Composite structure filter felt and its preparation method and application

A composite structure and filter felt technology, which is applied in the field of filter materials, can solve the problems of short service life, low air filtration efficiency, secondary pollution, etc., and achieve prolonging service life, improving charge persistence dependence, and high fiber specific surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

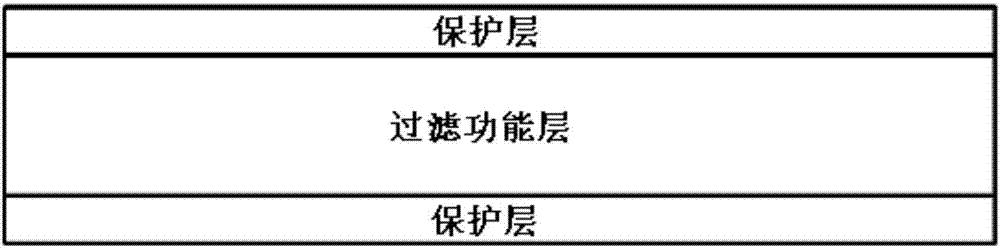

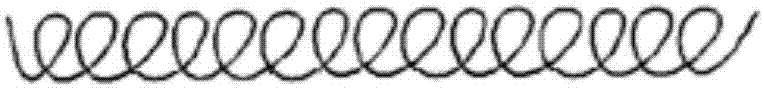

[0035] A filter felt with a composite structure in this embodiment, the schematic diagram of its laminated structure is as follows figure 1 As shown, it consists of a filter functional layer and a protective layer coated on the upper and lower surfaces of the filter functional layer, wherein the filter functional layer is composed of a regenerated fiber layer with a three-dimensional crimped structure fiber and an electrospun nanofiber layer. The protective layer on the upper and lower surfaces has a grammage of 25g / m 2 Metallocene polypropylene spunbonded single-layer nonwoven fabric; the regenerated fiber layer has a grammage of 15g / m 2 The Z-shaped crimped viscose fiber web layer, wherein the viscose fiber has a non-circular interface, no cavity, the fiber diameter is 30-35 μm, and the number of crimps is 12 / 25mm. The Z-shaped crimped viscose fiber Structural diagram such as figure 2 Shown; The nanofiber layer has a grammage of 0.8g / m 2 The polylactic acid fiber layer, ...

Embodiment 2

[0040] A filter felt with a composite structure in this embodiment, the schematic diagram of its laminated structure is as follows figure 1 As shown, it consists of a filter functional layer and a protective layer coated on the upper and lower surfaces of the filter functional layer, wherein the filter functional layer is composed of a regenerated fiber layer with a three-dimensional crimped structure fiber and an electrospun nanofiber layer. The protective layer on the upper and lower surfaces has a grammage of 20g / m 2 Metallocene polypropylene and ordinary polypropylene SMS nonwoven fabrics; the regenerated fiber layer is a helical crimped cuprammonium fiber single fiber, wherein the cuprammonium fiber has a cavity, the cavity ratio is 15%, and the fiber diameter is 20~ 25 μm, the number of crimps is 15 / 25mm, the structure schematic diagram of the copper ammonium fiber with helical crimp structure is as follows image 3 Shown; The nanofiber layer has a grammage of 0.1g / m 2...

Embodiment 3

[0045] A filter felt with a composite structure in this embodiment, the schematic diagram of its laminated structure is as follows figure 1 As shown, it consists of a filter functional layer and a protective layer coated on the upper and lower surfaces of the filter functional layer, wherein the filter functional layer is composed of a regenerated fiber layer with a three-dimensional crimped structure fiber and an electrospun nanofiber layer. The protective layer on the upper and lower surfaces has a grammage of 40g / m 2 of polyethylene and 25g / m 2 Polyolefin copolymer spunbonded nonwoven fabric; the regenerated fiber layer has a grammage of 10g / m 2 Saponified acetate fiber with wavy crimp structure, wherein the saponified acetate fiber has no cavity, non-circular cross-section, fiber diameter of 5-10 μm, and number of crimps is 8 / 25mm, the saponified acetate fiber with wavy crimp structure Structural diagram such as Figure 4 Shown; The nanofiber layer has a grammage of 1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com