Preparation method for high-purity methylal

A methylal, high-purity technology, applied in the field of high-purity methylal preparation, can solve problems such as excessive formaldehyde and methanol, not mentioned in the process flow and implementation cases, affecting the reaction effect of the reactive distillation tower, etc., to achieve reduction Formaldehyde content, the effect of improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

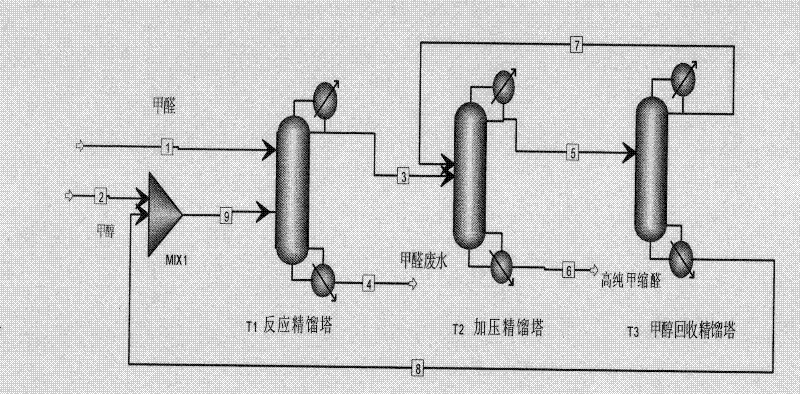

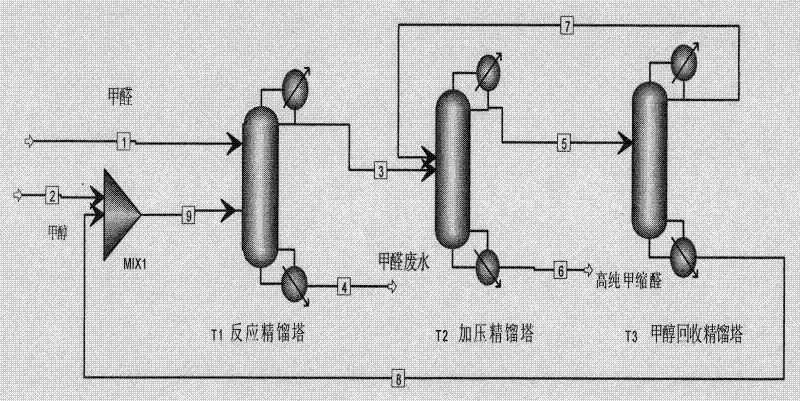

[0022] Reactive distillation tower T1: formaldehyde solution (1) is the formaldehyde aqueous solution that mass concentration is 8.66%, and feed rate is 420 kg / hour, and methanol raw material (2) feed rate is 82 kg / hour, and mass concentration is 99.5%, The number of rectification trays is 40, the position of the formaldehyde feed plate is at the 10th, and the position of the methanol feed plate is at the 30th. The catalyst strong acidic cation exchange resin is placed in the packed tower in the form of a catalyst package, and the reflux ratio is controlled at 3, the methylal that tower top obtains and the azeotrope (3) of methyl alcohol add up to 100 kilograms / hour, form 92.1% methylal, 7.8% methyl alcohol, 720ppm water, material 3 enters T2 tower, tower still discharges waste water ( 4) The formaldehyde content in the medium is 148ppm.

[0023] Pressurized distillation tower (T2): The operating pressure is 1.2Mpa, the number of theoretical plates is 40, the reflux ratio at t...

Embodiment 2

[0026]Reactive distillation tower T1: formaldehyde solution (1) is the formaldehyde aqueous solution that mass concentration is 8.66%, and feed rate is 420 kg / hour, and methanol raw material (2) feed rate is 81.5 kg / hour, and mass concentration is 99.5%, The number of rectification trays is 40, the position of the formaldehyde feed plate is at the 10th, and the position of the methanol feed plate is at the 30th. The catalyst strong acidic cation exchange resin is placed in the packed tower in the form of a catalyst package, and the reflux ratio is controlled at 3, the methylal that tower top obtains and the azeotrope (3) of methyl alcohol add up to 100 kilograms / hour, form 92.1% methylal, 7.8% methyl alcohol, 720ppm water, material 3 enters T2 tower, tower still discharges waste water ( 4) The formaldehyde content in the medium is 148ppm.

[0027] Pressurized rectification tower (T2): The operating pressure is 1.5Mpa, the number of theoretical plates is 40, the reflux ratio at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com