Polylactic acid composite fiber interior material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

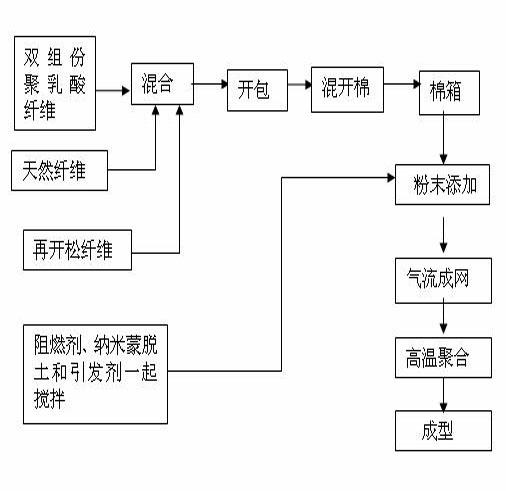

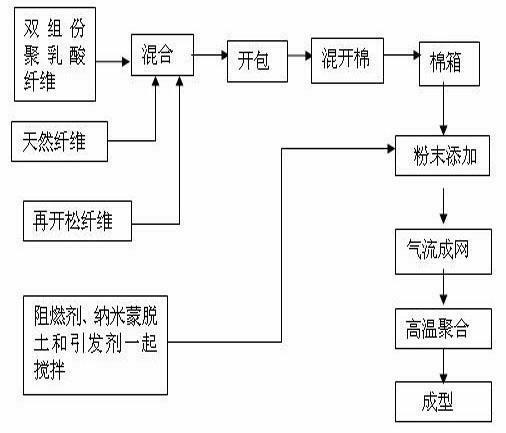

Method used

Image

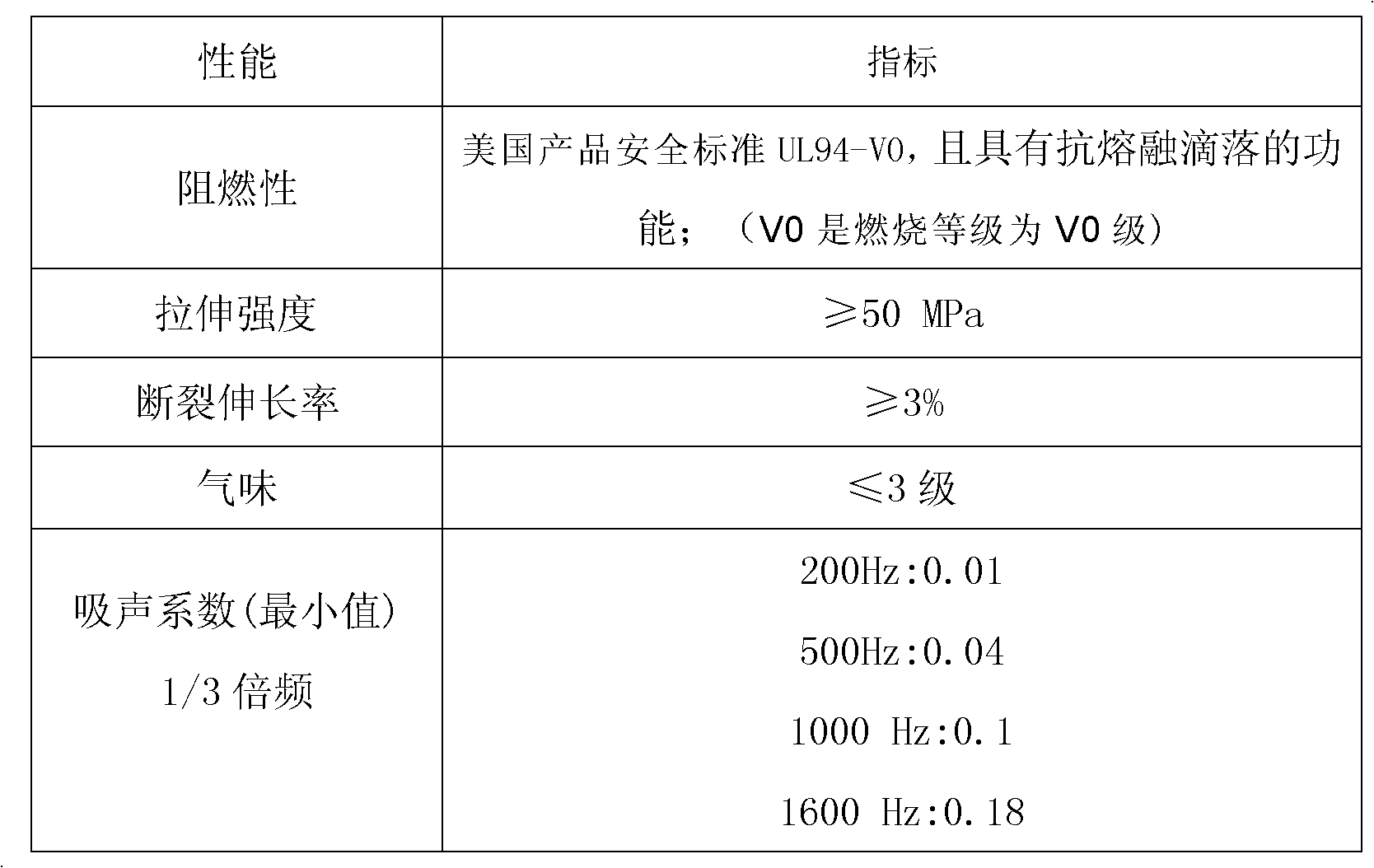

Examples

Embodiment 1

[0020] Take by weighing polylactic acid fiber 22kg, regenerated fiber 25kg, jute fiber 40kg respectively, the total amount of taking by weighing three kinds of fibers is 87Kg each time, mix in mixer and become mixed fiber. Respectively weigh 8 kg of flame retardant, 3 kg of nano-montmorillonite and 2 kg of initiator, mix uniformly, stir at a high speed for 10 minutes, and the screw speed is 100 rpm, and then extruded by the screw to cool and pulverize into powder.

[0021] After the mixed fiber is opened by the bale opener, it is sent to the mixed opener for further opening, and then sent to the cotton box, and the cotton box outputs the mixed fiber to the air-laid machine with a conveying curtain. Add the powder into the powder applicator, set the speed of the applicator spreading roller to 1.5 rpm, output the powder on the conveying curtain, and send it into the air-laid machine together with the mixed fibers to form a fiber web and convey it to in the oven. Control the ove...

Embodiment 2

[0026] Take by weighing 40kg of polylactic acid fiber, 25.9kg of regenerated fiber, and 22kg of jute fiber respectively, and the total amount of the three kinds of fibers is 87.9Kg each time, and they are mixed uniformly in a mixer to form a mixed fiber. Respectively weigh 10kg of flame retardant, 2kg of nano-montmorillonite and 0.1kg of initiator, mix uniformly, stir at a high speed for 15min at a screw speed of 150rpm, extrude, cool, and pulverize into powder.

[0027] After the mixed fiber is opened by the bale opener, it is sent to the mixed opener for further opening, and then sent to the cotton box, and the cotton box outputs the mixed fiber to the air-laid machine with a conveying curtain. Add the powder into the powder applicator, set the speed of the applicator spreading roller to 3 rpm, output the powder on the conveying curtain, and send it into the air-laid machine together with the mixed fibers to form a fiber web and convey it to in the oven. Control the tempera...

Embodiment 3

[0032] Take by weighing polylactic acid fiber 29kg, regenerated fiber 30kg, jute fiber 28kg respectively, the total amount of taking by weighing three kinds of fibers is 87Kg at every turn, mixes in mixer and becomes mixed fiber. Respectively weigh 9kg of flame retardant, 3kg of nano-montmorillonite and 1kg of initiator, mix uniformly, stir at a high speed for 15min at a screw speed of 150rpm, extrude, cool, and pulverize into powder.

[0033]After the mixed fiber is opened by the bale opener, it is sent to the mixed opener for further opening, and then sent to the cotton box, and the cotton box outputs the mixed fiber to the air-laid machine with a conveying curtain. Add the powder into the powder applicator, set the speed of the applicator spreading roller to 2 rpm, output the powder on the conveying curtain, and send it into the air-laid machine together with the mixed fibers to form a fiber web and convey it to in the oven. Control the temperature of the oven at 160°C, po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com