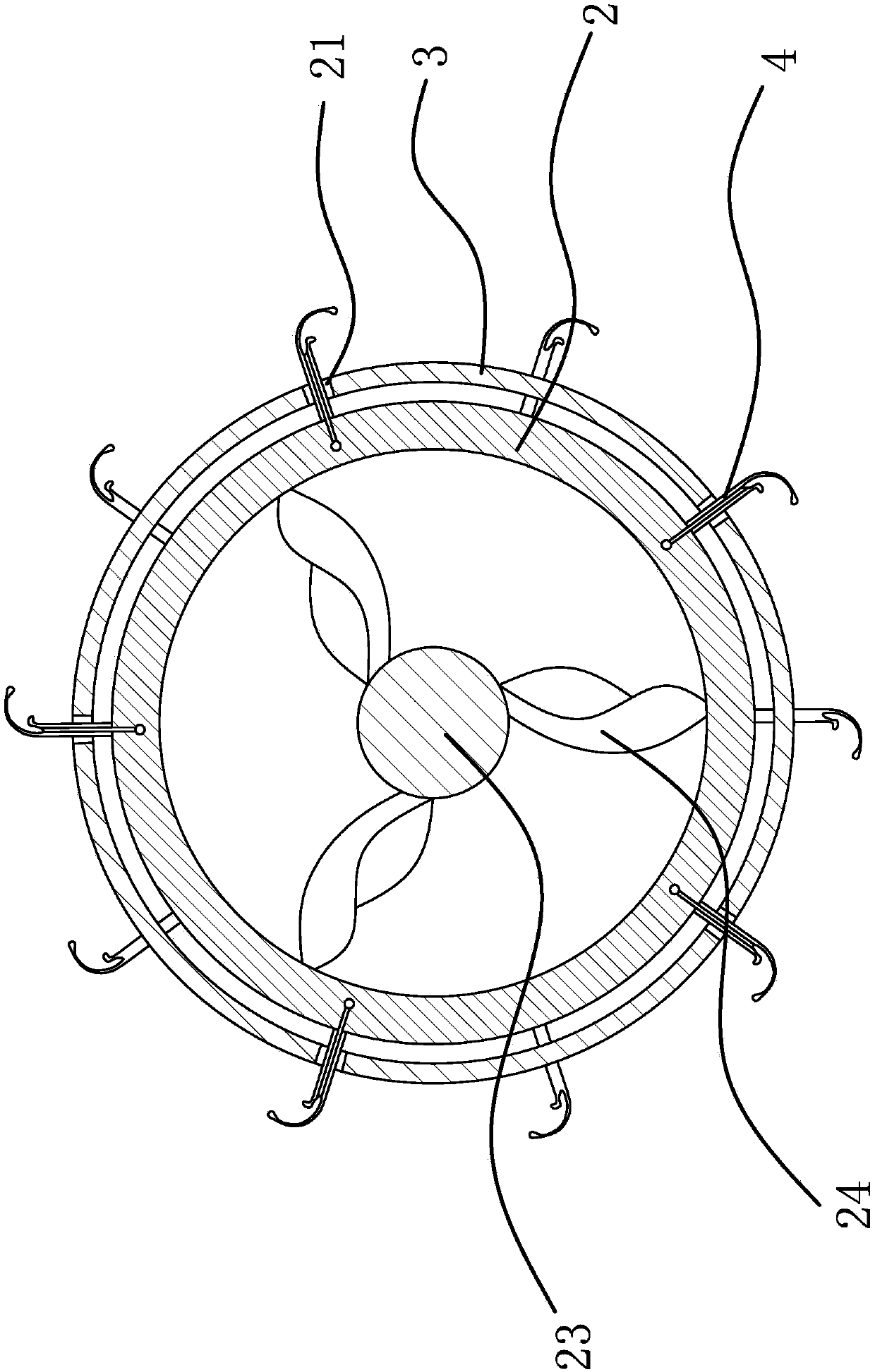

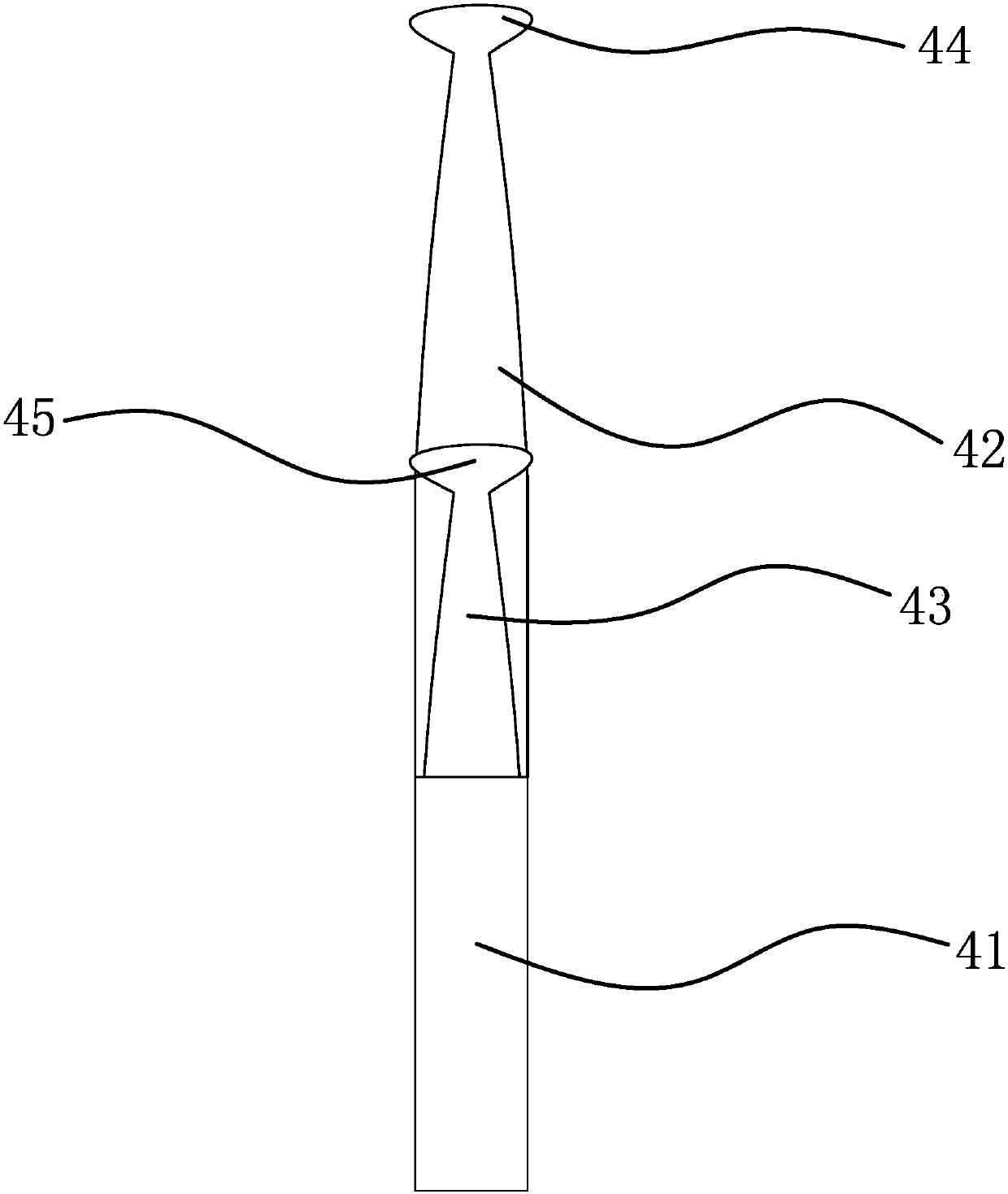

[0037] Such as figure 1 , figure 2 , Figure 5 , Figure 6 and Figure 7 As shown, the napping machine includes a main cylinder 1, several napping cylinders 2, a guide sleeve 3 corresponding to the napping cylinders 2 and a blower. The cylinder 2 is arranged in the corresponding avoidance opening 11, and the napping cylinder 2 partially protrudes from the avoidance opening 11, and a plurality of pull needles 4 are evenly arranged on the napping cylinder 2, and several guide sleeves 3 are provided with a plurality of holes arranged on the circumference of the guide sleeve 3. Guide groove 21, the guide groove 21 is corrugated, the guide sleeve 3 is fixedly connected with the main cylinder 1, the pull needle 4 is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com