Formaldehyde-free fixing agent and preparation method thereof

A color-fixing agent and formaldehyde technology, applied in the field of textile printing and dyeing, can solve the problem that the wet rubbing fastness is difficult to meet the requirements of high-quality products, and achieve the goal of improving dry rubbing fastness, improving wet and dry fastness, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A kind of preparation method of formaldehyde-free color-fixing agent of the present invention, realize by following steps:

[0029] (1) Add acrylamide monomers with ammonium groups, acryloyloxyethyl succinate, unsaturated chlorosilane monomers, and deionized water to the reactor in sequence, start stirring, and start heating to raise the temperature;

[0030] (2) When the temperature in the reactor rises to 30°C to 50°C, add an initiator solution, which is prepared from the initiator and part of the deionized water;

[0031] (3) The reactor is then placed in a microwave reactor, and then subjected to microwave radiation, after which, the microwave reactor is closed and the temperature is lowered to discharge the material to obtain the color fixing agent.

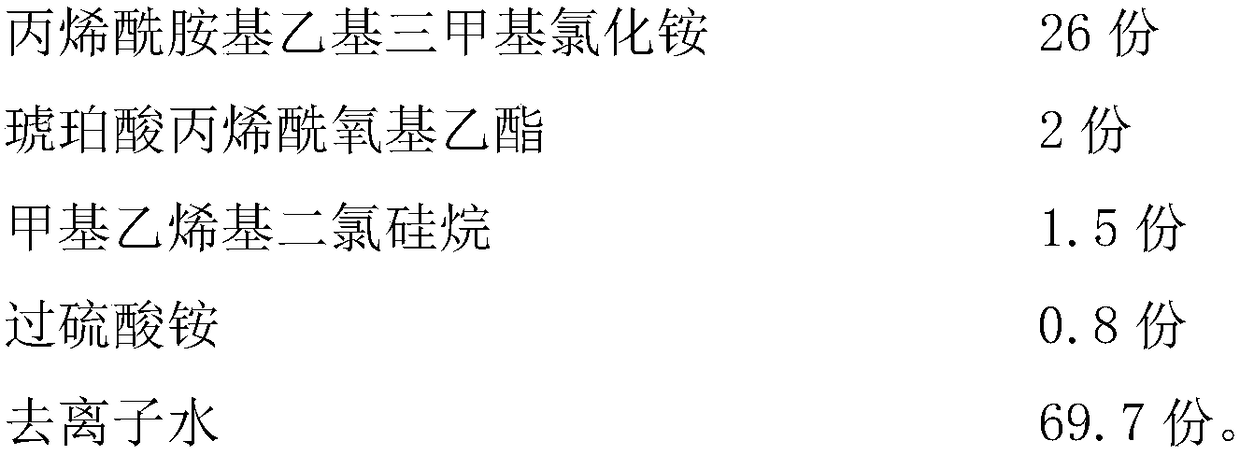

Embodiment 1

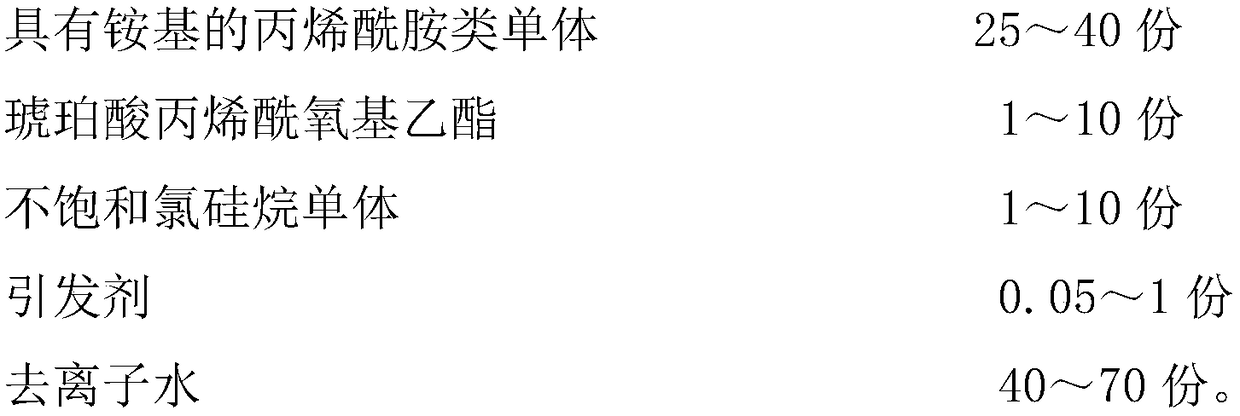

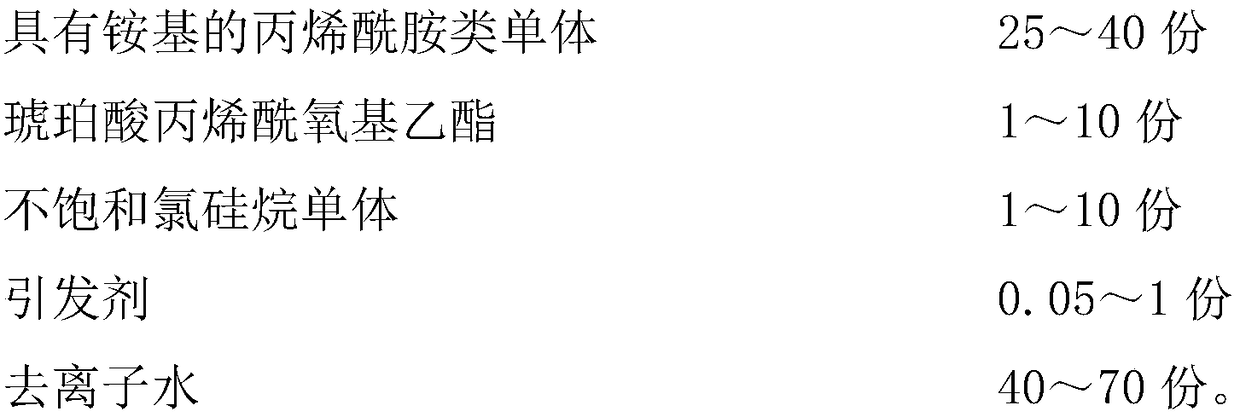

[0034] A formaldehyde-free color-fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0035]

[0036] A kind of preparation method of formaldehyde-free color-fixing agent of the present invention, realize by following steps:

[0037] (1) Add 26 parts of acrylamidoethyltrimethylammonium chloride, 2 parts of acryloyloxyethyl succinate, 1.5 parts of methylvinyl dichlorosilane, and 60.5 parts of deionized water into the reactor successively, Turn on the stirring and start to heat up;

[0038] (2) When the temperature in the reactor rose to 32°C, add the initiator solution, which was prepared from 0.8 parts of ammonium persulfate and 9.2 parts of deionized water;

[0039] (3) Reactor is placed in microwave reactor then, be 2450MHz with the frequency of microwave radiation, the microwave radiation above-mentioned reaction mixture that power is 600W, after radiation 5 minutes, thereafter, close microwave reactor and cool...

Embodiment 2

[0041] A formaldehyde-free color-fixing agent of the present invention is made of the following raw material components in proportions by mass:

[0042]

[0043] A kind of preparation method of formaldehyde-free color-fixing agent of the present invention, realize by following steps:

[0044] (1) Add 28 parts of acrylamidoethyltrimethylammonium chloride, 2 parts of acryloyloxyethyl succinate, 2.9 parts of methacryl dichlorosilane, and 55.6 parts of deionized water into the reactor successively, Turn on the stirring and start to heat up;

[0045] (2) When the temperature in the reactor rose to 35°C, add the initiator solution, which was prepared from 0.65 parts of ammonium persulfate and 9.35 parts of deionized water;

[0046] (3) Then the reactor is placed in a microwave reactor, and the frequency of microwave radiation is 2450MHz, and the microwave radiation power of 1200W is the above-mentioned reaction mixture. After 15 minutes of radiation, thereafter, the microwave re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com