Special spinneret plate for spinning PA6 bulk yarns

A spinneret and bulked yarn technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as high difficulty, high difficulty, difference in production efficiency and yield, and achieve temperature and viscosity Maintains an even, vibrant luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

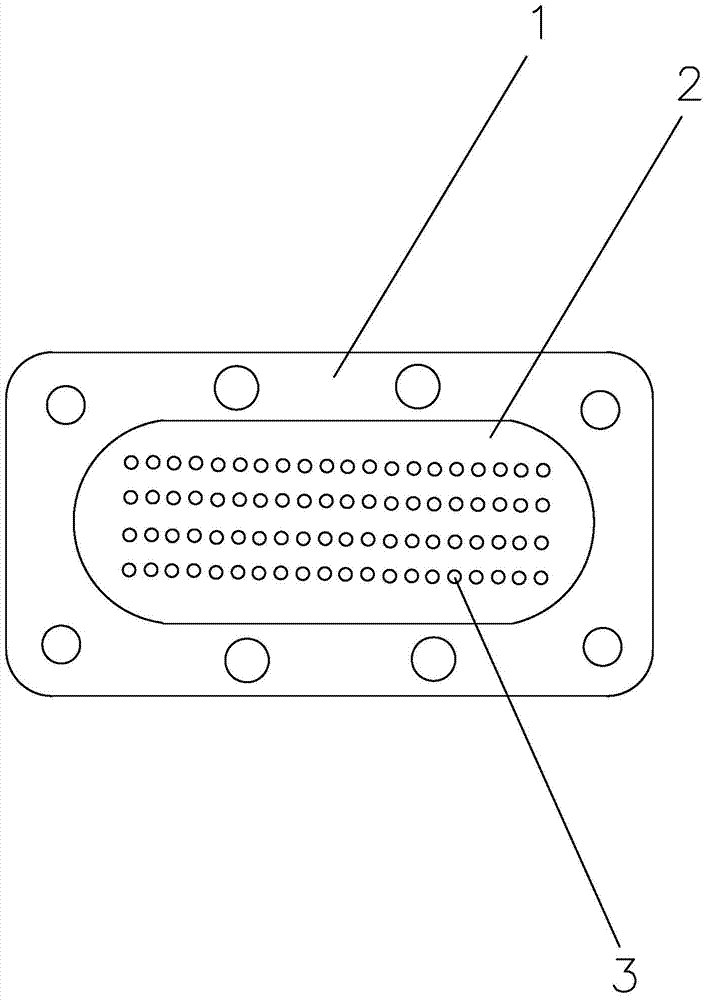

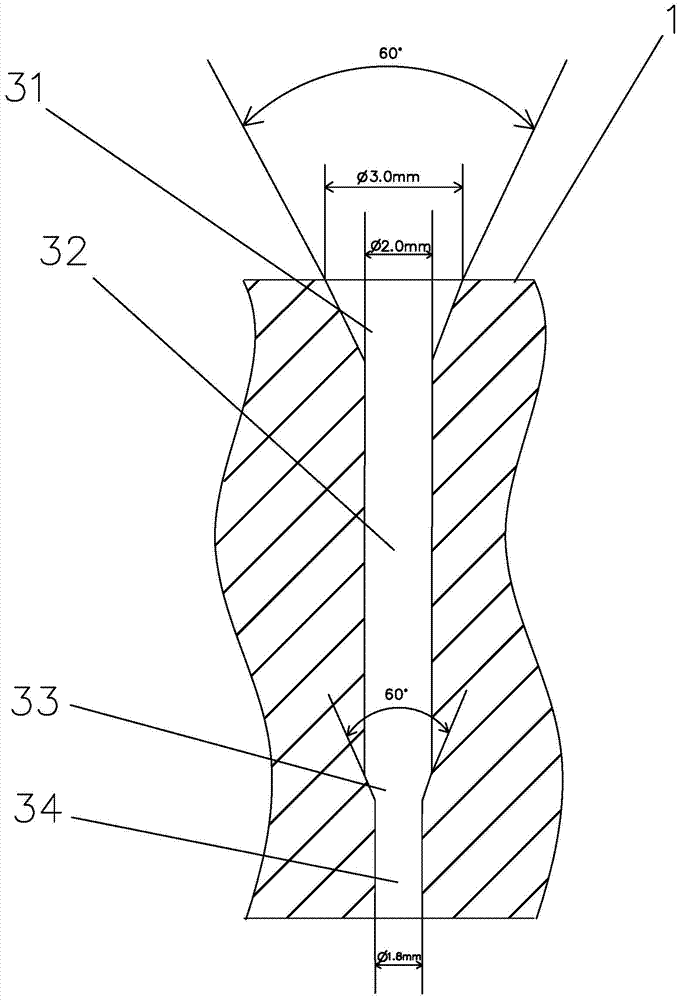

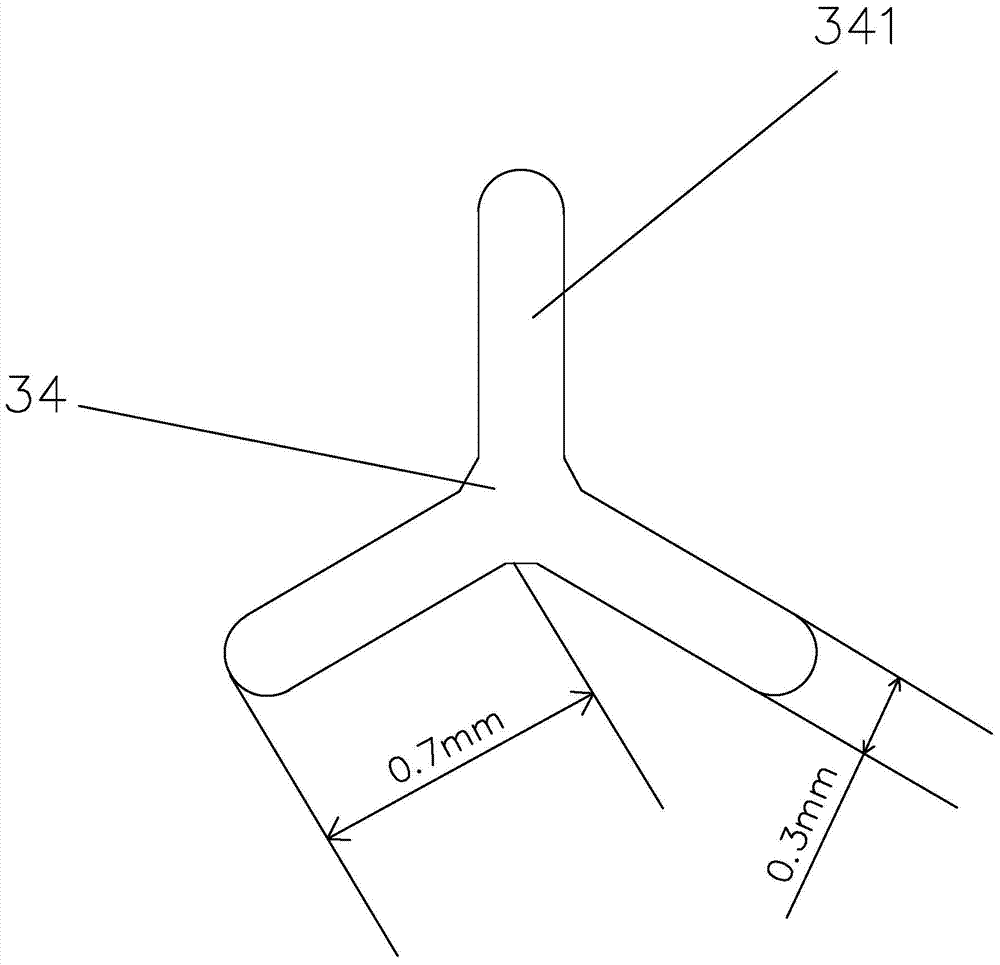

[0019] Such as figure 1 , figure 2 and image 3 As shown, a special spinneret for spinning PA6 bulked yarn, including a rectangular plate-shaped spinneret body 1, the middle part of the spinneret body 1 is provided with an oval spinneret hole area 2, and the spinneret hole area 2 is provided with 80 spinneret holes 3; the spinneret holes 3 are sequentially composed of an elastic convergence area 31, a guide hole 32, an elastic convergence area 33 and capillary holes 34 from top to bottom. 31 and the second area of elastic convergence 33 are rounded truncated structures, the capillary 34 is trilobal, and the three lobes 341 of the trilobal capillary 34 are evenly distributed outward along the center of the capillary 34, so The leaflet 341 has a length of 0.7mm and a width of 0.3mm.

[0020] Wherein, the convergence angles of the first elastic convergence zone 31 and the second elastic convergence zone 33 are both 60 degrees, and the diameter of the upper port of the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com