Patents

Literature

419 results about "Regenerating fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation for tussore silk fibroin solution and concentration method thereof

InactiveCN101445546AHigh molecular weightAvoid extensive hydrolysisPeptide preparation methodsAnimals/human peptidesFiberHigh concentration

The invention relates to a preparation for a tussore silk fibroin solution and a concentration method thereof. Fibroin fiber of tussores like tussah, japanese tusser, costor silkworm, and Actias selene Hubner are decontaminated, degummed and then dipped into a dissolving liquid containing neutral salt and alcohol materials, treated by ultrasonic for 5 to 120 minutes, and then dissolved under the temperature between 30 and 98 DEG C to obtain a silk dissolving fibroin. The fibroin dissolving liquid is dialyzed and desalted to obtain a tussore fibroin aqueous liquid; then the aqueous liquid is dewatered and concentrated by a semipermeable membrane by using a high water-absorbing matter to obtain the high concentration tussore fibroin solution with a molecular weight of 15 to 250 kDa and a concentration of 6 to 35 percent. As the neutral salt is used, the large extent hydrolyzation of acid and alkali to the silk fibroin is avoided; therefore, the molecular weight of the obtained tussore silk protein is higher; the tissore silk fibroin can be used for manufacturing tussore silk fibroin gel, powder, films, porous sponges, regenerated fibers, and the like. The invention provides new material for the fields of biomedicine, medicine, make-up, food, health product, and the like.

Owner:SUZHOU UNIV

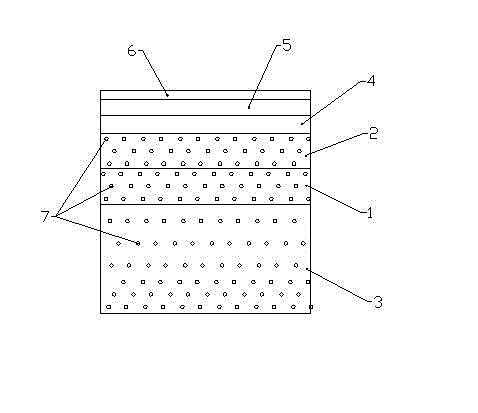

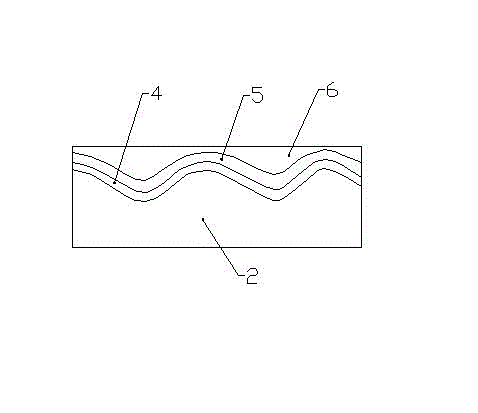

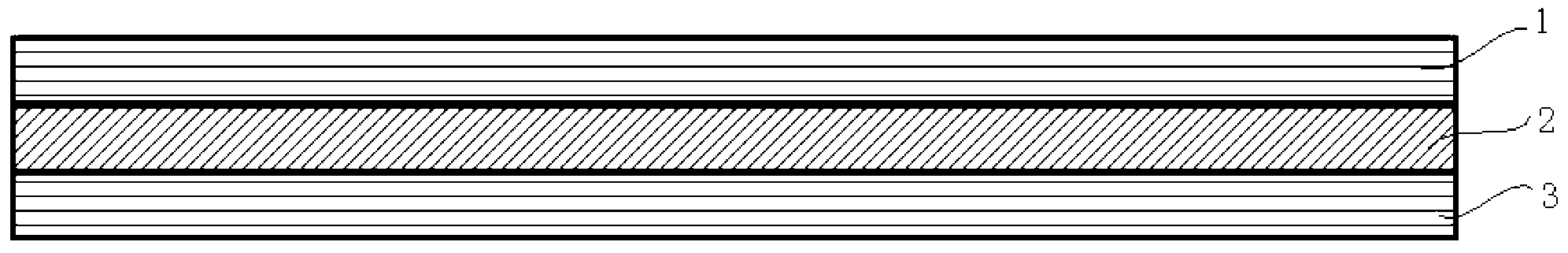

Nonwoven material and absorbing article comprising nonwoven material

ActiveUS8853108B2Good liquid receiving characteristicComfortable to wearOrnamental textile articlesLayered productsRegenerating fibersNatural fiber

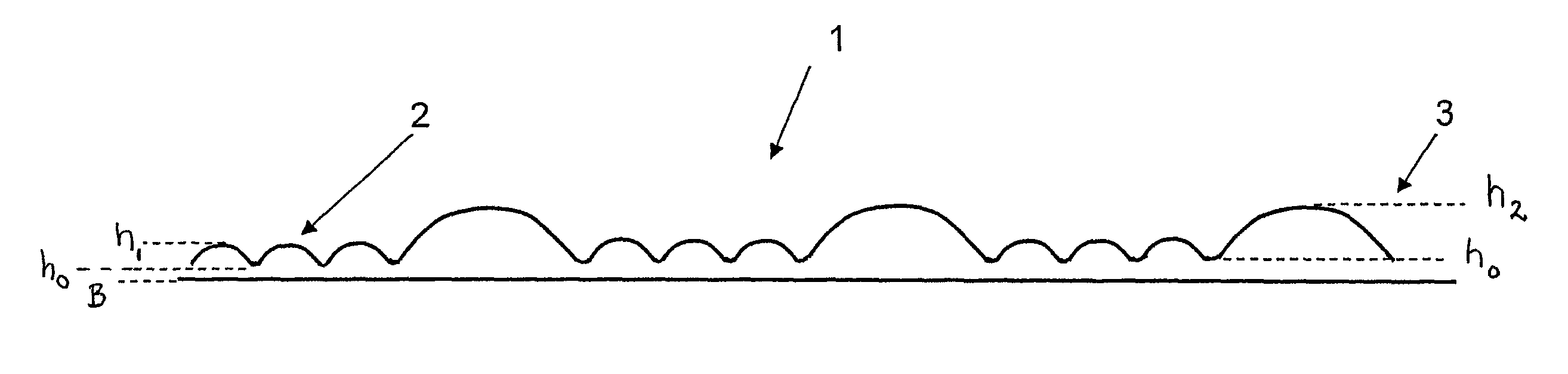

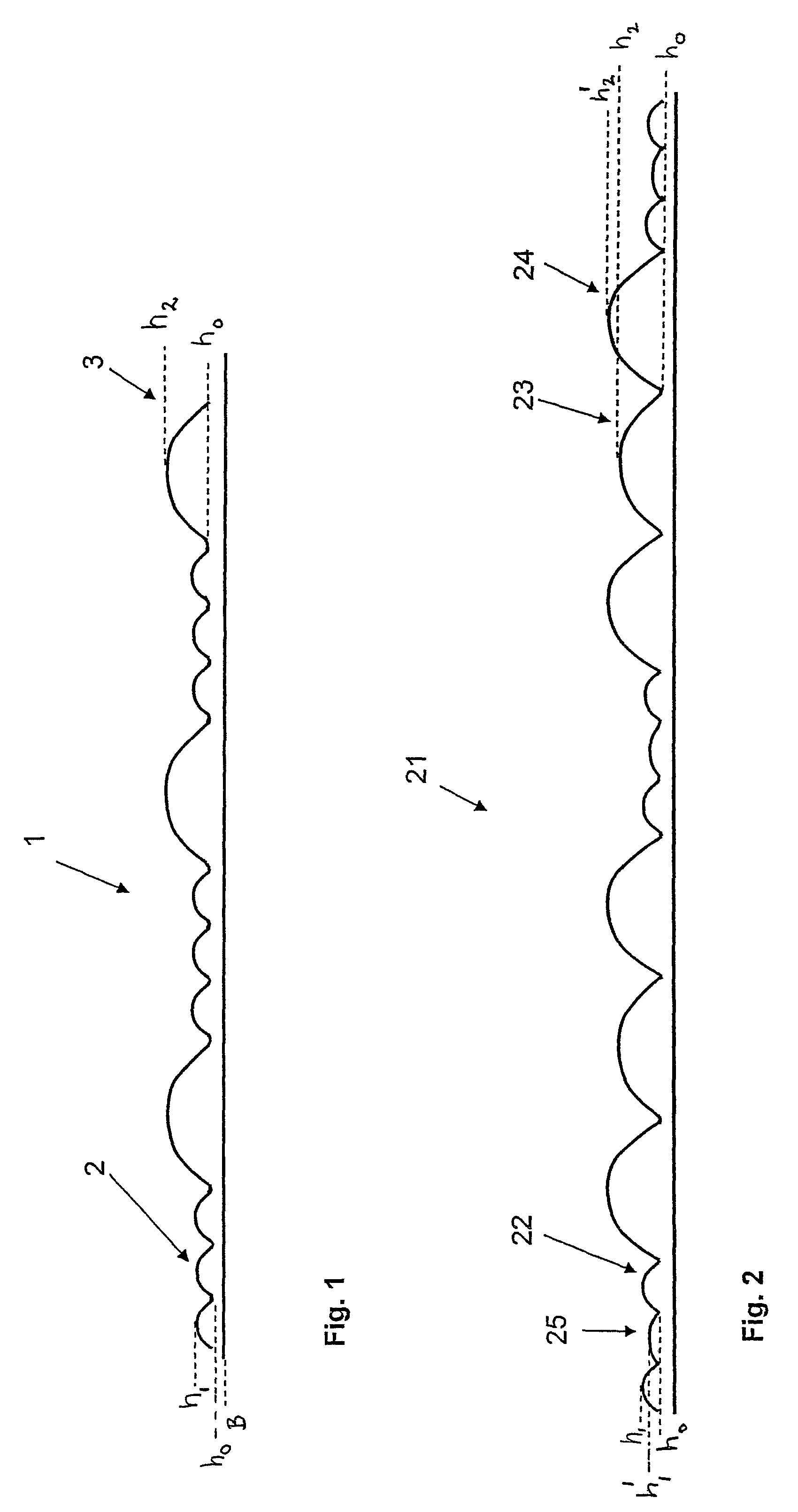

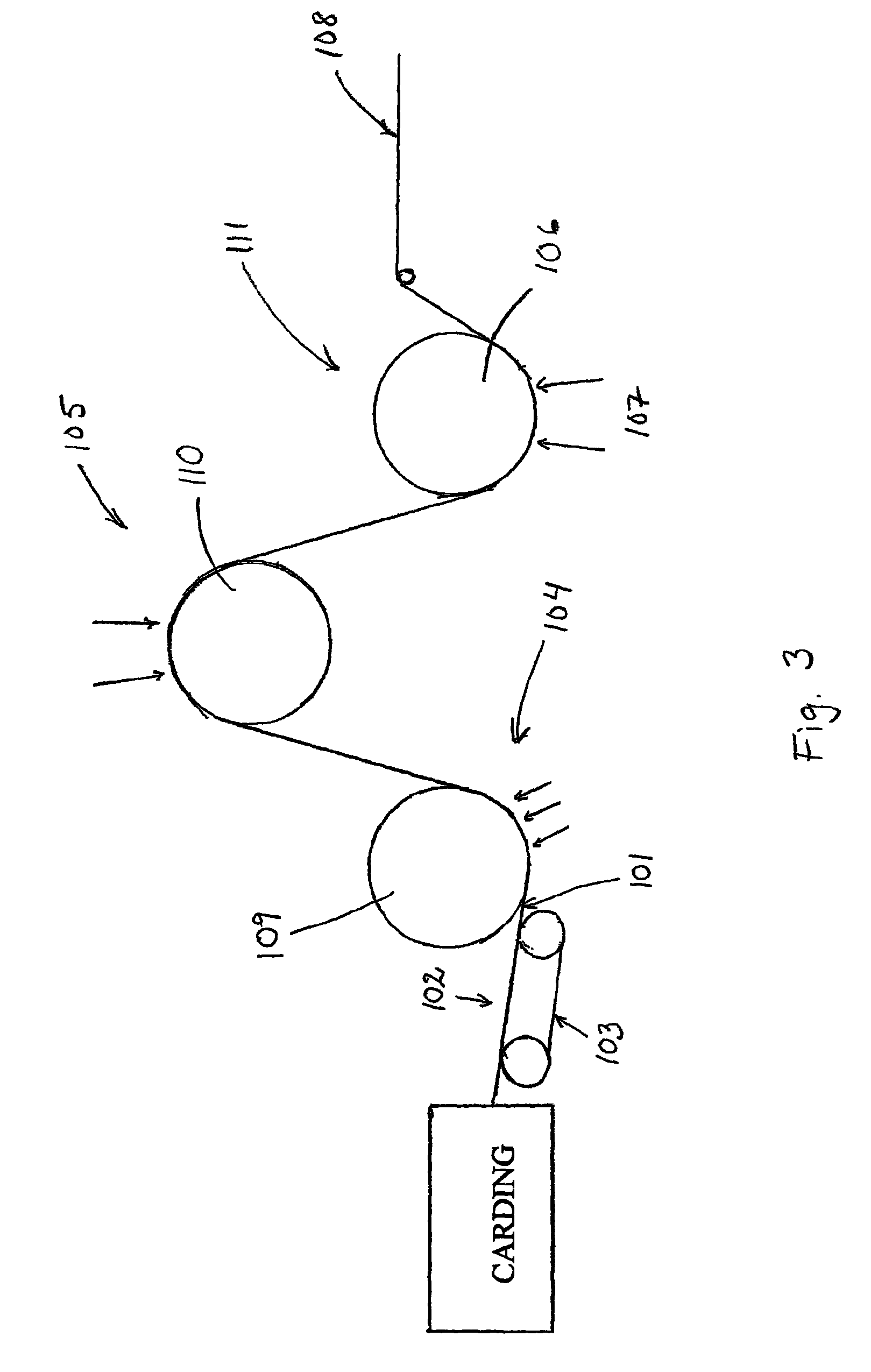

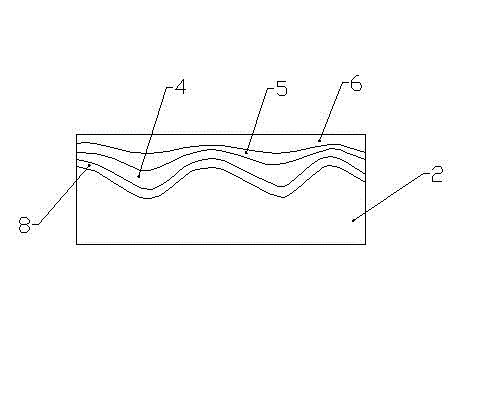

The present invention relates to a nonwoven material intended for use in absorbent products produced by the hydroentangling of a substrate web comprising at least one layer of fibers selected from amongst synthetic fibers, regenerated fibers and natural fibers, wherein the nonwoven material (1) has a base level h0 with protuberances (2, 3) on one side, wherein the protuberances (2, 3) form at least a first and a second surface structure respectively in the form of first (2) and second (3) protuberances from the base level h0, wherein the first protuberances (2) have a height h1 from the base level and the second protuberances (3) have a height h2 from the base level h0, where h2 is higher than h1, and each of the second protuberances (3) occupies an area of the surface of the base level at least 4 times greater than each of the first protuberances (2).The invention also relates to an absorbent product containing a nonwoven material in accordance with the above.

Owner:ESSITY HYGIENE & HEALTH AB

White-surface coated craft paper and production method thereof

ActiveCN102912689AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentRegenerating fibers

The invention discloses white-surface coated craft paper and a production method thereof. The white-surface coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer of the white-surface coated craft paper are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: mixing the bleached hardwood pulp, bleached softwood pulp and bleached regenerated fiber pulp DIP at any proportion, and manufacturing paper through a paper layer to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the white-surface coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

Regenerating fabric fiber plywood and its manufacturing method

InactiveCN101058210AImprove water resistanceImprove insulation performanceFlat articlesDomestic articlesFiberPolymer science

The invention relates to the manufacture for a regenerated knitting fiber laminated board. It sorted the material, removed impurities, processing the regenerated fiber rolling material, processing the waste fiber into flocculent reel, dipping and drying with adhesive of 20-25% of the material, using 45-48% formaldehyde-phenol resin dipping and drying the fiber reel, blank forming in compression ratio of 1: 1. 2, hot-press gluing in the temperature of 140deg.C+-5deg.C, pressure 30-35kg / cm2, keeping the temperature and pressure in 1min / mm, stereotyping and trimming. It can process the waste clothes directly. It is simple, strong in board strength, without deformation, low in cost.

Owner:李茂林

Biomass regenerated-fiber blended silky yarn and production method thereof

The invention provides a biomass regenerated-fiber blended silky yarn and a production method thereof. The biomass regenerated-fiber blended silky yarn is characterized in that blended yarn materials include pupa protein fibers and Levin bamboo fibers. The percentages of the pupa protein fibers and the Levin bamboo fibers, by weight, are 20-80% and 80-20%; the pupa protein fibers contain 18 kinds of amino acids and can fit and benefit skins and are noble in color and luster, and wastes are biodegradable; and the Levin bamboo fibers are high in wet-and-dry strength, are capable of bacteria resistance and bacteriostasis and are comfortable and soft and have silky color and luster, and wastes are biodegradable. One kind or a plurality of kinds of other biodegradable biomass regenerated fibers can be added into the blended yarn, the percentage of the sum of the other fibers by weight is 30-70%, and the percentage of the sum of the pupa protein fibers and the Levin bamboo fibers by weight is 30-70% (each fiber is no less than 15%). By processes of compact spinning and Siro compact spinning and Nu-Torque lower torsion moment spinning technology, the spun yarn is silky, has significant skin-benefit and comfortable functions, and is a novel ideal raw material for weaving woven or knitted superior fabrics.

Owner:RUGAO CITY DINGYAN TEXTILE

Production process of high-elasticity non-woven three-dimensional cotton

The invention discloses a production process of high-elasticity non-woven three-dimensional cotton, comprising the following steps: mixing a low melting point hot melting viscose fiber and at least two fibers of other fibers in proportion; opening and scotching, and feeding cotton and carding and delivering to a vertical lapping forming machine to carry out vertical forming process. A fiber net is continuously folded and descends in a forming curtain at the action that a pendulum-type swinging folding mechanism swings left and right reciprocately, becomes continuous fiber net layers which are arranged in a vertical direction in a steerable channel, and finally forming the three-dimensional cotton which is arranged in a vertical direction through heat setting and cooling setting. The production process in the invention realizes production through a conventional non-woven heat setting machine at the condition of not adding any chemical adhesive, and sets the product thickness and density according to the process requirements; the process is simple, practical and efficient; any fiber can be used as the basic fiber of the material; the regenerated fiber also can be used for forming; and the material source is wide, is easy to obtain, and is relatively environment-friendly.

Owner:杭州缔星纤维科技有限公司

High-artificial tissue engineering nerve repair material NGCS and preparation method thereof

The invention relates to a high simulation tissue engineering nerve repairing material NGCS and a preparing method thereof which is characterized in that the NGCS material comprises one, two or three raw materials of type I collagen, chitosan and gelatin. The NGCS material is made of the following raw materials by weight portions: 1-10 portions of type I collagen, 1 portion of chitosan and 1 portion of gelatin. The NGCS can be applied to both the basic research of the nerve injury repairing and the bridge repairing of clinical human spinal and peripheral nerve injuries or defects. The NGCS material is beneficial for the growth of nerve regenerated fiber and can be applied to the repairing of spinal and peripheral nerve injuries.

Owner:SHENZHEN YINGPULAN MEDICAL DEVICE

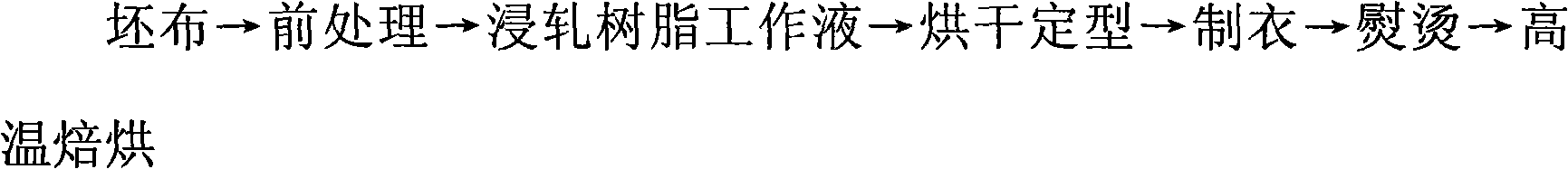

Method for making iron-free clothing using natural fiber and regenerated fiber fabric

InactiveCN101358407ADoes not have non-iron propertiesWith non-ironing functionWeft knittingVegetal fibresRegenerating fibersEngineering

The invention relates to a method for manufacturing ironing-free clothes with natural fiber and regenerated fiber fabric, which comprises the following process steps: fabric pre-processing; padding resin working solution; drying and shaping; clothes manufacturing; ironing; and baking at high temperature. The clothes manufactured by the method has good ironing free effect, small forceful impact on the clothes fabric, low production cost and high efficiency.

Owner:华明浩

Dual-blending woven regenerated yarn for men's clothing

InactiveCN104313747AGood hygroscopicityImprove breathabilityYarnProtective garmentYarnRegenerating fibers

The invention discloses a dual-blending woven regenerated yarn for men's clothing, formed by the first regenerated fiber yarn, the second regenerated fiber yarn and the third regenerated fiber yarn through blending weaving, the first regenerated fiber yarn is knitted by the polynosic fiber and the lyocell fiber, the second regenerated fiber yarn is knitted by the Lenzing modal fiber and the bamboo fiber, the third regenerated fiber yarn is knitted by the cupro fiber and viscose-based chitin fiber, the percentage by weight of the first regenerated fiber yarn, the second regenerated fiber yarn and the third regenerated fiber yarn is 35-43%, 31-35% and 26-30% respectively. The yarn in dual-blending woven mode is tight in yarn quality, the dual-blending woven regenerated yarn for men's clothing is good in hygroscopicity, better in breathability, good in dyeing property, good in elasticity, fast in moisture liberation and soft and comfortable in feeling as the natural regenerated yarn, the dual-blending woven regenerated yarn has anti-bacteria and deodorization function and health care function, and has environmental protection function.

Owner:苏州利森服饰贸易有限公司

Biomass-regenerated-fiber-blended soft smooth fabric and production method

The invention provides a biomass-regenerated-fiber-blended soft smooth fabric and a production method thereof. The blended fabric is prepared from raw materials of pupa protein fiber and Lyocell bamboo fiber, and a finished fabric comprises, by weight, 20-80% of the pupa protein fiber and 20-80% of the Lyocell bamboo fiber. By utilizing high blending performance of the pupa protein fiber and the Lyocell bamboo fiber, one or more other biomass regenerated fibers can be added into the blended fabric, and by weight, total content of the pupa protein fiber and the Lyocell bamboo fiber in the finished fabric is 30-70% (wherein one of the pupa protein fiber and the Lyocell bamboo fiber is not less than 15%) while total content of the other biomass regenerated fibers in the finished fabric is 30-70%. The biomass-regenerated-fiber-blended soft smooth fabric is green, environment-friendly, soft, smooth and good in moisture absorption, breathability and strength, has natural antibacterial property, and can be used for high-grade products of clothes, home textiles, decoration and the like.

Owner:RUGAO CITY DINGYAN TEXTILE

Automobile sound-insulating pad and manufacturing technique thereof

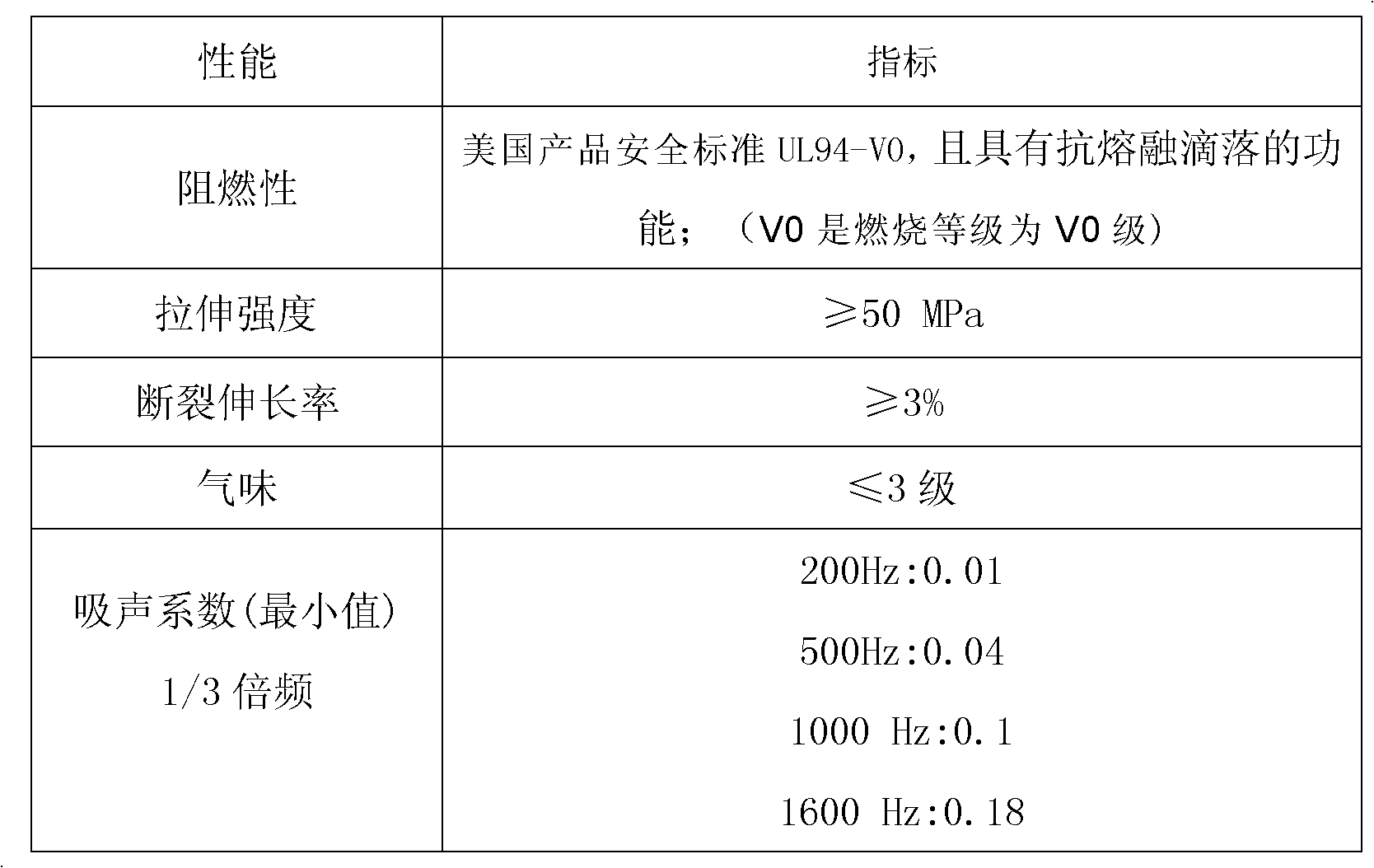

ActiveCN103303214AReduce weightImprove sound absorptionVehicle componentsPolyesterCompression molding

The invention relates to an automobile sound-insulating pad and a manufacturing technique thereof. The manufacturing technique is characterized by comprising the following processing steps: (1) low-melting-point PET (Polyethylene Terephthalate) fibers are carded by a carding machine, spread and stacked by a cotton spreading machine and strengthened by needle punching to form low-melting-point fiber layers; (2) after being mixed, regenerated fibers, polyester fibers and low-melting-point PET fibers are carded by the carding machine, spread and stacked by the cotton spreading machine and strengthened by needle punching to form a composite fiber felt; (3) one low-melting-point fiber layer, the composite fiber felt and the other low-melting-point fiber layer are strengthened by needle punching in sequence from the bottom up to form a semi-finished automobile sound-insulating pad; (4) the semi-finished automobile sound-insulating pad is placed in a forming die, and is subjected to compression molding by injecting steam into the forming die; (5) cooling is performed; (6) the semi-finished automobile sound-insulating pad is cut to reach a required overall size, and required holes are punched in the semi-finished automobile sound-insulating pad, thus obtaining the finished automobile sound-insulating pad. According to the invention, the sound absorption performance of the automobile sound-insulating pad is improved, the emission of odor and volatile organic compounds (VOC) is reduced, and materials are saved.

Owner:WUXI GISSING AUTO PARTS CO LTD

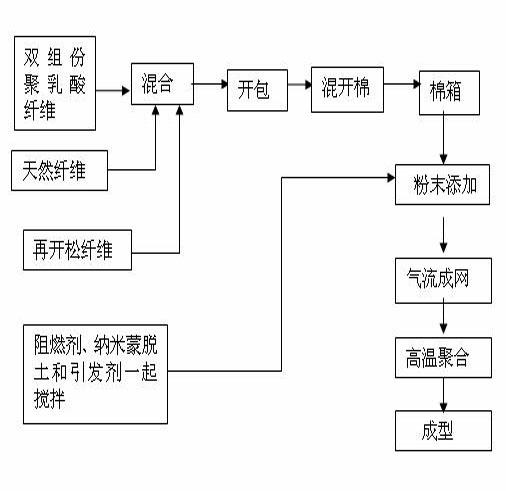

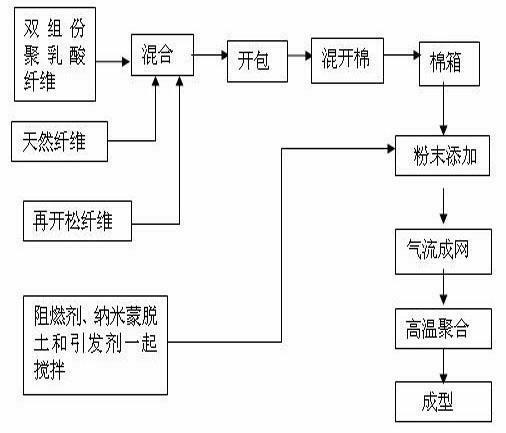

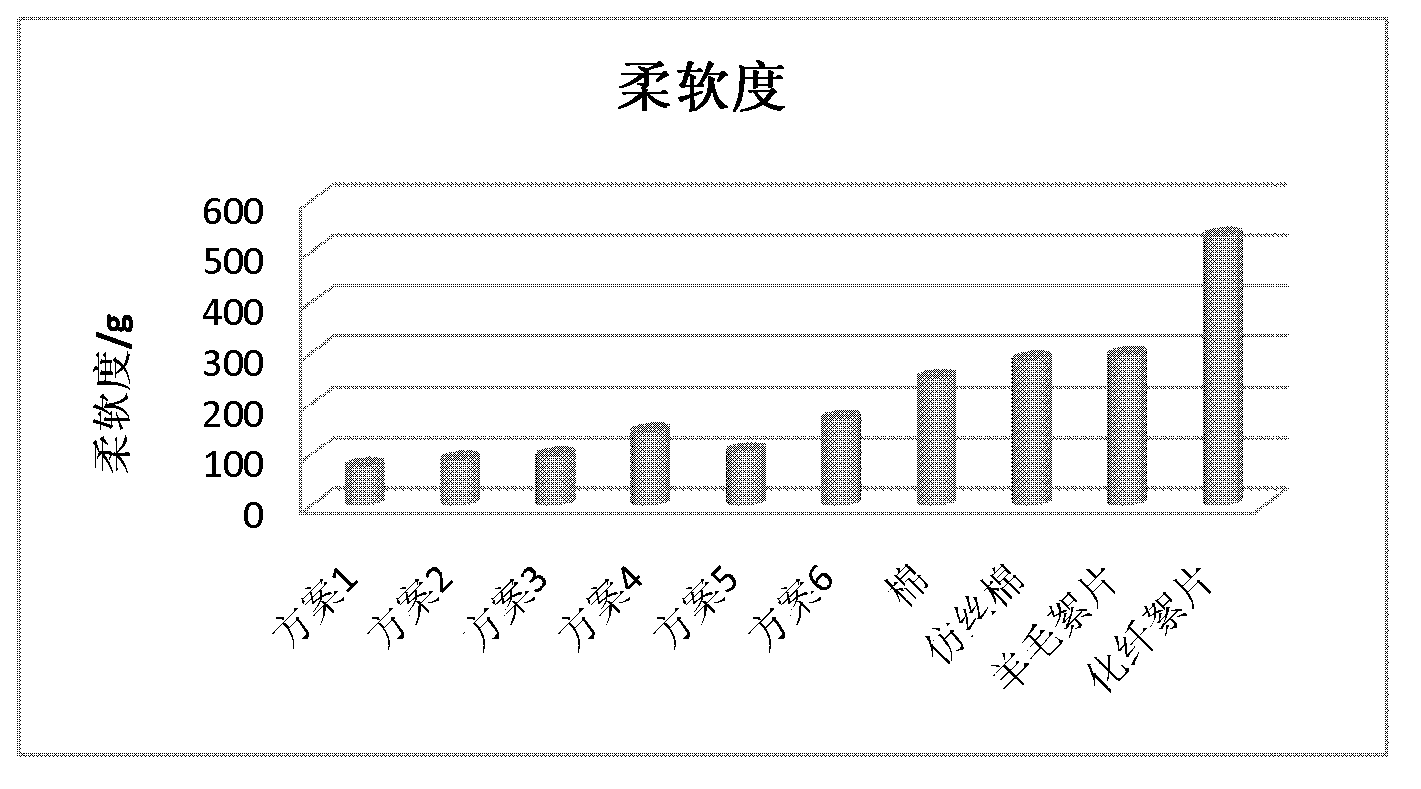

Polylactic acid composite fiber interior material and preparation method thereof

InactiveCN102619023AGood drapabilityImprove comfortNon-woven fabricsThermal insulationRegenerating fibers

The invention discloses a polylactic acid composite fiber interior material and a preparation method thereof. The polylactic acid composite fiber interior material consists of the following components in percentage by weight: 22 to 40 percent of polylactic acid fiber, 25 to 30 percent of regenerated fiber, 22 to 40 percent of natural fiber, 8 to 10 percent of flame retardant, 2 to 3 percent of nano-montmorillonite and 0.1 to 2 percent of initiator. The preparation method comprises the following steps of: uniformly mixing the two-component polylactic acid fiber, the regenerated fiber and the natural fiber to obtain mixed fibers; uniformly mixing the flame retardant, the nano-montmorillonite and the initiator, stirring, cooling, and grinding into powder; opening the mixed fibers by using an opener, further opening by using a hopper blending opener, feeding into a feed box, and outputting by using a transport lattice; and putting the powder onto the transport lattice, making the powder and the mixed fibers fed into an air-laid web forming machine to obtain a web, and polymerizing the web in an oven. The prepared interior material has high environment friendliness, elasticity, sound absorption, flame retardancy and thermal insulation.

Owner:镇江立达纤维工业有限责任公司

Method for manufacturing ceiba heat-preserving material and ceiba heat-preserving material

The invention relates to a method for manufacturing a ceiba heat-preserving material and a ceiba heat-preserving material manufactured by using the same. The method for manufacturing the ceiba heat-preserving material disclosed by the invention comprises the following steps of: 1, pretreating ceiba fibers; 2, opening and mixing ceibas; 3, feeding ceibas; 4, forming a net; 5, stretching; 7, spraying glue; and 8, performing post-treatment, wherein the pretreatment of the ceiba fibers comprises destaticization of ceiba fibers and mechanical premixing at the same time; and the manufactured ceiba heat-preserving material comprises the following fiber raw material components in percentage by mass: 10-30 percent of natural ceiba fiber, 55-80 percent of chemical fiber and regenerated fiber, and 5-15 percent of low-melting-point fiber. Due to the adoption of the method, the problems of easiness in flying, poor net forming property and unstable fiber net quality during treatment of ceibas are solved, and a ceiba heat-preserving material which is soft, comfortable and efficient in preserving heat can be provided.

Owner:3M CHINA

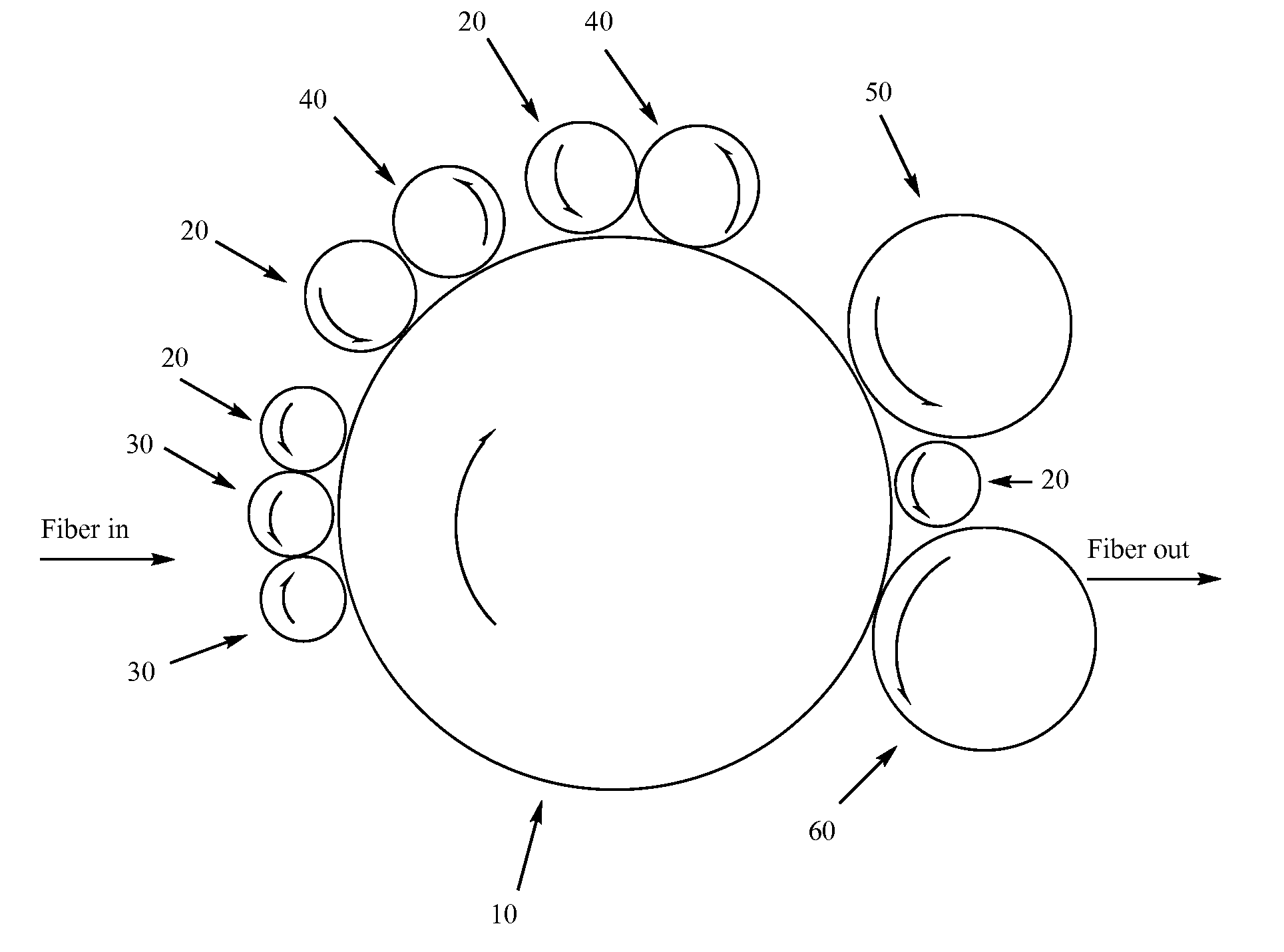

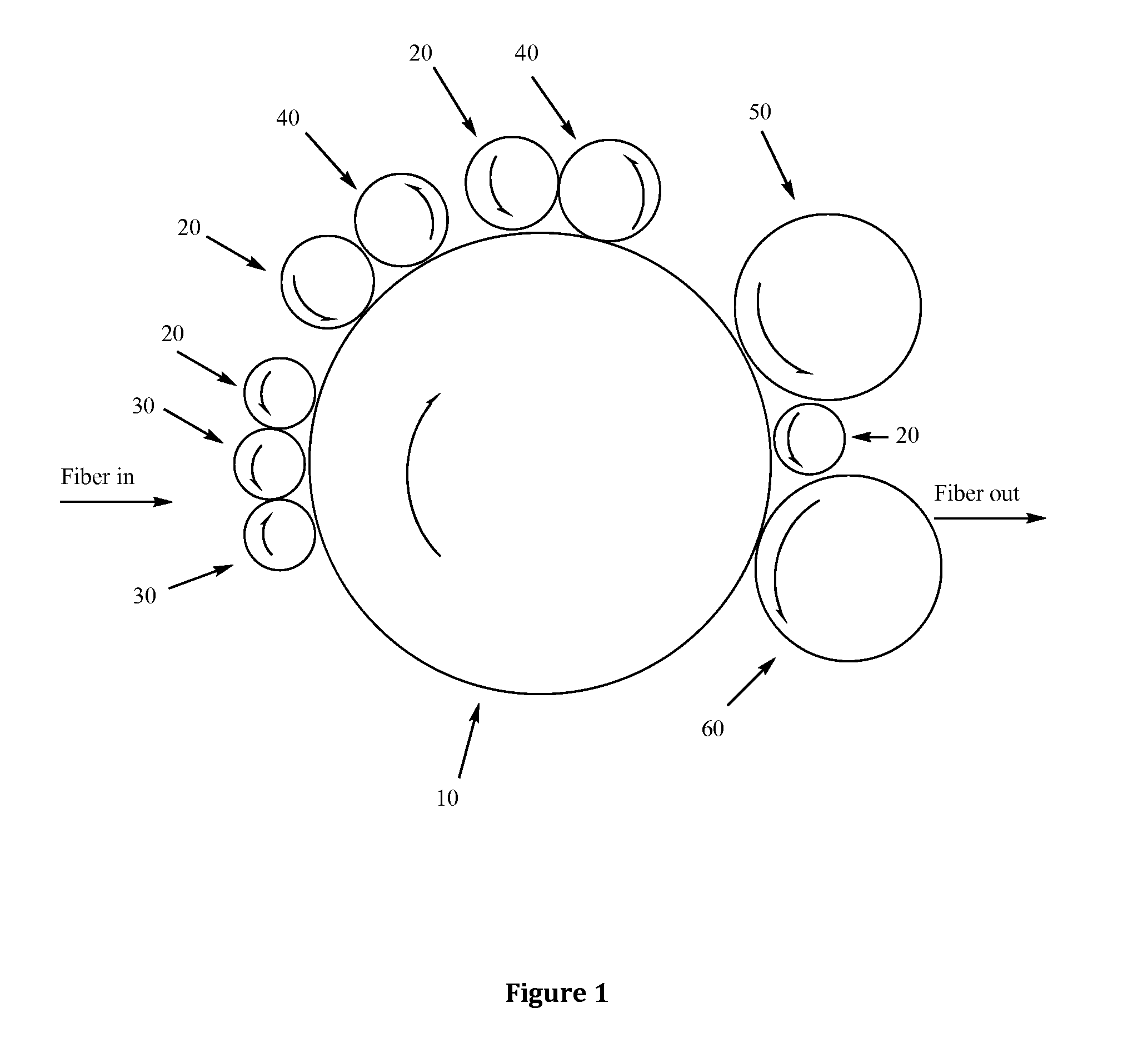

Process for regenerating post-consumer and post-industrial fibers

InactiveUS20110094691A1Uniform colorImprove product performanceGlass making apparatusTextile disintegration and recoveryFiberPolymer science

Processes for producing regenerated fibers from post-consumer and post-industrial waste are disclosed. The process generally involves obtaining a source of post-industrial and / or post-consumer scrap material comprising fibers, cutting the material into a desirable size in the range of from one square inch to thirty square inches, detangling the fibers, removing any finish from the fibers, if present, combing and / or picking the fibers to convert any threads into fibers, humidifying the fibers, and intimately blending the fibers. These regenerated fibers can be blended with other fibers, and intimately blended to provide a uniform blend of fibers. The fibers can then be subjected to a carding process to orient the fibers. The regenerated fibers can be used in any application that would otherwise use virgin fibers, including their use to form woven or non-woven materials.

Owner:PSIL HLDG LLC

Keratin crystal whisker enhanced homogeneous composite fiber and preparation method thereof

InactiveCN101575749AOvercome the technical bottleneck that the molecular weight is small and cannot be directly spun into fibersOvercome the technical bottleneck that cannot be directly spun into fibersMonocomponent protein artificial filamentWet spinning methodsFiberRegenerating fibers

The invention provides a keratin crystal whisker enhanced homogeneous composite fiber and a preparation method thereof. The keratin crystal whisker enhanced homogeneous composite fiber consists of keratin matrixes and keratin crystal whiskers dispersed in the keratin matrixes, wherein the weight ratio of the keratin crystal whiskers to the keratin matrixes is 10-30:70-90; and the keratin crystal whiskers are distributed in the composite fiber along the axial direction of the fiber. The keratin crystal whisker enhanced homogeneous composite fiber and the preparation method can achieve homogenization spinning processing of keratin regenerated fibers. The keratin crystal whiskers can be prepared from waste wools or other animal fiber materials without spinning values, the raw materials have wide sources, the cost is low and the processing technique is simple.

Owner:DONGHUA UNIV

Method for manufacturing moisture-absorption and perspiration finish fabric

The invention discloses a method for manufacturing a moisture-absorption and perspiration finish fabric. The method comprises the following steps: A, selecting a fabric; B, scouring and bleaching the fabric; C, mercerizing the fabric; D, dyeing the fabric; E, softly finishing the fabric; F, inspecting the fabric; G, carrying out moisture-absorption and perspiration treatment on the fabric; and H, baking and shaping the fabric. The method can be applied to cotton, hemp, wool, silk and other natural fiber fabrics or regenerated fiber fabrics; and the manufactured finish fabric has effects of duration, wash resistance, moisture absorption and perspiration, can greatly improve the grade and quality of clothes, and can replace dacron fabrics to a great extent.

Owner:何汉沛

Fiber article comprising a biodegradable plastic

ActiveUS7129190B2Increase resistancePoor in hydrolysis resistanceFibre treatmentWoven fabricsPolymer scienceNatural fiber

A fiber article having excellent hydrolysis resistance, characterized in that the article is fiber structure composed of 10 to 90% by weight of a fiber (A) comprised of a biodegradable plastic formulated with a carbodiimide compound as a stabilizer against hydrolysis and 90 to 10% by weight of at least one fiber (B) selected from a natural fiber, a regenerated fiber, a semi-synthetic fiber and a synthetic fiber, which fiber structure has been subjected to at least one treatment processing selected from scouring processing, bleaching processing, liquid ammonium processing, mercerization processing, biological processing, dyeing processing, or resin treatment, and concentration of total terminal carboxyl groups derived from the fiber (A) in said fiber article is not higher than 30 equivalents / ton based on the fiber (A), etc. It is an object of the present invention to solve conventional problems of a fiber or a fiber article comprising a biodegradable plastic, such as poor hydrolysis resistance, poor heat resistance, strength reduction and coloring by yellowing, and in particular to provide a fiber article superior in hydrolysis resistance, alkali resistance and dyeing resistance.

Owner:NISSHINBO IND INC

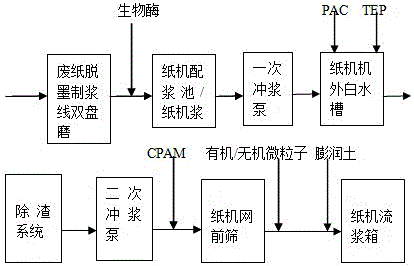

Method for improving net retention rate of regenerated fiber cultural paper

InactiveCN104562830APlay the role of efficient "cleaner"Improve stabilityPaper/cardboardSecondary cellulose fibresFiberRegenerating fibers

The invention discloses a method for improving net retention rate of regenerated fiber cultural paper. By adding a bio-enzyme+cationic poly aluminum chloride PAC+glue control agent TEP for combined treatment, most anionic trash in a paper machine system, particularly in a paper machine system which recycles waste paper pulp manufacturing cultural paper by 100% can be captured so as to play a role in an efficient cleaner of the paper machine system, and therefore, the paper machine system is stabilized and the retention rate is enhanced. By adopting the treatment method, the bottleneck that the retention rate is hard to enhance and the stability is poor due to interference of anionic trash when the waste paper pulp manufacturing cultural paper is recovered by 100% is directly broken through. The method not only has the characteristics of high net retention rate, controllability of the retention rate, good stability and the like, but also has good paper evenness of finished paper and dehydrating effect of the net.

Owner:DONGGUAN NINE DRAGONS PAPER IND

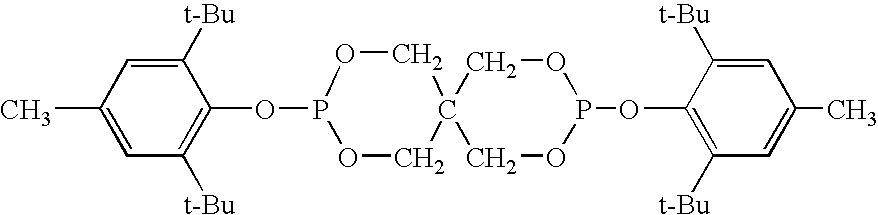

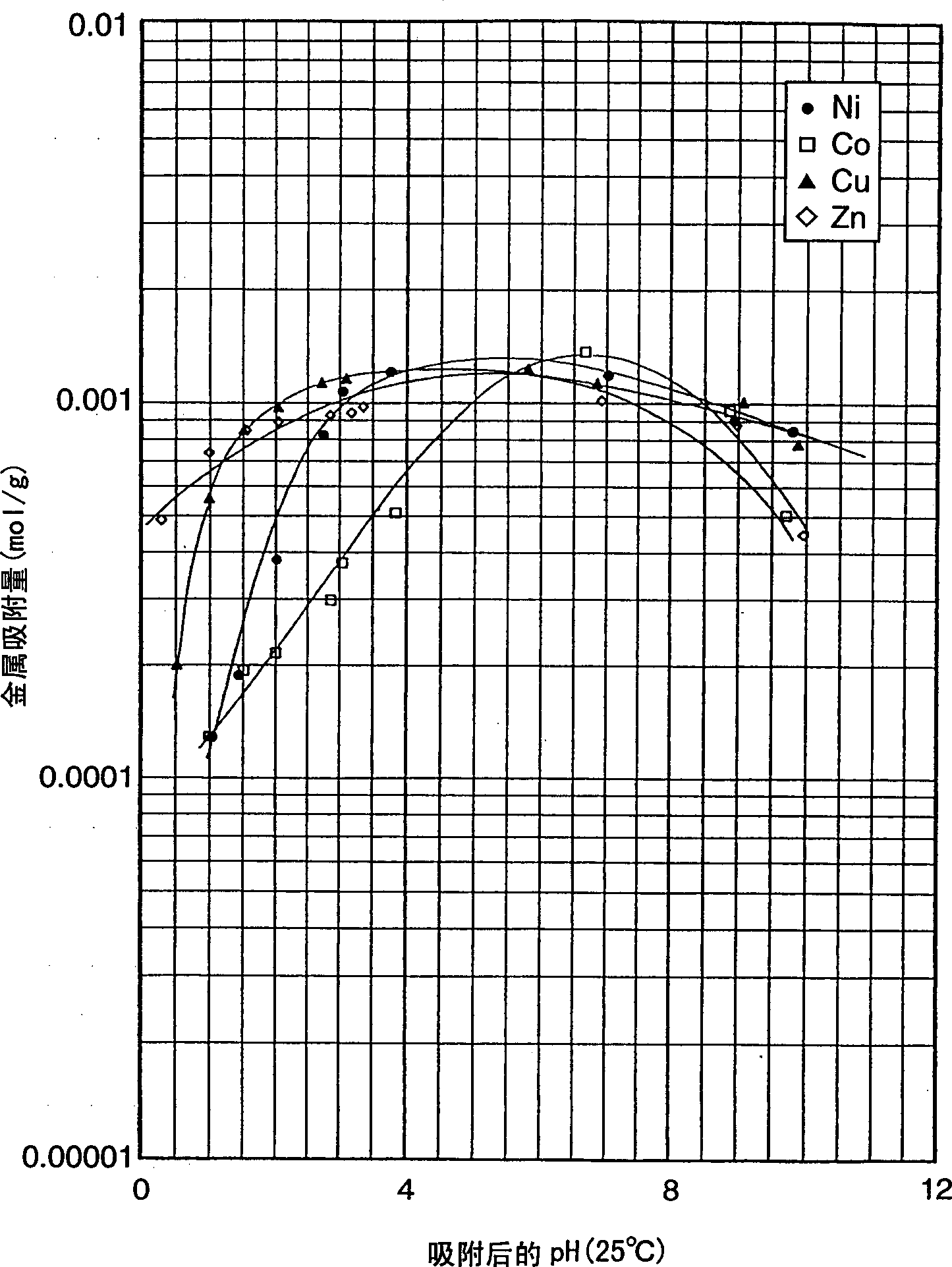

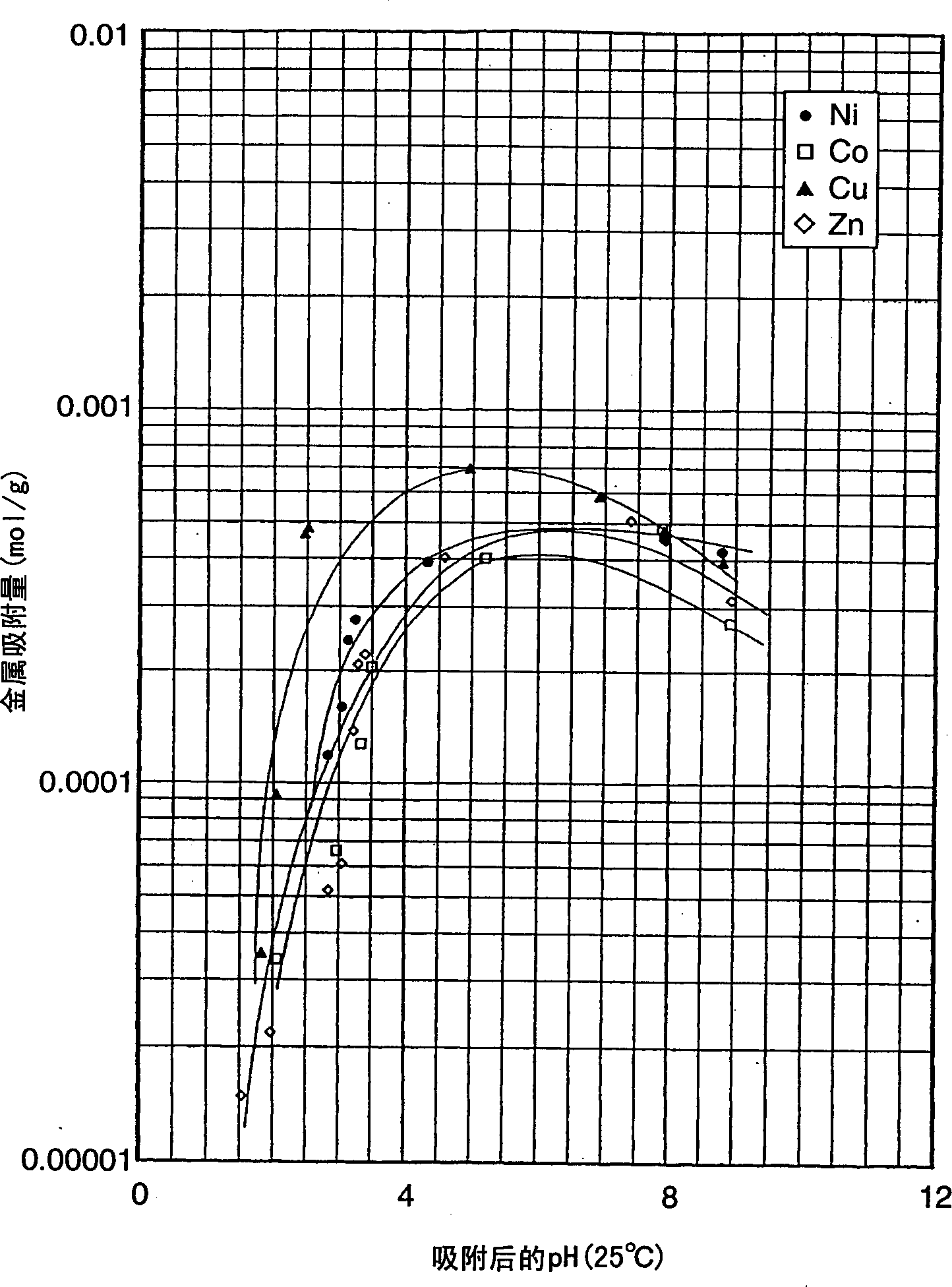

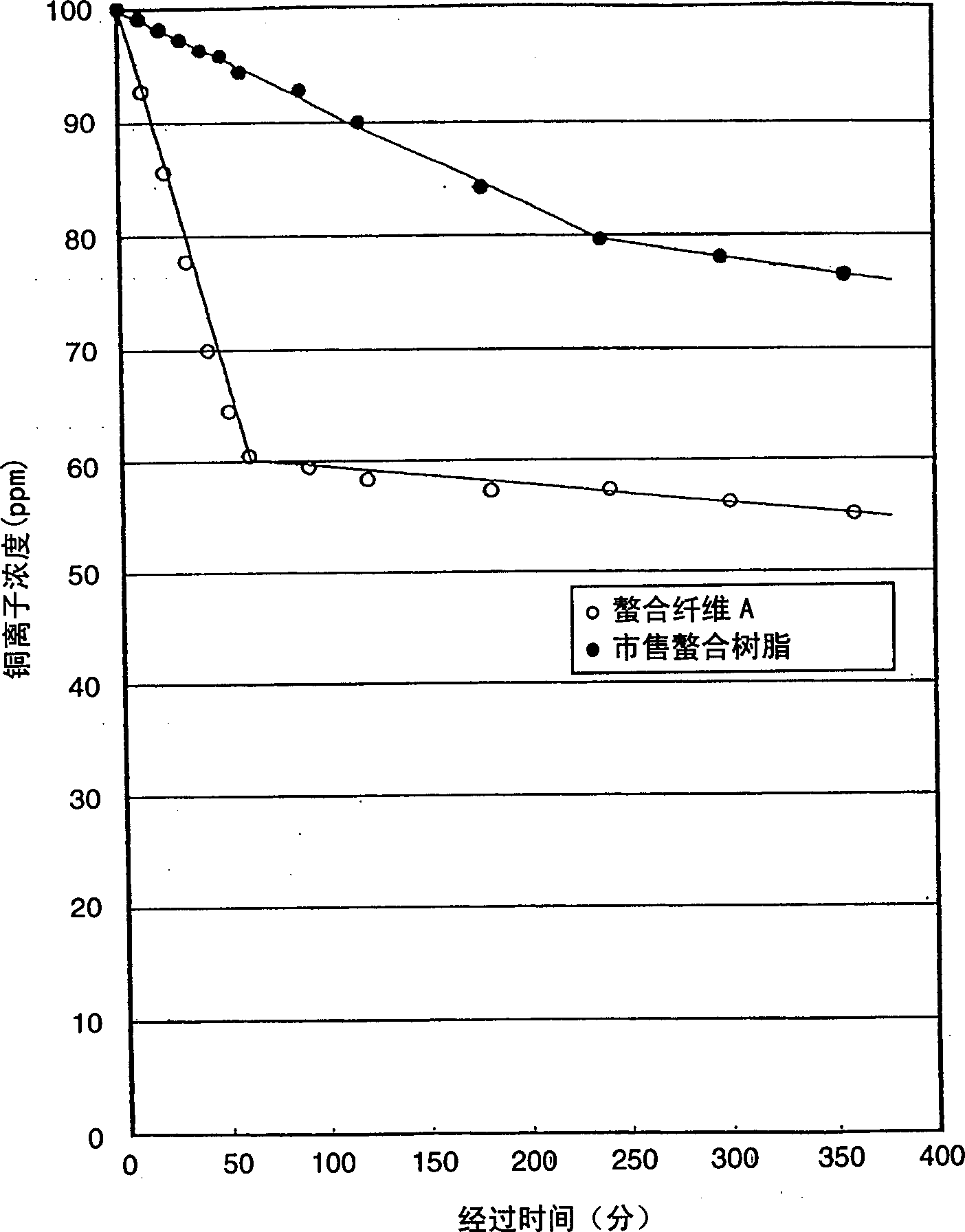

Fiber capable of forming metal chelate process for producing the same, method of trapping metal ion with the fiber, and method chelate fiber

InactiveCN1341176AIon-exchange process apparatusOther chemical processesThiocarboxylic acidRegenerating fibers

A fiber capable of forming a metal chelate and a process for producing the same are disclosed, wherein the fiber is characterized in that at least one metal chelate-forming compound selected from the group consisting of aminodicarboxylic acids, aminocarboxylic acids, thiocarboxylic acids and phosphoric acid, which are reactive with a glycidyl group, is bonded to a molecule of a natural fiber or regenerated fiber through a crosslinkable compound having a reactive double bond and a glycidyl group in its molecule. There are also disclosed a method of capturing metal ions using the fiber and a metal chelate fiber which can effectively make use of the characteristics of the metals and can be easily discarded or incinerated.

Owner:KIRESUTO +1

Solid acid catalyst containing catalytic active group and adsorption group and preparation and application of solid acid catalyst

ActiveCN103084188ASimple preparation processReduce the temperaturePhysical/chemical process catalystsOther chemical processesCelluloseFiber

The invention discloses a solid acid catalyst containing a catalytic active group and an adsorption group and preparation and application of the solid acid catalyst, which belong to the field of hydrolyzing cellulose to prepare a high-value-added platform chemical compound. The preparation method comprises the following steps of: under the protection of nitrogen, incompletely carbonizing sucralose for 0.5-20 hours at 300-500 DEG.C, adding concentrated sulphuric acid to the sucralose, performing sulfonation reaction on the sucralose for 1-20 hours at 100-200 DEG.C, adding a reaction mixture in water to separate a solid, washing the solid to be neutral by water, and drying the solid to obtain the solid acid catalyst containing the catalytic active group and the adsorption group. The solid acid catalyst is used for hydrolyzing cellose and / or cellulose, is environment-friendly, is high in activity, high in selectivity, easy to recycle and non-corrosive to devices, can be used for efficiently catalyzing crystal fibers, regenerated fibers pre-treated through ionic liquid and ball-milled cellulose, and is suitable for large-scale production. The preparation method is simple in process and low in energy consumption and needs short preparation time.

Owner:SOUTH CHINA UNIV OF TECH

100% regenerated fiber spunlace non-woven fabric

ActiveCN106048889AImprove cohesionImprove bindingFibre treatmentNon-woven fabricsCardingHair falling

The invention discloses a 100% regenerated fiber spunlace non-woven fabric which uses recycled spunlace non-woven fabric leftover material as a raw material. The production method of the 100% regenerated fiber spunlace non-woven fabric includes raw material pretreatment, raw material retreatment, opening, mixing and impurity removing, carding and netting, spunlace and primary drying, and drying and product finishing. Opening adopts a non-holding manner; a carding machine is additionally provided with a fiber cohesion roller and uses air flow to assist stripping; spunlace water is recycled water which is circularly supplied by a multilevel water circulation processing system, and filtering manners including an air flotation filtering manner, a sand filtering manner, a metal filtering manner and a bag refined filtering manner are used to filter out impurities in water; a novel safe emulsion is used to treat a spunlace fiber net by adoption of an impregnation method or a foam method; the cohesion and the combination among the regenerated fiber can be effectively improved, and the physical performance of the spunlace non-woven fabric finished product is improved; hair falling and bit falling can be avoid during use of the spunlace non-woven fabric, the service life of the spunlace non-woven fabric is prolonged, or the use times of the spunlace non-woven fabric are increased; and the spunlace non-woven fabric has excellent water absorbing performance, is durable and laundering-resistant, and can be used with most of cationic type antibacterial agents.

Owner:JIANGSU AIKOP NEW MATERIALS CO LTD

Colored kraft paper and production method thereof

ActiveCN102251429AImprove physical strengthReduce manufacturing costPaper recyclingPulp bleachingFiberRegenerating fibers

The invention discloses colored kraft paper and a production method thereof. The production method comprises the following steps: pulping waste paper, screening, purifying, floating, concentrating, dewatering, carrying out heat dispersion, and bleaching to obtain waste paper deinked pulp; mixing the waste paper deinked pulp with beaten commercial softwood pulp; and desanding, blending (including color mixing), screening, purifying, carrying out net shaping, squeezing, drying, calendering, winding, rewinding, and packing, wherein the absolute dry mass ratio of the waste paper deinked pulp to the commercial softwood pulp is 70-80%:20-30%. The colored kraft paper produced by the method has high physical strength, low production cost and good tissue evenness, the color of the paper can be adjusted in accordance with user preferences by adding dyes, and the appearance quality is obviously improved; as the used waste paper pulp is subjected to TCF (Total Chlorine Free) bleaching in the pulping process, organic halides (AOX) and dioxin which are difficult to biodegrade can not be produced in the production process, thereby having the advantage of realizing clean production; and 70% of regenerated fibers are used to reduce the consumption of virgin fibers, thereby saving wood and being environment friendly.

Owner:YUEYANG FOREST & PAPER CO LTD +1

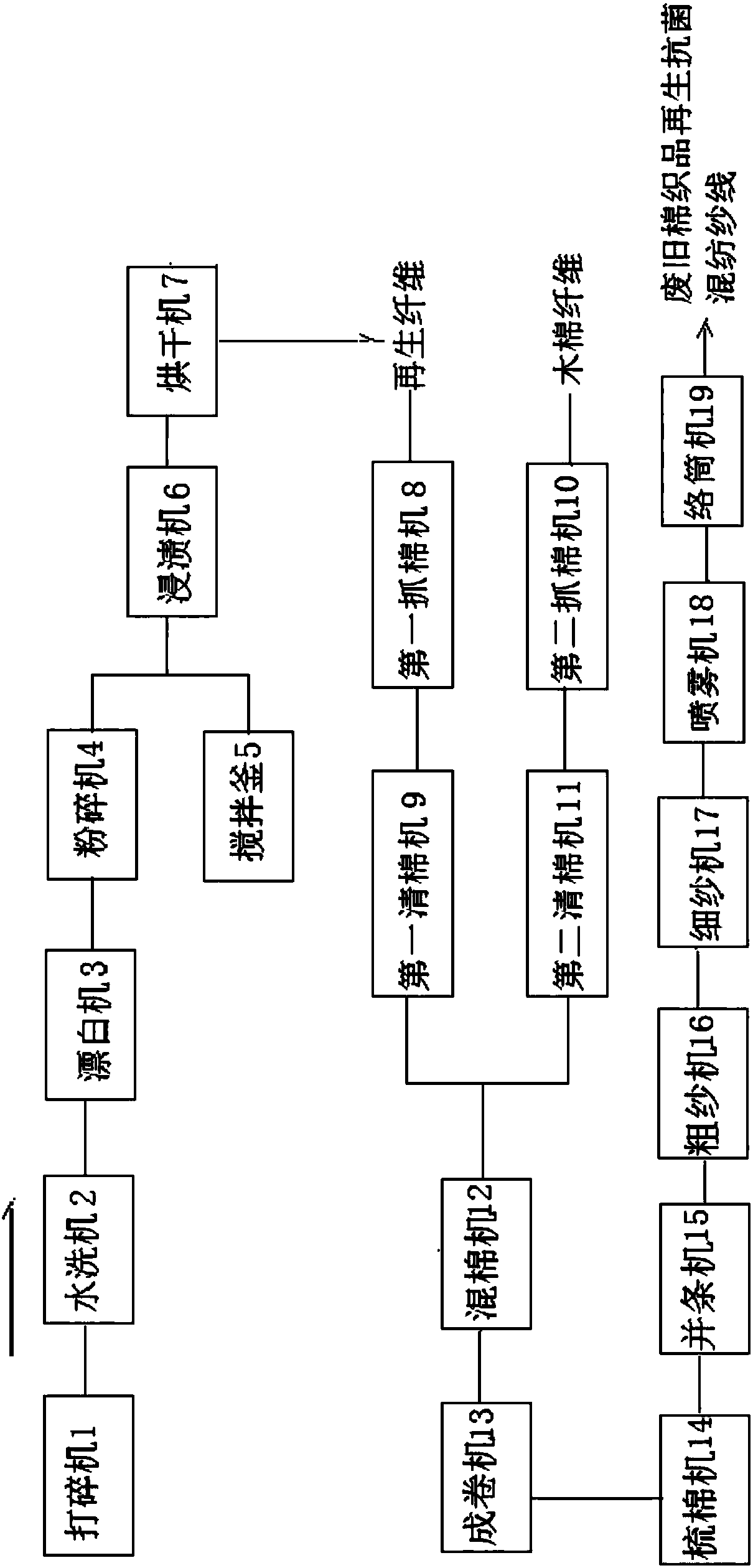

Waste cotton textile recycled antibacterial blended yarn for waste cotton texture and preparing method and system thereof

PendingCN107761209AImprove mechanical propertiesImprove wear resistanceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsYarnCarding

The invention relates to waste cotton textile recycled antibacterial blended yarn and a preparing method and system thereof. According to the waste cotton textile recycled antibacterial blended yarn,waste cotton textile and impregnated sizing agent are adopted for preparing recycled fiber, wherein the impregnated sizing agent comprises multiple functional components, the functional components areevenly spread in slits in the surface of the prepared recycled fiber, and thus the recycled fiber is better modified; the recycled fiber is further subjected to opening and cleaning, and the recycledfiber obtained after cleaning and bombax cotton fiber obtained after opening and cleaning are sufficiently mixed and then subjected to lapping, cotton carding, drawing, roving, spinning, mist spraying and coning in sequence. The prepared waste cotton textile recycled antibacterial blended yarn has good mechanical performance, anti-abrasion performance and stability, is durable, natural, environmentally friendly and harmless to the human body, and has good mildew-proof and antibacterial performance, the quality of recycled cotton yarn is improved, and the use range of the recycled cotton yarnis broadened.

Owner:深圳恒锋资源股份有限公司

Making method for bio-fiber/bamboo charcoal fiber/viscose fiber blended fabric

InactiveCN104726997AHas antibacterial propertiesGood physical and mechanical propertiesFibre treatmentArtificial filaments from viscosePolyesterPolymer science

The invention discloses a making method for bio-fiber / bamboo charcoal fiber / viscose fiber blended fabric. Selected warp and weft materials comprise, by mass, 15-45 parts of pupa bombycis protein fibers, 15-35 parts of lyocell bamboo fibers, 40-80 parts of viscose fibers, 8-15 parts of bamboo charcoal fibers, 60-95 parts of cotton fibers, 8-18 parts of super fine denier polyester, and 30-65 parts of other biomass regenerated fibers, the making procedure of fiber fabric comprises the steps of scutching, cotton carding, drawing, roving, spinning and weaving operations; the other biomass regenerated fibers are one type or more types of modal fibers, bamboo modal fibers, corn fibers, chitin fibers, Shengma fibers and rose fibers. According to the making method for the bio-fiber / bamboo charcoal fiber / viscose fiber blended fabric, by means of the performance complementation of different fibers, the overall performance of fiber spinning weaving cotton cloth is improved, and meanwhile hand feeling and texture of luxury fabric are achieved.

Owner:SUZHOU CHENHENG WEAVING

Process method of swaddling clothes anti-pilling

InactiveCN101358390AImprove cohesionReduce pillingFibre mixingMonocomponent copolyesters artificial filamentYarnPolyester

The invention relates to a processing method of a sweater, which resists fuzz and pilling; the method mixes loose fiber, mixes polyester low-melting short fiber with 1 percent to 30 percent of mass fraction and the raw material fiber of the sweater, spins into yarn, weaves into fabric, processes into the sweater, leads the polyester low-melting short fiber and the raw material fiber to form hot bonding points by conducting post heat treatment to the yarn, fabric or the sweater, and the heat treatment temperature is 70 DEG C to 190 DEG C; the raw material fiber of the sweater can be all types of animal hair, cotton, ramie, spun silk, synthetic fiber, regenerated fiber and the mixture of the fiber mentioned above; the melting point of the low-melting polyester is 70 DEG C to 170 DEG C, the low-melting polyester short fiber can be not only single-component fiber but also skin-core composite fiber; in the method, the low-melting polyester fiber is mixed by mixing the loose fiber, and the low-melting polyester fiber is melted by post heat treatment to be bonded with other fiber, to improve the cohesive force between the fiber in the yarn, so as to greatly improve the fuzz and pilling resistant performance of the sweater.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing regenerated straw fiber by directly spinning straw

InactiveCN102146591AWide variety of sourcesSolve pollutionArtificial filaments from cellulose solutionsWet spinning methodsFiberYarn

The invention discloses a method for preparing regenerated straw fiber by directly spinning straw, belonging to the field of spinning of regenerated fiber. The method is characterized by comprising the following steps of: (1) washing straw with water, drying in the air, smashing, bleaching and filtering to obtain pretreated straw powder; (2) mixing the pretreated straw powder with chlorinated 1- butyl-3-methyl glyoxaline in the mass ratio of 1:30, preheating, swelling, dropwise adding dimethyl sulfoxide, adding 5 mL of dimethyl sulfoxide into every 0.5g of straw powder and stirring at controlled temperature to obtain high-viscosity spinning liquid; (3) filtering the high-viscosity spinning liquid, defoaming, spirally extruding, spraying by using a porous spinning head, drawing and curing in a coagulation bath to obtain fiber yarn, wherein the coagulation bath is water or an ion liquid aqueous solution with the concentration of 1-60 percent, the temperature of the coagulation bath is between 0 DEG C and 90 DEG C and the spinning speed is between 5 meters per minute and 150 meters per minute; and (4) drawing the fiber yarn, washing with water, applying oil and drying to obtain the regenerated straw fiber. The method has the characteristics of simple process, small equipment investment and low running cost.

Owner:WUHAN TEXTILE UNIV

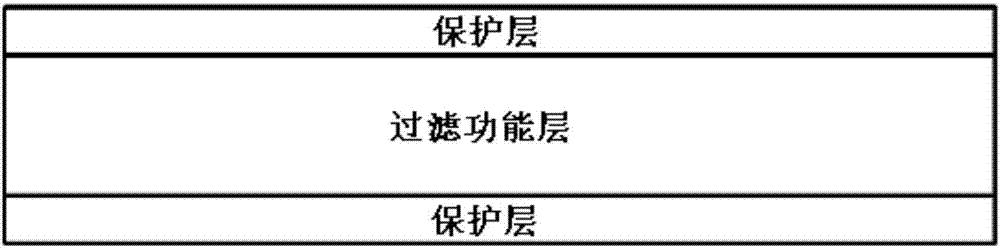

Composite structure filter felt and its preparation method and application

ActiveCN107224783ARenewableImprove filtration efficiencyGas treatmentDispersed particle filtrationElectrospinningFiltration

The invention belongs to the technical field of filter materials and discloses a composite structure filter felt and its preparation method and application. The composite structure filter felt is composed of a filtering function layer and protective layers coating the upper and lower surfaces of the filtering functional layer. The filtering function layer is prepared from a regenerated fiber layer containing 3D crimped structural fibers and an electrospinning nano-fiber layer through compounding. The composite structure filter felt has a fluffy filtering material skeleton structure of renewable micrometer fibers containing 3D crimped structural fibers and utilizes secondary electrospinning nanofibers attached to the micrometer fibers so that a high fiber specific surface area is obtained. The filter felt has the advantages of high filtration efficiency, low resistance and environmental friendliness.

Owner:SOUTH CHINA UNIV OF TECH +1

Blended regenerated cotton yarn and preparing method thereof

InactiveCN105803609AHigh strengthIncrease elasticityMonocomponent synthetic polymer artificial filamentYarnYarnCellulose

The invention discloses blended regenerated cotton yarn and a preparing method thereof, and relates to the technical field of textile. The blended regenerated cotton yarn is prepared from, by weight, 45-50 parts of waste cotton fabric, 20-24 parts of cotton yarn leftover materials, 45-49 parts of polyacrylonitrile fiber, 3-3.5 parts of phosphonolipid starch, 2.5-3 parts of special type low-fat pectin, 3-3.5 parts of calcium carbonate, 4.5-7 parts of nano-zinc oxide, 13.5-15 parts of liquid paraffin, 11-11.5 parts of nanometer titania, 2-2.8 parts of carboxymethylcellulose, 2-3 parts of glyceryl stearate and water. Fiber regeneration is achieved by means of waste cotton fabric and cotton yarn leftover materials, and regenerated fiber is blended with polyacrylonitrile short fiber to obtain the blended regenerated cotton yarn high in strength and ultraviolet resistance. The problem of poor ultraviolet resistance of existing blended regenerated cotton yarn can be solved.

Owner:SOUTHERN CHINA REGENERATED COTTON YARN WUZHOU CO LTD

Atmospheric plasma processing method used for fabric topical finish

InactiveCN101117764AEasy to operateShort processUltrasonic/sonic fibre treatmentRegenerating fibersEngineering

A normal-pressure plasma treating method for post-finishing of fabrics is disclosed by the present invention, which relates, in particular, to a normal-pressure plasma treating method for softening and decontaminating finishing of fabrics without chemical assistants and belongs to the technical field of textile processing. The present invention is characterized in that a fabric is positioned between electrodes of a plasma device and treated with corona or glow discharge for 3s-20min by voltage application after the power is switched on,. The fabric can be a natural fiber fabric, a synthesized fabric, a regenerated fiber fabric, a blended fabric of the above fabrics or an interwoven fabric of the above fabrics. The present invention has simple operation and short process and is free of the troublesome steps including padding, pre-baking and baking; without use of chemical assistants or water, the present invention is conducive to environment protection; the fabrics finished with the present invention feels soft and smooth.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

Mobile-phone antibacterial cleaning wet tissue

InactiveCN103417154AEfficient removalQuick removalDomestic applicationsDetergent perfumesEscherichia coliFiber

The invention provides a mobile-phone antibacterial cleaning wet tissue. The mobile-phone antibacterial cleaning wet tissue comprises base fabric and antibacterial cleaning agent, and the mobile-phone antibacterial cleaning wet tissue is manufactured by completely dipping the base fabric in the antibacterial cleaning agent. The base fabric is made of ultra-fine regenerated fiber non-woven fabric material. The antibacterial cleaning agent is formed by mixing 80-88% of purified water, 3-5% of moisturizing constituents, 3-5% of antibacterial constituents, 5-8% of cleaning constituents and 1-2% of natural fragrance constituents. By the adoption of the novel efficient broad-spectrum antibacterial technology, the antibacterial constituents of the mobile-phone antibacterial cleaning wet tissue can effectively clean away bacteria carried by the screen and the body of a mobile phone and have the anti-bacterial function and the anti-static function, wherein the bacteria can be staphylococcus aureus, escherichia coli and the like; the cleaning constituents can rapidly remove oil stains, sweat stains, dust, fingerprints and the like on the screen and the body of the mobile phone; the natural fragrance constituents can enable the mobile to emit natural fragrance after the mobile phone is wiped. Meanwhile, the mobile phone is wiped slightly with the mobile-phone antibacterial cleaning wet tissue, and the mobile-phone antibacterial cleaning wet tissue is simple and convenient to use; the mobile-phone antibacterial cleaning wet tissue is packaged simply and is convenient to carry.

Owner:LIANZHUANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com