Industrial device and continuous rectification method for extracting 1,2-propylene dichloride from chlorohydrin process epoxypropane waste liquid

A technology of propylene oxide and propylene oxide, which is applied in the field of extracting 1,2-dichloropropane, can solve the problems of difficulty in automatic control of rectification equipment, equipment corrosion, and small processing capacity, so as to avoid equipment corrosion and production. High Efficiency and Emission Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

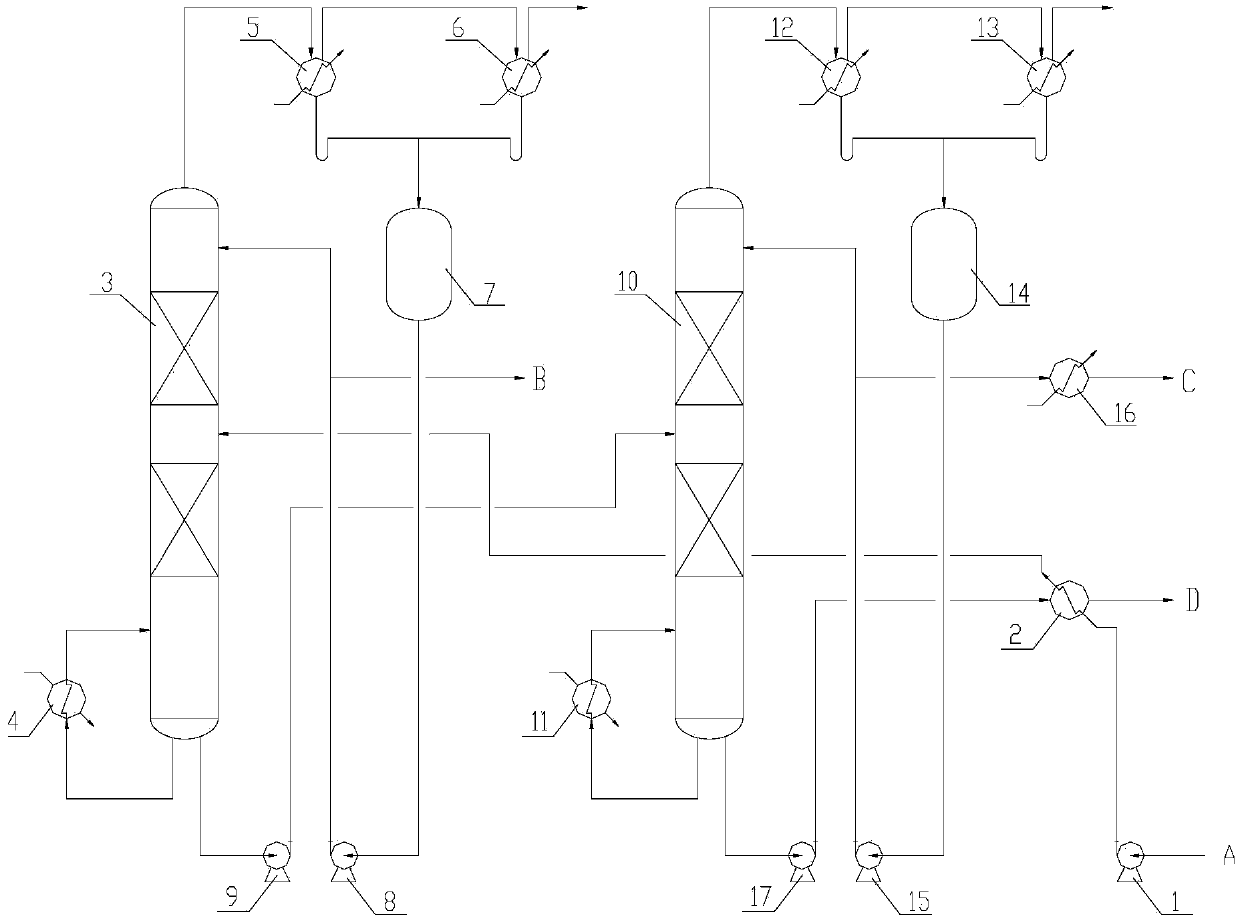

Embodiment example 1

[0043] The propylene oxide waste liquid that 3000kg / h dichloropropane content is 50% is sent into the propylene oxide waste liquid preheater 2 and the heavy component heat exchange that is extracted at the bottom of the second rectifying tower 10 with the waste liquid pump 1, The outlet temperature of the heavy component at the bottom of the second rectification column was controlled to be 45°C. The preheated propylene oxide waste liquid enters the first rectification tower 3 for rectification. Control the operating pressure at the top of the first rectification tower 3 to be 20KPa, the reflux ratio to be 1, the temperature at the bottom of the tower to be 60°C, and the temperature at the top of the tower to be 30°C. The mixed steam containing propylene oxide, propionaldehyde and water at the top of the tower enters the primary condenser 5 of the first rectification tower and is cooled to 35°C with cooling water, and the liquid phase enters the reflux tank 7 of the first recti...

Embodiment example 2

[0045] The propylene oxide waste liquid that 5000kg / h dichloropropane content is 70% is sent into the propylene oxide waste liquid preheater 2 and the heavy component heat exchange that is extracted at the bottom of the second rectifying tower 10 with the waste liquid pump 1, The outlet temperature of the heavy component at the bottom of the second rectification column was controlled to be 45°C. The preheated propylene oxide waste liquid enters the first rectification tower 3 for rectification. Control the operating pressure at the top of the first rectification tower 3 to be 70KPa, the reflux ratio to be 8, the temperature at the bottom of the tower to be 90°C, and the temperature at the top of the tower to be 40°C. The mixed steam containing propylene oxide, propionaldehyde and water at the top of the tower enters the primary condenser 5 of the first rectification tower and is cooled to 40°C with cooling water, and the liquid phase enters the reflux tank 7 of the first recti...

Embodiment example 3

[0047] The propylene oxide waste liquid that 7500kg / h dichloropropane content is 85% is sent into the propylene oxide waste liquid preheater 2 with the heavy component heat exchange that the second rectifying tower 10 tower bottoms extract with waste liquid pump 1, The outlet temperature of the heavy component at the bottom of the second rectification column was controlled to be 45°C. The preheated propylene oxide waste liquid enters the first rectification tower 3 for rectification. Control the operating pressure at the top of the first rectification tower 3 to be 101.33 KPa, the reflux ratio to be 20, the temperature at the bottom of the tower to be 120° C., and the temperature at the top of the tower to be 50° C. The mixed steam containing propylene oxide, propionaldehyde and water at the top of the tower enters the primary condenser 5 of the first rectification tower and is cooled to 45°C with cooling water, and the liquid phase enters the reflux tank 7 of the first rectif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com