Patents

Literature

505results about How to "Reduce formaldehyde content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Encapsulated active material with reduced formaldehyde potential

InactiveUS20070138671A1Reduce formaldehyde contentReduced potential for generatingDetergent compounding agentsCoated detergent compositionsPersonal careScavenger

The invention in its various embodiments provides a microcapsule product with reduced levels of formaldehyde. Formaldehyde levels are reduced by the inclusion of a formaldehyde scavenger. The microcapsules provided are well suited for rinse-off applications associated with personal care and cleaning products

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

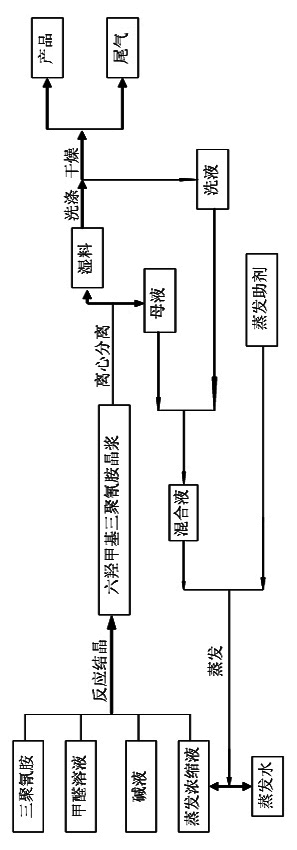

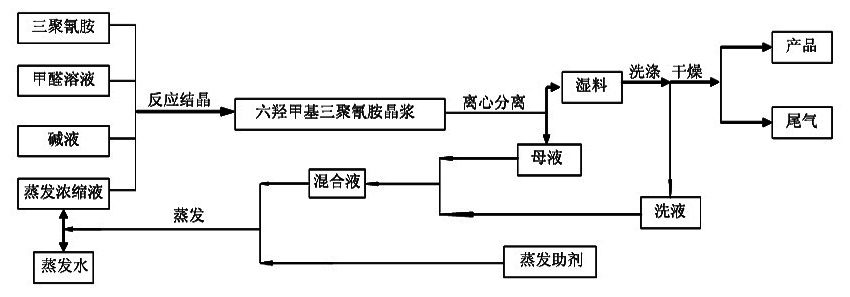

Process for producing hexamethylol melamine

ActiveCN102010380AReduce processingReduce processing difficultyOrganic chemistryWater/sewage treatment by heatingFormateEvaporation

The invention discloses a process for producing hexamethylol melamine, belonging to the field of production and preparation of hexamethylol melamine. The process comprises the steps such as mixing, reaction and crystallization, centrifugalization, evaporation and the like, wherein evaporation auxiliary formate is added when in evaporation so as to change the relative volatility of formaldehyde and water. Furthermore, the process for producing the hexamethylol melamine together with a formaldehyde device can also be used for co-production, so that the concentration of the produced formaldehyde solution is improved to 45wt%-55wt%. The produced hexamethylol melamine provided by the invention has the advantages of small amount of waste water and low formaldehyde content, namely, if 1 ton of hexamethylol melamine is produced, 1 ton of waste water containing 0.84wt% of formaldehyde is discharged. After the process provided by the invention and the formaldehyde device are used for co-production, the formaldehyde production cost and transportation cost are reduced, and the comprehensive cost is 10% less than that of other processes.

Owner:SICHUAN GOLDEN ELEPHANT SINCERITY CHEM CO LTD

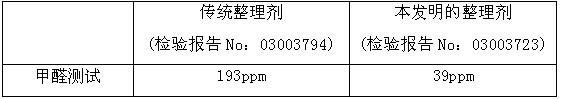

Sterilizing shape-memory-fabric finishing agent and finishing method

This invention discloses a sterilization shape memory fabric finishing agent and the processing method. It is composed of the following component and the weight percentage: the river character shape memory polyurethane ranging from 2-20%, the low formaldehyde which can prevent burning the reorganization resin 3-30%, the traditional Chinese medicine extraction used to sterilize 1-10%, the catalyst 1-5%, the remainder is the water. Various components should proportionate duplicate match then. This invention's sterilization river character shape memory fabric finishing agent formaldehyde content is low, the force slightly loses. Besides, it has the shape memory property, the high crease-resist performance, and the antibacterial health care function. So it may substitute for the traditional which can prevent burning the reorganization resin finishing fabric, and the application prospect is broad.

Owner:SOUTH CHINA AGRI UNIV

Technology for processing formaldehyde-free and benzo(alpha)pyrene-free smoked meat product

ActiveCN102742857AOptimizing the smoking processShorten process timeMeat/fish preservationFood preparationPyreneBenzene

The invention belongs to the field of food processing and discloses a technology for processing a formaldehyde-free and benzo(alpha)pyrene-free smoked meat product. The technology comprises the following steps of 1, raw material selection and pretreatment, 2, pickling liquid preparation and pickling, 3, washing and drying in air, 4, pre-heating, drying and smoking, and 5, heat dissipation, vacuum packaging, labeling and warehousing. The technology adopts a sectional-type baking technology, improves product quality and solves the problems of meat product surface scabbing, drying and hardening caused by the traditional technology. The technology simplifies and optimizes the traditional smoking technology, shortens processing time, reduces a production cost, obviously improves product quality, and well solves the problems of meat product surface scabbing, drying and hardening caused by the traditional technology. Through the combination of the processes and use of a smoking solution which has effects of coloring and improving a taste and is safe, the formaldehyde-free and benzo(alpha)pyrene-free smoked meat product is obtained.

Owner:NANJING AGRICULTURAL UNIVERSITY

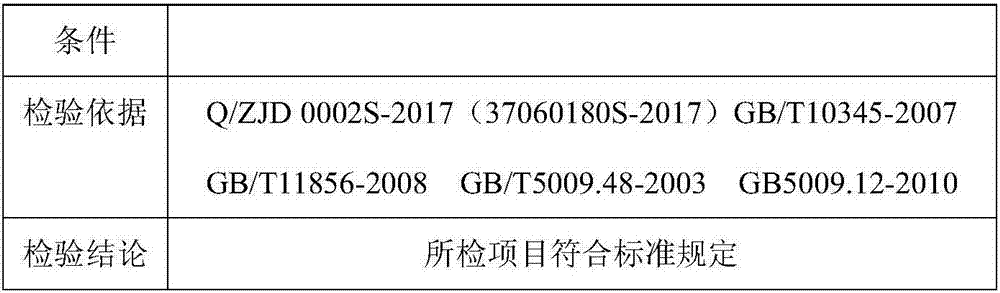

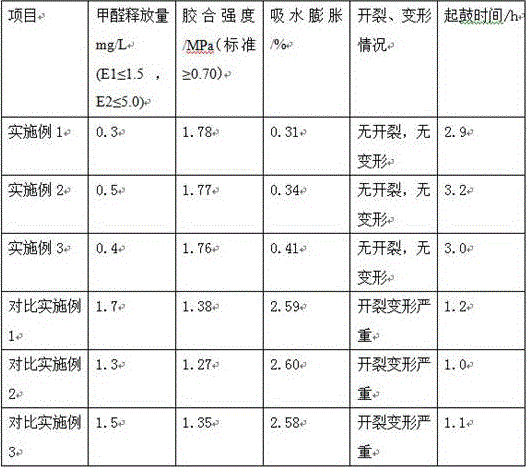

Production method for low-formaldehyde solid wood composite floor

ActiveCN105235024AAvoid gel effectLow residual formaldehydeLaminationLamination apparatusParquetinaSolid wood

The invention relates to a solid wood composite floor, in particular to a production method for a low-formaldehyde solid wood composite floor. The production method comprises the technological steps of wood plate slicing, drying, repairing, selecting, gluing, pre-pressing, hot pressing, edge cutting and sanding, and finished product obtaining. The key of the production method is that the residual amount of formaldehyde in adhesives is reduced by modifying the used urea-formaldehyde resin adhesives, so that the residual amount of the formaldehyde in the solid wood composite floor is reduced; by adopting high-quality plates and controlling process parameters in the production process, the quality of the produced solid wood composite floor is guaranteed. The content of the formaldehyde in the solid wood composite floor manufactured through the method is low, the quality of the floor is stable, and the floor is not prone to damage; the floor has the characteristics of being comfortable in foot feeling, resistant to abrasion, easy to install and clean, and high in stability.

Owner:DALIAN SHENGYU TECH DEV CO LTD

Blocking absorbent of formaldehyde and its preparing process and application

InactiveCN1359992ANon-toxicHeat resistantHyaluronic acid coatingsChitin coatingsHigh resistanceAcetic acid

A formaldehyde absorbent in sealed condition is prepared from chitosan, acetic acid and water. It can be used by spraying it on the surface of furniture or floor to absorb the formaldehyde released by them, or by preparing its solid and arranging the solid in furniture. Its advantages are high effect, no toxicity, and high resistance to high temp and rubbing.

Owner:刘晓阳

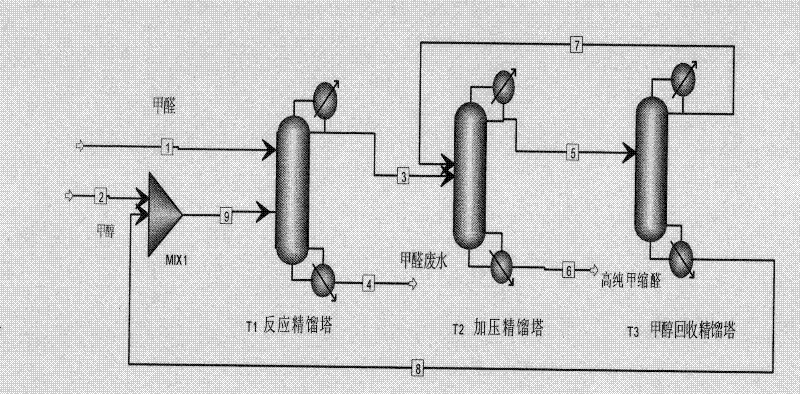

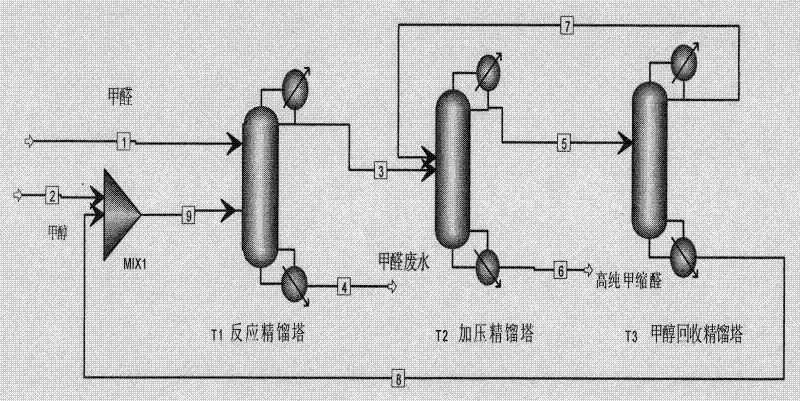

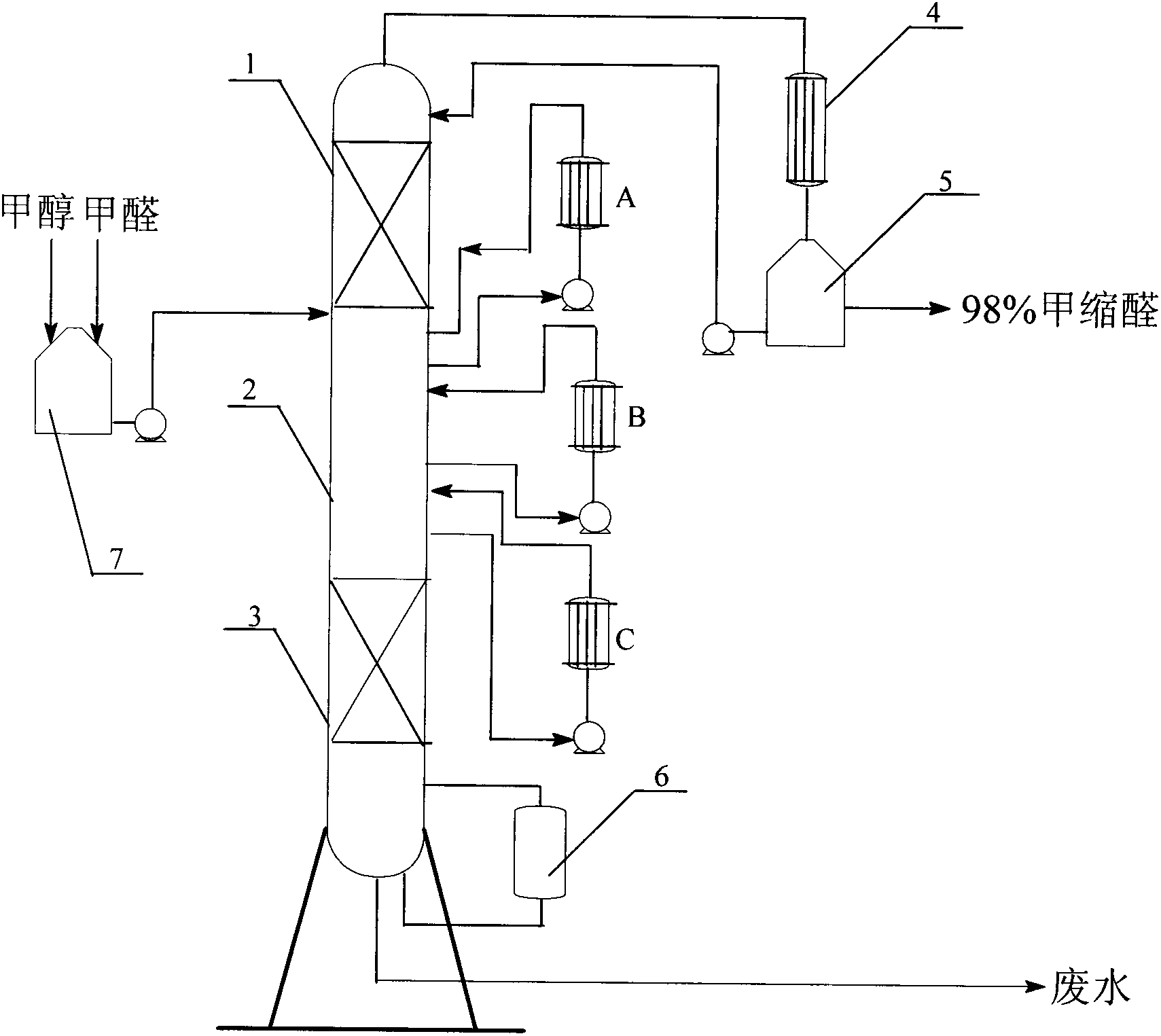

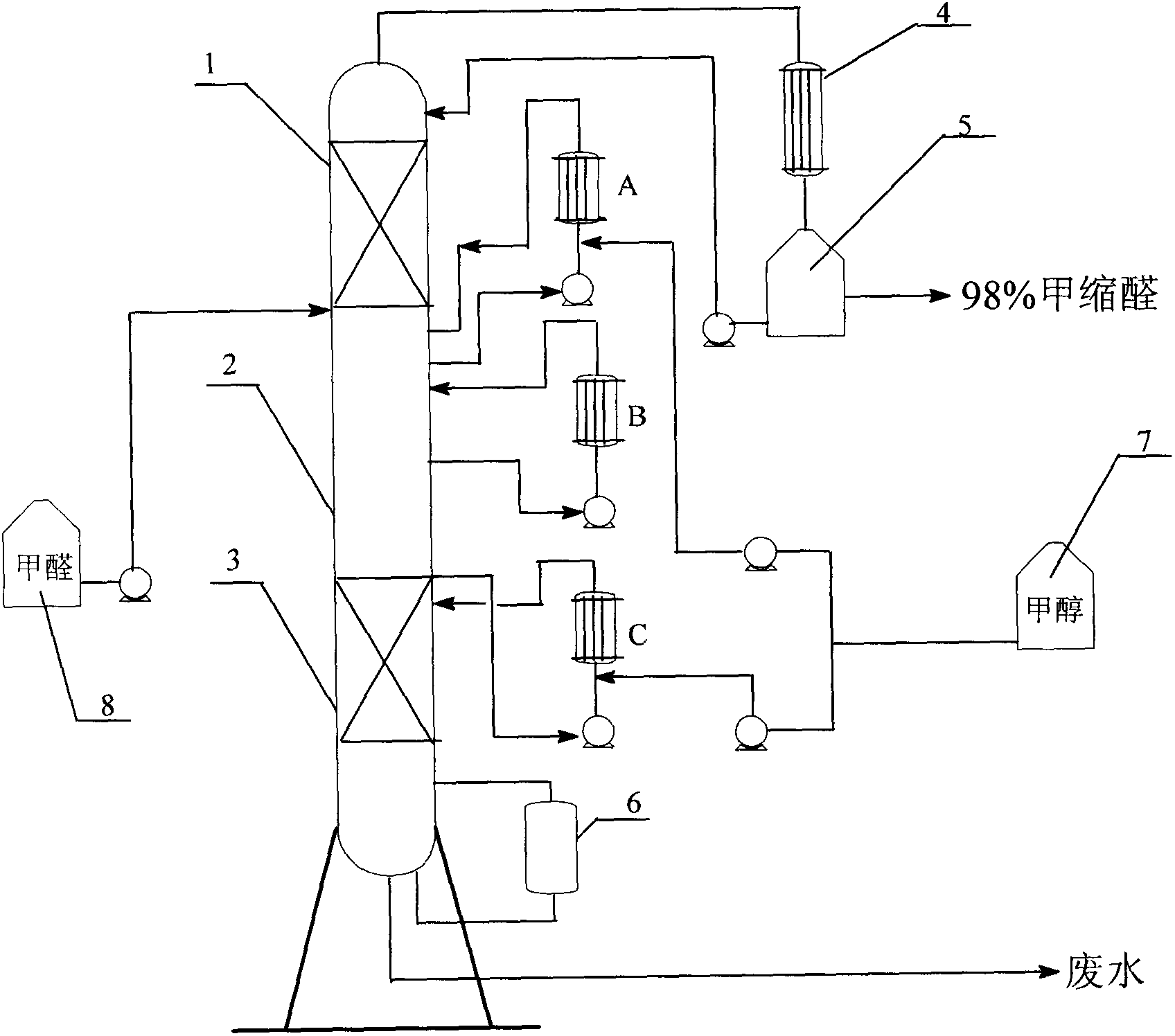

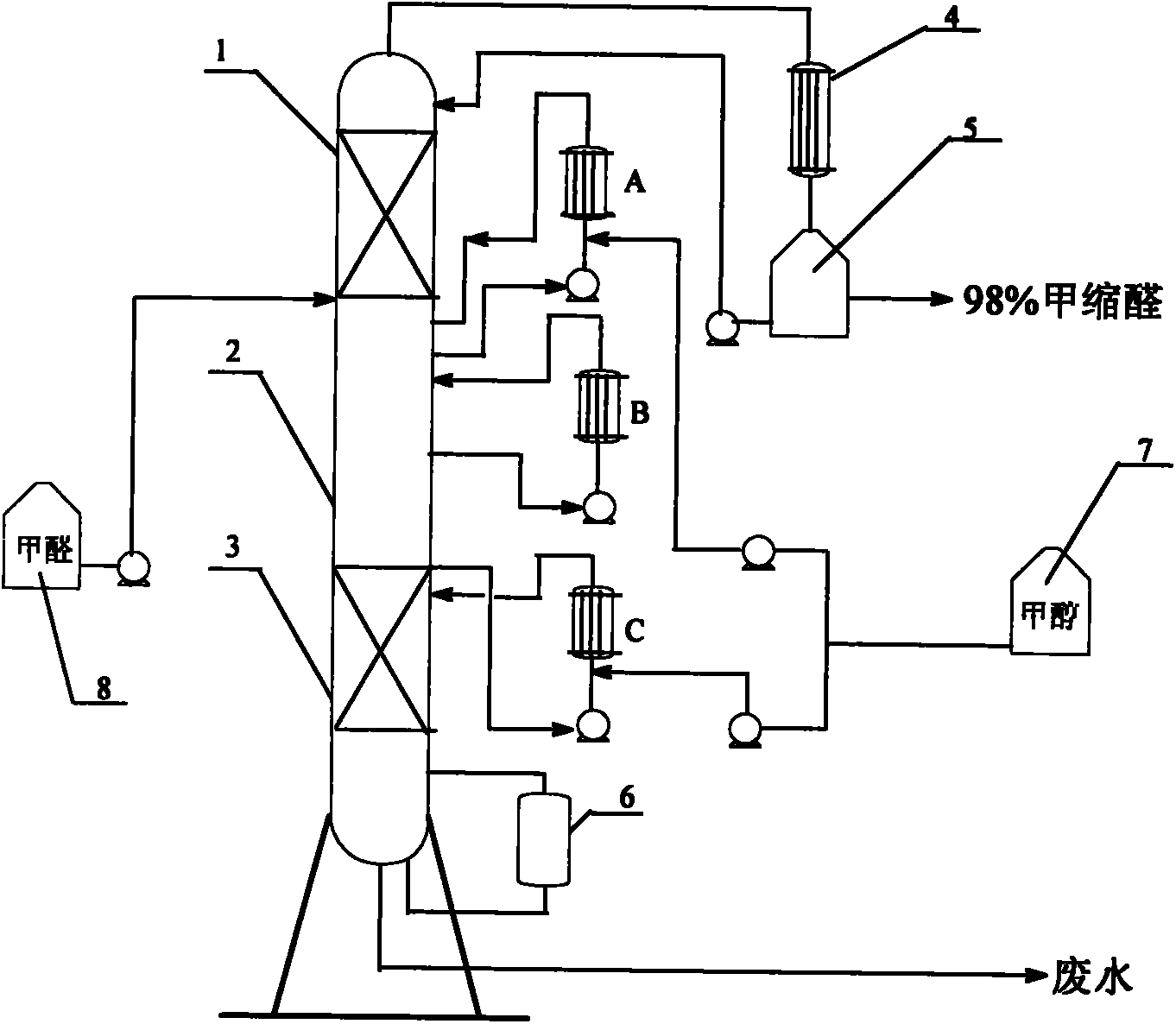

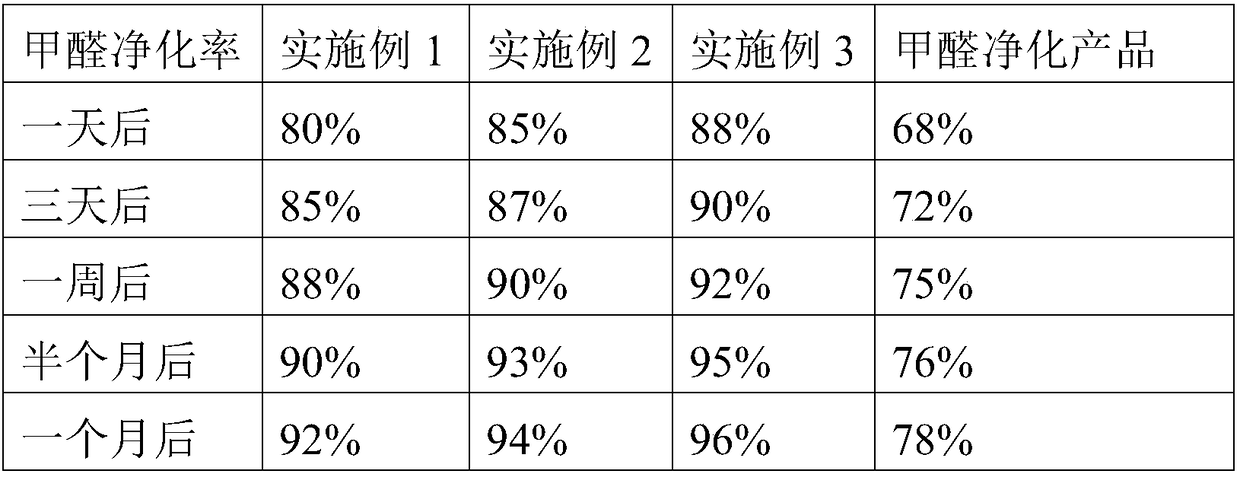

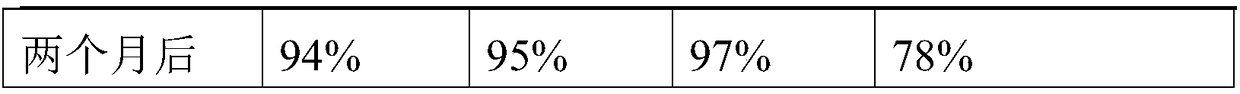

Preparation method for high-purity methylal

InactiveCN102417442AReduce formaldehyde contentIncrease profitOrganic chemistryOrganic compound preparationWastewaterVariable pressure

The invention provides a preparation method for high-purity methylal. A production technology has the advantage of low formaldehyde emission. According to the production technology, carbinol and formaldehyde are taken as raw materials, and a reaction rectifying technique and a variable pressure difference rectifying technique are used for preparing the high-purity methylal with the purity above 99.9%. The content of the formaldehyde in the discharged waste water is less than 500ppm. According to the whole technological process, the purity of the methylal product is promoted, the recycling use ratio of the materials is increased and the content of the formaldehyde in the waste water is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

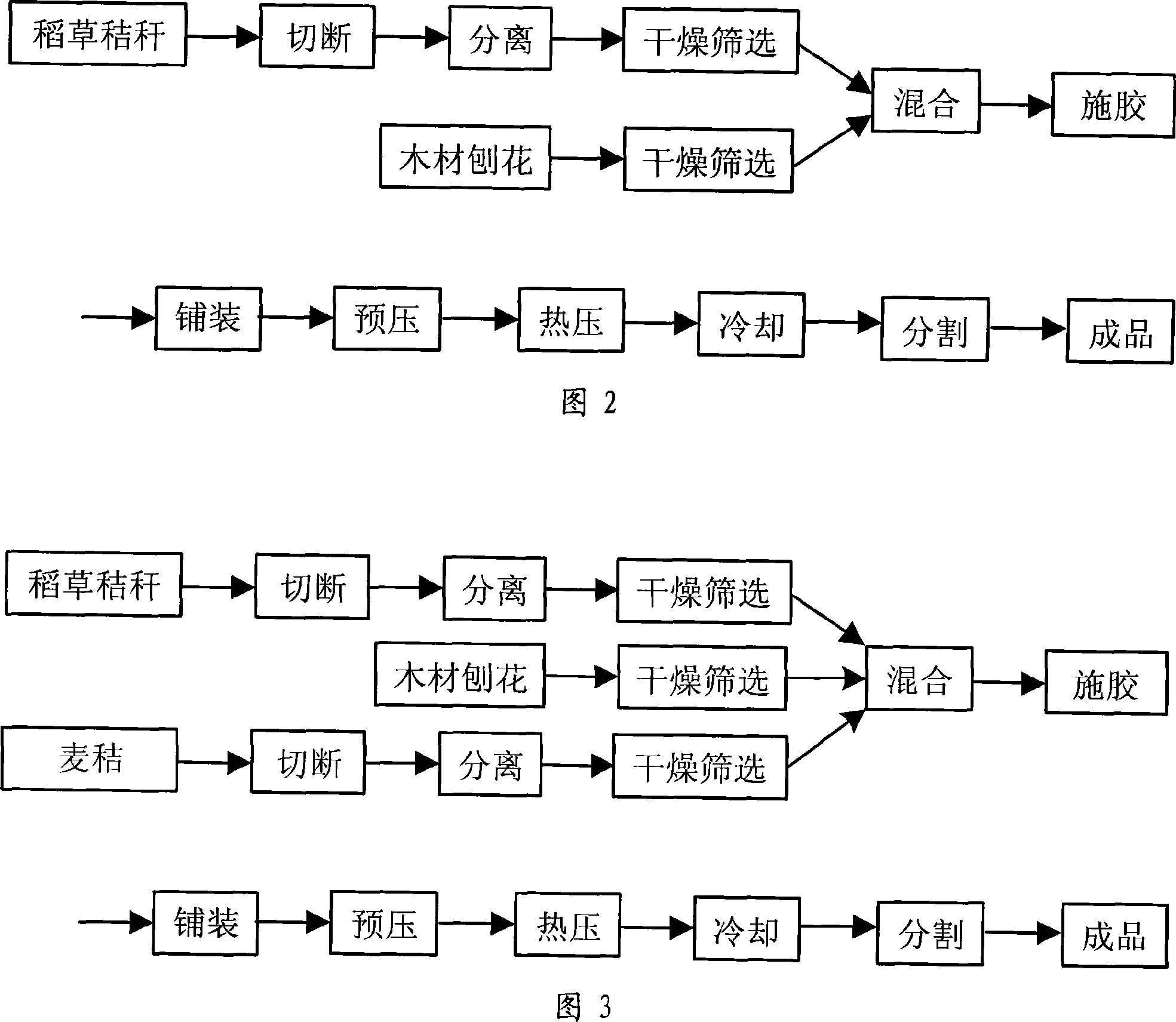

Method for making environment-friendly type composite vegetation high and medium density fiber board

InactiveCN1570275AReduce consumptionExpand sourceFibreboardWater-repelling agents additionTextile fiberCellulose

This invention discloses one environmental protection vegetation compound high school density fiberboard manufacture method. This method use straw stalk processing smashing,grinding paste, defibering, exerts urea resin rubber,preparation straw stalk executes the rubber textile fiber;then uses lumber grinding paste,defibering, exerts the urea resin rubber, preparation lumber executes rubber textile fiber, executes lumber rubber textile fiber and straw stalk executes rubber textile fiber according to the proportion mix; Executes rubber textile fiber paving to take shape, the thermo-compression becomes the high school density cellulose board; Is spatial airtight the element board through the center falls the aldehyde processing room, this processing room separated in two parts; falls aldehyde processing room to pass over the ammonia, causes the element board two sides to have the pressure difference, ammonia penetrates element board under the pressure difference function, the adjustment falls aldehyde processing room controlled variable, may prepare the E1 / E0 level environmental protection high and middle density fiberboard through the physical chemistry function. This invention reduced lumber consumption, protected the environment, and reduced the production cost, this product formaldehyde content has been low, guarantee product environmental protection target.

Owner:NANJING FORESTRY UNIV

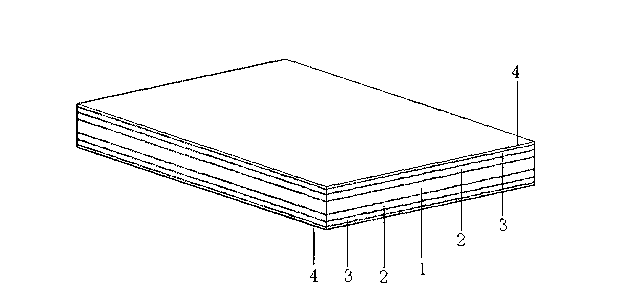

Manufacturing method of melamine ecological plate

InactiveCN103128804AReduce formaldehyde contentReduce production energy consumptionWood veneer joiningEmulsionEngineering

The invention discloses a manufacturing method of a melamine ecological plate. The ecological plate is compounded with a core plate, a middle plate layer, a slab layer and melamine impregnated paper. The core plate is stuck to the middle plate layer after an upper face and a lower face of the core plate are glued. After cold pressing and hot pressing, the core plate is repeatedly maintained, trimmed and sanded, and is glued and stuck to the slab layer. Similarly, after the cold pressing, hot pressing, trimming and sanding, the core plate is glued and stuck to the melamine impregnated paper. The ecological plate manufactured by the method is energy-saving and environment-friendly, and under the condition that energy consumption is not increased, the ecological plate is cold pressed before hot pressing so that a composite structure of the plate is firmer. Furthermore, in the process of pressing and gluing the melamine impregnated paper, emulsion free of formaldehyde is used as binding agent, and accordingly formaldehyde content of the plate is reduced.

Owner:江苏福庆木业有限公司

Urea resin and production thereof

A urea resin and its production are disclosed. The procedure is carried out by taking low-mol ratio methyl aldehyde and urea as raw materials, adding urea into methyl aldehyde by 4 times, activating methyl aldehyde at 50+-5 degrees C for 15-25mins before adding urea for first time, and adding into ammonia water to have rear-treatment after adding urea for fourth time to obtain final product. It is simple and cheap, has no any modifier and dewatering.

Owner:BEIJING FORESTRY UNIVERSITY +1

Natural polymer composite-base formaldehyde remover and preparation method thereof

InactiveCN101607174AImprove the level of environmental protectionFlexible usageDispersed particle separationAdhesiveNational standard

The invention discloses a formula of a formaldehyde remover made from a natural plant extract and a preparation method thereof. The raw material of the formaldehyde remover is the natural plant extract which can react with formaldehyde with high efficiency. After being prepared, the solution of the formaldehyde remover is added into adhesives, or sprayed on the surfaces of furniture or plates or sprayed into the air to make formaldehyde content of a post-processed products or space meet the requirements of national standards.

Owner:上海复爱绿色化学技术有限公司 +1

Colour development methyl aldehyde adsorption material and preparation method thereof

ActiveCN101468304AResponsivenessRapid pollutionMaterial analysis by observing effect on chemical indicatorOther chemical processesFormaldehyde productMethyl aldehyde

The invention discloses a chromogenic formaldehyde adsorbing material and a preparation method thereof. The adsorbing material consists of a carrier, a high molecular organic amine polymer, a polylol polymer and a formaldehyde reaction indicator, wherein the high molecular organic amine polymer and the polylol polymer account for 1 to 50 percent of formaldehyde adsorbent, the formaldehyde reaction indicator is little, and the balance being the carrier. The preparation method thereof comprises the following steps: mixing the high molecular organic amine polymer and the polylol polymer according to mass, adding deionized water to dilute the mixture so as to prepare formaldehyde reagent; mixing the formaldehyde reagent and the formaldehyde reaction indicator; and spraying or dipping the mixed solution onto the surface of the carrier, and drying the carrier and so on. The adsorbing material and the preparation method can quickly, thoroughly and continuously remove formaldehyde pollution in indoor air until the content of the formaldehyde is reduced to safe concentration, are nontoxic, pollution-free, safe and environment-friendly to use, and can intuitively show the reaction degree of the formaldehyde.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

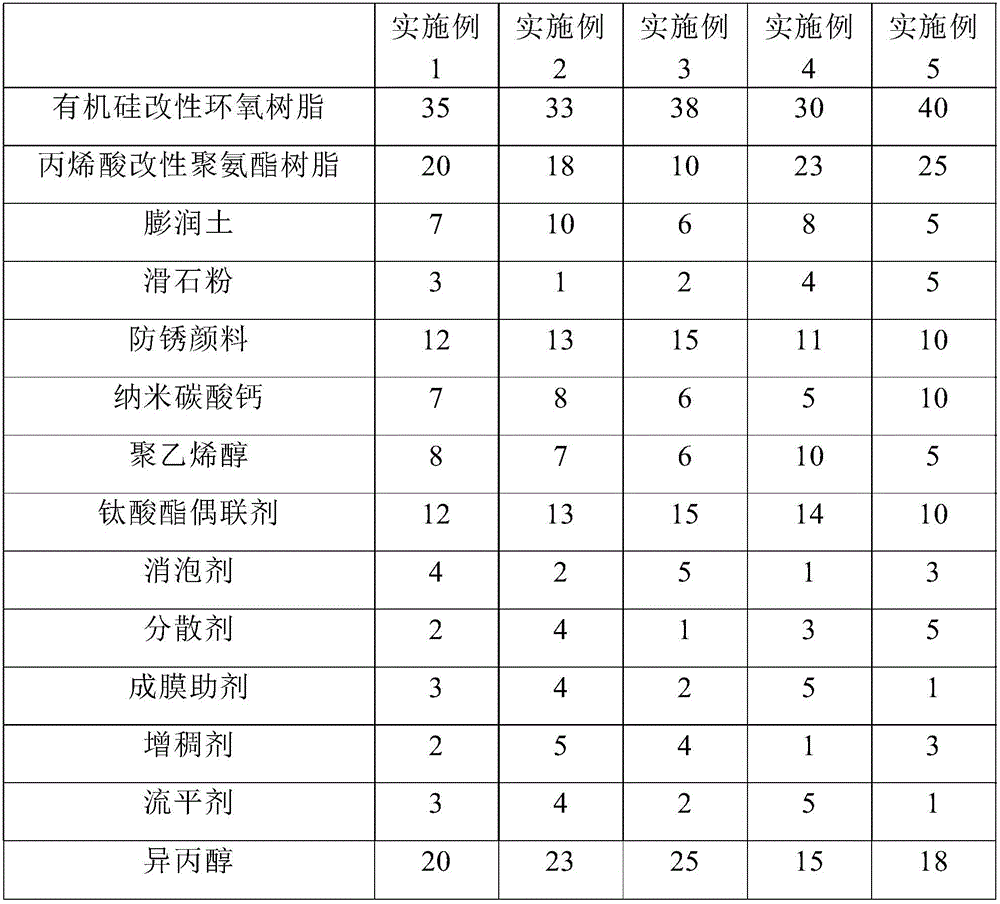

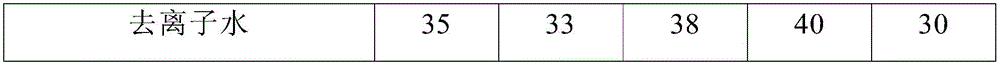

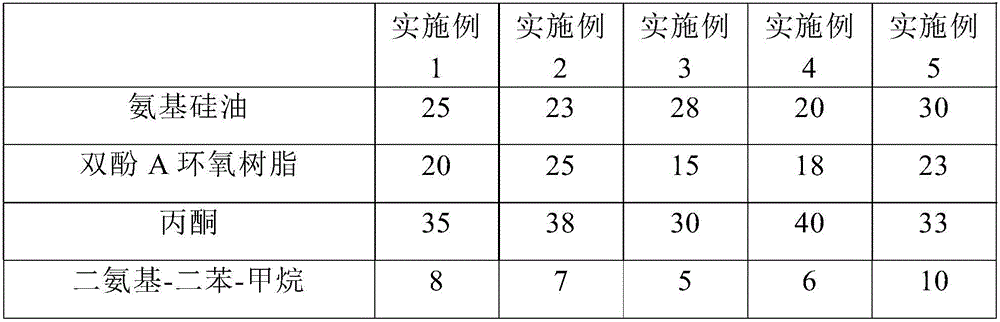

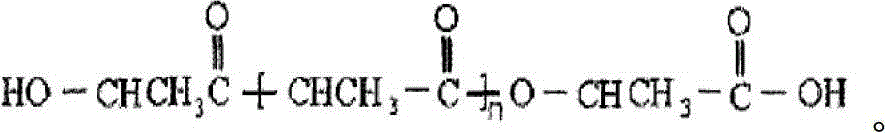

Environmentally friendly abrasion-resistant anticorrosive coating and preparation method thereof

InactiveCN106118360AHigh glossImprove antistatic performanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyPolyvinyl alcohol

The invention provides an environmentally friendly abrasion-resistant anticorrosive coating and a preparation method thereof. The environmentally friendly abrasion-resistant anticorrosive coating is prepared from, organic silicone modified epoxy resin, acrylic acid modified polyurethane resin, bentonite, talcum powder, antirust paint, nano calcium carbonate, polyvinyl alcohol, a titanate coupling agent, a defoaming agent, a dispersing agent, a coalescing agent, a thickening agent, a flatting agent, isopropyl alcohol and deionized water. The organic silicone modified epoxy resin and the acrylic acid modified polyurethane resin are matched, the modified epoxy resin and the polyurethane resin make the coating have good glossiness, good antistatic capability, better mechanical properties and ageing resistance and abrasion resistance properties, the added antirust paint can effectively improve the anticorrosive capability of the coating, also has price and environmental protection advantages, has strong adhesion, good ductility, high temperature resistant and long service life, roll-coating replaces spray-coating during coating, a production environment is effectively improved, and the coating is conducive to the body health of workers.

Owner:TAICANG JINXIN PAINT

Environment-friendly vehicle natural fiber composite material and preparation method as well as application thereof

ActiveCN102717558AReduce formaldehyde contentImprove low temperature impact resistanceSynthetic resin layered productsCellulosic plastic layered productsSlurryVolumetric Mass Density

The invention relates to an environment-friendly vehicle natural fiber composite material and a preparation method as well as application thereof. The preparation method of the vehicle natural fiber composite material comprises the following steps of: treating a continuous natural fiber fabric with water content of less than 0.2 percent by using a silane coupling agent; immersing the treated continuous natural fiber fabric in mixed slurry; drying the immersed continuous natural fiber fabric until the water content is less than 0.2 percent; soaking in molten polylactic acid with density of 1.22 g / cm<3>; performing hot pressing on the soaked fabric at 170-190 DEG C to obtain a natural fiber polylactic acid composite felt; and slicing the natural fiber polylactic acid composite felt, laminating and performing hot forming at 170-190 DEG C to obtain the vehicle natural fiber composite material. According to the vehicle natural fiber composite material, the natural fiber and the polylactic acid are used as raw materials, and the raw materials have environment-friendly sources, are renewable and can be completely degraded.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

Finishing agent composition for cotton-silk fabrics and processing method of cotton-silk easy-care shirt

InactiveCN105133315AOvercome the defect of poor anti-slip performanceRetain moisture permeabilityVegetal fibresAnimal fibresAdditive ingredientMoisture permeability

The invention discloses a finishing agent composition for cotton-silk fabrics. The finishing agent composition comprises the following ingredients by weight: 120 to 180 parts of dihydroxy ethylene-urea resin, 10 to 60 parts of a powerful protecting agent, 10 to 50 parts of a smoothing agent, 30 to 80 parts of a softening agent, 10 to 25 parts of a catalyst, 5 to 10 parts of an anti-fraying agent, 1 to 5 parts of a penetrating agent, and 5 to 10 parts of a formaldehyde scavenger. The invention further provides a processing method of a cotton-silk easy-care shirt. The processing method of the cotton-silk shirt garment comprises the following steps: prewashing, drying, material spraying, pre-drying, pressing, baking, purified water washing, drying and moisture regaining, wherein the finishing agent composition is uniformly applied onto the cotton-silk easy-care shirt in the material spraying step. The finishing agent composition is used for finishing process of the cotton-silk fabrics, and can be used for overcoming the defect that the anti-sliding property of the cotton-silk fabrics is lowered after conventional easy-care treatment, reserving the own moisture permeability, air permeability and natural drapability of the cotton-silk fabrics, and enabling the cotton-silk fabrics to have relatively high easy-care property. Therefore, people can wear the shirt comfortably, and the shirt is easy to care. Moreover, the formaldehyde content of the finished cotton-silk easy-care shirt can be lower than the national standard.

Owner:NINGBO YOUNGOR TECH

Formaldehyde scavenger for sleeve-fish and its application method

The invention discloses an effective, safe and economic squid formaldehyde scavenger, the scavenger is the extract from plant material and has the effective component of polyphenolic compound with concentration of 0.05 percent-0.15 percent (w / v). The invention also discloses a method for cleaning endogenous formaldehyde produced during squid processing by the formaldehyde scavenger, the squid is soaked adequately prior to processing, so the formaldehyde scavenger solution can be adequately permeated into squid muscle tissues, and squid meat slices are processed into products after soaking by a conventional method; and the formaldehyde produced by the squid meat pieces and plant polyphenolic compound in the squid muscle tissue generate reaction under the high temperature condition in the processing procedure and produce nontoxic high molecule substances. The method is easy and feasible and can greatly reduce formaldehyde content in squid product.

Owner:ZHEJIANG GONGSHANG UNIVERSITY +1

Polyacrylic ester coating adhesive emulsion and preparation method thereof

The invention discloses a polyacrylic ester coating adhesive emulsion, which is prepared from the following raw materials by weight percent: 20-50% of soft monomer, 5-20% of hard monomer, 0.5-2.0% of monomer containing carboxyl group, 1-5% of crosslinking monomer, 1-5% of emulsifier, 0.2-0.7% of initiator and the balance of deionized water, wherein the soft monomer is crylic acid alkyl ester; the hard monomer is one or two of methylpropenoic acid alkyl ester and styrene; the monomer containing carboxyl group is one or more of methacrylic acid, itaconic acid and maleic acid; and the corsslinking monomer is one or two of non-formaldehyde crosslinking monomer and inner crosslinking monomer containing two or more double bonds. The emulsion has good safety, no toxicity, low cost, high hydraulic pressure resistance, wide application range and the content of the formaldehyde of the coating accords with the European Union exit criteria. The invention also discloses a preparation method of the polyacrylic ester coating adhesive emulsion, which is simple to operate and is suitable for industrialized production.

Owner:ZHEJIANG UNIV

Photocatalystc composite floor board and production process of photocatalystc composite floor board

InactiveCN104989066ADoes not affect bond strengthAffect bond strengthLaminationLamination apparatusWood shavingsSurface layer

The invention relates to a photocatalystc composite floor board, and belongs to the field of a functional environment-friendly healthy floorboard. The formaldehyde emission content of the composite floorboard is less than 0.3mg / L; the antibacterial rate is higher than or equal to 90 percent; the surface wear-resistant coefficient is less than or equal to 0.08g / 100r; a substrate layer is an oriented shaving board layer; the oriented shaving board layer comprises an upper surface layer and a lower surface layer which are formed by glue mixing wood shavings in longitudinal arrangement according to the fiber direction and a core layer shaving layer formed by glue mixing wood shavings in transverse arrangement according to the fiber direction; and a decoration layer, a wear-resistant primer layer and a photocatalystc antibacterial paint decoration layer are sequentially arranged on the substrate layer. A production process of the photocatalystc composite floor board comprises the steps of shaving board layer sorting, glue preparation, glue distribution and assembling for the first time, cold pressing for the first time, core trimming, glue distribution and assembling for the second time, cold pressing for the second time, hot pressing for the first time, fixed-thickness sanding, edge cutting, puttying, polishing, sorting, reconditioning, glue distribution and veneering, cold pressing for the third time, hot pressing for the second time, multi-blade sawing, sanding, double-end milling, priming, finish paint preparing and finish paint painting. The composite floorboard has the advantages of good antibacterial function, high strength, good wear-resistant performance and comfortable foot feeling.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

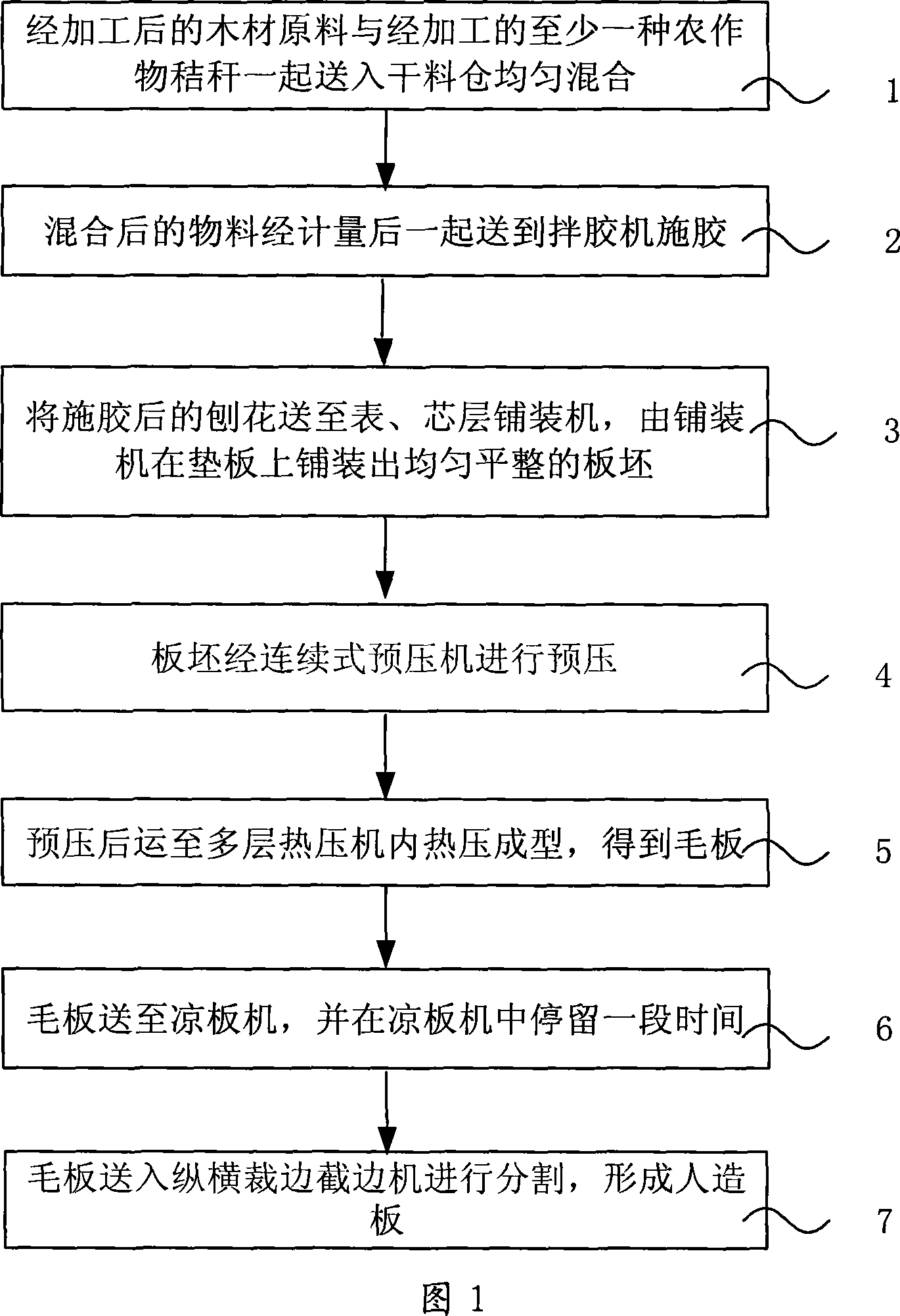

Method for manufacturing artificial board with crop stalk and wood mixing

ActiveCN101100085AAddress resource shortagesOptimize raw material structureFlat articlesDomestic articlesEngineeringHeat press

The present invention discloses the process of making artificial board with the crop stalk and timber. The process includes the following steps: mixing processed timber material and processed crop stalk material in a dry material bin, mixing with glue in a glue mixing machine, spreading in a spreading machine to form board blank, pre-pressurizing in a continuous pre-pressurizing machine, hot pressing in a hot press to form coarse board, cooling in a board cooling machine, and cutting in a margin cutting machine to obtain artificial board. Making artificial board with the crop stalk and timber can save timber and make artificial board with high quality.

Owner:WANHUA ECOBOARD INTEGRATED EQUIP CO LTD

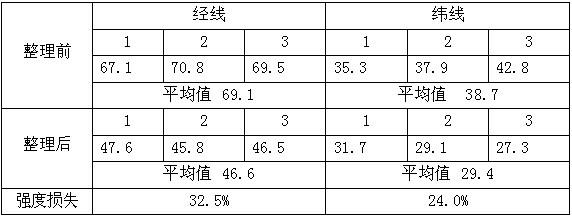

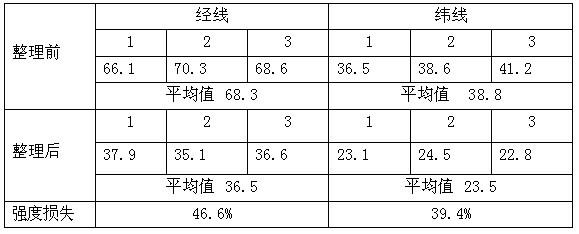

Denim-apparel fold finishing agent and fold finishing method

InactiveCN101851860AReduce formaldehyde contentReduce tear lossFibre treatmentDenimPolyvinyl alcohol

The invention relates to a denim-apparel fold finishing agent and a fold finishing method. The denim-apparel fold finishing agent comprises the following in percentage by weight: 30 to 35 percent of etherification 2D resin, 4 to 5 percent of catalyst, 5 to 10 percent of modified polyvinyl alcohol, 8 to 10 percent of cationic resin, and the balance of deionized water. The denim-apparel fold finishing method comprises the steps of preparing finishing liquid, soaking raw material in the finishing liquid, grasping folds with hands, drying, baking the obtained product in an oven, rubbing the obtained product with hands, spraying potassium permanganate, washing the obtained product with water, and the like. The denim-apparel fold finishing agent has relatively low formaldehyde content, thereby greatly reducing the loss of tearing force. The denim-apparel fold finishing method has the advantages of solving the problem that denim apparel is big in loss of tearing force, maintaining the original hand feel of the denim apparel to the utmost extent, ensuring that the denim apparel is easy to absorb softener and solid folds are easy to finalize and simplifying the production process of solid fold finishing.

Owner:东莞市广利行洗涤原料有限公司

Method for continuous production of high-concentration methylal

InactiveCN102351666AImprove conversion rateReduce formaldehyde contentOrganic chemistryOrganic compound preparationChemistryIntermediate storage

The invention relates to a method for continuous production of high-concentration methylal. The method is characterized by adopting methanol and formaldehyde for feeding respectively, controlling the content of each of formaldehyde and the methanol in each reactor and enabling the lowermost side reactor to adopt the process of enabling reactants of feed material of an upper-stage column plate to enter a lower-stage column plate; and the method comprises the following steps: a) a reaction rectification column is a packed column, formaldehyde is fed at the upper part of the reaction section, and methanol is fed through an inlet of the uppermost side reactor and the inlet of the lowermost side reactor; b) the reaction temperature of the side reactors is 60-80 DEG C from top to bottom, and liquid-phase reaction is performed on methanol and formaldehyde in the reactors to generate methylal; c) except for the lowermost side reactor, each reactor adopts the way of enabling extracted liquid from the lower-stage column plate of the rectification column to enter the reactor, and enabling reactor products to enter the upper-stage column plate of the rectification column; d) the lowermost side reactor adopts the way of enabling the extracted liquid from the upper-stage column plate of the rectification column to enter the reactor and enabling the reaction products to enter the lower-stage column plate of the rectification column; and e) the gas phase at the top of the column is condensed, then part of the condensed gas phase refluxes into the rectification column, and the other part of the condensed gas phase is extracted and introduced into a methylal intermediate storage tank; and liquid discharged from a column kettle is returned into a formaldehyde preparation unit for recycling or discharged after the liquid is treated to achieve the standard.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Nerve-soothing and qi-tonifying egg, ginger and shiitake mushroom stem floss and preparation method thereof

InactiveCN104970347AHigh economic valueImprove taste qualityNatural extract food ingredientsFood ingredient functionsLiquid glucoseMonosodium glutamate

The invention discloses nerve-soothing and qi-tonifying egg, ginger and shiitake mushroom stem floss which is prepared from the following raw materials in parts by weight: 50-65 parts of shiitake mushroom stems, 8-15 parts of egg liquor, 14-15.5 parts of ginger powder, 15-16 parts of bread crumbs, 4-5 parts of apple juice, 7-8 parts of cola, 1.8-2.3 parts of coconut shells, 2-2.6 parts of lucid ganoderma, 0.9-1.5 parts of Japanese eupatorium herb roots and a proper amount of cellulase, protease, 30-35% of liquid glucose, a1-2% citric acid solution, a 0.02-0.03% cysteine solution, refined salt, monosodium glutamate and pine needles. The shiitake mushroom stem floss disclosed by the invention is smoked, so that the fragrance is increased; the shiitake mushroom stem floss is fragrant and pure, long in aftertaste and good in taste quality; the nutrients of the shiitake mushroom stems are retained to the maximum extent, and formaldehyde in the shiitake mushroom stems is removed by virtue of the cysteine solution. By further adding the traditional Chinese medicinal materials such as coconut shells, lucid ganoderma, Japanese eupatorium herb roots and the like, the shiitake mushroom stem floss disclosed by the invention is endowed with the health-care functions of tonifying qi and soothing the nerves and relieving cough and asthma.

Owner:HEFEI MEIXIANGYUAN EGGS PROD

A microcapsule formaldehyde-removing agent and a preparing method thereof

ActiveCN109012133AMask the pungent smellReduce formaldehyde contentGas treatmentDispersed particle separationMass ratioPolyphenol

A microcapsule formaldehyde-removing agent and a preparing method thereof in the field of air purification are disclosed. The removing agent includes a core material and a wall material in a mass ratio of 1:2-6. The core material includes, by weight, 5-10 parts of tea polyphenols, 2-5 parts of aloe extract liquid, 3-5 parts of bracket plant extract liquid, 2-4 parts of Ottelia alismoides extract liquid, 5-10 parts of nanometer carbon black, 2-5 parts of nanometer silver, 2-3 parts of grape seed oil, 1-2 parts of cymbopogon citratus essential oil, 0.5-1 part of lavender essential oil, 0.5-1 part of eucalyptus essential oil, 3-10 parts of an emulsifier, 1.5-3 parts of a co-emulsifier, 1-3 parts of a dispersant and 1 part of a pH stabilizing agent. Uniformly dispersed formaldehyde-removing agent liquid particles are covered with a natural polymer film-forming material to form micro immobilized particles. Plant active components and the nanometer carbon black in the core materials are slowly released by passing through the wall material to remove formaldehyde in air, thus achieving an objective of removing formaldehyde for long term.

Owner:扬州润中信息科技有限公司

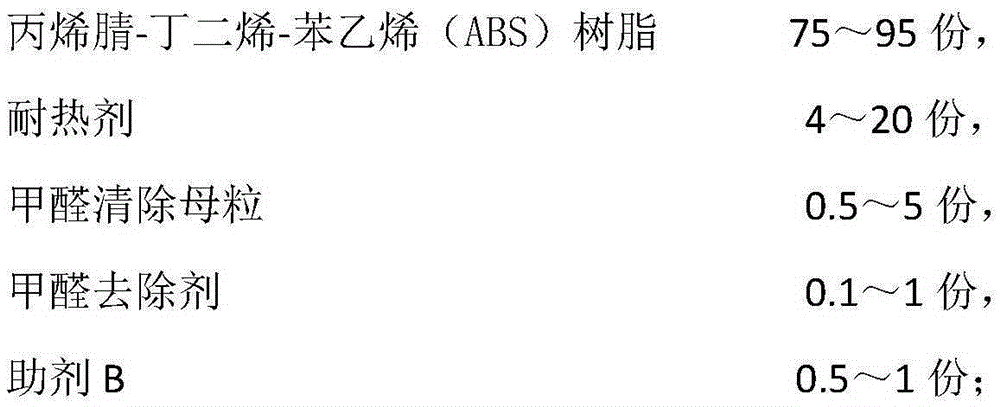

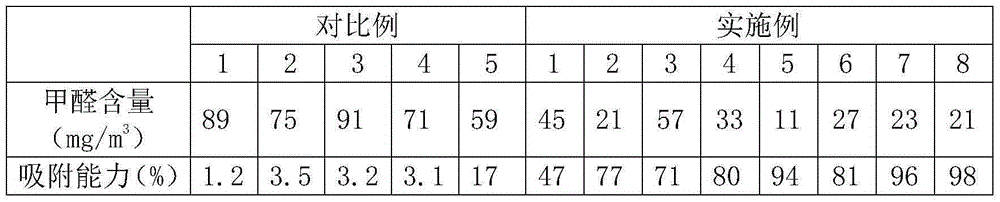

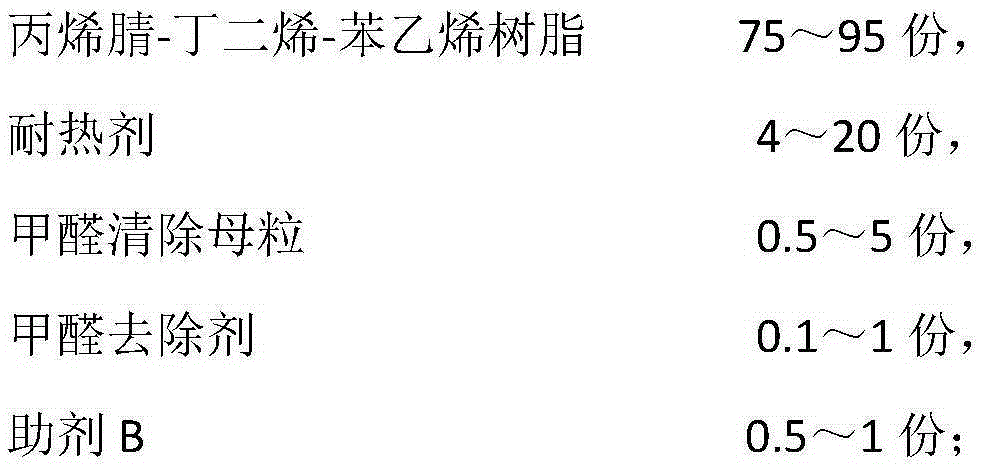

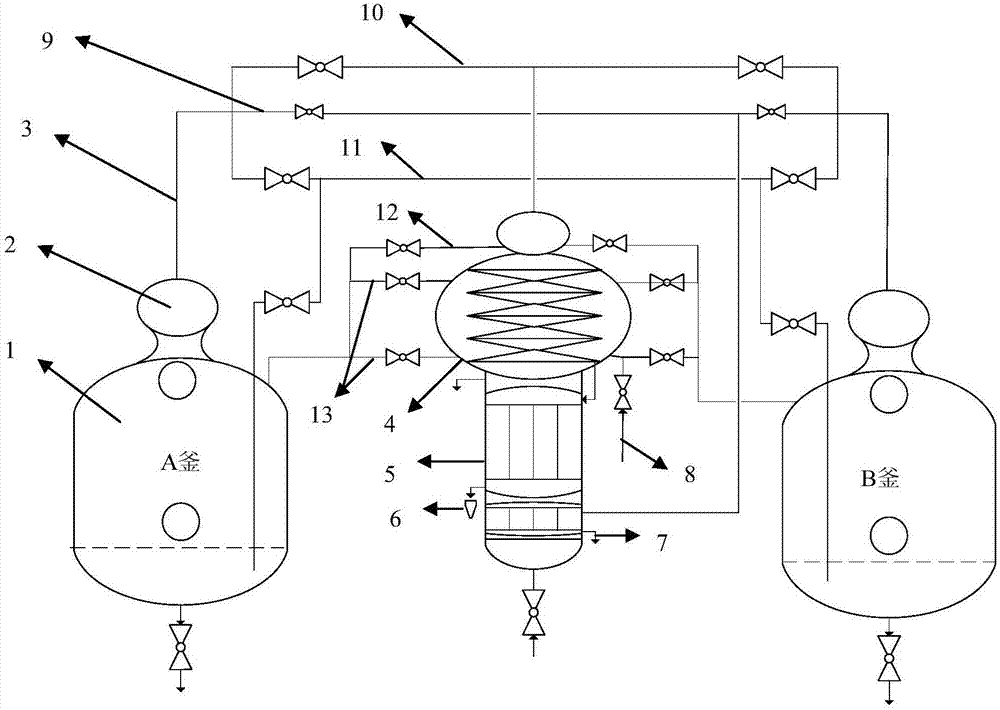

Self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and preparation method thereof

ActiveCN105385097AReduce formaldehyde contentFormaldehyde content suppressionClearing AgentAcrylonitrile butadiene styrene

The invention discloses a self-formaldehyde-clearing and heat-resistant acrylonitrile butadiene styrene (ABS) material and a preparation method thereof. The material is prepared from, by weight, 75-95 parts of ABS resin, 4-20 parts of heat resistant agent, 0.5-5 parts of formaldehyde clearing master batches, 0.1-1 part of formaldehyde clearing agent and 0.5-1 part of other auxiliaries. During preparation, the ABS resin, the heat resistant agent and other auxiliaries are mixed and fed through a main feeding port of a twin-screw extruder; the formaldehyde clearing master batches and the formaldehyde clearing agent are fed through the rear section of the extruder, and the material can be obtained through extruding and granulating. Thanks to the method, the content of formaldehyde in granules can be reduced by 40%, the content of formaldehyde in sealed space is reduced by 50% or above, and the content of other volatile organic compounds is reduced by 10% to 20% at the same time, so that the effects of controlling emission of material formaldehyde for a long time and inhibiting the content of formaldehyde in space are achieved.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Grape distilled wine and preparation method thereof

ActiveCN107129891AIncrease fruity aromaImprove typicalityMicroorganism based processesWine preparationVitis viniferaDistillation

The invention discloses grape distilled wine and a preparation method thereof. The preparation method includes: using vitis vinifera variety merlot as a raw material, and performing crushing and squeezing, low-temperature fermenting and one-time distillation to obtain distilled raw wine; aging, freezing, filtering and filling to obtain grape distilled wine of 62.0+ / -1.0%vol. One-time distillation is adopted to replace two-time distillation, so that energy consumption and distillation time are reduced. No additive is used in the whole production process of the distilled wine. The grape distilled wine obtained by the method has aroma of grape red berry, has mellow aroma endowed by the distillation process, is harmonious in wine body and presents fruity aroma and typical performance more sufficiently.

Owner:COFCO JUNDING CHATEAU

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

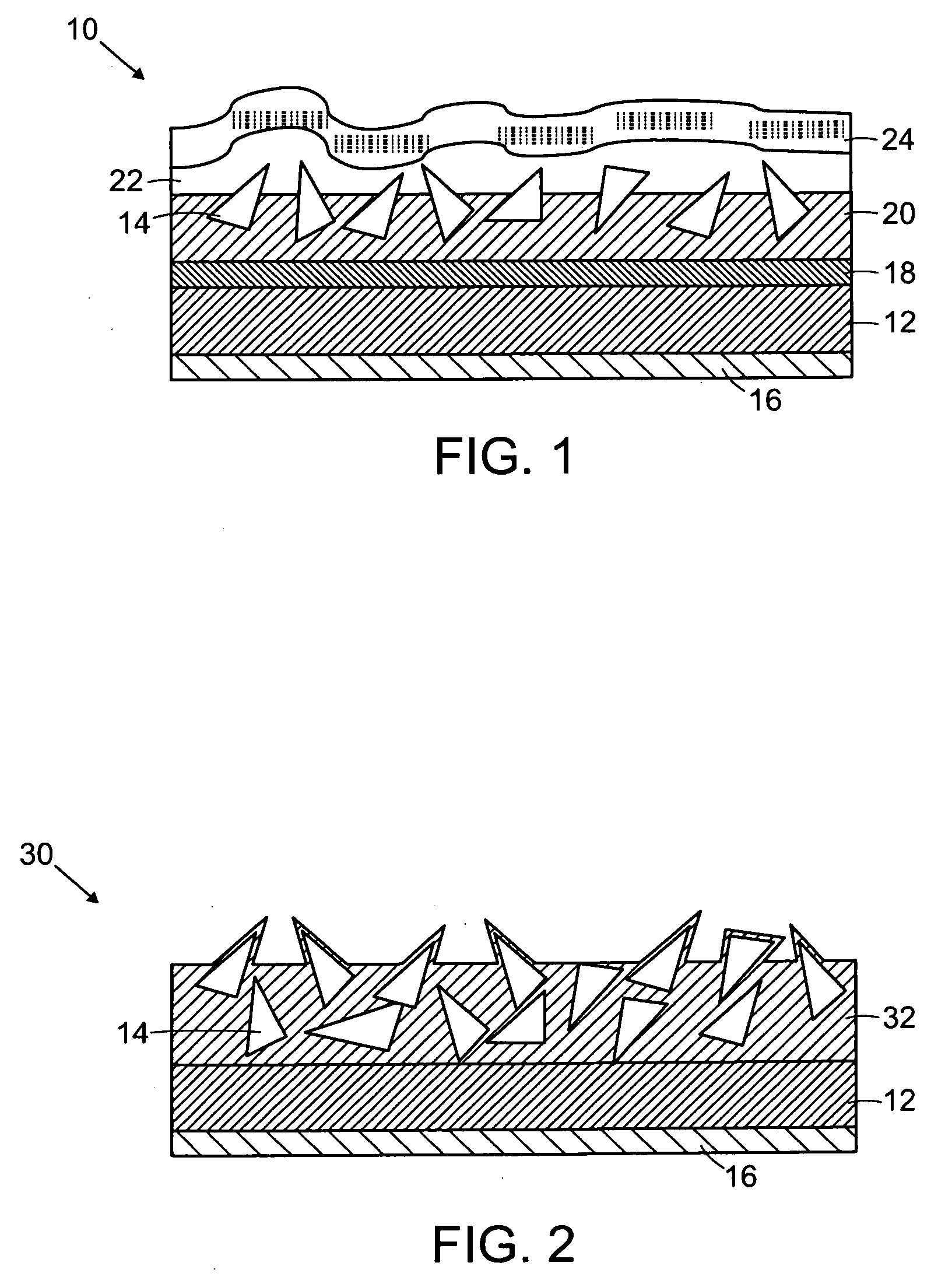

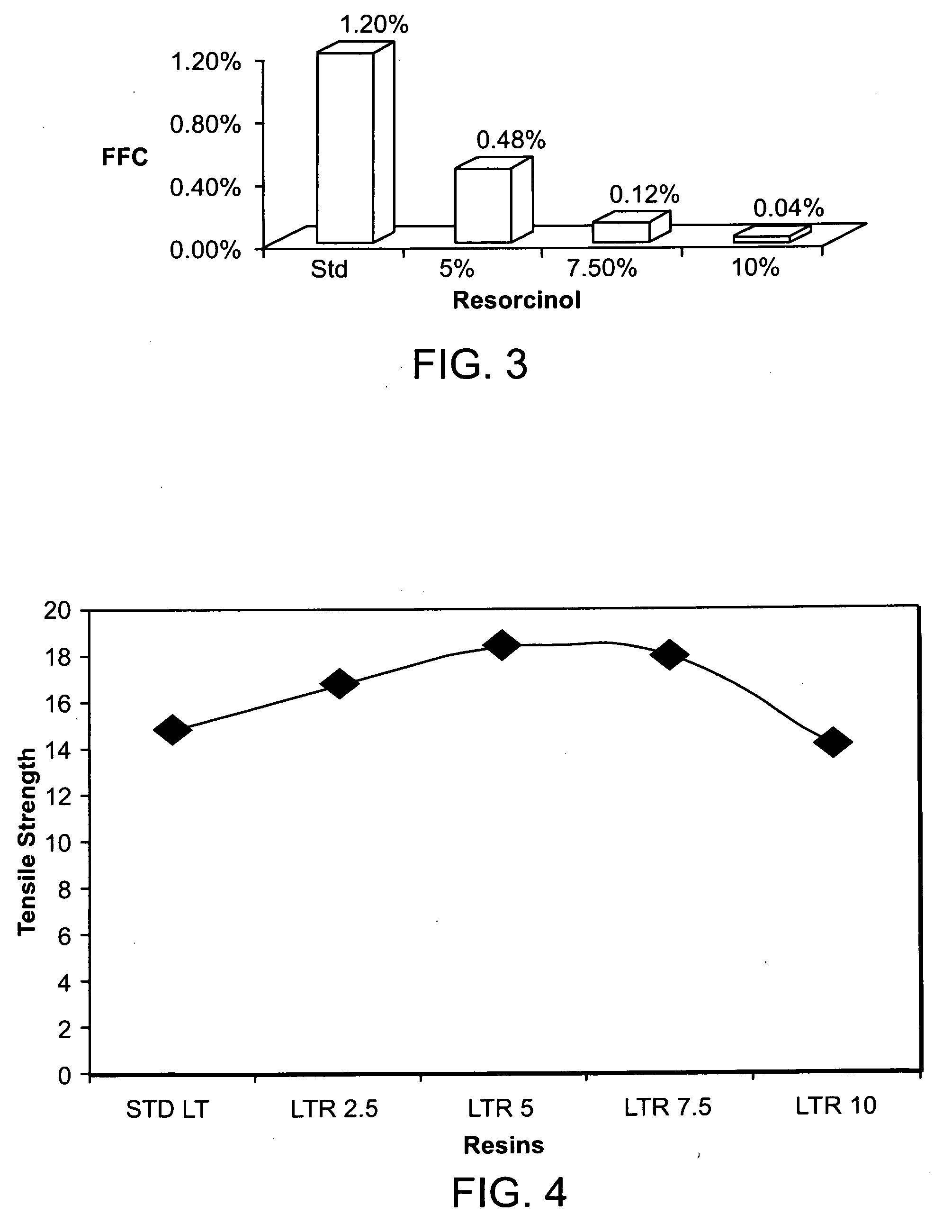

Phenolic resin formulation and coatings for abrasive products

InactiveUS20090149624A1Water tolerance can be relatively highGel time can be somewhat highAbrasion apparatusCoatingsBenzeneAlkaline catalyst

A resorcinol-modified phenolic resin composition is formed by reacting a basic catalyst, formaldehyde, water and a benzene-ol to form an intermediate composition to which resorcinol is subsequently added to reduce the presence of free formaldehyde. Optionally, an alkanolamine can be combined and reacted with the resorcinol-modified phenolic resin composition to form a resorcinol-alkanolamine-modified phenolic resin composition. The resorcinol-modified phenolic resin and the resorcinol-alkanolamine-modified phenolic resin compositions can be employed to coat abrasive products having a relatively low free formaldehyde content.

Owner:SAINT GOBAIN ABRASIVES INC +1

Environment-friendly flame-retardant straw board

ActiveCN107117927AOvercome the defect of high formaldehyde contentReduce formaldehyde contentChlorideUltra fine

The invention discloses an environment-friendly flame-retardant straw board. The straw board is prepared from the following raw materials in parts by weight: 50 to 100 parts of straw particles, 10 to 200 parts of flame retardant agent, and 1 to 50 parts of binding agent, wherein the flame retardant agent is prepared from the following raw materials: magnesium oxide, magnesium chloride, magnesium sulfate, nano stibium oxide and ultra-fine micro-silica powder; the binding agent is inorganic binding agent and is prepared from the following raw materials: aluminum sol, water glass, polyvinyl alcohol and deionized water. According to the environment-friendly flame-retardant straw board, by combining with the inorganic flame retardant agent and the inorganic binding agent with excellent performance, straw is used as a main raw material, so that the obtained straw board is flame-retardant without being carbonized and deformed at a high temperature of 1200 DEG C or more, and the production of harmful fume and gas is avoided; moreover, heat conduction on the straw board is avoided under a high temperature condition, and the straw board is not swelled once encountering the water, and the comprehensive performance is very excellent.

Owner:石植

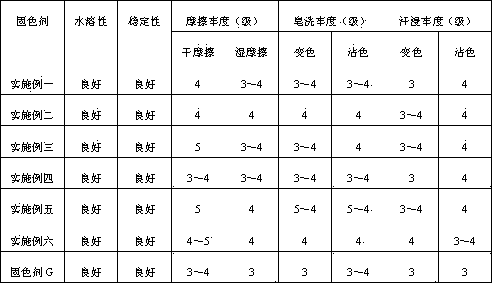

Micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent and preparation method thereof

The invention relates to the technical field of color fixing agents and provides a micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent which is capable of well improving the fastness of the textile to wet rubbing and the color fastness of the textile to washing. The micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent comprises the following raw material components in parts by weight: 50-60 parts of methacryloxyethyltrimethyl ammonium chloride, 0.25-5 parts of epoxy compound, 0.1-2 parts of crosslinking agent, 0.02-0.3 part of initiator and 35-45 parts of deionized water, wherein the methacryloxyethyltrimethyl ammonium chloride is a water solution with a weight percent concentration of 65-98 percent. Meanwhile, the invention provides a preparation method of the micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent.

Owner:FUJIAN QINGYUAN TECH

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com