Technology for preparing epoxypropane from propylene chlorohydrin through single acid process

A technology of propylene chlorohydrin and propylene oxide, applied in organic chemistry and other directions, can solve the problems of difficult treatment of saponification wastewater, increased total product cost, narrowed profit margins, etc., and achieves the effect of easy treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

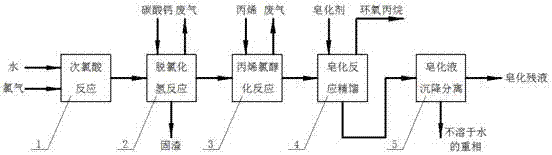

Embodiment 1

[0035] The propylene oxide production process of the single-acid method of propylene chlorohydrinization in Example 1 comprises a hypochlorous acid reaction unit (1), a dehydrochlorination reaction unit (2), a propylene chlorohydrinization reaction unit (3), a saponification reaction rectification unit (4 ) and saponification liquid sedimentation separation unit (5); the saponification agent used is calcium hydroxide slurry, and the operation process is: the raw material chlorine gas and water enter the hypochlorous acid reaction unit (1) and react to generate hypochlorous acid and hydrogen chloride; The hypochlorous acid and hydrogen chloride aqueous solution and calcium carbonate in the acid reaction unit (1) enter the dehydrochlorination reaction unit (2), in which the calcium carbonate reacts with hydrogen chloride to generate calcium chloride, water and carbon dioxide; into the solid residue discharge system; the dehydrochlorination liquid phase material exiting the dehydr...

Embodiment 2

[0037] Embodiment 2 is substantially the same as Embodiment 1, except that the saponification agent used is sodium hydroxide solution.

Embodiment 3

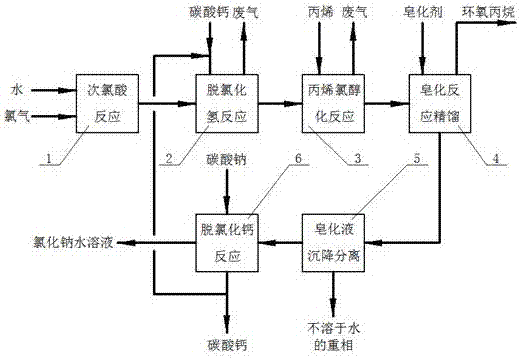

[0039] Example 3 is basically the same as Example 1, except that a saponification raffinate decalcification unit (6) is added after the saponification liquid sedimentation separation unit (5), and the saponification raffinate decalcification unit (6) Sodium carbonate is added to produce saponification solution. The saponification raffinate in the sedimentation separation unit (5) reacts with sodium carbonate in the saponification raffinate decalcification unit (6) to form sodium chloride and calcium carbonate precipitates, and the calcium carbonate circulates into the dehydrochlorination reaction. Unit (2); the liquid phase of the saponification raffinate decalcification unit (6) is sodium chloride solution. The technological process diagram of embodiment 3 sees figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com