Patents

Literature

81results about How to "Bright luster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation process for fine denier and superfine denier polypropylene fibers

InactiveCN101736416AReduce consumptionSave dyeing energyMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAbnormal shaped

The invention mainly discloses a preparation process for fine denier and superfine denier polypropylene fibers, which comprises the following steps of: adopting a spinning special material of which the melting point is between 165 and 175 DEG C; in a spinning device, extruding and melting the spinning special material by a single screw extruder, wherein a melt flows evenly; performing spinning through a round or abnormal spinneret orifice of a spinneret plate of a spinning box, wherein the spinning speed is 2,200 miters per minute; cooling and oiling tows; and then performing hot drawing and winding to finally obtain the fine denier and superfine denier polypropylene fibers of 0.5 to 2 deniers, wherein the hot drawing temperature is between 45 and 105 DEG C, the drawing multiple is 1.5 to 4 times, and the winding speed is 80 meters per minute for overfeeding. The preparation process is a nuisanceless, environment-friendly, energy-saving and innovative process, and the finally obtained product has the advantages of light in texture, high strength, good abrasion resistance and elastic resilience, small static electricity, small coefficient of heat conductivity and good electrical insulating property.

Owner:绍兴前瞻化纤有限公司

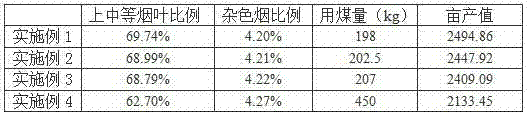

Curing process of flue-cured tobacco

InactiveCN101983589AStable color fixationStrong baking qualityTobacco preparationEngineeringCuring of tobacco

The invention discloses a curing process of flue-cured tobacco and belongs to the technical field of the curing technology of tobacco leaves. According to the curing characteristic of the leaves of the zhongyan 103, the temperature and the humidity, the curing process of tobacco leaf of the invention divides the whole process of the curing of tobacco leaves into five steps, namely firing-up and temperature control, yellowing of tobacco leaves, transition, colour setting of tobacco leaves and stem-drying of tobacco leaves, wherein the five steps have the three stages of yellowing stage, colour setting stage and stem-dring stage, thus the quality of the cured tobacco leaves is greatly increased. The curing process has high maneuverability and can obviously increase the tobacco leaf quality and high-class leaf ratio of flue-cured tobacco and reduce the rate of green tobacco; the ratios of high-class leaf and middle-class leaf in the cured tobacco leaves are increased by more than 10.65%, the ratio of the tobacco leaf with different colors is reduced by more than 1.67%, the ratio of tobacco leaves of which upper and middle parts are green is reduced by more than 7%; the output value is increased by more than 11.75%; and the cured tobacco leaves are bright-coloured and oily, the chemical composition tends to be coordinated, the sugar-nicotine ratio, the nitrogen-nicotine ratio and the total nicotine all meet the chemical composition quality evaluation standard of the crude tobacco; and the style characteristic of the zhongyan 103 is fully displayed, and the incomes of tobacco farmers are increased.

Owner:张永辉

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

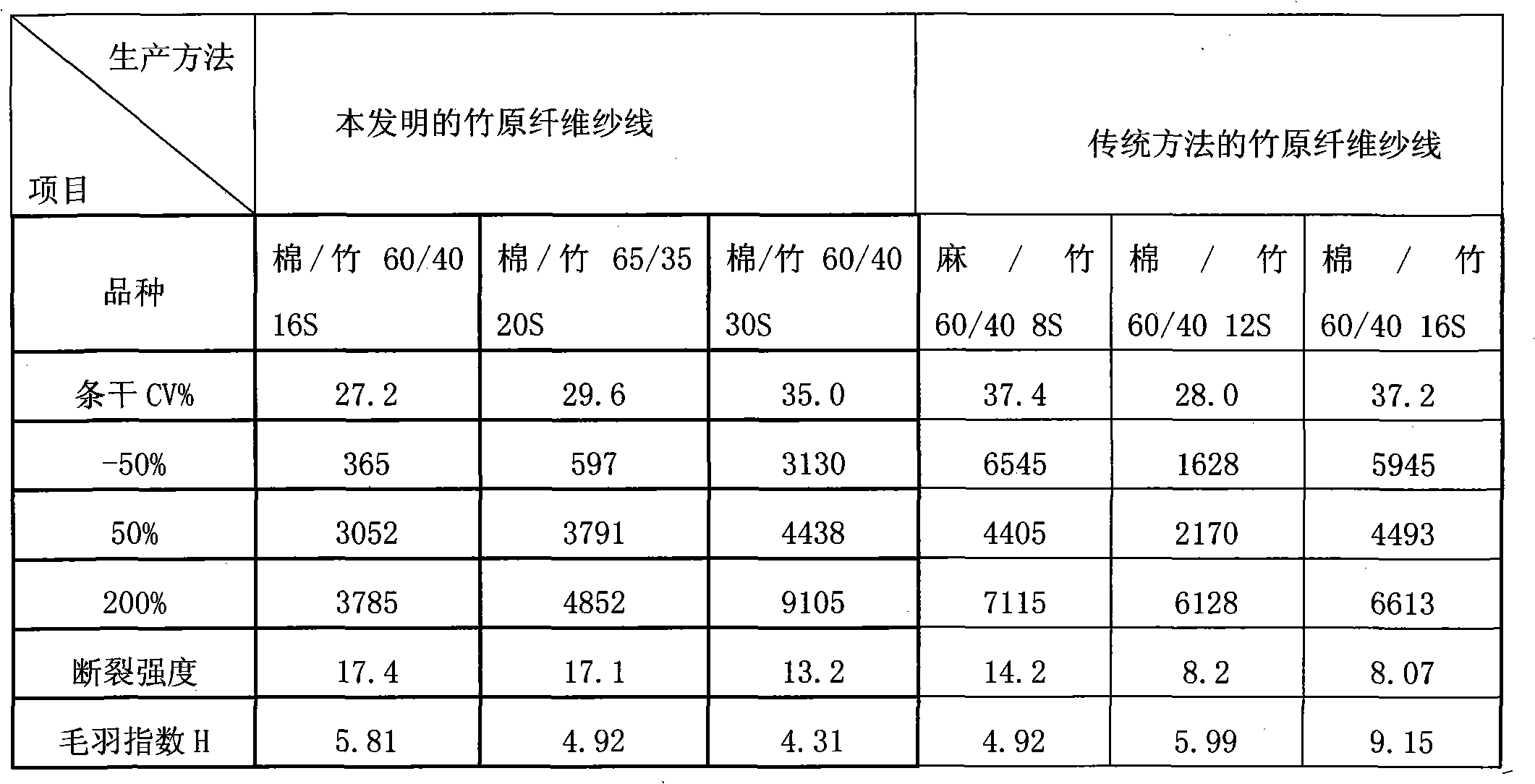

Bamboo fiber yarns and production method thereof

InactiveCN101967710AReduce tensionDecreased elastic strengthFibre mixingYarnEnvironmental resistanceYarn

The invention discloses bamboo fiber yarns and a production method thereof. The bamboo fiber yarns are prepared by spinning the following blended raw materials in part by weight: more than 5 and less than or equal to 95 parts of bamboo fibers (preferably 20 to 40 parts) and 60 to 80 parts of natural fibers (such as cotton) or environmentally-friendly differential fibers. The production method comprises the following steps of: blending slivers made of the bamboo fibers and the natural fibers (such as the cotton) or the environmentally-friendly differential fibers again; and drawing, roving, spinning and spooling for 2 to 3 times to prepare various blended bamboo fiber yarns with low bamboo fiber content, which have naturally antibacterial, bacteriostatic, anti-ultraviolet, hygroscopic, air-permeable characteristics and the like. A plurality of superfine grooves on the surfaces of the bamboo fibers contributes to the improvement on moisture absorption, so that the yarns have the function of dehumidifying. The production method has the advantages of uniqueness, effectiveness, easily controllable manufacturing process, basically no need of equipment replacement, low manufacturing cost and high production efficiency.

Owner:FUJIAN KARTEX TEXTILE

Comfortable skin-care warming health-care hollow porous yarn, and preparation method and application thereof

The invention provides a preparation method and application of a comfortable skin-care warming health-care hollow porous yarn. The comfortable skin-care warming health-care hollow porous yarn is formed by firstly blending and then processing such six hollow fibers (one or more fibers) as fine staple cotton fibers, seashell fibers (or Amicor antibiotic fibers or Cleancool fibers), water-soluble polyvinyl short fibers (or water-soluble polyvinyl filaments), kawo kawo fibers ( or Viloft fibers or Prolivon fibers or antibiotic hollow polyester fibers or Porel hollow fibers or Poral hollow fibers or micropore polyester fibers) and the like. The product has a body temperature adjustment effect, keeps a human body to always feel comfortable, is good in stiffness, feels soft and smooth, is good in drapability, unique in appearance and good in wrinkle resistance, enables a wearer to feel comfortable and is fluffy in texture, thereby being suitable for production of high-grade knitting machine woven fabrics, cold-proof underwear, bedding articles and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Gluconate water-soluble micronutrient fertilizer

The invention discloses a gluconate water-soluble micronutrient fertilizer. The fertilizer consists of the following substances in part by weight: 5 to 10 parts of ferrous gluconate, 5 to 10 parts of copper gluconate, 5 to 10 parts of zinc gluconate, 5 to 10 parts of manganese gluconate, 1 to 4 parts of complex boron gluconate, 0.05 to 0.1 part of ammonium molybdate and 60 to 70 parts of water. The invention also discloses a method for preparing the gluconate water-soluble micronutrient fertilizer. The fertilizer has the advantages of readily purchasable raw materials, simple process and stable performance and can be mixed with other acidic or neutral pesticides or bactericides to improve the pesticide effect.

Owner:金广彦

High-grade elastic moisture-absorbing quick-drying face fabric

InactiveCN1804198AImprove textureSoft touchWeft knittingBiochemical fibre treatmentYarnColour fastness

The disclosed processing method for a high-grade plastic hygroscopic quick-drying face fabric comprises: using cotton yarn as face yarn and terylene as ground yarn, joining elastic yarn for weft knitting; then, sorting by bio-enzyme and resin by turns, and treating for hygroscopic quick-drying. This product is fine and smooth for soft hand feeling, can show people elegant line and enhance stretch range by well elasticity and color fastness, and reduces its friction and stimulation to skin.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Curing process of flue-curing barn

InactiveCN102499431AEffective reflection of qualityStable color fixationTobacco preparationOperabilityDry-bulb temperature

The invention discloses a curing process of a flue-curing barn, and belongs to the technical field of a tobacco curing. The process comprises the following steps: an ignition and temperature control stage: heating and roasting by utilizing an air source heat pump unit independently; tobacco leaf yellowing stage: heating and roasting by utilizing the air source heat pump unit independently; tobacco leaf color fixing stage: heating by utilizing the air source heat pump unit independently when a dry-bulb temperature is between 44 and 50 DEG C, and heating by using a coal burning boiler independently when the dry-bulb temperature rises to over 50 DEG C; and a tobacco leaf stem drying stage: heating by using the coal burning boiler independently. The curing process has the advantages of safetyand insurance, strong operability, stability of tobacco leaf color fixation, good leaf shrinkage, great improvement of flavor quantity of tar and tobacco leaves, is simple to operate; and the technical scheme of the roasting process has strong operability, so that the tobacco leaf curing quality and superior leaf ratio can be remarkably improved, the tobacco leaf dry matter consumption is reduced, and the roasting effects of saving energy, reducing emission, increasing quality and improving efficiency can be achieved.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

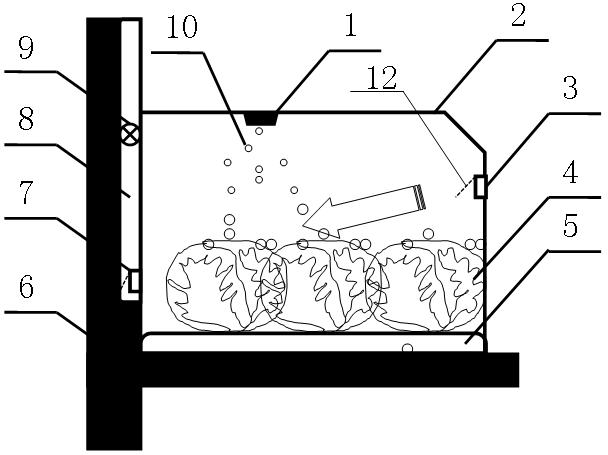

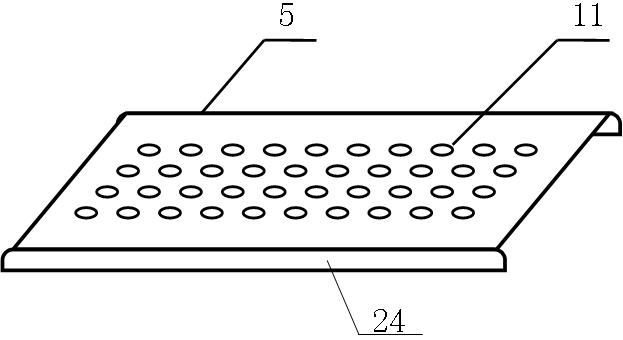

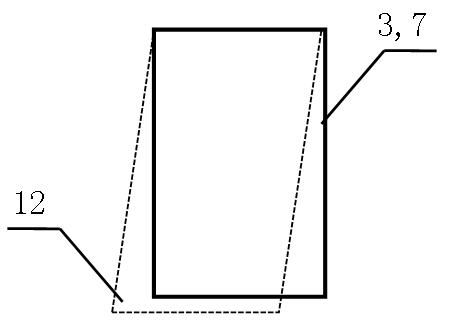

Fruit-vegetable box applicable to air-cooling refrigerator and rapid-cooling and moisturizing method of fruit-vegetable box

InactiveCN102620509AAggravate frostingFrosting remainsLighting and heating apparatusUltrasonic humidifiersHigh humidityEvaporation

The invention discloses a fruit-vegetable box applicable to an air-cooling refrigerator. The fruit-vegetable box comprises a box body, wherein a spraying device is arranged at the top in the box body; an air inlet is arranged at the upper part of the front side of the box body; an air outlet is backwards and convexly arranged at the lower part of the rear side of the box body and is communicated with an air duct of the refrigerator; the tops of the rear ends of the air inlet and the air outlet are respectively hinged with a wind board; and the wind boards are used for blocking the air inlet and the air outlet. The invention also discloses a rapid-cooling and moisturizing method of the fruit-vegetable box applicable to the air-cooling refrigerator. The fruit-vegetable box is provided with the air outlet connected with the air duct of the refrigerator, so that high-humidity gas in the fruit-vegetable box is directly conveyed out by the air duct of the refrigerator, and is prevented from entering a refrigerating chamber and further promoting the frosting phenomenon in the refrigerating chamber. The spraying device can carry out spraying and over-humidifying treatment on fruits and vegetables in advance, the circulating air of the refrigerator can carry out evaporation and cooling on the fruits and the vegetables, so that not only is rapid cooling of the fruits and the vegetables realized, but also high humidity of the fruits and the vegetables is maintained, and simultaneously, the frosting phenomenon in the refrigerating room can not be promoted.

Owner:HENAN XINFEI ELECTRICAL EQUIP

Yarn spinning technology for multi-fiber semi-worsted melange yarn and yarn

InactiveCN104878490AImprove insulation effectIncrease elasticityWool fibre washing/scouringAnimal materialCardingWorsted

The invention relates to a yarn spinning technology for multi-fiber semi-worsted melange yarn and the yarn prepared with the technology. The technological steps of the yarn mainly comprise raw material treatment, cotton carding, drawing, roving, spinning, self-spooling, doubling, two-for-one twisting and packaging of a finished product. Raw materials comprise mercerized wool fiber, nylon fiber, viscose fiber and cashmere wool fiber. The problems of high probability of water shrinkage and pilling of wool are solved with a more environment-friendly method, meanwhile, nylon, cashmere wool and viscose ingredients are added, and the heat retention property, the elasticity, the durability and the comfort degree of the product are increased; the production cost is lower, the prepared yarn has the characteristics of shrink resistance, good anti-pilling effect, natural luster, bright color, good elasticity, smooth hand feeling, heat retention and the like.

Owner:TONGXIANG YUNSHENG TEXTILE

Flue-cured tobacco baking method

ActiveCN106108097AEffective reflection of qualityStable color fixationTobacco preparationBiologyCuring of tobacco

The invention discloses a flue-cured tobacco baking method, and belongs to the technical field of tobacco blending and making. According to tobacco baking properties of a flue-cured tobacco variety of Yun tobacco 105, the whole tobacco baking process is a three-stage seven-step tobacco baking process including treatments at early stage of yellowing, middle stage of yellowing, late stage of yellowing, early stage of color fixing, late stage of color fixing, early stage of stem drying and later stage of stem drying according to the temperature and humidity, and the quality of the baked tobacco is greatly improved; the baking process is high in operability and can obviously improve the tobacco quality of flue-cured tobacco, increase the ratio of first-class tobacco and decrease the smoke rate; after baking is conducted, the ratio of first-class tobacco and middle-grade tobacco in the tobacco is increased by 10.65% or above, the ratio of variegated tobacco is decreased by 1.67% or above, and the greenish ratio of the tobacco on the upper-middle part is decreased by 7% or above; the production value is increased by 11.75% or above, the baked tobacco is bright in color and luster and oily, chemical components tend to coordination, the sugar-nicotine ratio, nitrogen-nicotine ratio and total nicotine all meet the quality evaluation criteria of original tobacco chemical compositions, the style and characteristics of Yun tobacco 105 can be fully embodied, and the income of tobacco growers is increased.

Owner:LUZHOU CO LTD SICHUAN TOBACCO

Cable lettering ink

The invention belongs to the field of printing technology, and particularly relates to cable lettering ink which is characterized by comprising the following raw materials in parts by weight: 4-6 parts of polyvinyl chloride resin, 5-9 parts of acrylate polymer, 30-40 parts of methyl ethyl ketone, 13-18 parts of toluene, 5-10 parts of isobutyl methacrylate, 10-18 parts of tetrahydrofuran, 3-5 parts of benzidine yellow or titanium dioxide or lithopone with fineness of 400-800 meshes, 6-10 parts of 2-lead ethylcaproate, 0.3-0.5 part of methylparaben or propylparaben or butylparaben and 3-4.5 parts of butyl acetate. The invention also discloses a preparation method of the lettering ink. The cable lettering ink and the preparation method provided by the invention have the main beneficial effects that the preparation method is simple and easy to master, and the qualified rate of the finished product is high; the lettering ink has the advantages of high adhesion, high drying speed, bright luster and longer shelf life.

Owner:STATE GRID CORP OF CHINA +1

Special process for dyeing and finishing multi-F viscose rayon

InactiveCN101880975AImprove verticalityImprove breathabilityLiquid/gas/vapor open-width material treatmentDyeing processAcetic acidCuprammonium rayon

The invention relates to a special process for dyeing and finishing multi-F viscose rayon, comprising the following steps of desizing by using sodium carbonate, neutralizing by using glacial acetic acid, rinsing by using tap water and the like. After the multi-F viscose rayon is specially dyed and finished, fabrics woven by the multi-F viscose rayon has a silk-imitating effect superior to that of fabrics woven by cuprammonium rayon raw materials produced in Japan, and the fabrics woven by the fibers have the advantages of favorable smoothness, air permeability and moisture absorption and bright luster after dyed.

Owner:王水泉

Method for manufacturing craft through waste bamboo

InactiveCN105252622ABright lusterHigh glossReed/straw treatmentAnthracene dyesPulp and paper industryColoring agents

The invention provides a method for manufacturing a craft through waste bamboo. The coloring treatment, softening treatment, drying treatment and carving treatment are sequentially conducted on the waste bamboo to obtain a craft product. The bamboo adopted in the method is reutilized bamboo after being wasted, and raw materials are low in cost and environmentally friendly. The method includes the specific steps that firstly, the gloss of the waste bamboo is made to be brighter through the coloring treatment, then the texture strength of the bamboo is improved through the softening treatment and the follow-up carving treatment is facilitated, and carved patterns are colored through a coloring agent after carving, so that the patterns are preserved for a long time and are free of discoloration.

Owner:安徽省丰蓼农业开发有限公司

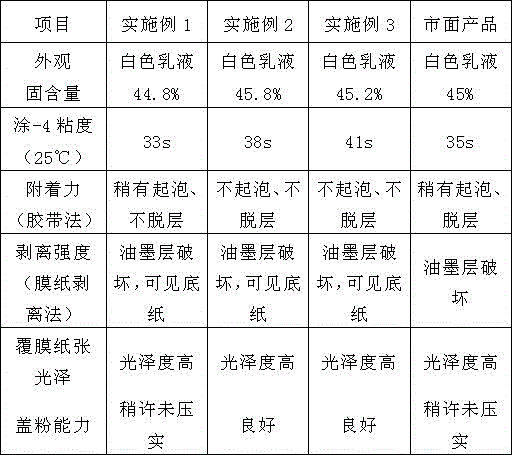

Aqueous dry lamination adhesive and preparation method thereof

ActiveCN105482745AFully bondedImprove adhesionEster polymer adhesivesRosin adhesivesSodium bicarbonateIsooctyl acrylate

The invention discloses an aqueous dry lamination adhesive and a preparation method thereof. Raw materials of the aqueous dry lamination adhesive comprise styrene, butyl acrylate, isooctyl acrylate, acrylonitrile, N-methylolacrylamide, hydroxyethyl acrylate, acrylic acid, rosin, potassium persulfate, sodium dodecylbenzene sulfonate, isooctyl phenol polyoxyethylene ether, sodium bicarbonate, deionized water, ammonia water, a wetting agent and antifoaming agent. Aqueous latex with a core-shell structure is prepared through a segmented polymerization technology, so functional groups make a substrate and a plastic film be fully bonded, and polymer molecular chains are self-crosslinked, thereby the adhesion and the peeling strength of the substrate are improved, the adhesive has excellent initial adhesion, pressure sensitivity and covering ability, the excellent leveling property and the dynamic wetability of the adhesive make a laminated product have brilliant gloss, and the adhesive can be widely used in paper plastic lamination.

Owner:常德市雄鹰科技有限责任公司

Real silk embossing process

InactiveCN105064080AHigh color fixing rateReasonable designDry-cleaning apparatus for textilesDyeing processHeat stabilityEngineering

The invention discloses a real silk embossing process, and relates to the field of textile, in particular to a real silk embossing method. the embossing method comprises the following steps: (1) pre-treatment: soaking real silk fabric in a pre-treatment liquid for 3h, taking out the treated real silk fabric, and airing the treated real silk fabric naturally, wherein the soaking temperature is 30 to 40 DEG C; (2) color paste embossing: embossing the pre-treated real silk fabric with color paste; (3) steaming: steaming the embossed real silk fabric; (4) water washing: washing the steamed real silk fabric with cold water; (5) fixation: carrying out a reaction at a saturated steam condition; (6) soaping: carrying out soaping at 80 DEG C for 10 to 15 min, and then carrying out cold water washing, wherein the soaping agent is modified tea saponin of which the concentration is 2-10 g / L; (7) airing: airing the real silk fabric washed with cold water naturally. The embossing process has the benefits that the design is reasonable; the prepared product is bright in color and luster, high in friction resistance and heat stability, the dyeing rate and fixation rate of embossing dye are improved, and the blooming possibility is low.

Owner:XINYUAN COCOON SILK GROUP

Preparation method for spicy sesame and peanut mixed sauce

The invention discloses spicy sesame and peanut mixed sauce and a preparation method thereof. The spicy sesame and peanut mixed sauce is prepared from following raw materials in parts by weight: 40 parts of sesame pulp, 60 parts of peanut pulp, 20 parts of high-quality peanut oil, 11.5 parts of aniseeds, 6-8 parts of dried and red pericarpium zanthoxyli powder, 3 parts of table salt, 1.6 parts of white granulated sugar, 1.2 parts of Xianweiwang and 0.8 part of chicken powder; an emulsifying agent comprises 1.3 parts of monoglyceride. In a preparation process, methods for controlling the grinding fineness of the raw materials, controlling the temperature of a grinding outlet, adding the emulsifying agent and different seasonings and the like are adopted to successfully solve the technical difficulties in the production of traditional sesame and peanut sauce that a product is easy to acidify, oil sauce is easy to layer and the taste is single, so that the spicy sesame and peanut mixed sauce which is easy to store, has high nutrition and is unique in taste. According to the technology, the utilization value of agricultural sideline products including sesames and peanuts are improved; a traditional preparation method for sesame sauce and peanut sauce is changed and a novel way for industrial development is explored.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

After-treatment assistant for cellulosic fiber fabric

InactiveCN106012523ALess likely to wrinkleReduce formaldehyde contentWrinkle resistant fibresAbrasion resistant fibresAfter treatmentPulp and paper industry

The invention relates to a post-finishing auxiliary agent for cellulose fiber fabrics, which is used for post-finishing cellulose fiber fabrics. The additives include the following components by weight: 32±2% modified N-methylol dihydroxyethylene urea, 35±2% silicone, 12±0.5% color fixing agent, 11±0.5% textile waterproof agent. After finishing the cellulose fiber fabric with the post-finishing auxiliary agent of the present invention, the cellulose fiber fabric is not easy to wrinkle and shrink during use, and the formaldehyde content of the fabric after finishing is far lower than 75ppm. Make the surface of cellulose fiber fabrics more rich and colorful, make the fabric feel fuller and more elastic, and at the same time give the fabric a silky touch, which helps to improve the effect of non-ironing finishing.

Owner:JIANGSU GIRMES SPECIAL TEXTILES

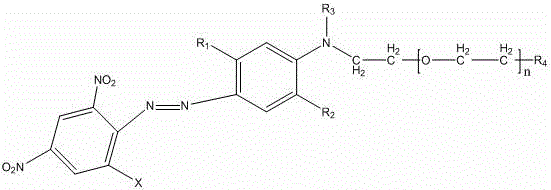

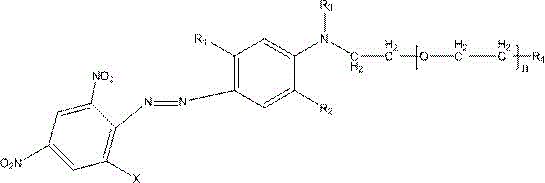

Strong-alkali-resistant moderate-temperature disperse violet dye as well as compound mixture and preparation method thereof

ActiveCN106118119AHas the function of strong alkali resistanceBright lusterMonoazo dyesNitrosylsulfuric acidDisperse dye

The invention discloses a strong-alkali-resistant moderate-temperature disperse violet dye as well as a compound mixture and a preparation method thereof. The strong-alkali-resistant moderate-temperature disperse violet dye is a compound of which the structure is as shown in a structural formula (I), and the compound is prepared in the way that 2-bromo-4,6-dinitroaniline or 2-chloro-4,6-dinitroaniline is diazotized by use of nitrosyl sulfuric acid, and the diazotized product is subjected to coupling reaction with m-substituted and o-substituted-N-aniline emulsion. The strong-alkali-resistant moderate-temperature disperse violet dye is environment-friendly in production process, can be applied to moderate-temperature dyeing of such hydrophobic fibers as polyester, nylon and spandex and blended fabrics of the hydrophobic fibers, is bright-colored, can replace disperse violet 28, disperse violet 31 and disperse violet 93, and can be compounded with azo-type disperse dyes and anthraquinone disperse dyes to achieve the functions of adjusting color tone and increasing effect so as to meet the demands of different application conditions. The strong-alkali-resistant moderate-temperature disperse violet dye is high in promotion performance, has favorable fastness in water washing, insolation, sublimation and the like, is excellent in comprehensive performance and has a wide application prospect.

Owner:烟台澳土复合材料有限公司

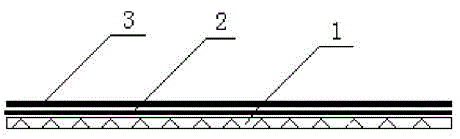

Completely-biodegradable pre-coating film

InactiveCN105567113AGood biocompatibilityImprove biodegradabilityMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesive primer layersPolyesterElastomer

The invention discloses a completely-biodegradable pre-coating film. The completely-biodegradable pre-coating film comprises a substrate, a middle layer and an adhesive layer, wherein the middle layer is positioned between the substrate and the adhesive layer; the substrate is prepared from the following materials in parts by weight: 1 to 10 parts of polyethylene terephthalate, 5 to 10 parts of biaxially oriented polypropylene thin film, 10 to 15 part of biaxially oriented polyester thin film, 1 to 5 parts of biaxially oriented nylon thin film and 1 to 4 parts of terpene resin; the middle layer is prepared from the following materials in parts by weight: 1 to 10 parts of polyethylene wax and 5 to 15 parts of elastomer; the adhesive layer is prepared from the following materials in parts by weight: 5 to 10 parts of ethylene-vinyl acetate resin, 1 to 5 parts of hydrogenated petroleum resin, 3 to 6 parts of hydrogenated rosin glycerol ester, 1 to 10 parts of petroleum resin and 1 to 10 parts of waterborne polyurethane. According to the completely-biodegradable pre-coating film disclosed by the invention, materials used by the completely-biodegradable pre-coating film have good biocompatibility, good biodegradability and good hot working performance of plastics, the completely-biodegradable pre-coating film is the first choice of biodegradable packaging materials, and the completely-biodegradable pre-coating film is better in biodegradability, quicker in degradation speed and more complete in degradation.

Owner:SHANGHAI HISUN ENVIRONMENT PROTECTION TECH CO LTD

Golden pearl cultivation method

InactiveCN109588349ANo surgical traumaImprove survival rateClimate change adaptationPisciculture and aquariaOperative woundNutrient solution

The invention discloses a golden pearl cultivation method. Golden cell fragments in donor pearl shells are adopted and treated by a pearl cultivation nutrient solution, treated golden cell fragments are implanted in pearl nucleuses of receptor pearl shells, and cultivation is performed in the natural environment. By means of the cultivated pearl shells, operative wounds are avoided, the survival rate is high, gold is formed naturally in pearl layers, and cultivated pearls are golden pearls, the nutrient solution is adopted for treatment during cultivation, so that the pearl layers are thickerthan those at the same cultivation ages. By use of cultivated pearls, pearl layers of obtained pearls have a golden effect, the thickness of pearl layers is increased, the longer the cultivation timeis, the thicker the pearl layers are, the brighter the color is and the more obvious the golden effect is.

Owner:北海汇善珠宝有限公司

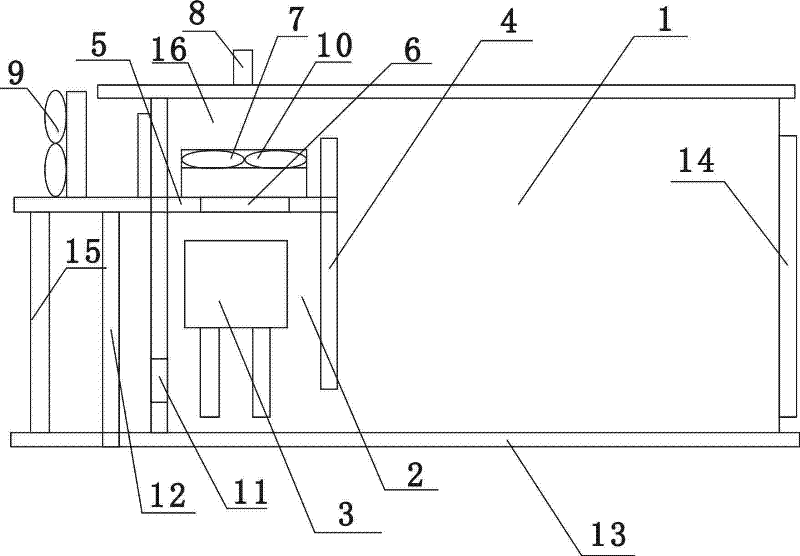

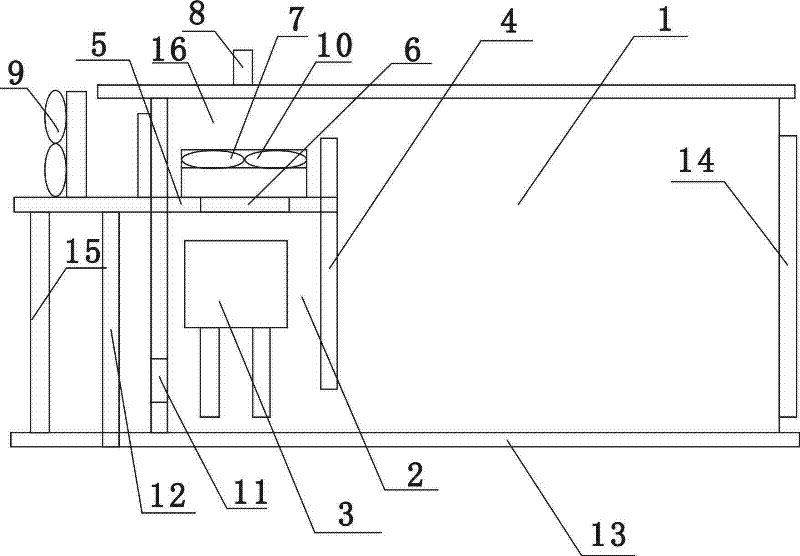

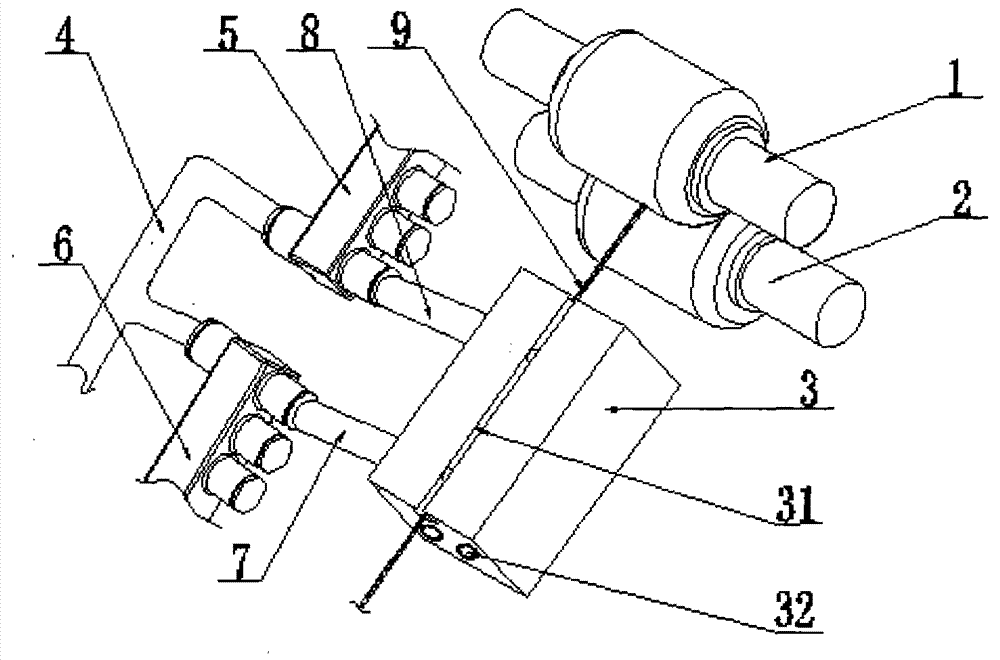

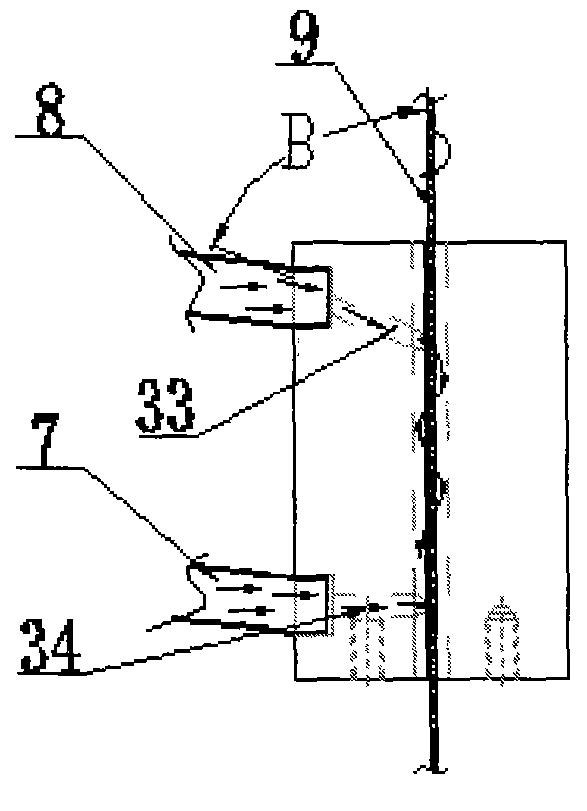

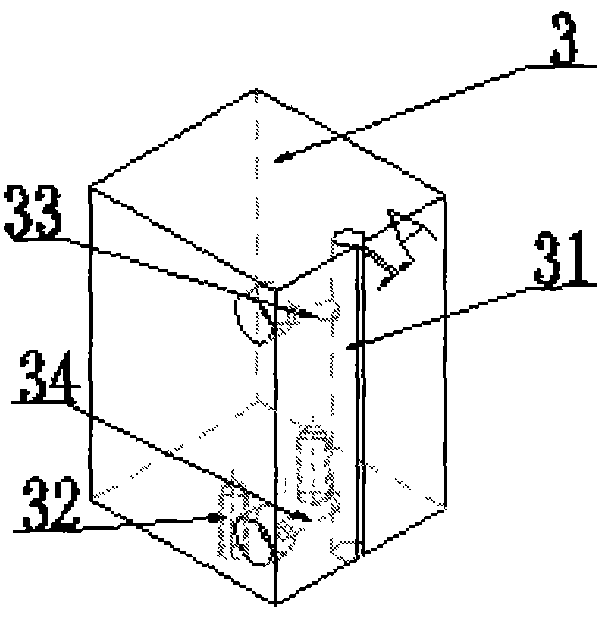

Spinning device for producing bright and clean yarn through spiral airflow

ActiveCN103614820AReduce generationSmooth appearanceContinuous wound-up machinesOpen-end spinning machinesYarnEngineering

The invention belongs to the technical field of spinning equipment, and discloses a spinning device for producing bright and clean yarn through spiral airflow. The spinning device comprises an upper twisting wheel and a lower twisting wheel, wherein yarn penetrates through the space between the upper twisting wheel and the lower twisting wheel and then penetrates through a yarn passing groove of a spiral airflow generator. The side edge of the spiral airflow generator is provided with two holes which are respectively a spiral air-blowing hole in the upper portion and a horizontal air-blowing hole in the lower portion, wherein the spiral air-blowing hole is connected with an external spiral air inlet pipe, the horizontal air-blowing hole is connected with an external horizontal air inlet pipe, the spiral air-blowing hole is tangent with the inner wall of the yarn passing groove and is arranged at a certain angle so that the airflow can rotate spirally along the inner wall of the yarn passing groove to blow yarn hairness to be twisted in the twisting direction of the yarn, and then the yarn hairness is fixed along with the twisting of the yarn. By means of the spinning device for producing the bright and clean yarn through the spiral airflow, the amount of generated yarn hairness can be reduced obviously, the produced bright and clean yarn is smooth in surface and high in strength, and a fabric made from the bright and clean yarn is fine and smooth in hand feel, comfortable to ware and bright-colored in gloss.

Owner:DEZHOU HENGFENG TEXTILES

Low-temperature shock-resistant fluorocarbon finishing paint for bridges and preparation method thereof

ActiveCN103709921AEffective protectionImprove buckling resistancePolyurea/polyurethane coatingsUltravioletTitanium

The invention discloses a low-temperature shock-resistant fluorocarbon finishing paint for bridges and a preparation method thereof. The finishing paint is composed of a component A and a component B, wherein the component A comprises the following components in parts by weight: 54-56 parts of trifluoro FEVE resin, 0-14 parts of diluter, 2.2-2.4 parts of dispersing agent, 25.5-29.8 parts of titanium white, 0.8-1.2 parts of thixotropic agent, 0.4-0.6 part of leveling agent, 0.8-1.2 parts of anti-ultraviolet absorbent and 0.3-0.8 part of silane coupling agent; the component B comprises the following components in parts by weight: 50 parts of isocyanate curing agent and 50 parts of diluter; and the weight ratio of the component A to the component B is 5:1. The paint can still have very high impact resistance at low temperature (-40 DEG C), has high glossiness and high gloss retention, and can be used as a bridge paint for cold areas.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN +2

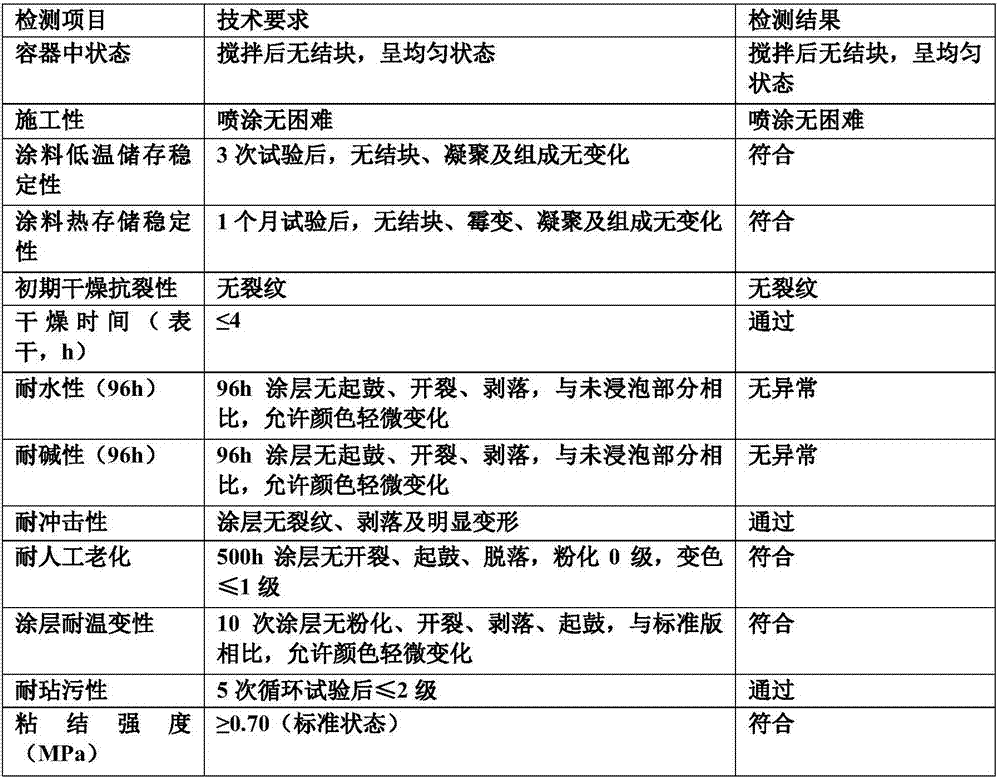

Stone-like coating for outer wall

The invention relates to the field of wall surface coatings, in particular to a stone-like coating for an outer wall. The stone-like coating is prepared from the following components in parts by mass:100 to 200 parts of emulsion, 300 to 400 parts of colored sand, 7 to 15 parts of a thickening agent, 0.5 to 1 part of a pH regulator, 8 to 15 parts of a coalescing agent, 0.5 to 1 part of a dispersing agent, 0.5 to 1 part of a defoaming agent, 0.5 to 1 part of a bactericide, 5 to 10 parts of a water repellent and 150 to 200 parts of deionized water, wherein the colored sand is used after being subjected to spray drying by using an aqueous solution of a chitosan / PEG blender. According to the stone-like coating for the outer wall, disclosed by the invention, the problems of high possibility oflayering, low film forming and drying speed and the like of an existing stone-like coating can be effectively solved; meanwhile, the usage of the colored sand in the formula is greatly reduced, so that the cost is reduced, and the application of natural colored sand in the coating is also facilitated.

Owner:YIWU INDAL & COMMERICAL COLLEGE

Method for preparing black garlic by fermenting with mixed bacteria

InactiveCN104305078AStrong penetrating powerPromote rapid reproductionFood preparationAdditive ingredientAllium sativum

The invention belongs to the field of food processing and particularly discloses a method for preparing black garlic by fermenting with mixed bacteria. According to the scheme, the method comprises the following steps: selecting raw materials, preparing the mixed bacteria, fermenting with the mixed bacteria, heating and boiling, standing for naturally fermenting, ageing, and drying to obtain the finished black garlic product, wherein the mixed bacteria are prepared from lactobacillus and saccharomycetes in a weight ratio of 2 to 1. The method has the advantages of short fermentation period, high production efficiency and low cost; the black color of the appearance of the black garlic is deepened, the color and luster of the black garlic are uniform and the black garlic is bright and glossy and has good mouth feel; nutritional ingredients are obviously improved, the total content of amino acids is more than 9% and the content of total sugar is more than 58%; and therefore, the black garlic has good market prospect and competitiveness.

Owner:徐州绿之野生物食品有限公司

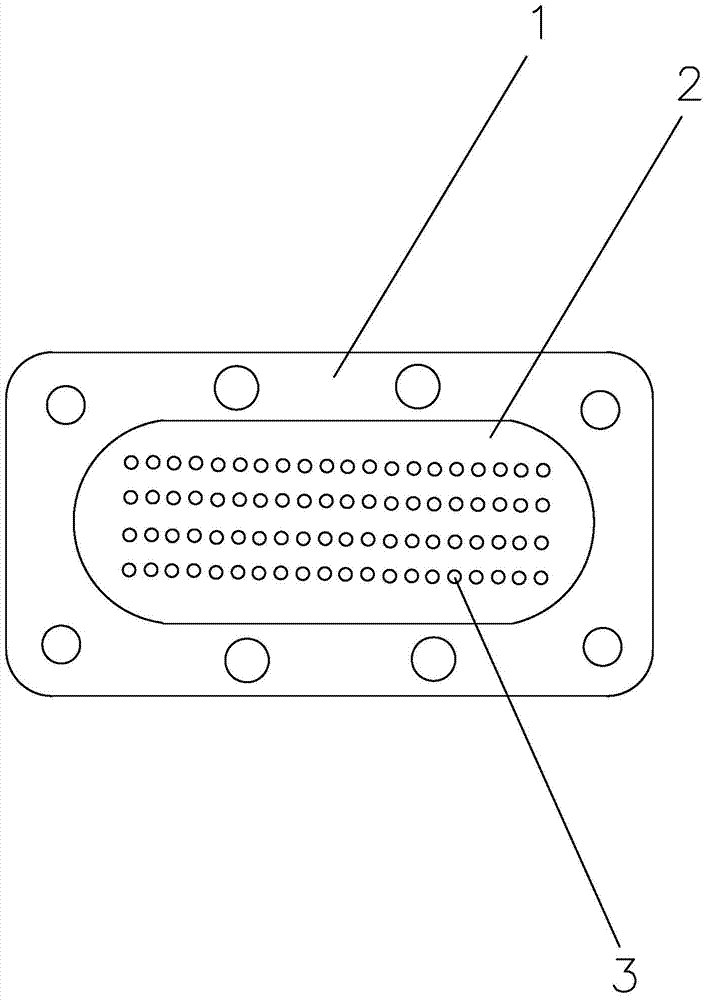

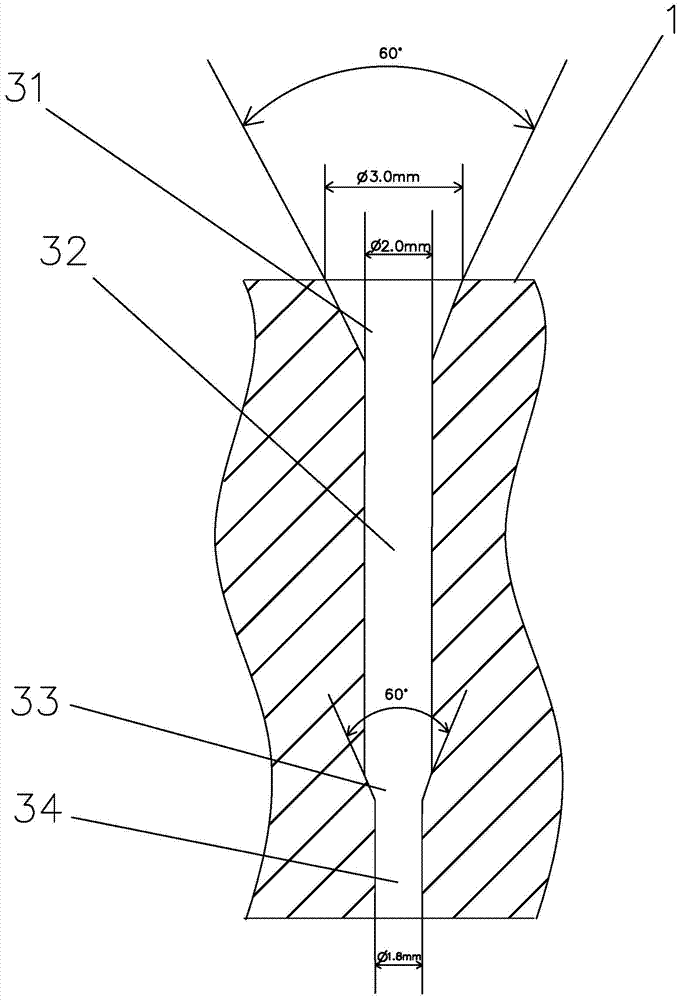

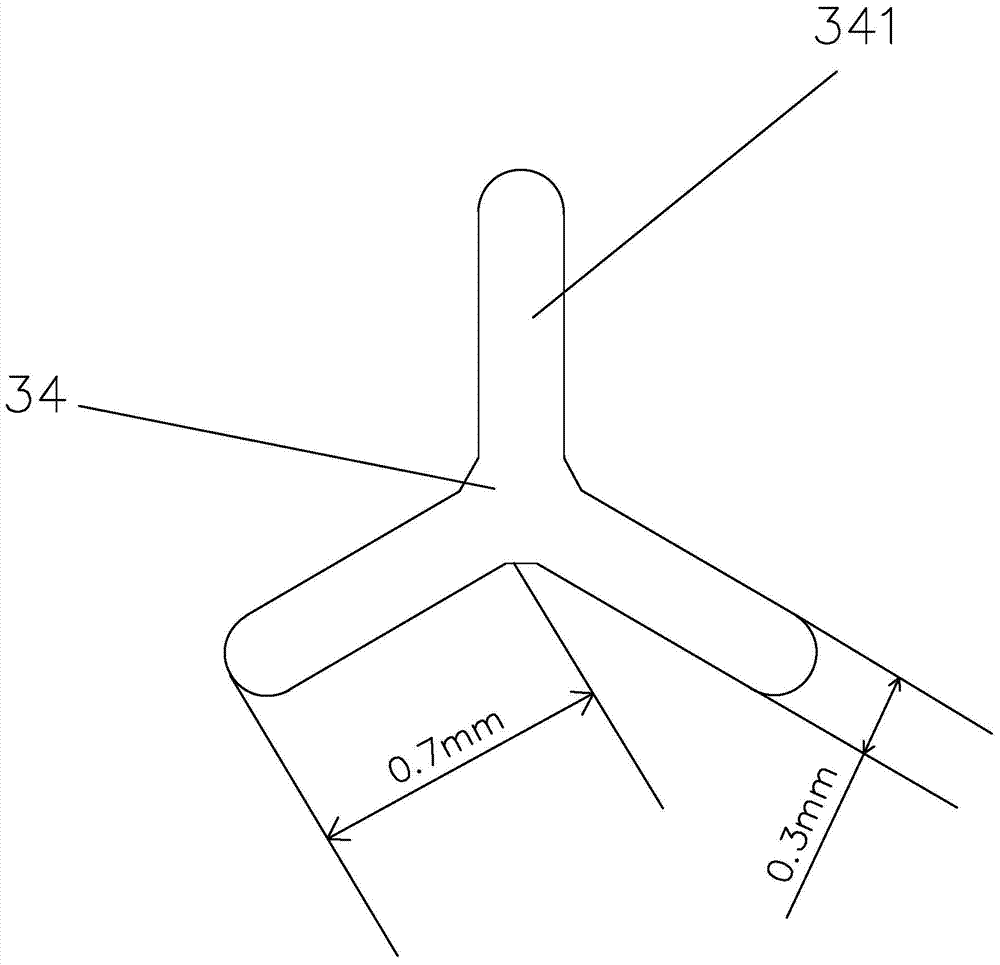

Special spinneret plate for spinning PA6 bulk yarns

The invention discloses a special spinneret plate for spinning PA6 bulk yarns. The special spinneret plate comprises an oblong-shaped spinneret plate body, wherein the middle part of the spinneret plate body is provided with an elliptical spinneret hole area, the interior of the spinneret hole area is provided with 80 spinneret holes, each spinneret hole consists of an elastic convergent area I, an elastic convergent area II and a capillary area from top to bottom in sequence, each elastic convergent area I and each elastic convergent area II are respectively of an inverted frustum-shaped structure, each capillary hole is of a three-blade shape, the three blades of each three-blade capillary hole are respectively and uniformly distributed along the center of the corresponding capillary hole to the outside, the length of each blade is 0.7mm, and the width is 0.3mm. The special spinneret plate has the advantages that a melting body is enabled to be slowly converged and transited to a guide hole for elastic loosening, and then is subject to the elastic convergence to enter each capillary hole for spinning, so the damage to the melting body due to the large shearing force caused by the melting body entering and exiting the guide hole in the spinneret plate is greatly reduced by the elastic convergent, the uniform temperature and viscosity of the melting body are kept, the fiber with high quality is favorably spun, the spun fiber has bright and attractive luster, and the requirement of the carpet industry on the luster of the bulk yarn is met.

Owner:TAICANG UNIVERSAL FIBERS COMPANY

Jun porcelain sapphire blue glaze and preparing method thereof

The invention discloses jun porcelain sapphire blue glaze. The jun porcelain sapphire blue glaze is prepared from, by weight, 40-48 parts of melilite, 14-18 parts of quartz, 12-18 parts of calcite, 12-18 parts of Ben drug, 3-5 parts of copper ore, 3-5 parts of zinc oxide, 0.5-1.5 parts of stannic oxide, 0.5-1.5 parts of copper oxide, 0.2-0.4 part of cobaltous oxide. The preparing method of the junporcelain sapphire blue glaze includes the following steps that the raw materials are smashed, mixed and put into a ball grinder to be grinded, water is added so that the mass concentration of the glaze can reach 55-56%, wet grinding is carried out by 8-10 hours, slurry obtained after wet grinding is screened through a screen of 200-300 mesh to obtain glaze slip; a green body is soaked in the glaze 1-2 times; sintering is carried out at the temperature of 1280-1320 DEG C.

Owner:禹州市锦丰源瓷业有限公司

Preparation method of tensile and aging resistant transfer film

InactiveCN109080359AGood adhesionImprove adhesionDecorative surface effectsOther printing apparatusUltraviolet lightsPhotochemistry

Owner:FOSHAN CHAOHONG NEW MATERIAL TECH CO LTD

Safety helmet protection paint and preparation method thereof

The invention discloses safety helmet protection paint and a preparation method thereof, and relates to the technical field of paint. The safety helmet protection paint is prepared from waterborne saturated polyester resin, ammonia neutralizers, white emulsion adhesives, beewax, defoaming agents, thickening agents, petroleum coke powder, waterborne white paste and deionized water, wherein the thickening agents comprise, by weight, hydroxymethyl fibers, bentonite, apatite, sea-foam stone powder and corn starch. The preparation method includes the steps: 1) adding 24-25 parts of waterborne saturated polyester resin into a container, stirring the waterborne saturated polyester resin by a high-speed disperser and gradually dripping the ammonia neutralizers while stirring; 2) completely grinding solid raw materials, adding all the solid raw materials into the container, and sufficiently mixing and emulsifying the solid raw materials; 3) adding the waterborne white paste and the white emulsion adhesives into the container, finally, adding the deionized water, continuing dispersion for 10-15 minutes and enabling a test pH (potential of hydrogen) value to range from 7.5 to 8.5 to obtain the paint. The paint is environmentally friendly, safe, free from pollution, high in hardness, not easy to scratch, convenient to produce and long in service life.

Owner:阜南县邰氏宇崴运动器材有限公司

Black garlic and preparation method thereof

InactiveCN104273467AImprove nutritional functionGood tasteFood preparationAllium sativumFermentation

The invention particularly relates to black garlic and a preparation method thereof, belonging to the field of food processing. According to the technical scheme, the preparation method comprises the following steps: adding garlic cloves into a fermentation tank, fermenting by virtue of a culture solution containing 3%-6% of a compound bacteria fermenting agent in percentage by weight at 35-36 DEG C for 24 hours, then fermenting for 72 hours after the temperature is adjusted to be 39-31 DEG C, and after the fermentation, putting the garlic cloves into stainless steel discs, wherein round holes having the diameters phi of 5cm are formed in the periphery and the bottom of the stainless steel discs, and the thickness of the added garlic cloves is 10cm; introducing steam into the stainless steel discs, fermenting at the temperature of 95-100 DEG C for 48-72 hours, so as to obtain black garlic intermediates, wherein the fermenting humidity is 95%-100%; putting the black garlic intermediates into polyethylene bags, tightening openings of the polyethylene bags, ripening for one week at 5-8 DEG C, carrying out aeration-drying on the ripened black garlic at a shade place, carrying out calculation and vacuum packaging, and carrying out sterilization by virtue of boiling water of 100 DEG C for 25 minutes, so as to obtain the finished black garlic. The preparation method is reasonable and simple in process, easy to operate and suitable for large-scale production.

Owner:徐州绿之野生物食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com