Automobile sound-insulating pad and manufacturing technique thereof

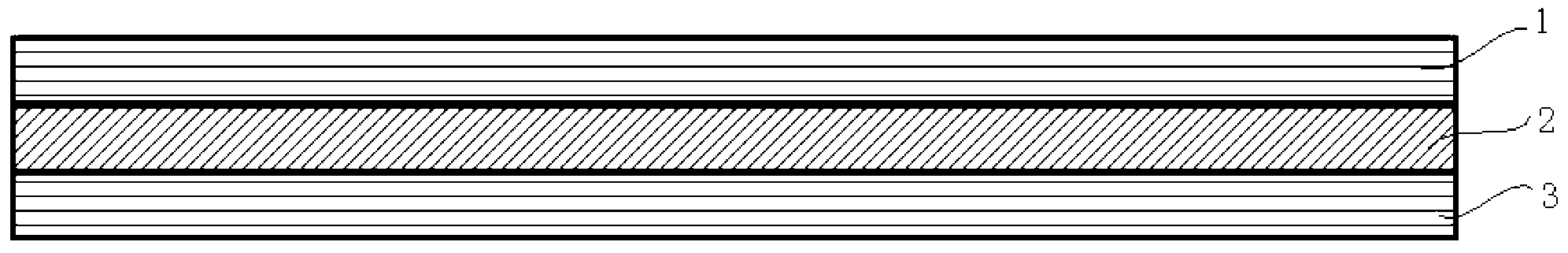

A technology of automobile sound insulation mat and manufacturing process, which is applied in vehicle parts, transportation and packaging, etc., can solve the problems of fiber felt with strong smell, fiber felt exposed, easy to pollute the environment, etc., to improve the sound absorption coefficient of low-frequency waves, and the sound absorption effect is good , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one: a kind of manufacturing process of automobile sound insulation pad, comprises following process step:

[0027] (1) Preparation of low-melting point fiber layer: Send low-melting point PET fiber from cotton feeder to carding machine for carding to form low-melting point fiber web; transport the low-melting point fiber web to cotton laying machine to form low-melting point fiber Among them, the speed of the cotton feeding machine is 20Hz, the speed of the carding machine doffer is 350 rpm, and the reciprocating frequency of the cotton laying machine is 4Hz; The speed is 200 rpm; the density of the low melting point fiber layer is 100g / m 2 ;

[0028] (2) Preparation of mixed fiber felt: Mix regenerated fiber, polyester fiber and low-melting point PET fiber evenly in a weight ratio of 40:20:20 to obtain mixed fiber; send the mixed fiber from the cotton feeder to the carding machine for carding to form Mixed fiber web; the mixed fiber web is transported to ...

Embodiment 2

[0033] Embodiment two: a kind of manufacturing process of automobile sound insulation pad, comprises following process step:

[0034] (1) Preparation of low-melting point fiber layer: Send low-melting point PET fiber from cotton feeder to carding machine for carding to form low-melting point fiber web; transport the low-melting point fiber web to cotton laying machine to form low-melting point fiber Among them, the speed of the cotton feeding machine is 30Hz, the speed of the carding machine doffer is 450 rpm, and the reciprocating frequency of the cotton laying machine is 10Hz; The speed is 300 rpm; the density of the low melting point fiber layer is 250g / m 2 ;

[0035] (2) Preparation of mixed fiber felt: Mix regenerated fiber, polyester fiber and low-melting point PET fiber evenly in a weight ratio of 60:30:30 to obtain mixed fiber; send the mixed fiber from the cotton feeder to the carding machine for carding to form Mixed fiber web; the mixed fiber web is transported to...

Embodiment 3

[0040] Embodiment three: a kind of manufacturing process of automobile sound insulation pad, comprises following process step:

[0041] (1) Preparation of low-melting point fiber layer: Send low-melting point PET fiber from cotton feeder to carding machine for carding to form low-melting point fiber web; transport the low-melting point fiber web to cotton laying machine to form low-melting point fiber layer; wherein, the speed of the cotton feeding machine is 25Hz, the speed of the carding machine doffer is 400 rpm, and the reciprocating frequency of the cotton laying machine is 5Hz; The speed is 250 rpm; the density of the low melting point fiber layer is 200g / m 2 ;

[0042] (2) Preparation of mixed fiber felt: Mix regenerated fiber, polyester fiber and low melting point PET fiber evenly in a weight ratio of 50:25:25 to obtain mixed fiber; send the mixed fiber from the cotton feeder to the carding machine for carding to form Mixed fiber web; the mixed fiber web is transport...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com