A kind of method that phase-transfer catalysis prepares 1,2 propanediamine

A technology of phase transfer catalysis and phase transfer catalyst, applied in the field of chemical technology synthesis, can solve the problems of insufficient contact of reactants, low reaction yield, etc., and achieve the effects of reducing production cost, simple operation and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

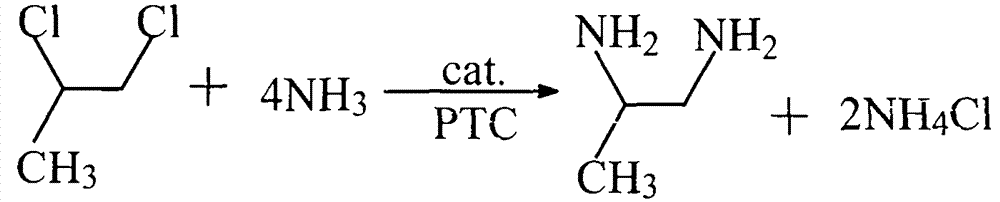

Image

Examples

Embodiment 1

[0035] Add 5 mL of 1,2-dichloropropane, 0.5 g of CuO, 100 mL of ammonia water, and 1% tetramethylammonium chloride into the reaction kettle. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. Cool down to room temperature, remove unreacted ammonia gas, and detect by gas chromatography, the yield of 1,2-propanediamine is 67.16%.

Embodiment 2

[0037] Add 5 mL of 1,2-dichloropropane, 0.5 g of CuO, 100 mL of ammonia water, and 10% tetramethylammonium chloride into the reaction kettle. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. Cool down to room temperature, remove unreacted ammonia gas, and detect by gas chromatography, the yield of 1,2-propanediamine is 64.61%.

Embodiment 3

[0039] Add 5 mL of 1,2-dichloropropane, 0.5 g of CuO, 100 mL of ammonia water, and 1% cetyltrimethylammonium bromide into the reaction kettle. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. Cool down to room temperature, remove unreacted ammonia gas, and detect by gas chromatography, the yield of 1,2-propanediamine is 65.70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com