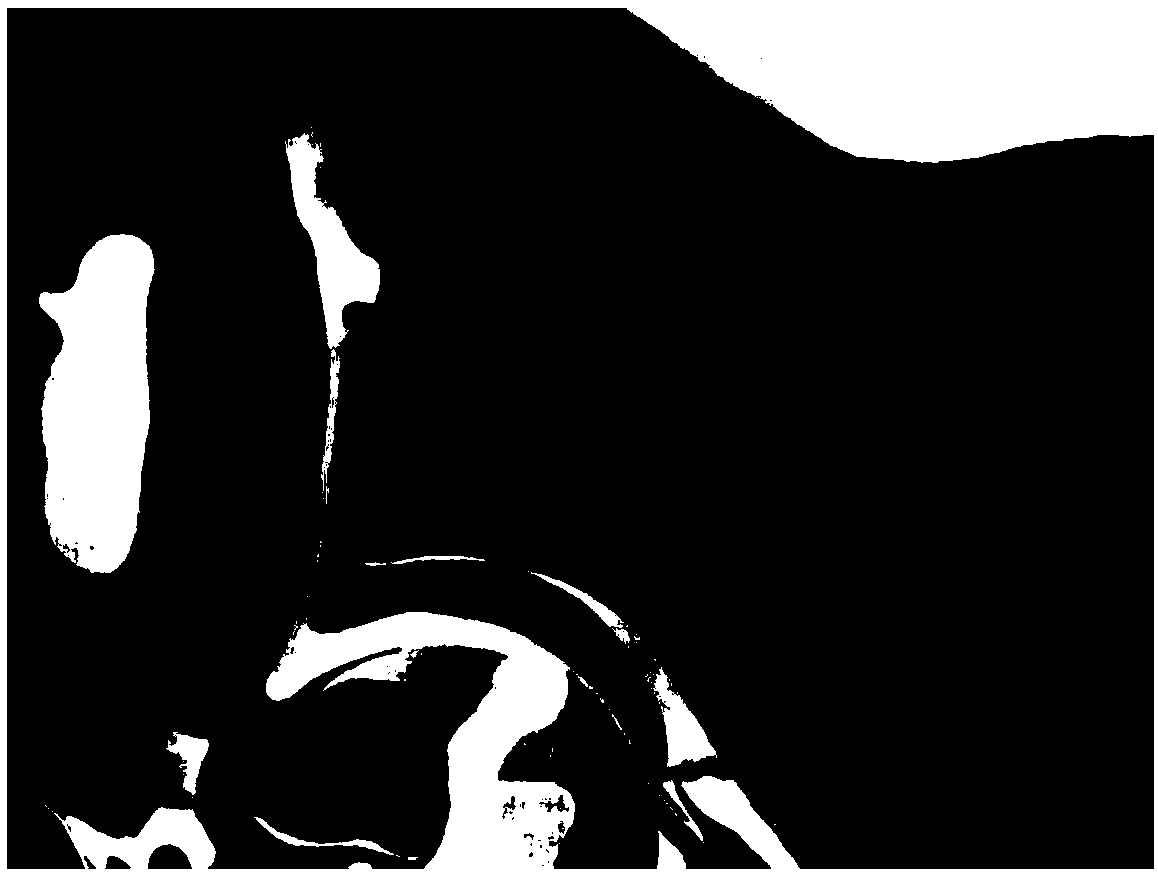

Patents

Literature

52results about How to "High color fastness to washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

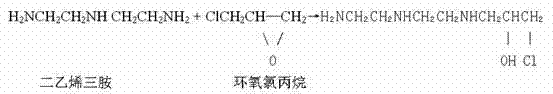

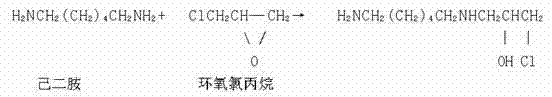

Preparation method of formaldehyde-free color fixative

The invention relates to a preparation method of a formaldehyde-free color fixative. The invention is characterized in that amines and epoxy chloropropane react to generate a condensate, wherein the amines are total amines and prepared by mixing hexamethylendiamine and other substances; and the other substances can be one or more of ammonia water, monomethyl amine, dimethyl amine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine, tetraethylenepentamine, ethylene diamine, urea and urea substitute. The color fixative has the advantages of high color fastness, small influence on sensitive color tone, low consumption, no environment pollution of formaldehyde, accessible raw materials and simple production technique, can enhance the dry / wet fastness to rubbing and the color fastness to water washing, and basically does not generate color phase variations when fixing emerald blue, bright blue and other sensitive color dyes.

Owner:JIANGSU NIMATE SCI & TECH CO LTD

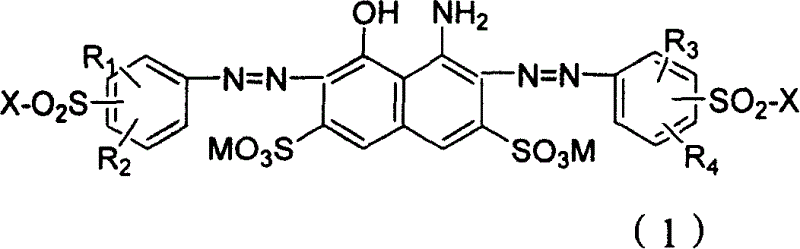

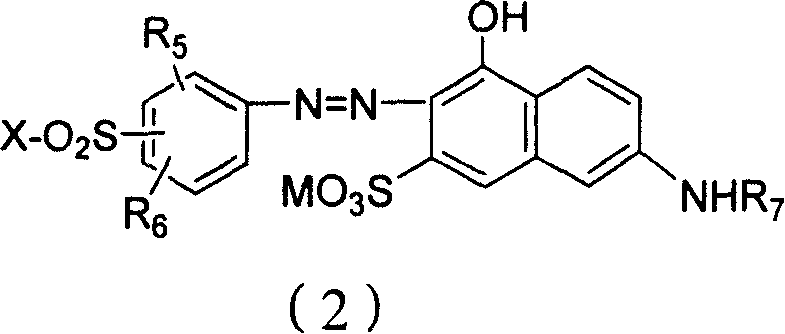

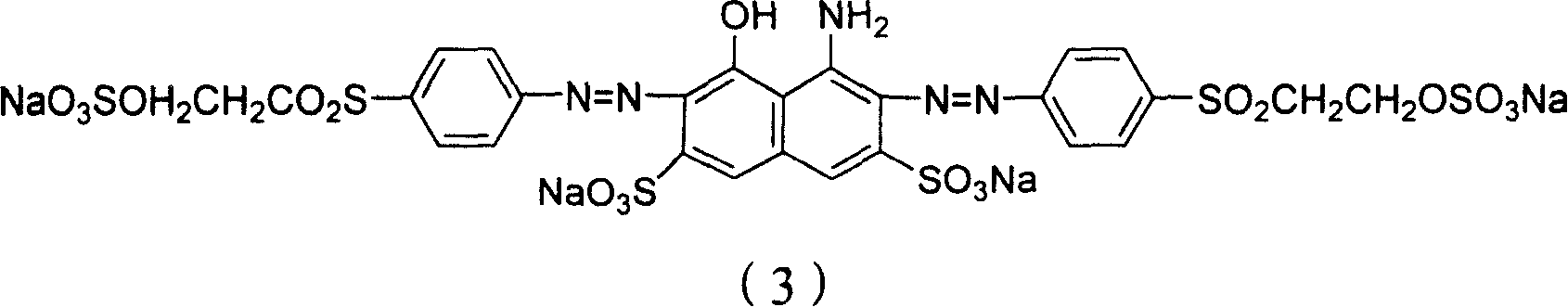

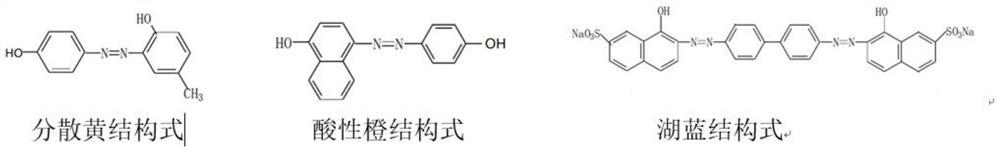

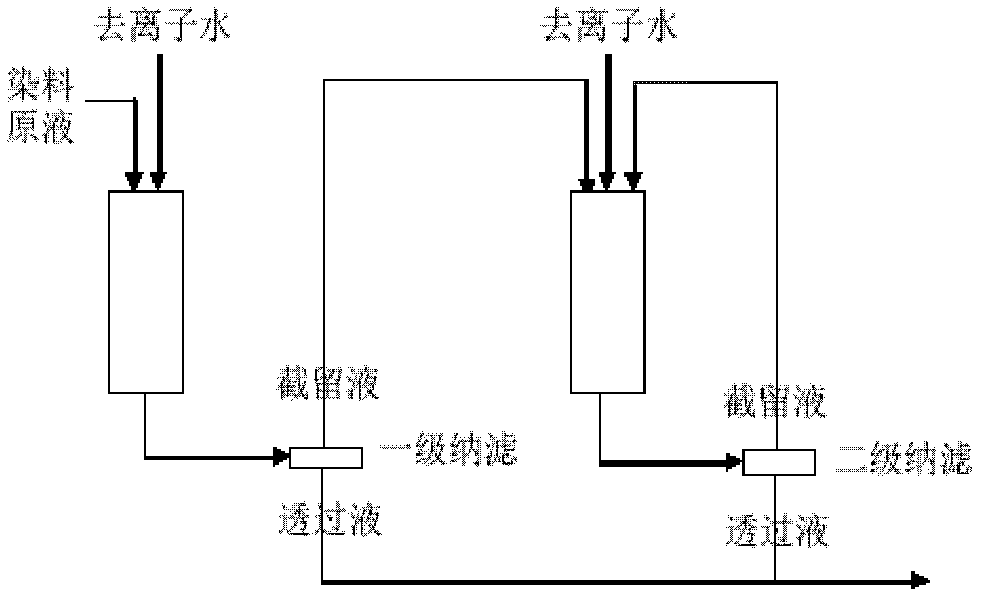

Composite active black dye for cellulose dyeing

InactiveCN1746231AImprove washabilityHigh color fastness to washingOrganic dyesDyeing processDyeingPhotochemistry

Owner:ZHEJIANG SHUNLONG CHEM

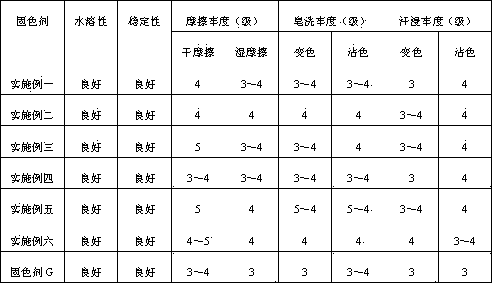

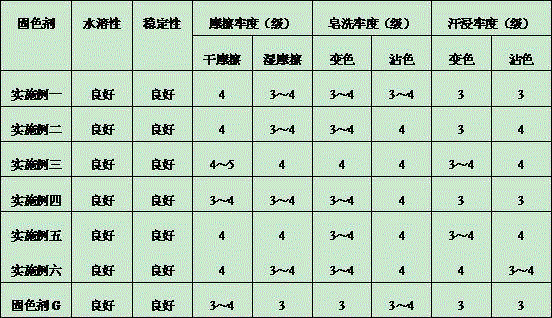

Micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent and preparation method thereof

The invention relates to the technical field of color fixing agents and provides a micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent which is capable of well improving the fastness of the textile to wet rubbing and the color fastness of the textile to washing. The micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent comprises the following raw material components in parts by weight: 50-60 parts of methacryloxyethyltrimethyl ammonium chloride, 0.25-5 parts of epoxy compound, 0.1-2 parts of crosslinking agent, 0.02-0.3 part of initiator and 35-45 parts of deionized water, wherein the methacryloxyethyltrimethyl ammonium chloride is a water solution with a weight percent concentration of 65-98 percent. Meanwhile, the invention provides a preparation method of the micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent.

Owner:FUJIAN QINGYUAN TECH

Cationic type formaldehyde-free color fixing agent for reactive dye and preparation method thereof

The invention relates to the technical field of color fixing agents, and provides a cationic type formaldehyde-free color fixing agent for reactive dye, wherein through the cationic type formaldehyde-free color fixing agent, the wet rubbing fastness and washing color fastness of textiles can be better improved. The cationic type formaldehyde-free color fixing agent for the reactive dye is prepared from, by mass, 50-60 parts of dimethyl diallyl ammonium chloride, 0.2-10 parts of monomers containing tertiary amino groups, 0.1-5 parts of cross-linking agents, 0.01-0.3 part of initiating agents and 30-48 parts of deionized water, wherein an aqueous solution with the mass percentage concentration of 60+ / -0.5% or 65+ / -0.5% is adopted as the dimethyl diallyl ammonium chloride. Meanwhile, the invention further provides a preparation method of the cationic type formaldehyde-free color fixing agent for the reactive dye.

Owner:SHISHI QINGYUAN FINE CHEM

Linen printing and dyeing method with high dye-uptake rate, as well as linen product printed and dyed by method

InactiveCN105507035AImprove friction resistanceHigh color fastness to washingDyeing processPulp and paper industryLinen cloth

The invention a linen printing and dyeing method with high dye-uptake rate, as well as a linen product printed and dyed by the method. The method comprises the following steps: conducting destarching treatment, boiling-off treatment and bleaching treatment on a linen raw material in sequence, and conducting printing and dyeing treatment to obtain the linen product, wherein the printing and dyeing auxiliary is one or more of 2,3-epoxypropyltrimethyl ammonium chloride, tartaric acid and benzalkonium chloride, and the mass ratio of the printing and dyeing auxiliary to a dye mordant is 1:(10-50). According to the provided linen printing and dyeing method with high dye-uptake rate, linen can be dyed with very high tint amount, and the printed and dyed linen has very high friction resistance and very high water washing resistant color fastness. Besides, the provided linen printing and dyeing method is low in raw material cost, simple to operate, good in operability and very suitable for industrial printing and dyeing.

Owner:FOSHAN JUCHENG BIOCHEM TECH RES & DEV CO LTD

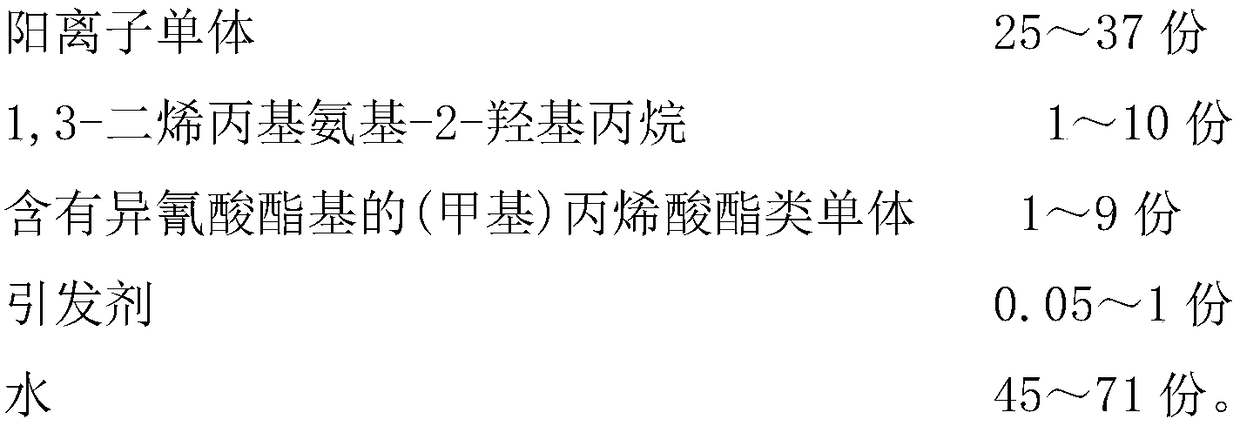

Textile printing and dyeing fixer and preparation method thereof

InactiveCN108824035AImprove bindingImprove dry rubbing fastnessDyeing processTextile printerRoom temperature

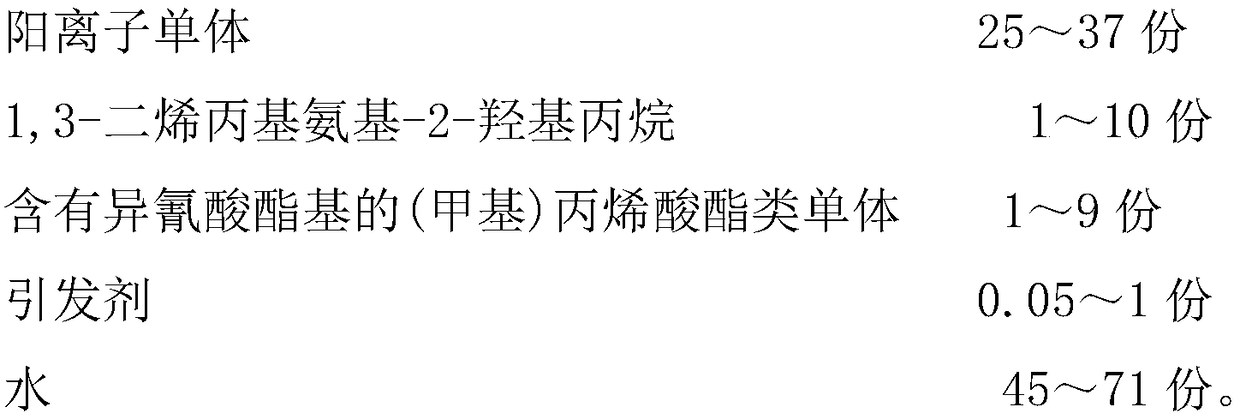

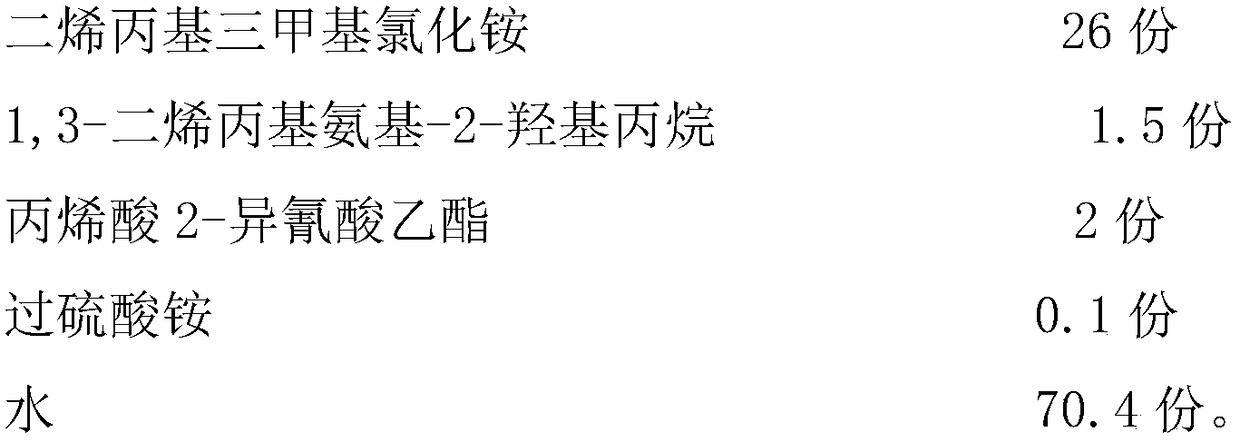

The invention provides a textile printing and dyeing fixer and a preparation method thereof. The preparation method comprises the following steps: (1) putting a cationic monomer, 1,3-diallylamino-2-hydroxypropane, a (methyl)acrylate monomer containing an isocyanate group and water into a polymerization reaction vessel, uniformly stirring, heating and warming; (2) in a condition without oxygen anda condition of stirring, dropwise adding initiator solution to the polymerization reaction vessel, performing a polymerization reaction, wherein a temperature of the polymerization reaction is 80-100DEG C, and a mass concentration of the initiator solution is 1-10%, so the initiator solution is prepared by an initiator and a part of the water, and completely dropwise adding the initiator solutionwithin 1-3 hours; and (3) after completely dropwise adding, in the temperature of the polymerization reaction, continuously performing the polymerization reaction for 1-3 hours, cooling to room temperature, and discharging, to obtain the fixer.

Owner:陈国宝

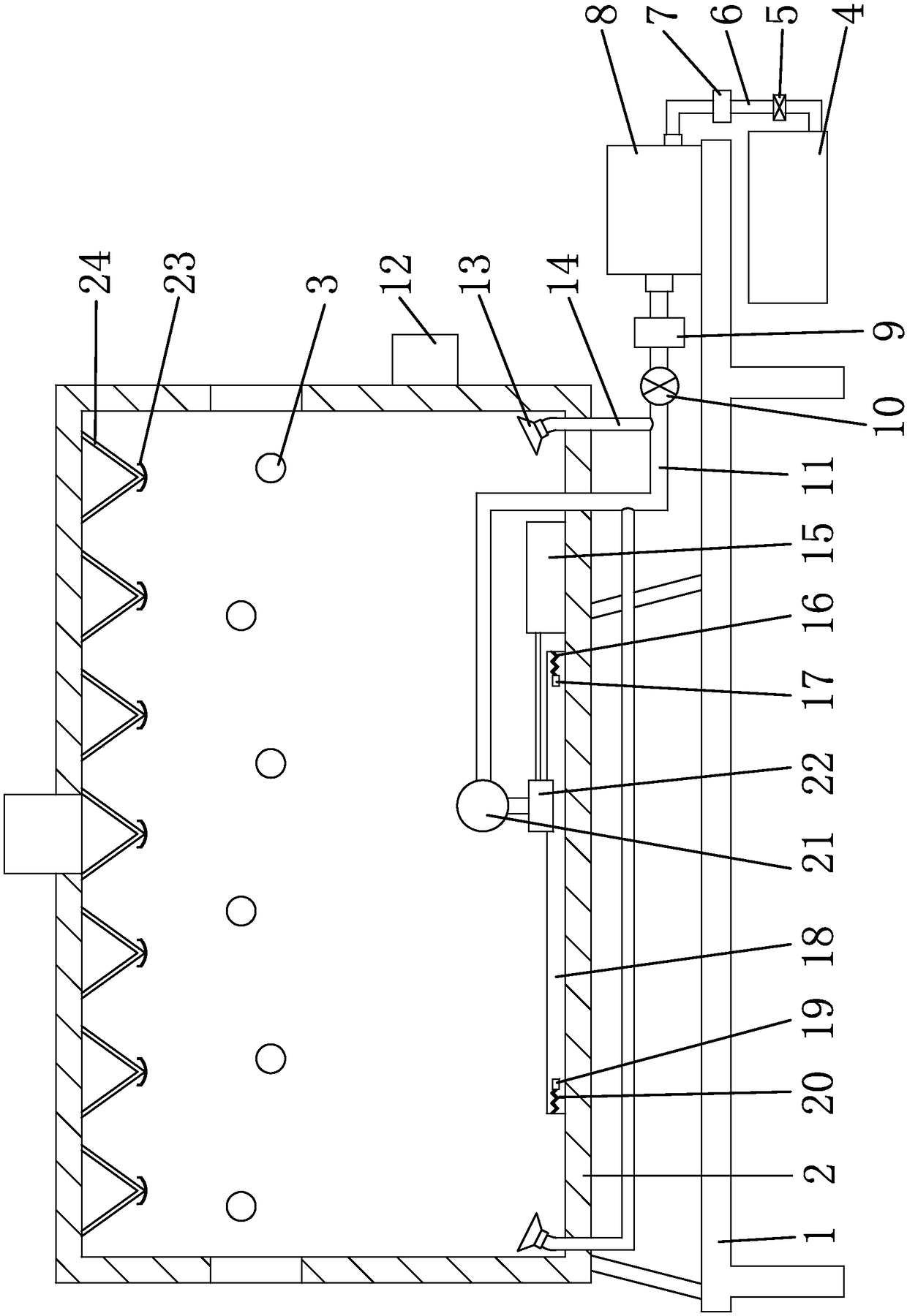

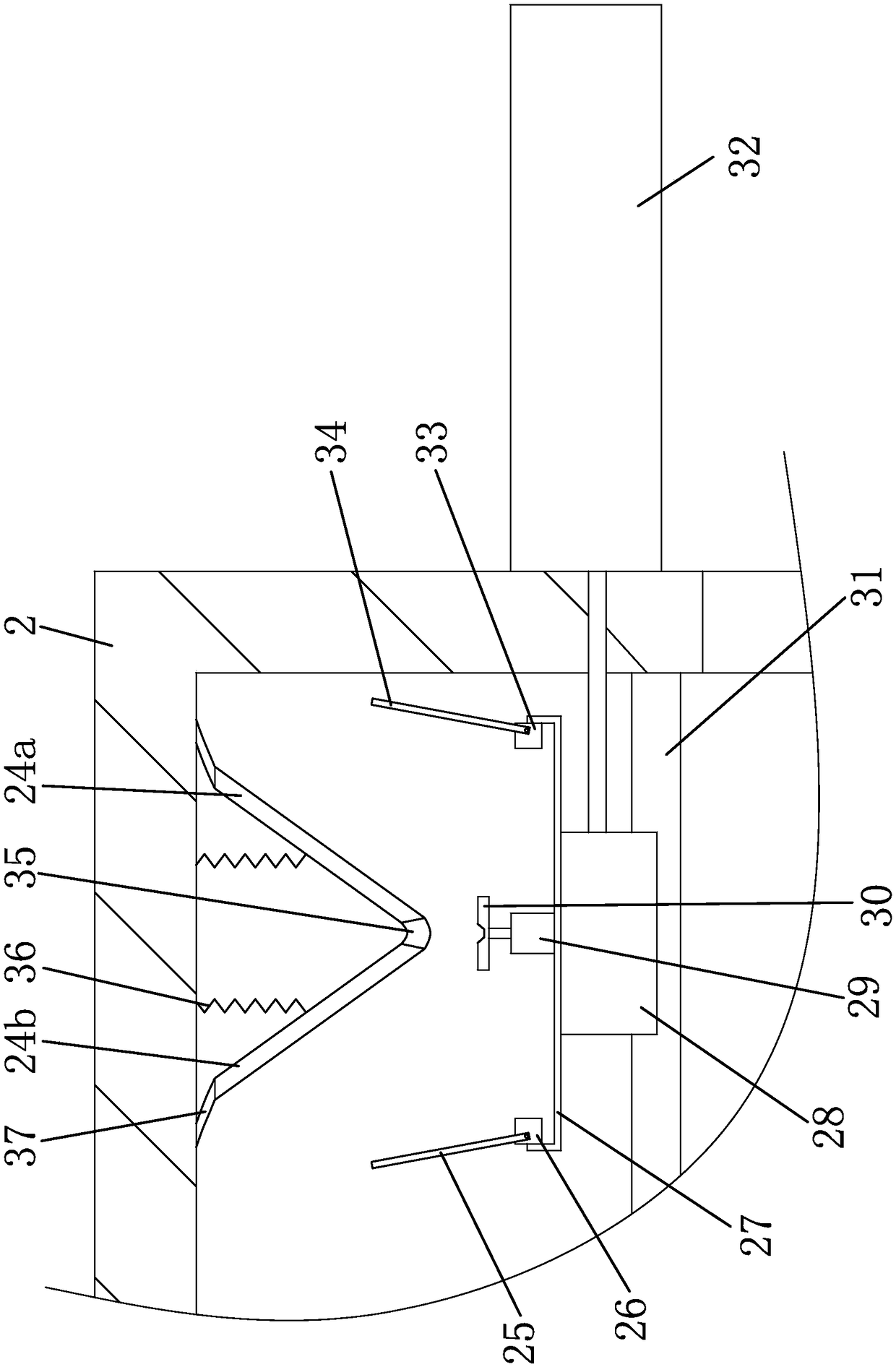

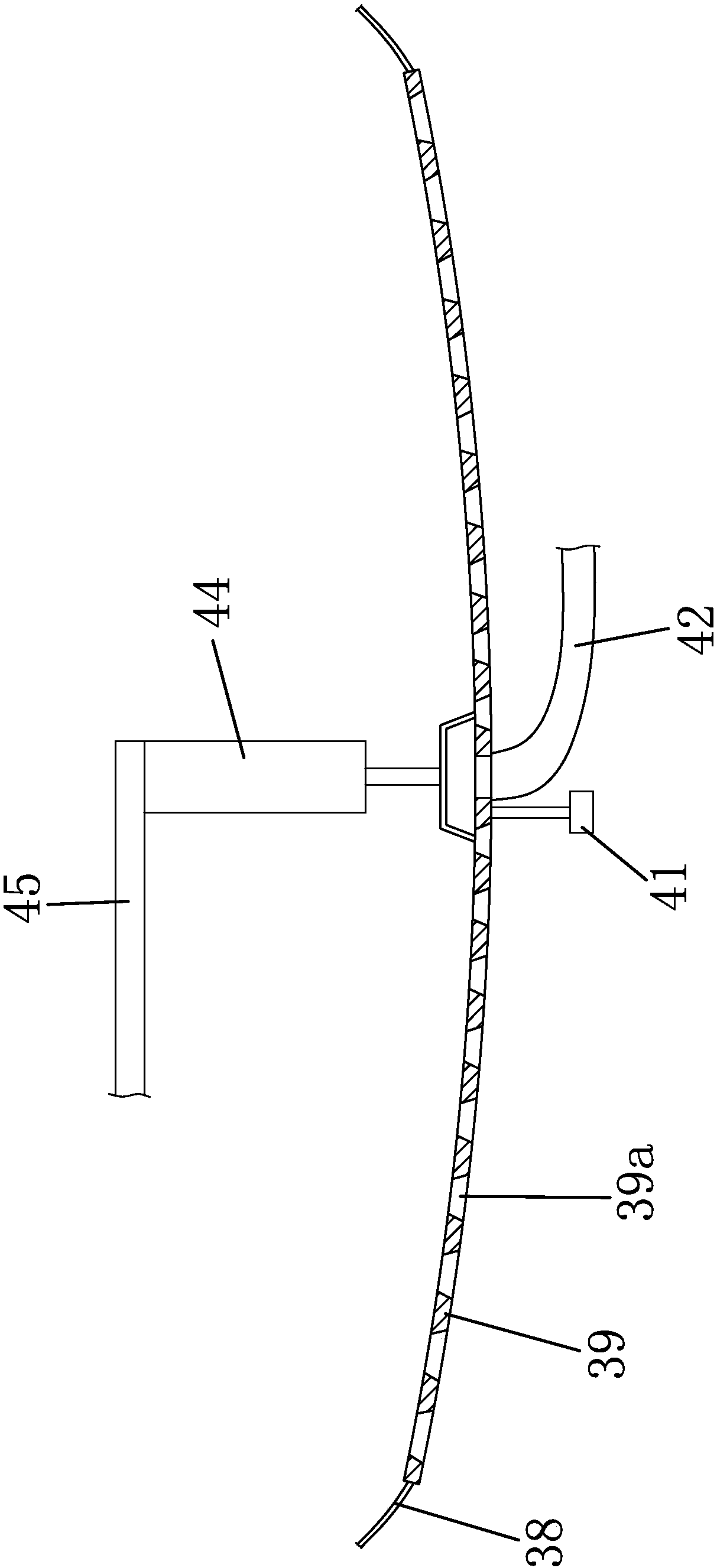

Photocatalysis antibiotic finishing agent and process for application of final finish of fabric

InactiveCN1793482AImprove light fastnessHigh color fastness to washingFibre treatmentEngineeringAnti bacterial

The invention discloses fabric with good anti-bacterial, mould proofing, special smell removing performance and its post finishing method. The finished fabric has good feel, fastness, anti-bacterial, mould proofing, anti-static, and serviceability. Photocatalyst anti-bacterial finish is made up of over 99.60% photocatalyst and 0.30-0.40% soft penetrant SF-508 by weight ratio. The post finishing method includes the following steps: selecting textile fabric; two times dipping and rolling in liquid groove; and the running roller pressure is 0.5-1KG / CM2; drying in drying apparatus at 120 centigrade degree for 120s; baking in baker at 150 centigrade degree for 150s; gaining the finished product.

Owner:FOSHAN ZHONGFANGLIAN INSPECTION TECH SERVICE CO LTD +1

Chinlon extra dark color dyeing process

ActiveCN111235913AIntensity effectImprove bindingFibre typesUltrasonic/sonic fibre treatmentColour fastnessYarn

The invention provides a chinlon extra dark color dyeing process. Firstly, a calcium carbonate solution is used for performing surface grinding on chinlon yarns, the grinding strength and the particlesize of calcium carbonate are controlled to prevent too much impact on the strength of the chinlon yarns, meanwhile, a large number of pits are formed on the surfaces of the smooth chinlon yarns, andthe combination of subsequent dyes and fibers is facilitated; and the natural dye used for dyeing and a dyeing auxiliary are stirred uniformly to obtain the natural dye liquor, and after dyeing by using a dip dyeing process, the dyeing can be completed by soaping and high-temperature fixation. According to the chinlon extra dark color dyeing process provided by the invention, although the bath ratio of the calcium carbonate solution treatment used in the invention is relatively high, the calcium carbonate solution can be used repeatedly; and in the subsequent dyeing process, one-step processis carried out, and then soaping and high-temperature fixation treatments are carried out. According to the dyeing method provided by the invention, post-treatment is not needed after dyeing, the procedure is greatly simplified, and the obtained ultra-dark yarn has high soaping color fastness; and compared with a traditional dyeing method, the effect of energy saving and environmental protection is remarkable.

Owner:华维新材料科技(杭州)有限公司

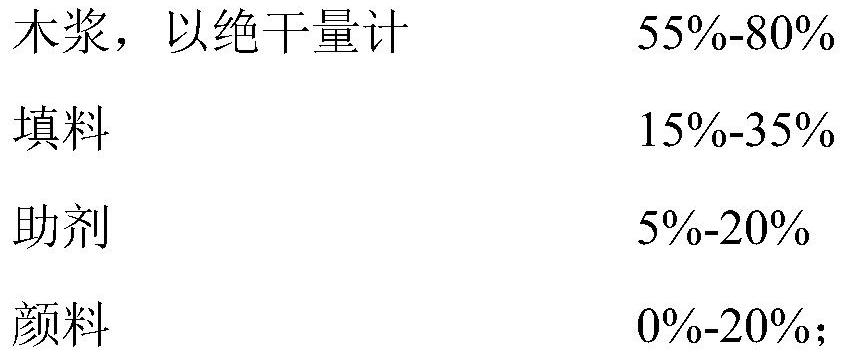

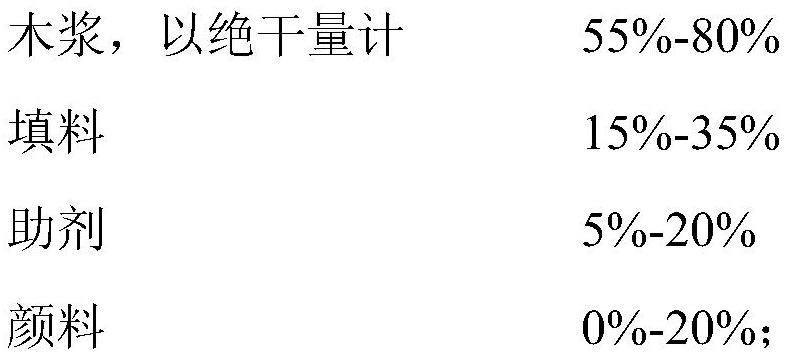

Overcoating base paper used for outdoor highly-strengthened plate and preparation method of overcoating base paper

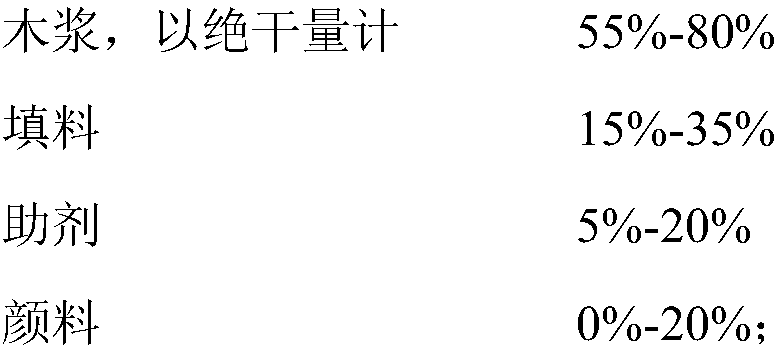

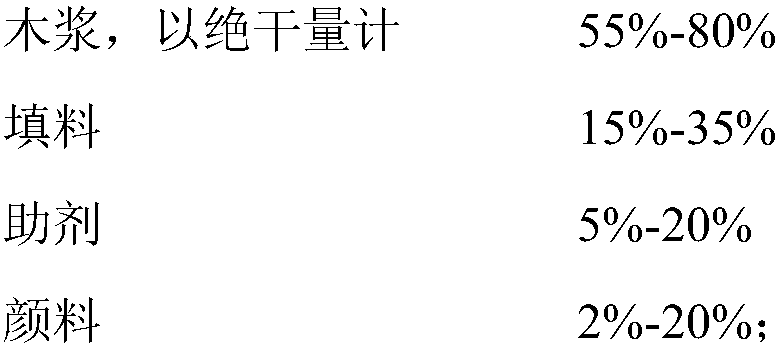

ActiveCN108130815AIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberPapermaking

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

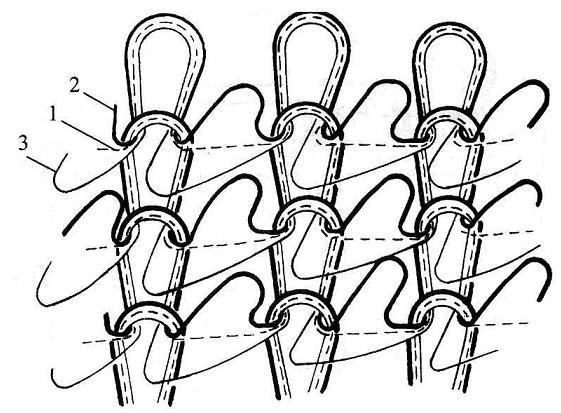

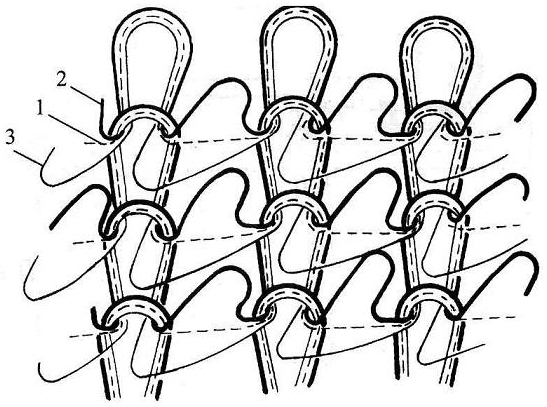

Raw liquor coloring terylene terry knitted fabrics

InactiveCN102154769AAnti-staticSimple processing technologyWeft knittingRougheningFiberCarbon fibers

The invention discloses raw liquor coloring terylene terry knitted fabrics. The raw liquor coloring terylene terry knitted fabrics contain raw liquor coloring terylene fibers and have the characteristics that: the raw liquor coloring terylene terry knitted fabrics also contain terylene cocona yarns and permanently conductive terylene carbon fibers, and the raw liquor coloring terylene fibers, terylene cocona yarns and terylene carbon fibers jointly form a double-face terry structure. In the invention, the raw liquor coloring terylene fibers, terylene cocona yarns and terylene carbon fibers undergo blended weaving to produce the double-face terry fabrics, which not only keep original advantages of the terylene materials, namely the color fastness to daylight exposure and the color fastness to high-temperature water washing are both high, but also have the advantages of static resistance, no balling-up, moisture absorption and the like. In addition, the raw liquor coloring terylene terry knitted fabrics also have the advantages of simple processing technology, high durability and the like.

Owner:BOYANG COMPOSITE FABRIC TECH KUSN

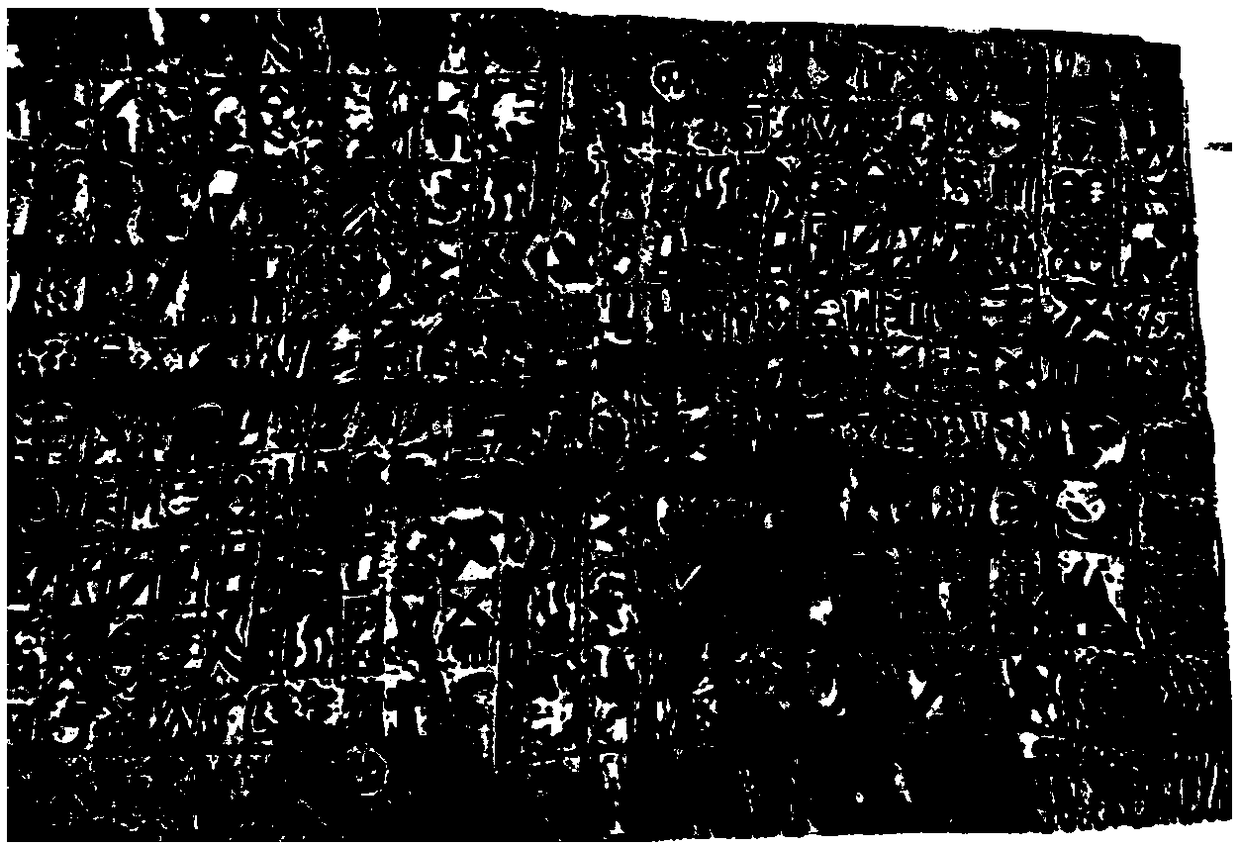

Silk fabric color fixing agent and preparation method thereof

InactiveCN106702791AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processDichloropropaneHue

The invention discloses a silk fabric color fixing agent and a preparation method thereof. The color fixing agent is prepared from the following raw materials in parts by weight: 41-49 parts of alkyl alcohol polyoxyethyl ether S, 5-13 parts of propylene dichloride, 10-18 parts of poly-dimethyl diallyl ammonium chloride, 17-25 parts of dimethyl sulfoxide, 3-7 parts of fatty alcohol-polyoxyethylene ether and 13-21 parts of dichloroacetic acid. The method comprises the steps of mixing the alkyl alcohol polyoxyethyl ether S, the dimethyl sulfoxide and the poly-dimethyl diallyl ammonium chloride, and carrying out heating and stirring treatment; adding a fatty alcohol-polyoxyethylene ether solution, and carrying out heating and stirring treatment; adding the propylene dichloride, and carrying out heating and stirring treatment; and dropwise adding a dichloroacetic acid solution, carrying out heating and stirring treatment, and cooling to a room temperature. The prepared color fixing agent has high dye fastness under the interaction of raw materials, the dry and wet rubbing fastness and the color fastness to washing can be significantly improved, a hue change is not generated during fixation of an active dye, and the silk fabric color fixing agent is free of formaldehyde, environment-friendly, free of secondary pollution and simple in production technology, is suitable for industrial production and is extremely suitable for the field of fixation of the active dye.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Dyed fabric and preparation method thereof

The invention provides a dyed fabric preparation method. The preparation method comprises the steps of: obtaining tung tree leaves, placing the tung tree leaves in water at 85 to 95 DEG C, and performing reflux extraction to obtain a tung oil leaf dye; placing a gray cloth in a modifier solution for modification treatment to obtain the modified gray cloth; taking the tung oil leaves and spreadingthe tung oil leaves on the modified gray cloth, placing the modified gray cloth with the tung tree leaves in a hot press for hot pressing, and printing the tung oil leaf pattern on the modified gray cloth; placing the modified gray cloth with the tung tree leaf pattern in the tung oil leaf dye for dyeing treatment; and placing the dyed modified gray cloth in a fixing agent solution for fixing treatment to obtain the product. The dyed fabric prepared by the above method has a large amount of dyeing, high color fastness to washing, and sunlight resistance.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

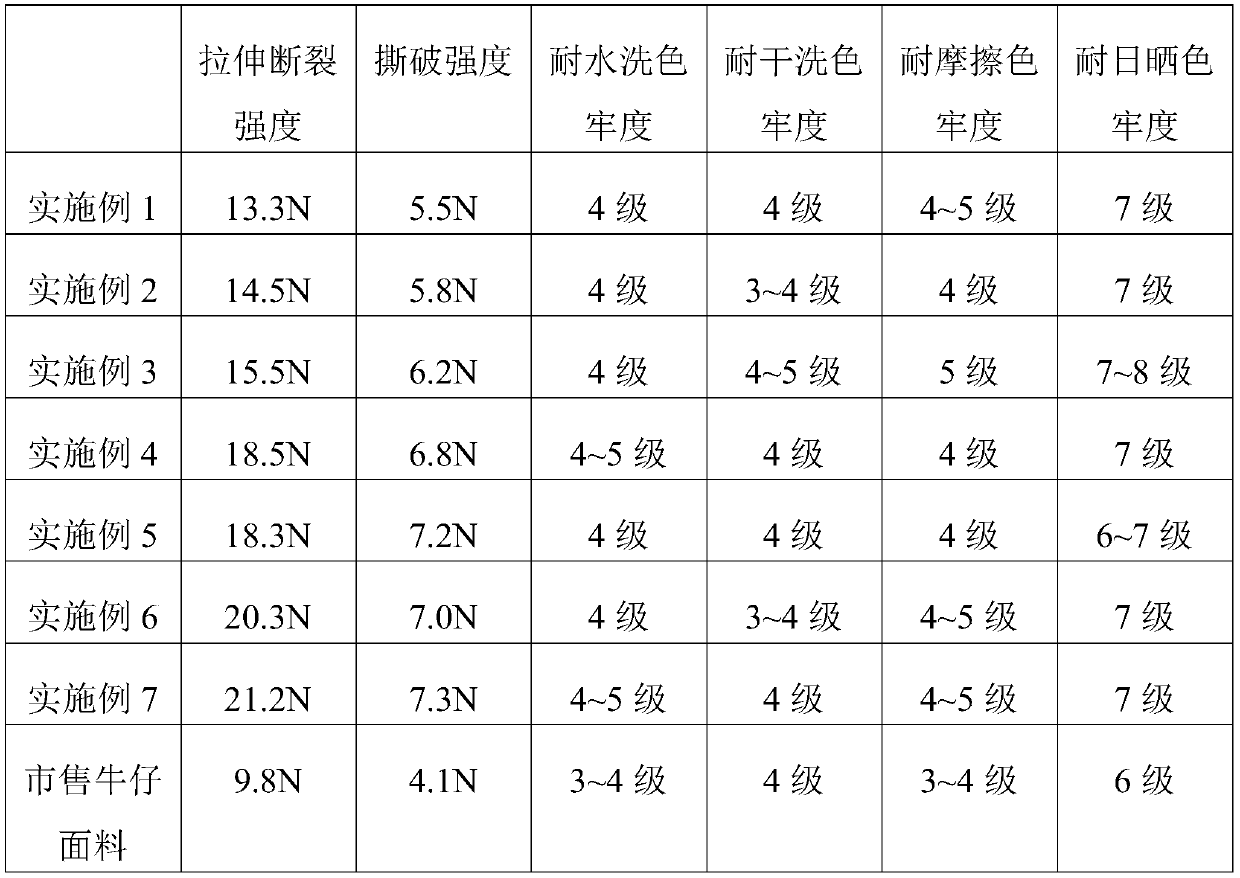

Tannin jean fabric and manufacturing method thereof

PendingCN110952212AImprove tensile strength at breakHigh color fastness to washingWoven fabricsFiberColour fastness

The invention relates to a tannin jean fabric and a manufacturing method thereof. The manufacturing method comprises the following steps of spinning regenerated cotton; or blending the regenerated cotton with organic cotton; or blending the regenerated cotton, regenerated fiber and coffee grounds; or blending the regenerated cotton, the organic cotton, the regenerated fiber and the coffee grounds;obtaining a spun yarn; sequentially warping, permeating and dyeing the spun yarn to obtain dyed spun yarn; interweaving the dyed yarns into cloth in a warp yarn and weft yarn mode to obtain primary jean fabric; and singeing, skewing and preshrinking the primary jean fabric to obtain the tannin jean fabric. According to the preparation method, four raw materials of the regenerated fiber, the coffee grounds, the regenerated cotton and the organic cotton are reasonably selected, so that pollution is greatly reduced in the manufacturing process, and the wearability of the jean fabric, such as tensile breaking strength, tearing strength, color fastness to washing, color fastness to dry cleaning, color fastness to rubbing and color fastness to sunlight, can be kept at a higher level through scientific proportioning of the raw materials.

Owner:侯宇昊

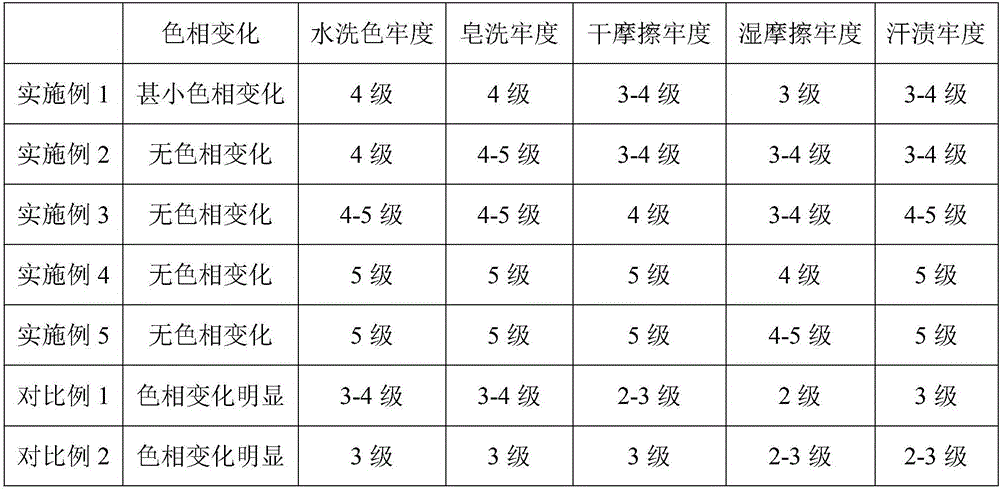

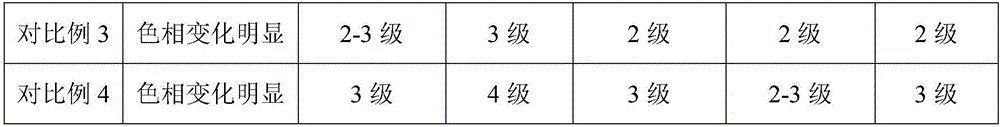

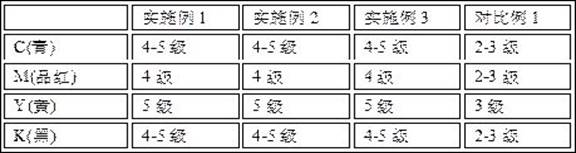

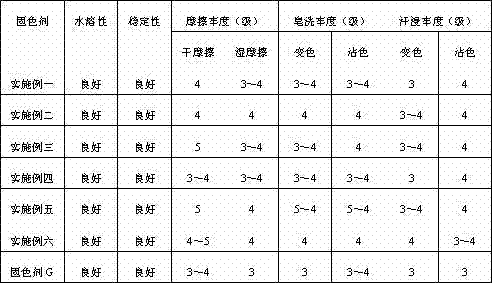

A preparing method of a sensitive color fixing agent and the fixing agent

InactiveCN106948196AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processFixative/StainChemistry

A preparing method of a sensitive color fixing agent and the fixing agent are disclosed. During preparation, methyl ethyl ketone peroxide and a 6-hydroxy-2-naphthoic acid solution are mixed, heated and stirred; dimethylformamide is added into the mixture; the mixture is heated and stirred; then a tris(nonylphenyl)phosphite solution is added into the mixture; and the mixture is stirred at 110-112 DEG C for 20-25 min, then stirred at 65-70 DEG C for 50-55 min and cooled to room temperature to obtain the fixing agent. Under interactions of raw materials, the fixing agent has advantages of high dyeing fastness, capability of significantly increasing dry and wet rubbing fastness and water-washing color fastness, and the like. Hue changes do not occur substantially during color fixing of dye for sensitive colors such as turquoise blue and cobalt blue. The fixing agent is free of formaldehyde and is environmentally friendly. A production process is simple. The fixing agent does not influence chlorine fastness, light fastness or perspiration fastness of dyed fabrics, influences of color fixing treatment on fabrics by the fixing agent are low, and chromatic aberration can be controlled to be the 4-5 level. Treated fabrics have good color fixing effects and an influence on hand feeling is low.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

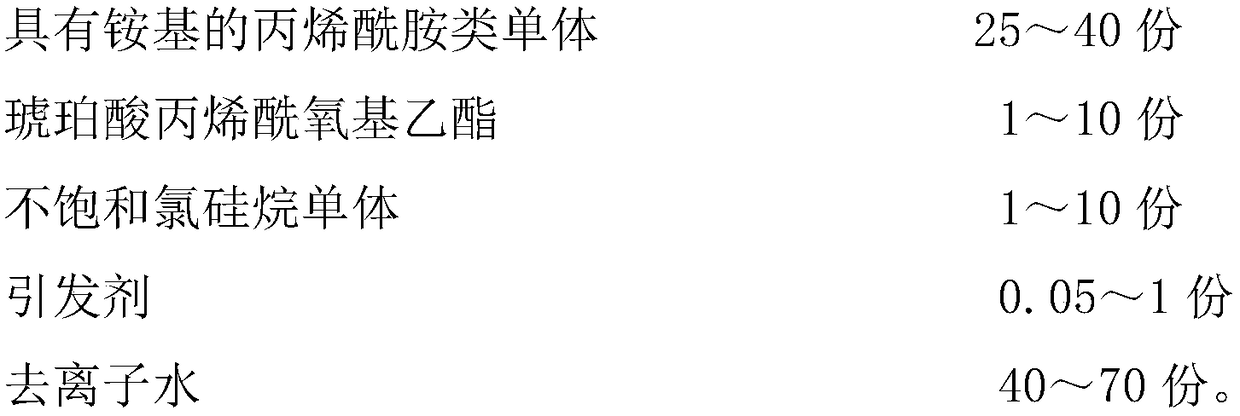

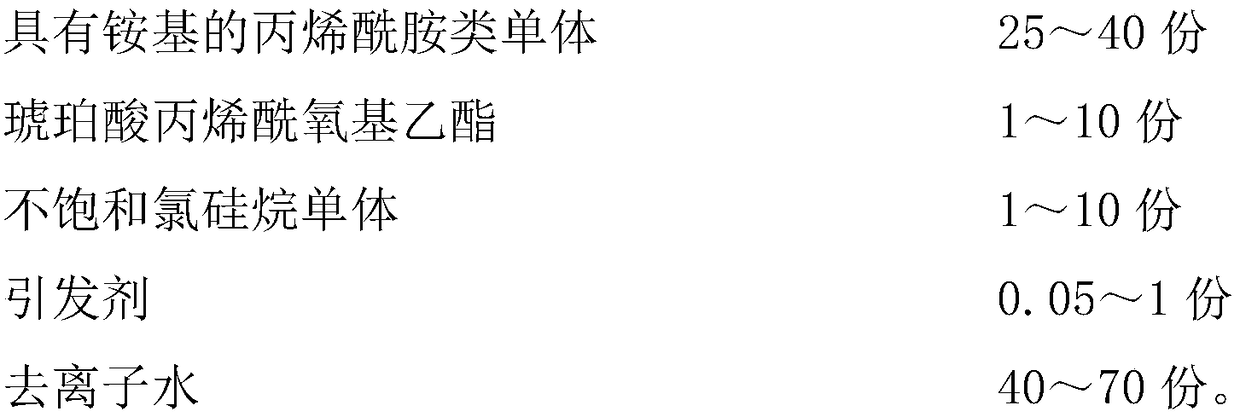

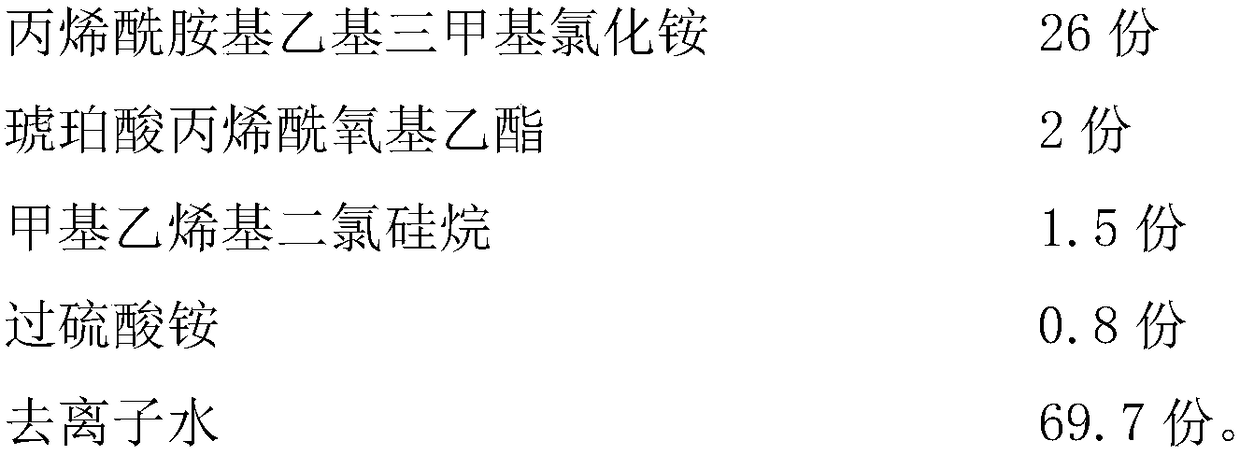

Formaldehyde-free fixing agent and preparation method thereof

InactiveCN108660813AImprove bindingImprove dry rubbing fastnessDyeing processSuccinatesMicrowave irradiation

The invention relates to a formaldehyde-free fixing agent and a preparation method thereof. The preparation method comprises the following steps: (1) sequentially adding an acrylamide monomers havingammonium groups, acryloyloxy ethyl succinate, an unsaturated chlorosilane monomer and deionized water into a reactor, then starting to stir, and heating; (2) when the temperature in the reactor risesto 30-50 DEG C, adding an initiator solution, wherein the initiator solution is prepared from an initiator and part of the deionized water; (3) then, putting the reactor into a microwave reactor for performing microwave irradiation; after that, turning off the microwave reactor, cooling and discharging to obtain the fixing agent.

Owner:曾文华

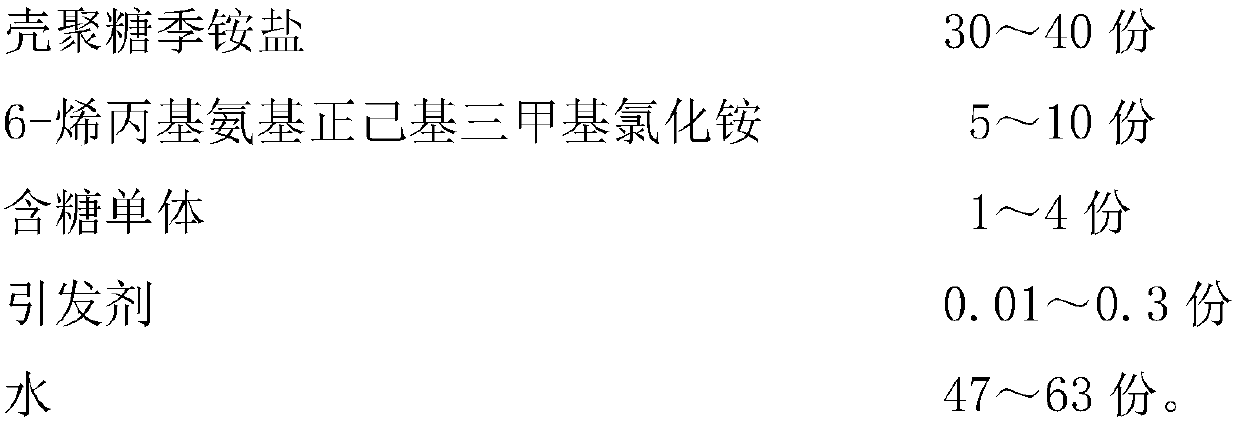

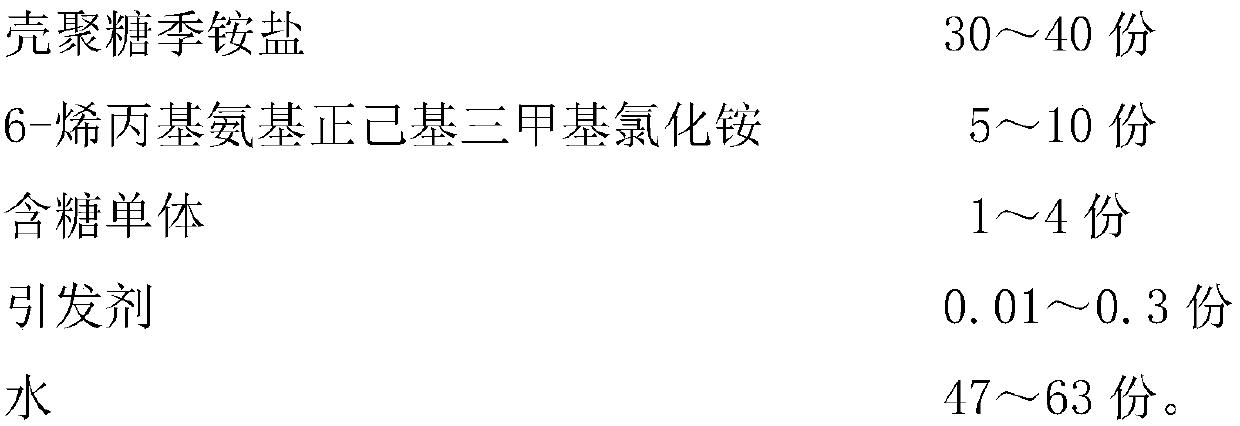

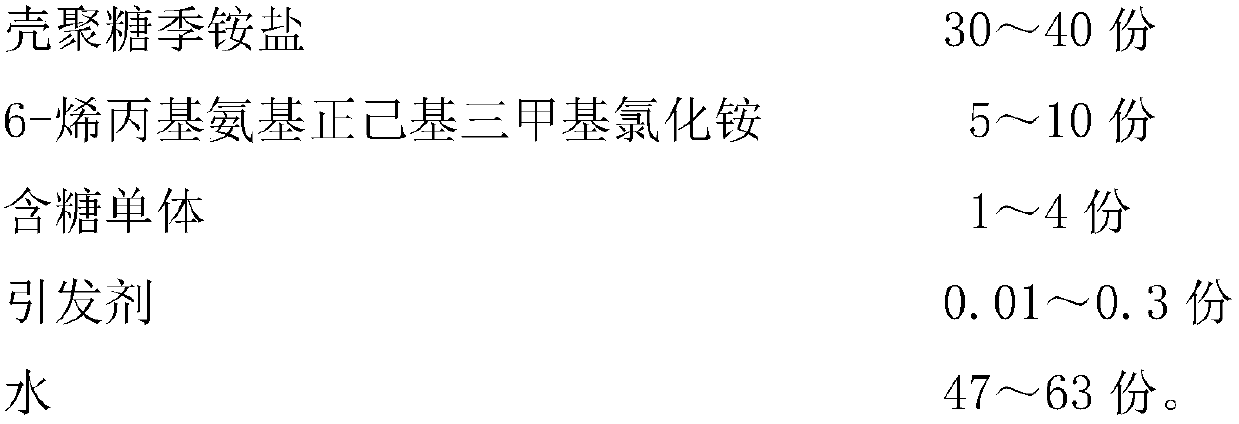

Cationic formaldehyde-free color fixing agent and preparation method thereof

InactiveCN109096436AImprove dry rubbing fastnessImprove color fastnessDyeing processChemistryFormaldehyde free

The invention provides a cationic formaldehyde-free color fixing agent and a preparation method thereof. The preparation method includes step (1) of placing a certain amount of water and chitosan quaternary ammonium salt into a four-port reaction bottle, and under the protection of nitrogen, heating with oil bath to 85-120 DEG C; step (2) of respectively adding dropwise a mixed solution of 6-allyl-amino-n-hexyl-trimethylammonium chloride, a sugar-containing monomer and water, additionally adding dropwise an initiator solution with a mass concentration of 1% to 3%, wherein the initiator solution is prepared from an initiator and water; step (3) of controlling the adding of the mixed solution of the 6-allyl-amino-n-hexyl-trimethylammonium chloride, the sugar-containing monomer and the waterand the initiator solution to be completely at the same time, wherein the dropwise adding time is 3-6 h; step (4) of keeping the temperature to continue the reaction for 1-3 h after the dropwise adding, and performing cooling and discharging to obtain the color fixing agent.

Owner:陈国宝

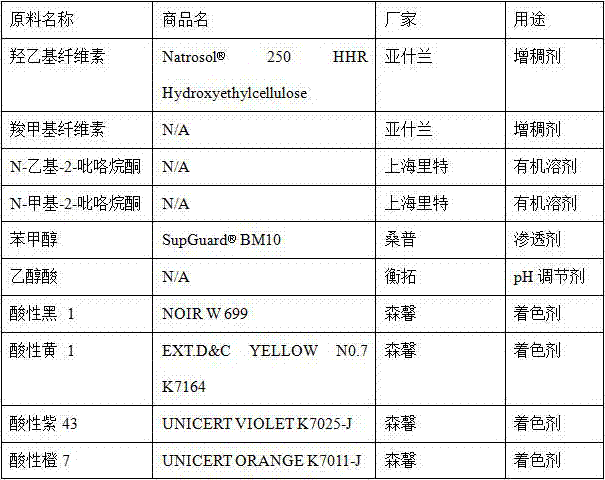

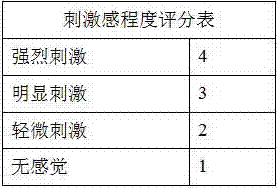

Acidic hair dye and hair dyeing method thereof

InactiveCN107997986AGood coloring effectGood color fastness to washingCosmetic preparationsHair cosmeticsCelluloseHair dyes

The invention discloses an acidic hair dye. The acidic hair dye is prepared from the following components by weight percent: 0.5 to 3 percent of cellulose thickening agent, 5 to 15 percent of cyclic ketone, 5 to 15 percent of aromatic alcohols, 0.01 to 1 percent of acidic dye, 0 to 1.5 percent of pH adjusting agent, 0 to 2 percent of additives, and the balance of water. The acidic hair dye has theadvantages of rapidness in coloring, good in coloring performance, high in washing color fastness, no irritation for skin and the like. The invention also discloses a coloring method of the hair dye.The coloring method has the characteristics of rapidness in coloring, good coloring performance, high washing color fastness, no irritation to the skin and the like.

Owner:HUAANTANG BIOTECH GRP CO LTD

Environment-friendly dyeing method of chinlon and cotton blended fabric

The invention discloses an environment-friendly dyeing method of chinlon and cotton blended fabric. The method comprises the following steps: adding natural dye into a dye vat filled with a mixed solution of ethanol and deionized water to prepare a dye solution; immersing the blended fabric into the deionized water, adding tea saponin and calcium carbonate, then heating and carrying out ultrasonictreatment, then immersing the blended fabric into an organic acid solution, and then dehydrating and drying the blended fabric; putting the blended fabric into the dye solution, and carrying out ultrasonic dyeing; and washing the blended fabric with water, and carrying out soaping, secondary rinsing with water, dehydrating, drying and shaping. According to the dyeing method, a large amount of organic dyeing aids do not need to be added for dyeing, only a small amount of calcium carbonate and organic acid need to be added in the dyeing process, the other raw materials are natural raw materialswhich are safe and harmless to human bodies, and after dyeing, the blended fabric is high in soaping color fastness and free of chromatic aberration between polyamide fiber and cotton fibers.

Owner:浙江贝隆纺织有限公司

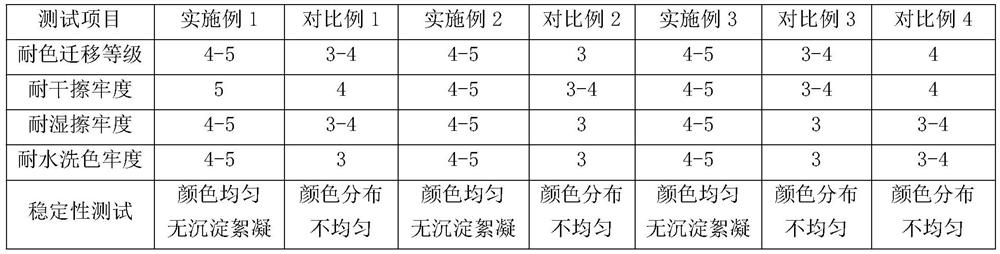

Colored waterborne polyurethane and preparation method thereof

PendingCN113501927AImprove reaction efficiencyImprove utilization efficiencyTextiles and paperPolymer sciencePolyol

The invention discloses colored waterborne polyurethane which is prepared from the following raw materials in parts by weight: 50-200 parts of diisocyanate, 150-350 parts of conventional dihydric alcohol, 50-120 parts of colored polyester polyol, 1-20 parts of micromolecule chain extender, 10-45 parts of hydrophilic chain extender and 400-1200 parts of deionized water. The colored polyester polyol is prepared from the following raw materials in parts by weight: 20-100 parts of binary acid, 30-110 parts of a micromolecular chain extender, 5-20 parts of dye containing active hydroxyl and 0.1-0.5 part of tetrabutyl titanate, wherein the mole number of hydroxyl to carboxyl is (1.1-1.3): 1. According to the colored waterborne polyurethane, the colored group is synthesized into a polyurethane molecular chain in situ through a chemical reaction, and the dye is combined with polyurethane through a chemical bond, so that the defects of color migration, low rubbing fastness and low water fastness are overcome; meanwhile, the dye and the polyurethane are in the same molecular structure and belong to a system, so that the stability is higher, and the flooding phenomenon is avoided. When being applied to the microfiber leather, the colored waterborne polyurethane has higher color fastness to washing, color fastness to rubbing and color migration resistance levels.

Owner:明新梅诺卡(江苏)新材料有限公司

Indigo blue printed fabric and printing method thereof

The invention relates to a printing method of indigo blue printed fabric. The printing method comprises the following steps that indigo blue, caustic soda and sodium hydrosulfite with the weight ratiobeing 1 to (0.5-2) to (1-5) are added into the water at the temperature of 50-70 DEG C, mixed and stirred, and mixed liquid is obtained; an acrylic polymer is added into the mixed liquid, the mixtureis filtered, and indigo blue slurry is obtained, wherein the movement viscosity of the indigo blue slurry is 30 mm<2> / s-50 mm<2> / s; a silk screen board is spread on the fabric, and coated with the indigo blue slurry, and the fabric with a pattern is obtained; and the fabric with the pattern is naturally air-dried, washed, and dried, and the indigo blue printed fabric is obtained. The printing method can omit the complex technological procedures includingof ageing, oxidizing and desizing while ensuring the printing effect of the fabric, shortens the technological period, and can reduce the emission of waste water and waste gas.

Owner:ZHUHAI JIAN XUAN CLOTHING LTD

Preparation method of colored special-shaped acrylic fibers by wet spinning

PendingCN111101224AUniform colorHigh color fastness to washingWet spinning methodsMonocomponent synthetic polymer artificial filamentColour fastnessPolymer science

The invention relates to a preparation method of colored special-shaped acrylic fibers by wet spinning. The preparation method comprises the steps of pigment dispersion, color paste homogenization, online blending by online addition before spinning, extrusion by a spinneret, twice coagulation bath for forming, densification, heat setting and the like. The acrylic fibers prepared by the method canbe applied to the field of fur, have a relatively low lustering temperature, do not need a post dyeing process, and are uniform in color and high in color fastness.

Owner:CHINA PETROLEUM & CHEM CORP +1

Improved all-cotton fabric printing method

ActiveCN108505369ANot easy to fadeHigh color fastness to washingTransfer printing processDry-cleaning apparatus for textilesRoom temperatureEngineering

The invention provides an improved all-cotton fabric printing method, and solves the technical problems that a direct printing method is used in a conventional processing technology, a cloth materialis faded easily after water washing for many times and the water washing fastness is poor. The improved all-cotton fabric printing method includes the following steps: a, sizing: pretreating an all-cotton fabric with a sizing material; b, printing: directly spray-printing a thin film with a reactive dye gravure printing ink to form a pattern, and then transfer-printing the pattern on the thin filmto the sized all-cotton fabric; c, steaming: putting the all-cotton fabric after printing into a steamer, and steaming; d, cooling: after cooling to room temperature, tearing off the thin film on theall-cotton fabric; e, water washing: washing for 3 min in cold water with the temperature of 18 DEG C, then placing in hot water with the temperature of 58 DEG C, washing for 10 min, finally, placingin cold water with the temperature of 15 DEG C, washing for 4 min, and then spin-drying; and f, putting the water-washed all-cotton fabric into a setting machine and setting the shape. The printing method has the advantages of high water washing resistance and high color fastness.

Owner:绍兴久邀信息科技有限公司

A kind of reactive dye inkjet printing ink and preparation method thereof

Owner:DONGHUA UNIV +1

A kind of preparation method of cotton fabric yellow vegetable dye

ActiveCN105733298BAbundant resourcesRaw materials are cheap and easy to getNatural dyesDyeing processChemical synthesisOrganic solvent

The invention relates to a preparation method of a cotton fabric yellow vegetable dye. The preparation method is characterized by comprising: putting orange peels into water according to a mass ratio of 1:(10-20), performing heating and ultrasonic treatment, and performing drying after filtration to obtain a dye 1; putting white jasmine petals into an organic solvent according to a solid-liquid ratio of 1:(30-50), performing heating and intermittent ultrasonic treatment, and performing filtration, vacuum concentration and drying sequentially to obtain a dye 2; and mixing the dye 1, the dye 2 and loess according to a mass ratio of 10:(10-20):(0.5-1) to obtain the cotton fabric yellow vegetable dye. According to the preparation method of the cotton fabric yellow vegetable dye, provided by the invention, the required plant resources are rich, the raw materials are low in price and easy to obtain, the preparation method is simple and is good in safety, and no chemical synthetic dye exists during the preparation to cause pollution to the environment, so that the preparation method can be applied to cleaning production of the printing and dyeing industry, and can be used for mass production. The prepared cotton fabric yellow vegetable dye has a certain anti-oxidation function, causes no environmental pollution, is nontoxic to human bodies, and is convenient to store and transport.

Owner:ZHEJIANG HAIMING IND CO LTD

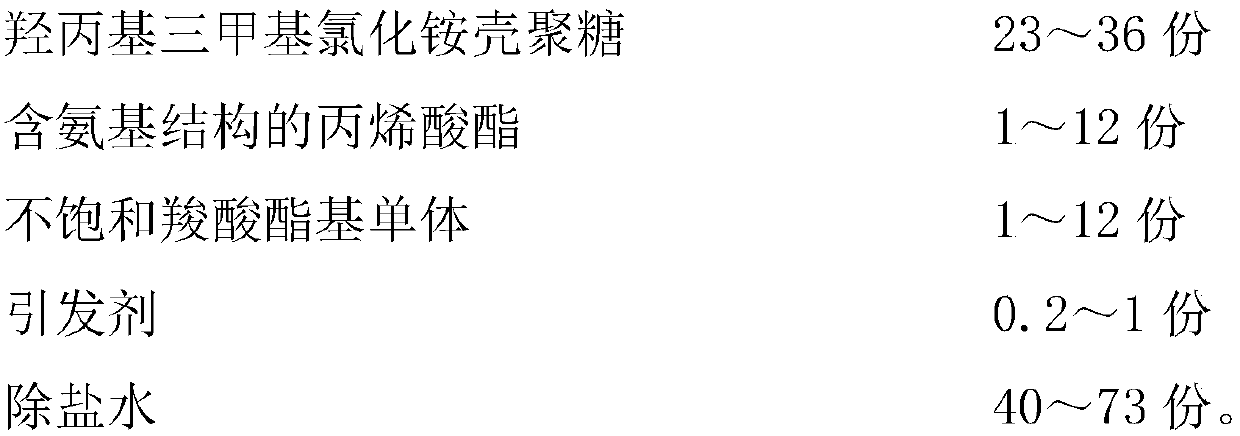

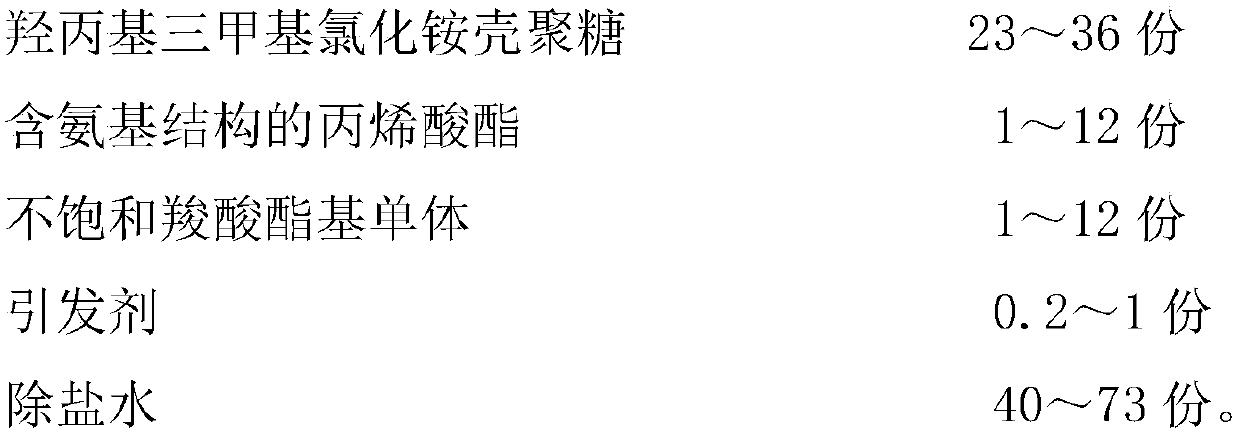

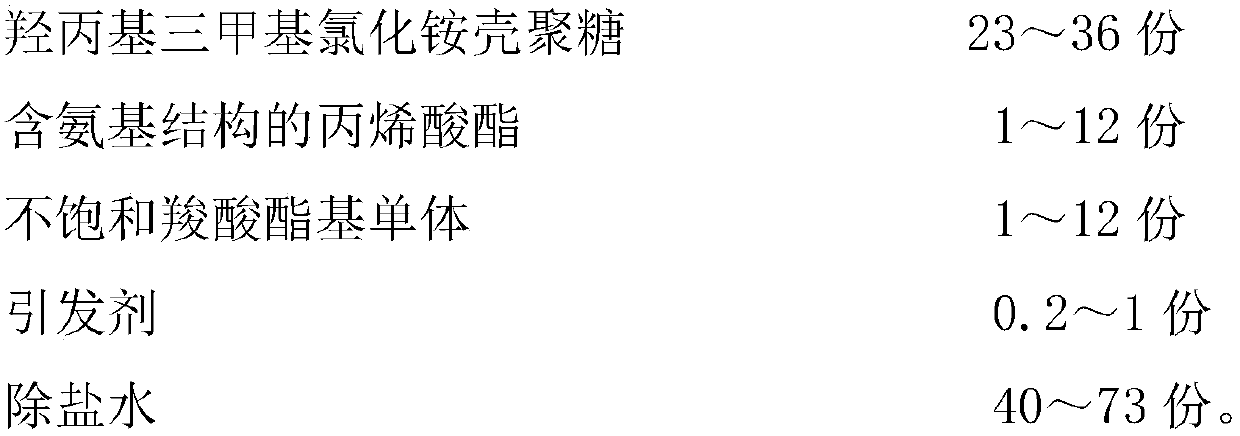

Formaldehyde-free color fixing agent for acid dyes and preparation method thereof

InactiveCN109096437AImprove bindingImprove dry rubbing fastnessDyeing processHydroxypropyltrimethyl ammonium chloride chitosanAcid dye

The invention relates to a formaldehyde-free color fixing agent for acid dyes and a preparation method thereof. The preparation method includes step (1) of adding hydroxypropyl trimethyl ammonium chloride chitosan, acrylic ester containing an amino structure, unsaturated carboxylate-based monomer and demineralized water into a stirring polymerization reactor, starting to stir, and beginning to heat; step (2) of starting to add an initiator solution with a mass concentration of 1-10% when the temperature of the stirring polymerization reactor rises to 95-130 DEG C, wherein the initiator solution is prepared from an initiator and part of the demineralized water, and the time for adding dropwise is 3-6 h; (3) maintaining the temperature after the adding performed dropwise to continue the reaction for 1-3 h, and performing cooling and discharging to obtain the color fixing agent.

Owner:曾文华

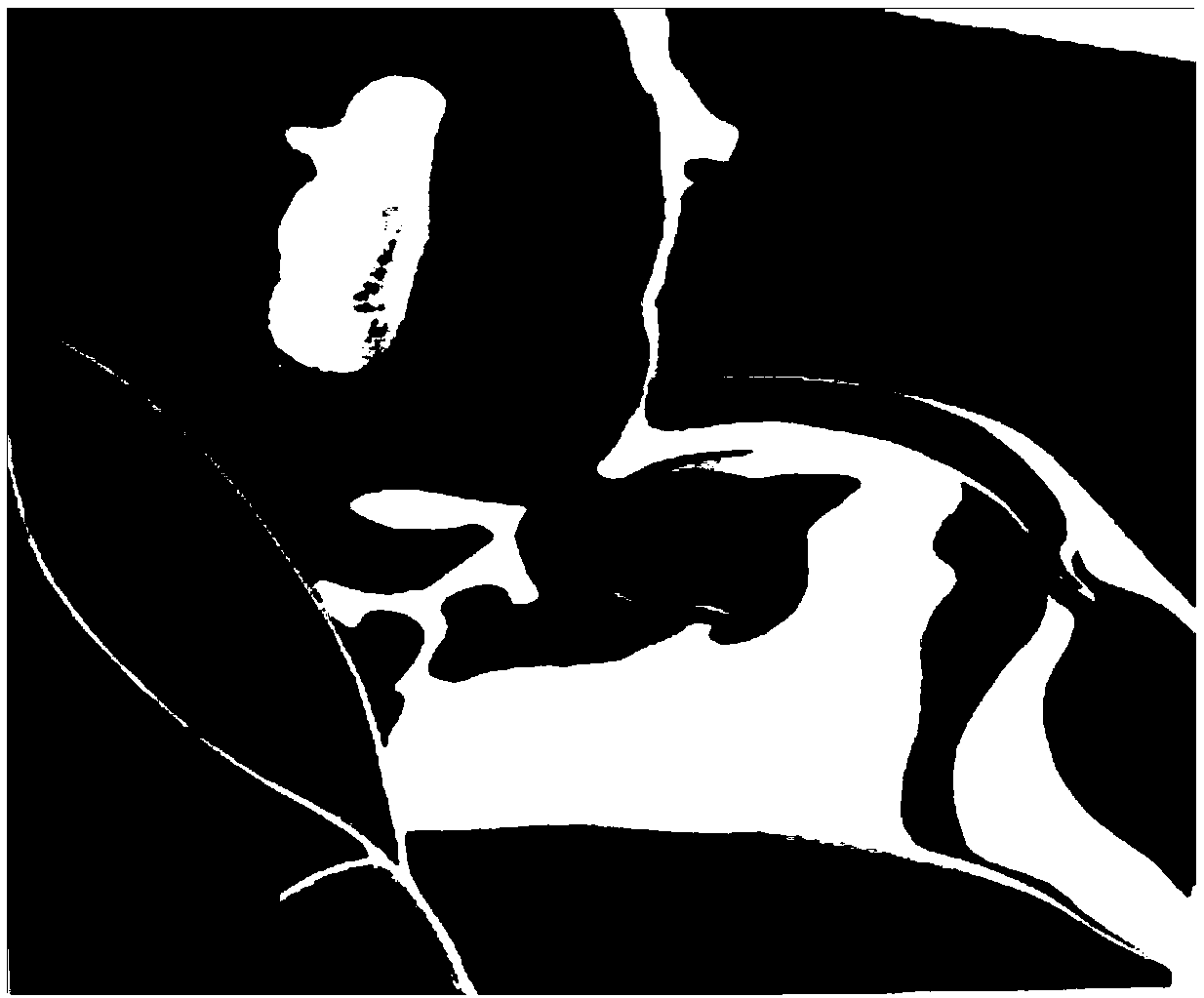

A kind of preparation method of Cui Lan special acid color fixing agent and prepared color fixing agent

ActiveCN106758416BHigh color fastnessImprove dry and wet rubbing fastnessDyeing processDiethylene glycol monobutyl etherColor changes

The invention discloses a preparation method of a novel acid color fixing agent special for emerald blue dye and a prepared color fixing agent. During preparation, the preparation method comprises the following steps: mixing bisphenol S with diethylene glycol monobutyl ether, heating to 85 DEG C, carrying out stirring treatment for 34 minutes, then adding a polyethyleneimine solution, cooling to 66 DEG C, and carrying out the stirring treatment for 72 minutes; then adding a dichloroacetic acid solution, and carrying out the stirring treatment for 85 minutes under a temperature of 76 DEG C; then dropwise adding a sodium borohydride solution within 10 minutes, carrying out the stirring treatment under the temperature of 70 DEG C after completing adding dropwise, and cooling to a room temperature, thus obtaining the color fixing agent. Under interaction of all raw materials, the color fixing agent prepared by the invention has the advantages that the dyeing fastness is high, dry-wet rubbing fastness and washing color fastness can be remarkably increased, the influence on sensitive colored light is small, the usage is small, and the like; during color fixation of dye in sensitive colors of emerald blue, brilliant blue and the like, no color change is fundamentally generated, the environment is not polluted as no formaldehyde exists, the raw materials are easy to obtain, and a production technology is simple.

Owner:江西德盛精细化学品有限公司

Preparation method of high-permeability paste for polyester-cotton blended fabric

PendingCN112323519AImprove permeabilityImprove dye penetrationDyeing processPolyesterSodium bicarbonate

The invention discloses a high-permeability paste for polyester-cotton blended fabric. The high-permeability paste comprises the following raw materials in parts by weight: 35-45 parts of attapulgite,100 parts of water, 10-15 parts of chitosan, 3-8 parts of sodium bicarbonate, 1-2 parts of modified nano silicon dioxide, 2-5 parts of octadecylamine polyoxyethylene ether and 5-12 parts of aluminumchloride. The attapulgite, the chitosan, the modified nano silicon dioxide and aluminum oxide react together under an alkaline condition to obtain the dyeing paste with a good permeation effect. According to the paste, conventional nano silicon dioxide is replaced with the nano silicon dioxide with double bonds and epoxy groups grafted on the surface, so that the dyeing permeability of the polyester fabric can be remarkably improved, the hand feeling can be smoother, the washing color fastness is high, and decolorization is not liable to occur. In order to reduce the color difference of polyester fibers and cotton fibers in the dyeing process, the octadecylamine polyoxyethylene ether with a color separation effect is further added, the effect is remarkable, and the dyeing effect without color difference can be basically achieved.

Owner:浙江贝隆纺织有限公司

Preparation method of novel acid color fixing agent special for emerald blue dye and prepared color fixing agent

ActiveCN106758416AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processDiethylene glycol monobutyl etherColor changes

The invention discloses a preparation method of a novel acid color fixing agent special for emerald blue dye and a prepared color fixing agent. During preparation, the preparation method comprises the following steps: mixing bisphenol S with diethylene glycol monobutyl ether, heating to 85 DEG C, carrying out stirring treatment for 34 minutes, then adding a polyethyleneimine solution, cooling to 66 DEG C, and carrying out the stirring treatment for 72 minutes; then adding a dichloroacetic acid solution, and carrying out the stirring treatment for 85 minutes under a temperature of 76 DEG C; then dropwise adding a sodium borohydride solution within 10 minutes, carrying out the stirring treatment under the temperature of 70 DEG C after completing adding dropwise, and cooling to a room temperature, thus obtaining the color fixing agent. Under interaction of all raw materials, the color fixing agent prepared by the invention has the advantages that the dyeing fastness is high, dry-wet rubbing fastness and washing color fastness can be remarkably increased, the influence on sensitive colored light is small, the usage is small, and the like; during color fixation of dye in sensitive colors of emerald blue, brilliant blue and the like, no color change is fundamentally generated, the environment is not polluted as no formaldehyde exists, the raw materials are easy to obtain, and a production technology is simple.

Owner:江西德盛精细化学品有限公司

Finishing base paper for outdoor high-strength board and preparation method thereof

ActiveCN108130815BIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberSilicic acid

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

Micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent and preparation method thereof

The invention relates to the technical field of color fixing agents and provides a micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent which is capable of well improving the fastness of the textile to wet rubbing and the color fastness of the textile to washing. The micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent comprises the following raw material components in parts by weight: 50-60 parts of methacryloxyethyltrimethyl ammonium chloride, 0.25-5 parts of epoxy compound, 0.1-2 parts of crosslinking agent, 0.02-0.3 part of initiator and 35-45 parts of deionized water, wherein the methacryloxyethyltrimethyl ammonium chloride is a water solution with a weight percent concentration of 65-98 percent. Meanwhile, the invention provides a preparation method of the micro-crosslinking type poly(methacryloxyethyltrimethyl ammonium chloride) modified color fixing agent.

Owner:FUJIAN QINGYUAN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com