Automatic hydraulic molding machine for pulverized coal

A forming machine and forming mechanism technology, which is applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problems of imperfect design of feeding mechanism and forming mechanism, insufficient compactness of profiles, frequent occurrence of personal safety accidents, etc. Achieve the effects of good production continuity, manpower saving and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention, a pulverized coal automatic hydraulic molding machine, its specific implementation is as follows:

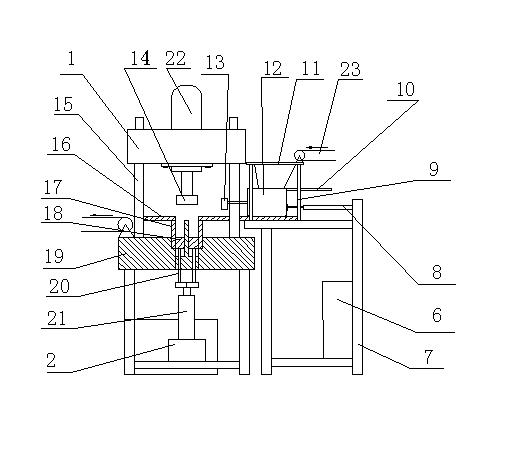

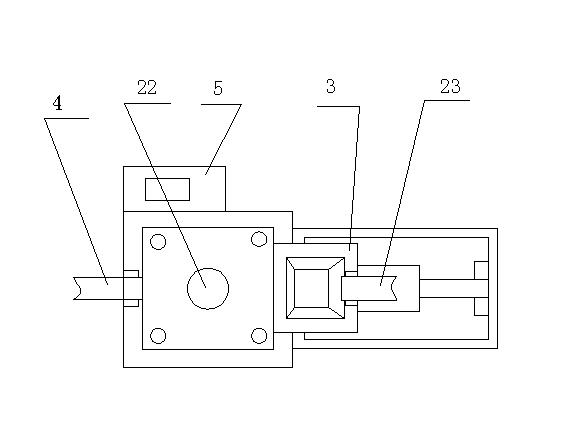

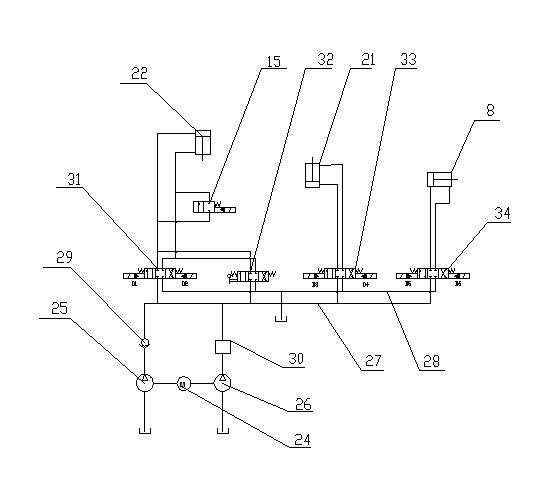

[0029] Such as figure 1 and figure 2 As shown, a pulverized coal automatic hydraulic molding machine includes a molding mechanism 1, a pushing mechanism 2, a feeding mechanism 3, a conveyor belt 4, a hydraulic control system 5, an electrical control system 6 and a frame 7, and at the left end of the frame 7 there is Push-out mechanism 2, molding mechanism 1 is arranged on the upper end of push-out mechanism 2, and is arranged on the upper end surface of workbench 19 in push-out mechanism 2 by pillar 15, also is provided with a conveyer belt 4 at the left end of workbench 19, on the upper end of frame 7 The feeding mechanism 3 is set, and the electrical control system 6 is set on the lower side of the frame 7;

[0030] In the present invention, the forming mechanism 1 includes a stamping head 14 and a forming cylinder 22 , and the stamping head 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com