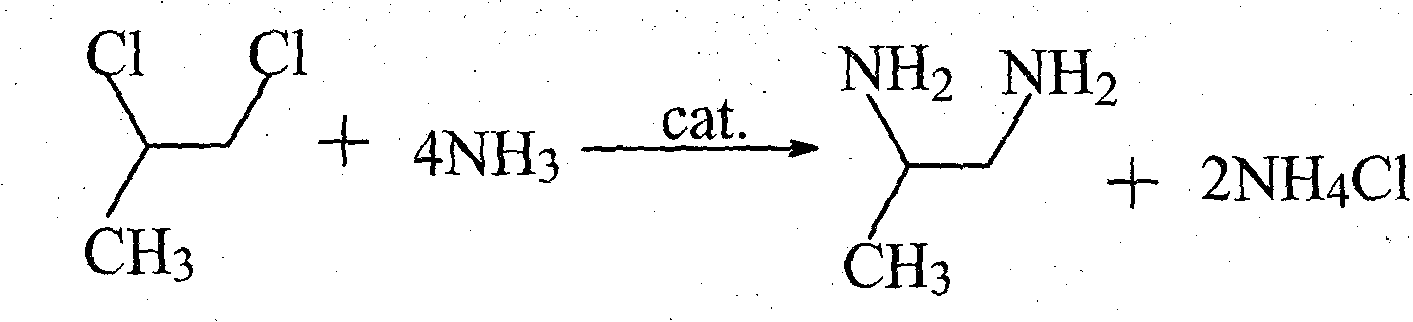

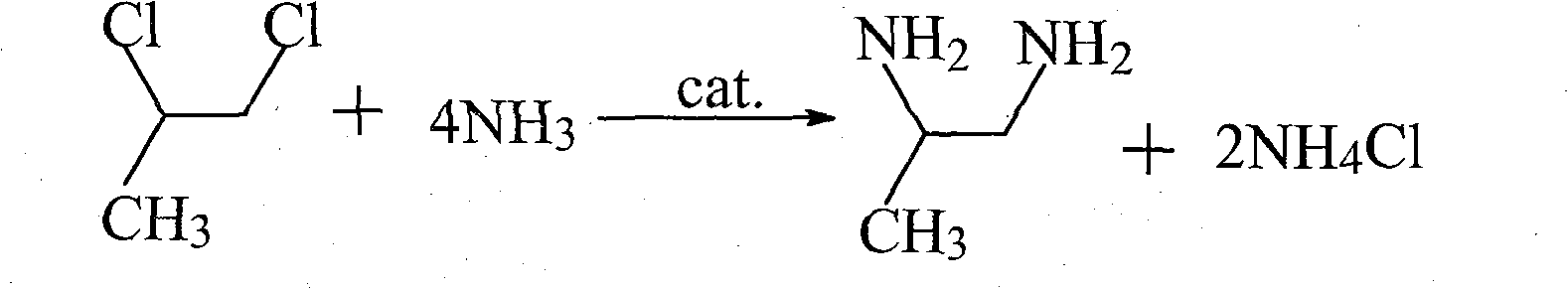

Supported catalyst for preparation of 1, 2-propane diamine

A supported catalyst, propylene diamine technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, preparation of amino-substituted functional groups, etc., can solve the problem of insufficient reaction, rapidity, side reactions, etc. problem, to achieve the effect of being beneficial to industrialized production, convenient operation and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Accurately weigh 1g SiO 2 Suspend it in 20 mL distilled water, then weigh 0.3196 g CuCl 2 2H 2 O, it was added to the suspension, and the mixture was sonicated for 30min so that the SiO 2 for uniform dispersion. Heat the mixture after ultrasonication at 100°C until the solution is evaporated to dryness, then transfer it to an incubator at 120°C for 2 hours, and finally transfer it to a muffle furnace for calcination at 400°C for 3 hours . The prepared catalyst CuO / SiO 2 for the next catalytic reaction. The content of CuO is 15% of the weight of the carrier. Add 5 mL of 1,2-dichloropropane, 0.5 g CuO / SiO to the reaction kettle 2 , 100mL ammonia water. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. The temperature was lowered to room temperature, unreacted ammonia gas was removed, and gas chromatography was used to detect that the yield of 1,2-propanediamine was 64.72%...

Embodiment 2

[0019] Accurately weigh 1g TiO 2 Suspend it in 20 mL distilled water, then weigh 0.3196 g CuCl 2 2H 2 O, it was added to the suspension, and the mixture was sonicated for 30min so that the TiO 2 for uniform dispersion. Heat the mixture after ultrasonication at 100°C until the solution is evaporated to dryness, then transfer it to an incubator at 120°C for 2 hours, and finally transfer it to a muffle furnace for calcination at 400°C for 3 hours . The prepared catalyst CuO / TiO 2 for the next catalytic reaction. The content of CuO is 15% of the weight of the carrier. Add 5 mL of 1,2-dichloropropane, 0.5 g CuO / TiO to the reaction kettle 2 , 100mL ammonia water. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. The temperature was lowered to room temperature, unreacted ammonia gas was removed, and gas chromatography was used to detect that the yield of 1,2-propanediamine was 66.03%...

Embodiment 3

[0021] Accurately weigh 1g Al 2 o 3 Suspend it in 20 mL distilled water, then weigh 0.3196 g CuCl 2 2H 2 O, it was added to the suspension, and the mixture was sonicated for 30 minutes to remove Al 2 o 3 for uniform dispersion. Heat the mixture after ultrasonication at 100°C until the solution is evaporated to dryness, then transfer it to an incubator at 120°C for 2 hours, and finally transfer it to a muffle furnace for calcination at 400°C for 3 hours . The prepared catalyst CuO / Al 2 o 3 for the next catalytic reaction. The content of CuO is 15% of the weight of the carrier. Add 5 mL of 1,2-dichloropropane, 0.5 g CuO / Al to the reaction kettle 2 o 3 , 100mL ammonia water. The reaction kettle was put into a homogeneous reactor and rotated at a constant speed, and the temperature was raised to 160° C. for 3 hours. Cool down to room temperature, remove unreacted ammonia gas, and detect by gas chromatography, the yield of 1,2-propanediamine is 68.39%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com