High-moisture-absorptivity mineral dryer and preparation method thereof

A desiccant and high moisture absorption technology, which is applied in the field of molecular sieves and its preparation, can solve the problems of inability to achieve drying effect, fail to meet market demand, and low hygroscopicity rate, and achieve stable hygroscopic performance, fast moisture absorption rate, and high moisture absorption rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

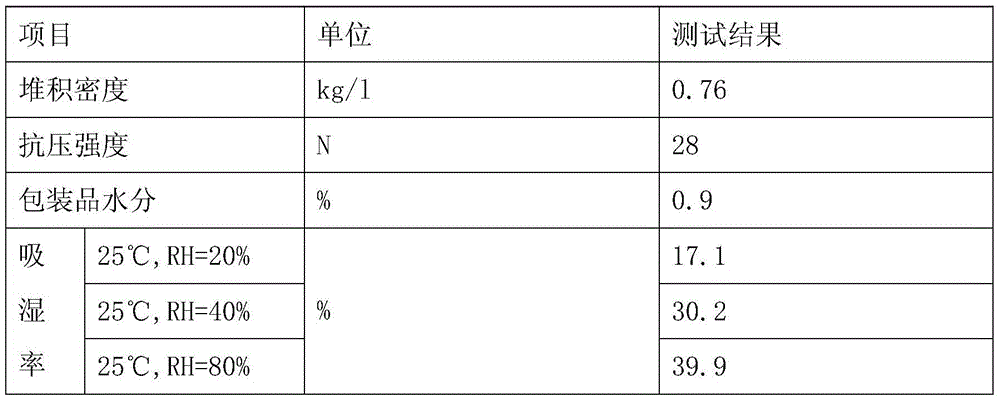

[0016] A mineral desiccant with high moisture absorption rate, made of the following raw materials by weight (kg): halloysite 26, bauxite 35, turquoise 23, dolomite 20, cement slag 22, rock wool powder 11, 4A molecular sieve 9 , aluminum potassium sulfate 8, quicklime 7, calcium chloride 6, modifier 106;

[0017] The preparation method of described modifying agent is as follows: a, get the raw material of following weight (kg): konjac glucomannan 4, polyvinylpyrrolidone 3, hydroxyethyl methylcellulose 2.5, hydroxypropyl xanthan gum 5, Alginate triethanolamine salt 3, acrylic acid 40, potassium persulfate 0.2, N, N-methylenebisacrylamide 0.03; b, konjac glucomannan, polyvinylpyrrolidone, hydroxyethyl methylcellulose, hydroxypropyl Base xanthan gum and alginate triethanolamine salt are mixed evenly and then added to acrylic acid, stirred and swelled for 1 hour under nitrogen protection, then potassium persulfate and N,N-methylenebisacrylamide are added, and stirred evenly.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com