100% regenerated fiber spunlace non-woven fabric

A technology for spunlace non-woven fabrics and regenerated fibers, which is applied in fiber processing, non-woven fabrics, textiles and papermaking, etc., can solve the problems of water quality decline, poor cohesion and strength, and high dust content, and achieve extended service life or The number of times, the effect of improving cohesion and bonding, and improving physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

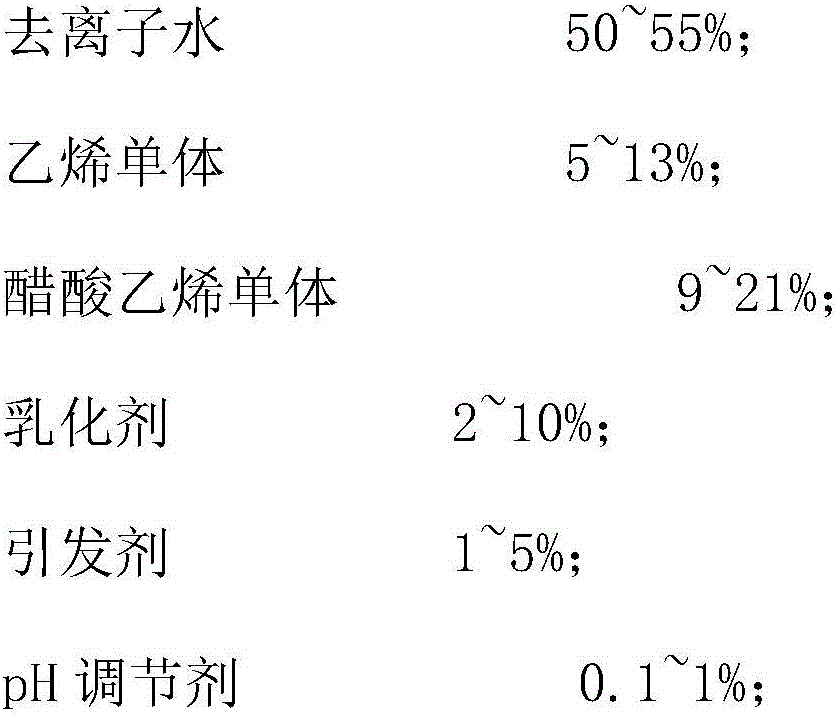

Image

Examples

Embodiment 1

[0042] A 100% regenerated fiber spunlace nonwoven fabric, characterized in that the method for producing a 100% regenerated fiber spunlace nonwoven fabric comprises the following steps:

[0043] (1) Raw material pretreatment: recycle scraps of spunlace non-woven fabrics or scraps of garment factories, carry out sub-inspection, and remove contaminated and contaminated scraps;

[0044] (2) Raw material reprocessing: On the raw materials sorted in step (1), spray a special fiber treatment agent in a spray mode, and stack the leftovers sprayed with the special fiber treatment agent from bottom to top, and then cover Cover the film tightly for 24 hours;

[0045] (3) Opening: Take off the film, take out the leftover material, and open it, focusing on removing impurities and fine dust;

[0046] (4) Mixing and impurity removal: Feed the opened regenerated fiber into the cotton mixing system for further mixing, dust removal and impurity removal;

[0047] (5) Carding into a net: It is carded by ...

Embodiment 2

[0058] A 100% regenerated fiber spunlace nonwoven fabric, characterized in that the method for producing a 100% regenerated fiber spunlace nonwoven fabric comprises the following steps:

[0059] (1) Raw material pretreatment: recycle scraps of spunlace non-woven fabrics or scraps of garment factories, carry out sub-inspection, and remove contaminated and contaminated scraps;

[0060] (2) Raw material reprocessing: On the raw materials sorted in step (1), spray a special fiber treatment agent in a spray mode, and stack the leftovers sprayed with the special fiber treatment agent from bottom to top, and then cover The film is sealed for 26 hours;

[0061] (3) Opening: Remove the film, take out the leftover material, and open it, focusing on removing impurities and fine dust;

[0062] (4) Mixing and impurity removal: feed the opened regenerated fiber into the cotton mixing system for further mixing, dust removal and impurity removal;

[0063] (5) Carding into a net: It is carded by a fixe...

Embodiment 3

[0074] A 100% regenerated fiber spunlace non-woven fabric, characterized in that the method for producing a 100% regenerated fiber spunlace non-woven fabric comprises the following steps:

[0075] (1) Raw material pretreatment: recycle scraps of spunlace non-woven fabrics or scraps of garment factories, carry out sub-inspection, and remove contaminated and contaminated scraps;

[0076] (2) Raw material reprocessing: On the raw materials sorted in step (1), spray a special fiber treatment agent in a spray mode, and stack the leftovers sprayed with the special fiber treatment agent from bottom to top, and then cover Cover the film tightly for 30 hours;

[0077] (3) Opening: Remove the film, take out the leftover material, and open it, focusing on removing impurities and fine dust;

[0078] (4) Mixing and impurity removal: feed the opened regenerated fiber into the cotton mixing system for further mixing, dust removal and impurity removal;

[0079] (5) Carding into a net: It is carded by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com