Method for manufacturing ceiba heat-preserving material and ceiba heat-preserving material

A kapok and kapok fiber technology, applied in non-woven fabrics, textiles, papermaking, fiber processing, etc., can solve the problems of unstable fiber web quality and poor web formation, achieve soft hand feel, overcome poor web formation, and effectively keep warm in texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

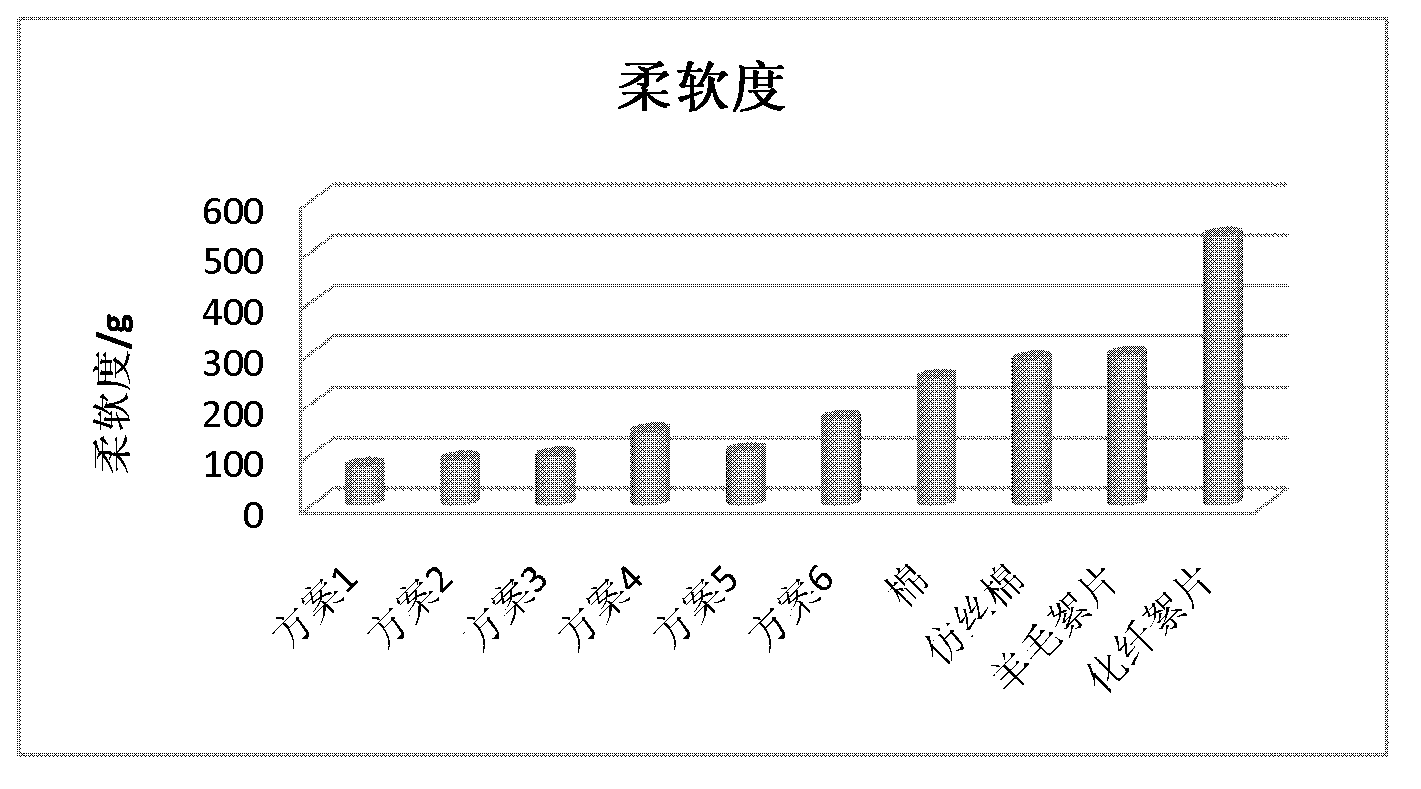

Embodiment 1

[0035] The components and weight percentages of selected fiber raw materials are: kapok fiber (imported from Indonesia) 30%; 2.2dtex polyester solid fiber (YZW122 model product produced by Yizheng Chemical Fiber) 62%; 2.2dtex low-melting point polyester fiber (produced by Huvis) U11 model products) 8%. Operate as follows: 1. Put the kapok fiber in the premixer first, then spray the antistatic agent (water) on the kapok fiber with a ratio of 3%, premix for 4 hours, and control the air humidity > 60%; 2. Opening and mixing cotton; 3. Adjusting the feeding air volume power to 20Hz; 4. Carding; 5. Cross-lapping; 6. Drafting with a draft ratio of 1:1.6; Acrylic emulsion, the K2 model product produced by Rohm and Haas Company), the amount of spray glue is 2g / m 2 ; 8. Pass through an oven (temperature 130° C.), lightly ironed with a hot roller, and cooled by a blower; 9. Winding; 10. Packing. Obtain the kapok thermal insulation material sample of scheme 1 of the present invention. ...

Embodiment 2

[0037]The components and weight percentages of selected fiber raw materials are: kapok fiber (imported from Indonesia) 24%; 2.2dtex polyester solid fiber (YZW122 model product produced by Yizheng Chemical Fiber) 68%; 4.4dtex low-melting point polyester fiber (produced by Yuanfang Industry) SN-84501CM model product) 8%. Operate according to the following process: 1. Put the kapok fiber in the pre-mixer first, then spray the antistatic additive (silicone oil) on the kapok fiber at a ratio of 1%, pre-mix for 2 hours, and control the air humidity > 60% ; 2. Opening and mixing cotton; 3. Adjusting the cotton feeding air volume power to 25Hz; 4. Carding; 5. Cross-lapping; 6. Drafting with a draft ratio of 1:1.1; Polyvinyl acetate emulsion, VAE 707 model product produced by Beijing Zhonghui United Company), the amount of spray glue is 4g / m 2 ; 8. Pass through an oven (temperature 130° C.), lightly ironed with a hot roller, and cooled by a blower; 9. Winding; 10. Packing. Obtain the...

Embodiment 3

[0039] The components and weight percentages of selected fiber raw materials are: kapok fiber (imported from Indonesia) 24%; 3.33dtex three-dimensional hollow polyester fiber (YZK600 model product produced by Yizheng Chemical Fiber) 44%; 2.2dtex solid silicon-containing polyester fiber (Yizheng Chemical Fiber) YZW122 model product produced) 20%; 2.2dtex low-melting point polyester fiber (SN-84501CM model product produced by Yuanfang Industry) 12%. . Operate according to the following process: 1. Put the kapok fiber in the pre-mixer first, then spray the antistatic additive (water) on the kapok fiber at a ratio of 3%, pre-mix for 2 hours, and control the air humidity > 60% ; 2. Opening and mixing cotton; 3. Adjusting the cotton feeding air volume power to 30Hz; 4. Carding; 5. Cross-lapping; 6. Drafting with a draft ratio of 1:1.4; Pure acrylic emulsion, K2 model product produced by Rohm and Haas Company), the amount of spray glue is 1g / m 2 ; 8. Pass through an oven (temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com