Patents

Literature

36results about How to "Improve dry rubbing fastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based coating composition for wall paper and wall paper thereof

InactiveCN1489624AImprove dry rubbing fastnessTextiles and paperEmulsion paintsWater basedPVA - Polyvinyl alcohol

A water-based coating composition for wallpapers which comprises fibrous monoclinic titanium dioxide, a reactive silicone compound, and polyvinyl alcohol as effective ingredients; and a wallpaper having a coating layer formed from the water-based coating composition. The wallpaper is excellent not only in the function of protecting interior members or in deodorizing or antibacterial performance but in decorative properties, whiteness, texture, and appearance.

Owner:爱斯旺株式会社 +1

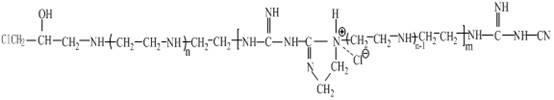

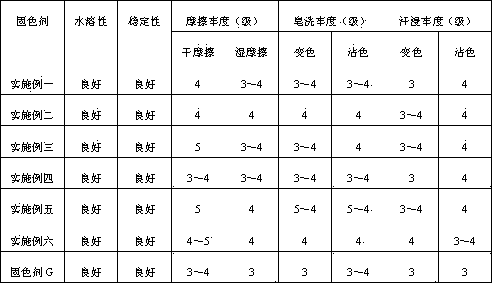

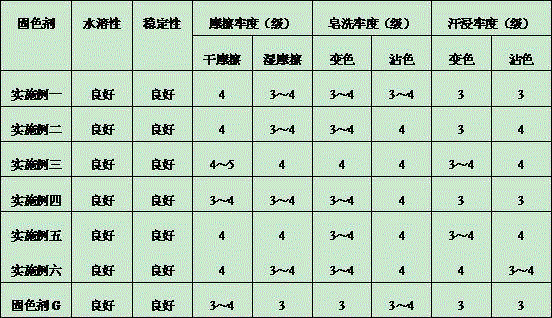

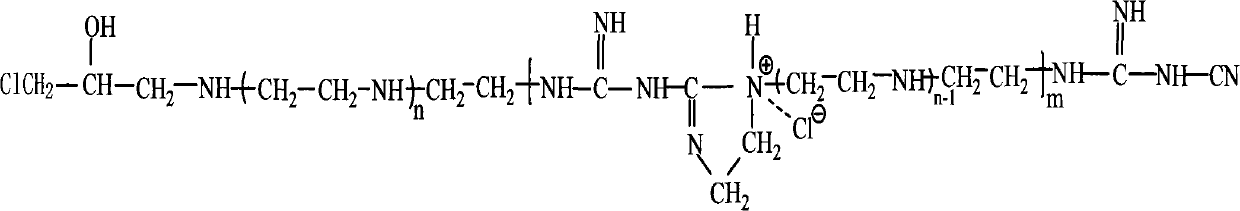

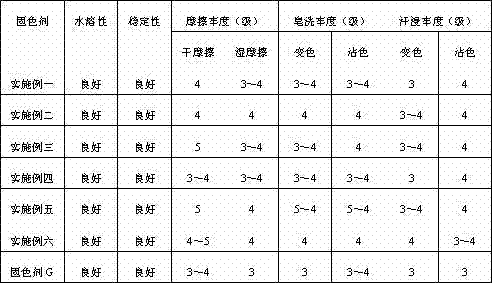

Formaldehyde-free fixing agent for active dye

InactiveCN102493232AHigh color fastnessLow water solubilityDyeing processPolymer chemistryFormaldehyde free

The invention discloses a formaldehyde-free fixing agent for an active dye. The formaldehyde-free fixing agent is prepared by compounding 2 to 4 compounds. The formaldehyde-free fixing agent has reactive functional groups and high cationic property, can effectively improve the dry rubbing fastness, wet rubbing fastness and color fastness to washing of fabrics dyed by the active dye, and has a little influence on the color tone of the fabrics.

Owner:SUZHOU UNIV

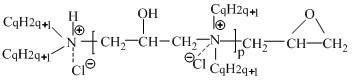

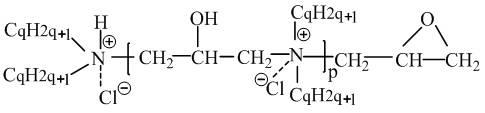

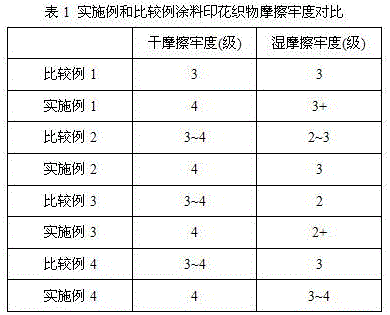

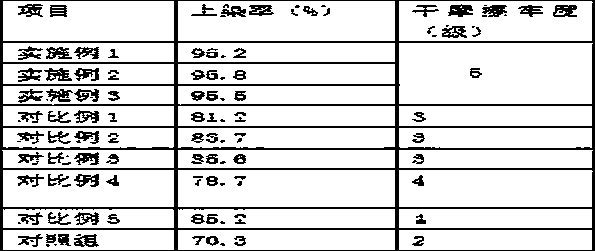

Micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent and preparation method thereof

The invention relates to the technical field of color fixing agents and provides a micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent which is capable of well improving the fastness of the textile to wet rubbing and the color fastness of the textile to washing. The micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent comprises the following raw material components in parts by weight: 50-60 parts of methacryloxyethyltrimethyl ammonium chloride, 0.25-5 parts of epoxy compound, 0.1-2 parts of crosslinking agent, 0.02-0.3 part of initiator and 35-45 parts of deionized water, wherein the methacryloxyethyltrimethyl ammonium chloride is a water solution with a weight percent concentration of 65-98 percent. Meanwhile, the invention provides a preparation method of the micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent.

Owner:FUJIAN QINGYUAN TECH

Cationic type formaldehyde-free color fixing agent for reactive dye and preparation method thereof

The invention relates to the technical field of color fixing agents, and provides a cationic type formaldehyde-free color fixing agent for reactive dye, wherein through the cationic type formaldehyde-free color fixing agent, the wet rubbing fastness and washing color fastness of textiles can be better improved. The cationic type formaldehyde-free color fixing agent for the reactive dye is prepared from, by mass, 50-60 parts of dimethyl diallyl ammonium chloride, 0.2-10 parts of monomers containing tertiary amino groups, 0.1-5 parts of cross-linking agents, 0.01-0.3 part of initiating agents and 30-48 parts of deionized water, wherein an aqueous solution with the mass percentage concentration of 60+ / -0.5% or 65+ / -0.5% is adopted as the dimethyl diallyl ammonium chloride. Meanwhile, the invention further provides a preparation method of the cationic type formaldehyde-free color fixing agent for the reactive dye.

Owner:SHISHI QINGYUAN FINE CHEM

Water-borne coating for wallpaper

The invention relates to decorative materials, in particular to a water-borne coating for wallpaper, which uses fibrous monoclinic crystal class titanium dioxide, silane compounds with more than three valences and nonionic polyatomic alcohol as main active ingredients, and provides the water-borne coating for the wallpaper, which integrates advantages of decoration, attractive appearance, antibacterium, deodorization, protection and particularly excellent wear-resistant performance into a whole.

Owner:ANHUI JINDUN PAINT

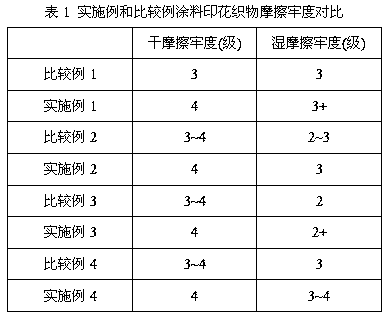

Dry rubbing fastness improver for pigment printing fabric as well as preparation and using method of improver

ActiveCN106835754AImprove dry rubbing fastnessEasy to prepareDyeing processScreen printingPolymer science

The invention discloses a dry rubbing fastness improver for a pigment printing fabric as well as a preparation and using method of the improver. The dry rubbing fastness improver for the pigment printing fabric comprises the following components in percentage by weight: 50-80% of a lubricating agent, 5-8% of a cross-linking agent, 0.5-2% of a thickening agent, and 10-44.5% of deionized water. The method comprises the following steps: accurately weighing the various components, uniformly stirring, and preparing the dry rubbing fastness improver for the pigment printing fabric with a viscosity range of 20000-30000mPa.s; directly adding 0.1-2% of the dry rubbing fastness improver for the pigment printing fabric into the prepared coating printing size, completing printing by using rotary screen printing or flat screen printing, drying and roasting, so that the dry rubbing fastness of the pigment printing fabric can be improved to level 4.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Method for improving dry rubbing fastness of smooth-haired slubbed product

The invention relates to a method for improving dry rubbing fastness of a smooth-haired slubbed product. The process flow of the method is as follows: getting grey cloth of the smooth-haired product, performing primary washing, milling, re-washing, dewatering, drying, decating, napping, shearing, performing wet brushing, drying, lustring, shearing, steaming and trimming, steaming and brushing, decating and getting a finished product, wherein the milling process conditions are as follows: auxiliary agents comprise 2% owf (on weight of fabric)-2.5% owf of Igephon T, 3% owf-3.5% owf of oleate soap and 0.8-1% owf of Invalon DAM dispersant; the milling time is 60-90min; and the milling temperature is 45-50 DEG C. The method mainly comprises the steps that the dispersant is added in the milling process to disperse dust and dye particles which are washed down so as to prevent the dust and the dye particles from being re-stained on fabric, enable the dust and the dye particles to be washed away in the subsequent washing process and further improve the dry rubbing fastness. According to the method, compared with normal products, the dry rubbing fastness of slubbing can be improved from level half to level1.

Owner:JIANGSU SUNSHINE GRP CO LTD

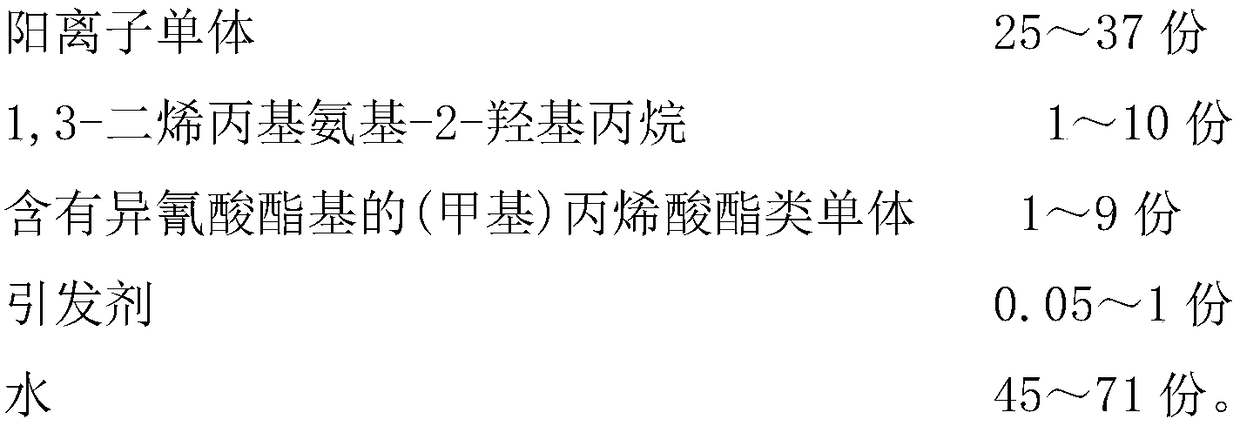

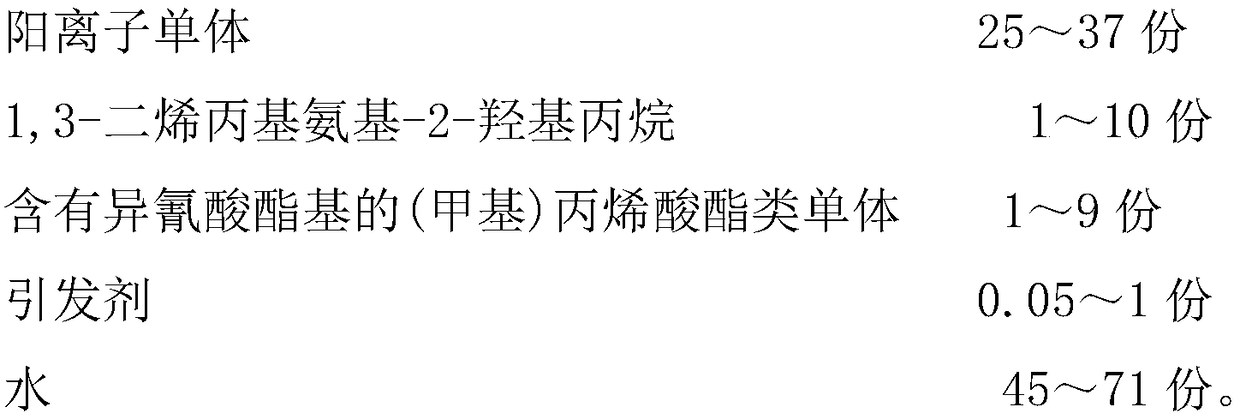

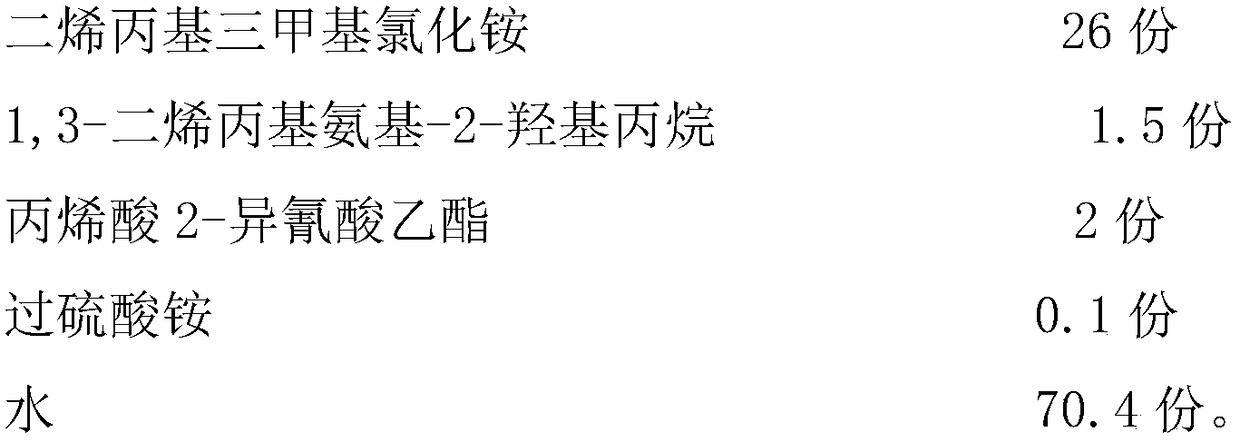

Textile printing and dyeing fixer and preparation method thereof

InactiveCN108824035AImprove bindingImprove dry rubbing fastnessDyeing processTextile printerRoom temperature

The invention provides a textile printing and dyeing fixer and a preparation method thereof. The preparation method comprises the following steps: (1) putting a cationic monomer, 1,3-diallylamino-2-hydroxypropane, a (methyl)acrylate monomer containing an isocyanate group and water into a polymerization reaction vessel, uniformly stirring, heating and warming; (2) in a condition without oxygen anda condition of stirring, dropwise adding initiator solution to the polymerization reaction vessel, performing a polymerization reaction, wherein a temperature of the polymerization reaction is 80-100DEG C, and a mass concentration of the initiator solution is 1-10%, so the initiator solution is prepared by an initiator and a part of the water, and completely dropwise adding the initiator solutionwithin 1-3 hours; and (3) after completely dropwise adding, in the temperature of the polymerization reaction, continuously performing the polymerization reaction for 1-3 hours, cooling to room temperature, and discharging, to obtain the fixer.

Owner:陈国宝

Formaldehyde-free fixing agent and preparation method thereof

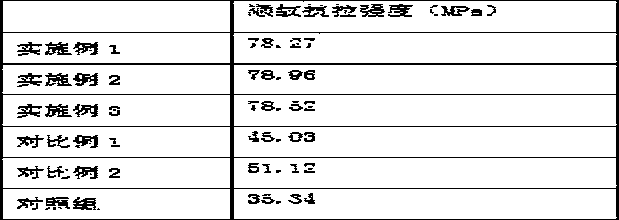

InactiveCN108660813AImprove bindingImprove dry rubbing fastnessDyeing processSuccinatesMicrowave irradiation

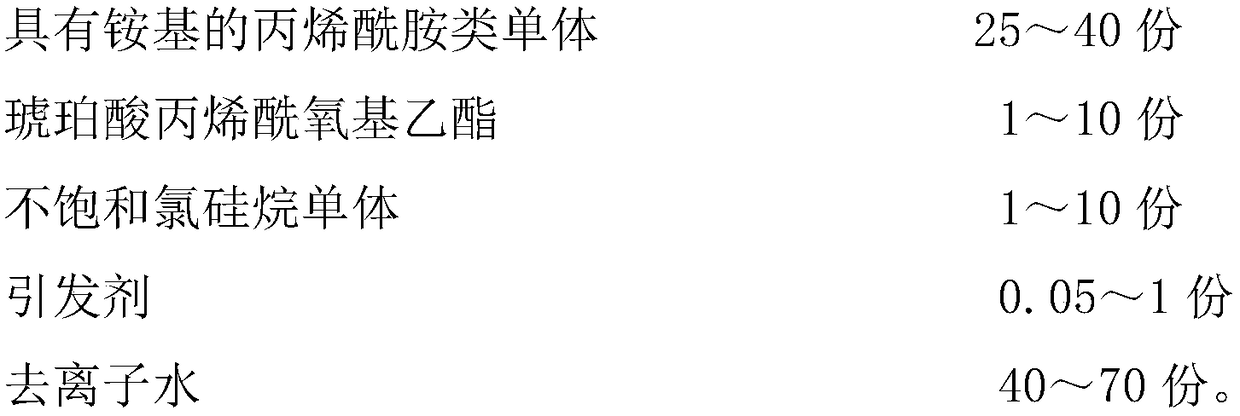

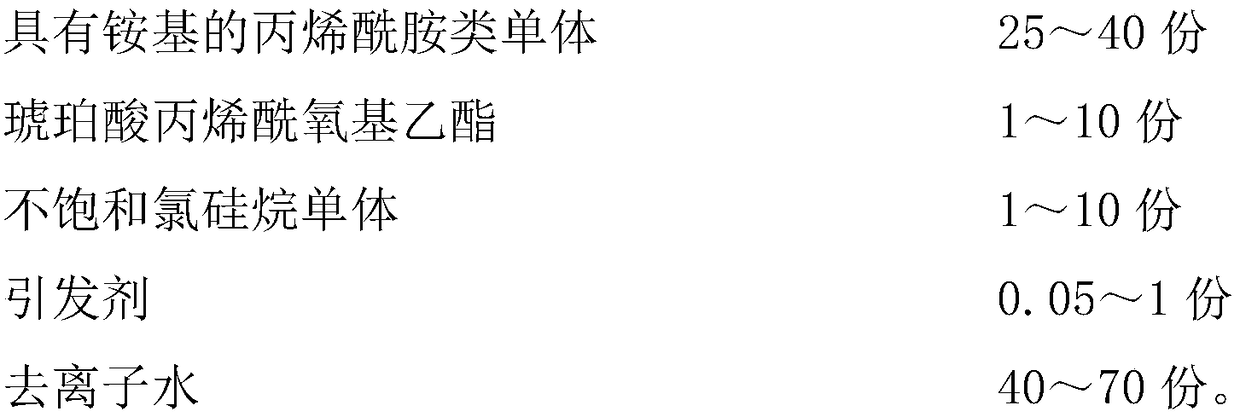

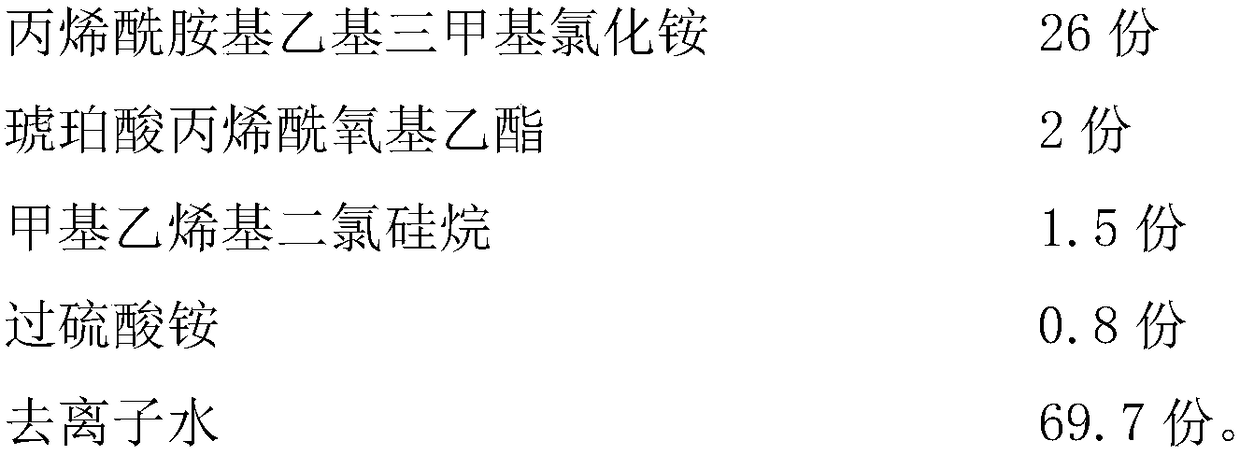

The invention relates to a formaldehyde-free fixing agent and a preparation method thereof. The preparation method comprises the following steps: (1) sequentially adding an acrylamide monomers havingammonium groups, acryloyloxy ethyl succinate, an unsaturated chlorosilane monomer and deionized water into a reactor, then starting to stir, and heating; (2) when the temperature in the reactor risesto 30-50 DEG C, adding an initiator solution, wherein the initiator solution is prepared from an initiator and part of the deionized water; (3) then, putting the reactor into a microwave reactor for performing microwave irradiation; after that, turning off the microwave reactor, cooling and discharging to obtain the fixing agent.

Owner:曾文华

Efficient environment-friendly acidic color fixing agent and preparation method thereof

InactiveCN109763363AWide variety of sourcesMeet environmental protection requirementsDyeing processSqualaneEthyl acetate

The invention discloses an efficient environment-friendly acid fixing agent and a preparation method thereof, relates to the field of printing and dyeing aids, and aims to solve the problem that the existing acid fixing agent is not environmentally friendly. The product is prepared from the following raw materials in parts by weight: 18-21.7 parts of isopropanol, 0.26-0.44 parts of sodium persulfate, 5.8-7.2 parts of chitosan, 6.6-8.4 parts of iso-tridecanol polyoxyethylene ether, 1.8-2.7 parts of squalane, 87-102 parts of deionized water, 2.2-3.5 parts of strong alkali powder, 5-6 parts of 2-(2-ethoxyethoxy)ethyl acetate and 4.9-6.8 parts of dimethylamine. The fixing agent comprises widely sourced raw materials, does not contain formaldehyde, and meets the requirement of environmental protection; reactive groups are gathered on the surface of the product, and can be subjected to a crosslinking reaction with hydroxy in acid dye, so that the combination degree of the acid dye and clothis higher, and dry rubbing fastness, wet rubbing fastness and color fastness to washing of the acid dye are improved.

Owner:江西德盛精细化学品有限公司

Water-based coating composition for wall paper and wall paper thereof

InactiveCN1221616CImprove dry rubbing fastnessTextiles and paperEmulsion paintsWater basedPVA - Polyvinyl alcohol

Owner:爱斯旺株式会社 +1

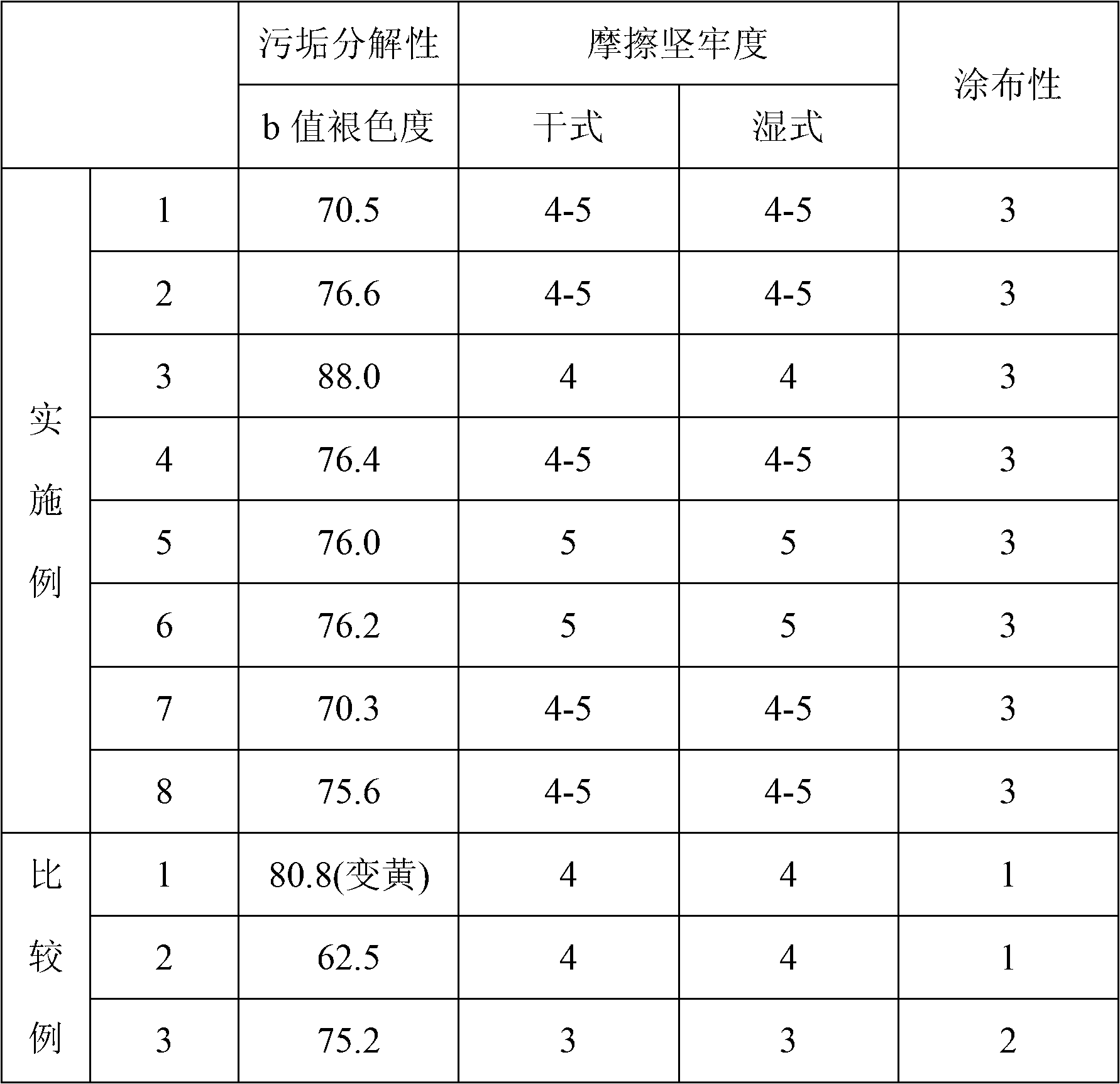

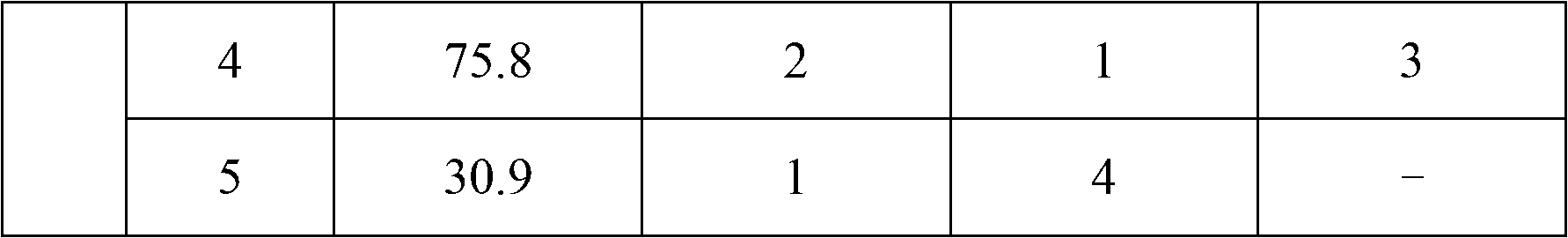

Method for preparing pigment printing adhesive by graphene oxide modified polyacrylate

ActiveCN103554346BImprove mechanical propertiesImprove performanceNon-macromolecular adhesive additivesEster polymer adhesivesEmulsionGraphene

A method for preparing a pigment printing binder from oxidized graphene modified polyacrylate comprises the following steps: dissolving ammonium persulfate in deionized water and placing the mixture in a reactor of 75-80 DEG C; adding an emulsion A and an initiator aqueous solution A, adding an emulsion B and an initiator aqueous solution B, keeping warm at 75-80 DEG C and reacting for 2 hours after dripping, cooling, adjusting pH to 4.0-6.5 by the use of an ammoniacal liquor, and discharging to prepare a polyacrylate emulsion; stirring an oxidized graphene aqueous solution and adding the oxidized graphene aqueous solution into the polyacrylate emulsion so as to obtain the pigment printing binder. The pigment printing binder is prepared by introducing oxidized graphene in modification of the polyacrylate emulsion. Under the condition of the same dosage of the binder, oxidized graphene is added to raise dry and wet rub fastness of a printed fabric, and softness and washing fastness of the fabric are basically unchanged.

Owner:威海联桥新材料科技股份有限公司

Processing technology capable of improving dyeing property of rattan

InactiveCN108839180AImprove dyeing effectHigh tensile strengthWood treatment detailsReed/straw treatmentRubbingEnzyme

The invention belongs to the technical field of art crafts, and particularly relates to a processing technology capable of improving the dyeing property of rattan. The processing technology comprisesthe following steps of a, activating treatment, and b, biological enzyme preparation treatment. The dyeing property of the rattan processed through the processing technology is obviously improved. According to the processing technology, through the step a, the dry rubbing fastness is obviously improved, and through the step b, the dye-uptake is obviously increased.

Owner:阜南县中信柳木工艺品有限公司

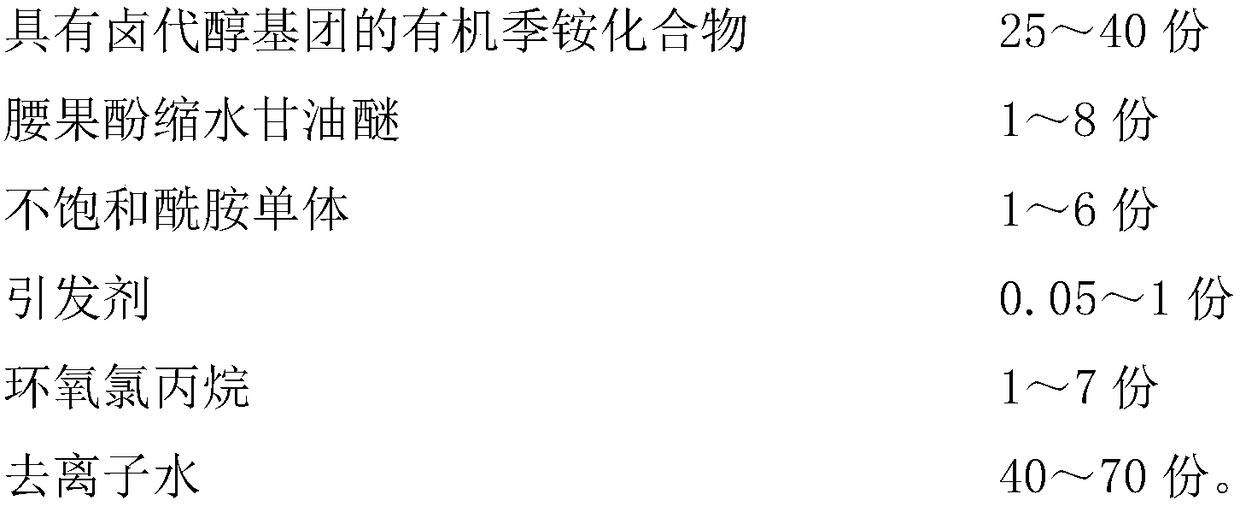

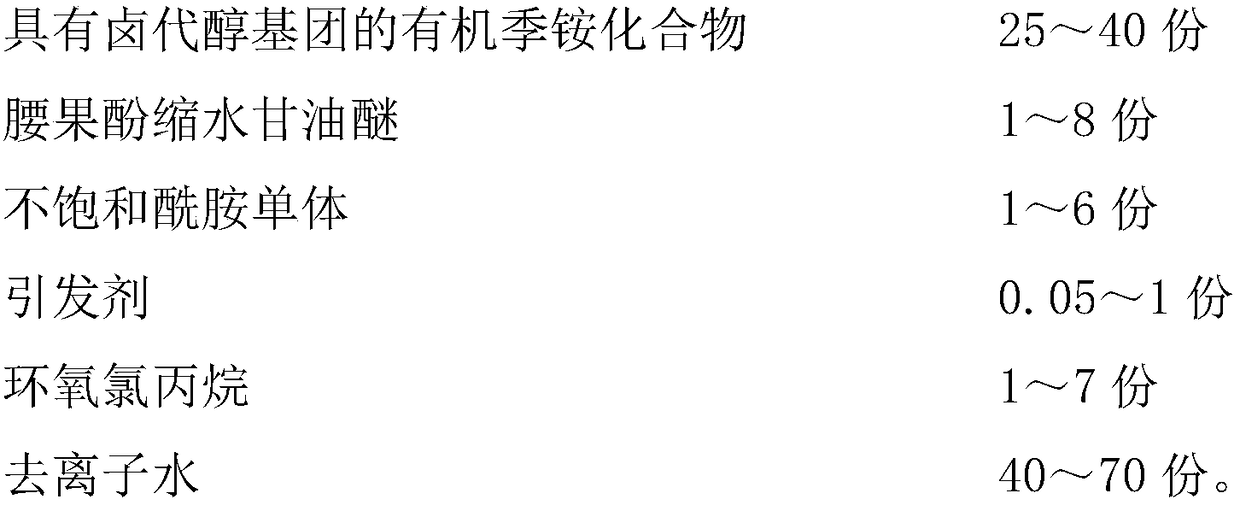

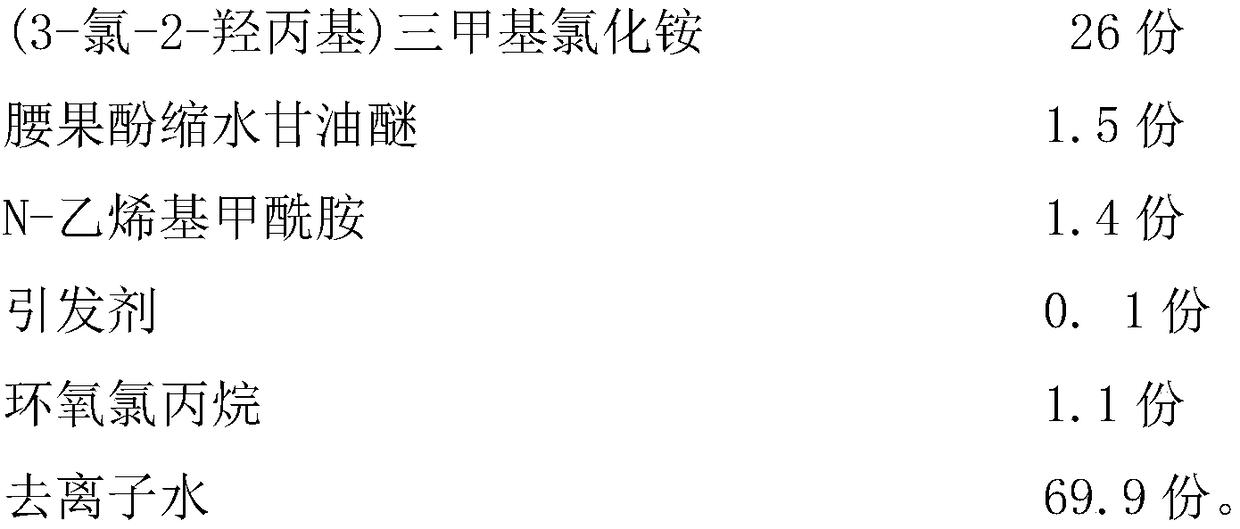

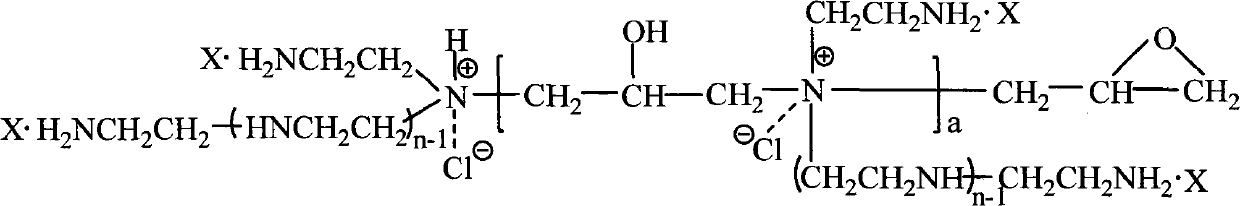

Fabric color fixing agent and preparation method thereof

InactiveCN108797163AImprove bindingImprove dry rubbing fastnessDyeing processAmmonium compoundsGlycidyl ethers

The invention relates to a fabric color fixing agent and a preparation method thereof. The method comprises the following steps: (1) sequentially adding an organic quaternary ammonium compound havinga halohydrin group, cardanol glycidyl ether and deionized water into a reaction kettle, starting stirring, and starting to heat up; (2) adding an unsaturated amide monomer and the deionized water intoa first high-level tank and stirring until the mixture is uniformly mixed, and adding an initiator and the deionized water into a second high-level tank and stirring until the mixture is fully dissolved; when the temperature in the reaction kettle rises to 85-120 DEG C, performing nitrogen protection, then opening two high-level tanks, and dropwise adding the solution of the two high-level tanksinto the reaction kettle at a constant rate, wherein the dropwise addition time is 3-6 hours; (3) then, dropwise adding epoxy chloropropane into the reaction kettle, controlling the dropwise additiontime to be 1-3 hours, maintaining the temperature to be 100-135 DEG C, then carrying out a reaction for 1-3 hours under the condition of heat preservation, and cooling and discharging after the heat preservation process is finished so as to obtain the color fixing agent.

Owner:李美琴

Formaldehyde-free color fixing agent for acid dyes and preparation method thereof

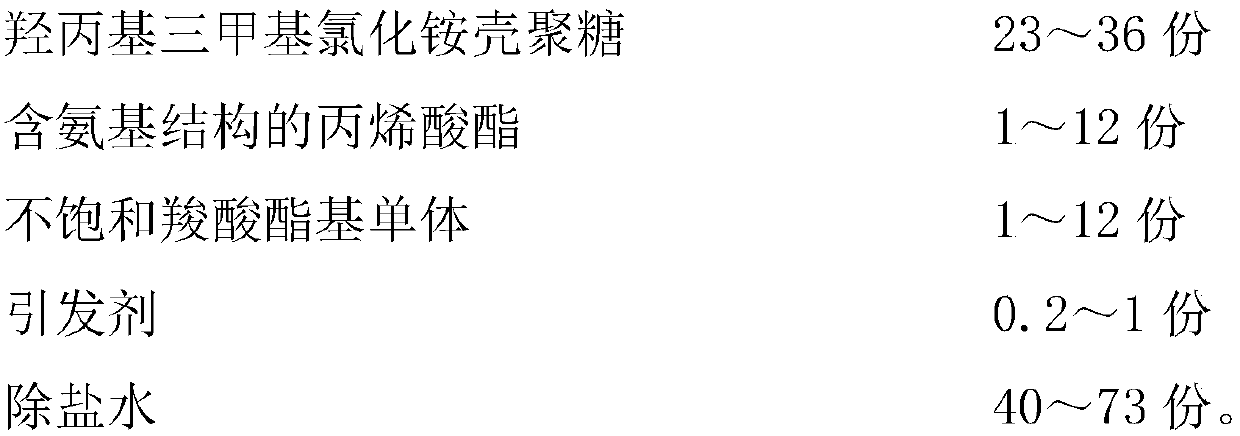

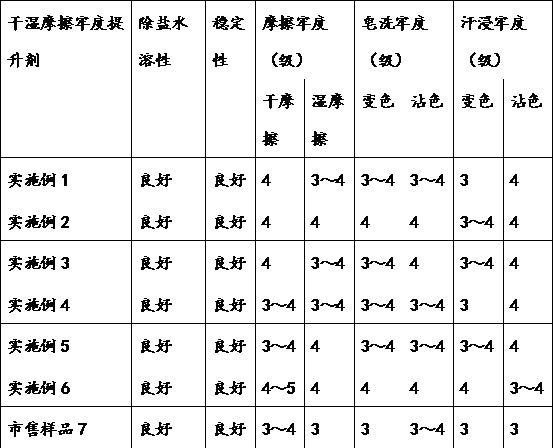

InactiveCN109096437AImprove bindingImprove dry rubbing fastnessDyeing processHydroxypropyltrimethyl ammonium chloride chitosanAcid dye

The invention relates to a formaldehyde-free color fixing agent for acid dyes and a preparation method thereof. The preparation method includes step (1) of adding hydroxypropyl trimethyl ammonium chloride chitosan, acrylic ester containing an amino structure, unsaturated carboxylate-based monomer and demineralized water into a stirring polymerization reactor, starting to stir, and beginning to heat; step (2) of starting to add an initiator solution with a mass concentration of 1-10% when the temperature of the stirring polymerization reactor rises to 95-130 DEG C, wherein the initiator solution is prepared from an initiator and part of the demineralized water, and the time for adding dropwise is 3-6 h; (3) maintaining the temperature after the adding performed dropwise to continue the reaction for 1-3 h, and performing cooling and discharging to obtain the color fixing agent.

Owner:曾文华

Printing and dyeing method for cotton fabric

ActiveCN106835772AImprove wet rubbing fastnessImprove dry rubbing fastnessDyeing processOxalateMethyl salicylate

The invention discloses a printing and dyeing method for cotton fabric. The printing and dyeing method includes the steps of dyeing, washing and drying. Before dyeing, methyl salicylate and hydrogen peroxide are adopted for pretreating the cotton fabric. During dyeing, dodecylamine polyoxyethylene ether accounting for 6-10 wt% of the mass of dye liquor, titanium dioxide accounting for 0.5-2 wt% of the mass of the dye liquor, ethyl oxalate accounting for 3-7 wt% of the mass of the dye liquor and phenylpropanol accounting for 1-3 wt% of the mass of the dye liquor are added into the dye liquor. According to pretreatment, the cotton fabric is put in a solution with the concentration of methyl salicylate being 10-15 g / L and the concentration of hydrogen peroxide being 25-30 g / L for 15 min. Dodecylamine polyoxyethylene ether, titanium dioxide, ethyl oxalate and phenylpropanol need to be firstly mixed before the dye liquor is added, and then the mixture is subjected to ultrasonic treatment for 28 min. The dye uptake of dyestuff during dyeing of the cotton fabric can be obviously increased, wet friction firmness, dry friction firmness and illumination firmness are all remarkably improved, and the structure of the cotton fabric is not changed. The printing and dyeing method is simple in process, convenient to treat, remarkable in effect and suitable for large-scale application and popularization.

Owner:绍兴百丽恒印染有限公司

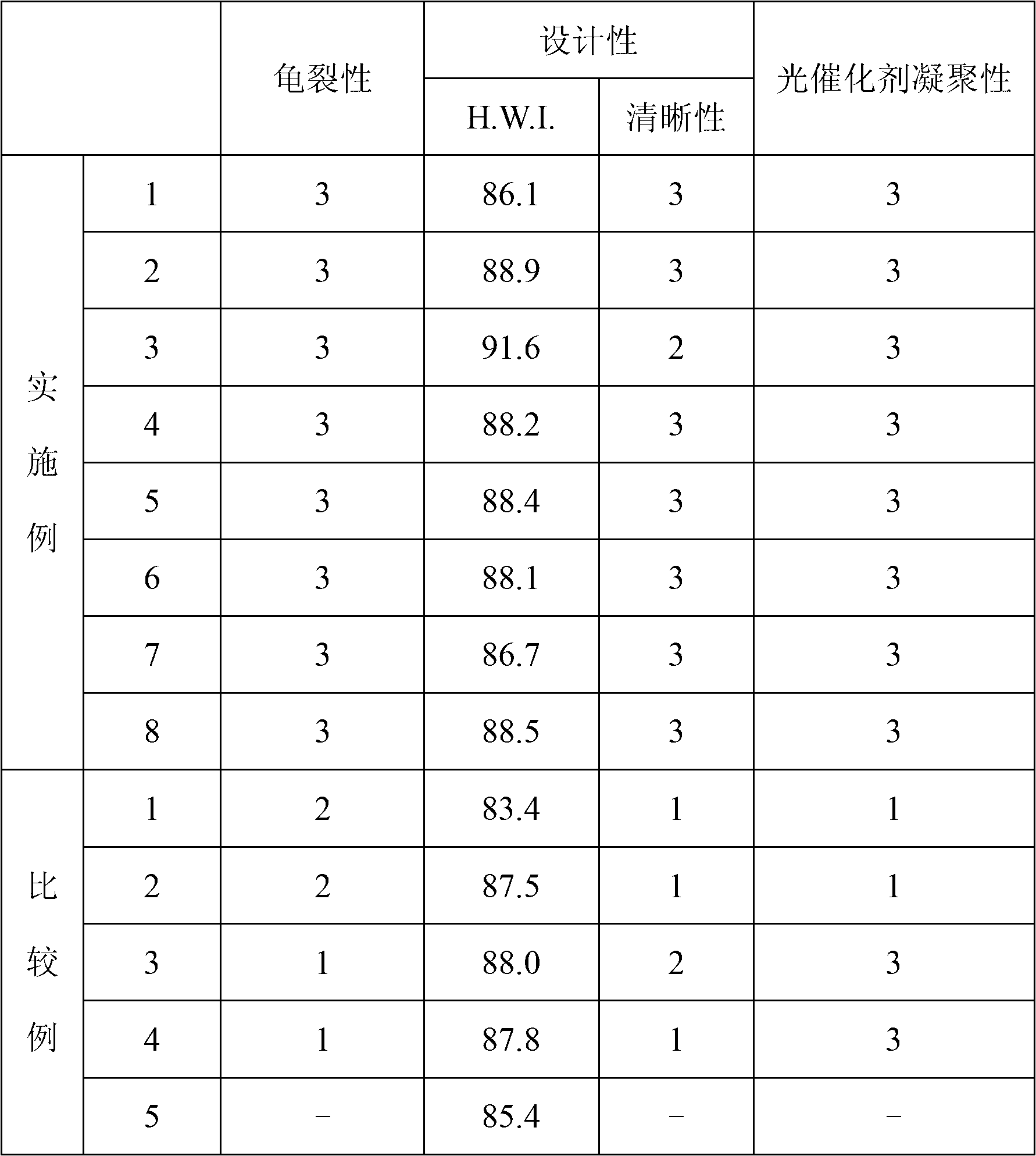

A kind of modified carboxymethyl starch polymer and its preparation method and application

ActiveCN110016103BImprove dry rubbing fastnessImprove color fastnessDyeing processVegetal fibresIsocyanatePolymer

The invention discloses a modified carboxymethyl starch polymer and its preparation method and application. The modified carboxymethyl starch polymer is prepared from the following raw material components in parts by mass: carboxymethyl starch 33~ 42 parts, 1 to 5 parts of modifier, 1 to 5 parts of vinyl isocyanate, 2 to 6 parts of epichlorohydrin, 0.2 to 0.8 parts of initiator, 48 to 62 parts of desalinated water, which are used as dry and wet rubbing fastness improvement When the agent is used, it has the advantages of high color fastness, can improve the dry and wet fastness, and the color fastness to washing with desalinated water, has little effect on the shade of sensitive colors, and has the advantages of less dosage.

Owner:FUJIAN QINGYUAN TECH

Formaldehyde-free color-fixing agent of active dye

The invention discloses a formaldehyde-free color-fixing agent of an active dye, which is prepared with 2-4 compounds. The formaldehyde-free color-fixing agent comprises a reactive functional group, has high cationic performance, and can effectively improve the dry rubbing fastness, wet rubbing fastness, color fastness to washing of the fabric dyed with the active dye. Moreover, the formaldehyde-free color-fixing agent has little effect on the color light of the fabric.

Owner:SUZHOU UNIV

Water-based paint for wallpaper

ActiveCN102704335BImprove dry rubbing fastnessCoatings with pigmentsCoatingsSilane compoundsWater based

The invention relates to decorative materials, in particular to a water-borne coating for wallpaper, which uses fibrous monoclinic crystal class titanium dioxide, silane compounds with more than three valences and nonionic polyatomic alcohol as main active ingredients, and provides the water-borne coating for the wallpaper, which integrates advantages of decoration, attractive appearance, antibacterium, deodorization, protection and particularly excellent wear-resistant performance into a whole.

Owner:ANHUI JINDUN PAINT

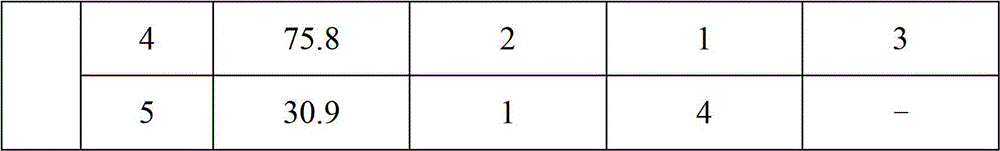

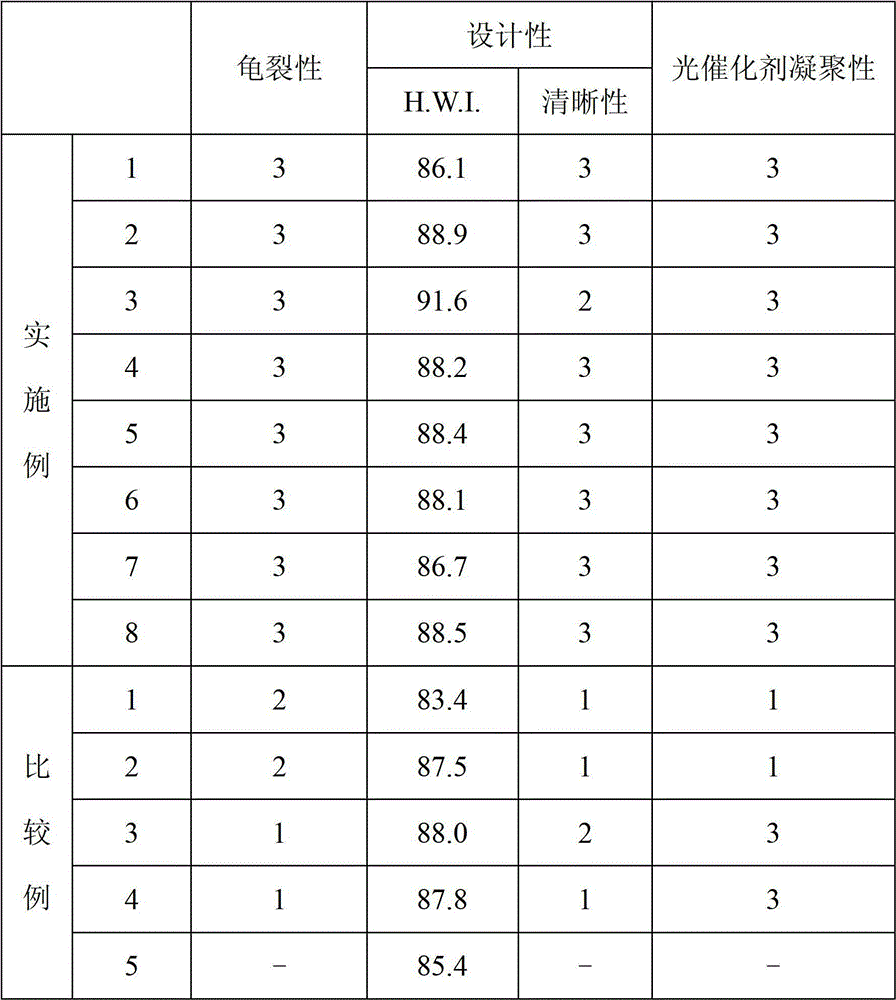

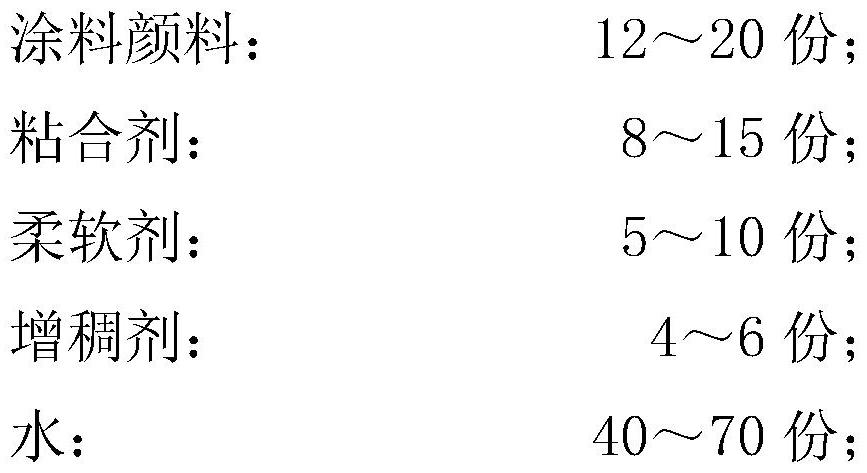

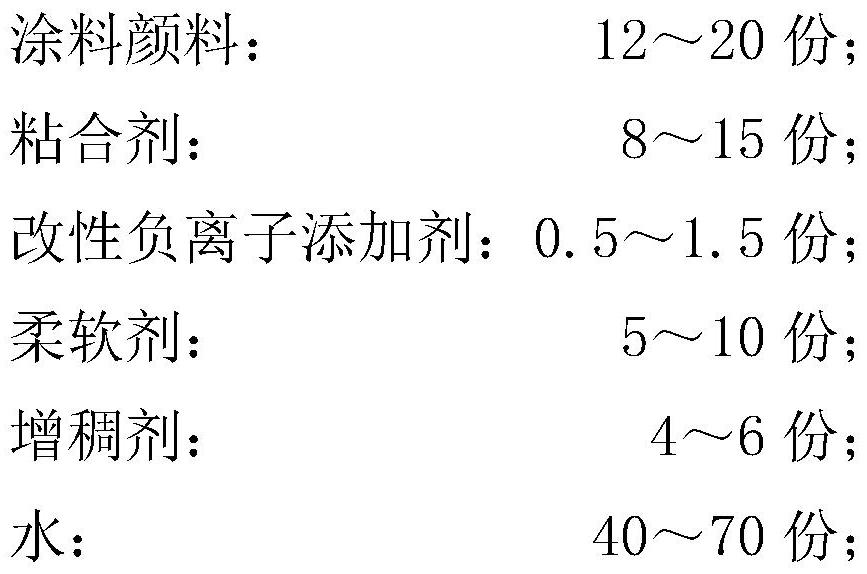

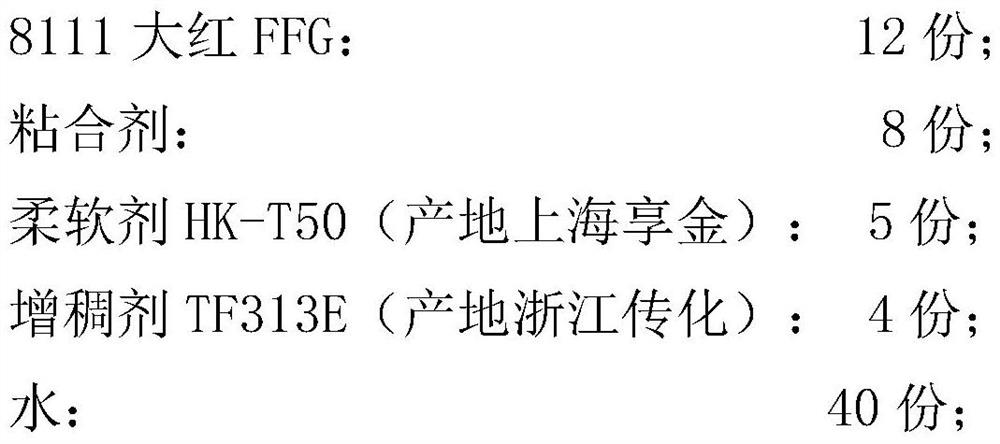

Pigment printing process

The invention discloses a pigment printing process and relates to the technical field of textile processing. The pigment printing process of the present invention includes processes such as paint preparation, paste mixing, printing, and baking and color fixing; a preparation method of an adhesive is also disclosed, which improves the adhesive force of the adhesive, pigments and fabrics, and improves The handle and fastness of the pigment printing adhesive are improved; a preparation method of a modified negative ion additive is also disclosed, which has the effects of reducing radiation and protecting health; the fabric prepared by the process of the invention has good hand quality, and dry friction The fastness, wet rubbing fastness, hand feel and color are good, and it has a good market prospect.

Owner:安徽省翰先纺织科技有限公司

Micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent and preparation method thereof

The invention relates to the technical field of color fixing agents and provides a micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent which is capable of well improving the fastness of the textile to wet rubbing and the color fastness of the textile to washing. The micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent comprises the following raw material components in parts by weight: 50-60 parts of methacryloxyethyltrimethyl ammonium chloride, 0.25-5 parts of epoxy compound, 0.1-2 parts of crosslinking agent, 0.02-0.3 part of initiator and 35-45 parts of deionized water, wherein the methacryloxyethyltrimethyl ammonium chloride is a water solution with a weight percent concentration of 65-98 percent. Meanwhile, the invention provides a preparation method of the micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent.

Owner:FUJIAN QINGYUAN TECH

Leather mildew-prevention and antibacterial agent and preparation method thereof

The invention discloses a leather mildew-prevention and antibacterial agent and a preparation method thereof, and belongs to the field of leather mildew prevention. A bonding additive is prepared fromcasein by modifying with hexamethylenetetramine and the like, so that a mildew preventive can have better compatibility with leather collagen and penetrate into leather more, bonding fastness and dryrubbing fastness are improved, and the mildew preventive can be retained for a long time; a prepared antibacterial active agent improves polymerizability and easy dispersibility of the mildew preventive, and can be uniformly dispersed on the leather surface and firmly combined with the leather, and mildew preventive efficiency is improved; a prepared spreading wax-based additive enables the mildew preventive to form a film and spread on the leather surface by means of lower surface energy, penetrates into the leather to perform moistening, and improves leather hand feeling; on the other hand,water on the leather surface is stopped by a hydrophobic chain introduced by the wax-based additive, the influence of external oxygen and water vapor on leather quality is reduced, and mildew prevention is fundamentally performed. The problem that quality and appearance of leather are affected by poor mildew-prevention and antibacterial effects of current mildew preventives is solved.

Owner:汪逸凡

A kind of pigment printing fabric dry rubbing fastness improving agent and its preparation and use method

ActiveCN106835754BImprove dry rubbing fastnessEasy to prepareDyeing processScreen printingPolymer science

The invention discloses a dry rubbing fastness improver for a pigment printing fabric as well as a preparation and using method of the improver. The dry rubbing fastness improver for the pigment printing fabric comprises the following components in percentage by weight: 50-80% of a lubricating agent, 5-8% of a cross-linking agent, 0.5-2% of a thickening agent, and 10-44.5% of deionized water. The method comprises the following steps: accurately weighing the various components, uniformly stirring, and preparing the dry rubbing fastness improver for the pigment printing fabric with a viscosity range of 20000-30000mPa.s; directly adding 0.1-2% of the dry rubbing fastness improver for the pigment printing fabric into the prepared coating printing size, completing printing by using rotary screen printing or flat screen printing, drying and roasting, so that the dry rubbing fastness of the pigment printing fabric can be improved to level 4.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

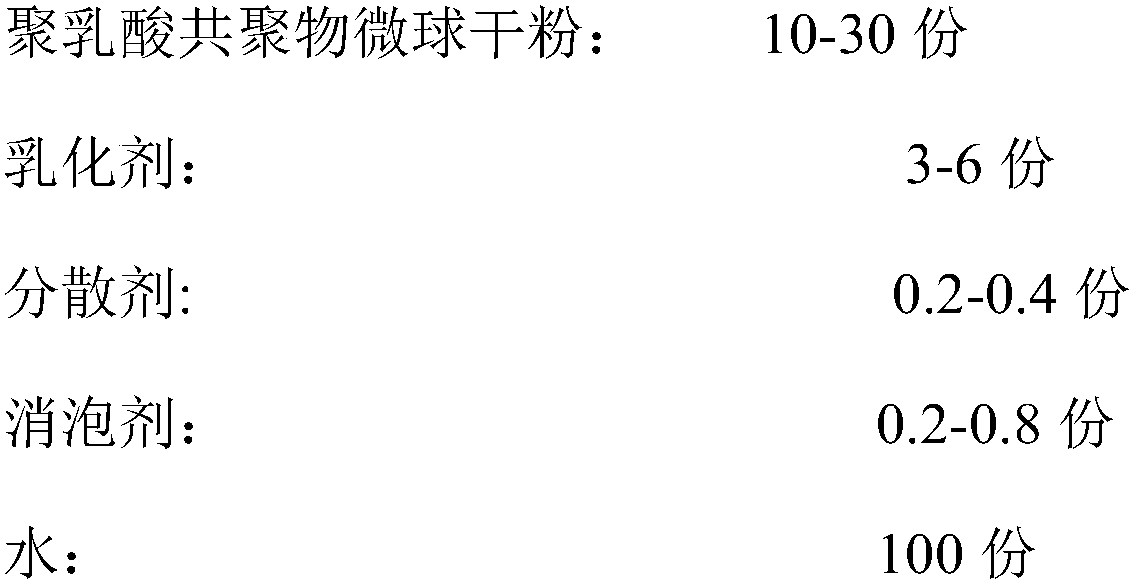

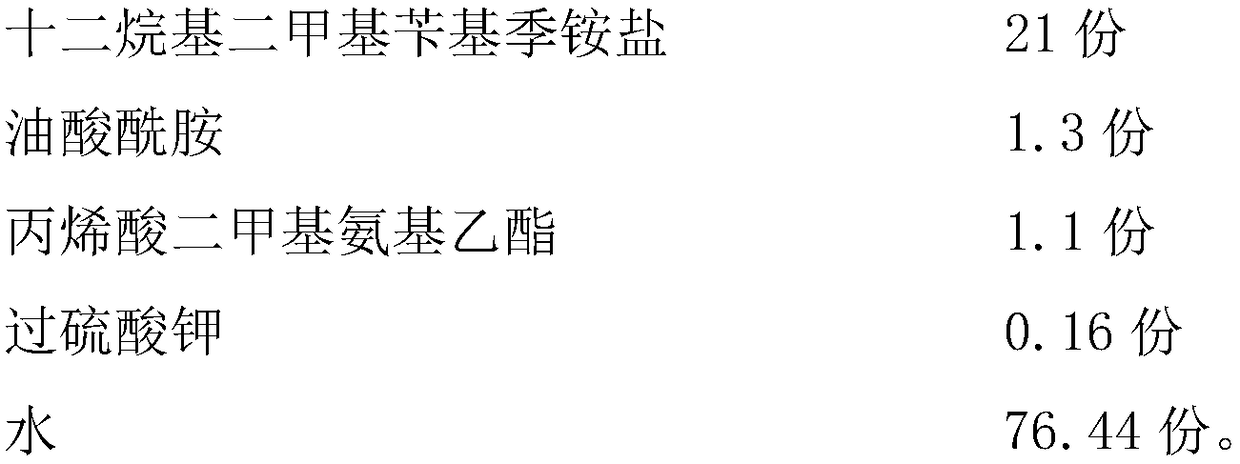

Rapid dyeing method for superfine fiber suede leather

InactiveCN109594362ASolve the problems of low wet rubbing fastness, discolored dyeing, and easy fading of dark colorsBiodegradableFibre typesDyeing processMicrosphereDark color

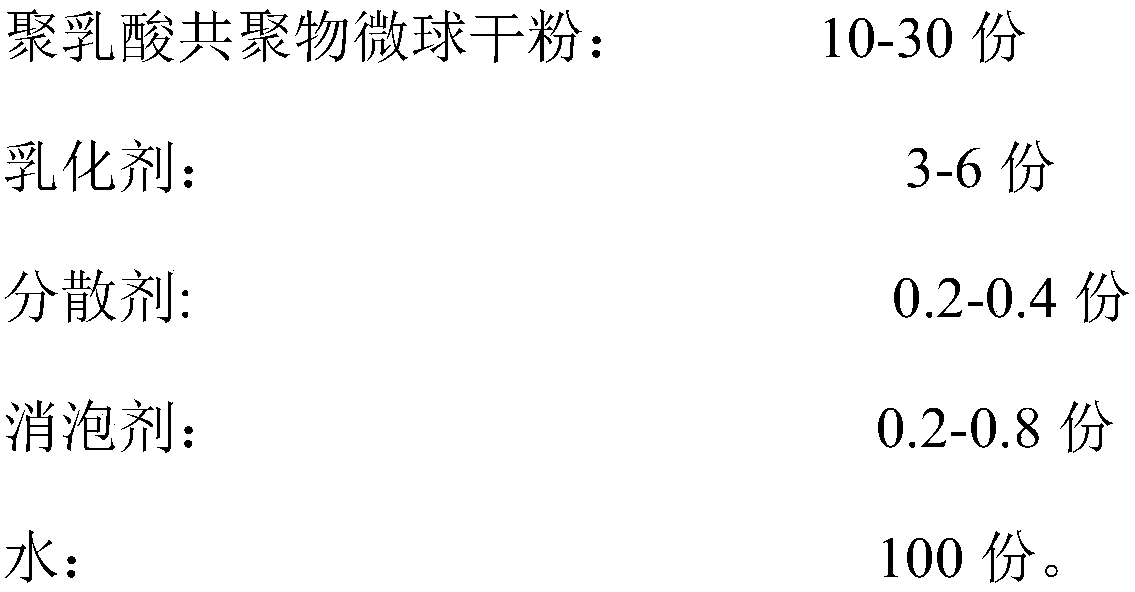

The invention discloses a rapid dyeing method for superfine fiber suede leather. The rapid dyeing method comprises the following steps: soaking superfine fiber suede leather into a treatment liquid, carrying out soaking rolling, drying after soaking rolling, and dyeing the dried superfine fiber suede leather, wherein the treatment liquid comprises the following components in parts by weight: 10-30parts of polylactic acid copolymer micro-sphere dry powder, 3-6 parts of an emulsifier, 0.2-0.4 part of a dispersant, 0.2-0.8 part of a defoaming agent and 100 parts of water. By adopting the rapid dyeing method, the problems that in the prior art the superfine fiber suede leather is low in wet friction fastness and dark colors of dyeing patterns are easily faded in common dyeing of the superfinefiber suede leather are solved, and the polylactic acid copolymer micro-sphere dry powder has biological degradability and is environmentally friendly.

Owner:HUAFON MICROFIBER SHANGHAI

Aldehyde-free color fixing agent for acid dyeing and preparation method thereof

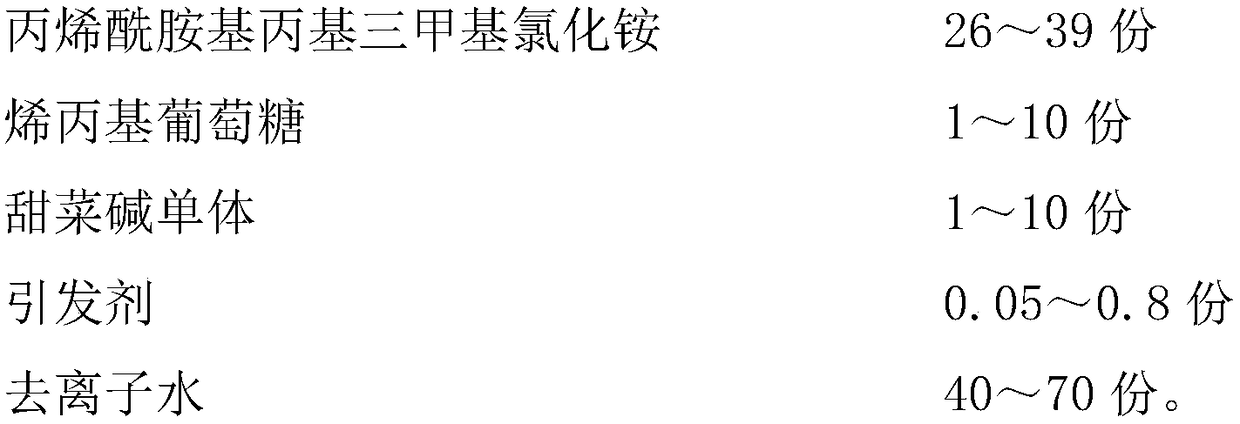

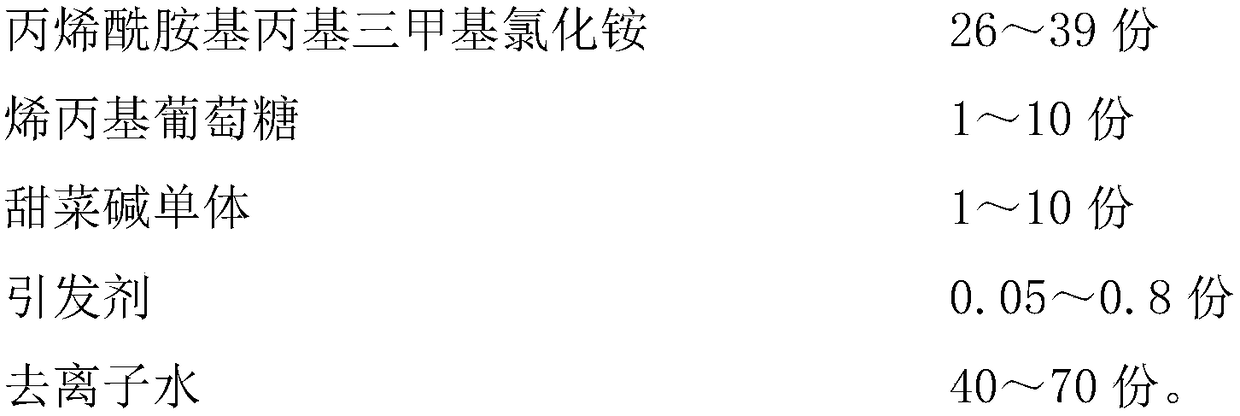

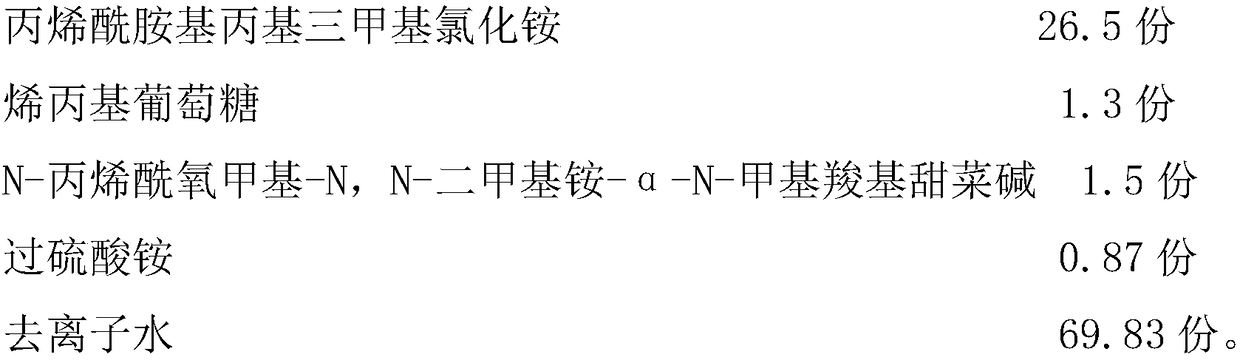

InactiveCN108774907AImprove bindingImprove dry rubbing fastnessDyeing processUltraviolet lightsD-Glucose

The invention relates to an aldehyde-free color fixing agent for acid dyeing and a preparation method thereof. The preparation method comprises the following steps: (1) adding acrylamidopropyl trimethylammonium chloride, allyl glucose, betaine monomer and deionized water into a reactor, starting stirring, starting heating; (2) when the temperature in the reactor rises to 85-120 DEG C, dripping aninitiator solution with a mass concentration of 1 to 10%, wherein the initiator solution is prepared from the initiator and partial deionized water, and the dropping time is controlled to be 3 to 6 hours, irradiating the reaction liquid with ultraviolet light during dripping process, wherein the irradiation time is 1 to 8 hours; and (3) keeping the temperature and continuing to react for 1 to 3 hours, cooling, and discharging materials to obtain the color fixing agent.

Owner:曾文华

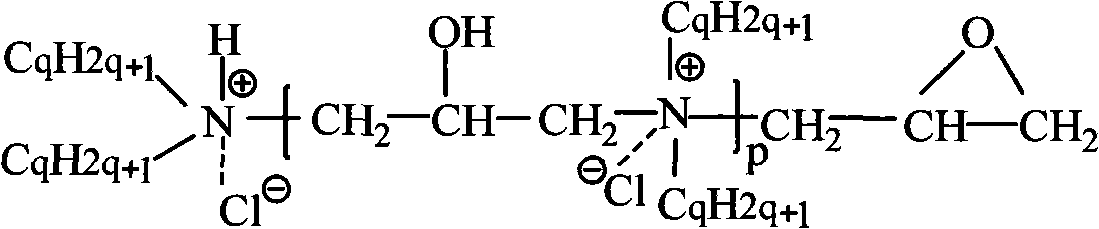

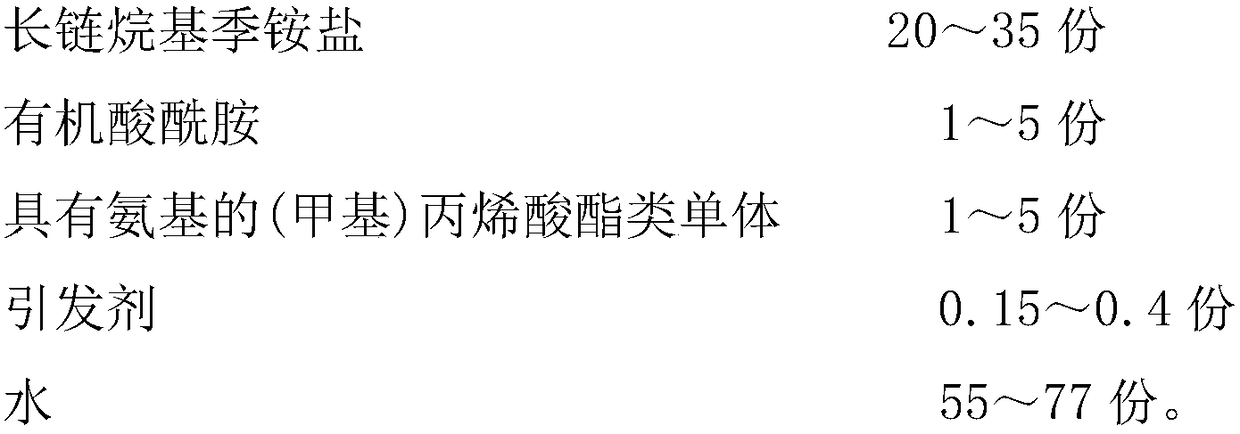

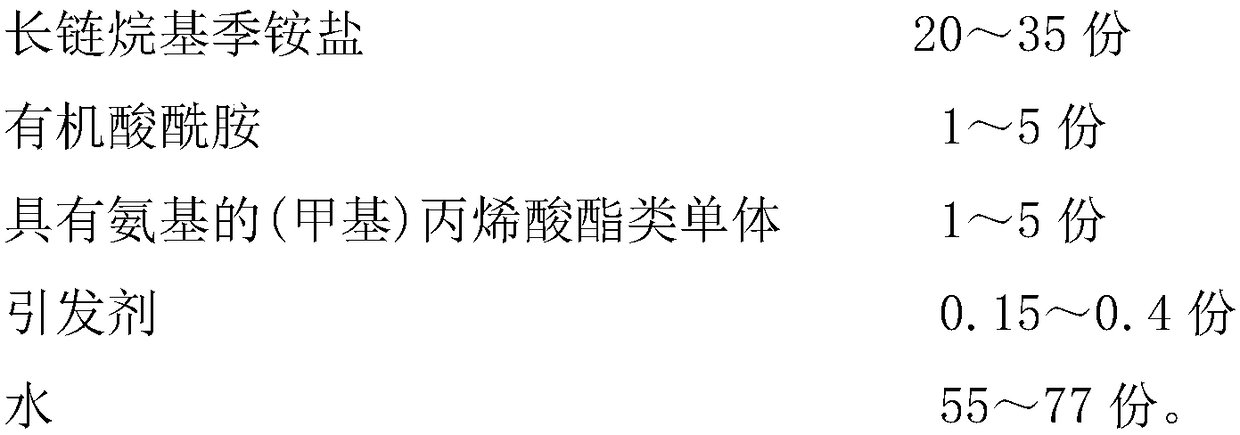

Quaternary ammonium salt cationic color fixing agent and preparation method thereof

InactiveCN108660811AImprove bindingImprove dry rubbing fastnessDyeing processOrganic acidMethyl group

The invention relates to a quaternary ammonium salt cationic color fixing agent and a preparation method thereof. The preparation method comprises the following steps that (1) long-chain alkyl quaternary ammonium salt, organic acid amide and water are added into a reaction vessel provided with a thermometer, an oil bath pan and a stirrer, stirring is started, and heating is started; (2) when the temperature in the reaction vessel rises to 85-120 DEG C, a mixed solution of a (methyl) acrylate monomer with amino groups, an initiator and the water is dropwise added and is dropwise added completely within 3-6 hours; and (3) after dropwise adding is completed, the temperature is continuously kept for reaction for 1-3 hours, and cooling and discharging are carried out so as to obtain the color fixing agent.

Owner:李美琴

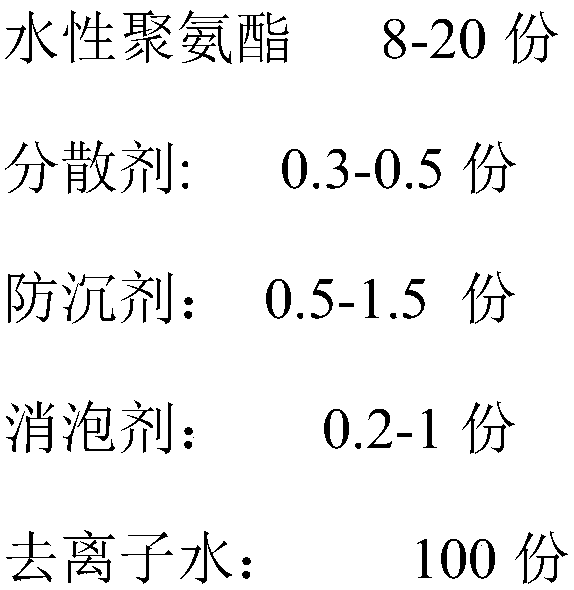

Rapid dyeing method for superfine fiber suede leather

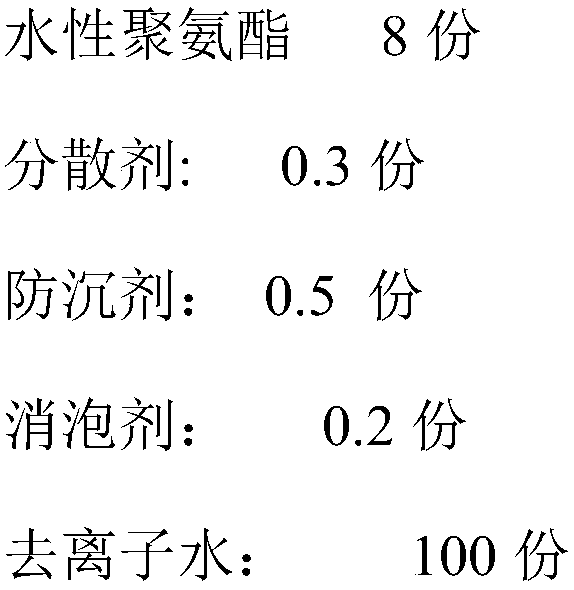

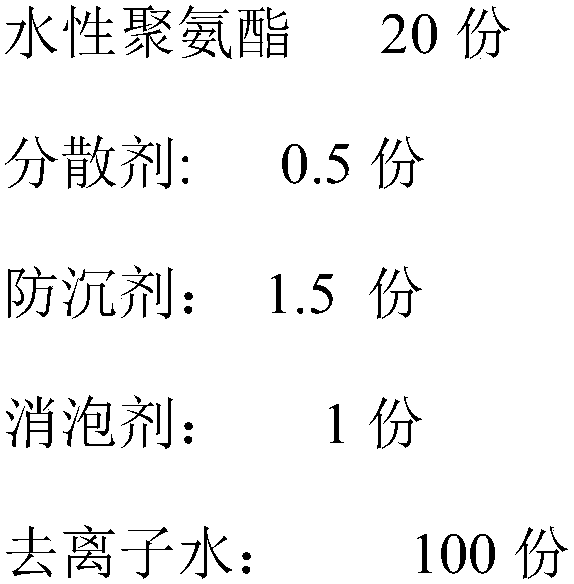

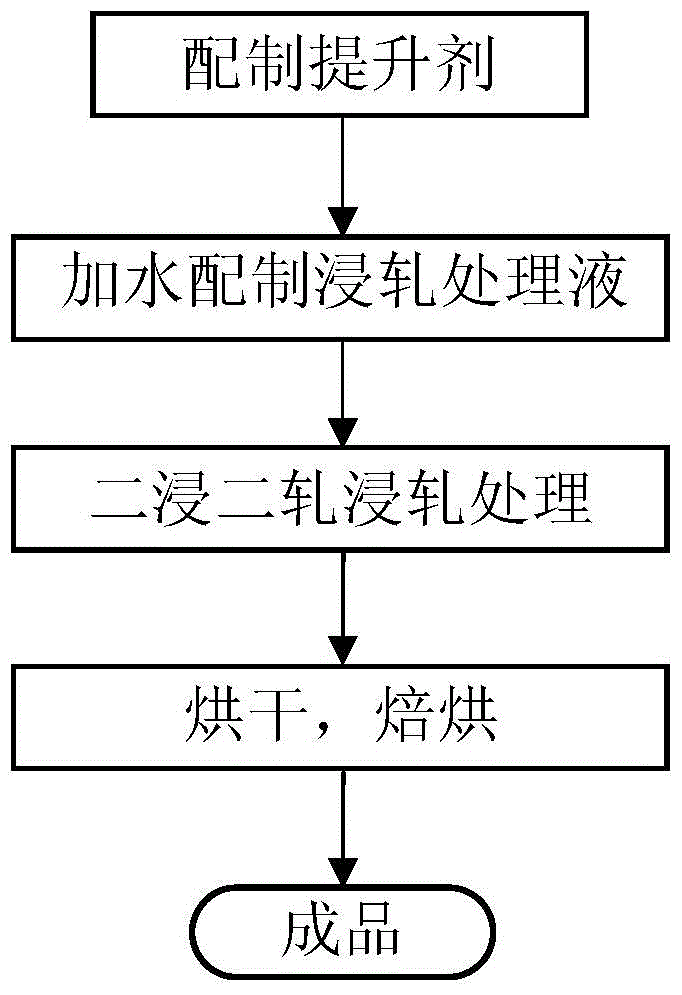

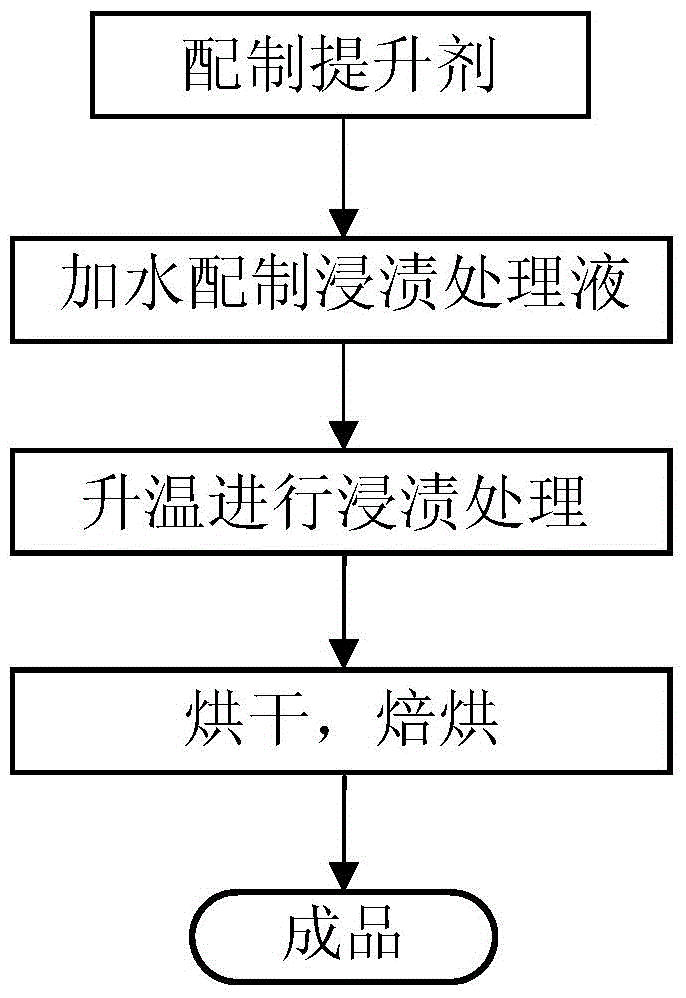

The invention discloses a rapid dyeing method for superfine fiber suede leather. The rapid deying method comprises the following steps: soaking superfine fiber suede leather into a treatment liquid, carrying out soaking rolling, drying after soaking rolling, and dyeing the dried superfine fiber suede leather, wherein the treatment liquid comprises the following components in parts by weight: 8-20parts of waterborne polyurethane, 0.3-0.5 part of a dispersant, 0.5-1.5 parts of an anti-sinking agent, 0.2-1 part of a defoaming agent and 100 parts of deionized water. As waterborne polyurethane micro particles are fed into gaps of a superfine fiber, uniform dyeing is achieved in later dyeing, and dyeing depths, color uniformity, dry friction fastness and wet friction fastness can be all improved. By adopting the rapid dyeing method, the problems that in the prior art the superfine fiber suede leather is low in wet friction fastness and dark colors of dyeing patterns are easily faded in common dyeing of the superfine fiber suede leather are solved.

Owner:HUAFON MICROFIBER SHANGHAI

Method for improving dry rubbing fastness of smooth-haired slubbed product

The invention relates to a method for improving dry rubbing fastness of a smooth-haired slubbed product. The process flow of the method is as follows: getting grey cloth of the smooth-haired product, performing primary washing, milling, re-washing, dewatering, drying, decating, napping, shearing, performing wet brushing, drying, lustring, shearing, steaming and trimming, steaming and brushing, decating and getting a finished product, wherein the milling process conditions are as follows: auxiliary agents comprise 2% owf (on weight of fabric)-2.5% owf of Igephon T, 3% owf-3.5% owf of oleate soap and 0.8-1% owf of Invalon DAM dispersant; the milling time is 60-90min; and the milling temperature is 45-50 DEG C. The method mainly comprises the steps that the dispersant is added in the milling process to disperse dust and dye particles which are washed down so as to prevent the dust and the dye particles from being re-stained on fabric, enable the dust and the dye particles to be washed away in the subsequent washing process and further improve the dry rubbing fastness. According to the method, compared with normal products, the dry rubbing fastness of slubbing can be improved from level half to level1.

Owner:JIANGSU SUNSHINE GRP CO LTD

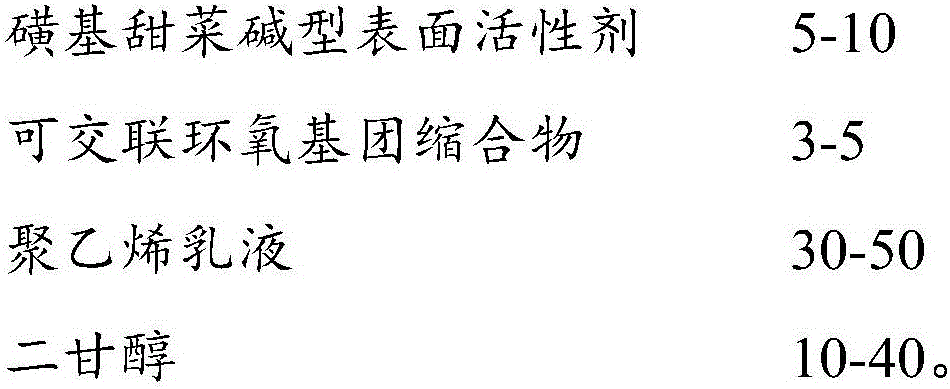

A kind of dry rubbing fastness improving agent of textile dyeing and its preparation method and dry rubbing fastness improving process

The invention discloses a textile dyeing substance dry friction fastness improving agent, a preparation method thereof, and an improving technology. The improving agent is composed of sulphobetaine type ampholytic surfactant, crosslinkable epoxy group condensate, polyethylene emulsion, and diglycol. The preparation method comprises the following steps: preparing a sulphobetaine type ampholytic surfactant in advance, adding the surfactant into a reactor, and heating under stirring to dissolve the surfactant; carrying out water bath at a temperature of 80 to 90 DEG C, stirring, cooling, and saving for later use; adding diglycol, polyethylene emulsion, and crosslinkable epoxy group condensate in sequence, evenly mixing, and finally filtering to obtain the improving agent. The invention also provides a unique padding technology and impregnating technology using the provided improving agent. The provided improving agent, preparation method, and processing technology are developed though long-term research, development, and practices, can effectively improve the dry friction fastness of textile dyeing substances, and fulfill the technical blank for improving the dry friction fastness in the textile post-treatment.

Owner:上海兴康超纤新材料有限公司

Overcoat liquid for inkjet textile printing, ink set for inkjet textile printing, and inkjet textile printing method

PendingUS20210395553A1Improve dry rubbing fastnessImprove wet rubbing fastnessDuplicating/marking methodsInksTextile printerPolymer science

Provided are: an overcoat liquid for inkjet textile printing including particles of an anionic polyurethane, particles of a wax, a water-soluble organic solvent, and water, wherein the content of the particles of the anionic polyurethane is 4 mass % to 20 mass % relative to the total amount of the overcoat liquid, the content of the particles of the wax is 0.1 mass % to 3 mass % relative to the total amount of the overcoat liquid, and the content of the water-soluble organic solvent satisfies formula (1) in units of mass %, an ink set for inkjet textile printing; and an inkjet textile printing method.0.7×A+0.8×B+C<20 (1)See the specification for definitions of A, B, and C.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com