Preparation method of powder-metallurgy refrigeration compressor valve sheet

A refrigeration compressor and powder metallurgy technology, applied in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of low material utilization rate and slow valve processing speed, and achieve good pressing performance and material utilization rate. High and cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the embodiments of the drawings.

[0025] A method for manufacturing a valve plate of a powder metallurgy refrigeration compressor includes the following steps in sequence:

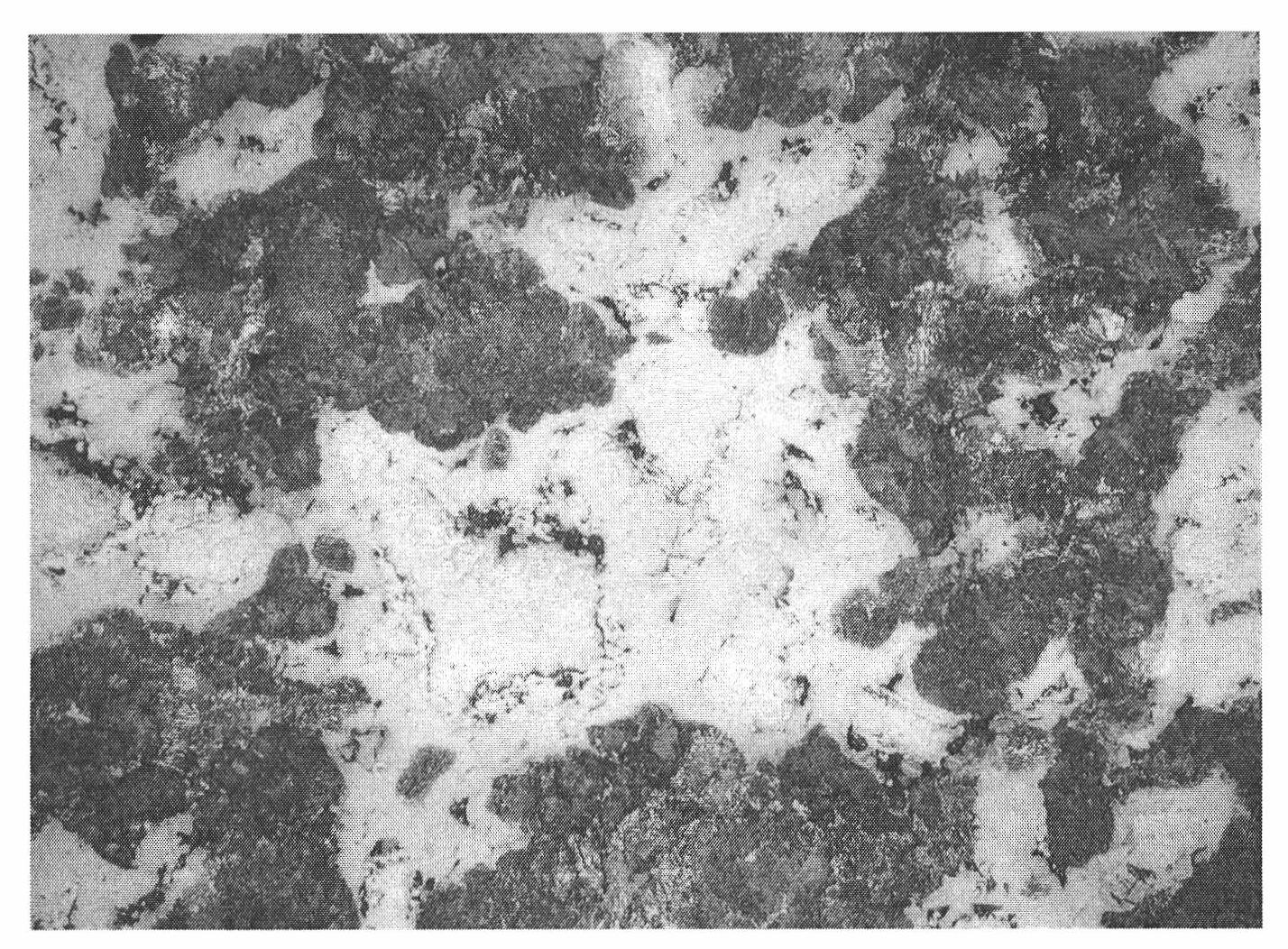

[0026] 1. Combine iron powder, high-alloy master powder, graphite powder, manganese sulfide powder and zinc stearate powder in a certain proportion (iron powder is the balance: high-alloy master powder 20-24%: graphite powder 0.6-0.8%: sulfurization Manganese powder 0.4~0.6%: zinc stearate powder 0.65~0.75%) mixed so that the percentage of each element in the total composition is: carbon 0.5~2.0%, cobalt 3.0~6.5%, chromium 2.5~4.5% ; Molybdenum 2.5-4.5%, nickel 0.5-2.0%, vanadium 0.2-1.0%, not more than 3% of inevitable impurities, the balance is iron.

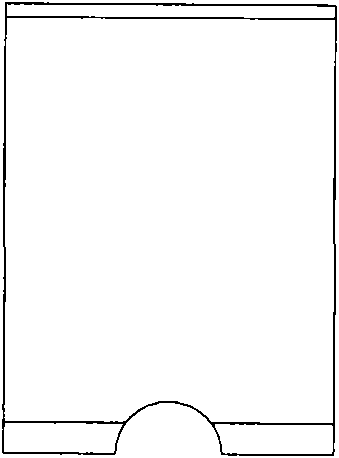

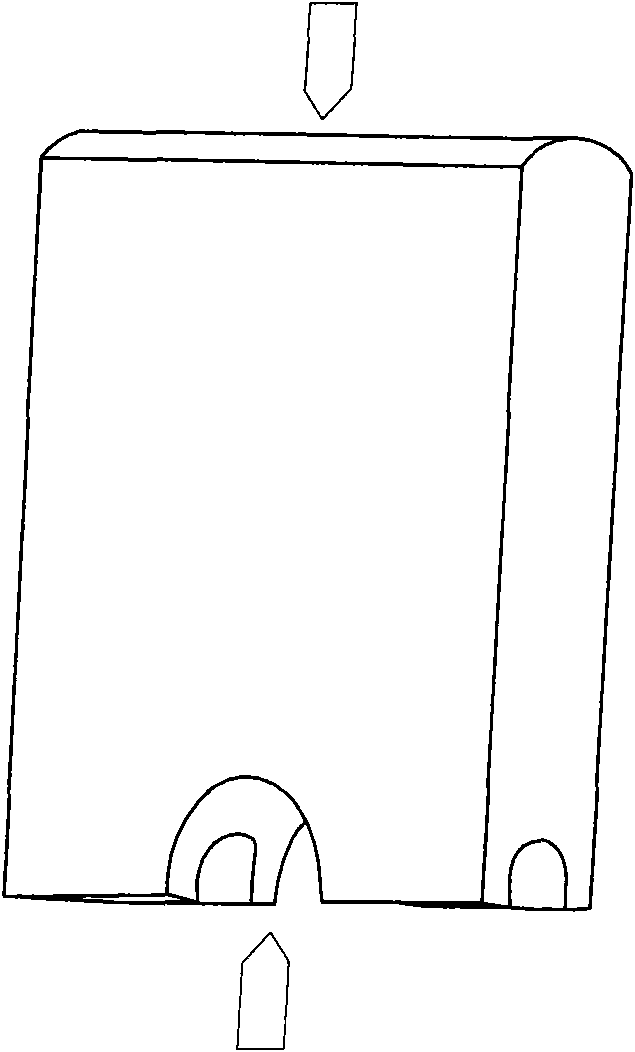

[0027] 2. Press the evenly mixed valve material powder on an automatic forming press figure 2 As shown in the forming schematic diagram, the powder metallurgy valve disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com