Silk fabric color fixing agent and preparation method thereof

A color-fixing agent and technology for silk fabrics, applied in dyeing, textiles and papermaking, etc., can solve problems such as hue changes, prevent shedding or hydrolysis, improve color fastness, and have no secondary pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

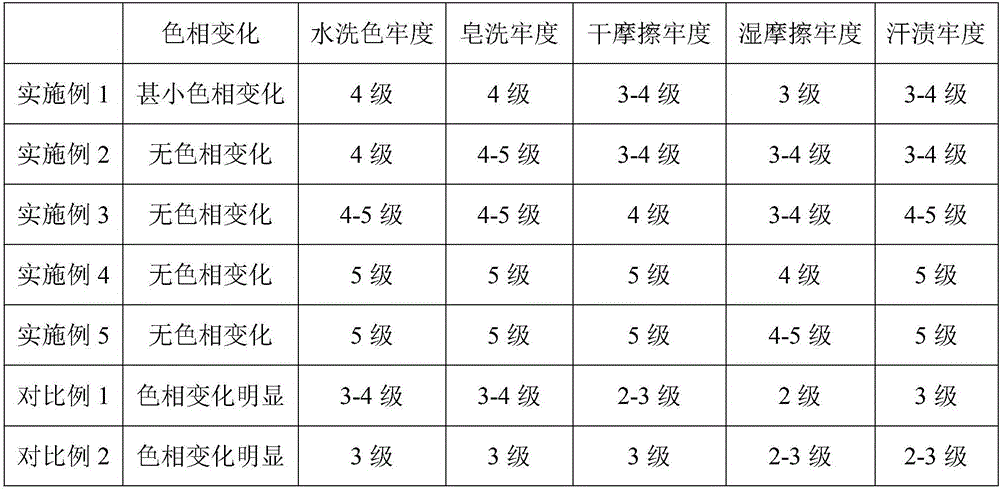

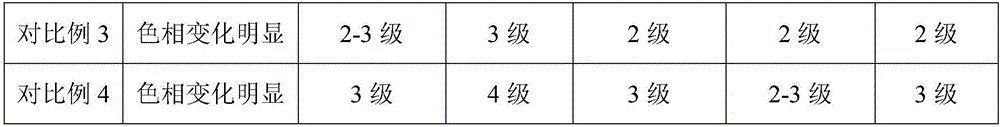

Examples

Embodiment 1

[0015] In the embodiment of the present invention, a color fixing agent for silk fabrics is composed of the following raw materials in parts by weight: 41 parts of alkanolamide polyoxyethylene ether S, 5 parts of dichloropropane, polydimethyldiallyl chloride Ammonium 10 parts, dimethyl sulfoxide 17 parts, fatty alcohol polyoxyethylene ether 3 parts, dichloroacetic acid 13 parts.

[0016] Dichloroacetic acid and deionized water are mixed to prepare a dichloroacetic acid solution with a mass concentration of 17%; fatty alcohol polyoxyethylene ether is mixed with deionized water whose mass is 8.7 times to prepare a fatty alcohol polyoxyethylene ether solution. Mix alkanolamide polyoxyethylene ether S with dimethyl sulfoxide and polydimethyldiallylammonium chloride, raise the temperature to 60°C, and stir at this temperature for 40 minutes, then add fatty alcohol poly Oxyethylene ether solution, heated up to 94°C and stirred at this temperature for 22 minutes; then added dichlorop...

Embodiment 2

[0018] In the embodiment of the present invention, a color fixing agent for silk fabrics is composed of the following raw materials in parts by weight: 49 parts of alkanolamide polyoxyethylene ether S, 13 parts of dichloropropane, polydimethyldiallyl chloride 18 parts of ammonium, 25 parts of dimethyl sulfoxide, 7 parts of fatty alcohol polyoxyethylene ether, and 21 parts of dichloroacetic acid.

[0019] Dichloroacetic acid and deionized water are mixed to prepare a dichloroacetic acid solution with a mass concentration of 17%; fatty alcohol polyoxyethylene ether is mixed with deionized water whose mass is 8.7 times to prepare a fatty alcohol polyoxyethylene ether solution. Mix alkanolamide polyoxyethylene ether S with dimethyl sulfoxide and polydimethyldiallylammonium chloride, raise the temperature to 60°C, and stir at this temperature for 40 minutes, then add fatty alcohol poly Oxyethylene ether solution, heated up to 94°C and stirred at this temperature for 22 minutes; the...

Embodiment 3

[0021] In the embodiment of the present invention, a color fixing agent for silk fabrics is composed of the following raw materials in parts by weight: 43 parts of alkanolamide polyoxyethylene ether S, 7 parts of dichloropropane, polydimethyldiallyl chloride 12 parts of ammonium, 19 parts of dimethyl sulfoxide, 4 parts of fatty alcohol polyoxyethylene ether, and 15 parts of dichloroacetic acid.

[0022] Dichloroacetic acid and deionized water are mixed to prepare a dichloroacetic acid solution with a mass concentration of 17%; fatty alcohol polyoxyethylene ether is mixed with deionized water whose mass is 8.7 times to prepare a fatty alcohol polyoxyethylene ether solution. Mix alkanolamide polyoxyethylene ether S with dimethyl sulfoxide and polydimethyldiallylammonium chloride, raise the temperature to 60°C, and stir at this temperature for 40 minutes, then add fatty alcohol poly Oxyethylene ether solution, heated up to 94°C and stirred at this temperature for 22 minutes; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com