Method for improving net retention rate of regenerated fiber cultural paper

A retention rate and paper machine technology, applied in the field of waste paper papermaking, can solve the problems of large retention rate interference, low first-pass retention rate, and low waste paper utilization rate, so as to facilitate the operation rate, stability and retention of paper machines The effect of improving efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

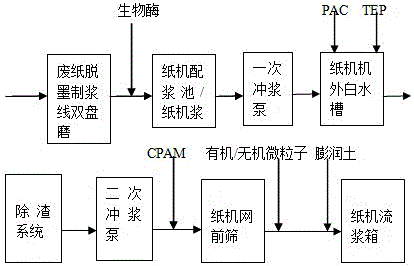

[0042] A method for improving the retention rate of regenerated fiber cultural paper network, the method steps are as follows:

[0043] 1) Biological enzyme treatment

[0044] First, use a small flow metering pump to add biological enzyme 0.1kg / t paper to the 1.0m outlet of the double disc mill outlet of the waste paper deinking pulp line to carry out biological enzyme treatment on the waste paper pulp. The flow rate of the biological enzyme is 50ml / min. The temperature of waste paper pulp is controlled at <50°C, and the pH value of waste paper pulp is controlled at 7.0.

[0045] 2) Combined treatment of cationic polyaluminum chloride PAC and sticky matter control agent TEP

[0046] Use a small flow metering pump to add cationic polyaluminum chloride PAC 4.0kg / t paper to the entrance of the white water tank outside the paper machine at 0.5m, the flow rate of cationic polyaluminum chloride PAC is 1.0l / min, and then use a small flow metering pump Add sticky matter control agen...

Embodiment 2

[0050] A method for improving the retention rate of regenerated fiber cultural paper network, the method steps are as follows:

[0051] 1) Biological enzyme treatment

[0052] First, use a small flow metering pump to add biological enzyme 0.2kg / t paper to the outlet of the double disc mill of the waste paper deinking pulp line 1.0m to carry out biological enzyme treatment on the waste paper pulp. The flow rate of the biological enzyme is 70ml / min. The temperature of the waste paper pulp is controlled at <50°C, and the pH value of the waste paper pulp is controlled at 8.0.

[0053] 2) Combined treatment of cationic polyaluminum chloride PAC and sticky matter control agent TEP

[0054] Use a small flow metering pump to add cationic polyaluminum chloride PAC 5.0kg / t paper to the entrance of the white water tank outside the paper machine at 0.5m, the flow rate of cationic polyaluminum chloride PAC is 5.0l / min, and then use a small flow metering pump Add sticky matter control age...

Embodiment 3

[0058] A method for improving the retention rate of regenerated fiber cultural paper network, the method steps are as follows:

[0059] 1) Biological enzyme treatment

[0060] First, use a small flow metering pump to add biological enzyme 0.15kg / t paper to the 1.0m outlet of the double disc mill outlet of the waste paper deinking pulp line to carry out biological enzyme treatment on the waste paper pulp. The flow rate of the biological enzyme is 90ml / min. The temperature of waste paper pulp is controlled at <50°C, and the pH value of waste paper pulp is controlled at 7.5.

[0061] 2) Combined treatment of cationic polyaluminum chloride PAC and sticky matter control agent TEP

[0062] Use a small flow metering pump to add cationic polyaluminum chloride PAC 4.5kg / t paper to the 0.5m entrance of the white water tank outside the paper machine. The flow rate of cationic polyaluminum chloride PAC is 3.0l / min, and then use a small flow metering pump to feed Add sticky matter contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com