Method for making iron-free clothing using natural fiber and regenerated fiber fabric

A technology of regenerated fiber and natural fiber, applied in the direction of fiber type, fiber treatment, plant fiber, etc., can solve the problems of affecting the effect of non-ironing, increasing production cost, low production efficiency, etc., and achieves reduced strength damage, stable shape, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

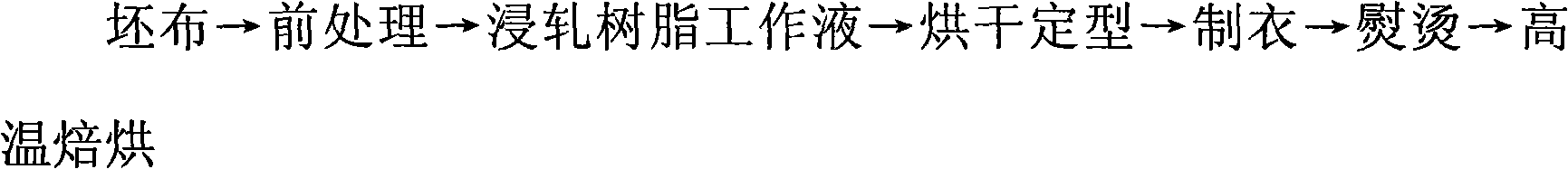

Method used

Image

Examples

Embodiment 1

[0054] 1. Fabric pre-treatment

[0055] Set the specification to 40 S ×21 S / 2×100×50×58” cotton yarn-dyed Oxford spinning is subjected to pre-treatments such as singeing, desizing, mercerizing, pickling, etc., so that the pH value of the cloth surface is within the range of 4.5-7.

[0056] 2. Padding resin working fluid

[0057] The padding resin working solution formula is selected: etherified dimethylol dihydroxyethylene urea resin 90g / l, magnesium chloride 15g / l, amino silicone oil emulsion 18g / l, polyoxyethylene wax emulsion 25g / l. Use glacial acetic acid to adjust the pH of the working solution to 4.5-5, and pad the pre-treated cotton yarn-dyed Oxford fabric on the setting car, using one dipping and one rolling, the dipping time: 1 second, and the roll pressure is 0.3Pa. The surplus rate is 70%.

[0058] 3. Drying and shaping

[0059] The speed of the shaping car is 50m / min, and the temperature of the drying room is 110°C.

[0060] 4. Clothing

[0061] The shaped c...

Embodiment 2

[0067] It is 100 that the fabric of embodiment 1 is changed into specification S / 2×100 S / 2×130×90×58” cotton yarn-dyed poplin, change the baking temperature to 135°C, and keep the rest unchanged, another non-ironing shirt can be made.

Embodiment 3

[0069] 1. Fabric pre-treatment

[0070] Set the specification to 100 S / 2×40 S ×160×90×58 / 59” cotton khaki is subjected to pre-treatments such as singeing, desizing, scouring, mercerizing, dyeing, etc., and pickling to make the pH of the fabric within the range of 4.5-7.

[0071] 2. Padding resin working fluid

[0072] Select resin working fluid formula: etherified dimethylol dihydroxyethylene urea resin 80g / l, magnesium chloride heptahydrate: 20g / l, amino silicone oil emulsion 20g / l, polyoxyethylene wax emulsion 20g / l, add glacial acetic acid to adjust Until the pH value of the resin working solution is 4-4.5. The pre-treated fabric is pad-rolled on the sizing car, using two-dipping and two-rolling, the first dipping time is 0.5 seconds, the roll pressure is 0.3Pa, the excess rate is 70%, the second dipping time is 0.5 seconds, and the roll pressure is 0.35Pa , The surplus rate is 70%.

[0073] 3. Drying and shaping

[0074] The speed of the shaping car is 55m / min, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com