Patents

Literature

375results about How to "Improve production continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

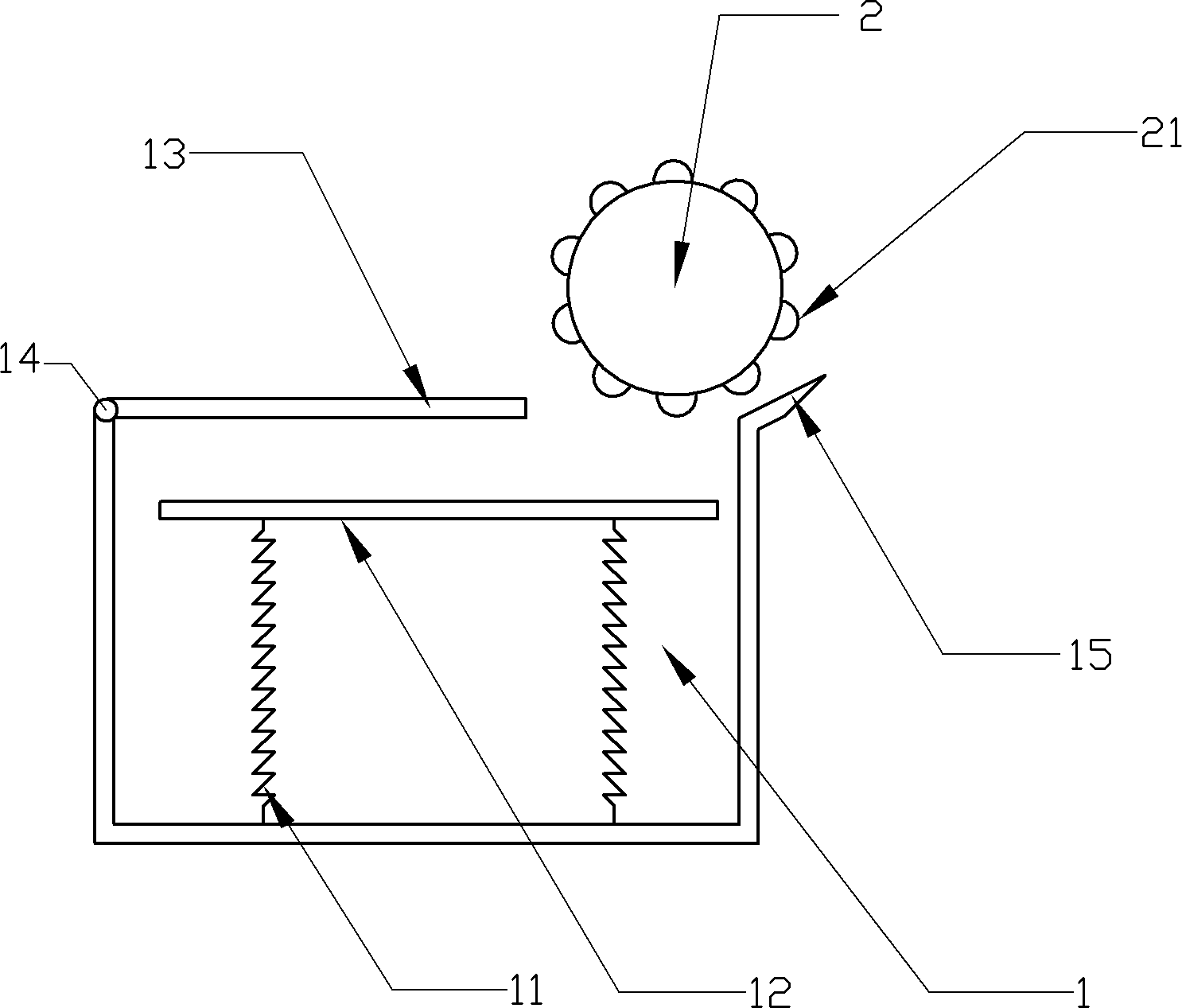

Solar thermophotovoltaic hydrogen generating device

InactiveCN101974764AIncrease temperatureImprove photoelectric conversion efficiencyCellsEnergy inputEngineeringThermophotovoltaic

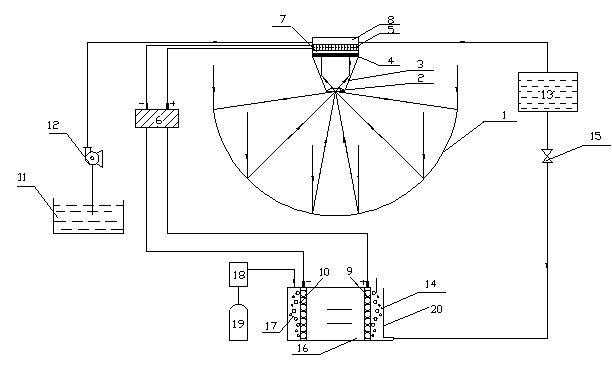

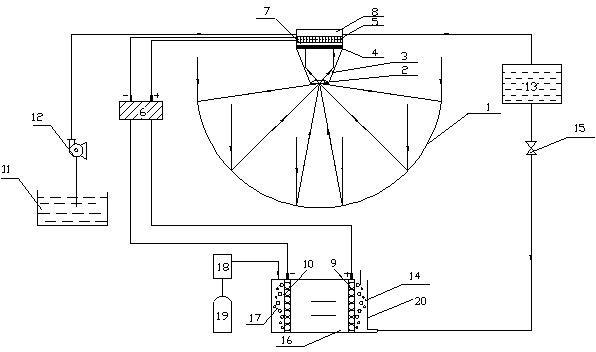

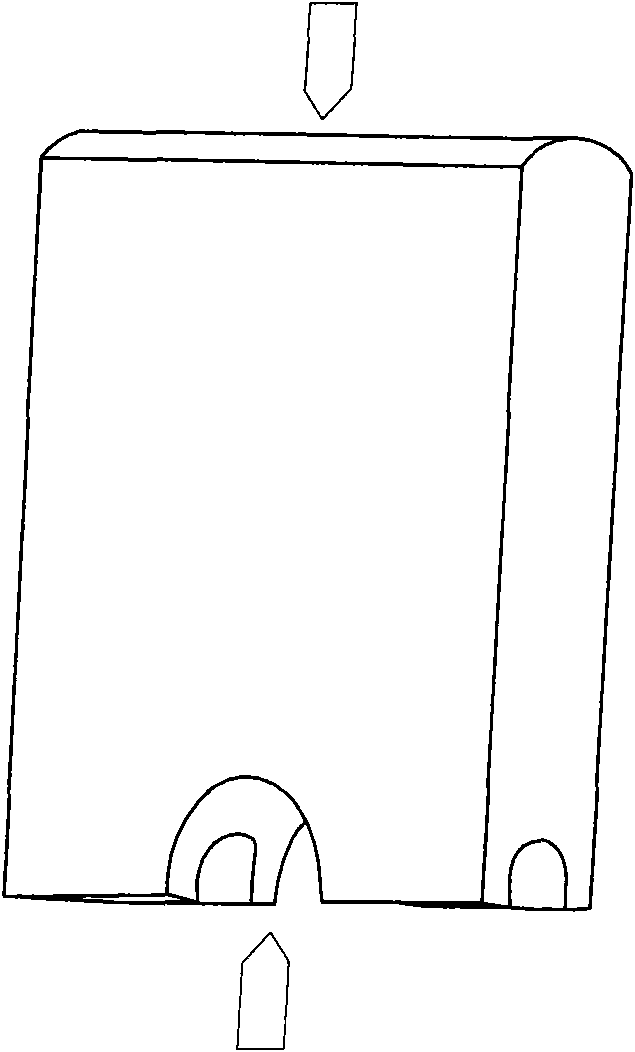

The invention provides a device for generating hydrogen by electrolyzing water by using a solar thermophotovoltaic system and belongs to the technical field of solar utilization and hydrogen production by electrolysis. The device consists of two main parts: an improved solar thermophotovoltaic system and a water electrolysis-based hydrogen generation system. The improved solar thermophotovoltaic system has higher conversion efficiency and high output power than a system based on common photovoltaic technology and can provide sufficient current power supply for a water electrolysis-based hydrogen generation device. The device uses the power generated by the system in hydrogen generation by electrolysis, the hydrogen is stored, and thus, the problem that the output of the photovoltaic power generator varies with the change of weather and the alternation of day and night. In addition, the cooling of a photovoltaic cell in the device is liquid cooling, the aqueous solution for electrolysis is preheated before being introduced into an electrolytic cell, the power consumption in an electrolysis process is reduced, and thus, the solar utilization rate is further improved.

Owner:JIANGSU UNIV

Preparation method of powder-metallurgy refrigeration compressor valve sheet

ActiveCN102380613AHigh forming densityImprove production continuityTurbinesOther manufacturing equipments/toolsRefrigeration compressorAlloy

The invention relates to a preparation method of a powder-metallurgy refrigeration compressor valve sheet. The preparation method is characterized by comprising the following steps of: mixing iron powder, high-alloy main powder, graphite powder, manganese sulfide powder and zinc stearate powder according to certain proportion, leading the weight percentage of all elements in the total components to be as follows: 0.5-2.0% of carbon, 3.0-6.5% of cobalt, 2.5-4.5% of chromium, 2.5-4.5% of molybdenum, 0.5-2.0% of nickel, 0.2-1.0% of vanadium, less than 3% of impurities and the balance of iron; using a mold to press and form the mixture to obtain a powder-metallurgy green blank; putting the green blank in a sintering furnace to sinter for more than 5 minutes with the sintering temperature being 1150-1250 DEG C; carrying out repressing and finishing on the sintered blank; carrying out quenching and annealing under the protective atmosphere; and carrying out grinding on the valve sheet. In the preparation method, the problems of the adding mode and effective alloying of the powder-metallurgy high alloy are solved, and higher forming density needed by the powder-metallurgy valve sheet material under higher alloy content is realized, so that the powder-metallurgy refrigeration compressor valve sheet achieves the needed wear resistance. The prepared powder-metallurgy refrigeration compressor valve sheet has the advantages of low material cost, high material utilization ratio and suitability for large-batch production.

Owner:NBTM NEW MATERIALS GRP

Process for preparing glass fiber composite type silicon dioxide aerogel insulation quilt

The invention discloses a process for preparing a glass fiber composite type silicon dioxide aerogel insulation quilt. The process mainly comprises the following steps: absorbing a silicon dioxide aerogel liquid till being saturated by using a glass fiber quilt, gelling under specific conditions, and drying supercutical fluid CO2 to form a reinforced aerogel material. The glass fiber composite type silicon dioxide aerogel insulation quilt prepared by using the process is excellent in heat preservation property, mechanical property and fireproof and waterproof property, and is convenient to construct. By adopting the process, a solvent replacement step is avoided, the operation is simple and easy, the operation process is controllable, and continuous production can be achieved.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

Premixed flow-state stabilized soil

InactiveCN107401159AReduce occupancyAchieve recyclingBuilding constructionsOrganic fertilisersSoil massEngineering

The invention provides premixed flow-state stabilized soil. The premixed flow-state stabilized soil is characterized in that the premixed flow-state stabilized soil is a building material which is formed by taking natural soil mass obtained nearby as a primary material, taking a soil mass stabilizing agent as a secondary material and conducting conveying and even stirring through ground machines after adding a certain ratio of water, has liquidity and has certain strength after being hardened, and the premixed flow-state stabilized soil can be widely used for foundation stabilization, groove backfilling, road roadbeds, foundation pit supporting and protecting curtain walls and mine goaf backfilling; and according to component properties of soil and different requirements for finished product strength, materials forming the premixed flow-state stabilized soil include, by mass, 58%-92% of the soil and 8%-42% of the soil mass stabilizing agent. The stabilized soil is high in strength and good in stability after being stabilized, and the premixed flow-state stabilized soil has the beneficial effects that resources are saved, cost is saved, environment friendliness is achieved, construction is flexible, operation is convenient, and the application range is wide.

Owner:王继忠 +1

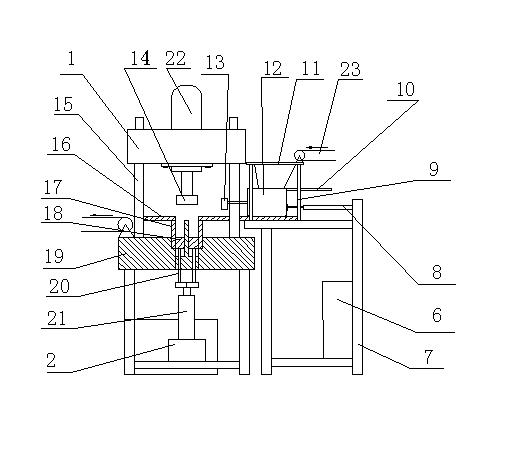

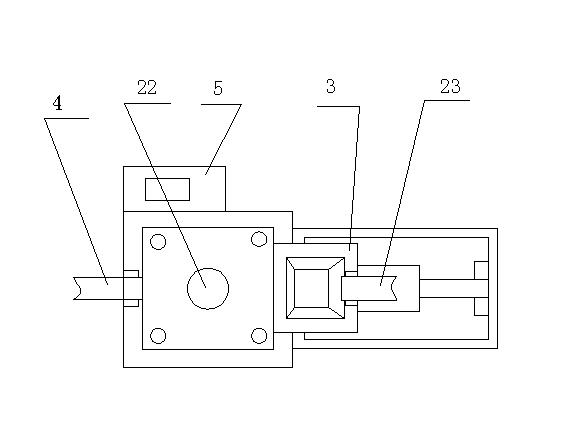

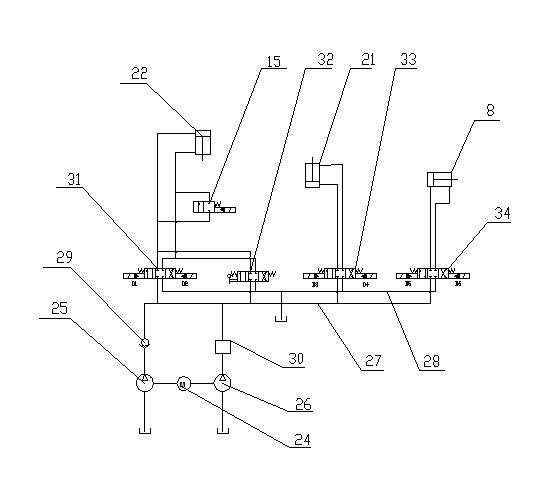

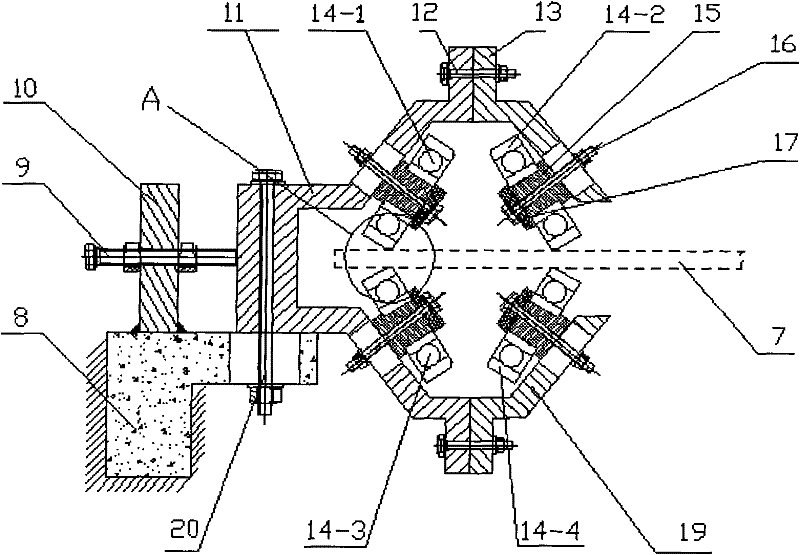

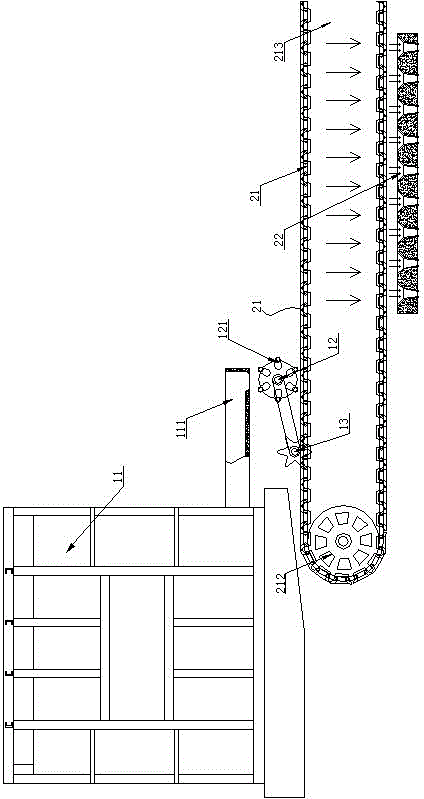

Automatic hydraulic molding machine for pulverized coal

InactiveCN102120367AHigh degree of automationImprove production continuityPress ramControl systemMolding machine

The invention provides an automatic hydraulic molding machine for pulverized coal. The machine mainly comprises a frame, a molding mechanism, a feeding mechanism, a pushing mechanism, a hydraulic control system and an electrical control system, wherein the pushing mechanism is arranged on one side of the frame; the molding mechanism is arranged on the upper part of the pushing mechanism through apillar; the feeding mechanism is arranged on the frame; and the feeding mechanism mainly comprises a feeding cylinder, a storage hopper, a feeding cart, a conveying plate and a feeding belt, the storage hopper is arranged on the frame through a mounting bracket, the feeding belt is arranged at the opening of the upper end of the storage hopper, the feeding cart is arranged on the lower side of the storage hopper, and the feeding cart is connected with the feeding cylinder. The device optimally integrates the feeding mechanism, the molding mechanism and the pushing mechanism, and is cooperatedwith constant material feeding and discharging molded blocks to ensure that the whole production process does not require staff on duty, thus the device has the advantages of high automation degree, good production continuity performance and high production efficiency improved by over 2 times, and can be widely applied to industrial production.

Owner:平顶山市通运矿山机械厂

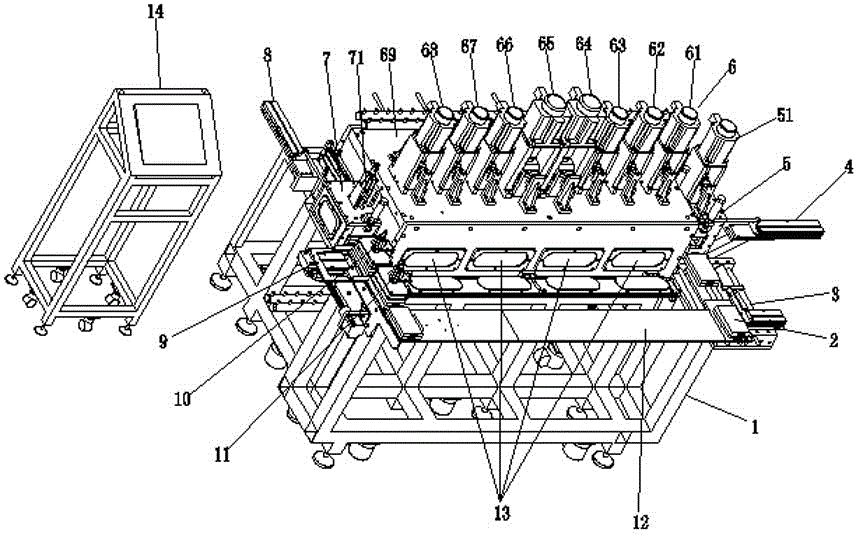

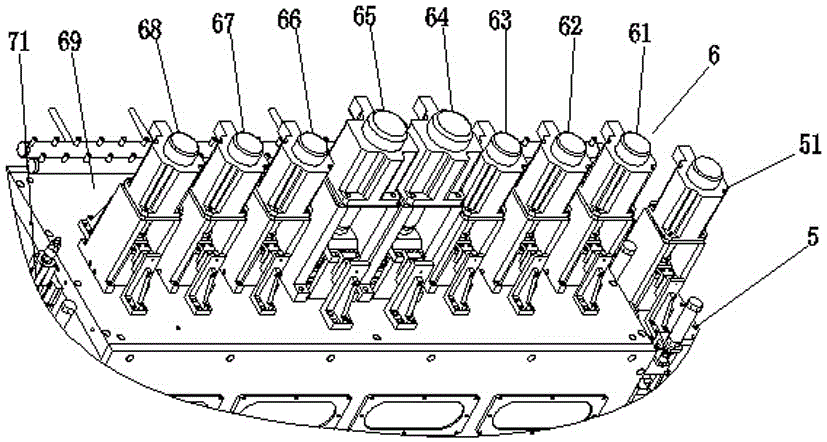

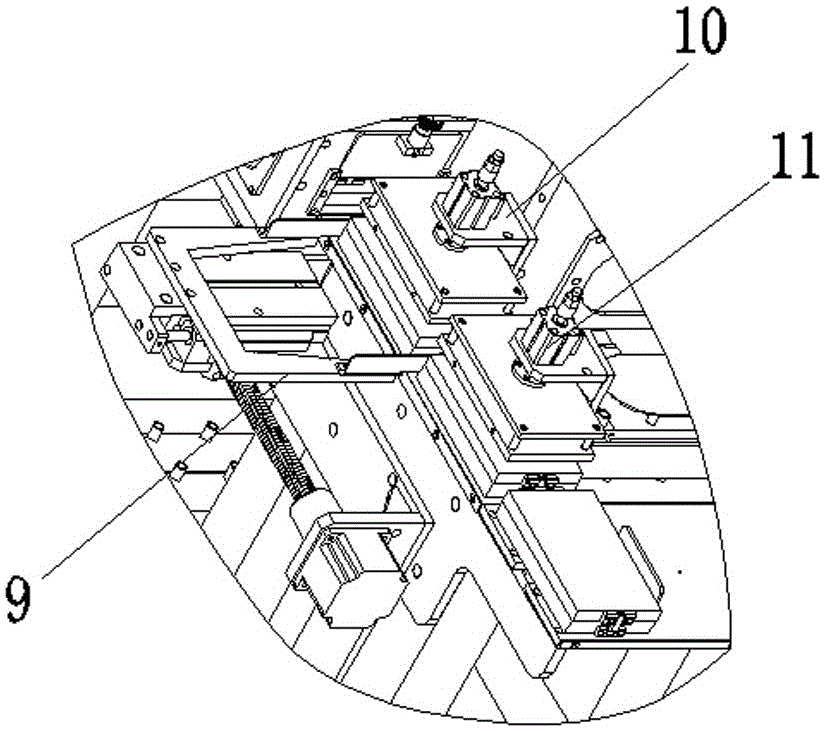

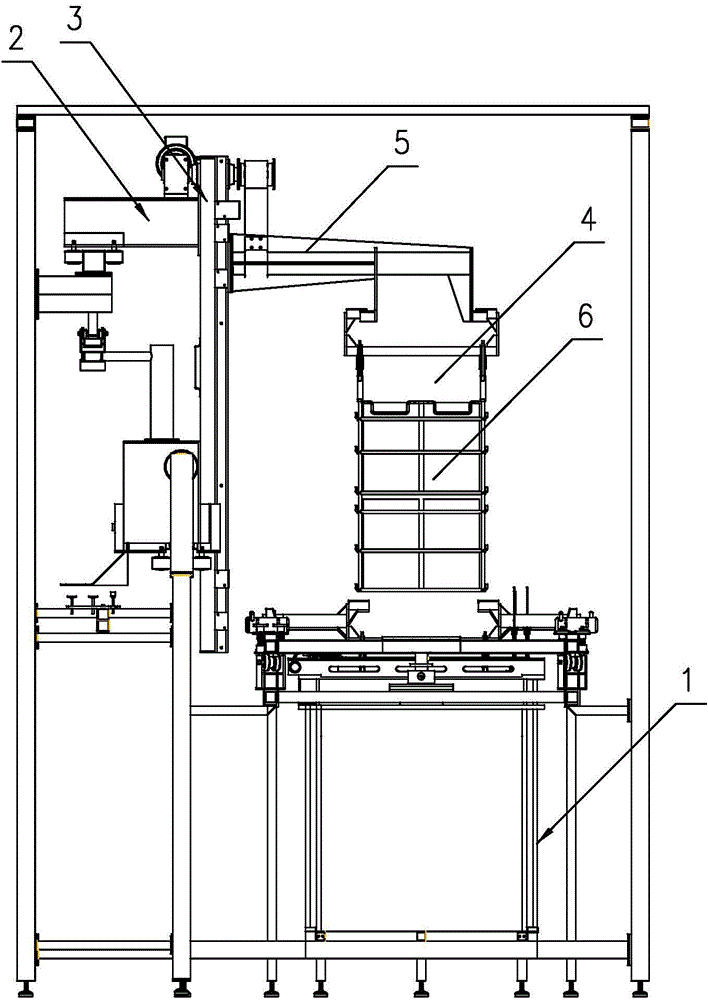

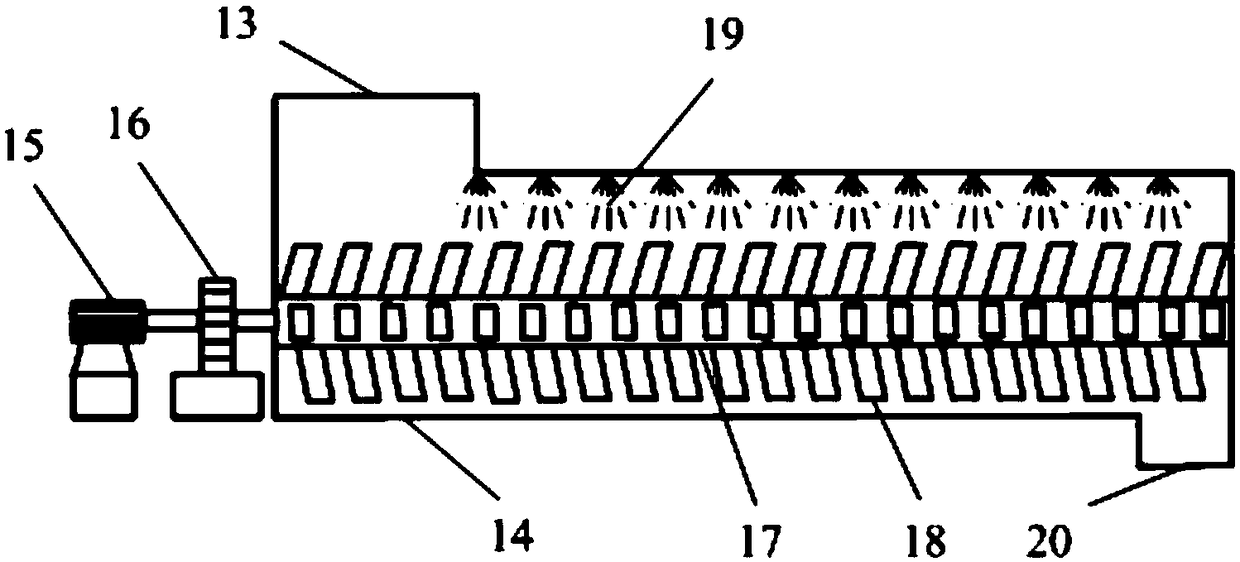

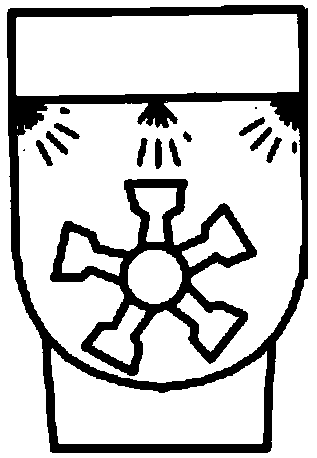

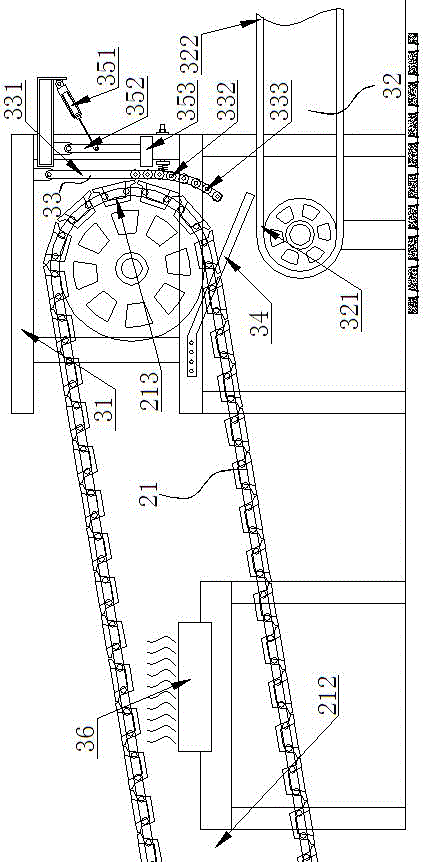

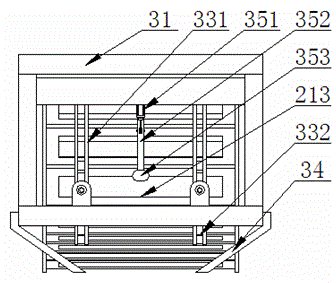

Hot-bending forming machine for mobile phone glass and watch surface covers

InactiveCN106316081AUniform heating effectImprove production continuityGlass reforming apparatusEngineeringHeating effect

The invention discloses a hot-bending forming machine for mobile phone glass and watch surface covers. The hot-bending forming machine comprises a rack and an operation console, wherein a forming part is arranged on the rack and comprises a forming bin, mold preheating mechanisms, a forming mechanism, a shaping mechanism, mold precooling mechanisms and a mold first cooling mechanism are sequentially arranged from an inlet end to an outlet end in the forming bin, and a forking and conveying mechanism for conveying a mold to each mechanism is arranged on the back side of the forming bin; a transition bin is arranged outside the inlet end of the forming bin, a mold feeding mechanism is arranged in front of the transition bin, a mold pushing mechanism is arranged on the outer side of the transition bin, and a first mold preheating mechanism is arranged in the transition bin; a discharging bin is arranged outside the outlet end of the forming bin, a second mold cooling mechanism is arranged in the discharging bin, a discharged material pushing mechanism is arranged on the back side of the discharging bin, a secondary cooling mechanism is arranged in front of the discharging bin, and a discharging cooling and conveying mechanism is arranged on the outer side of the secondary cooling mechanism. The hot-bending forming machine for the mobile phone glass and the watch surface covers has the advantages of uniform heating effect, good production continuity, high production efficiency and the like.

Owner:饶武良

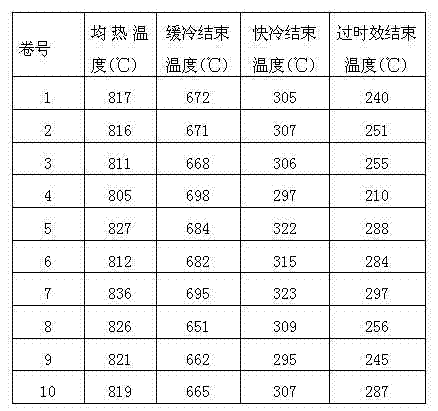

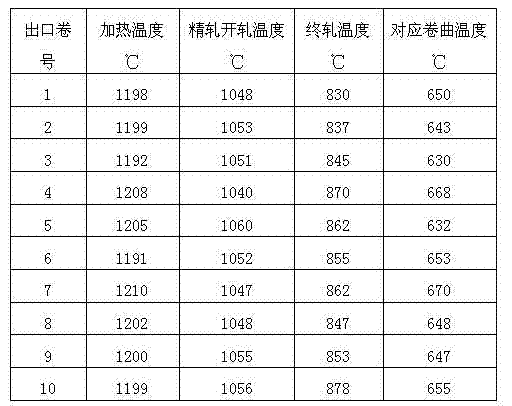

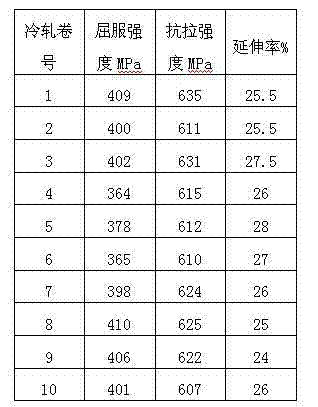

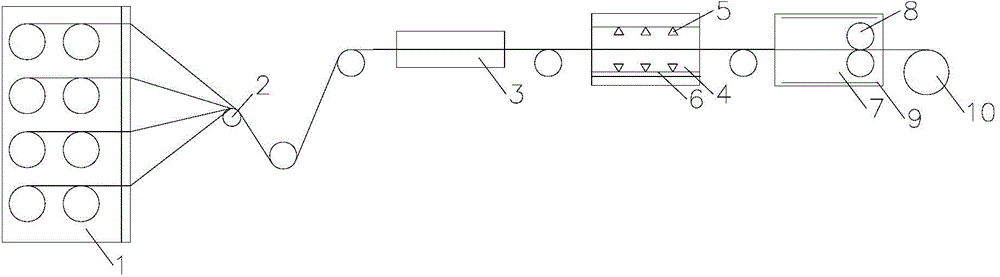

Production method of 600MPa grade cold rolling dual-phase steel

The invention relates to a production method of 600MPa grade cold rolling dual-phase steel and belongs to the technical field of metallurgical sheet material production. The technical scheme of the production method comprises working procedures of smelting in a converter, LF (ladle furnace) refining, continuous casting, hot rolling, cold rolling and continuous annealing. The final chemical components according to mass percent are as follows: 0.06-0.09% of C, 0.4-0.6% of Si, 1.65-1.75% of Mn, less than or equal to 0.01% of P, less than or equal to 0.015% of S, 0.025-0.06% of Als, less than or equal to 0.004% of N, and the balance of Fe. Molten iron requirements in the procedure of smelting in the converter are as follows: S is less than or equal to 0.040%, desulfurization target S is less than or equal to 0.010%, added steel scrap is 4-8% of total mass of the molten iron, and hot metal ratio is more than or equal to 85%. In the production method, no alloy element is added; composition of C-Si-Mn series dual-phase steel is improved; Si content is decreased; Al content is increased; and cold rolling dual-phase steel with low yield ratio and high elongation coefficient is produced by improving smelting, hot rolling, cold rolling and continuous annealing processes; the cost is low; the production procedures are continuous; and the product quality is stable. The mechanical property of the finished product is as follows: yield strength is about 360-430MPa, tensile strength is more than or equal to 600MPa, and elongation coefficient is more than or equal to 25%.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Novel sea-island fiber synthetic leather base cloth and production technology thereof

ActiveCN108589028ASolve pollutionNo emissionsConjugated synthetic polymer artificial filamentsNon-woven fabricsPolyethylene terephthalate glycolDecomposition

The invention discloses novel sea-island fiber synthetic leather base cloth. The novel sea-island fiber synthetic leather base cloth is a net which is prepared from water-soluble sea-island fibers byneedle punching and is of a three-dimensional network structure; a sea-island fiber needle-punched fabric layer is prepared from the sea-island fibers with water-soluble PVA (polyvinyl acetate) as a marine component and a PA (polyamide) or PET (polyethylene terephthalate) material as an island phase component by lapping and needle punching, wherein the island phase component accounts for 60%-85% of a fiber section area, the marine component accounts for 40%-15% of the fiber section area, denier of the sea-island fibers is 1.6-14 dtex, breaking strength is 3-6 cN / dtex, elongation at break is 7%-10%, single fiber denier of the island phase component is 0.8 dtex or lower, PVA is water-soluble PVA mater batch, and the melting point is 180-190 DEG C; the melting range is 175-195 DEG C, and thethermal decomposition temperature is 210-220 DEG C. The invention further discloses a production technology of the base cloth. The problem of pollution caused by the fact that complex fibers are treated and prepared from traditional PVA chips by adopting an organic solvent is solved, and the purpose of composite melt spinning with island phase resin is achieved.

Owner:浙江泓泰德建新纤维有限公司

Preparation method of self-hydrophobic silicon dioxide aerogel composite material

InactiveCN109437832ANot easy to cause crackingUniform structure distributionMaterials preparationSolvent

The invention discloses a preparation method of a self-hydrophobic silicon dioxide aerogel composite material. The method comprises the following steps of (1) sol preparation: preparing the sol from raw materials comprising silicon source precursors, hydrophobic modifiers, solvents, water and hydrolysis catalysts; (2) alcogel preparation by compounding sol and substrates; (3) aging of alcogel; (4)silicon dioxide aerogel composite material preparation by supercritical CO2 drying of aged alcogel; (5) aerogel composite material finished product correlation performance detection. The prepared self-hydrophobic silicon dioxide aerogel composite material has the excellent heat insulation performance, waterproof performance, fireproof and mechanical performance; the construction is convenient. The preparation method avoids a single hydrophobic modification step; the technical production steps are simplified; the operation is simple and easy; the process is controllable; the production continuity is realized.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

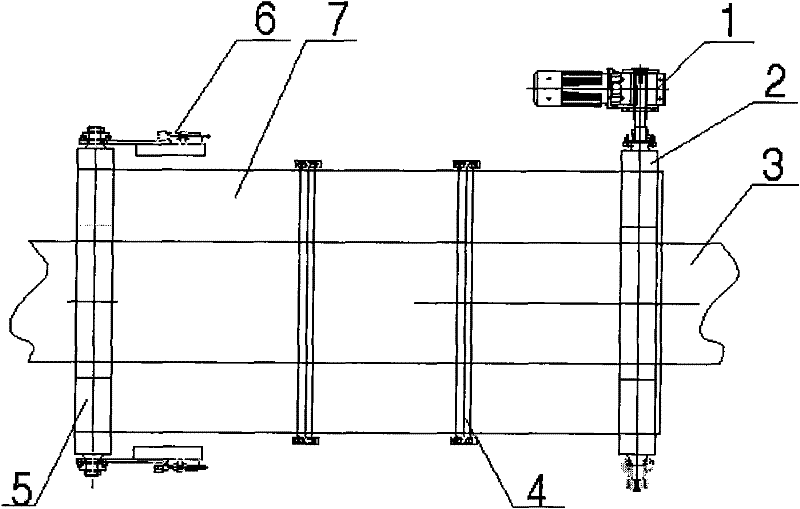

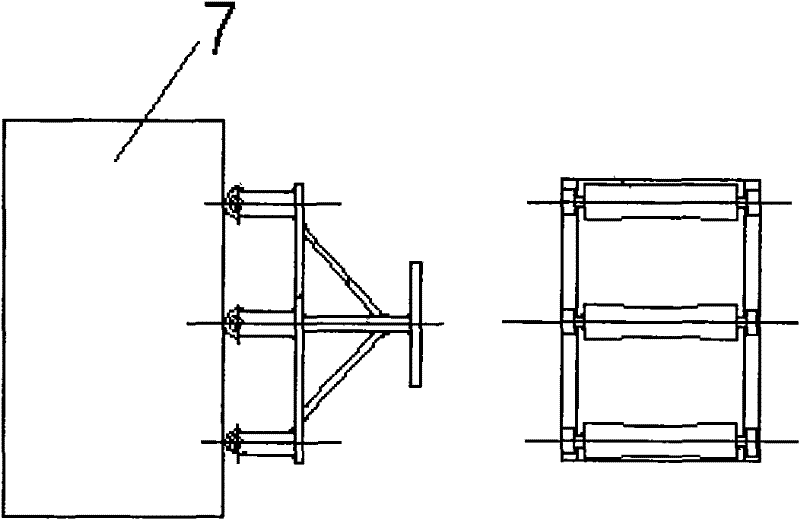

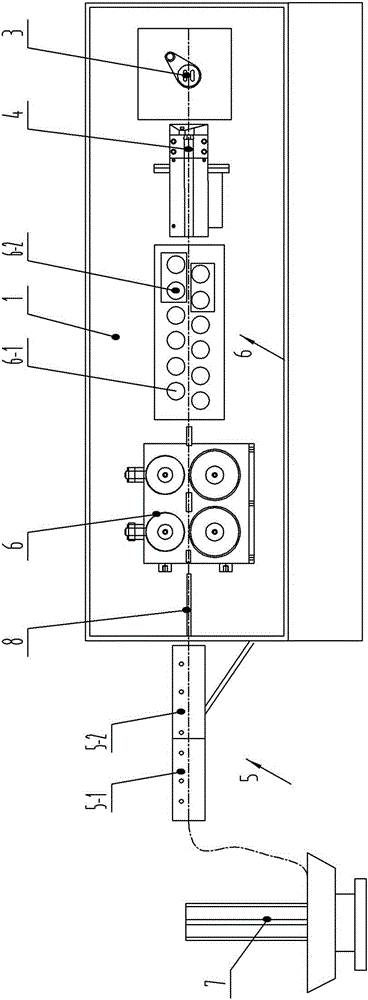

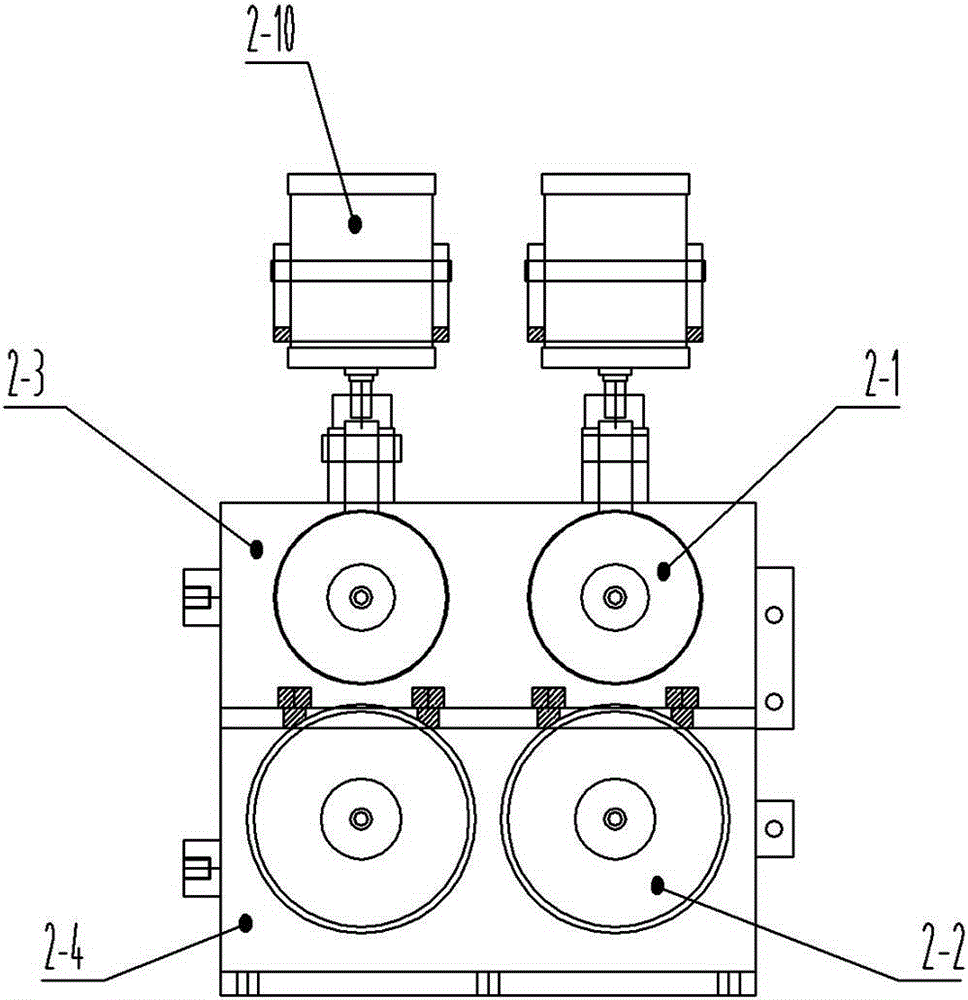

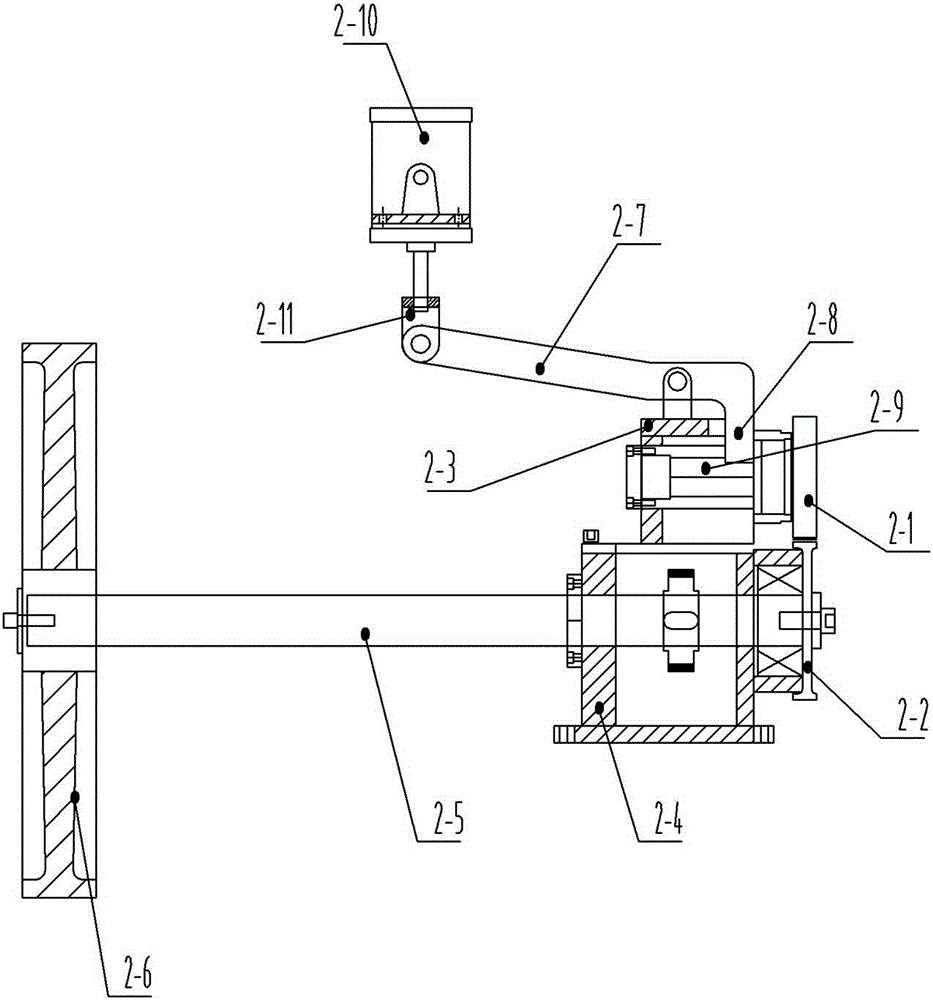

Equipment for preparing continuous functionalized carbon fiber enhanced thermoplastic resin base prepreg tape

The invention discloses equipment for preparing continuous functionalized carbon fiber enhanced thermoplastic resin base prepreg tape. The equipment comprises a yarn rack, a yarn guiding device, a spraying device, a hot press moulding device, and a reeling roller; and the yarn rack, the yarn guiding device, the spraying device, the hot pressing moulding device, and the reeling roller are sequentially arranged from the front to the rear. A functionalized carbon fiber splitting device is arranged between the yarn guiding device and the spraying device, and the spraying device is used to spray thermoplastic resin powder suspension over the splitted functionalized carbon fibers. A splitting device is added before the spraying device and the spraying device is used to spray suspension containing thermoplastic resin powder over the functionalized carbon fibers to effectively control the prepreg tape resin content so as to prepare uniform and low porosity continuous functionalized carbon fiber enhanced thermoplastic prepreg tape. The equipment has the advantages of simple structure and good production continuity.

Owner:DONGHUA UNIV

Preparation process of high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket

The invention provides a preparation process of a high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket. The high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket is mainly prepared by doping magnesium hydroxide into a glass fiber compound silicon dioxide aerogel by virtue of a sol-gel method and a supercutical fluid CO2 drying technology based on excellent characteristics of magnesium hydroxide. The high-temperature-resistant hydrophobic silicon dioxide aerogel heat-isolating blanket prepared by the process provided by the invention has excellent insulating property and mechanical property, good high-temperature-resistant hydrophobic property, and is convenient to construct. The preparation method avoids a step of replacing a solvent, and is simple to operate, controllable in process and continuous in production. The preparation process provided by the invention belongs to the technical field of chemical materials.

Owner:GUIZHOU AEROSPACE WUJIANG MACHINERY & ELECTRICITYEQUIP

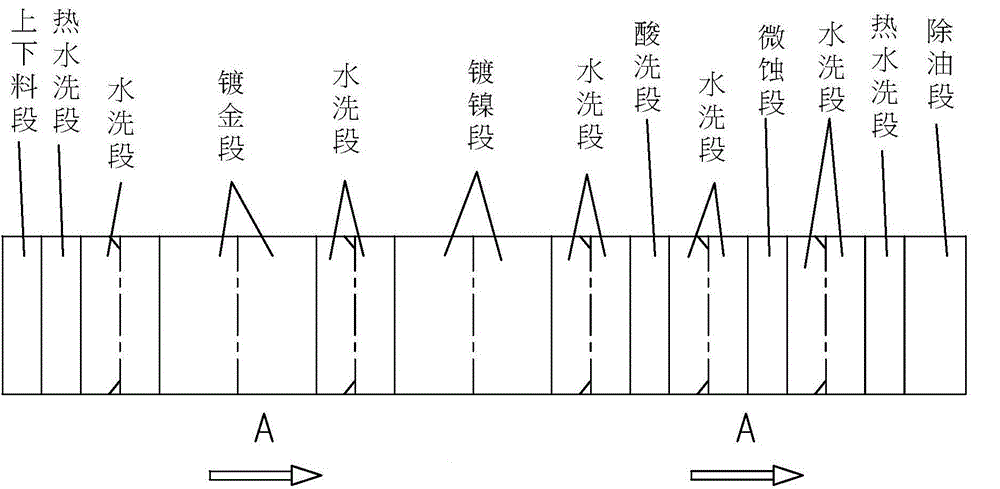

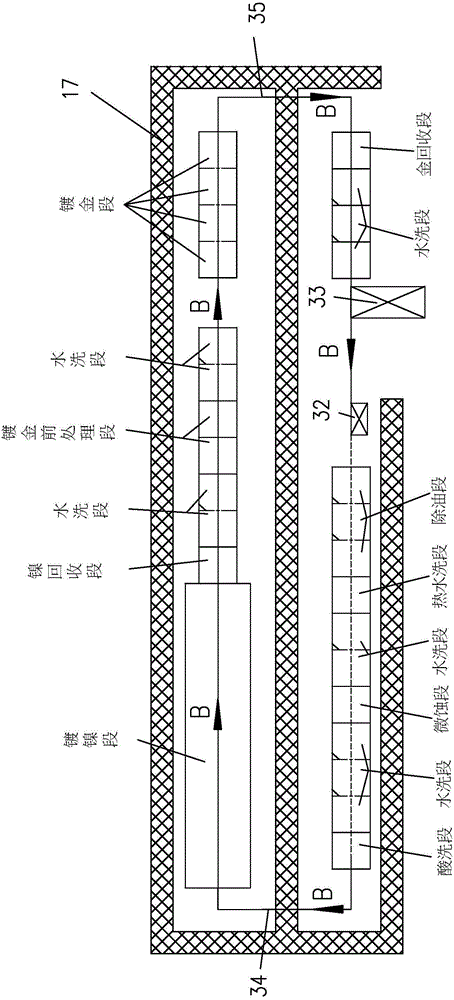

Vertical continuous PCB nickel or gold plating equipment

The invention discloses vertical continuous PCB nickel or gold plating equipment, comprising an electric control device, a nickel plating bath, a gold plating bath, a rack, a conveying mechanism, a nickel plating pretreatment tank, a nickel plating post-treatment tank, a gold plating pretreatment tank and a gold plating post-treatment tank, wherein the conveying mechanism is arranged on the rack, and is arranged above each tank body; the electric control device controls PCB plates to be conveyed to the corresponding treatment tank to gradually immerse or lift; the length direction of the nickel plating bath is consistent with the process flow direction; the conveying mechanism is used for gradually and continuously immersing the PCB plates into the nickel plating bath; each PCB plate is soaked into the nickel plating bath under the drive of the conveying mechanism, and moves along the length direction of the nickel plating bath; anodes are respectively arranged on two side walls of the nickel plating bath; the panels of the PCB plates are opposite to the anodes; two anodes are symmetrically distributed on two sides of each PCB plate; the consistency and the uniformity of the surface coatings of different PCB plates are ensured; the subsequent continuous gold plating consistency and uniformity are improved; waste of a liquid medicine is reduced; the wastewater treatment difficulty is lowered; the environmental pollution is reduced; and the cost is also reduced.

Owner:朱和平 +1

PET/PVA sea-island fiber with water-soluble sea facies, and production process of PET/PVA sea-island fiber

ActiveCN108486683AEnables thermoplastic processingNo emissionsFilament/thread formingConjugated synthetic polymer artificial filamentsPolyolSpinning

The invention discloses a PET / PVA sea-island fiber with water-soluble sea facies. The PET / PVA sea-island fiber with the water-soluble sea facies is obtained through stretching and heat setting a nascent fiber formed by adopting PET as an island face component and PVA as a sea face component, wherein the island face component of the nascent fiber accounts for 60 percent to 85 percent of the cross section area of the fiber; the sea component accounts for 40 percent to 15 percent of the cross section area of the fiber; water-soluble PVA master batch is prepared by blending the following raw materials in parts by weight: 50 to 70 parts of polyvinyl alcohol, 15 to 25 parts of polyhydric alcohol or salt compound modifier, 3 to 7 parts of an antioxidant, 3 to 7 parts of a lubricating agent, and 25 to 35 parts of deionized water. The invention also provides a production process of the sea-island fiber. Compared with traditional PVA, according to the PET / PVA sea-island fiber with the water-soluble sea facies, provided by the invention, the melting point is reduced, so that the PVA sea component can be melt and compositely spun with the PET with a high melting point, the problem of PVA decomposition cannot happen while the melting point is reached, and the problem that the traditional PVA is decomposed when encountering the high-temperature PET so that melting and composite spinning cannot be achieved is solved.

Owner:浙江泓泰德建新纤维有限公司

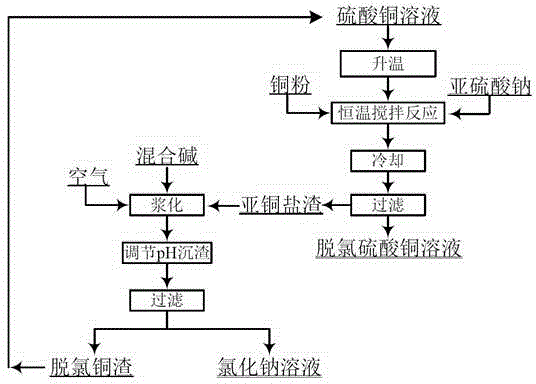

Method for removing chloride ions in copper sulphate solution

ActiveCN105671313AEconomic solution to removalIncrease concentrationProcess efficiency improvementHigh concentrationSulfite salt

The invention relates to an economic method for removing chloride ions in a copper sulphate solution. The method comprises the following steps: adjusting a pH value and oxido reduction potential and adjusting copper sulphate with sodium carbonate and sodium sulfite to a reaction interval where Na2[CuCl3] can stable exist; carrying out heating, adding elemental copper powder, allowing Na2[CuCl3] in the solution and the elemental copper powder to undergo comproportionation so as to produce a white CuCl cuprous salt precipitate insoluble in water; and carrying out full cooling to separate cuprous salt sediment and the copper sulphate solution so as to obtain a dechlorinated copper sulphate solution. The method utilizes the characteristic that wet cuprous salt sediment is not stable under the condition of a high pH value to convert the wet cuprous salt sediment into dechlorinated copper residues consisting of CuO, CuCO3 and Cu(OH)2 and to return the dechlorinated copper residues into a system for reuse, and a produced sodium chloride solution has high concentration and can be directly used for evaporative preparation of industrial NaCl. The method is widely applicable to removal of chloride ions of various concentrations from high-concentration copper sulphate solutions; reagents added for reaction do not influence quality; except cost for heating, operation cost is negligible; and the method is economic and easily practicable.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

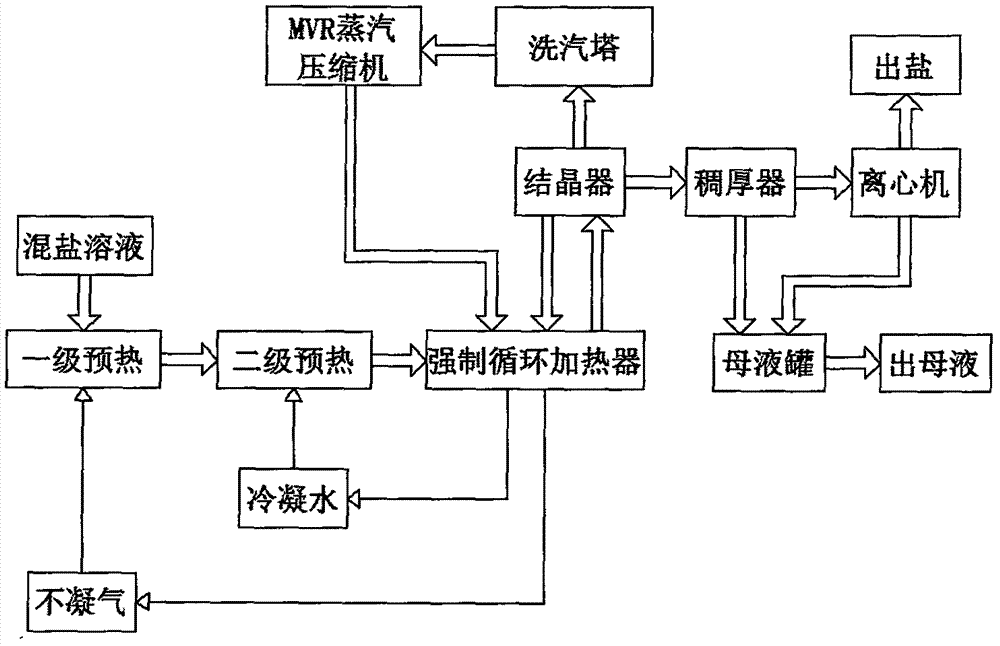

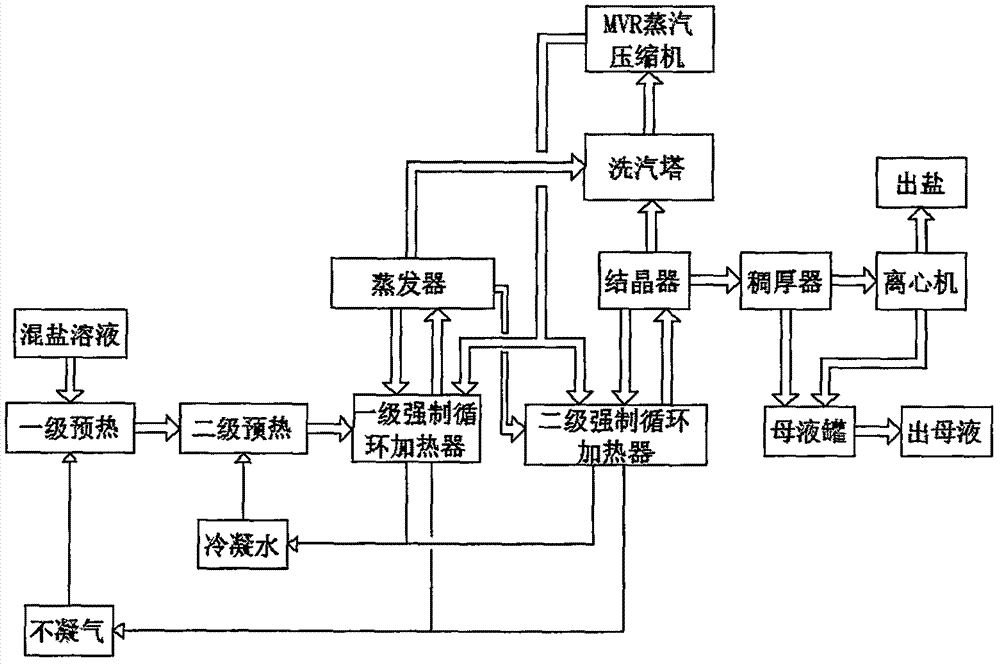

MVR evaporative concentration and crystallization process for extracting lithium from salt lake brine

InactiveCN107308662ASystem stabilityGood production continuityEvaporation with vapour compressionSeawater treatmentChemistryMulti effect

The invention relates to a MVR evaporative concentration and crystallization process for extracting lithium from salt lake brine. The process comprises the following steps: preheating of a stock solution; MVR evaporative concentration and crystallization; and MVR vapor compression. The process employs MVR vapor recompression technology for evaporative concentration of the salt lake brine, and a small number of sodium chloride crystals are precipitated during evaporative concentration, so energy consumption and operation cost are lowered, the technical advancement of the process is improved, and the process overcomes the problem that conventional equipment only concentrates a lithium solution and is incapable of realizing precipitation of high-purity sodium chloride salt crystals in the process of multi-effect evaporation.

Owner:BEIJING PUREN MEIHUA ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH

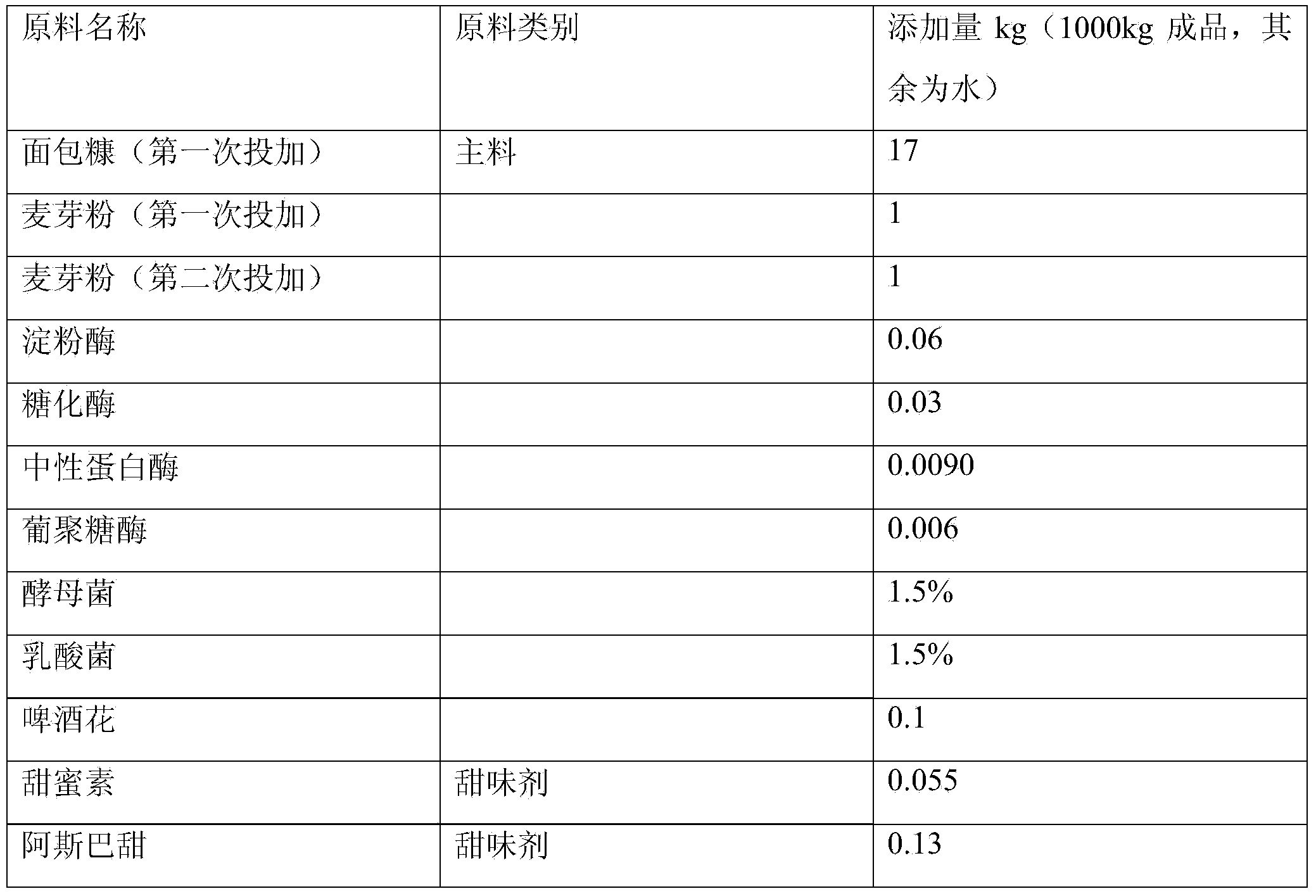

Method for preparing kbac beverage

InactiveCN103865728AReduce in quantityUniform particle sizeAlcoholic beverage preparationGlucanaseNeutral protease

The invention relates to a method for preparing a kbac beverage. The method comprises the following steps: adding water into a saccharifying tank, heating to be 35 DEG C, adding breadcrumbs, uniformly stirring, adding malt flour, heating to be 65 DEG C, adding alpha-amylase, heating to be 90 DEG C, stopping stirring, heating to be 100 DEG C, keeping the temperature for 20 minutes, cooling to be 52 DEG C, adding beta-glucanase, neutral protease and malt flour, keeping the temperature for 70 minutes, heating to be 60 DEG C, adding saccharifying enzyme, heating to be 63 DEG C, keeping the temperature for 40 minutes, heating to be 68 DEG C, keeping the temperature for 20 minutes, heating to be 78 DEG C, standing for 60 minutes to obtain a saccharification liquid, and filtering to obtain supernate. On the basis that the kbac fermented beverage prepared by using the method provided by the invention does not affect the original rich nutrition and health value, the biologic stability of a product is greatly improved, and the product is better in stability and taste within the expiration date. The product stability is that the nutrient substance can be separated for 180-200 days increased from 3-40 days.

Owner:TIANJIN QIULIN KWAS FOOD SCI & TECH

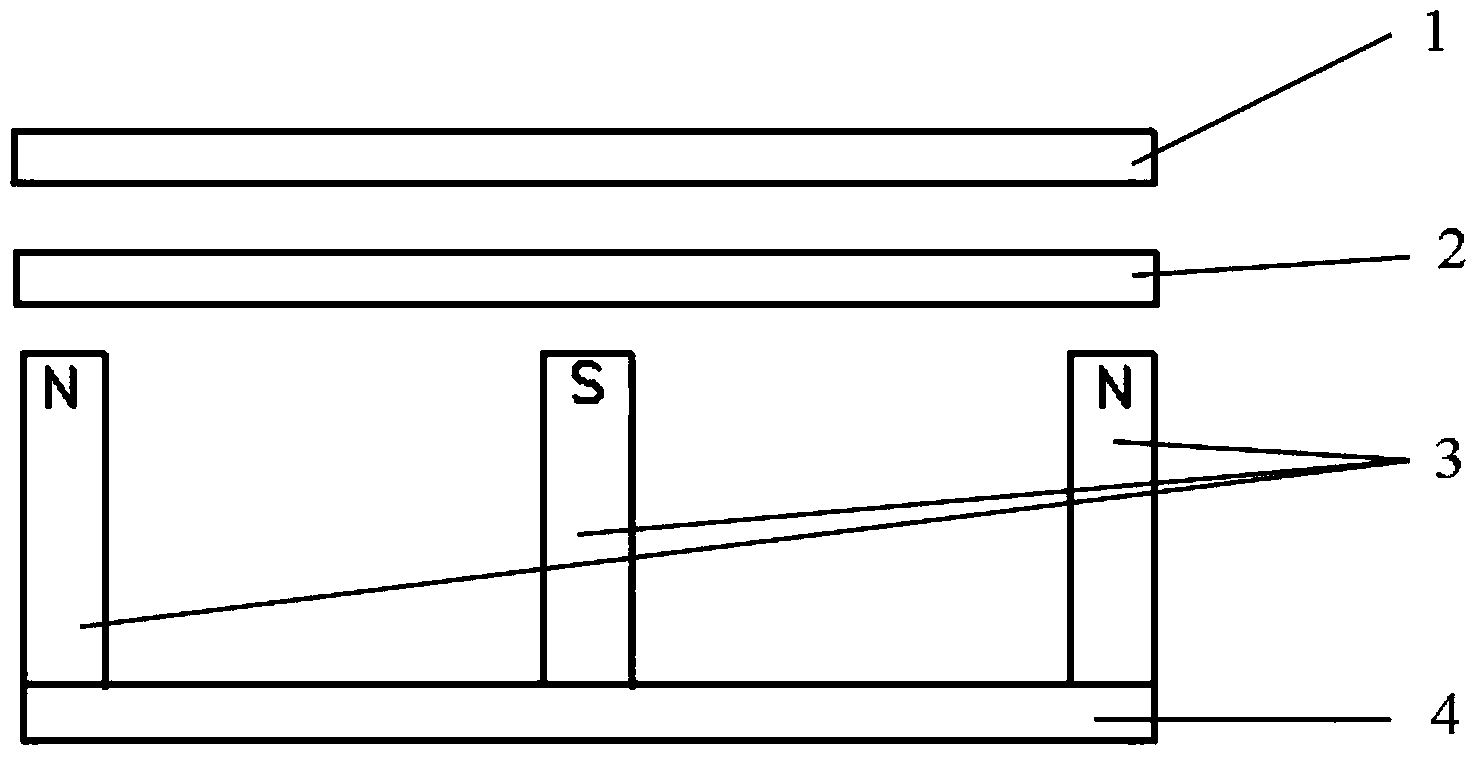

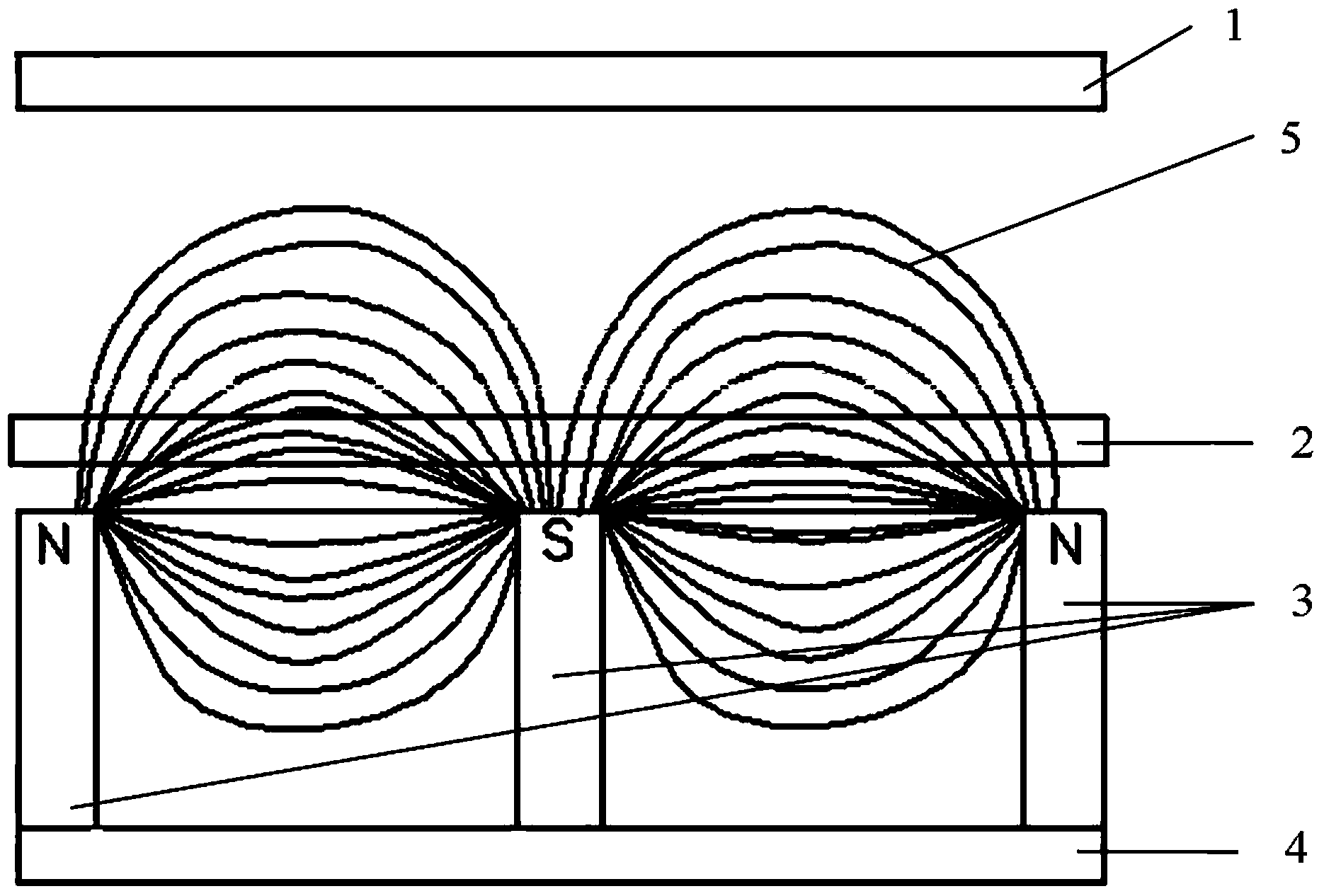

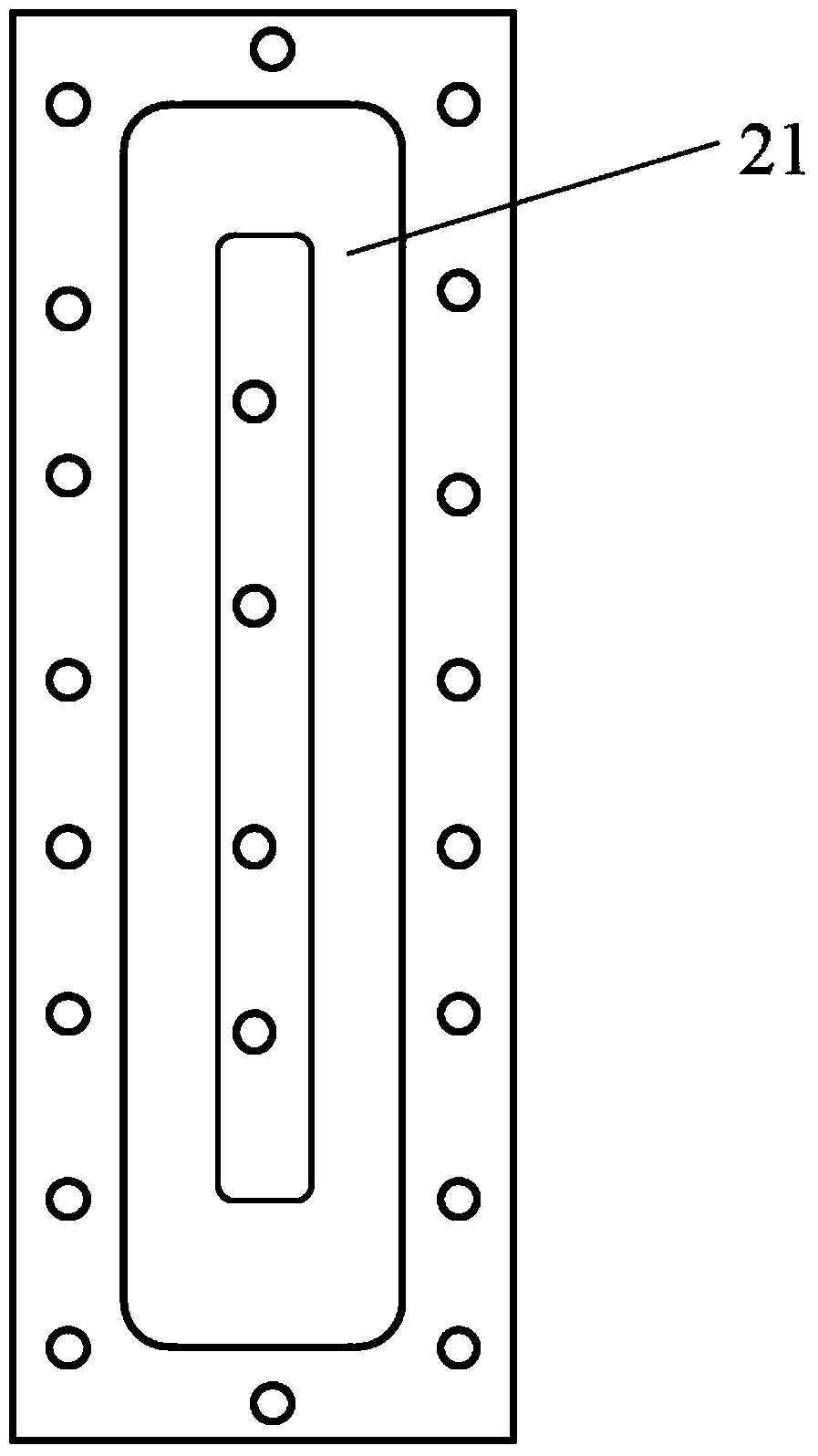

Self-adaptive magnetic field adjustment type magnetic-controlled sputter coating device and coating method thereof

ActiveCN103556122AReal-time monitoring of magnetic field strengthIncrease profitVacuum evaporation coatingSputtering coatingElectricityTarget surface

The invention discloses a self-adaptive magnetic field adjustment type magnetic-controlled sputter coating device. An electrified coil is arranged between adjacent permanent magnets; a hall sensor is arranged between the electrified coil and a magnet yoke; a length direction of the electrified coil is vertical to directions of magnetic poles of the permanent magnets; a magnetic field strength detecting system is externally connected with the hall sensor and applied to real-time monitoring of the magnetic field strength; a circuit control module is externally connected with the electrified coil and electrically connected with the magnetic field strength detecting system; current flowing through the electrified coil is adjusted according to data of the magnetic field strength detecting system, so that magnetic field distribution is changed and the magnetic field is in a most optimized state all the time, namely, magnetic force lines and a target surface are located on the same plane to the greatest extent, so that the effect of a maximum utilization rate of target material is achieved; meanwhile, the magnetic field strength can be monitored in real time and adjusted without the need of interrupting the coating process, so that the production efficiency is high.

Owner:SUZHOU JUZHEN PHOTOELECTRIC

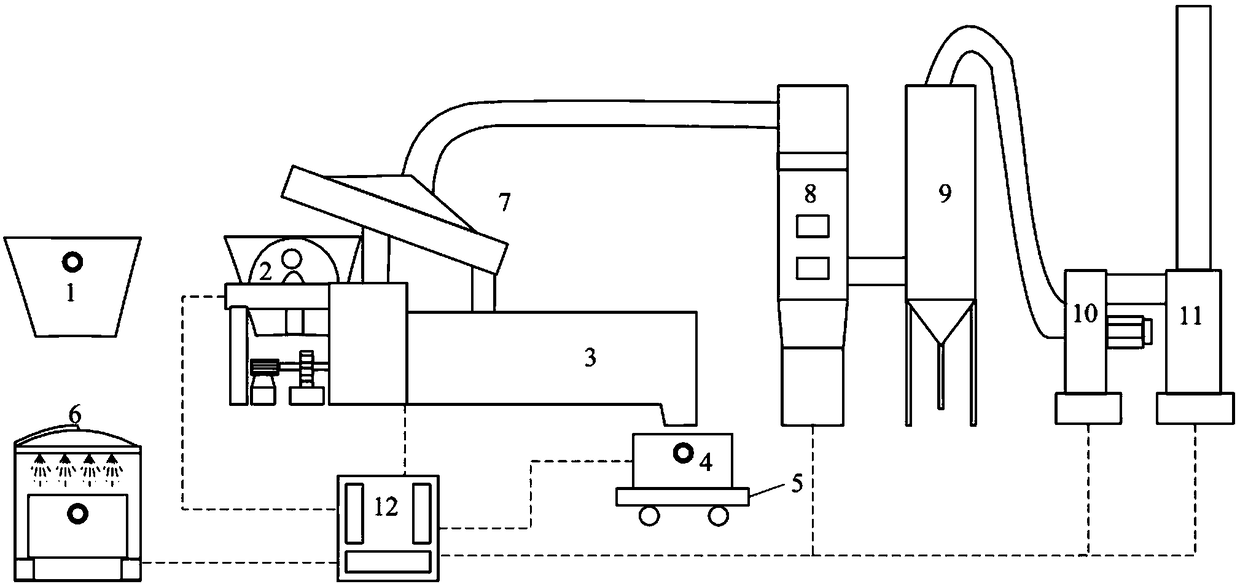

Melted steel dreg spiral crushing device and method

PendingCN109112238AHigh degree of automationGood production continuityRecycling and recovery technologiesBatch productionFlue gas

The invention relates to a melted steel dreg spiral crushing device and method. The melted steel dreg spiral crushing device comprises a dreg tank (1), a rollover machine (2), a spiral crusher (3), aslag groove (4), a dreg discharging machine (5), a hot suffocating tank (6), a flue gas treatment system and a control system (12); the rollover machine is used for pouring dreg; the fixed shaft of the spiral crusher can be used for continuously crushing melted steel dreg; the melted steel dreg can be continuously poured into the spiral crusher; the spiral crusher is used for crushing the steel dreg and driving the steel dreg to a dreg outlet while being rotated according to a certain speed; the device has the advantages that continuous production of steel dreg treatment is realized, a previous batch production manner is changed and the steel dreg treatment efficiency is greatly improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

A belt online adjusting device capable of preventing belt deviation

ActiveCN102161422APrevent deviationDoes not affect tensionConveyorsWebs handlingPressboardEngineering

A belt online adjusting device capable of preventing belt deviation comprises pinch rollers, pinch roller support components and pinch roller angle adjusting components, wherein the pinch roller support components allow the pinch rollers to be arranged above and below a belt in a symmetrical V-type manner and simultaneously execute the belt positioning from above, below, left and right. The device in the invention avoids the problems of band steel deviation, folding of band threading and piling-up of steels, which are caused by the floating movement and deviation of the belt; wedge-shaped shafts enable the pinch rollers to execute three-dimensional 360-degree adjustment and are connected with the pressboards through key slots, thereby guaranteeing the synchronized adjustments of the pinch rollers and the pressboards and accordingly improving the adjustment speed; and the pinch rollers can prevent the edge damage after the belt deviates. The device in the invention has a small request for installation positions, is capable of online change and adjustment and can be widely applied to belt conveying equipment of galvanizing machine sets or other machine sets in the industry of cold rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

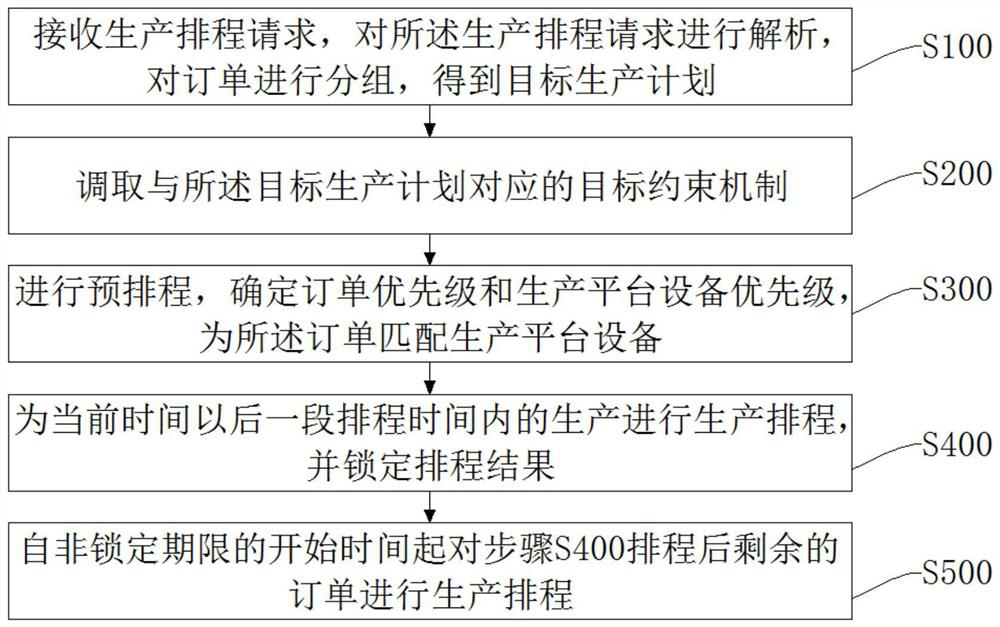

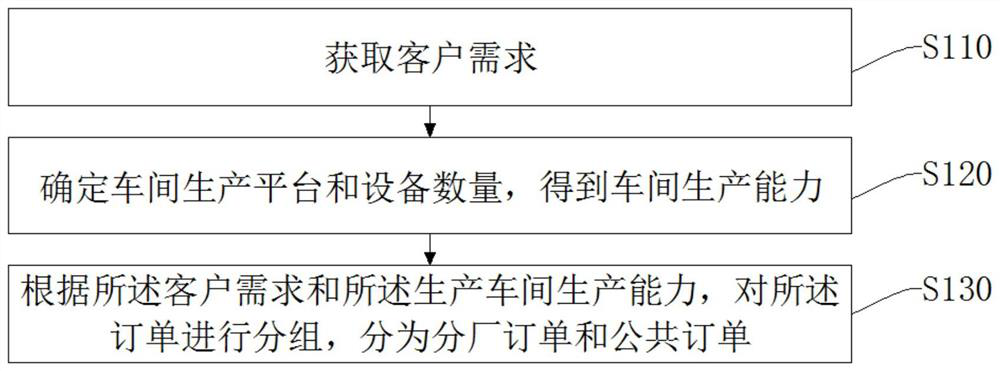

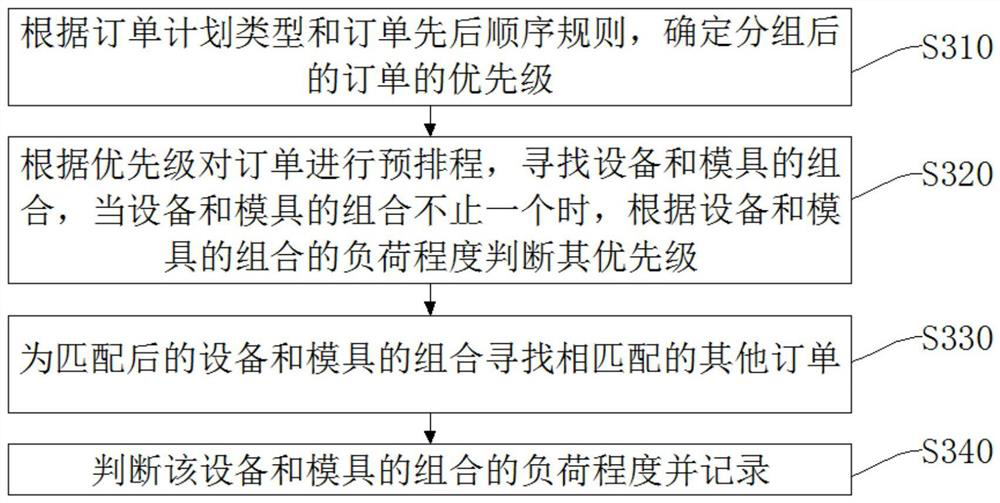

Profile extrusion production scheduling method, readable storage medium and device

PendingCN111882196AImprove production and operation efficiencyMeet production requirementsBuying/selling/leasing transactionsResourcesBusiness enterpriseProcess engineering

The invention discloses a profile extrusion production scheduling method, a readable storage medium and a device, and the method comprises the steps: S100) receiving a production scheduling request, carrying out the analysis of the production scheduling request, carrying out the grouping of orders, and obtaining a target production plan; S200) calling a target constraint mechanism corresponding tothe target production plan, wherein the target constraint mechanism comprises an order sequence rule and a resource load balancing principle; S300) performing pre-scheduling, determining an order priority and a production platform equipment priority, and matching production platform equipment for the order; S400) carrying out the production scheduling on production in a period of scheduling timeafter the current time, determining the order priority in the production scheduling, enabling the production scheduling to be matched with production platform equipment, and locking a scheduling result is locked. According to the method, the matching schedule meets the production requirements, the equipment utilization rate is obviously improved, the delivery time is shortened, and the enterpriseproduction and operation efficiency and the enterprise core competitiveness are improved.

Owner:安徽海螺信息技术工程有限责任公司

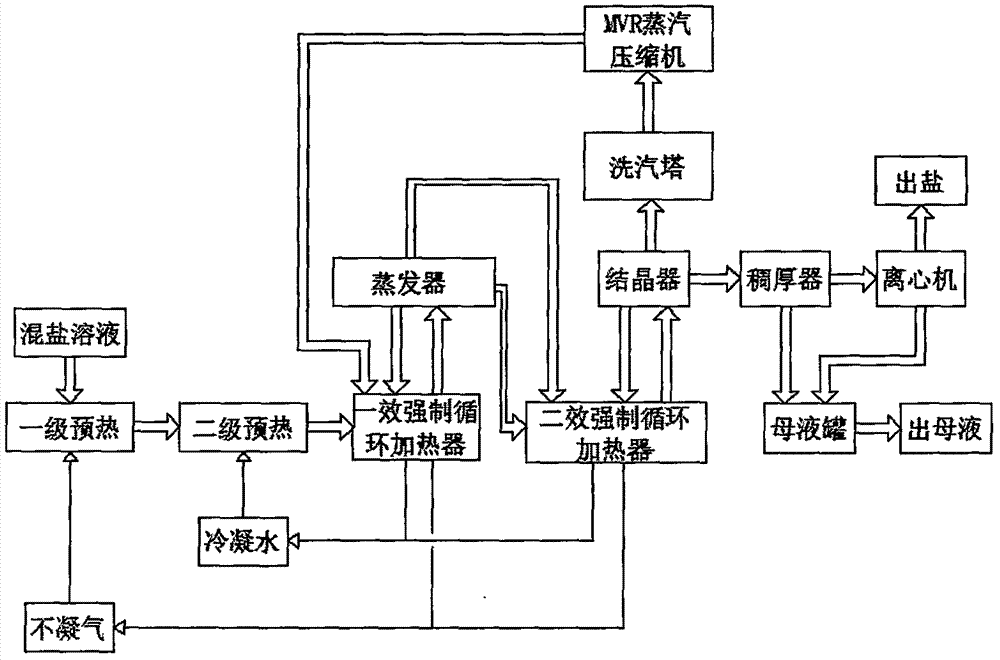

MVR evaporation and concentration process of NMMO solvent

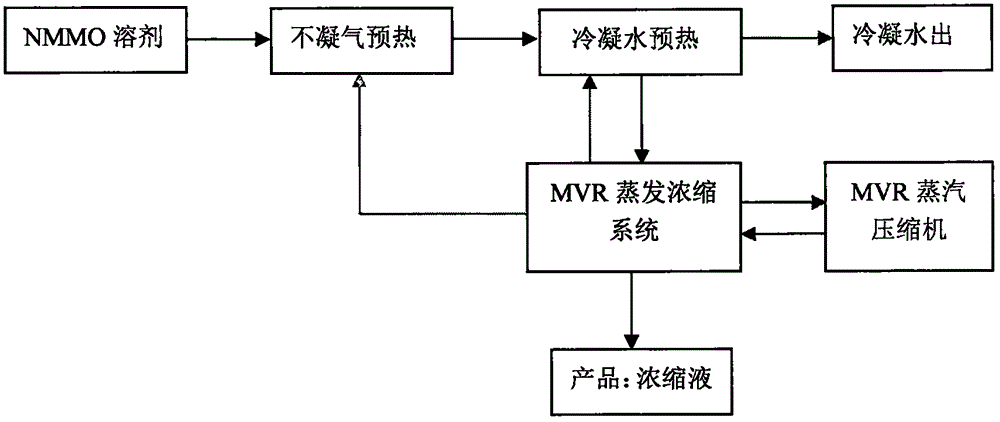

InactiveCN105854319AEasy to implementImprove production continuityOrganic chemistryEvaporation with vapour compressionEvaporationProcess engineering

A MVR evaporation and concentration process of an NMMO solvent includes a preheating part and an MVR evaporation and concentration system, wherein the preheating part includes a non-condensable gas preheating part and a condensed water preheating part, waste heat of the system is fully utilized without additionally supplemented heat energy, and the heat energy consumption is reduced; the MVR evaporation and concentration system includes a vacuum system utilizing secondary steam heating, evaporative concentration, secondary steam re-compression and independence, can reasonably utilize the effective temperature difference of the system to reduce energy consumption, and can also ensure the stable operation of the system. The process adopts an MVR evaporation and concentration mode, greatly reduces the energy consumption, reduces the operation costs and can also meet the high-vacuum requirement of the system.

Owner:BEIJING PUREN MEIHUA ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH

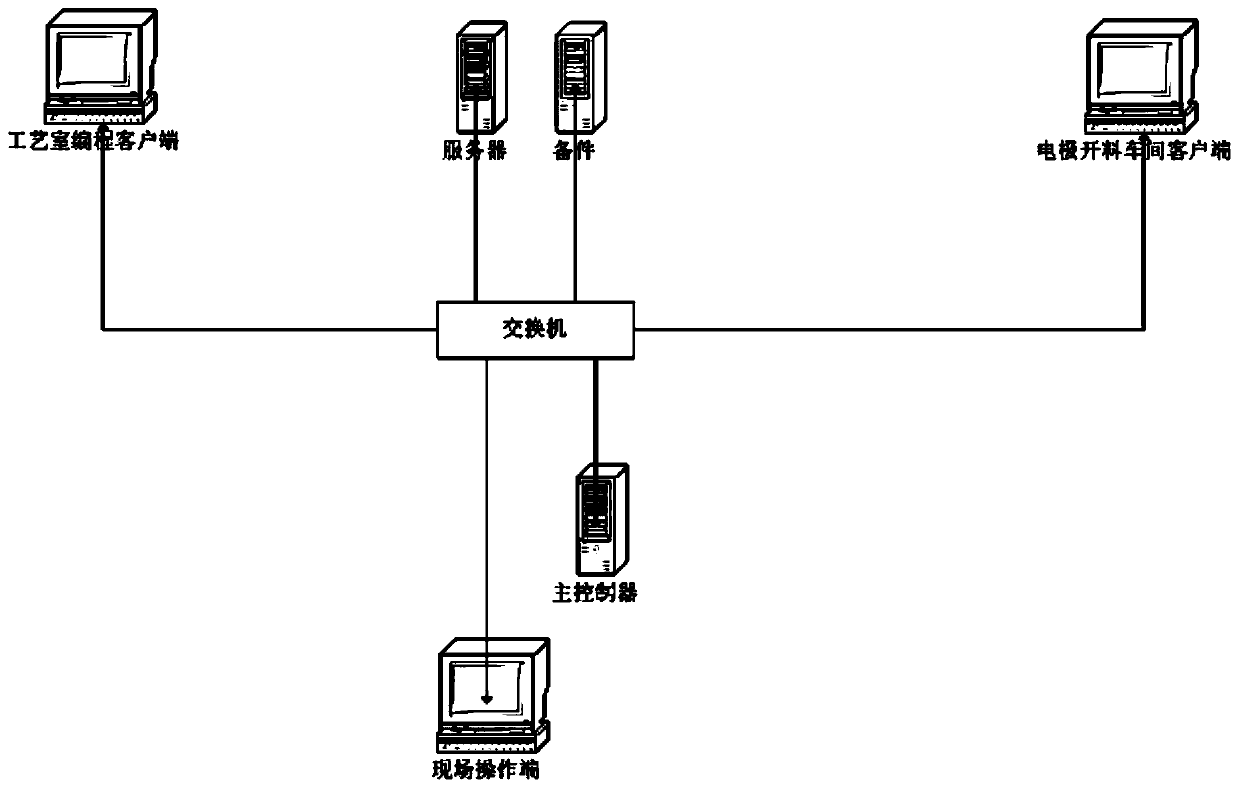

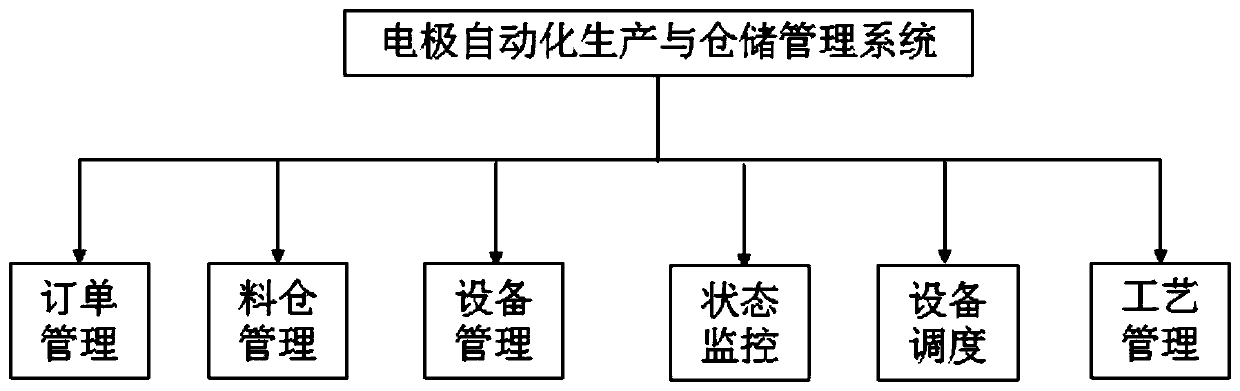

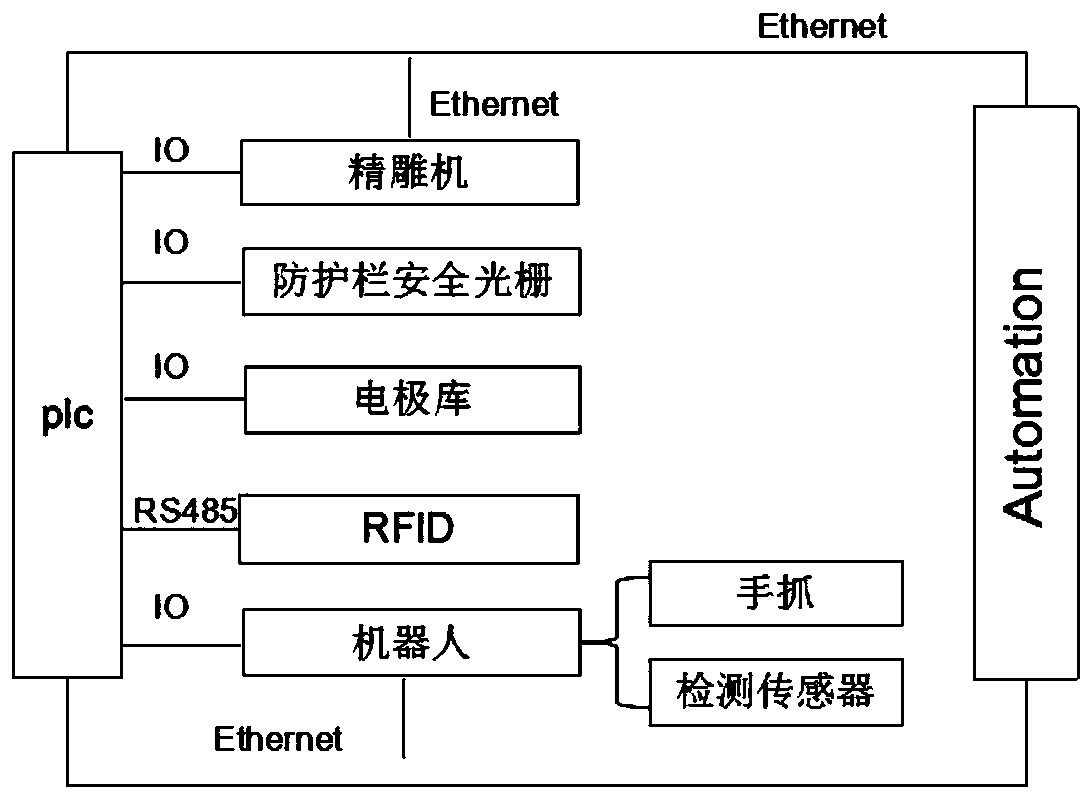

Electrode automatic production and storage management system

ActiveCN109978096AShort processing cycleImprove production continuityData processing applicationsCo-operative working arrangementsOrder formRaw material

The invention discloses an electrode automatic production and storage management system which comprises a user client, a server and a main controller. The user client is used for inputting and editingthe production information to the server and sending the production information to the server; and the server is used for receiving the information transmitted by the user client and analyzing the task type, and calling a business data processing function according to the task type, wherein the business data processing function directly operates the database form or the file, updates the databaseform and issues the file; and the main controller is used for realizing the order management, equipment management, equipment scheduling, state monitoring, stock bin management and process management. An on-site operation end is used for the processing priority adjustment and raw material warehouse-out and warehouse-in operations; and a CNC flexible machining workshop is used for processing the electrode blank into a finished product. According to the invention, the electrode production, application and storage management services are fused together, so that the production continuity, the reliability and the traceability are improved.

Owner:西安精雕软件科技有限公司

Hoop bending machine

The invention belongs to the technical field of steel bar hoop bending equipment, and particularly relates to a hoop bending machine. The hoop bending machine comprises a machine frame. The machine frame is provided with a drawing mechanism, two straightening mechanisms, a bending mechanism and a shearing mechanism. The straightening mechanisms comprise the front-back straightening mechanism and the top-bottom straightening mechanism, the front-back straightening mechanism and the top-bottom straightening mechanism are arranged on the two sides of the drawing mechanism respectively, and a pay-off rack is arranged in front of the front-back straightening mechanism. The drawing mechanism comprises a pressing wheel set, a drawing wheel set and supports, wherein the pressing wheel set and the drawing wheel set are arranged in parallel in the vertical direction in a matched mode, the end, where a driving drawing wheel of the drawing wheel set is located, of a drawing input shaft is connected with a synchronous belt drive mechanism, and a pressing mechanism is arranged corresponding to each pressing wheel. The bending mechanism comprises a case, a main shaft and a bending shaft, the main shaft is arranged in the case and connected to the synchronous belt drive mechanism, a central shaft is installed at one end of the main shaft, a bending sleeve is arranged between the main shaft and the case in a sleeving mode, and the bending shaft is arranged on the side, close to the central shaft, of the bending sleeve. The hoop bending machine is high in automation degree, high in response speed of high speed start and stop and forward and reverse rotation, short in machining cycle and low in cost.

Owner:郑州市聚能建筑机械有限公司

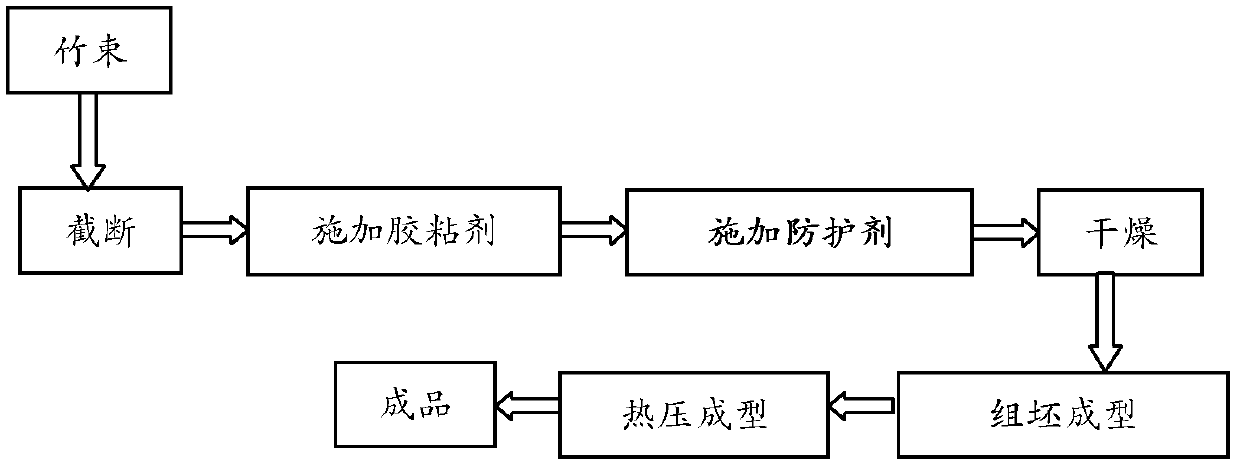

Preparation method of recombinant bamboo

InactiveCN103286842AEfficient curingFix compatibility issuesFlat articlesDomestic articlesAdhesiveCorrosion resistant

The invention relates to a preparation method of recombinant bamboo. The preparation method comprises the following steps: cutting off a bamboo filament bundle into bamboo sections with the required length; applying an adhesive to the cut-off bamboo filament bundle and curing the adhesive; applying protective agents to the bamboo filament bundle, so that the protective agents are uniformly distributed on the surface of the bamboo filament bundle; drying the bamboo filament bundle; and paving the dry bamboo filament bundle into a plate blank and performing hot-press molding. The recombinant bamboo prepared by the method can synchronously realize flame-retardant, corrosion-resistant, mildew-proof and insect-preventing effects and has the characteristics of comprehensive distribution of pesticide effect, long residual period, high penetrability and the like.

Owner:BEI JING NEW BUILDING MATERIALGRP

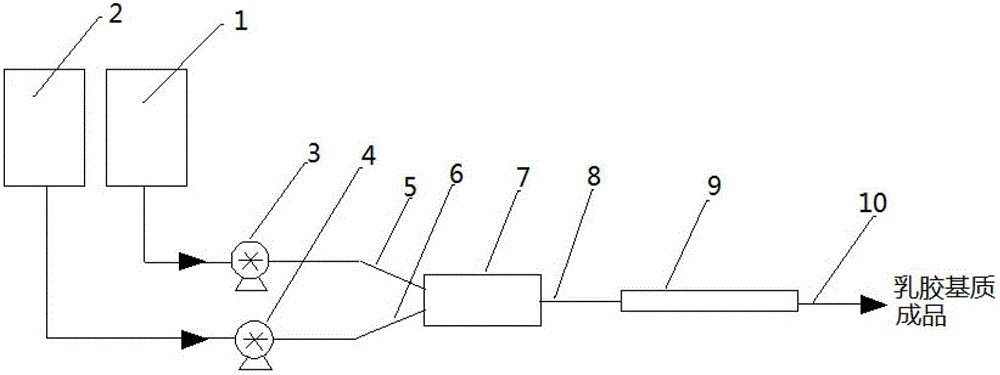

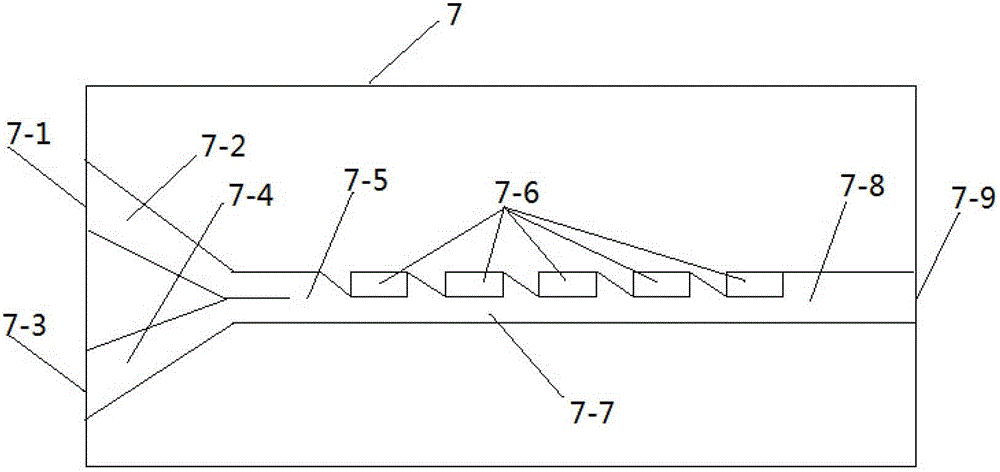

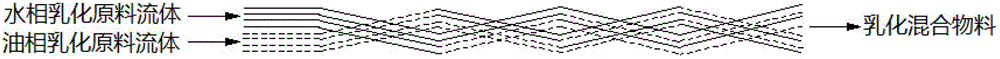

Emulsification device and method for safely preparing emulsion matrix

InactiveCN102976872AImprove the emulsification effectImprove mixing efficiencyExplosive working-up apparatusPolymer chemistryMaterial transfer

The invention relates to an emulsification device for safely preparing an emulsion matrix, which comprises a water-phase emulsification material transfer pump, a water-phase emulsification material transfer pipe, an oil-phase emulsification material transfer pump and an oil-phase emulsification material transfer pipe, wherein the water-phase emulsification material transfer pump and the water-phase emulsification material transfer pipe are connected; and the oil-phase emulsification material transfer pump and the oil-phase emulsification material transfer pipe are connected. The emulsification device is characterized by further comprising an emulsification mixer with a slope-shaped rectangular mixing cavity channel, an emulsification mixture transfer pipe, an emulsification time delay mixer with a built-in honeycombed filling material mixing pipe cavity and an emulsion matrix finished product discharge pipe, wherein the water-phase emulsification material transfer pipe and the oil-phase emulsification material transfer pipe are respectively connected with a water-phase emulsification material inlet cavity and an oil-phase emulsification material inlet cavity of the emulsification mixer; and the emulsification mixer, the emulsification mixture transfer pipe, the emulsification time delay mixer and the emulsion matrix finished product discharge pipe are sequentially connected. According to the emulsification method provided by the invention, two-phase emulsification materials are subjected to primary emulsification of the emulsification mixer and secondary emulsification of the emulsification time delay mixer, thus obtaining the emulsion matrix finished product. The invention has the advantages of high safety, good emulsification quality, high production efficiency and the like.

Owner:NANJING UNIV OF SCI & TECH +1

Aluminum alloy ingot casting automatic production line

ActiveCN104972106AHigh degree of automationImprove production continuityCasting plantsMetallurgyIngot casting

The present invention discloses an aluminum alloy ingot casting automatic production line which comprises a smelting casting system, a cooling conveying system, an ingot casting discharge system and a stacking sideslip system; the smelting casting system comprises a smelting combustor and a molten aluminum casting mechanism; the cooling conveying system comprises an aluminum ingot cooling conveyer belt, and a plurality of ingot casting molds are disposed on the aluminum ingot cooling conveyer belt; the ingot casting discharge system comprises a discharge support and an aluminum ingot finished product conveyer belt, the aluminum ingot finished product conveyer belt comprises an aluminum ingot receiving end and an aluminum ingot stacking end, an aluminum ingot discharge end of the aluminum ingot cooling conveyer belt is disposed over the aluminum ingot receiving end of the aluminum ingot finished product conveyer belt, and a discharge upper guide rail and a discharge lower guide rail are disposed on the discharge support; and the stacking sideslip system comprises a stacking sideslip beam, a stacking sideslip support seat, a stacking elevating support seat, a grabbing mechanism, a gradual decline stacking platform and a stacking conveyer belt. The aluminum alloy ingot casting automatic production line is advantaged by high automation degree, good production continuity and smooth transition of various processes.

Owner:铜陵康达铝合金制品有限责任公司

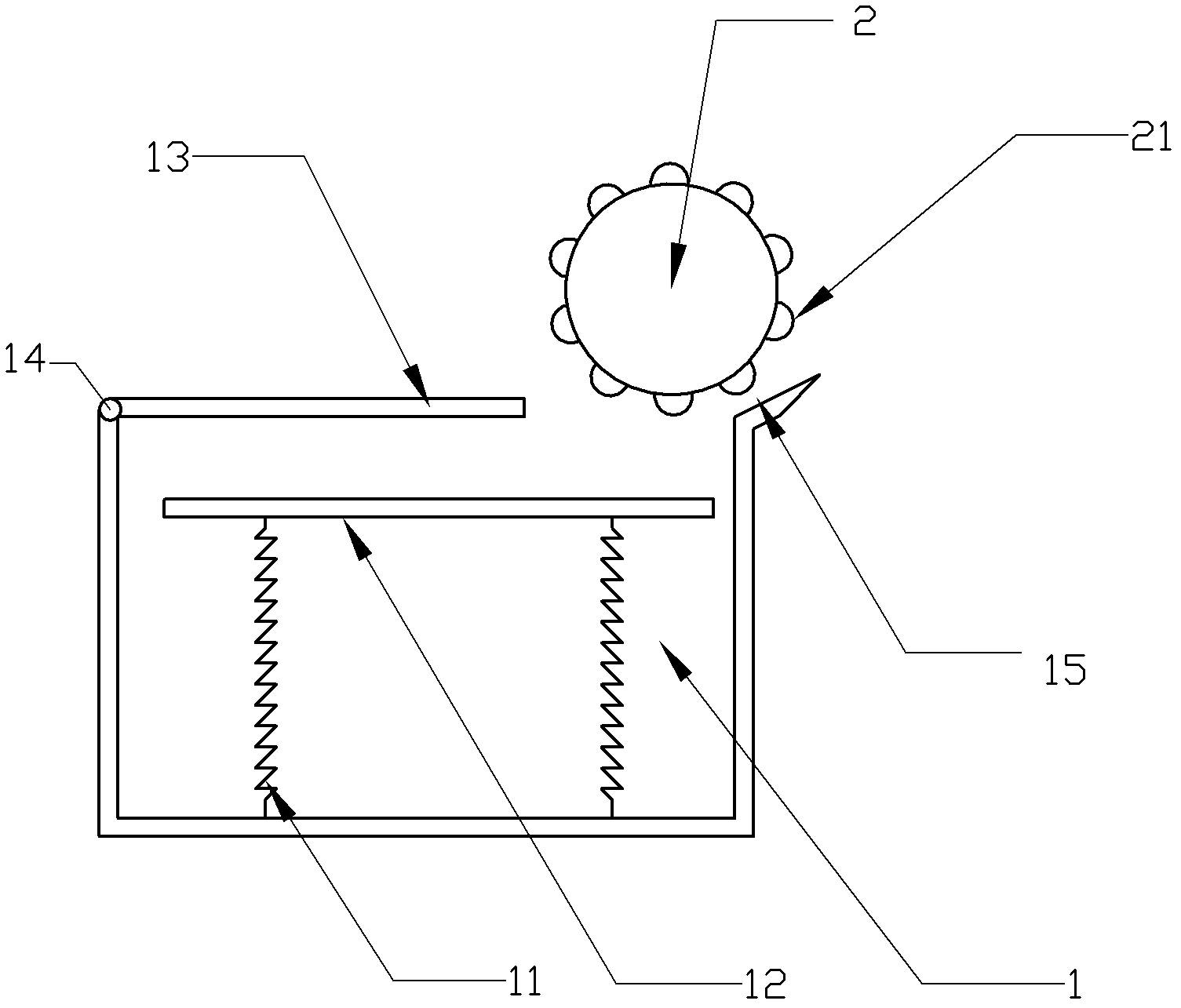

Automatic bag feeding machine for valve bags

InactiveCN102674038AImprove production continuityIncrease productivityArticle separationEngineeringRubbing

The invention discloses an automatic bag feeding machine for valve bags, which belongs to the field of auxiliary mechanisms of packaging machinery and is mainly used for solving the problems of low working efficiency and poor production continuity of manual bag feeding. The automatic bag feeding machine comprises a bag containing box and a bag rubbing roller, wherein an opening is arranged on the upper surface of the bag containing box, one side of the opening is hinged with a top cover, the top cover is smaller than the opening of the bag containing box, a spring is arranged at the bottom of the bag containing box, the upper surface of the spring is connected with a bag supporting plate, a matching inclined plane which is low at inside and high at outside is arranged on the vertical surface of the bag containing box, which is close to the bag inlet direction, and the lowest point of the matching inclined plane is positioned below the bottom surface of the top cover and in the position with the thickness of one layer of the valve bag; and the bag rubbing roller with salient points on the surface is arranged above the other side of the opening on the upper surface of the bag containing box, and the lowest point on the radial surface of the salient points of the bag rubbing roller is flush with the lowest point of the matching inclined plane. The automatic bag feeding machine for the valve bags, disclosed by the invention, can realize automatic bag feeding of the valve bags, high production continuity and high working efficiency.

Owner:JINAN LIYU MACHINERY TECH

Preparation method of herba dendrobii tea

The invention relates to a preparation method of herba dendrobii tea, which comprises the following steps: harvesting the herba dendrobii, washing, cutting into sections, and baking in a constant-temperature drying room; after taking the herba dendrobii out of the drying room, performing microwave treatment to obtain dry tea; adding water and decocting and mixing the filtrates; concentrating, standing and filtering to obtain a herba dendrobii extract; and drying, grinding, sieving, sterilizing and sub-packaging. The preparation method is scientific and reasonable and simple and easy to implement and has high production continuity; the types of the obtained medicinal tea are diverse, and the purity of the herba dendrobii extract is high; the baking temperature is moderate, the time is proper, and a good aroma extraction effect can be achieved; and the medicinal active ingredients of herba dendrobii tea can be maintained to the greatest degree, and the nutritional value is increased. The herba dendrobii tea prepared by the method provided by the invention has the functions of benefiting stomach, promoting fluid production, nourishing yin, clearing heat, resisting aging, improving immunity and the like and is easy to carry, convenient to use, nature and pureness and the like.

Owner:ANQING CITY LYUYIN AGRI DEV

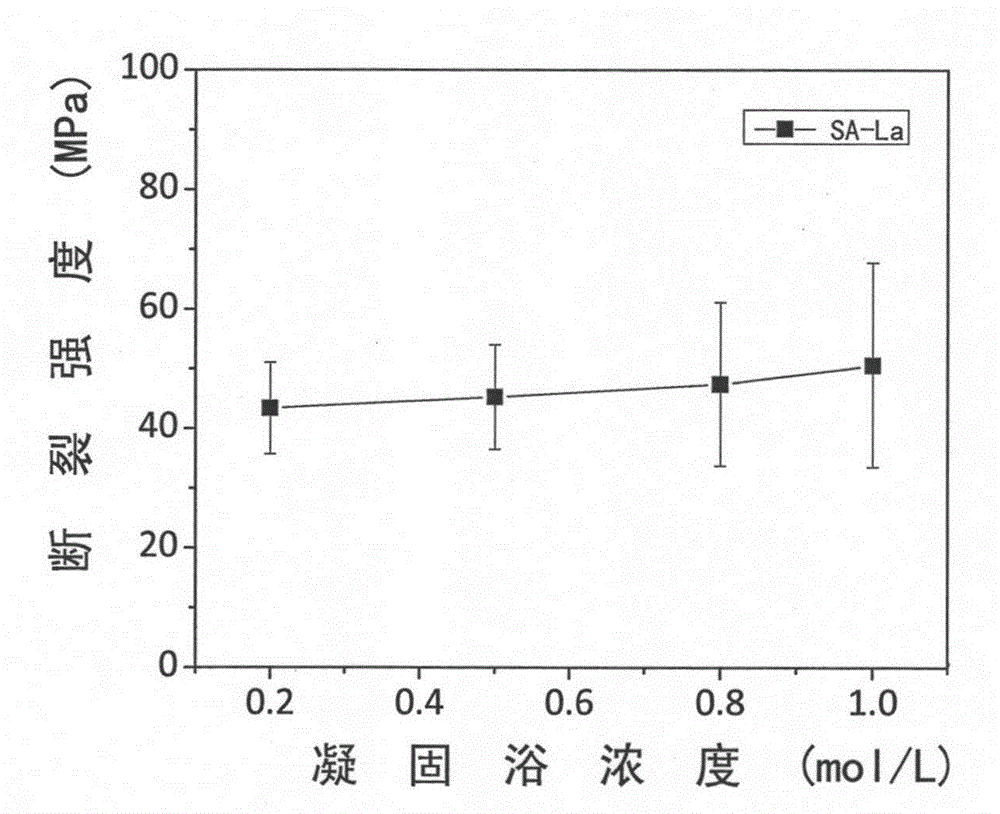

Method for preparing rare earth polysaccharide composite fibers

InactiveCN104451931AImprove water absorptionGood biocompatibilityArtificial filaments from cellulose derivativesWet spinning methodsFiberRare earth

The invention provides a method for preparing rare earth polysaccharide composite fibers. The method is characterized by comprising the following specific steps: step 1, dissolving polysaccharides to prepare a spinning solution; step 2, preparing a coagulating bath, wherein the coagulating bath contains rare earth metal ions; step 3, metering the spinning solution obtained in the step 1 by virtue of a metering pump, extruding the spinning solution to enter the coagulating bath obtained in the step 2 by virtue of a spinning nozzle, wherein the polysaccharides and the rare earth metal ions are subjected to coordination complexation, and the fibers are subjected to coagulation forming; and step 4, cleaning the obtained fibers by virtue of deionized water and drying, thus obtaining the rare earth polysaccharide composite fibers. According to the method disclosed by the invention, the spinning solution with a certain concentration is prepared by utilizing the polysaccharides, the rare earth metal ions are prepared into the coagulating bath of a certain concentration, and the rare earth polysaccharide composite fibers are prepared by virtue of coordination of the polysaccharides and the rare earth metal ions. The spinneret orifice is not blocked during wet spinning, and the spinning operation has high production continuity.

Owner:DONGHUA UNIV

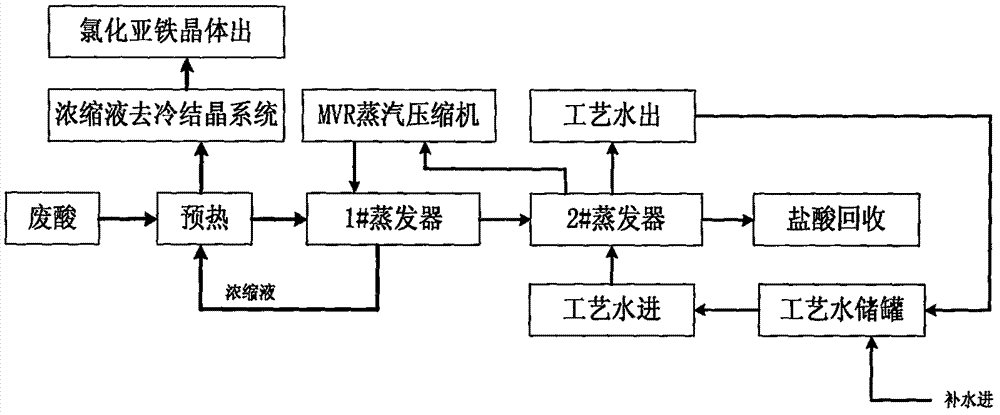

MVR evaporative concentration and recovery process for waste acid containing hydrochloric acid

InactiveCN107311239ASystem stabilityGood production continuityChlorine/hydrogen-chloride purificationChemical industryThermal stateCorrosion

The invention relates to a MVR evaporative concentration and recovery process for waste acid containing hydrochloric acid. The process comprises the following four steps: preheating; MVR evaporative concentration; recovery of hydrochloric acid; and cooling crystallization of a concentrate. During preheating, a high-temperature concentrate containing considerable ferrous chloride and obtained after concentration by an evaporator No. 1 is used for preheating raw waste acid, and waste acid enters a preheating system via a feeding pump and is heated to an evaporation temperature; during MVR evaporative concentration, the preheated waste acid enters an evaporator system No. 1 and is mixed with circulating feed liquid in an evaporator No. 2, then the obtained mixture enters the evaporator No. 2, and then vapor-liquid mixed feed liquid is separated; during recovery of hydrochloric acid, process water and hydrochloric acid steam are subjected to heat exchanging in the evaporator No. 2, and hydrochloric acid steam is condensed to form thermal-state dilute hydrochloric acid; during cooling crystallization of the concentrate, changes of the concentration of the ferrous chloride concentrate are controlled, and discharging is reasonably controlled; and the ferrous chloride concentrate enters a concentrate cooling crystallization system so as to obtain ferrous chloride crystals. The MVR evaporative concentration and recovery process provided by the invention is stable in system, energy-saving and friendly to environment and can effectively overcome the problem of corrosion of high-temperature hydrogen chloride gas to equipment.

Owner:BEIJING PUREN MEIHUA ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com