White-surface coated craft paper and production method thereof

A technology for coating kraft cardboard and production methods, which is applied in the field of kraft cardboard, and can solve the problem of uneven coverage of the pigment layer on the paper surface and ink absorption, easy delamination, breakage, bursting of the kraft cardboard, and difficulty in delamination, etc. problems, to achieve the effect of improving the covering effect of paint, facilitating the subsequent coating operation, and stabilizing the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

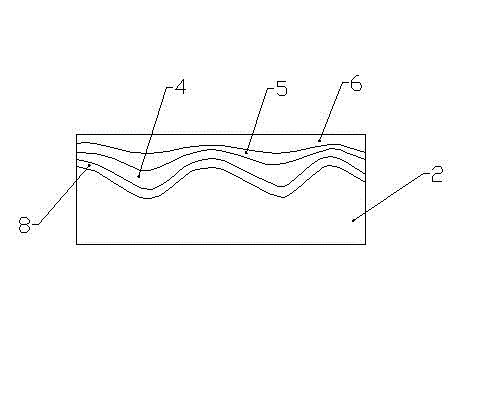

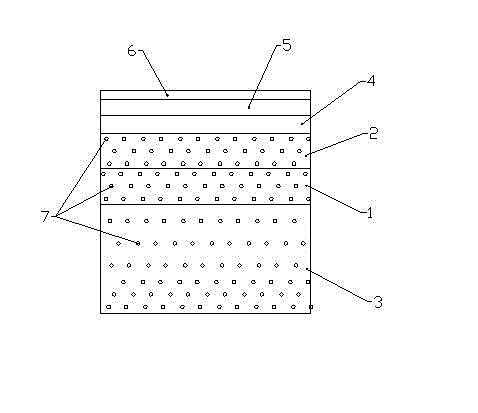

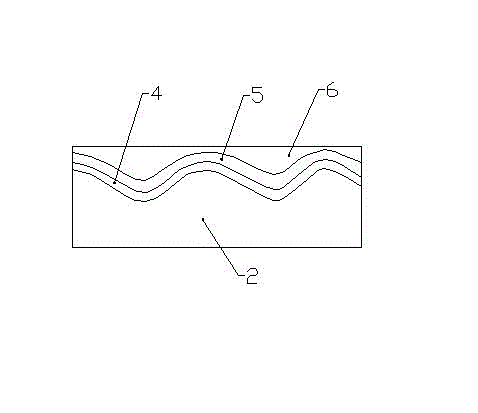

[0064] Example 1, such as figure 2 As shown, a white surface coated kraft cardboard comprises a core paper layer 1, the upper side of the core paper layer is a face paper layer 2, and the lower side is a bottom paper layer 3, and the upper surface of the face paper layer 2 is provided with three layers of coating Layers, from bottom to top are base coat 4, middle coat 5, and top coat 6.

[0065] The above-mentioned production method of white surface coated kraftboard comprises: waste paper batching; preparation of waste paper slurry; paper layer papermaking; coating base paper compounding, pre-drying, sizing, post-drying; coating and post-processing steps; wherein,

[0066] 1. Waste paper ingredients: In order to solve the problem of multiple sources of waste paper and disordered quality in large-scale production, the mass ratio of American waste: national waste: European waste: Japanese waste is 50%: 20%: 15%: 15%. Fully mixed first, and then pulping, the uniform mixing of...

Embodiment 2

[0100] Example 2, except that the following is different from Example 1, other processes are the same as in Example 1: in the step of making the bottom paper layer, 60% of the long-fiber waste paper pulp and 40% of the short-fiber waste paper pulp; in the step of making the core paper layer, Long fiber waste paper pulp 100%; in the step of making the face paper layer, use 100% bleached recycled fiber pulp DIP; in the sizing step, the concentration of starch paste is 1%, and the amount of penetrant, wet strength agent and paper strengthening agent to starch is respectively 1%, 10%, 1%; the latex in the base coat coating, mid coat coating and top coat coating steps consisted of 100% synthetic latex.

Embodiment 3

[0101] Embodiment 3, except following difference with embodiment 1, other processes are all the same as embodiment 1: make the bottom

[0102] In the paper layer step, long-fiber waste paper pulp is 40% and short-fiber waste paper pulp is 60%; in the core paper layer step, long-fiber waste paper pulp is 70% and short-fiber waste paper pulp is 30%; Pulp 30%, bleached hardwood pulp 50%, DIP pulp 20%; in the sizing step, the concentration of starch paste is 2%, and the amount of penetrant, wet strength agent, and paper strengthening agent to starch is 3%, 3%, and 3% respectively ; The latex in the primer coating, mid-coat coating and top coat coating steps is composed of 80% synthetic latex and 20% biological latex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freeness | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com