Tannin jean fabric and manufacturing method thereof

A manufacturing method and fabric technology, applied in textiles and papermaking, textiles, fabrics, etc., can solve large carcinogenic waste water, pure cotton products denim fabrics cannot meet various standards for wearability, and irreversible damage to the skin and respiratory tract, etc. problem, to achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

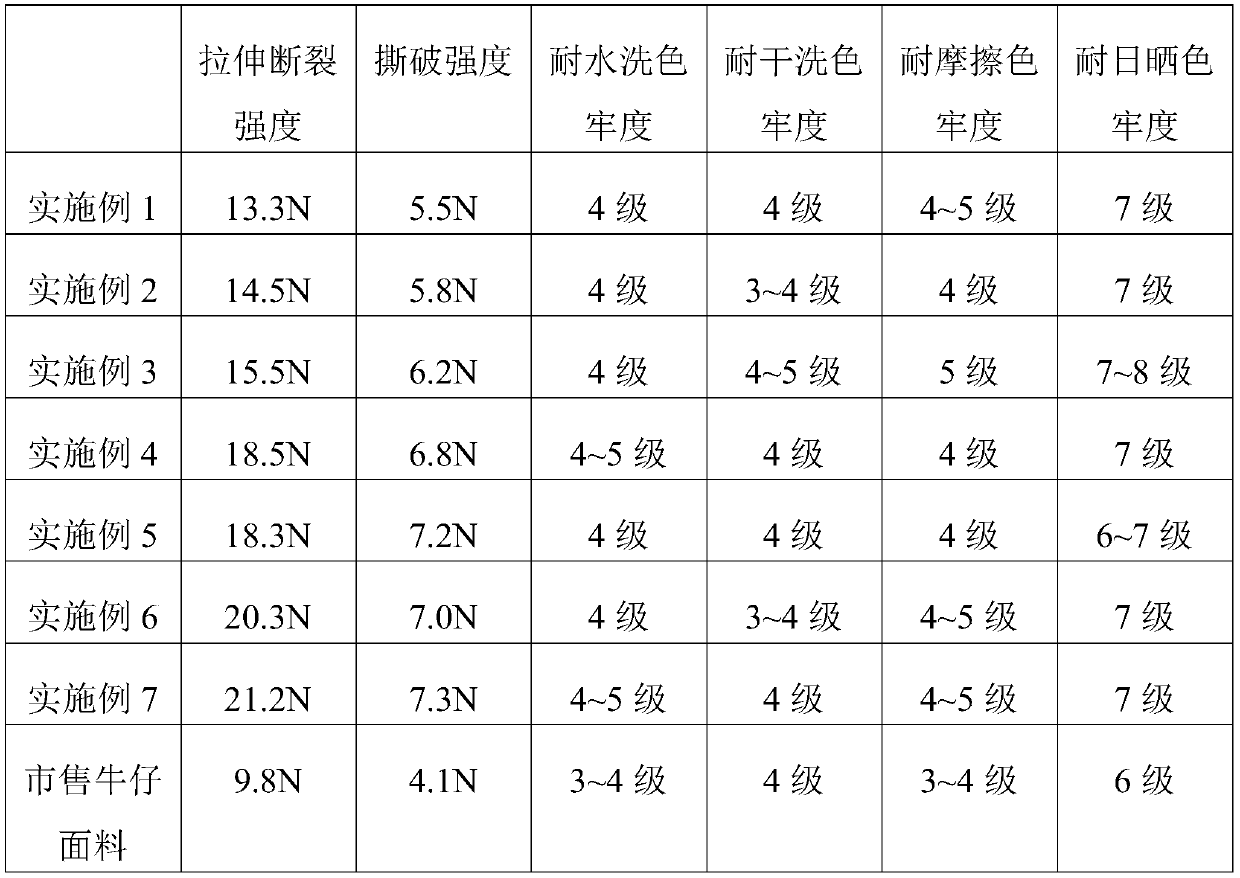

Examples

Embodiment 1

[0025] The present embodiment provides a kind of manufacture method of tannin denim cloth, comprises the steps:

[0026] (1) Weaving 1000kg of recycled cotton to obtain spinning yarn with a specification of 100D;

[0027] (2) The spun yarn obtained in step (1) is first warped under the conditions of a drawing tension of 90N and a vehicle speed of 60m / min, and then the spun yarn is spun under the conditions of a penetrant concentration of 2g / L and a temperature of 20°C. The yarn is infiltrated, and finally the spun yarn is dyed under the condition of pH 12 to obtain dyed spun yarn;

[0028] (3) interweaving the dyed and spun yarns obtained in step (2) into 3 / 1 left twill cloth in the mode of warp and weft yarns to obtain denim initial fabric;

[0029] (4) The raw denim fabric obtained in step (3) is singed, skewed and pre-shrunk to obtain a tannin denim fabric with a shrinkage rate of 2.5%.

Embodiment 2

[0031] The present embodiment provides a kind of manufacture method of tannin denim cloth, comprises the steps:

[0032] (1) Weaving 300kg of regenerated cotton and 700kg of organic cotton to obtain a blended yarn with a specification of 150D;

[0033] (2) The blended yarn obtained in step (1) is first warped under the conditions of a drawing tension of 110N and a vehicle speed of 80m / min, and then warped under the conditions of a penetrant concentration of 2g / L and a temperature of 25°C. The blended yarn is infiltrated, and finally the blended yarn is dyed under the condition of pH 13 to obtain the dyed blended yarn;

[0034] (3) interweaving the dyed blended yarn gained in step (2) into 3 / 1 right-hand twill in the mode of warp and weft, to obtain denim initial fabric;

[0035] (4) The raw denim fabric obtained in step (3) is subjected to singeing, biasing and pre-shrinking to obtain a tannin denim fabric with a shrinkage rate of 2.0%.

Embodiment 3

[0037] The present embodiment provides a kind of manufacture method of tannin denim fabric, and the difference with embodiment 2 is, the weight ratio of regenerated cotton and organic cotton is different in step (1), specifically: 500kg regenerated cotton and 500kg organic cotton are carried out Weaving, get the blended yarn that specification is 150D. All the other steps are the same as in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com