Patents

Literature

31 results about "Propylene dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene Dichloride (1,2-Dichloropropane) 78-87-5. Hazard Summary. Propylene dichloride is used as a chemical intermediate in several industries. Acute (short-term) inhalation exposure to high levels of propylene dichloride by humans results in effects on the lungs, gastrointestinal system, blood, liver, kidneys, central nervous system, and eyes.

Process of producing logistic tray with waste plastics

InactiveCN1887952AReduce pollutionHigh strengthRigid containersProduction logisticsPolyethylene glycol

The process of producing logistic tray with waste plastics relates to utilization of waste plastics. Waste polyethylene and polypropylene plastics are produced into logistic tray through the steps of washing, drying, sorting, crushing, adding modifier and injection molding. The modifier comprises propylene dichloride resin, calcium carbonate, stearate and surfactant polyethylene glycol. The present invention produces logistic tray with waste plastic completely and is environment friendly, and the produced logistic tray has high strength, durable and with less deformation.

Owner:HUBEI TONGJITANG PHARMACY

Method for preparing 4,4'-dichloro sulfobenzide

ActiveCN106349126AMild reaction conditionsHigh reaction yieldOrganic chemistryOrganic compound preparationAcetic acidReaction temperature

The invention discloses a method for preparing 4,4'-dichloro sulfobenzide. 4,4'-dichloro diphenyl sulfoxide is taken as a raw material, sulfuric acid is taken as a catalyst and propylene dichloride and glacial acetic acid are taken as solvents. Under the reaction temperature at 60-90 DEG C, hydrogen peroxide is taken as an oxidizing agent and is used for oxidizing 4,4'-dichloro diphenyl sulfoxide and preparing 4,4'-dichloro sulfobenzide, wherein the concentration of hydrogen peroxide is 30%-50% and the dosage of the catalyst sulfuric acid is 6%-12% of the quantity of 4,4'-dichloro diphenyl sulfoxide, the dosage of the dissolvent propylene dichloride is 80%-120% of the quantity of 4,4'-dichloro diphenyl sulfoxide, the dosage of the glacial acetic acid is 15%-20% of the quantity of 4,4'-dichloro diphenyl sulfoxide and the reaction time is 90-120 minutes. The method provided by the invention has the advantages of mild reaction condition, high reaction yield, high catalytic efficiency and recoverable catalytic system and reaction solvent.

Owner:江西金海新能源科技有限公司

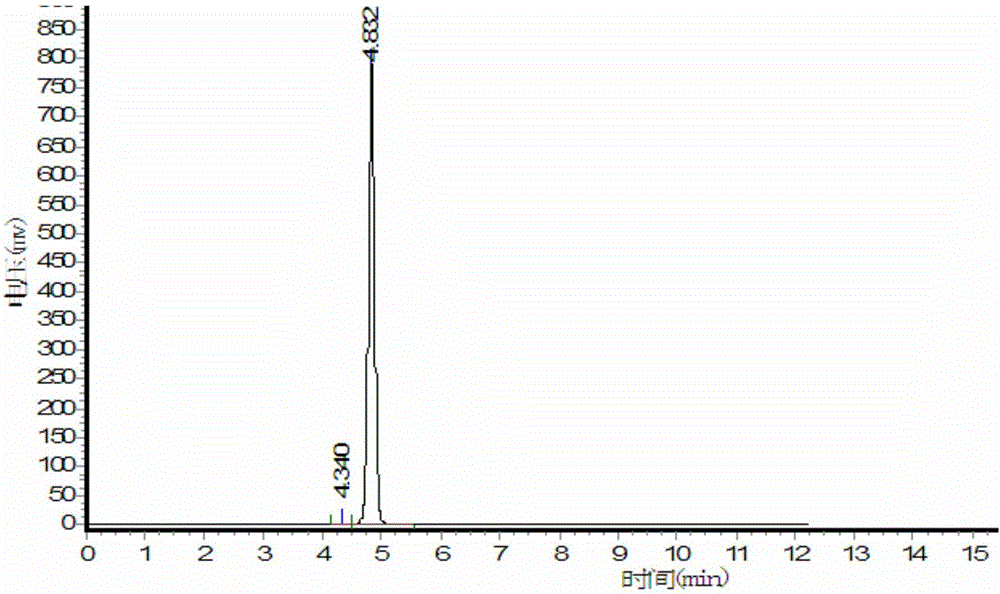

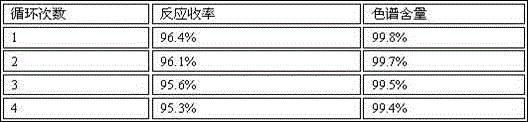

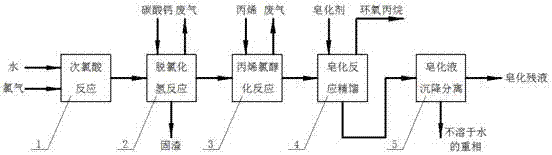

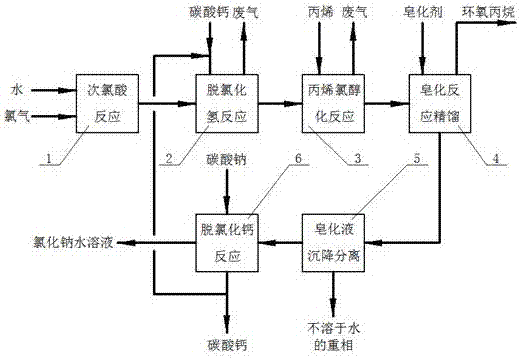

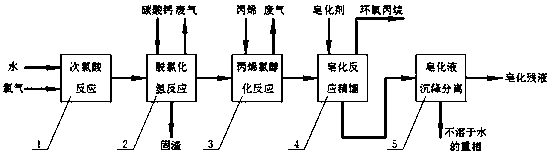

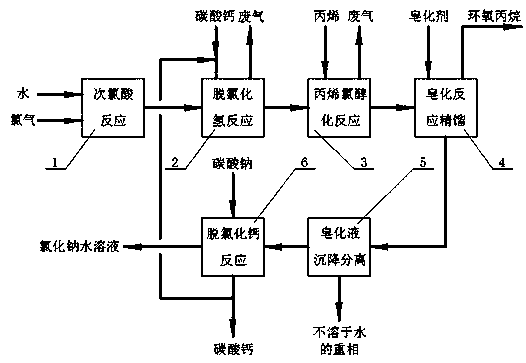

Technology for preparing epoxypropane from propylene chlorohydrin through single acid process

The invention provides a technology for preparing epoxypropane from propylene chlorohydrin through a single acid process. According to the invention, firstly, chlorine reacts with water so as to generate hypochlorous acid and hydrogen chloride, and hydrogen chloride is removed with calcium carbonate before the propylene chlorohydrin reaction, so that chlorine and propylene are prevented from coming into contact with each other to generate propylene dichloride and chloropropanol and hydrogen chloride are prevented from coming into contact with each other to generate propylene dichloride. Propylene and chlorine are added. According to the invention, the yield of epoxypropane can be obviously increased. According to the invention, only epoxypropane is distilled in a saponification distillation process, the operation of steam stripping for propylene dichloride is not required and the energy consumption can be obviously reduced. Calcium chloride in saponification wastewater is converted into sodium chloride and calcium carbonate under the effect of sodium carbonate; the calcium carbonate is reused for removing hydrogen chloride generated from hypochlorous acid reaction or preparing calcium carbonate commodity; the saponification wastewater containing sodium chloride is used for electrolysis alkali preparation or evaporation concentration and membrane separation concentration so as to acquire industrial sodium chloride.

Owner:吴剑华

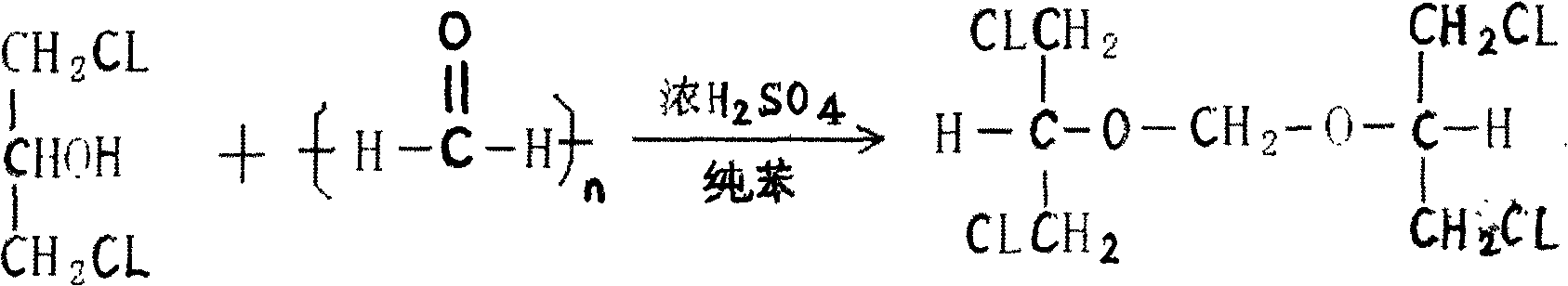

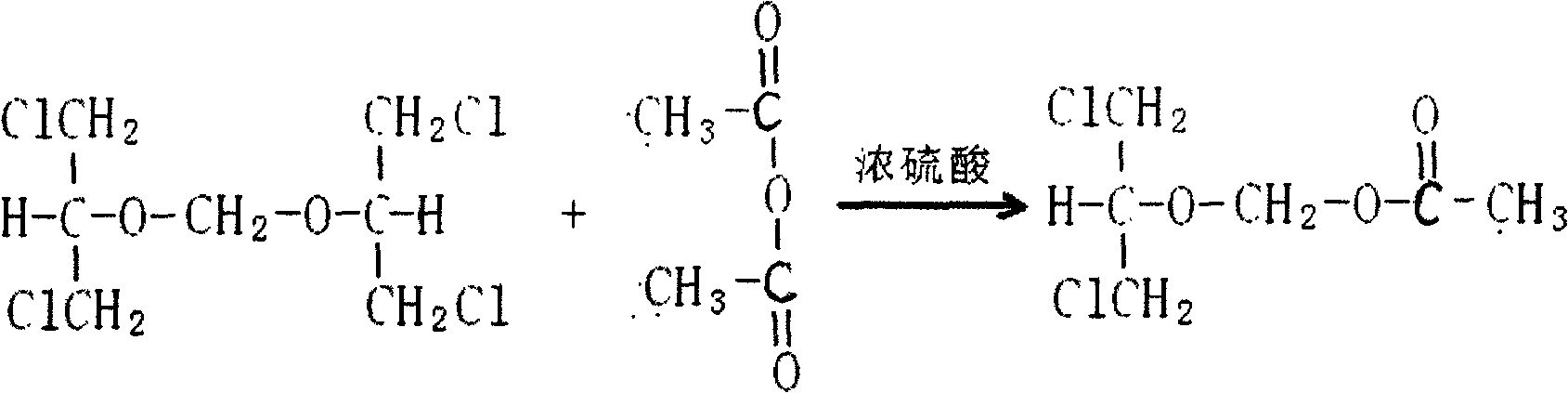

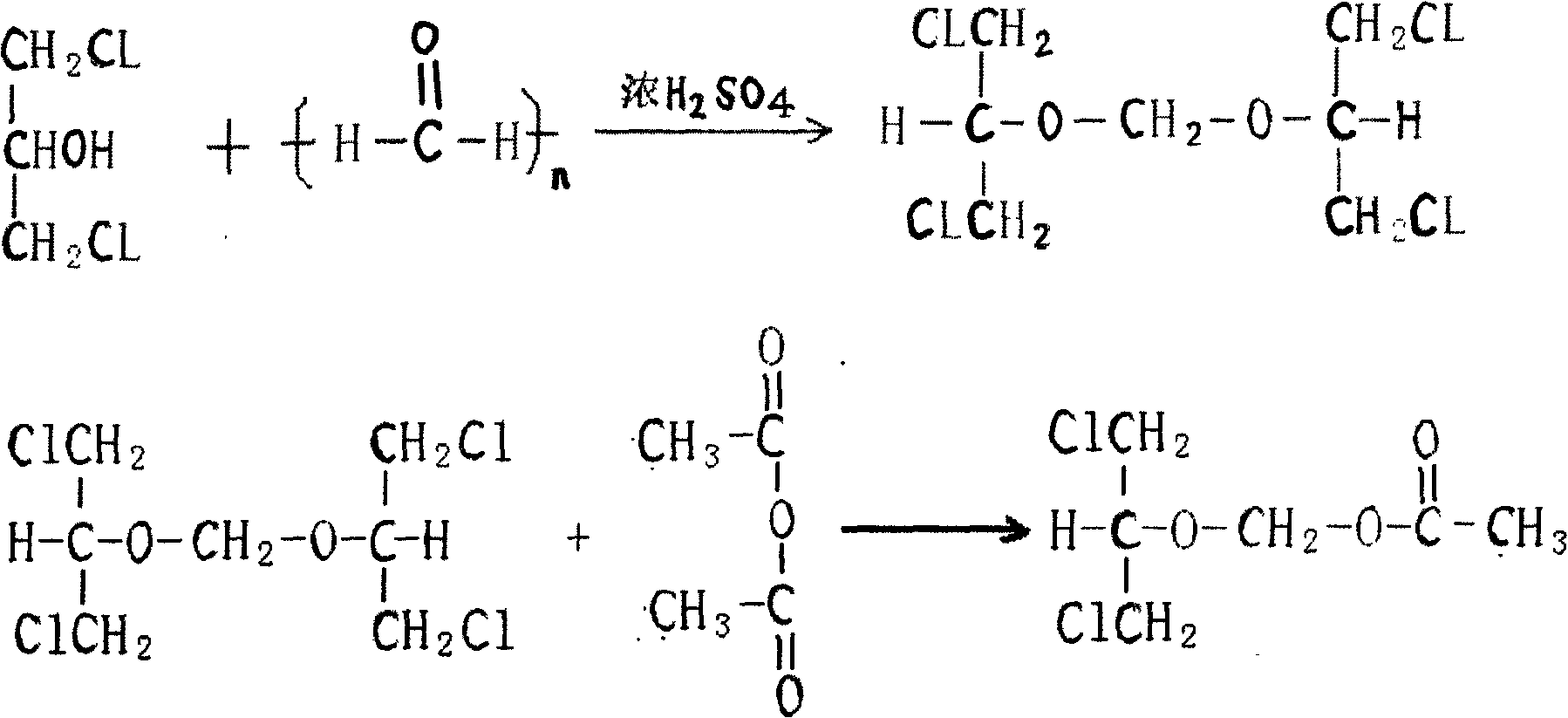

Preparation method of 2-acetoxyl group methoxy group-1.3-propylene dichloride

InactiveCN103130642AQuality improvementShort reaction timeOrganic compound preparationCarboxylic acid esters preparationAlcoholAcetic anhydride

Disclosed is a preparation method of 2-acetoxyl group methoxy group-1.3-propylene dichloride. The following substances are extracted according to weight ratio: 250kg of 1.3-dichloro-2-propyl alcohol, 60kg of paraformaldehyde, 3.68kg of vitriol, 250kg of acetic anhydride and 5kg of potassium acetate; the 1.3-dichloro-2-propyl alcohol, the paraformaldehyde and the vitriol are added to a clean and dry reaction still and are warmed slowly, the temperature rises to 96 DEG C to 98 DEG C in 2 hours, and heat preservation is carried out for 2 hours; the temperature is lowered to 10 DEG C after heat preservation, the acetic anhydride is dropped to the reaction still, and the temperature is kept between 15 DEG C and 20 DEG C; after the acetic anhydride is added, the temperature rises to 35 DEG C to 40 DEG C, and heat preservation is carried out for 10 hours; the potassium acetate is added to the reaction still, stirring is conducted, the acetic anhydride is recycled in vacuum to 100 DEG C, the temperature is lowered to 20 DEG C, and filtering is conducted; and filter liquor is pumped into a rectifying still, steamed cut fraction in a state of 115 DEG C / 10mmHg is collected, and the 2-acetoxyl group methoxy group-1.3-propylene dichloride with 80% of weight yield and more than or equal to 95% of content is obtained. According to the preparation method of the 2-acetoxyl group methoxy group-1.3-propylene dichloride, production cost is reduced, and yield is improved.

Owner:HUBEI BAOLE PHARMA

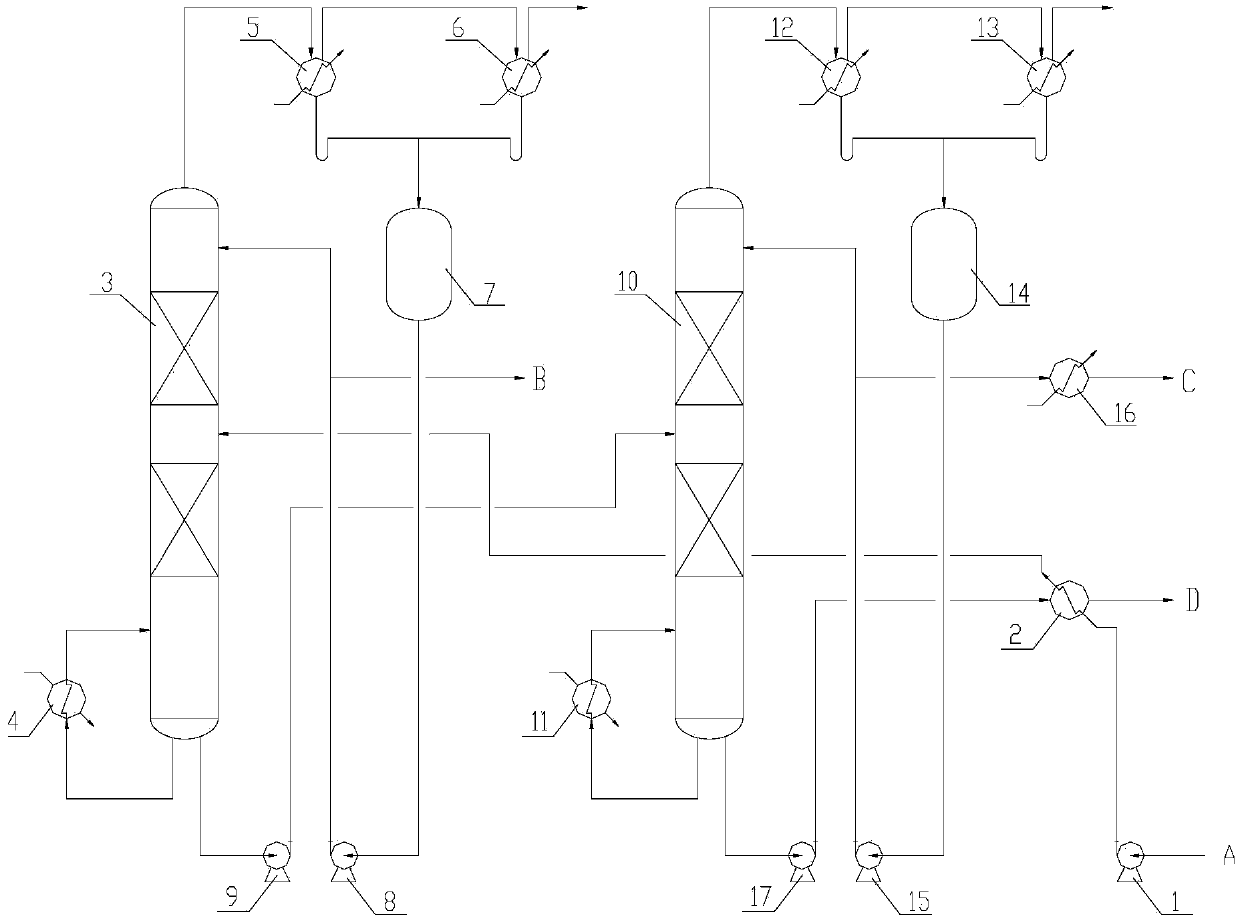

Industrial device and continuous rectification method for extracting 1,2-propylene dichloride from chlorohydrin process epoxypropane waste liquid

InactiveCN104211564AEmission reductionNo irritating smellHalogenated hydrocarbon preparation1,2-DichloropropaneEconomic benefits

The invention relates to an industrial device and a continuous rectification method for extracting 1,2-propylene dichloride from chlorohydrin process epoxypropane waste liquid. The method comprises the following steps: rectifying the epoxypropane waste liquid, condensing stage by stage, rectifying, condensing, and separating to obtain 1,2-propylene dichloride. The method has the advantages that obtained 1,2-propylene dichloride is colorless, transparent and free of pungent smell and has the purity of 95%-99% by weight and the yield of 90%-95%, and equipment corrosion is avoided. According to the continuous rectification process, an azeotropic agent-water does not need to be added, so that the problem of equipment corrosion is avoided; meanwhile, the rectification process is continuously carried out, so that the production efficiency is high and the product quality is stable; moreover, the rectification process can be continuously carried out along with the industrial device for epoxypropane production by adopting the chlorohydrin process, so that the discharge amount of the epoxypropane waste liquid is greatly reduced and the economic benefits of enterprises are increased.

Owner:TIANJIN UNIV

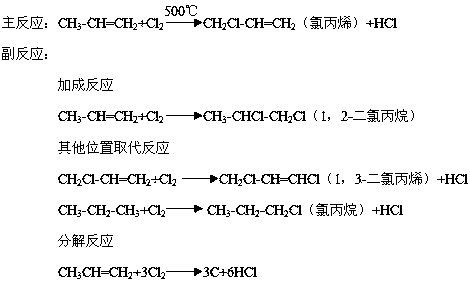

Chlorination process in chloropropene production

InactiveCN103724157ALess side effectsImprove production continuityHalogenated hydrocarbon preparationDichloropropaneWater chlorination

The invention discloses a chlorination process in chloropropene production. The process comprises the following steps: gasifying liquid chlorine through a chlorine evaporator, allowing the chlorine to enter a chlorine buffer tank, metering, and feeding the chlorine into a mixing section of a chlorination reactor; pretreating a raw material propylene, and feeding the propylene into the chlorination reactor to react with the chlorine, wherein the reaction product comprises mixed gas of chloropropene, 1,2-propylene dichloride+1,3-dichloropropene, excessive propylene and hydrogen chloride. The chlorination process is improved, the yield is 85% after improvement, side reactions are reduced, and the production continuity is improved.

Owner:SHANDONG HIYI CHEM TECH

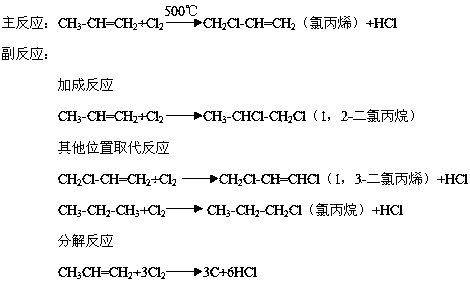

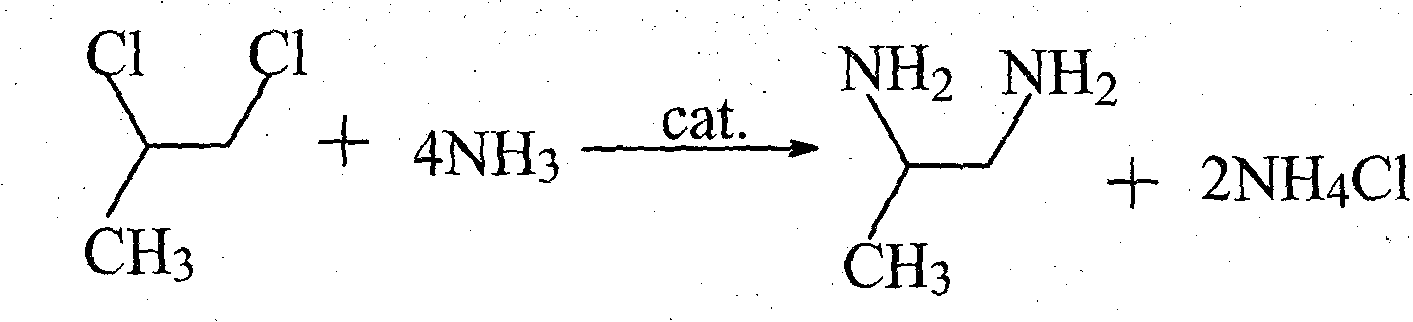

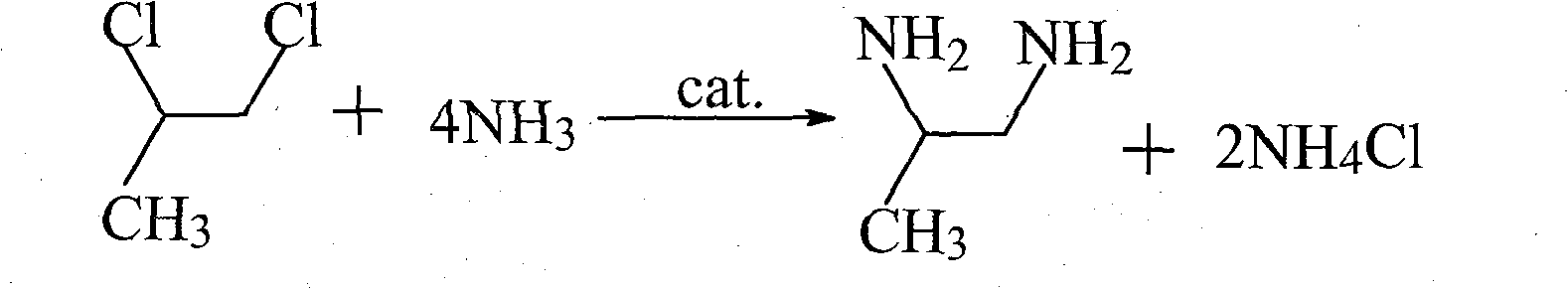

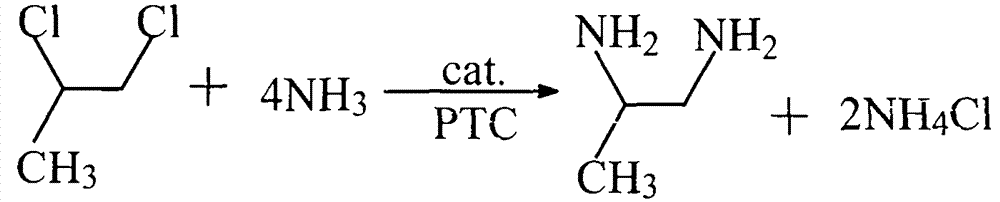

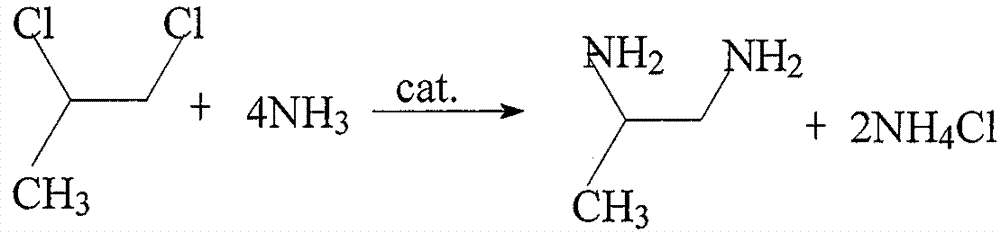

Supported catalyst for preparation of 1, 2-propane diamine

InactiveCN103664634AHigh yieldReduce manufacturing costAmino preparation by functional substitutionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureAmmonia

The invention discloses a supported catalyst for preparation of 1, 2-propane diamine through catalysis. The 1, 2-propane diamine is prepared by a method comprising main synthesis steps of adding 1, 2-propylene dichloride, ammonia water, and the supported catalyst into a reaction kettle; rotating the reaction kettle in a homogeneous phase reactor at constant speed; carrying out amination at reaction temperature of 140 DEG C-170 DEG C so as to prepare the 1, 2-propane diamine, wherein the yield of the 1, 2-propane diamine is more than 65%; and after reaction, firstly removing unreacted ammonia gas, and then distilling at normal pressure so as to obtain a 1, 2-propane diamine aqueous solution. The supported catalyst has the advantages that the yield of the 1, 2-propane diamine prepared by catalysis of the supported catalyst is relatively high; the byproduct 1, 2-propylene dichloride generated in production of chloropropene is taken as the raw material, so that the production cost is greatly lowered; the reaction process is simple, the operation is convenient; the method is safe and environment-friendly and is beneficial to industrial production.

Owner:UNIV OF JINAN

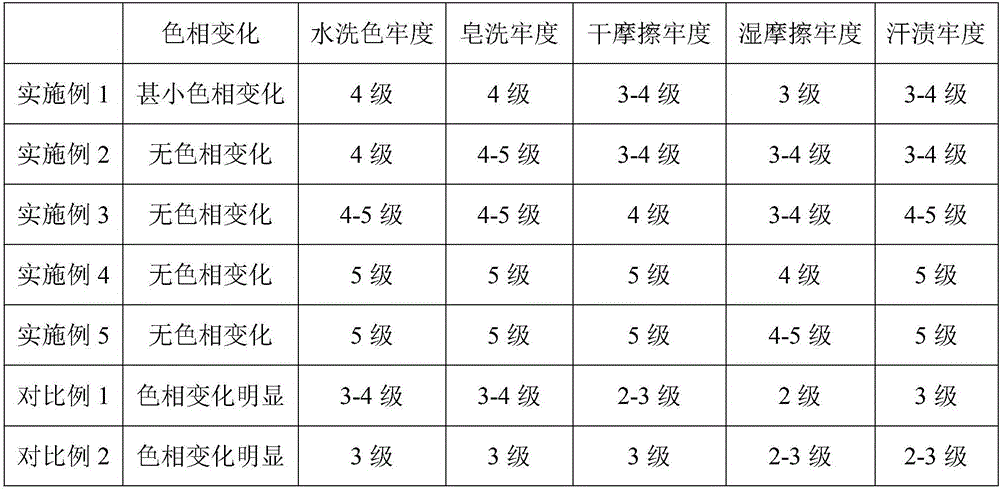

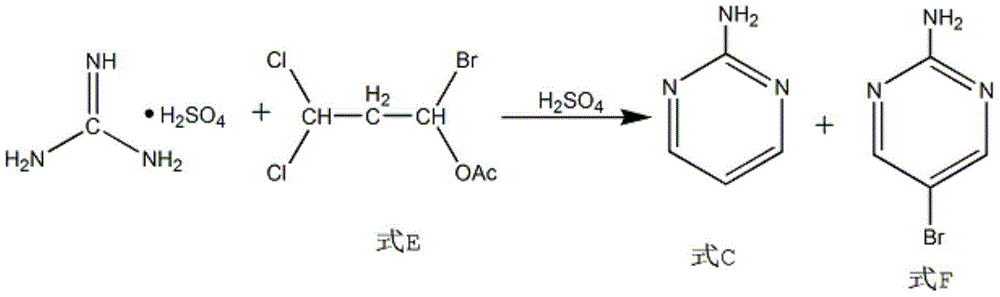

Silk fabric color fixing agent and preparation method thereof

InactiveCN106702791AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processDichloropropaneHue

The invention discloses a silk fabric color fixing agent and a preparation method thereof. The color fixing agent is prepared from the following raw materials in parts by weight: 41-49 parts of alkyl alcohol polyoxyethyl ether S, 5-13 parts of propylene dichloride, 10-18 parts of poly-dimethyl diallyl ammonium chloride, 17-25 parts of dimethyl sulfoxide, 3-7 parts of fatty alcohol-polyoxyethylene ether and 13-21 parts of dichloroacetic acid. The method comprises the steps of mixing the alkyl alcohol polyoxyethyl ether S, the dimethyl sulfoxide and the poly-dimethyl diallyl ammonium chloride, and carrying out heating and stirring treatment; adding a fatty alcohol-polyoxyethylene ether solution, and carrying out heating and stirring treatment; adding the propylene dichloride, and carrying out heating and stirring treatment; and dropwise adding a dichloroacetic acid solution, carrying out heating and stirring treatment, and cooling to a room temperature. The prepared color fixing agent has high dye fastness under the interaction of raw materials, the dry and wet rubbing fastness and the color fastness to washing can be significantly improved, a hue change is not generated during fixation of an active dye, and the silk fabric color fixing agent is free of formaldehyde, environment-friendly, free of secondary pollution and simple in production technology, is suitable for industrial production and is extremely suitable for the field of fixation of the active dye.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

Reactive dye color fixing agent and preparation method thereof

ActiveCN106758415AHigh color fastnessImprove dry and wet rubbing fastnessDyeing processColor changesFatty alcohol

The invention discloses a reactive dye color fixing agent and a preparation method thereof. The color fixing agent is prepared from the following raw materials in parts by weight: 41-49 parts of bisphenol S, 5-13 parts of propylene dichloride, 10-18 parts of dimethyl formamide, 17-25 parts of dimethyl sulfoxide, 3-7 parts of fatty alcohol-polyoxyethylene ether and 13-21 parts of dichloroacetic acid. The preparation method comprises the steps of mixing the bisphenol S with the dimethyl sulfoxide and the dimethyl formamide, heating and stirring an obtained mixture; then, adding a fatty alcohol-polyoxyethylene ether solution, heating and stirring; after that, adding the propylene dichloride, heating and stirring; dropwise adding a dichloroacetic acid solution, heating and stirring, and cooling to the room temperature to obtain the reactive dye color fixing agent. The color fixing agent prepared by the method has the advantages of being high in dyeing fastness, capable of obviously improving dry-wet rubbing fastness and color fastness to washing, and the like under the interaction of all the raw materials, and enables reactive dyes basically not to have color change when being used for carrying out color fixation on the reactive dyes; furthermore, the reactive dye color fixing agent is formaldehyde-free, environment-friendly, free from secondary pollution, simple in production technology, suitable for industrial production and especially suitable for the field of color fixation of the reactive dyes.

Owner:宁波澳翔精细化工有限公司

Environment-friendly energy-saving cleaning agent and preparation method thereof

InactiveCN105316131AIncreased durabilityReduce volatilityNon-surface-active detergent solventsTetrachloroethyleneHigh volume manufacturing

The invention provides an environment-friendly energy-saving cleaning agent. The cleaning agent is prepared from, by weight, 20-70 parts of propylene dichloride and 30-80 parts of tetrachloroethylene. The preparation method of the environment-friendly energy-saving cleaning agent comprises the steps of mixing and uniformly stirring substances in the formula at the normal temperature. Previous trichloro ethylene is replaced with the cleaning agent, and compared with the previous trichloro ethylene, the cleaning agent is higher in durability, low in smell, free of toxicity, applicable to low temperature, low in volatility, simple in process and suitable for mass production.

Owner:岑业勤

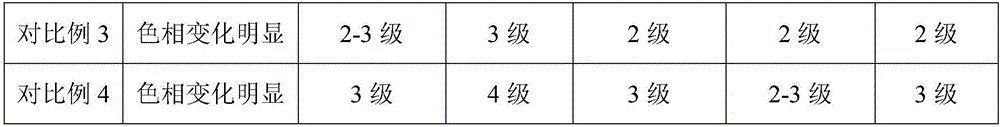

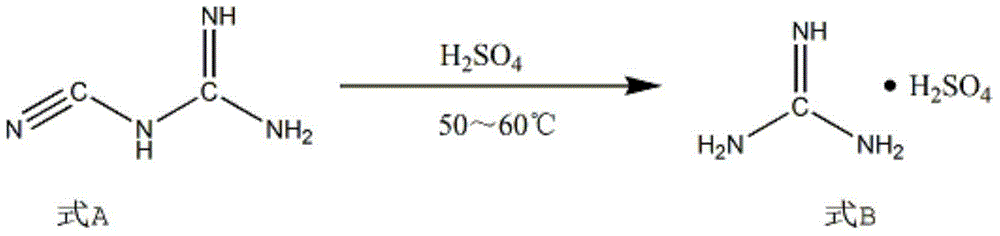

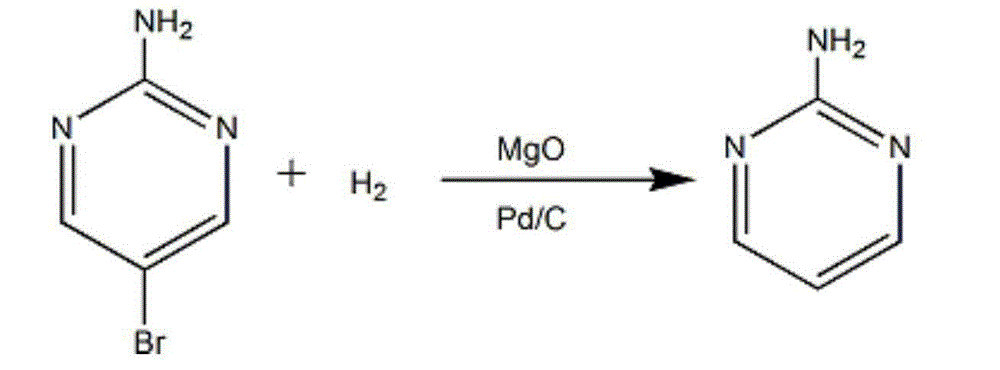

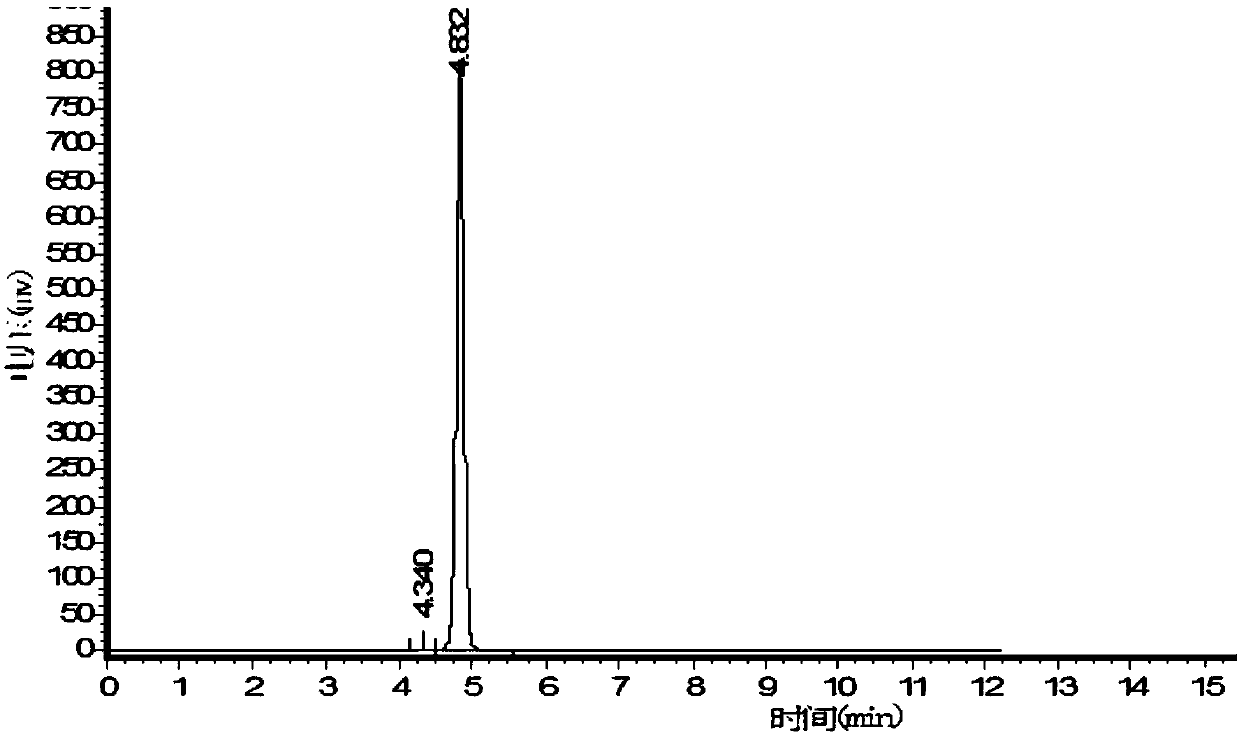

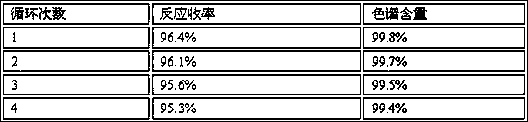

Synthesis method of 2-chloropyrimidine

The invention discloses a synthesis method of 2-chloropyrimidine. The synthesis method comprises the steps of dissolving dicyandiamide in sulfuric acid at 2-6 DEG C, heating at 50-60 DEG C for hydrolysis reaction for 4-6h to form guanidine sulfate, allowing guanidine sulfate to carry out cyclization reaction with 1-bromine-1-acetyl-3,3-propylene dichloride (Formula E) for 5-8h at 50-60 DEG C in the presence of sulfuric acid at a mass concentration of 94-96wt% to form 2-aminopyrimidine and 2-amino-5-bromopyrimidine, hydrogenizing and reducing 2-aminopyrimidine and 2-amino-5-bromopyrimidine to 2-aminopyrimidine at 55-65 DEG C under the catalysis of a palladium-carbon catalyst and magnesium oxide at the same time, and reducing 2-aminopyrimidine to the product at subzero10-5 DEG C by taking NaNO2, HCl and ZnCl2 as catalysts. Through the preparation route, higher-purity and upper-yield 2-chloropyrimidine is obtained.

Owner:TAICANG YUNTONG BIOCHEM ENG

Anti-rusting and anticorrosive finish coat for steel and iron and preparation method thereof

InactiveCN105925104AThe appearance of the coating film is smooth and smoothWidely producedAnti-corrosive paintsPolymer scienceMeth-

The invention discloses an anti-rusting and anticorrosive finish coat for steel and iron and a preparation method thereof. Xylene, polystyrene, butyl acrylate, ethyl acetate, propylene glycol, titanium pigment, barium sulfate, propylene dichloride, trimethylolpropane, phthalic anhydride, butanol, styrene, benzoyl peroxide and tricresyl phosphate are weighed and taken; the raw materials are agitated, and then are ground, so as to prepare the anti-rusting and anticorrosive finish coat for the steel and the iron. A paint film is uniform and bright in appearance, has water resistance lasting for 1 to 5 months, viscosity of 20s to 60s, flexibility of 1mm to 3mm, adhesive force of level 1, ageing resistance lasting for 60d to 80d, shock strength of 55kg / cm to 95kg / cm, fineness of 12 to 16 microns, solid content of 42 to 48 percent, surface drying time of 10h to 14h and actual drying time of 16h to 20h; the anti-rusting and anticorrosive finish coat for the steel and the iron can be widely produced and used for continually replacing existing materials.

Owner:WUXI EPIC TECH

Fuel oil additive mixture

Owner:黄慧娟

Antiseptic paint for inner wall of automotive water tank and preparation method of antiseptic paint

InactiveCN105885498AReduce formaldehyde contentImprove cold resistanceFireproof paintsAnti-corrosive paintsTemperature resistanceFumed silica

The invention relates to an antiseptic paint for an inner wall of an automotive water tank and a preparation method of the antiseptic paint. The antiseptic paint is mainly prepared from the following components: dibutyl phthalate, a TGIC (triglycidyl isocyanurate) curing agent, diacyloxyheptane dibutyltin, borax, ammonium polyphosphate temperature-resistant aid, acidic oxidant, a sand ripple agent, fumed silica, transparent zinc oxide, asbestos powder, nanosilicon dioxide, chlorinated rubber, titanium dioxide, talcum powder, barium sulfate, an anti-settling agent, a defoaming agent, pigments, titanium white powder, bamboo shoots, water, smoked plum, radix astragali seu hedysari, poria cocos, fritillary bulb, fructus aurantii, radix angelicae sinensis, sodium tripolyphosphate, hydrolytic polymaleic anhydride, sodium xylene sulfonate, alkylphenol polyoxyethylene, ethylene glycol monoethyl ether condensate, methylene dichloride, methylene trichloride, propylene dichloride, phenol, methanoic acid, hydrofluoric acid and paraffin. The paint prepared by adopting the preparation method is free from extraneous odor, has the formaldehyde content far lower than the national standards, releases a unique aroma at the same time, is suitable for use in household appliances and furniture, has high high-temperature resistance and cold resistance, and effectively overcomes the defects of an existing paint.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Method for preparing 4,4'-dichlorodiphenyl sulfone

ActiveCN106349126BMild reaction conditionsHigh reaction yieldOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention discloses a method for preparing 4,4'-dichloro sulfobenzide. 4,4'-dichloro diphenyl sulfoxide is taken as a raw material, sulfuric acid is taken as a catalyst and propylene dichloride and glacial acetic acid are taken as solvents. Under the reaction temperature at 60-90 DEG C, hydrogen peroxide is taken as an oxidizing agent and is used for oxidizing 4,4'-dichloro diphenyl sulfoxide and preparing 4,4'-dichloro sulfobenzide, wherein the concentration of hydrogen peroxide is 30%-50% and the dosage of the catalyst sulfuric acid is 6%-12% of the quantity of 4,4'-dichloro diphenyl sulfoxide, the dosage of the dissolvent propylene dichloride is 80%-120% of the quantity of 4,4'-dichloro diphenyl sulfoxide, the dosage of the glacial acetic acid is 15%-20% of the quantity of 4,4'-dichloro diphenyl sulfoxide and the reaction time is 90-120 minutes. The method provided by the invention has the advantages of mild reaction condition, high reaction yield, high catalytic efficiency and recoverable catalytic system and reaction solvent.

Owner:江西金海新能源科技有限公司

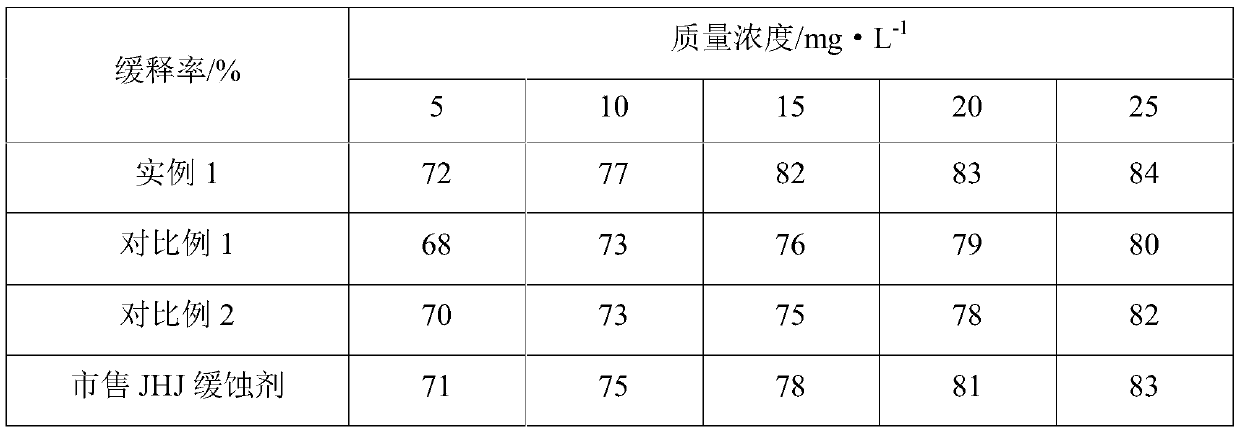

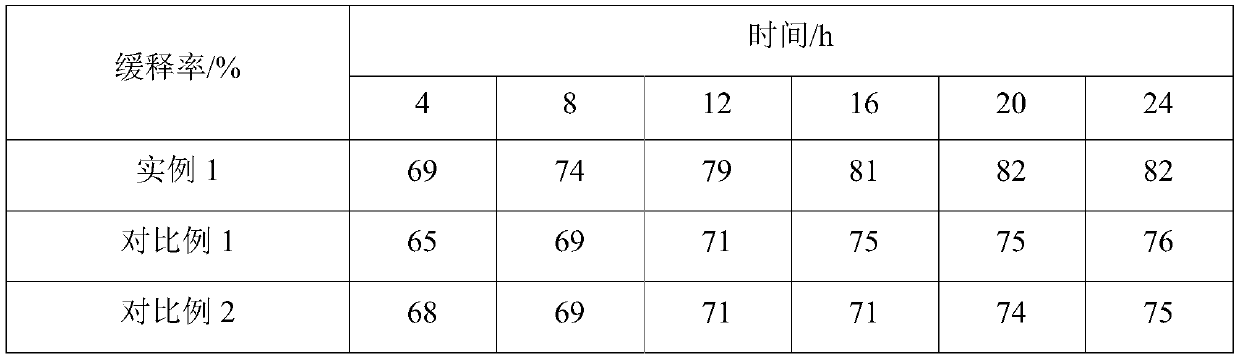

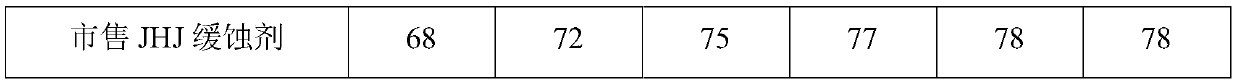

Antioxidant corrosion inhibitor

The invention discloses an antioxidant corrosion inhibitor. The antioxidant corrosion inhibitor is prepared through the steps of charging dicyanodiamine, a catalyst and zeolite into a reaction kettleand adding propylene dichloride to obtain an intermediate body; pasting starch, adding acrylamide, and continuously adding an initiating agent in the mixing process to obtain a copolymer; and chargingthe intermediate body, the copolymer, benzotriazole, sulfide and silicate into the reaction kettle in sequence to be fixed and then cooled to the indoor temperature to obtain the antioxidant corrosion inhibitor. Through the antioxidant corrosion inhibitor, a compact and firm protective film can be formed on the surfaces of oil gas equipment and a gathering transport pipeline in a moist high-temperature environment, and corrosion of a sewage medium to the oil gas equipment and the gathering transport pipeline is effectively prevented. The antioxidant corrosion inhibitor has the excellent high-temperature antioxidant performance.

Owner:上海贵通新材料科技有限公司

Paint remover capable of rapidly removing paint

The invention discloses a paint remover capable of rapidly removing paint. The paint remover comprises in parts by weight, 25 parts of dichloromethane, 30 parts of trichloromethane, 10 parts of propylene dichloride, 7 parts of paraffin, 15 parts of phenol, 10 parts of glycerin, 11 parts of eucalyptus oil and 15 parts of formic acid. The paint remover is simple in raw material, low in cost and toxicity, rapid in paint removing speed, good in effect and can be used for removing coatings of epoxy resin paint and organic silicon and amino baking paint.

Owner:启东市震宇玩具有限公司

Method for synthesizing 1,2-propane diamine

InactiveCN103664636AEmission reductionIncrease profitAmino preparation by functional substitutionDichloropropaneRoom temperature

The invention discloses a method for synthesizing 1,2-propane diamine. The method takes 1,2-propylene dichloride as a raw material and specifically comprises the following steps: (1) feeding a catalyst, a solvent water and 1,2-propylene dichloride into a high-pressure reaction kettle, and closing the high-pressure kettle; (2) introducing liquid ammonia into the reaction kettle; and (3) rapidly raising the temperature to be 160-180 DEG C, keeping the temperature to react for 250-300 minutes, cooling to be the room temperature, and slowly discharging redundant ammonia gas to be recycled within longer than 10 hours. The method is economic and environment-friendly, the utilization rate of 1,2-propylene dichloride is improved, the yield of the 1,2-propane diamine is improved, the cost is saved, and the emission of pollutant is reduced.

Owner:QINGDAO WINCHANCE TECH

Paint thinner

The invention provides a paint thinner. The paint thinner is characterized by being prepared from, by weight, 20-30 parts of propylene dichloride, 12-16 parts of n-butyl acetate, 5-15 parts of butanone, 15-20 parts of ethyl acetate, 13-17 parts of ethyl butyrate, 3-7 parts of silicone oil, 10-15 parts of dodecyl phosphate salt and 1-5 parts of glycerinum. The paint thinner has the advantages of being convenient to use, low in cost and harmless to the human body.

Owner:霍碧滢

A kind of method that phase-transfer catalysis prepares 1,2 propanediamine

InactiveCN103664635BReduce manufacturing costHigh reaction yieldAmino preparation by functional substitutionEpoxyEpichlorohydrin

The invention introduces preparation of 1,2-propane diamine, and mainly emphasizes an application of a phase-transfer catalyst to reactions. A major reaction process comprises the following steps: (1) adding propylene dichloride, ammonia water, a catalyst and the phase-transfer catalyst into a reaction kettle; (2) putting the reaction kettle into which raw materials are added into a homogeneous phase reactor; (3) reacting at 140-170 DEG C and 25 Hz, evaporating unreacted ammonia gas under the normal pressure after the reaction is finished, and distilling to obtain an aqueous solution of propane diamine. The method disclosed by the invention has the advantages that the propylene dichloride being a byproduct produced in the production of epoxy chloropropane is taken as a raw material, i.e.,, waste is utilized, and thus the production cost is reduced; the phase-transfer catalyst is added in a reaction process, so that the reaction yield is greatly increased; meanwhile, the method is simple, is easy to operate, and is easy for realizing industrial production.

Owner:UNIV OF JINAN

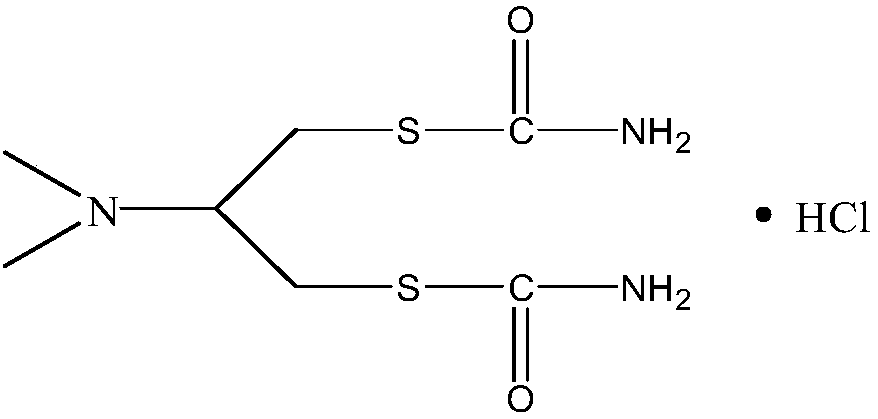

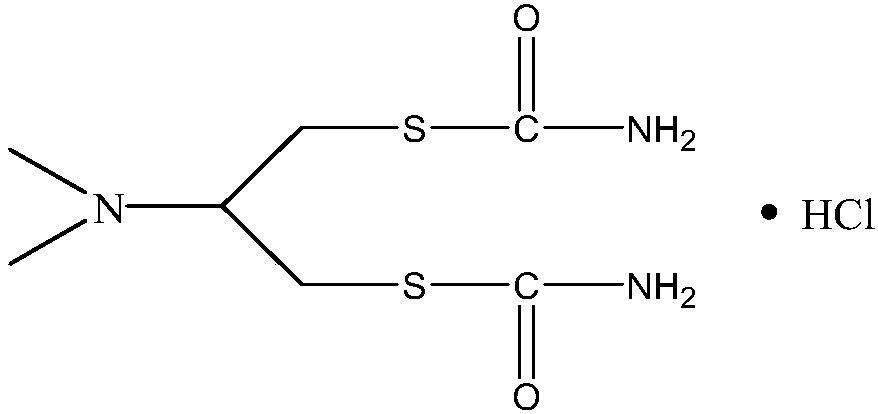

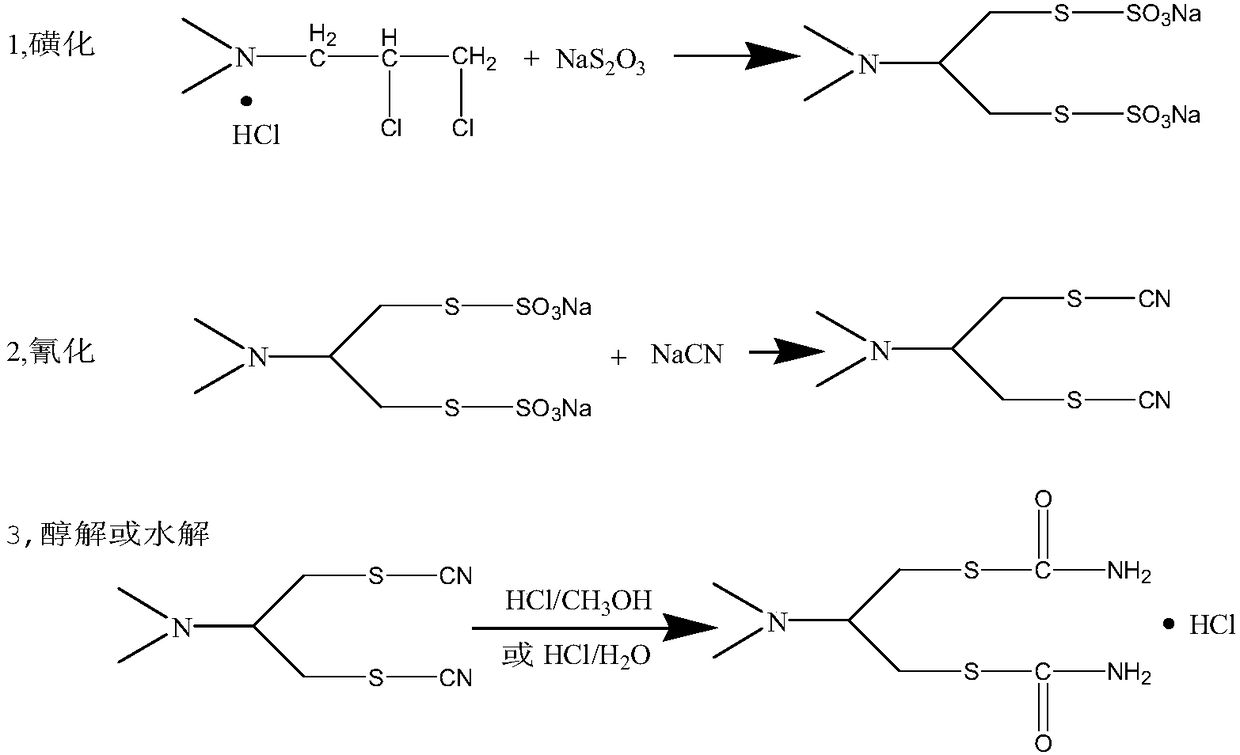

The synthetic method of cartap

ActiveCN106748937BReduce utilizationReduce capacity requirementsOrganic chemistrySulfite saltSynthesis methods

The invention provides a synthesis method of cartap, and relates to a synthesis method of 1,3-bis(carbamyl sulfonium)-2-(N,N-dimethylamino) propane hydrochloride. An original medicine of cartap is prepared from carbon oxysulfide, ammonia and 1-(N,N-dimethylamino)-2,3-propylene dichloride (chloride for short) through a one-pot method in an alkaline solution. By the adoption of the one-pot method for reaction step by step to prepare the cartap, the synthesis method has the advantages of low equipment investment, low energy consumption, easiness and convenience for operation and substantial improvement of the conversion rate. According to the synthesis method, the use of organic raw materials such as sodium thiosulfate (sodium thiosulfate) and sodium cyanide is avoided, so that generation of a large amount of sewage containing sodium sulfite and sodium cyanide is avoided. The synthesis method substantially increases the selectivity and the conversion rate in a reaction process, thus improving the production efficiency and greatly reducing the production cost.

Owner:仪征市海帆化工有限公司

Supported catalysts for the preparation of 1,2‑propylenediamine

InactiveCN103664634BHigh yieldReduce manufacturing costAmino preparation by functional substitutionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystReaction temperature

The invention discloses a supported catalyst for preparation of 1, 2-propane diamine through catalysis. The 1, 2-propane diamine is prepared by a method comprising main synthesis steps of adding 1, 2-propylene dichloride, ammonia water, and the supported catalyst into a reaction kettle; rotating the reaction kettle in a homogeneous phase reactor at constant speed; carrying out amination at reaction temperature of 140 DEG C-170 DEG C so as to prepare the 1, 2-propane diamine, wherein the yield of the 1, 2-propane diamine is more than 65%; and after reaction, firstly removing unreacted ammonia gas, and then distilling at normal pressure so as to obtain a 1, 2-propane diamine aqueous solution. The supported catalyst has the advantages that the yield of the 1, 2-propane diamine prepared by catalysis of the supported catalyst is relatively high; the byproduct 1, 2-propylene dichloride generated in production of chloropropene is taken as the raw material, so that the production cost is greatly lowered; the reaction process is simple, the operation is convenient; the method is safe and environment-friendly and is beneficial to industrial production.

Owner:UNIV OF JINAN

A kind of reactive dye fixing agent and preparation method thereof

ActiveCN106758415BHigh color fastnessImprove dry and wet rubbing fastnessDyeing processColor changesFatty alcohol

The invention discloses a reactive dye color fixing agent and a preparation method thereof. The color fixing agent is prepared from the following raw materials in parts by weight: 41-49 parts of bisphenol S, 5-13 parts of propylene dichloride, 10-18 parts of dimethyl formamide, 17-25 parts of dimethyl sulfoxide, 3-7 parts of fatty alcohol-polyoxyethylene ether and 13-21 parts of dichloroacetic acid. The preparation method comprises the steps of mixing the bisphenol S with the dimethyl sulfoxide and the dimethyl formamide, heating and stirring an obtained mixture; then, adding a fatty alcohol-polyoxyethylene ether solution, heating and stirring; after that, adding the propylene dichloride, heating and stirring; dropwise adding a dichloroacetic acid solution, heating and stirring, and cooling to the room temperature to obtain the reactive dye color fixing agent. The color fixing agent prepared by the method has the advantages of being high in dyeing fastness, capable of obviously improving dry-wet rubbing fastness and color fastness to washing, and the like under the interaction of all the raw materials, and enables reactive dyes basically not to have color change when being used for carrying out color fixation on the reactive dyes; furthermore, the reactive dye color fixing agent is formaldehyde-free, environment-friendly, free from secondary pollution, simple in production technology, suitable for industrial production and especially suitable for the field of color fixation of the reactive dyes.

Owner:宁波澳翔精细化工有限公司

Cleaning agent for live electrical equipment

InactiveCN1240819CSimple recipeEasy to useNon-surface-active detergent compositionsCleansing AgentsSilicone fluid

The invention discloses a cleaning agent for live electrical equipment whose constituents by weight percentage are, propylene dichloride 95-99.5%, dimethicone 0.5-5%.

Owner:荣小平

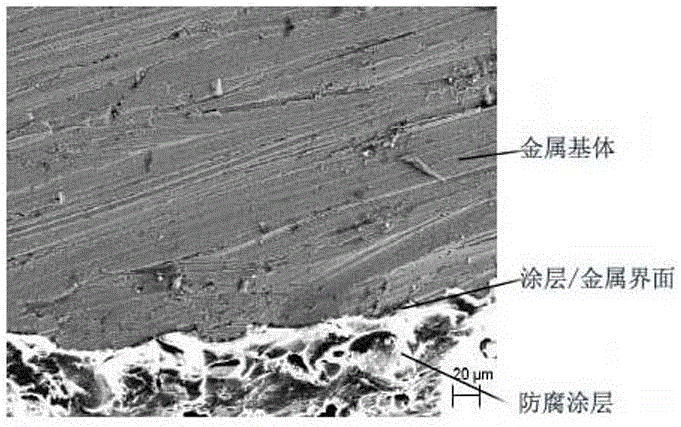

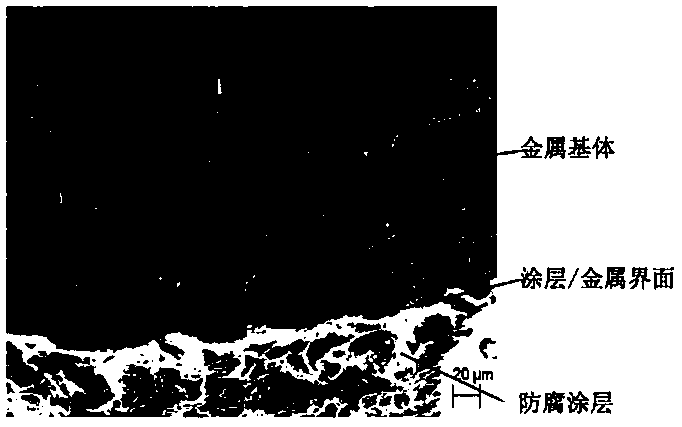

Organosilicon-aluminum powder corrosion inhibitor preparation method, organosilicon-aluminum powder corrosion inhibitor and application of organosilicon-aluminum powder corrosion inhibitor

ActiveCN105778687AEnhanced interactionImproved performance against atmospheric corrosion protectionAnti-corrosive paintsAcrylic resinCellulose acetate

The invention discloses an organosilicon-aluminum powder corrosion inhibitor preparation method, an organosilicon-aluminum powder corrosion inhibitor and application of the organosilicon-aluminum powder corrosion inhibitor. The preparation method includes (1), preparing a cellulose acetate precursor from cellulose acetate butyrate, propylene dichloride, acetic ether and ethylene glycol; (2), preparing organosilicon heat-resistant aluminum paint from organosilicon-modified acrylic resin, hydroxy acrylic resin, the cellulose acetate precursor, an adhesion promoter, nano-montmorillonite, aluminum paste and butyl acetate; (3), mixing the organosilicon heat-resistant aluminum paint with a curing agent so as to obtain the organosilicon-aluminum powder corrosion inhibitor. The organosilicon-aluminum powder corrosion inhibitor is high in operating temperature and good in anticorrosion effect and can be particularly applied to atmospheric corrosion protection of steel 91 / P91 of power station boiler pipes.

Owner:STATE GRID CORP OF CHINA +2

Preparation method of organosilicon aluminum powder corrosion inhibitor, organosilicon aluminum powder corrosion inhibitor and application thereof

ActiveCN105778687BEnhanced interactionImproved performance against atmospheric corrosion protectionAnti-corrosive paintsCellulose acetateAcrylic resin

The invention discloses an organosilicon-aluminum powder corrosion inhibitor preparation method, an organosilicon-aluminum powder corrosion inhibitor and application of the organosilicon-aluminum powder corrosion inhibitor. The preparation method includes (1), preparing a cellulose acetate precursor from cellulose acetate butyrate, propylene dichloride, acetic ether and ethylene glycol; (2), preparing organosilicon heat-resistant aluminum paint from organosilicon-modified acrylic resin, hydroxy acrylic resin, the cellulose acetate precursor, an adhesion promoter, nano-montmorillonite, aluminum paste and butyl acetate; (3), mixing the organosilicon heat-resistant aluminum paint with a curing agent so as to obtain the organosilicon-aluminum powder corrosion inhibitor. The organosilicon-aluminum powder corrosion inhibitor is high in operating temperature and good in anticorrosion effect and can be particularly applied to atmospheric corrosion protection of steel 91 / P91 of power station boiler pipes.

Owner:STATE GRID CORP OF CHINA +2

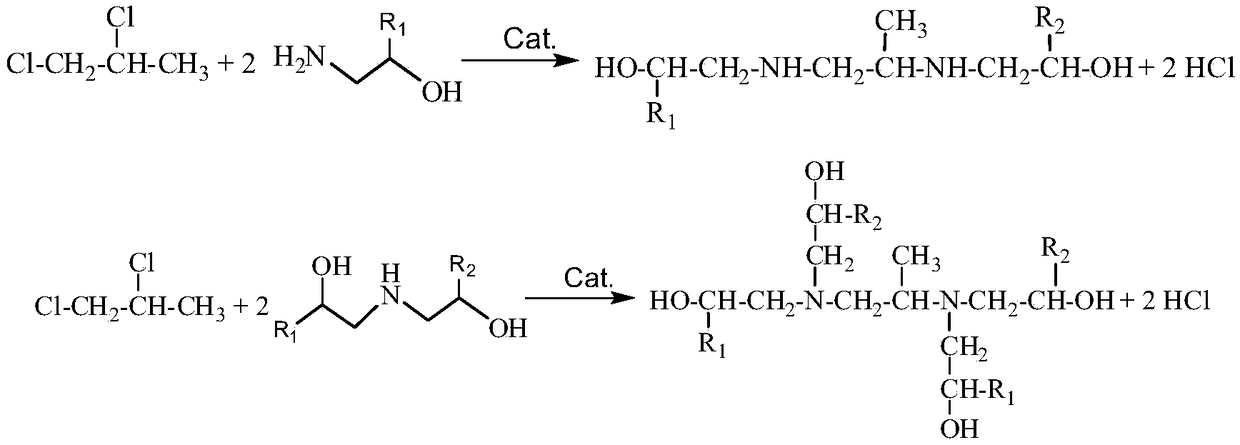

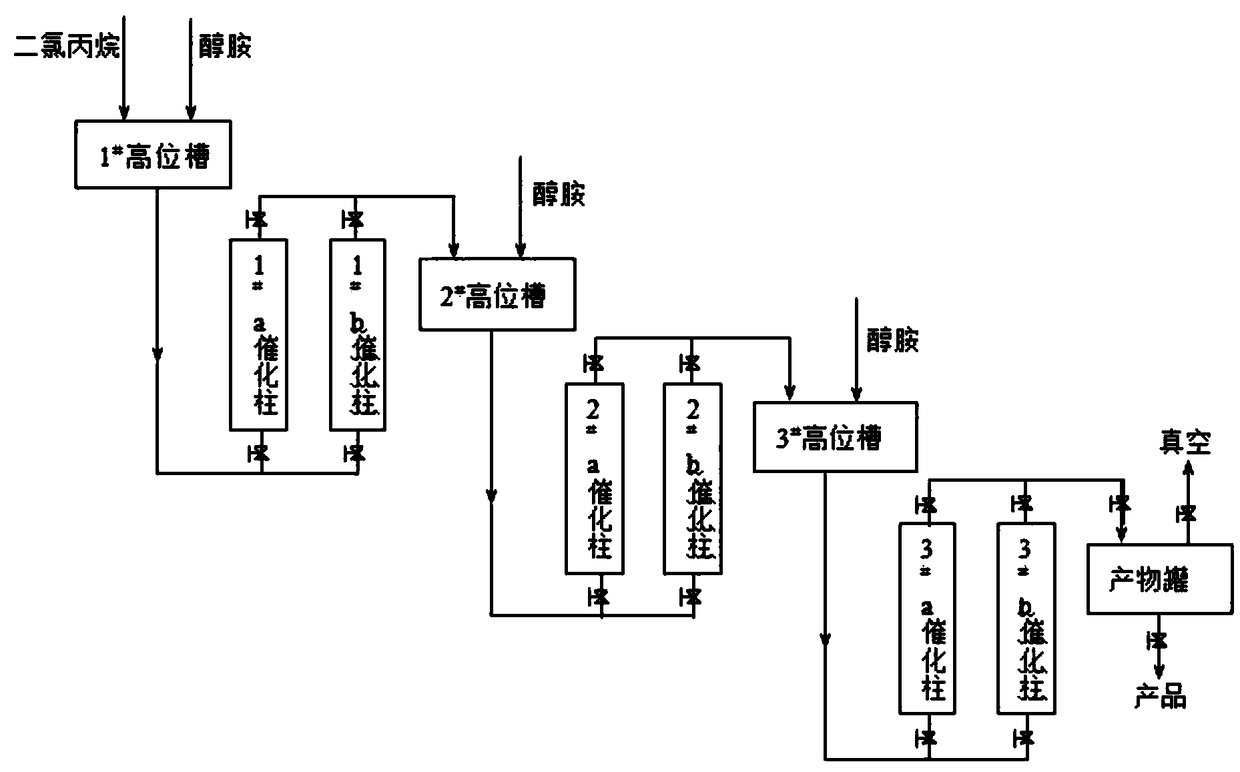

Preparation method of multielement alcohol amine

ActiveCN108863821AMild reaction conditionsReduce operating costsPhysical/chemical process catalystsOrganic compound preparationAlcoholDeep processing

The invention relates to a preparation method of multielement alcohol amine and belongs to the technical field of organic chemicals. The preparation method comprises the following step: continuously-flowing propylene dichloride and alcohol amine added stepwise react on a solid catalyst on design equipment to synthesize the multielement alcohol amine. The invention provides a deep processing methodof the propylene dichloride, and the problem that other application ways of the propylene dichloride pollute the environment is solved, the used catalyst can be regenerated and repeatedly used, therefore, the deep processing method belongs to a pollution-free chemical process; the preparation method of the multielement alcohol amine provided by the invention has the advantages of mild condition,low operation cost, high production efficiency and flexible functionality adjustment of multielement alcohol amine, and is suitable for industrial production.

Owner:NANJING POLYTECHNIC INSITUTE +1

Child toy surface paint and preparation method thereof

InactiveCN105820667AReduce formaldehyde contentImprove cold resistanceFireproof paintsRubber derivative coatingsAngelica Sinensis RootBorax

The invention provides child toy surface paint and a preparation method thereof. The paint is mainly prepared from dibutyl phthalate, a TGIC curing agent, edetic acid, borax, an ammonium polyphosphate temperature-resistant auxiliary, an acidic oxidant, a sand ripple agent, sulfamic acid, dispersing agent NNO, asbestos powder, nano silicon dioxide, chlorinated rubber, ammonium chloride, talcum powder, barium sulfate, an anti-settling agent, a defoaming agent, pigment, leucoxene powder, bamboo shoots, water, fructus mume, radix astragali, poria cocos, fritillaria, fructus aurantii, radix angelica sinensis, an aqueous solution of alkyl polyglycoside, sodium alkyl benzene sulfonate, nipagin, sodium silicate, lemon essence, ethyl alcohol, isopropanol, dichloromethane, trichloromethane, propylene dichloride, phenol, formic acid, hydrofluoric acid and paraffin. The paint prepared through the method is free of peculiar smell, the formaldehyde content is far lower than that in national standards, the paint releases unique fragrance, is suitable for being used on household appliances and furniture and is high in high temperature resistance and cold resistance, and defects of existing paint are effectively overcome.

Owner:ANHUI HUAHUI SUYE TECH SHARE CO LTD

Powerful metal adhesive

InactiveCN107384228ADiffusion fastSpread evenlyNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveAlkylphenol

The invention relates to a powerful metal adhesive. The powerful metal adhesive is prepared from the following components: chloroprene rubber, styrene, waterborne polyurethane resin, liquid paraffin, methylbenzene, dimethyl carbonate, propylene dichloride, methyl methacrylate, alkylphenol polyoxyethylene ether sodium sulfate and organic tin catalysts. Through experiments, the special waterborne polyurethane resin can be replaced, so that the adhesion properties such as viscosity and peeling strength and the like of the adhesive are greatly improved; the powerful metal adhesive has obvious effect and broad market prospects.

Owner:HEFEI CITY TENVER PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com